Study on Mechanical Characteristics of Rock Surrounding the Roadway under Different Section Shapes

Abstract

:1. Introduction

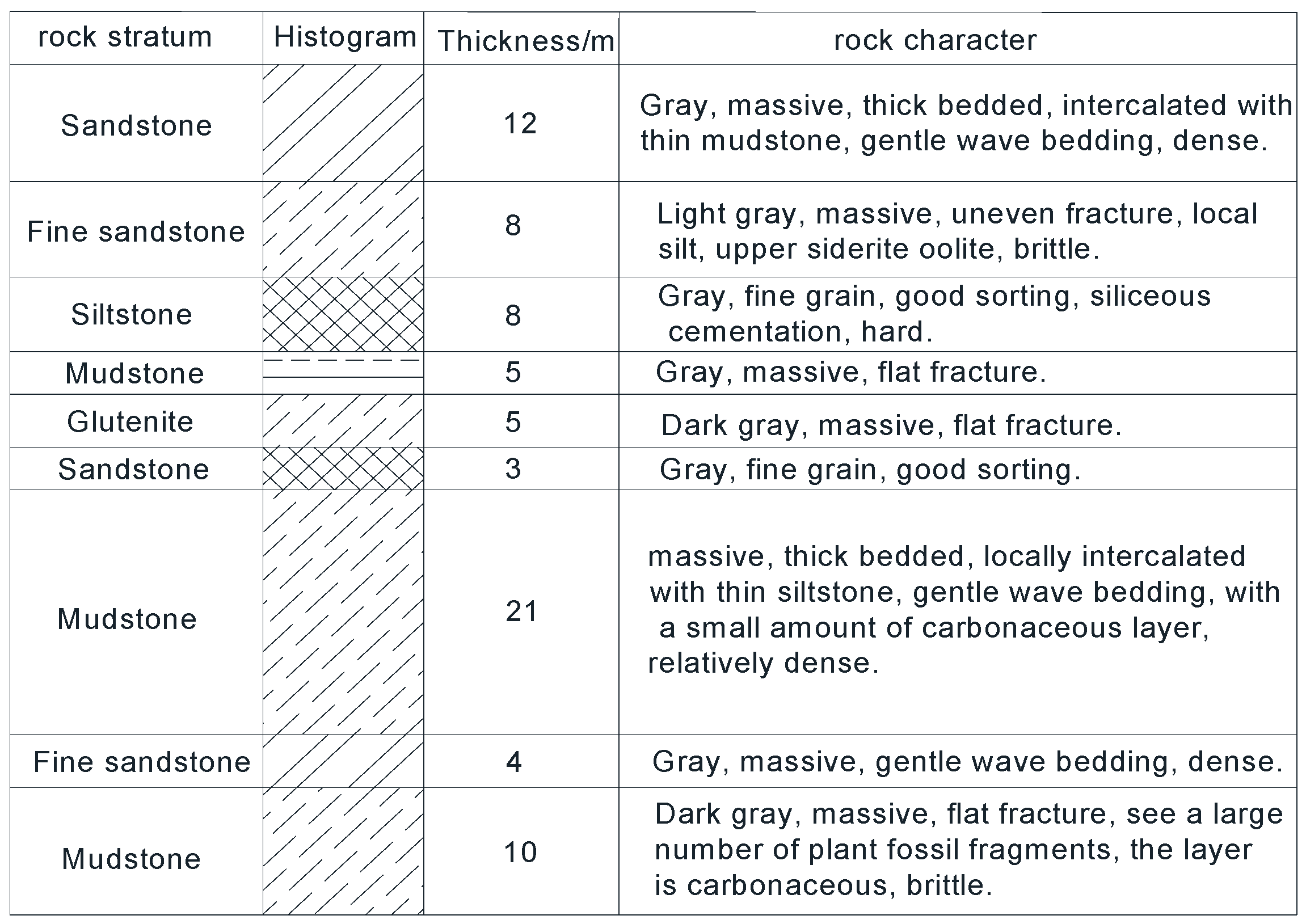

2. Engineering Background and Numerical Model

2.1. Engineering Background

2.2. Establishment of a Numerical Model

3. Influence of Section Shape on the Stability of Roadway Surrounding Rock

3.1. Influence of Section Shape on Cloud Distribution of Maximum Principal Stress in Surrounding Rock

3.2. Influence of Section Shape on Cloud Distribution of Minimum Principal Stress in Surrounding Rock

3.3. Influence of Section Shape on Vertical Displacement Cloud Distribution of Surrounding Rock

3.4. Step-by-Step Influence of Section Shape on Horizontal Displacement Cloud Map of Surrounding Rock

3.5. Influence of Section Shape on the Morphology of the Surrounding Rock Damage Zone

3.6. Influence of Section Shape on the Form of the Destructive Danger Area of Surrounding Rock

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, N.J.; Zhao, X.D.; Zhao, Z.Q. Stability analysis and control of roof in deep mining roadway. J. China Coal Soc. 2015, 40, 2287–2295. [Google Scholar]

- Zhang, J.W.; Song, Z.X.; Liu, J.L. Architecture of Structural Regulation Technology for Rock Burst Disaster in Deep Mining of Coal Mine. Coal Sci. Technol. 2022, 50, 27–36. [Google Scholar]

- Jing, H.W.; Wu, J.Y.; Yin, Q. Deformation and destructive characteristics of anchorage structure of surrounding rock in deep roadway. Int. J. Min. Sci. Technol. 2020, 30, 17–32. [Google Scholar] [CrossRef]

- Wang, W.J.; Yuan, C.; Yu, W.J. Deep large deformation of roadway surrounding rock stability control method research. J. Coal 2016, 9, 2921–2931. [Google Scholar]

- Lou, J.F.; Gao, F.Q.; Yang, J.H. Characteristics of evolution of mining-induced stress field in the longwall panel: Insights from physical modeling. Int. J. Coal Sci. Technol. 2021, 8, 938–955. [Google Scholar] [CrossRef]

- Wang, J.C.; Fu, Q. Theory and Application of Granular Medium Flow in Top Coal Emission from Fully-mechanized Coal Caving in Low Position. J. China Coal Soc. 2002, 27, 337–340. [Google Scholar]

- Ning, S.R.; Su, H.; Gao, J. Research on Automatic Section Precision Forming of Boom-Type Roadheader. In Proceedings of the International Conference on Intelligent Systems Research and Mechatronics Engineering, Zhengzhou, China, 11–13 April 2015; Atlantis Press: Paris, France, 2015; Volume 121, pp. 1250–1256. [Google Scholar]

- Wang, J.H. Mechanism and effect analysis of bolt and cable combined support in whole coal roadway. J. China Coal Soc. 2012, 37, 1–7. [Google Scholar]

- Yuan, J. Effects of Air Dilution on Hinghly Preheated Air Combustion in a Regenerative Furnace. Energy Fules 1999, 13, 99–104. [Google Scholar] [CrossRef]

- Huang, Q.X.; Liu, Y.W. Limit Self-stabilizing Balanced Arch Theory of Roadway Surrounding Rock Support. J. Min. Saf. Eng. 2014, 31, 354–358. [Google Scholar]

- Ma, N.J.; Zhao, Z.Q.; Feng, J.C. Supporting Technology of Tunnel Butting Long Bolt under Difficult Condition. Coal Sci. Technol. 2013, 41, 117–121. [Google Scholar]

- Kang, H.P.; Jiang, T.M.; Gao, F.Q. Effect of pretensioned stress to rock bolting. J. China Coal Soc. 2007, 32, 2287–2295. [Google Scholar]

- He, M.C.; Guo, Z.B. Mechanical Characteristics and Engineering Application of Transversely Resistant Large Deformation Anchor Bolt. Chin. J. Rock Mech. Eng. 2014, 33, 1297–1308. [Google Scholar]

- Wang, J.C.; Wang, L.; Guo, Y. Determination of Support Resistance Based on Roof and Coal Wall Control. J. China Coal Soc. 2014, 39, 1619–1624. [Google Scholar]

- Wang, J.H. New development of rock bolting technology for coal roadway in China. J. China Coal Soc. 2007, 32, 113–118. [Google Scholar]

- Jiang, Y.D.; Zhao, Y.X.; Liu, W.G. Research on floor heave of roadway in deep mining. Chin. J. Rock Mech. Eng. 2004, 23, 2396–2401. [Google Scholar]

- Li, G.C.; Zhang, N.; Wang, C.; Zhang, N.-C.; Li, B.-Y. Optimizing the Section Shape of Roadways in High Stress Ground by Numerical Simulation. J. China Univ. Min. Technol. 2010, 39, 652–658. [Google Scholar]

- Xie, H.P.; Yu, G.M.; Yang, L. Research on the Fractal Effects of Crack Network in Overlying strata Stratum. China J. Rock Mech. Eng. 1999, 18, 147–151. [Google Scholar]

- Wang, Z.G.; Zhou, H.W.; Xie, H.P. Research on Fractal Characterization of Mined Crack Network Evolution in Overlying strata Stratum under Deep Mining. Rock Soil Mech. 2009, 30, 2403–2408. [Google Scholar]

- Huang, D.; Tan, Q.; Huang, R.Q. Fractal Characteristics of Fragmentation and Correlation with Energy of Marble under Unloading with High Confining Pressure. China J. Rock Mech. Eng. 2012, 31, 1379–1389. [Google Scholar]

- Chen, J.H.; Liu, P.; Liu, L.; Zeng, B.; Zhao, H.; Zhang, C.; Zhang, J.; Li, D. Anchorage performance of a modified cable anchor subjected to different joint opening conditions. Constr. Build. Mater. 2022, 336, 127558. [Google Scholar] [CrossRef]

- Chen, J.H.; Zeng, B.Q.; Liu, L.; Tao, K.; Zhao, H.; Zhang, C.; Zhang, J.; Li, D. Investigating the anchorage performance of full-grouted anchor bolts with a modified numerical simulation method. Eng. Fail. Anal. 2022, 141, 106640. [Google Scholar] [CrossRef]

- Xu, S.; Gao, L.; Liu, P.Z.; Zhang, P.D.; Liu, P.; Ma, Z.Q.; Kang, X.T. Section shape optimization of gob-side coal-rock roadway in inclined coal seam. Coal Eng. 2022, 54, 122–128. [Google Scholar]

- Liu, F.; Gao, M.Z.; Guo, Z.R.; Zhou, C.T.; Wang, J. Study on the propagation mechanism of blast waves using the ultra-dynamic strain test system. Smart Struct. Syst. 2021, 28, 143–152. [Google Scholar]

- Huang, B.X.; Zhang, N.; Jing, H.W.; Kan, J.G.; Meng, B.; Li, N. Large deformation theory of rheology and structural instability of the surrounding rock in deep mining roadway. J. China Coal Soc. 2020, 45, 911–926. [Google Scholar]

- Wang, J.C.; Liu, F.; Wang, Z.H. Experimental investigation on the movement law of top coal in steeply inclined ultra-thick coal seams. Acta Mech. Sin. 2021, 37, 631–648. [Google Scholar] [CrossRef]

- Wang, J.C.; Wang, Z.H.; Tang, Y.S.; Li, M.; Chang, K.L.; Gong, H.; Xu, G.L. Experimental study on mining-induced dynamic load of main roof in deeply buried thick coal seam with weakly consolidated thin bed rock. China J. Rock Mech. Eng. [CrossRef]

- Liu, F.; Guo, Z.R.; Lv, H.Y.; Cheng, Z.B. Test and analysis of blast wave in mortar test block. Int. J. Rock Mech. Min. Sci. 2018, 108, 80–85. [Google Scholar] [CrossRef]

- Wang, Y.; Song, Z.Y.; Mao, T.Q.; Zhu, C. Macro-Meso Fracture and Instability Behaviors of Hollow-Cylinder Granite Containing Fissures Subjected to Freeze–Thaw–Fatigue Load. Rock Mech. Rock Eng. 2022, 55, 4051–4071. [Google Scholar] [CrossRef]

- Si, G.Y.; Durucan, S.; Jamnikar, S.; Lazar, J.; Abraham, K.; Korre, A.; Shi, J.-Q.; Zavšek, S.; Mutke, G.; Lurka, A. Seismic monitoring and analysis of excessive gas emissions in heterogeneous coal seams. Int. J. Coal Geol. 2015, 149, 41–54. [Google Scholar] [CrossRef]

- Wang, Y.; Yi, X.; Han, J.; Xia, Y. Acoustic emission and computed tomography investigation on fatigue failure of fissure-contained hollow-cylinder granite: Cavity diameter effect. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 2243–2260. [Google Scholar] [CrossRef]

- Cao, W.Z.; Shi, J.Q.; Si, G.Y.; Durucan, S.; Korre, A. Numerical modelling of microseismicity associated with longwall coal mining. Int. J. Coal Geol. 2018, 193, 30–45. [Google Scholar] [CrossRef]

- Wang, Y.; Mao, T.; Xia, Y.; Li, X.; Yi, X. Macro-meso fatigue failure of bimrocks with various block content subjected to multistage fatigue triaxial loads. Int. J. Fatigue 2022, 163, 107014. [Google Scholar] [CrossRef]

- Qian, M.G.; Xu, J.L.; Wang, J.C. Mining Pressure and Ground Control, 3rd ed.; China University of Mining and Technology Press: Xuzhou, China, 2021. [Google Scholar]

- Wang, J.C.; Wang, Z.H.; Yang, S.L. A coupled macro-and meso-mechanical model for heterogeneous coal. Int. J. Rock Mech. Min. Sci. 2017, 94, 64–81. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. Practical estimates of rock mass strength. Int. J. Rock Mech. Min. Sci. 1997, 34, 1165–1186. [Google Scholar] [CrossRef]

- Shabanimashcool, M.; Li, C.C. Numerical modelling of longwall mining and stability analysis of the gates in a coal mine. Int. J. Rock Mech. Min. Sci. 2012, 51, 24–34. [Google Scholar] [CrossRef]

- Suchowerska, A.M.; Merifield, R.S.; Carter, J.P. Vertical stress changes in multi-seam mining under supercritical longwall panels. Int. J. Rock Mech. Min. Sci. 2013, 61, 306–320. [Google Scholar] [CrossRef]

- Li, T.; Gong, H.; Xu, G.L. Study on the influence of in situ stress distribution on the stability of roadway surrounding rock. Adv. Civ. Eng. 2021, 2021, 3570523. [Google Scholar] [CrossRef]

| Rock Parameter | Siltstone | Mudstone | Glutenite | Sandstone |

| Bulk modulus/GPa | 1.11 | 0.83 | 1.0 | 0.97 |

| Shear modulus/GPa | 0.83 | 0.38 | 0.6 | 0.72 |

| Cohesive forces/MPa | 6.0 | 3.0 | 4.0 | 5.0 |

| Angle of internal friction/° | 38 | 32 | 34 | 38 |

| Angle of dilatancy/° | 10 | 10 | 10 | 10 |

| Tensile strength/MPa | 2.5 | 1.0 | 1.5 | 2.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Li, Z.; Liu, F. Study on Mechanical Characteristics of Rock Surrounding the Roadway under Different Section Shapes. Minerals 2022, 12, 1504. https://doi.org/10.3390/min12121504

Li T, Li Z, Liu F. Study on Mechanical Characteristics of Rock Surrounding the Roadway under Different Section Shapes. Minerals. 2022; 12(12):1504. https://doi.org/10.3390/min12121504

Chicago/Turabian StyleLi, Tao, Zheng Li, and Fei Liu. 2022. "Study on Mechanical Characteristics of Rock Surrounding the Roadway under Different Section Shapes" Minerals 12, no. 12: 1504. https://doi.org/10.3390/min12121504

APA StyleLi, T., Li, Z., & Liu, F. (2022). Study on Mechanical Characteristics of Rock Surrounding the Roadway under Different Section Shapes. Minerals, 12(12), 1504. https://doi.org/10.3390/min12121504