Effect of Slurry Concentration on the Ceramic Ball Grinding Characteristics of Magnetite

Abstract

1. Introduction

2. Theoretical Background

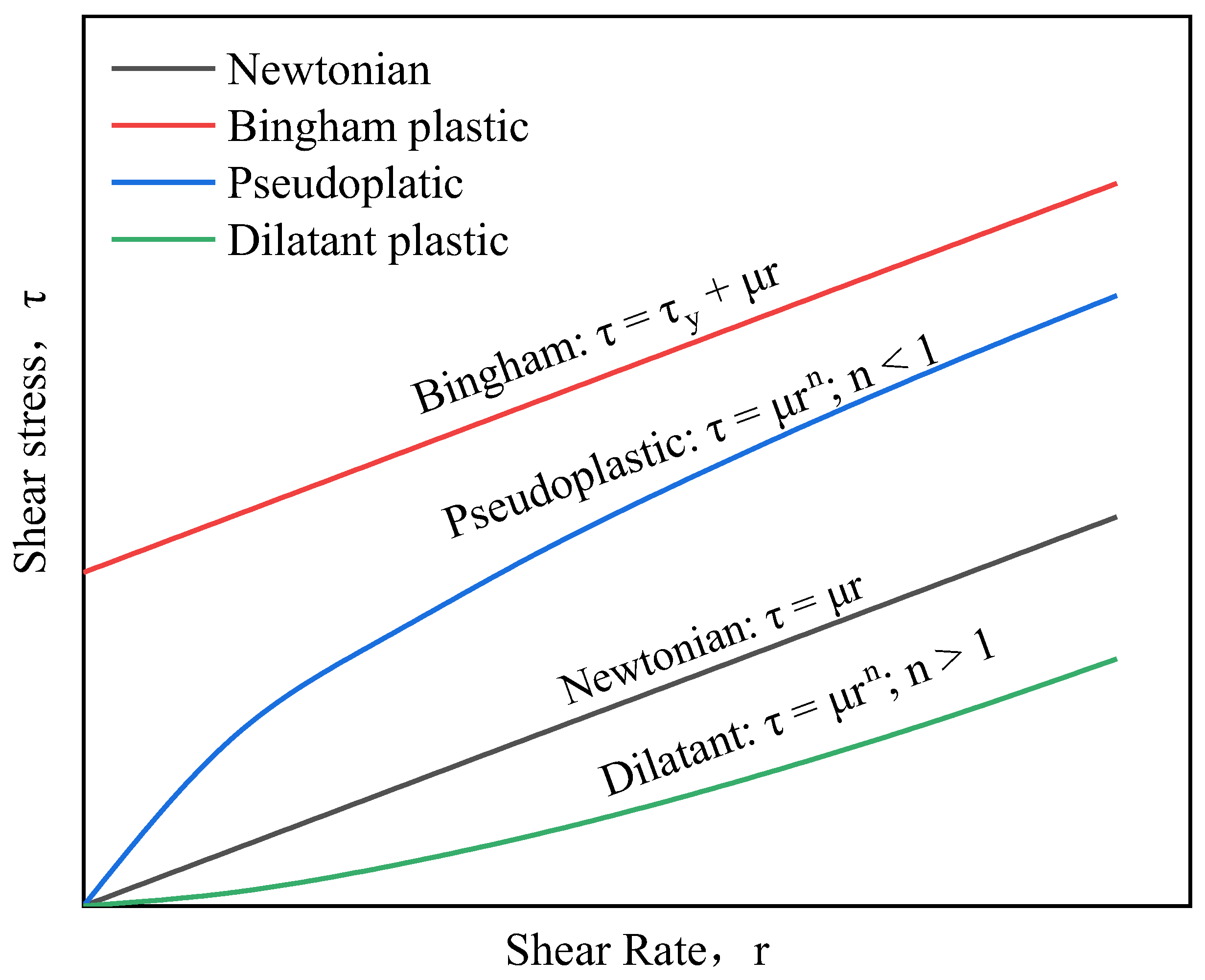

2.1. Slurry Rheology

2.2. Population Balance Model

- (1)

- G-H algorithm created by Kapur [32]:

- (2)

- BII algorithm created by Austin [35]:

2.3. Zero-Order Output Characteristics

3. Materials and Methods

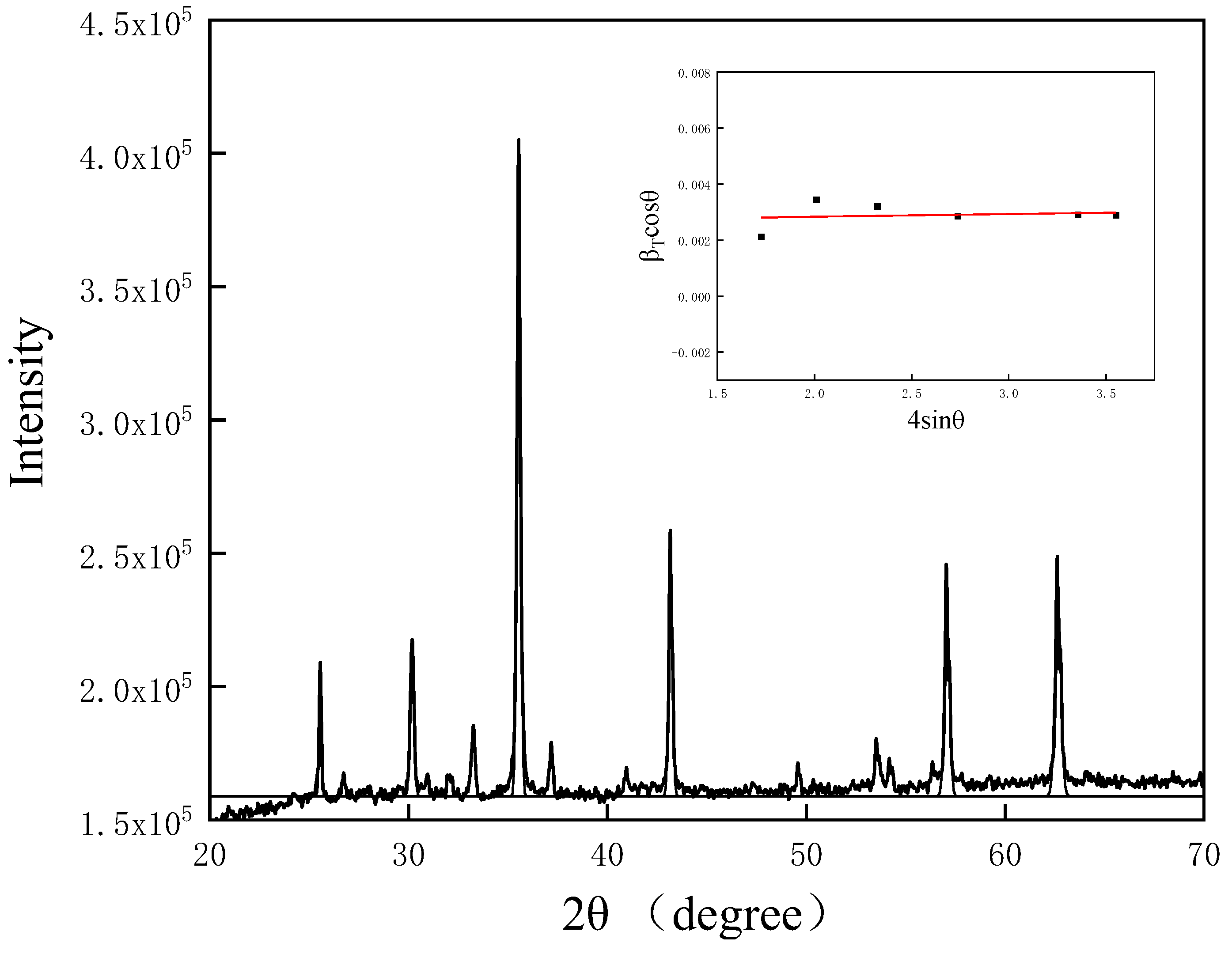

3.1. Materials

3.2. Methods

4. Results

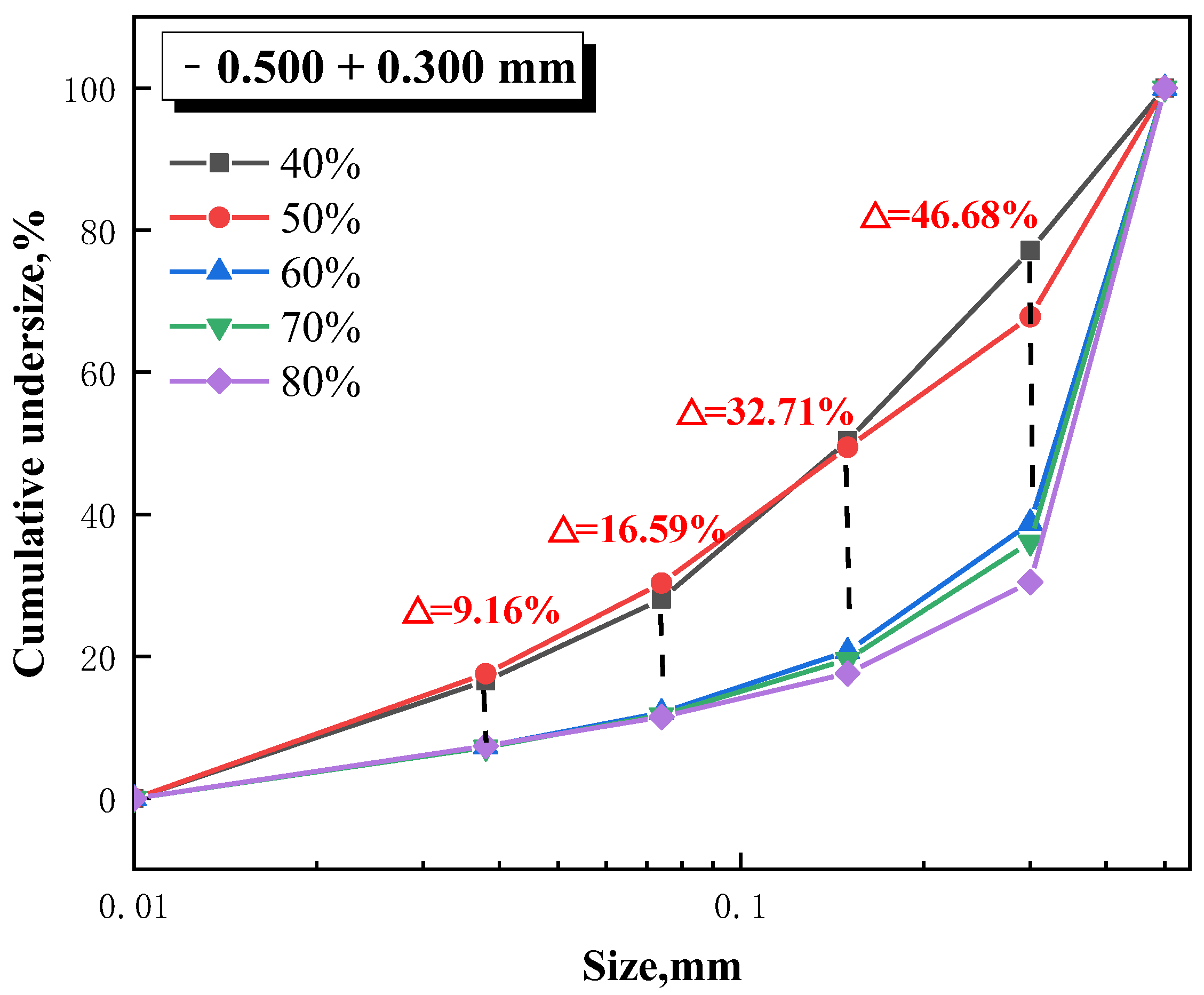

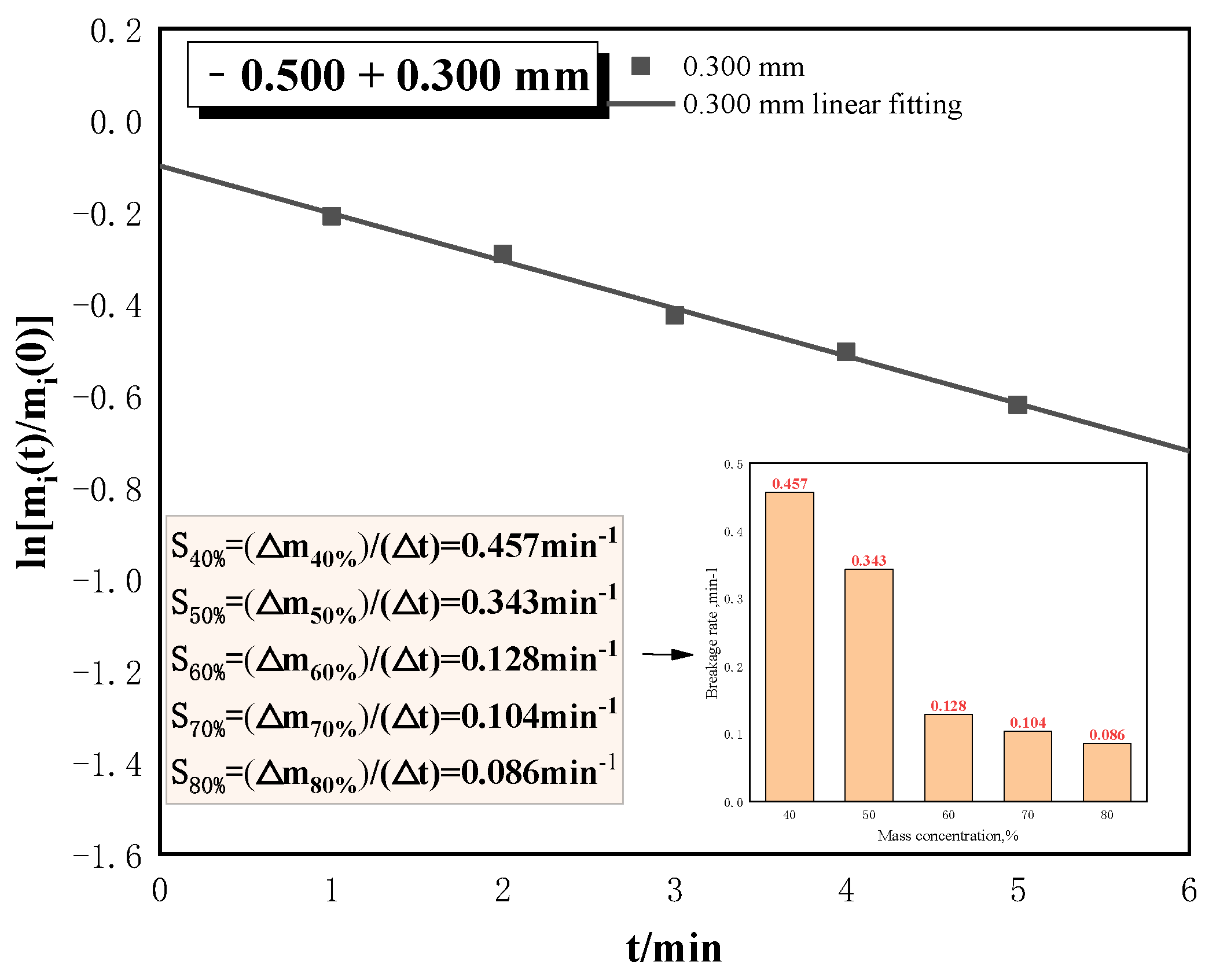

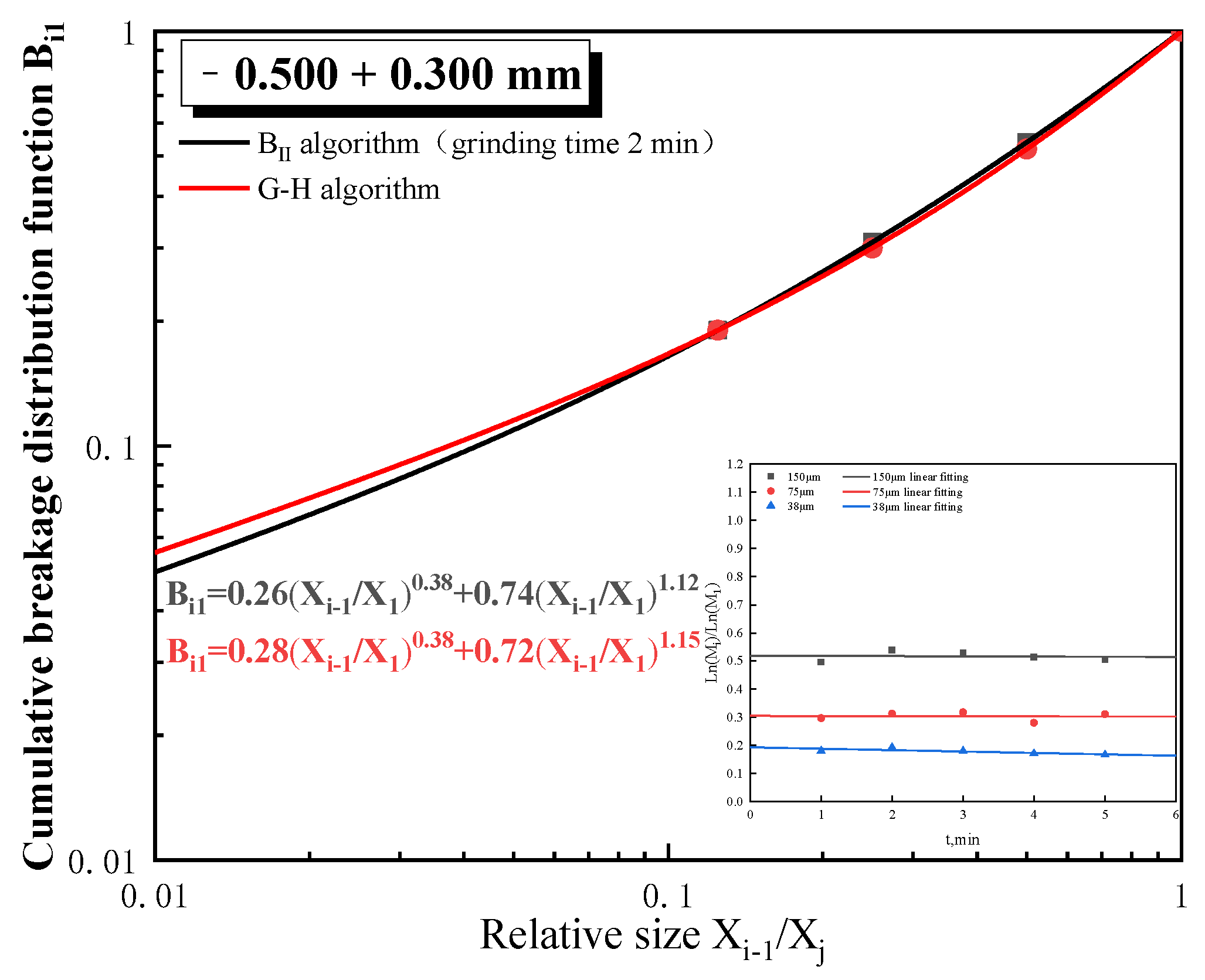

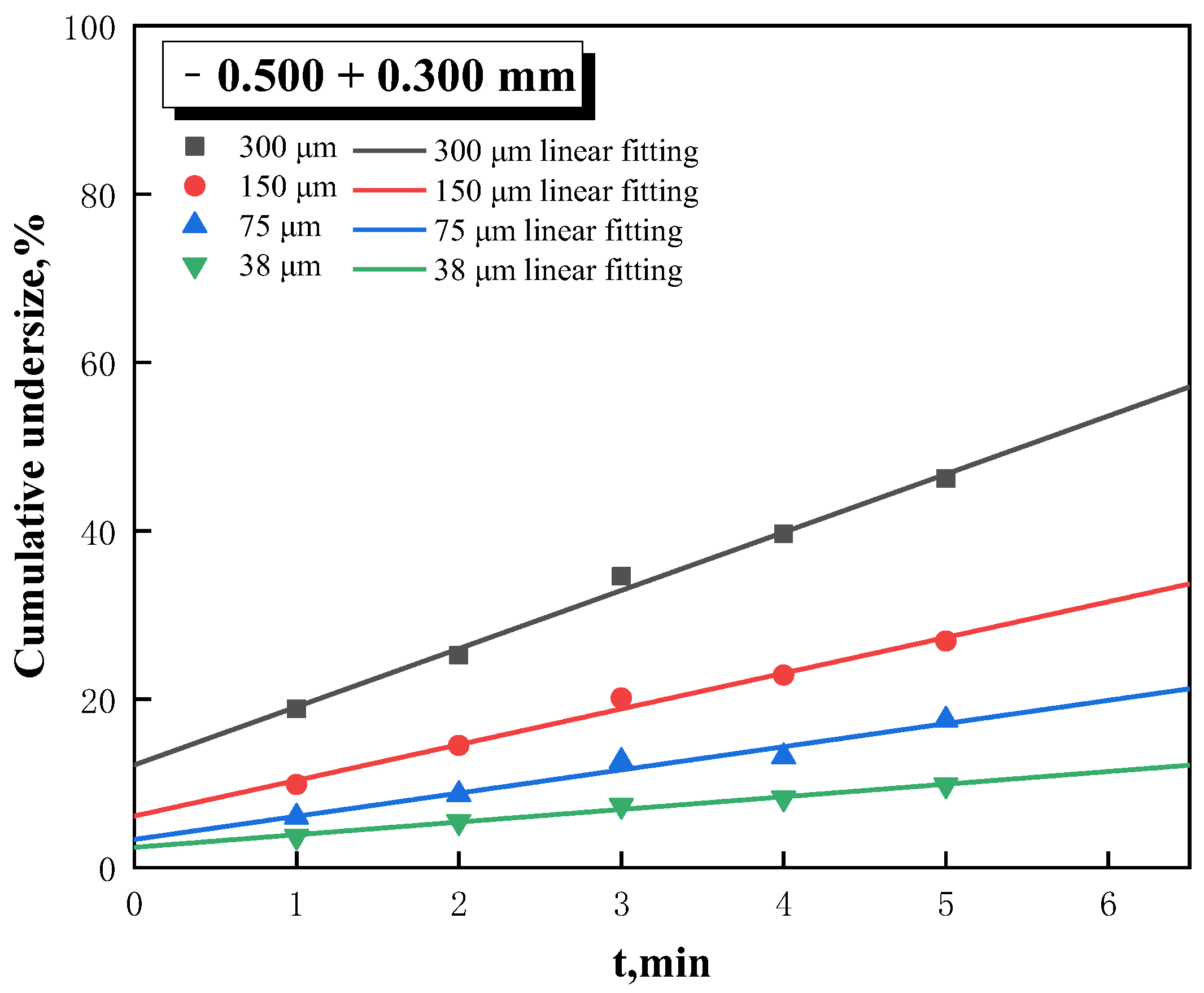

4.1. −0.500 + 0.300 mm Size Class

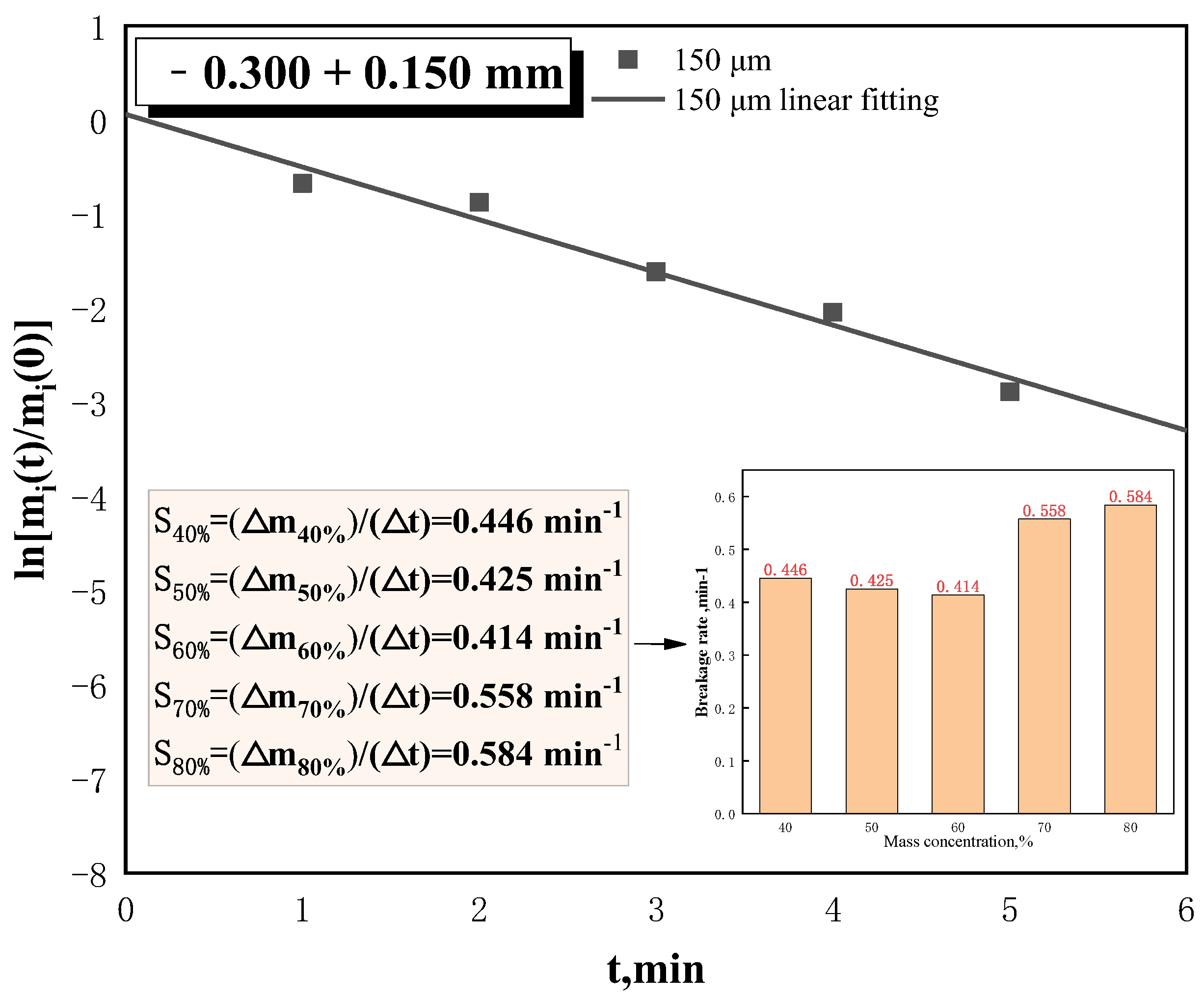

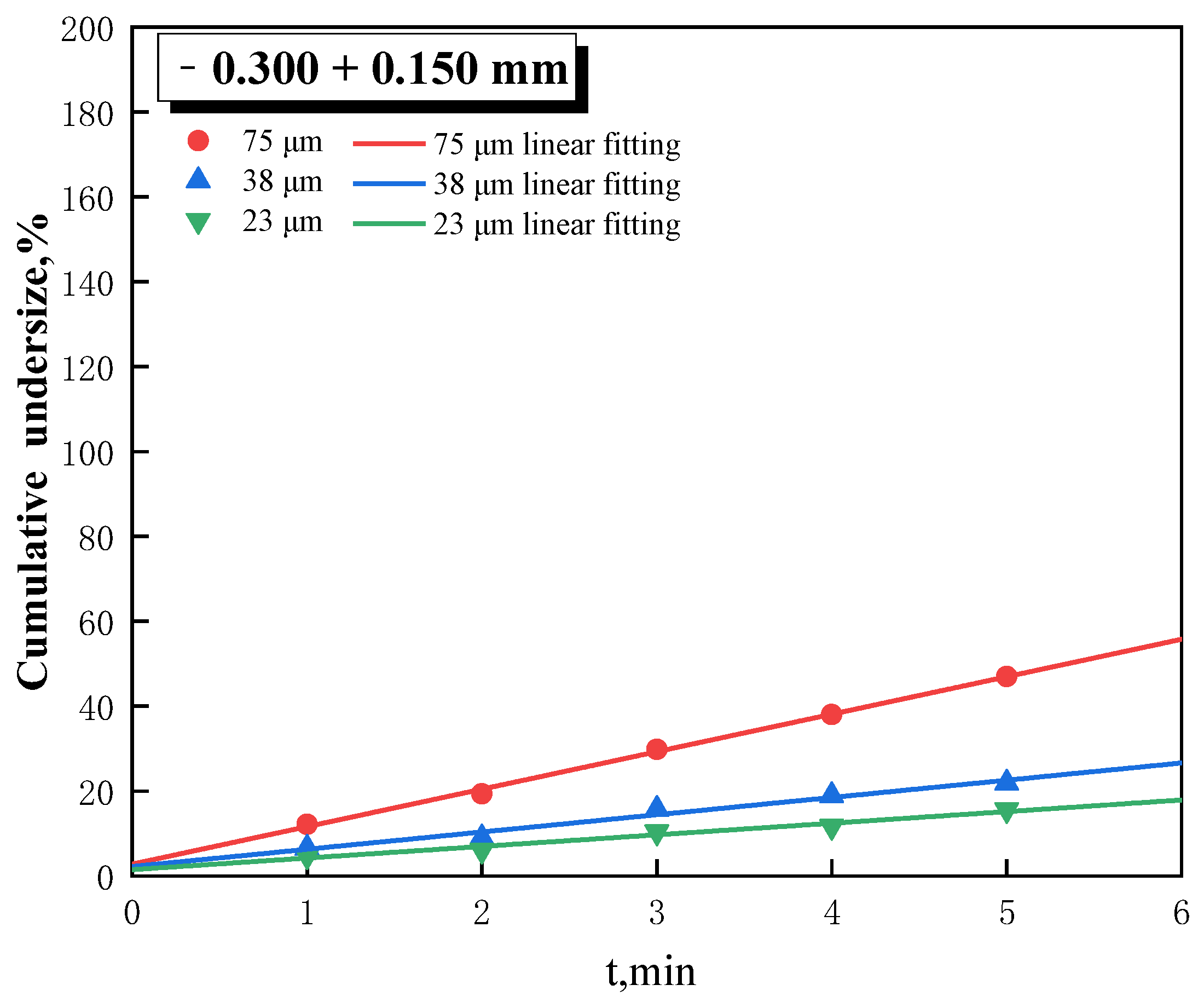

4.2. −0.300 + 0.150 mm Size Class

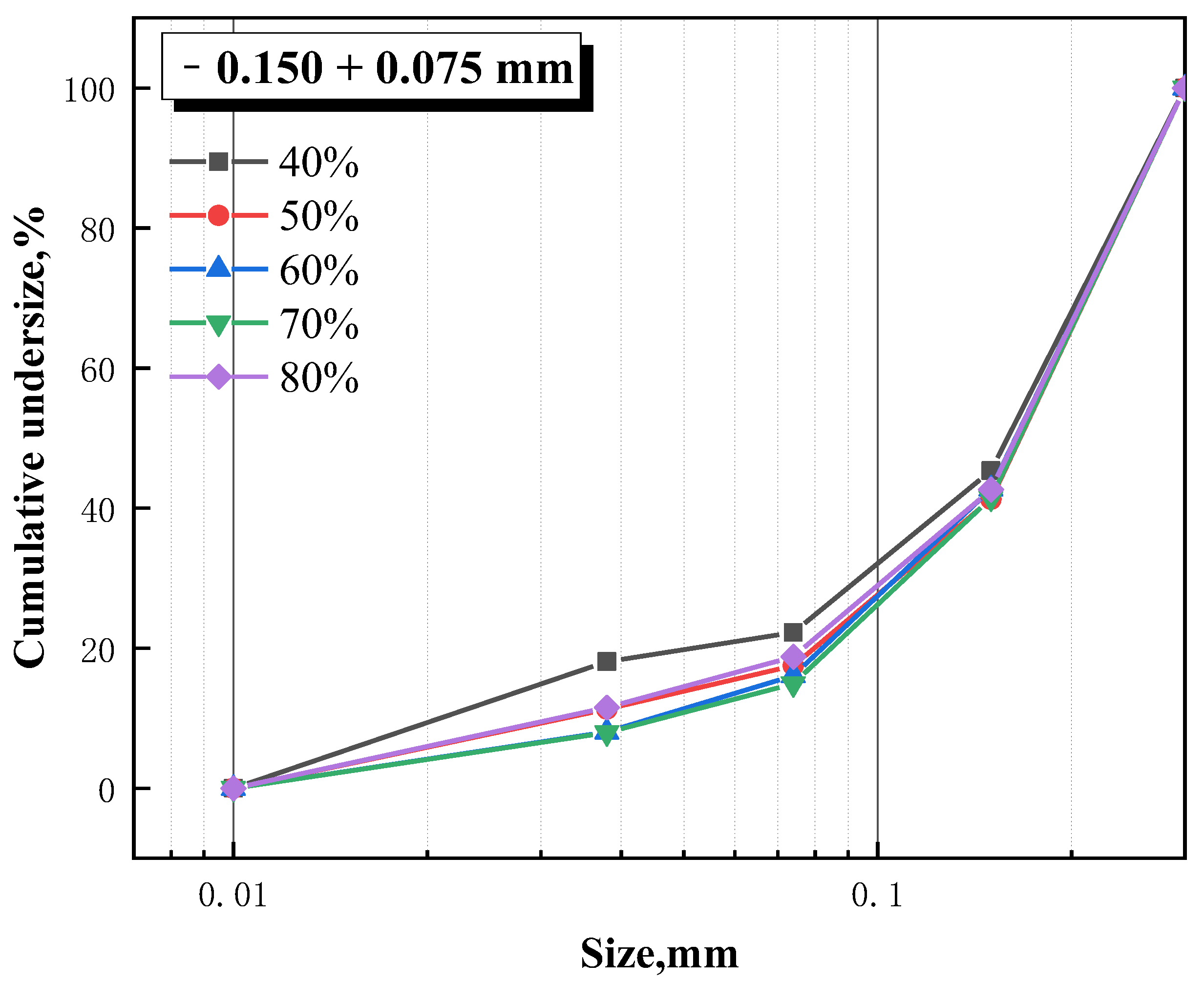

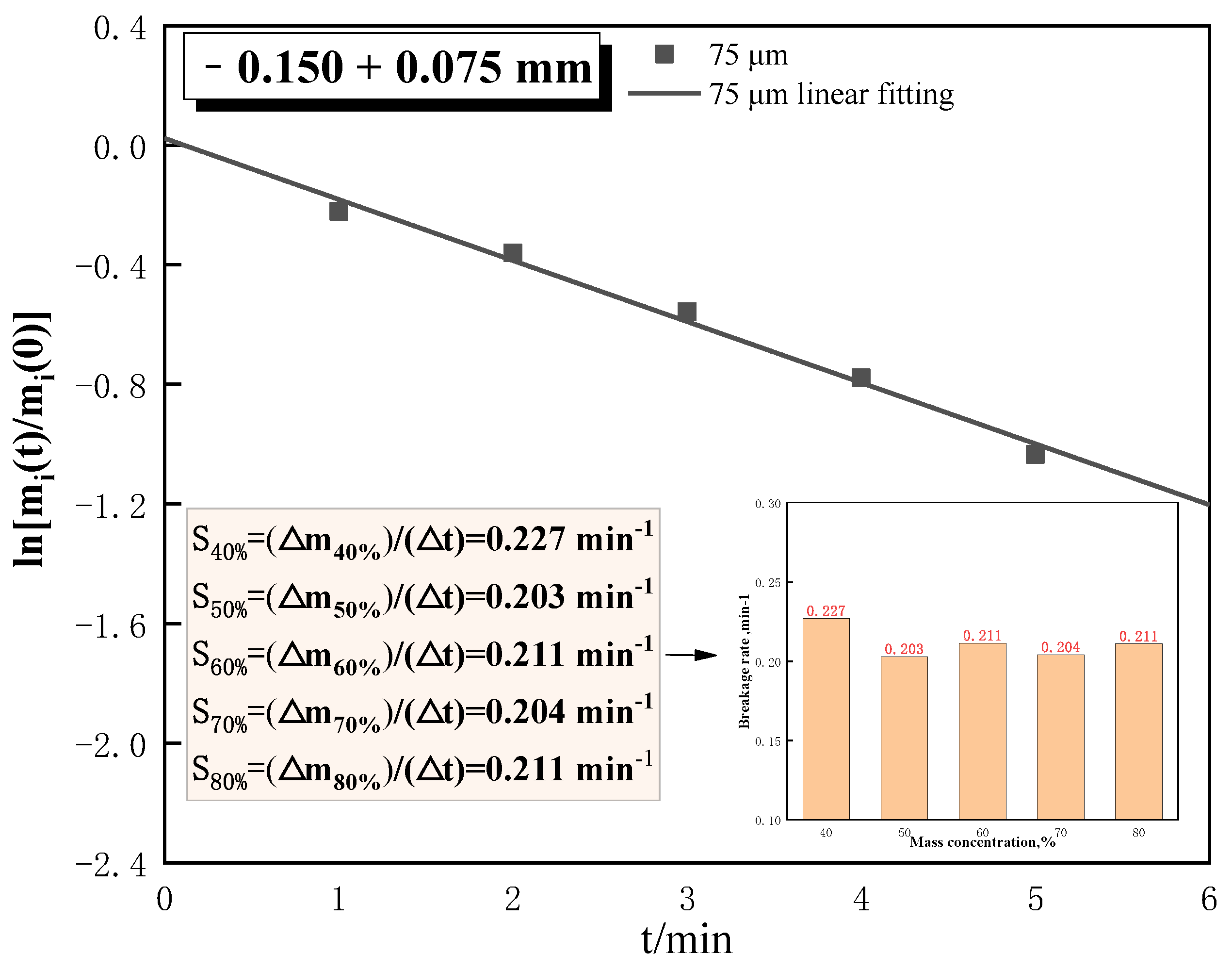

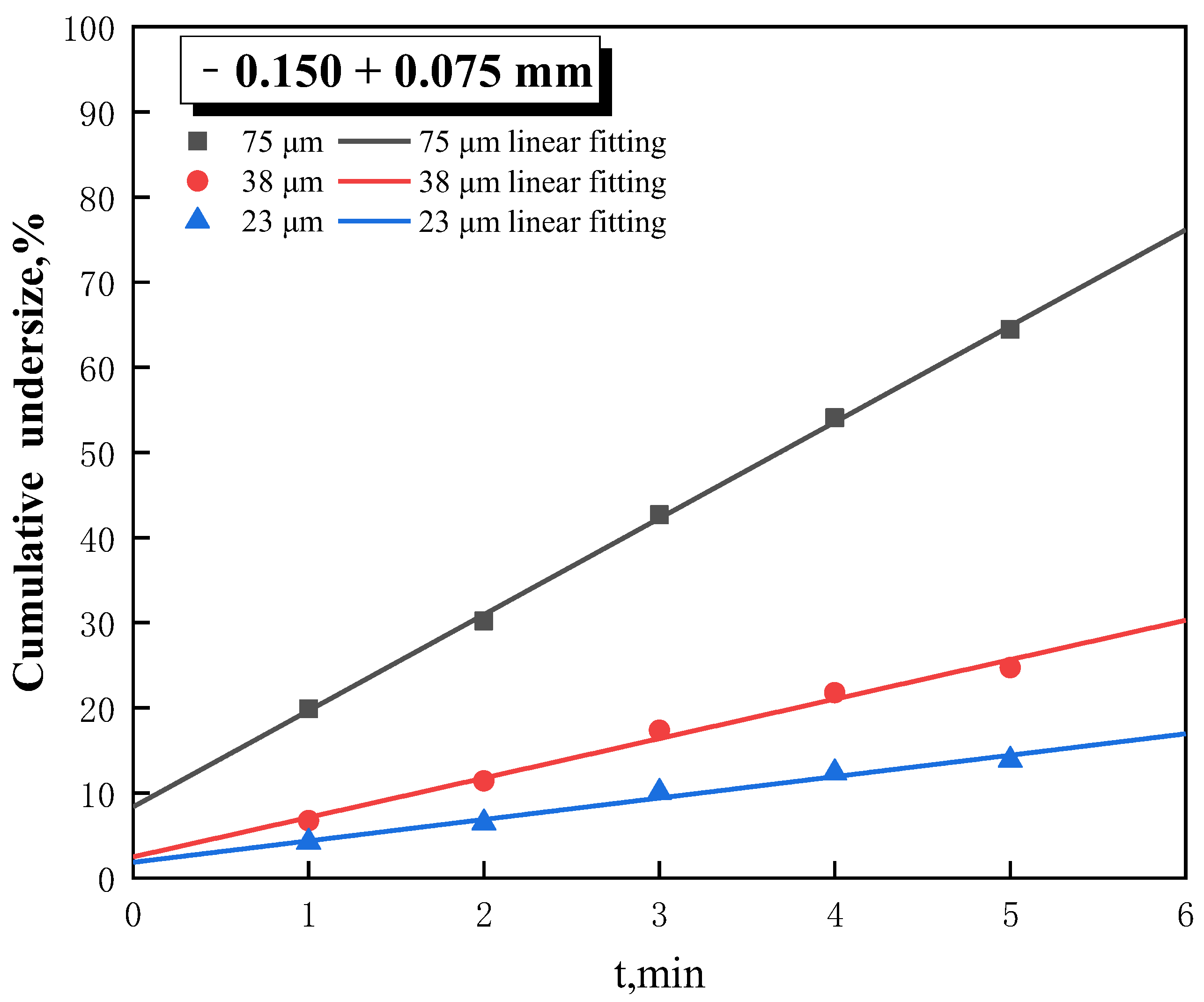

4.3. −0.150 + 0.075 mm Size Class

5. Comparison and Discussion

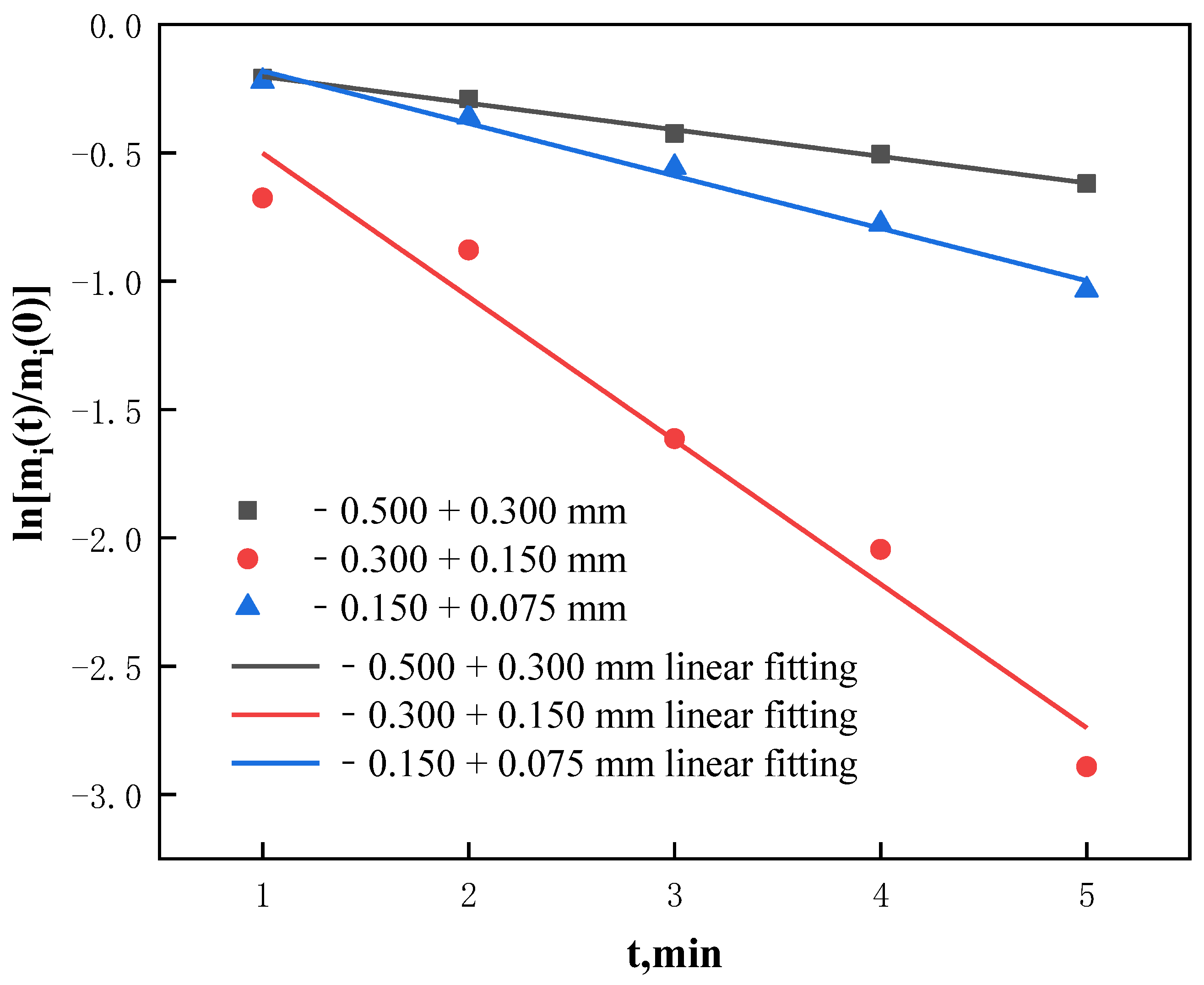

5.1. Breakage Rate Function and Distribution Function

5.2. Zero-Order Output Characteristics

6. Conclusions

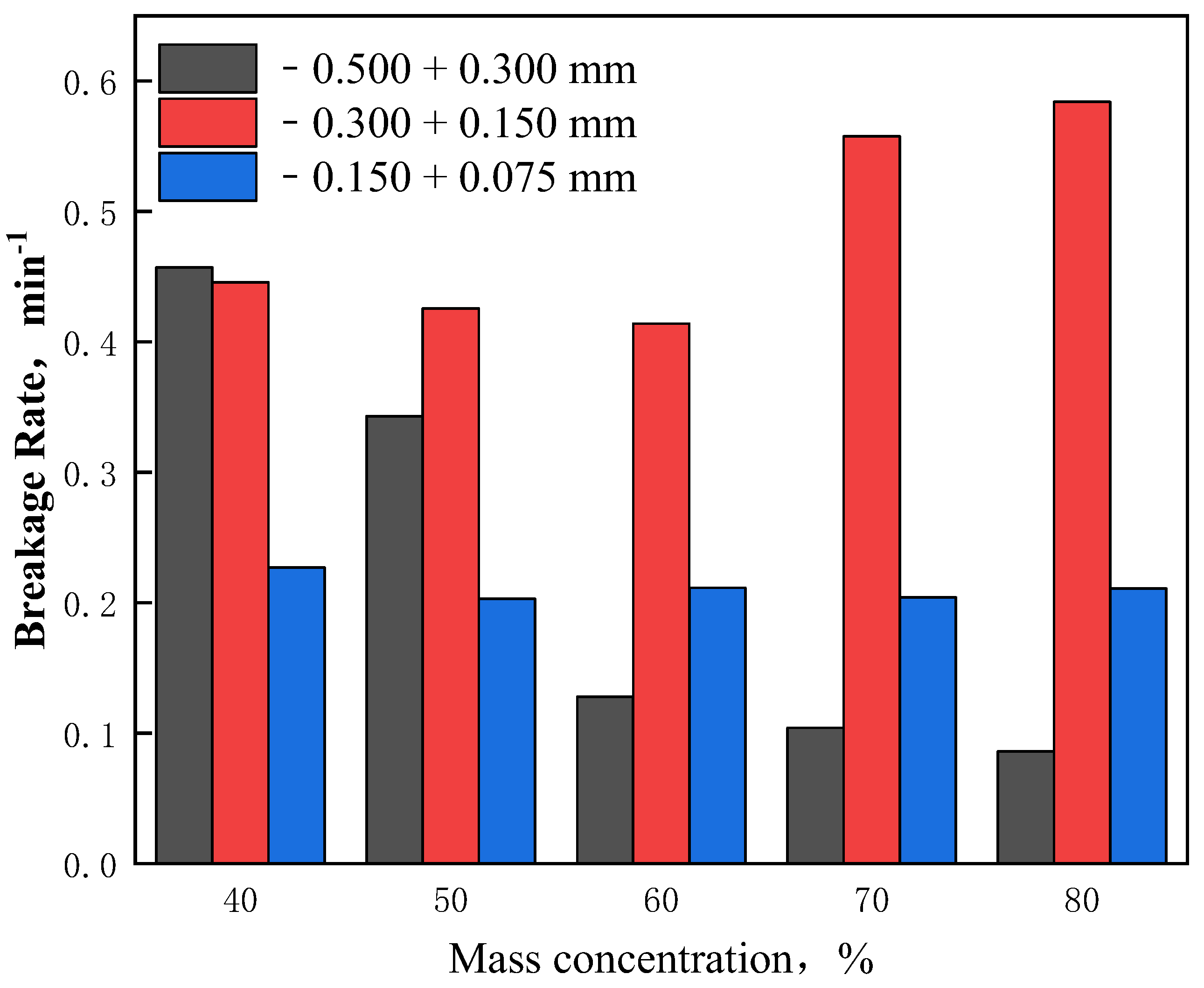

- In ceramic ball grinding of magnetite, the mass concentration of the slurry is a pivotal indicator of the rate of breakage, especially for coarse particles. When the grinding concentration is higher than 50%, the breakage rate of magnetite nosedives to 1/3 of the value at low mass concentrations.

- The standard deviations of the breakage rates of the three size classes with respect to the grinding concentration are 0.1491, 0.071, and 0.0086, respectively, indicating that the sensitivity of the grinding effect to the concentration gradually drops as the feed size decreases.

- In ceramic ball grinding of magnetite, the breakage rate of −0.300 + 0.150 mm reached 0.558 min−1, higher than 0.104 min−1 for −0.500 + 0.300 mm and 0.204 min−1 for −0.150 + 0.075 mm. Because magnetite of this size class does not have the mechanical strength of −0.500 + 0.300 mm, it does require the specific energy needed to crush −0.150 + 0.075 mm.

- The parameter changes in both the distribution function and the zero-order output characteristics indicate that the primary mode of fragmentation in ceramic ball grinding has changed compared to steel grinding.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Norgate, T.; Haque, N. Energy and greenhouse gas impacts of mining and mineral processing operations. J. Clean. Prod. 2010, 18, 266–274. [Google Scholar] [CrossRef]

- Austin, L.G. A Review: Introduction to the MathmaticaI Description of Grinding as a Rate Process. Powder Technol. 1971, 5, 1–17. [Google Scholar] [CrossRef]

- Kwon, J.; Jeong, J.; Cho, H. Simulation and optimization of a two-stage ball mill grinding circuit of molybdenum ore. Adv. Powder Technol. 2016, 27, 1073–1085. [Google Scholar] [CrossRef]

- Herbst, J.A. Scale-up procedure for continuous grinding mill design using population balance models. Int. J. Miner. Process. 1980, 7, 1–31. [Google Scholar] [CrossRef]

- Wei, H.; He, Y.; Wang, S.; Xie, W.; Zuo, W.; Shi, F. Effects of circulating load and grinding feed on the grinding kinetics of cement clinker in an industrial CKP mill. Powder Technol. 2014, 253, 193–197. [Google Scholar] [CrossRef]

- Prziwara, P.; Kwade, A. Grinding aid additives for dry fine grinding processes—Part II: Continuous and industrial grinding. Powder Technol. 2021, 394, 207–213. [Google Scholar] [CrossRef]

- Shahbazi, B.; Jafari, M.; Parian, M.; Rosenkranz, J.; Chehreh Chelgani, S. Study on the impacts of media shapes on the performance of tumbling mills—A review. Miner. Eng. 2020, 157, 106490. [Google Scholar] [CrossRef]

- Gupta, V.K. Effect of particulate environment on the grinding kinetics of mixtures of minerals in ball mills. Powder Technol. 2020, 375, 549–558. [Google Scholar] [CrossRef]

- Liu, S.; Li, Q.; Song, J. Study on the grinding kinetics of copper tailing powder. Powder Technol. 2018, 330, 105–113. [Google Scholar] [CrossRef]

- Genç, Ö.; Ergün, Ş.L.; Benzer, A.H. The dependence of specific discharge and breakage rate functions on feed size distributions, operational and design parameters of industrial scale multi-compartment cement ball mills. Powder Technol. 2013, 239, 137–146. [Google Scholar] [CrossRef]

- Gupta, V.K. Energy absorption and specific breakage rate of particles under different operating conditions in dry ball milling. Powder Technol. 2020, 361, 827–835. [Google Scholar] [CrossRef]

- Zhang, X.; Qin, Y.; Jin, J.; Li, Y.; Gao, P. High-efficiency and energy-conservation grinding technology using a special ceramic-medium stirred mill: A pilot-scale study. Powder Technol. 2022, 396, 354–365. [Google Scholar] [CrossRef]

- Faria, P.M.C.; Rajamani, R.K.; Tavares, L.M. Optimization of Solids Concentration in Iron Ore Ball Milling through Modeling and Simulation. Minerals 2019, 9, 366. [Google Scholar] [CrossRef]

- Li, C.; Gao, Z. Effect of grinding media on the surface property and flotation behavior of scheelite particles. Powder Technol. 2017, 322, 386–392. [Google Scholar] [CrossRef]

- Bu, X.; Chen, Y.; Ma, G.; Sun, Y.; Ni, C.; Xie, G. Differences in dry and wet grinding with a high solid concentration of coking coal using a laboratory conical ball mill: Breakage rate, morphological characterization, and induction time. Adv. Powder Technol. 2019, 30, 2703–2711. [Google Scholar] [CrossRef]

- Ding, Z.; Yin, Z.; Liu, L.; Chen, Q. Effect of grinding parameters on the rheology of pyrite–heptane slurry in a laboratory stirred media mill. Miner. Eng. 2007, 20, 701–709. [Google Scholar] [CrossRef]

- He, M.; Wang, Y.; Forssberg, E. Parameter effects on wet ultrafine grinding of limestone through slurry rheology in a stirred media mill. Powder Technol. 2006, 161, 10–21. [Google Scholar] [CrossRef]

- Inam, M.A.; Ouattara, S.; Frances, C. Effects of concentration of dispersions on particle sizing during production of fine particles in wet grinding process. Powder Technol. 2011, 208, 329–336. [Google Scholar] [CrossRef]

- Tan, H.; Skinner, W.; Addai-Mensah, J. Influence of fluorite on the isothermal leaching and rheological behaviours of chlorite mineral pulps at low pH. Int. J. Miner. Process. 2013, 123, 1–8. [Google Scholar] [CrossRef]

- Tucker, P. The influence of pulp density on the selective grinding of ores. Miner. Eng. Int. J. Miner. Process. 1984, 12, 273–284. [Google Scholar] [CrossRef]

- Merrill, J.; Voisin, L.; Montenegro, V.; Ihle, C.F.; McFarlane, A. Slurry rheology prediction based on hyperspectral characterization models for minerals quantification. Miner. Eng. 2017, 109, 126–134. [Google Scholar] [CrossRef]

- Moys, M.H. Grinding to nano-sizes: Effect of media size and slurry viscosity. Miner. Eng. 2015, 74, 64–67. [Google Scholar] [CrossRef]

- Zhang, X.; Han, Y.; Gao, P.; Li, Y. Effects of grinding media on grinding products and flotation performance of chalcopyrite. Miner. Eng. 2020, 145, 106070. [Google Scholar] [CrossRef]

- Fang, X.; Wu, C.; Liao, N.; Yuan, C.; Xie, B.; Tong, J. The first attempt of applying ceramic balls in industrial tumbling mill: A case study. Miner. Eng. 2022, 180, 107504. [Google Scholar] [CrossRef]

- Fang, X.; Wu, C.; Yuan, C.; Liao, N.; Chen, Z.; Li, Y.; Lai, J.; Zhang, Z. Can ceramic balls and steel balls be combined in an industrial tumbling mill? Powder Technol. 2022, 412, 118020. [Google Scholar] [CrossRef]

- Kumar Inwati, G.; Kumar, P.; Roos, W.D.; Swart, H.C. Thermally induced structural metamorphosis of ZnO:Rb nanostructures for antibacterial impacts. Colloids Surf B Biointerfaces 2020, 188, 110821. [Google Scholar] [CrossRef] [PubMed]

- Klimpel, R.R. The Influence of Material Breakage Properties and Associated Slurry Rheology on Breakage Rates in the Wet Grinding of Coal/Ores in Tumbling Media Mills. Part. Sci. Technol. 2007, 2, 147–156. [Google Scholar] [CrossRef]

- KAWATRA, S.K. Rheological Effects in Grinding Circuits. Int. J. Miner. Process. 1988, 22, 251–259. [Google Scholar] [CrossRef]

- Shi, F.N. Estimation of shear rates inside a ball mill. Int. J. Miner. Process. 1999, 57, 167–183. [Google Scholar] [CrossRef]

- Reid, K.J. A solution to the batch grinding equation. Chem. Eng. Sci. 1965, 20, 953–963. [Google Scholar] [CrossRef]

- Austin, L.G. Methods for Determination of Breakage Distribution Parameters. Powder Technol. 1971, 72, 215–222. [Google Scholar] [CrossRef]

- Kapur, P.C. Appropriate solutions to the discretized batch grinding equation. Chem. Eng. Sci. 1970, 25, 1111–1113. [Google Scholar] [CrossRef]

- Epstein, B. The mathematical description of certain breakagemechanisms leading to the logarithmiconormal distribution. Certain. Break. Mechanisms. 1947, 471–477. [Google Scholar]

- Epstein, B. Logarithmico-Normal Distribution in Breakage of Solids. Ind. Eng. Chem. 1948, 40, 2289–2291. [Google Scholar] [CrossRef]

- Austin, L.G. Note on influence of interval size on the first-order hypothesis of grlndlng. Powder Technol. 1971, 71, 109–110. [Google Scholar] [CrossRef]

- Austin, L.G. A discussion of equations for the analysis of batch grinding data. Powder Technol. 1999, 106, 71–77. [Google Scholar] [CrossRef]

- Chimwani, N.; Glasser, D.; Hildebrandt, D.; Metzger, M.J.; Mulenga, F.K. Determination of the milling parameters of a platinum group minerals ore to optimize product size distribution for flotation purposes. Miner. Eng. 2013, 43–44, 67–78. [Google Scholar] [CrossRef]

- Cruz, N.; Peng, Y. Rheology measurements for flotation slurries with high clay contents—A critical review. Miner. Eng. 2016, 98, 137–150. [Google Scholar] [CrossRef]

- Basnayaka, L.; Subasinghe, N.; Albijanic, B. Influence of clays on the slurry rheology and flotation of a pyritic gold ore. Appl. Clay Sci. 2017, 136, 230–238. [Google Scholar] [CrossRef]

- Liao, N.; Wu, C.; Xu, J.; Feng, B.; Wu, J.; Gong, Y. Effect of Grinding Media on Grinding-Flotation Behavior of Chalcopyrite and Pyrite. Front. Mater. 2020, 7, 176. [Google Scholar] [CrossRef]

- Mathe, E.; Cruz, C.; Lucay, F.A.; Gálvez, E.D.; Cisternas, L.A. Development of a grinding model based on flotation performance. Miner. Eng. 2021, 166, 106890. [Google Scholar] [CrossRef]

- Austin, L.G. An analysis of fine grinding in ball mill. Powder Technol. 1981, 28, 83–90. [Google Scholar] [CrossRef]

- Gupta, V.K. The Estimation of Bate and Breakage Distribution P ammeters from Batch Grinding Data for a Complex Pyritic Ore Using a Back-Calculation Method. Powder Technol. 1981, 28, 97–106. [Google Scholar] [CrossRef]

- Venkataraman, K.S. Application of the Population Balance Model to the Grinding of Mixtures of Minerals. Powder Technol. 1984, 39, 133–142. [Google Scholar] [CrossRef]

- Kumar, P.; Inwati, G.K.; Mathpal, M.C.; Ghosh, S.; Roos, W.D.; Swart, H.C. Defects induced enhancement of antifungal activities of Zn doped CuO nanostructures. Appl. Surf. Sci. 2021, 560, 150026. [Google Scholar] [CrossRef]

- Hennart, S.L.A.; Wildeboer, W.J.; van Hee, P.; Meesters, G.M.H. Identification of the grinding mechanisms and their origin in a stirred ball mill using population balances. Chem. Eng. Sci. 2009, 64, 4123–4130. [Google Scholar] [CrossRef]

- Sato, A.C.K.; Cunha, R.L. Effect of particle size on rheological properties of jaboticaba pulp. J. Food Eng. 2009, 91, 566–570. [Google Scholar] [CrossRef]

| Size Class/mm | Feed of the Secondary Ball Mill | |||

|---|---|---|---|---|

| Yield/% | Cumulative Undersize/% | Grade/% | Iron Content/% | |

| +0.500 | 6.19 | 100.00 | 31.31 | 3.47 |

| −0.500 + 0.300 | 6.59 | 93.81 | 40.65 | 4.80 |

| −0.300 + 0.150 | 23.23 | 87.22 | 50.65 | 21.09 |

| −0.150 + 0.075 | 29.46 | 63.99 | 60.44 | 31.92 |

| −0.075 + 0.038 | 17.85 | 34.53 | 60.99 | 19.51 |

| −0.038 + 0.023 | 7.44 | 16.68 | 64.75 | 8.64 |

| −0.023 + 0.019 | 7.49 | 9.24 | 63.82 | 8.57 |

| −0.019 + 0.010 | 0.42 | 1.75 | 63.42 | 0.48 |

| −0.010 | 1.33 | 1.33 | 63.28 | 1.51 |

| Sum/% | 100.00 | - | 55.78 | 100.00 |

| Category | Steel Ball | Ceramic Ball |

|---|---|---|

| Elements | Fe, Cr, C | Al, Si |

| Trace elements | Si, Mn, P, Mo, Al | Ca, Mg |

| True density/ | 7.3~7.8 | 3.7 |

| Bulk density/ | 4.85 | 2.3 |

| Mohs hardness | 6.8 | 9.0 |

| Self-wear/ | 60 | 5 |

| Size Classes/mm | φ | γ | β |

|---|---|---|---|

| −0.500 + 0.300 | 0.26 | 0.38 | 1.12 |

| −0.300 + 0.150 | 0.23 | 0.65 | 3.86 |

| △ | +0.03 | −0.27 | −2.74 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, C.; Wu, C.; Fang, X.; Liao, N.; Tong, J.; Yu, C. Effect of Slurry Concentration on the Ceramic Ball Grinding Characteristics of Magnetite. Minerals 2022, 12, 1569. https://doi.org/10.3390/min12121569

Yuan C, Wu C, Fang X, Liao N, Tong J, Yu C. Effect of Slurry Concentration on the Ceramic Ball Grinding Characteristics of Magnetite. Minerals. 2022; 12(12):1569. https://doi.org/10.3390/min12121569

Chicago/Turabian StyleYuan, Chengfang, Caibin Wu, Xin Fang, Ningning Liao, Jiaqi Tong, and Chao Yu. 2022. "Effect of Slurry Concentration on the Ceramic Ball Grinding Characteristics of Magnetite" Minerals 12, no. 12: 1569. https://doi.org/10.3390/min12121569

APA StyleYuan, C., Wu, C., Fang, X., Liao, N., Tong, J., & Yu, C. (2022). Effect of Slurry Concentration on the Ceramic Ball Grinding Characteristics of Magnetite. Minerals, 12(12), 1569. https://doi.org/10.3390/min12121569