Study on Shear Characteristics and Failure Mechanism of Inclined Layered Backfill in Mining Solid Waste Utilization

Abstract

:1. Introduction

2. Materials and Method

2.1. Raw Materials

2.2. Layered CPB Specimens Preparation

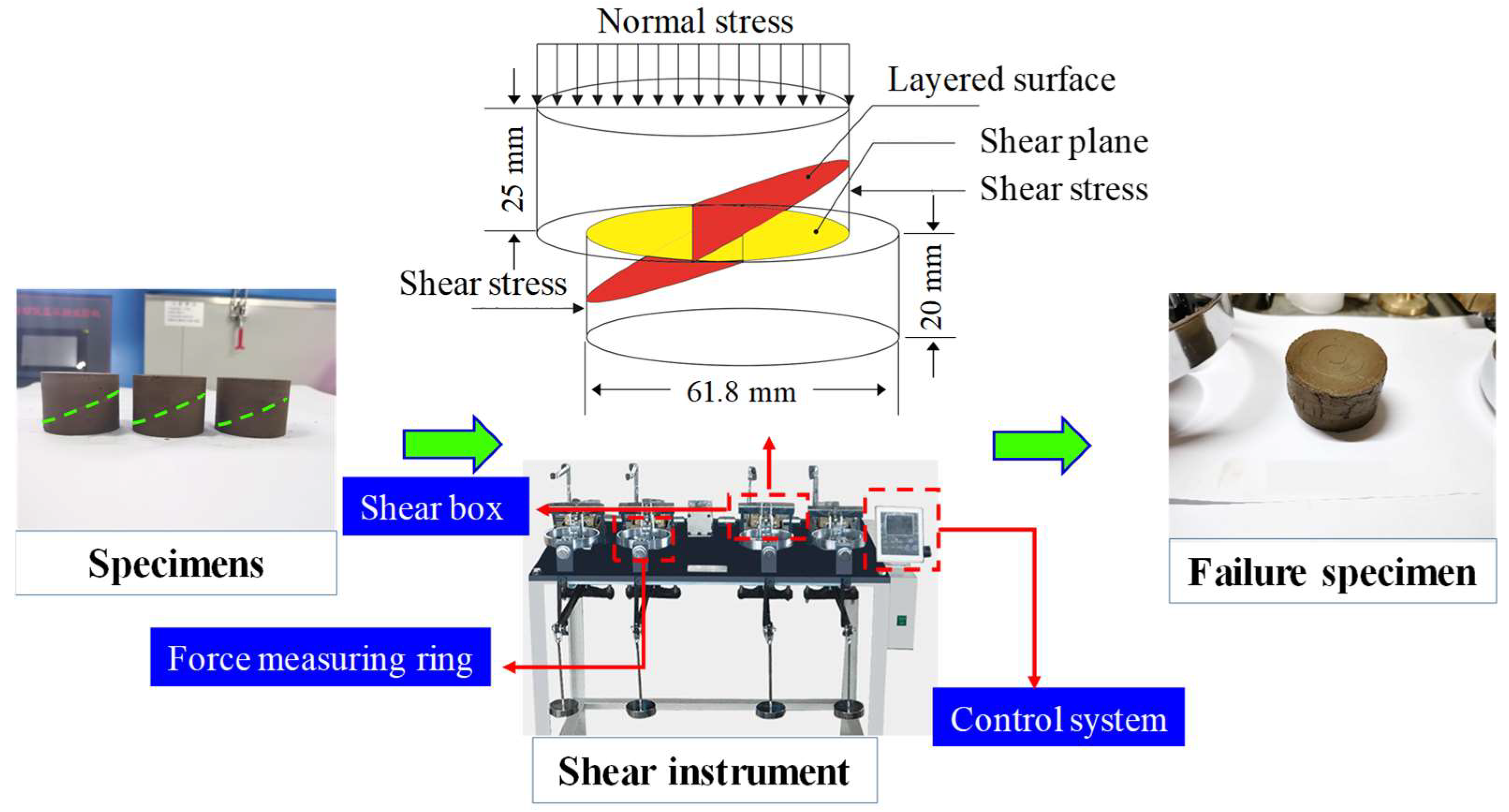

2.3. Direct Shear Test

2.4. Establishment of Numerical Model

3. Result and Discussion

3.1. Shear Stress(τ) and Shear Displacement(δ)

3.2. Shear Strength

3.3. Cohesion and Internal Friction Angle

3.4. Analysis of Shear Strength Mechanism

4. Crack Propagation Law and Damage Mode Analysis

4.1. Numerical Simulation Reliability Verification

4.2. Analysis of Crack Evolution Law

- No crack or minimal crack generation stage (O1A1): at the beginning of loading, the CPB was in the linear elastic deformation stage, and the shear stress was lower than the inter-particle bond strength; at this time, although the CPB shear stress increased, there were no cracks generated or the CPB just began to break along the weaker bond at both ends of the shear plane to produce a very small number of micro-cracks with low growth rate.

- Rapid crack growth stage (A1B1): in the middle period of loading, the CPB entered the yielding stage; as the shear stress gradually increased and became greater than the bond strength between the particles, a large number of bonding bonds began to break, resulting in a large number of cracks along the shear surface of the CPB.

- Crack slow growth stage (B1C1): late loading, the CPB into the plastic damage stage, the internal cracks have basically extended and penetrated along the shear surface, and the CPB was substantially destroyed. Due to the action of normal stress, the CPB shear strength was mainly controlled by the inter-particle friction strength, with only a very small number of secondary cracks near the shear surface; therefore, the number of cracks continued to increase in this stage, but the growth rate gradually decreased. Taking the CPB under 2-L-25 and 100 kPa normal stress as an example, the effect of normal stress and layered angle on the crack evolution law is analyzed, as shown in Figure 15.

4.3. Analysis of Failure Mode

5. Conclusions

- The τ-δ curves of each group of CPB can be divided into three stages: linear elastic deformation stage, yielding stage and plastic shear failure stage. The normal stress has an important influence on the shear strength of the CPB; the higher the normal stress, the higher the shear strength, and the slower to reach the shear strength. When the normal stress is 100 kPa, the shear strength of CPB is controlled by cohesion and friction, but when the normal stress is greater than 100 kPa, the shear strength is mainly controlled by friction.

- The layering phenomenon weakens the integrity of the CPB; the shear strength and C of layered CPB are negatively correlated with the layer angle. Especially when the layered angle increases from 20° to 25°, the normal bearing structure of layered CPB changes greatly; its shear strength decreases by 35.13% (100 kPa normal stress), and cohesion decreases by 43.43%. With the increase of layer angle, the internal friction angle decreases first and then increases slightly and reaches the lowest when the layered angle is 15°.

- The numerical simulation results of PFC show that the crack evolution law inside the CPB is approximately the same, which can be divided into no crack or tiny crack generation stage, rapid crack growth stage and slow crack growth stage. The total number of cracks during the damage of the CPB is positively correlated with the normal stress, which means the higher the normal stress, the more the total number of cracks. Under the same normal stress, the total number of cracks when the layered CPB is damaged is lower than the complete CPB. With the increase of layer angle, a certain number of tensile cracks were gradually generated along the layered CPB near the layered surface, and the number gradually increased.

- The failure mode of CPB under the normal stress of 100 kPa is caused by shear cracks penetrating along the shear surface. When the normal stress increases to 200 kPa, the CPB shows a spindle-shaped failure. When the normal stress continues to increase to 300 kPa and 400 kPa, the CPB shows inverted Z-shaped conjugate shear failure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, W.; Wang, H.; Hou, K. Control of waste rock-tailings paste backfill for active mining subsidence areas. J. Clean. Prod. 2018, 171, 567–579. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.H.; Ivannikov, A.; Khayrutdinov, A.; Tyulyaeva, Y. Geotechnology using composite materials from man-made waste is a paradigm of sustainable development. Mater. Today Proc. 2021, 38, 2078–2082. [Google Scholar] [CrossRef]

- Sari, M.; Yilmaz, E.; Kasap, T.; Guner, N. Strength and microstructure evolution in cemented mine backfill with low and high pH pyritic tailings: Effect of mineral admixtures. Constr. Build. Mater. 2022, 328, 127109. [Google Scholar] [CrossRef]

- Li, H.; Wu, A.; Jiang, G.; Wang, X. Effect of operational factors on reproducibility of yield stress measurement based on the vane method for cemented paste backfill. Constr. Build. Mater. 2022, 348, 128709. [Google Scholar] [CrossRef]

- Hefni, M.; Ahmed, H.A.M.; Omar, E.S.; Ali, M.A. The potential re-use of saudi mine tailings in mine backfill: A path towards sustainable mining in Saudi Arabia. Sustainability 2021, 13, 6204. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, S.; Li, J.; Li, Z. Experimental study on energy dissipation of layered backfill under impact load. Constr. Build. Mater. 2022, 347, 128478. [Google Scholar] [CrossRef]

- Fang, K.; Fall, M. Shear Behaviour of Rock–Tailings Backfill Interface: Effect of Cementation, Rock Type, and Rock Surface Roughness. Geotech. Geol. Eng. 2021, 39, 1753–1770. [Google Scholar] [CrossRef]

- Wu, A.; Ruan, Z.; Wang, J. Rheological behavior of paste in metal mines. Int. J. Miner. Metall. Mater. 2022, 29, 717–726. [Google Scholar] [CrossRef]

- Jiao, H.; Chen, W.; Wu, A.; Yang, Y.; Ruan, Z.; Honaker, R.; Chen, X.; Yu, J. Flocculated unclassified tailings settling efficiency improvement by particle collision optimization in the feedwell. Int. J. Miner. Metall. Mater. 2022, 29, 2126–2135. [Google Scholar] [CrossRef]

- Ruan, Z.; Wu, A.; Bürger, R.; Betancourt, F.; Wang, Y.; Wang, Y.; Jiao, H.; Wang, S. Effect of interparticle interactions on the yield stress of thickened flocculated copper mineral tailings slurry. Powder. Technol. 2021, 392, 278–285. [Google Scholar] [CrossRef]

- Huang, Z.; Cao, S.; Yilmaz, E. Investigation on the flexural strength, failure pattern and microstructural characteristics of combined fibers reinforced cemented tailings backfill. Constr. Build. Mater. 2021, 300, 124005. [Google Scholar] [CrossRef]

- Xue, G.; Yilmaz, E.; Feng, G.; Cao, S. Bending behavior and failure mode of cemented tailings backfill composites incorporating different fibers for sustainable construction. Constr. Build. Mater. 2021, 289, 123163. [Google Scholar] [CrossRef]

- Qin, S.; Cao, S.; Yilmaz, E. Employing U-shaped 3D printed polymer to improve flexural properties of cementitious tailings backfills. Constr. Build. Mater. 2022, 320, 126296. [Google Scholar] [CrossRef]

- Xu, W.; Cao, P. Fracture behaviour of cemented tailing backfill with pre-existing crack and thermal treatment under three-point bending loading: Experimental studies and particle flow code simulation. Eng. Fract. Mech. 2018, 195, 129–141. [Google Scholar] [CrossRef]

- Qiu, H.; Zhang, F.; Liu, L.; Huan, C.; Hou, D.; Kang, W. Experimental study on acoustic emission characteristics of cemented rock-tailings backfill. Constr. Build. Mater. 2022, 315, 125278. [Google Scholar] [CrossRef]

- Sun, W.; Hou, K.; Yang, Z.; Wen, Y. X-ray CT three-dimensional reconstruction and discrete element analysis of the cement paste backfill pore structure under uniaxial compression. Constr. Build. Mater. 2017, 138, 69–78. [Google Scholar] [CrossRef]

- Song, X.; Hao, Y.; Wang, S.; Zhang, L.; Liu, W.; Li, J. Mechanical properties, crack evolution and damage characteristics of prefabricated fractured cemented paste backfill under uniaxial compression. Constr. Build. Mater. 2022, 330, 127251. [Google Scholar] [CrossRef]

- Yu, X.; John, K.; Tan, Y.; Song, W.; Huang, K. Mechanical properties and fracturing of rock-backfill composite specimens under triaxial compression. Constr. Build. Mater. 2021, 304, 124577. [Google Scholar] [CrossRef]

- Xue, G.; Yilmaz, E. Strength, acoustic, and fractal behavior of fiber reinforced cemented tailings backfill subjected to triaxial compression loads. Constr. Build. Mater. 2022, 338, 127667. [Google Scholar] [CrossRef]

- Chen, T.; Zhao, K.; Yan, Y.; Zhou, Y.; He, Z.; Guo, L. Mechanical properties and acoustic emission response of cemented tailings backfill under variable angle shear. Constr. Build. Mater. 2022, 343, 128114. [Google Scholar] [CrossRef]

- Libos, L.; Cui, L.; Liu, X. Effect of curing temperature on time-dependent shear behavior and properties of polypropylene fiber-reinforced cemented paste backfill. Constr. Build. Mater. 2021, 311, 125302. [Google Scholar] [CrossRef]

- Xiu, Z.; Wang, S.; Ji, Y.; Wang, F.; Ren, F.; Nguyen, V. The effects of dry and wet rock surfaces on shear behavior of the interface between rock and cemented paste backfill. Powder. Technol. 2021, 381, 324–337. [Google Scholar] [CrossRef]

- Xue, G.; Yilmaz, E.; Song, W.; Cao, S. Mechanical, flexural and microstructural properties of cement-tailings matrix composites: Effects of fiber type and dosage. Compos. Part B 2019, 172, 131–142. [Google Scholar] [CrossRef]

- Sun, W.; Wu, A.; Hou, K.; Yang, Y.; Liu, L.; Wen, Y. Real-time observation of meso-fracture process in backfill body during mine subsidence using X-ray CT under uniaxial compressive conditions. Constr. Build. Mater. 2016, 113, 153–162. [Google Scholar] [CrossRef]

- Xiu, Z.; Wang, S.; Ji, Y.; Wang, F.; Ren, F. Experimental study on the triaxial mechanical behaviors of the Cemented Paste Backfill: Effect of curing time, drainage conditions and curing temperature. Constr. Build. Mater. 2022, 301, 113828. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Xu, W.; Zuo, J. Effect of inclined interface angle on shear strength and deformation response of cemented paste backfill-rock under triaxial compression. Constr. Build. Mater. 2021, 279, 122478. [Google Scholar] [CrossRef]

- Fang, K.; Fall, M. Effects of curing temperature on shear behaviour of cemented paste backfill-rock interface. Int. J. Rock. Mech. Min. 2018, 112, 184–192. [Google Scholar] [CrossRef]

- Gao, T.; Sun, W.; Liu, Z.; Cheng, H. Investigation on fracture characteristics and failure pattern of inclined layered cemented tailings backfill. Constr. Build. Mater. 2022, 343, 128110. [Google Scholar] [CrossRef]

- Chen, S.; Jin, A.; Zhao, Y.; Li, H.; Wang, J. Mechanical properties and deformation mechanism of stratified cemented tailings backfill under unconfined compression. Constr. Build. Mater. 2022, 335, 127205. [Google Scholar] [CrossRef]

- Cao, S.; Song, W.; Yilmaz, E. Influence of structural factors on uniaxial compressive strength of cemented tailings backfill. Constr. Build. Mater. 2018, 174, 190–201. [Google Scholar] [CrossRef]

- Wang, J.; Fu, J.; Song, W.; Zhang, Y.; Wang, Y. Mechanical behavior, acoustic emission properties and damage evolution of cemented paste backfill considering structural feature. Constr. Build. Mater. 2020, 261, 119958. [Google Scholar] [CrossRef]

- Wang, J.; Fu, J.; Song, W.; Zhang, Y.; Wu, S. Acoustic emission characteristics and damage evolution process of layered cemented tailings backfill under uniaxial compression. Constr. Build. Mater. 2021, 295, 123663. [Google Scholar] [CrossRef]

- Zhang, C.; Fu, J.; Song, W.; Kang, M.; Li, T.; Wang, N. Analysis on mechanical behavior and failure characteristics of layered cemented paste backfill(LCPB) under triaxial compression. Constr. Build. Mater. 2022, 324, 126631. [Google Scholar] [CrossRef]

- Wang, J.; Song, W.; Cao, S.; Tan, Y. Mechanical properties and failure modes of stratified backfill under triaxial cyclic loading and unloading. Int. J. Min. Sci. Technol. 2019, 29, 809–814. [Google Scholar] [CrossRef]

- Wang, J.; Song, W.; Cao, S.; Tan, Y. Mechanical properties and microstructure of layered cemented paste backfill under triaxial cyclic loading and unloading. Constr. Build. Mater. 2020, 257, 119540. [Google Scholar] [CrossRef]

- Li, J.; Sun, W.; Li, Q.; Chen, S.; Yuan, M.; Xia, H. Influence of Layered Angle on Dynamic Characteristics of Backfill under Impact Loading. Minerals 2022, 12, 511. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Wei, C.; Zhang, Q. Dynamic mechanical properties and instability behavior of layered backfill under intermediate strain rates. Trans. Nonferrous Met. Soc. China 2017, 27, 1608–1617. [Google Scholar] [CrossRef]

- Mashifana, T.; Sithole, T. Clean production of sustainable backfill material from waste gold tailings and slag. J. Clean. Prod. 2021, 308, 127357. [Google Scholar] [CrossRef]

- Cao, S.; Yilmaz, E.; Song, W. Damage constitutive model and strength criterion on strength, toughness and microstructure of early age cemented tailings backfill. Constr. Build. Mater. 2019, 223, 44–54. [Google Scholar] [CrossRef]

| Compound | SiO2 | Al2O3 | TFe | CaO | MgO | S | Zn | Cu | Others |

|---|---|---|---|---|---|---|---|---|---|

| Tailings/wt% | 45.9 | 12.3 | 11.1 | 6.0 | 2.1 | 0.5 | 0.07 | 0.04 | 22.1 |

| Serial Number | Cement/Tailing | Mass Concentration/% | Number of Layers | Angle of Layers/° |

|---|---|---|---|---|

| N-L | 1:20 | 68 | 1 | - |

| 2-L-5 | 1:20 | 68 | 2 | 5 |

| 2-L-10 | 1:20 | 68 | 2 | 10 |

| 2-L-15 | 1:20 | 68 | 2 | 15 |

| 2-L-20 | 1:20 | 68 | 2 | 20 |

| 2-L-25 | 1:20 | 68 | 2 | 25 |

| Specimen ID | Shear Strength /kPa | C/kPa | φ/° | |||

|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | |||

| N-L | 160.28 | 216.71 | 280.67 | 349.4 | 93.94 | 32.27 |

| 2-L-5 | 139.53 | 197.18 | 261.44 | 312.17 | 82.03 | 30.21 |

| 2-L-10 | 136.42 | 193.54 | 249.16 | 305.28 | 80.54 | 29.35 |

| 2-L-15 | 126.25 | 185.62 | 237.38 | 289.67 | 74.22 | 28.46 |

| 2-L-20 | 115.52 | 173.53 | 229.05 | 284.72 | 59.93 | 29.38 |

| 2-L-25 | 90.52 | 144.47 | 210.32 | 257.72 | 33.90 | 29.57 |

| Function Type | Normal Stress/kPa | Raj2 Average | |||

|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | ||

| Linear | y = 157.32 − 2.38x | y = 216.50 − 2.51x | y = 274.18 − 2.45x | y = 328.75 − 2.59x | 0.898 |

| Polynomial | y = 135.15 + 1.42x − 0.13x2 | y = 188.99 + 2.21x − 0.16x2 | y = 269.45 − 1.64x − 0.03x2 | y = 313.97 − 0.06x − 0.08x2 | 0.970 |

| Exponential | y = 139.70 − 0.005x2.83 | y = 196.44 − 0.001x3.36 | y = 267.66 − 0.89x1.29 | y = 313.18 − 0.07x2.06 | 0.975 |

| Type | Parameter | Value |

|---|---|---|

| Particles | density/(kg·m−3) | 2.7e3 |

| porosity | 0.12 | |

| fric | 0.5 | |

| radius of particles/m | 9.885e−5~7.853e−4 | |

| damp | 0.7 | |

| Linear Model | emod/Pa | 5e6 |

| kratio | 2.0 | |

| fric | 0.1 | |

| Linear Parallel Bond Model | pb_emod/Pa | 1e5 |

| kratio | 2.0 | |

| pb_coh/Pa | 3e4 | |

| pb_ten/Pa | 3e4 | |

| pb_fa/° | 30 | |

| pb_radius/m | 1.0 | |

| Smooth-Joint Contact Model | sj_kn/(N·m−1) | 1e7 |

| sj_ks/(N·m−1) | 1e7 | |

| sj_fric | 0.1 | |

| sj_large | 1.0 |

| Specimen ID | Picture Type | Normal Stress /kPa | |||

|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | ||

| N-L | Cracks |  |  |  |  |

| blocks | |||||

| 2-L-5 | Cracks |  |  |  |  |

| blocks | |||||

| 2-L-15 | Cracks |  |  |  |  |

| blocks | |||||

| 2-L-25 | Cracks |  |  |  |  |

| blocks | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, T.; Sun, W.; Li, Z.; Fan, K.; Jiang, M.; Cheng, H. Study on Shear Characteristics and Failure Mechanism of Inclined Layered Backfill in Mining Solid Waste Utilization. Minerals 2022, 12, 1540. https://doi.org/10.3390/min12121540

Gao T, Sun W, Li Z, Fan K, Jiang M, Cheng H. Study on Shear Characteristics and Failure Mechanism of Inclined Layered Backfill in Mining Solid Waste Utilization. Minerals. 2022; 12(12):1540. https://doi.org/10.3390/min12121540

Chicago/Turabian StyleGao, Tong, Wei Sun, Zhaoyu Li, Kai Fan, Minggui Jiang, and Haiyong Cheng. 2022. "Study on Shear Characteristics and Failure Mechanism of Inclined Layered Backfill in Mining Solid Waste Utilization" Minerals 12, no. 12: 1540. https://doi.org/10.3390/min12121540

APA StyleGao, T., Sun, W., Li, Z., Fan, K., Jiang, M., & Cheng, H. (2022). Study on Shear Characteristics and Failure Mechanism of Inclined Layered Backfill in Mining Solid Waste Utilization. Minerals, 12(12), 1540. https://doi.org/10.3390/min12121540