Production Decline Analysis of Tight Conglomerate Reservoirs with Small Well Spacing, Based on the Fractal Characteristics of Fracture Networks

Abstract

1. Introduction

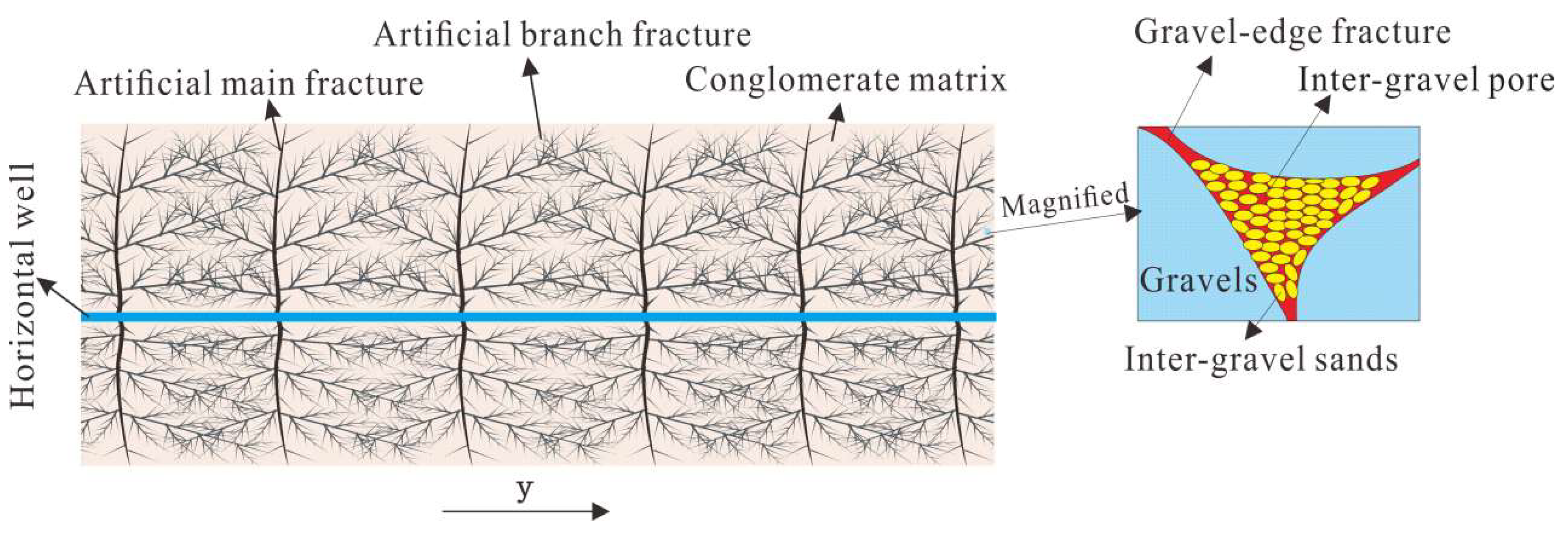

2. Fracture and Matrix Characteristics of Conglomerate Reservoir

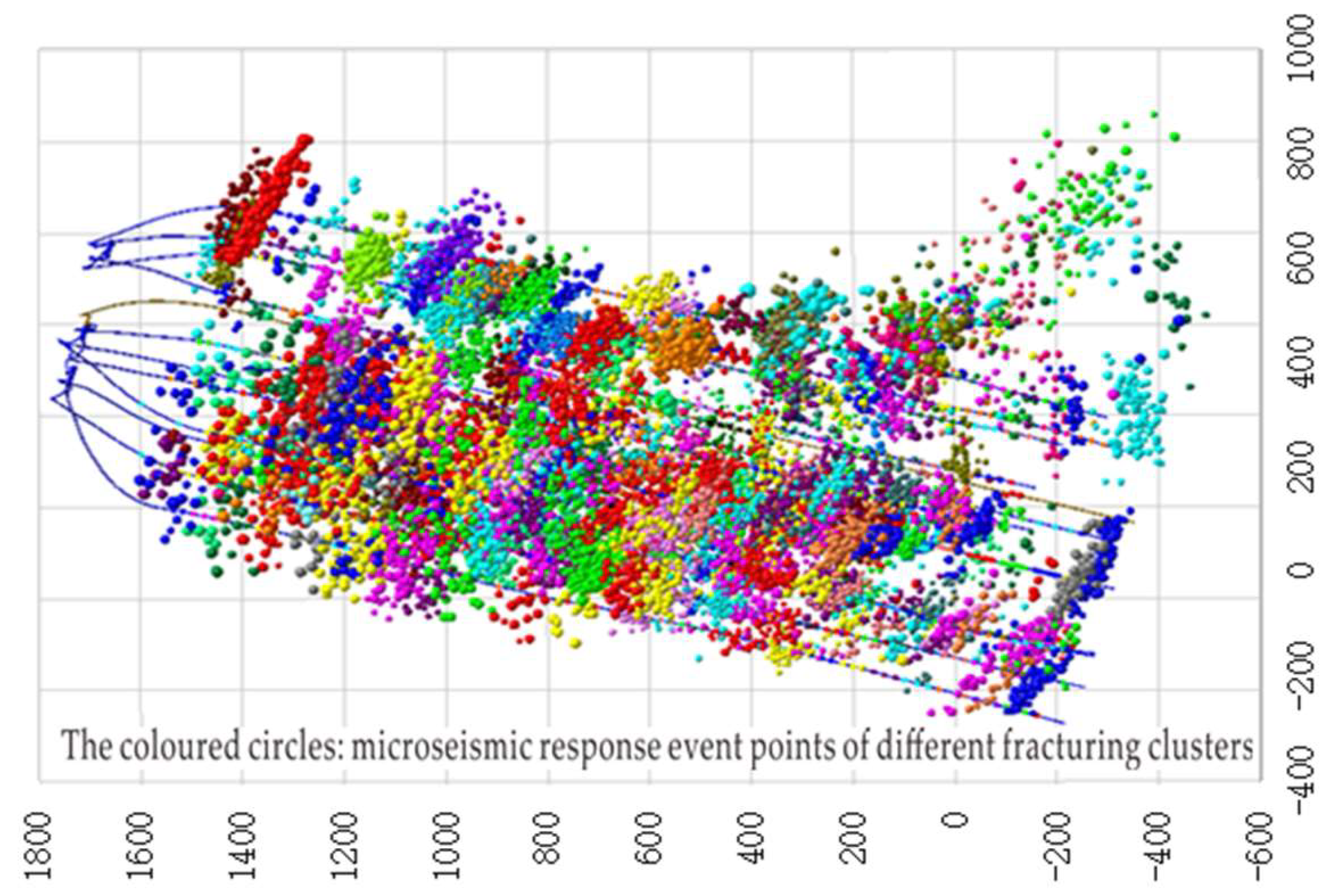

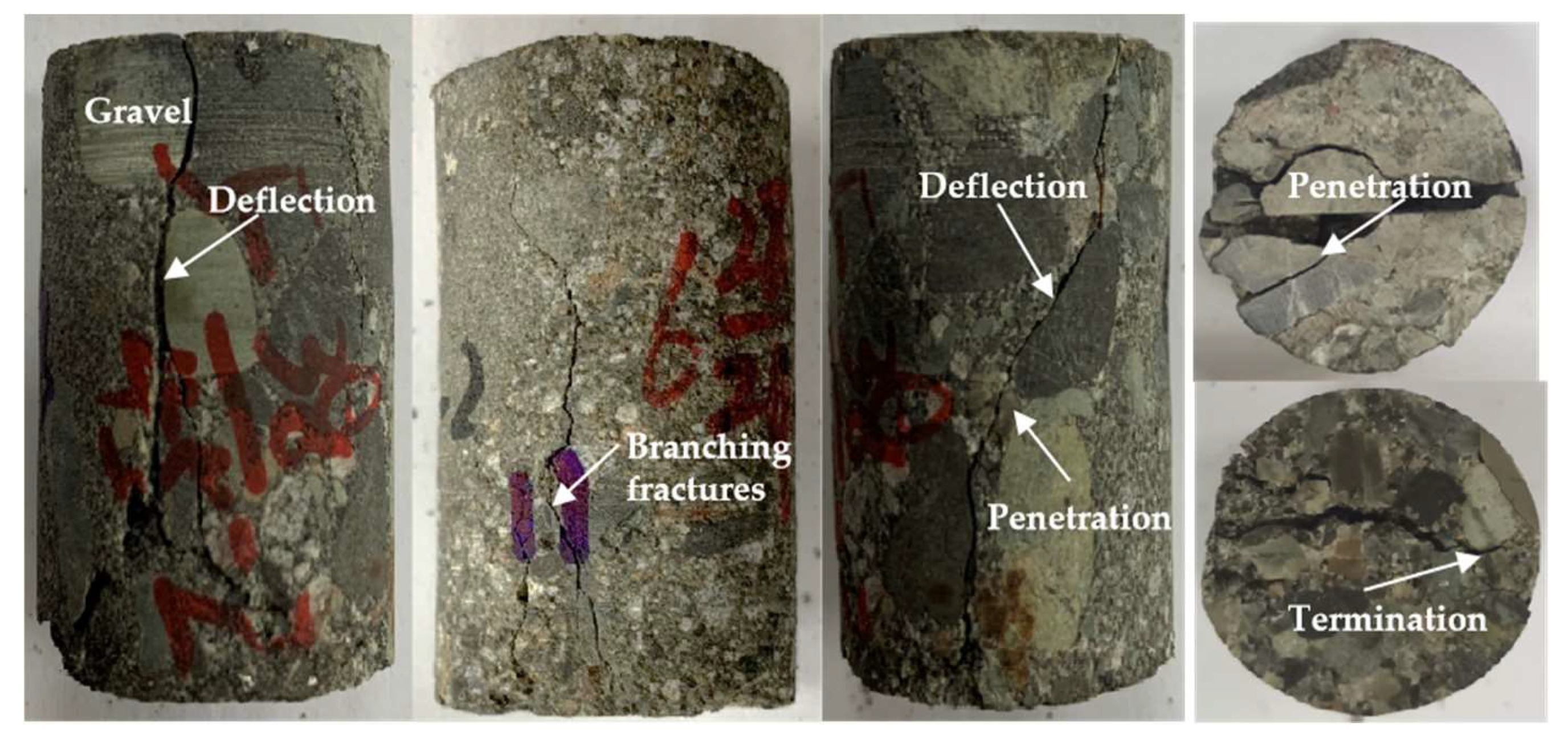

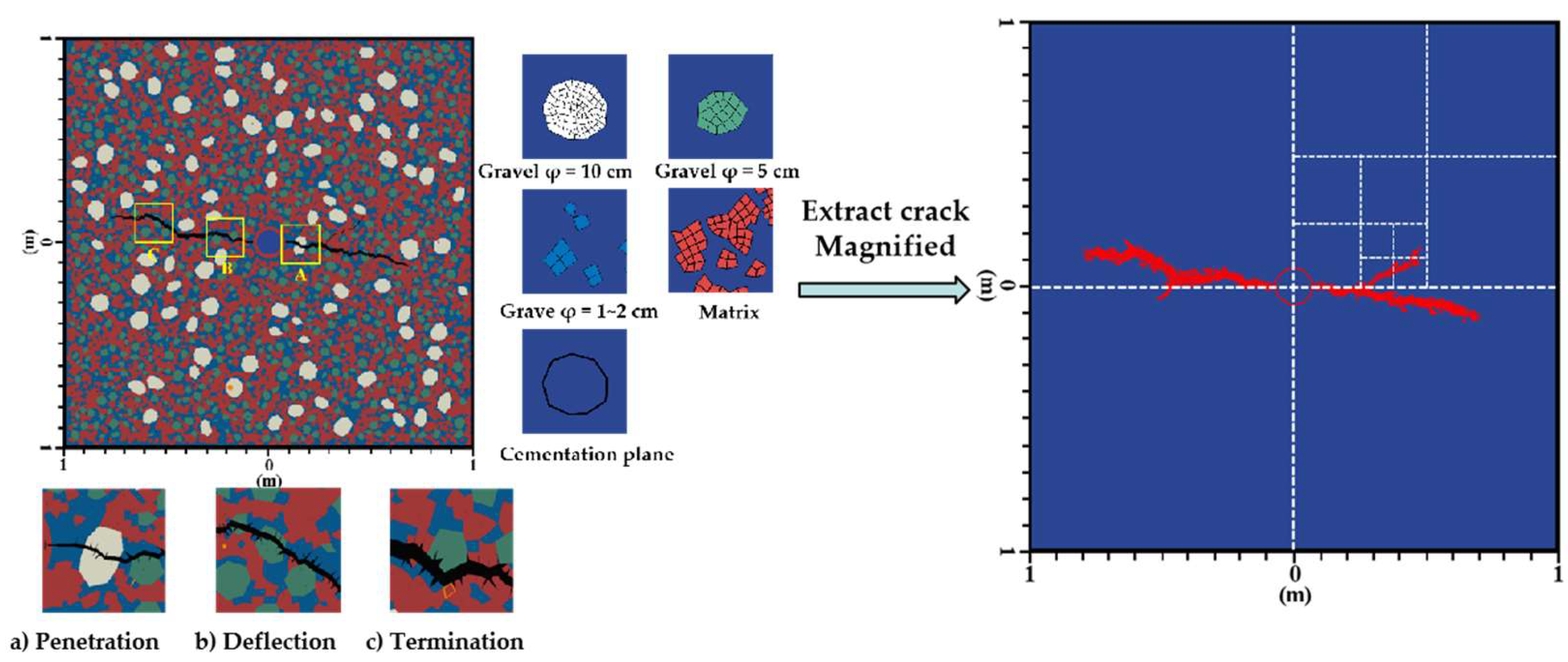

2.1. Characteristics of Fracturing Network

2.2. Matrix Seepage Description

3. Mathematical Model

3.1. Physical Assumptions

- (1)

- A fractured horizontal well with finite fracture conductivity is located in the center of the bounded conglomerate reservoir and fracturing results in the complex fracture network, consisting of main fractures and artificial micro fractures (in other words, artificial branch fractures).

- (2)

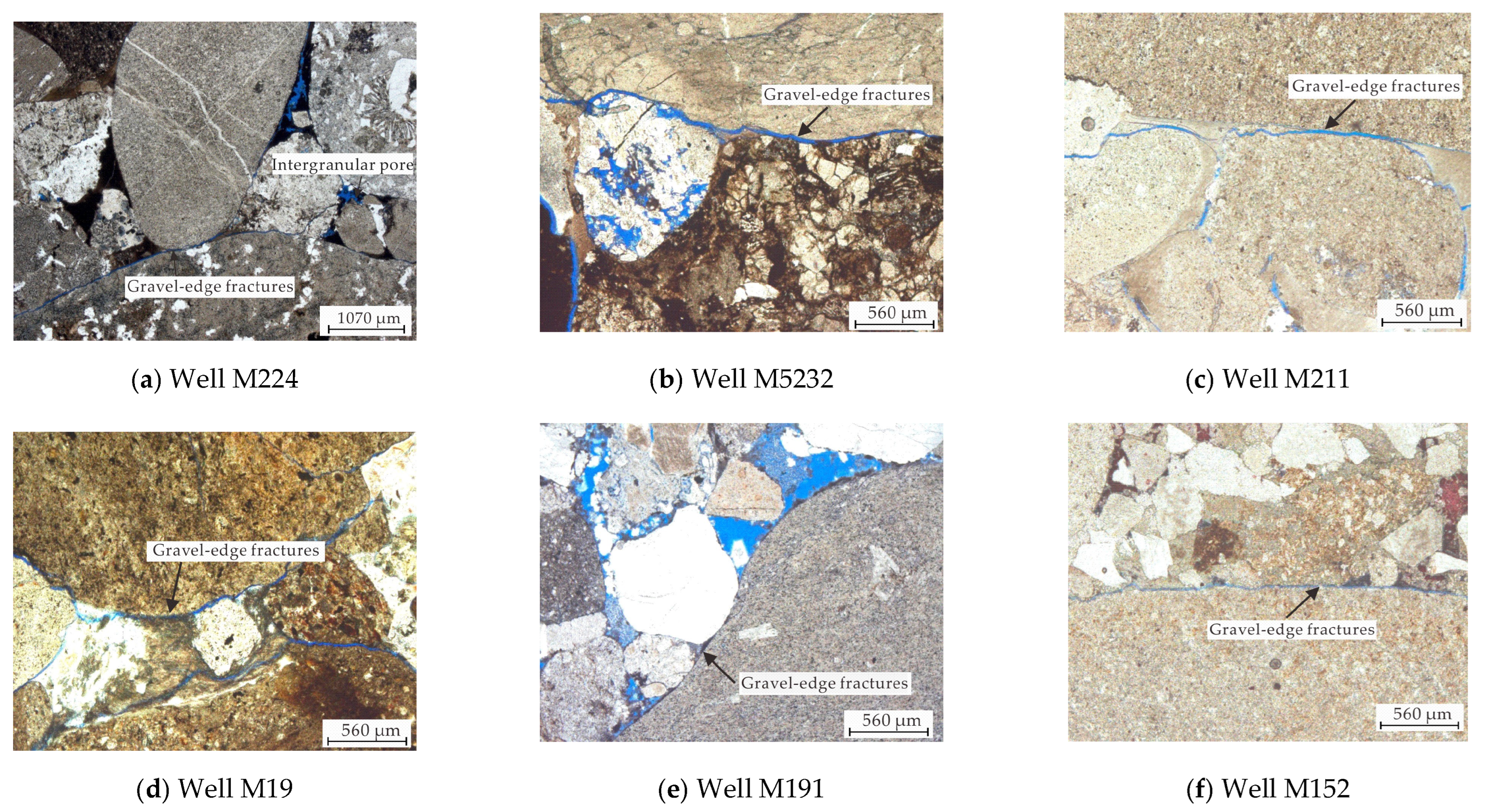

- The conglomerate reservoir matrix features the multi-modal structure that satisfies the structural characteristic of “pseudo-multi-porosity” [15,16,17] and the effects of clay minerals on the conglomerate pore structure are ignored—the conglomerate reservoir is considered as bi-modal and thus treated as the “pseudo-dual-porosity medium” composed of the inter-gravel pore formed purely by sands around gravels and the gravel–edge fracture formed by gravels and objects in contact with such gravels.

- (3)

- It is assumed that pseudo-steady cross flow occurs from the inter-gravel pore to the gravel–edge fracture, while unsteady flow, following the De Swaan model [23], exists from the gravel–edge fracture to the artificial micro fracture; the linear Darcy flow is present from the artificial micro fracture to the main fracture and also from the main fracture to the wellbore.

- (4)

- n fractured zones are formed and evenly distributed along the horizontal wellbore after fracturing and each consists of the main fracture and numerous micro artificial fractures [24]. The artificial micro fracture follows a given fractal characteristic and the main fracture is stress sensitive.

- (5)

- The rock and fluid are both slightly compressible. The production proceeds at a constant production rate. The effects of gravity, capillary pressure, reservoir temperature variation, and wellbore friction are neglected.

3.2. Mathematic Model

3.2.1. SRV Region

- (1)

- Reservoir matrix

- (2)

- Artificial micro fractures

3.2.2. Main Fracture Region

3.3. Solving the Model and Plotting Type Curves

3.3.1. SRV Region

- (1)

- Reservoir matrix

- (2)

- Artificial micro fractures

3.3.2. Main Fracture Region

3.3.3. Blasingame Type Curves

4. Results and Discussion

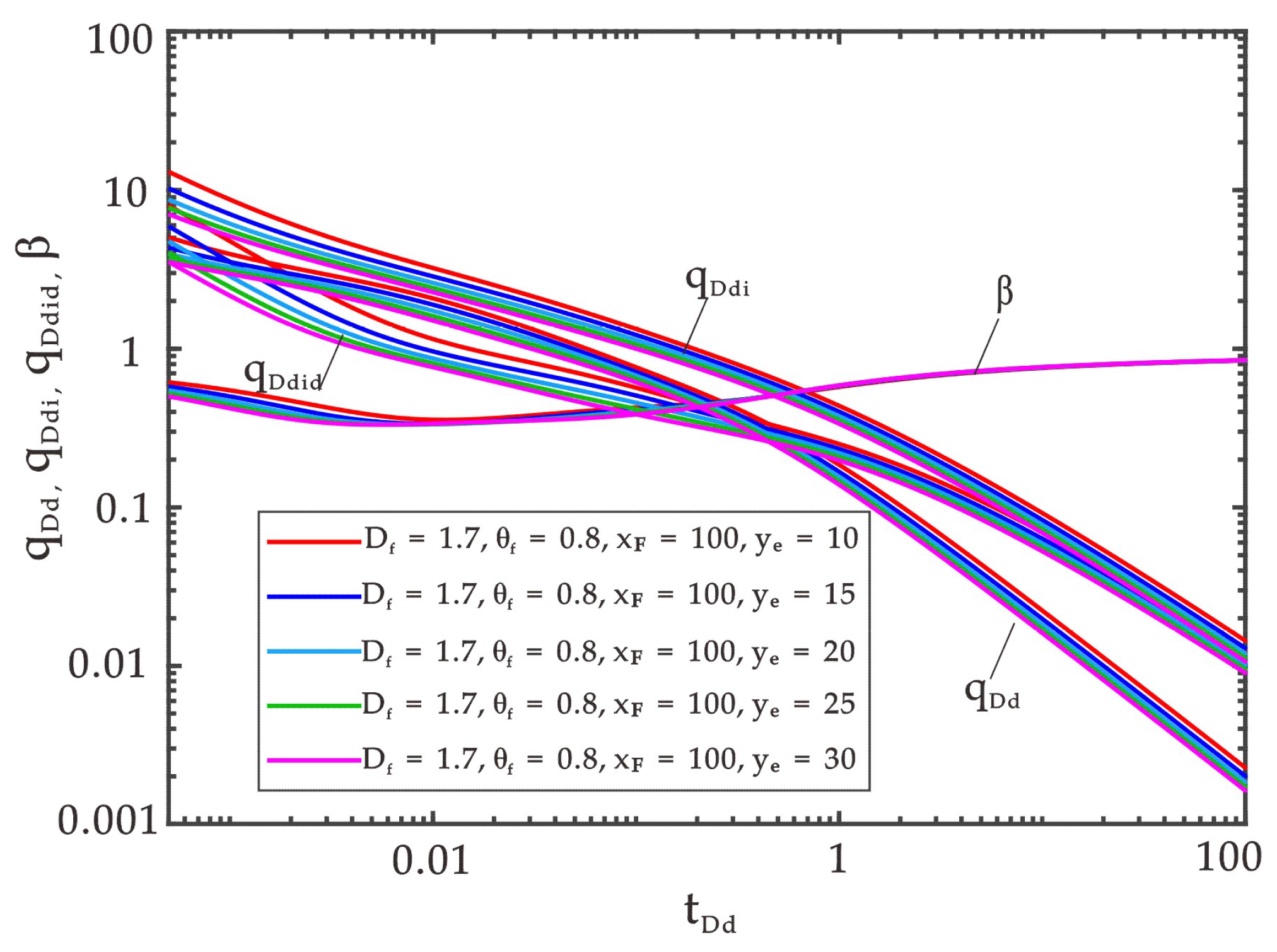

4.1. Effects of the Fractal Dimension on the Curve Shape

4.2. Effects of the Anomalous Diffusion Exponent on the Curve Shape

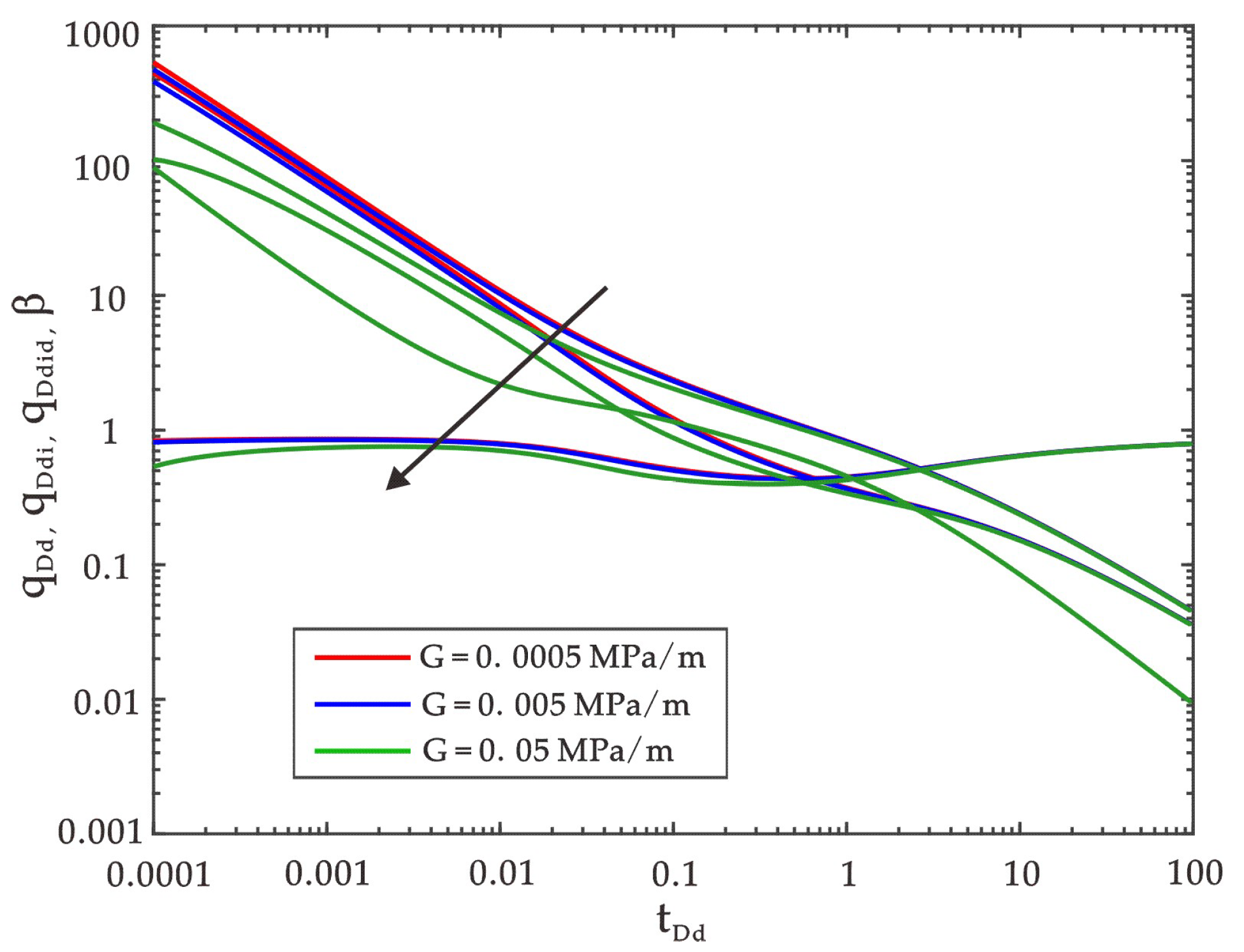

4.3. Effects of the Fluid Flow Threshold Pressure on the Shape Curve

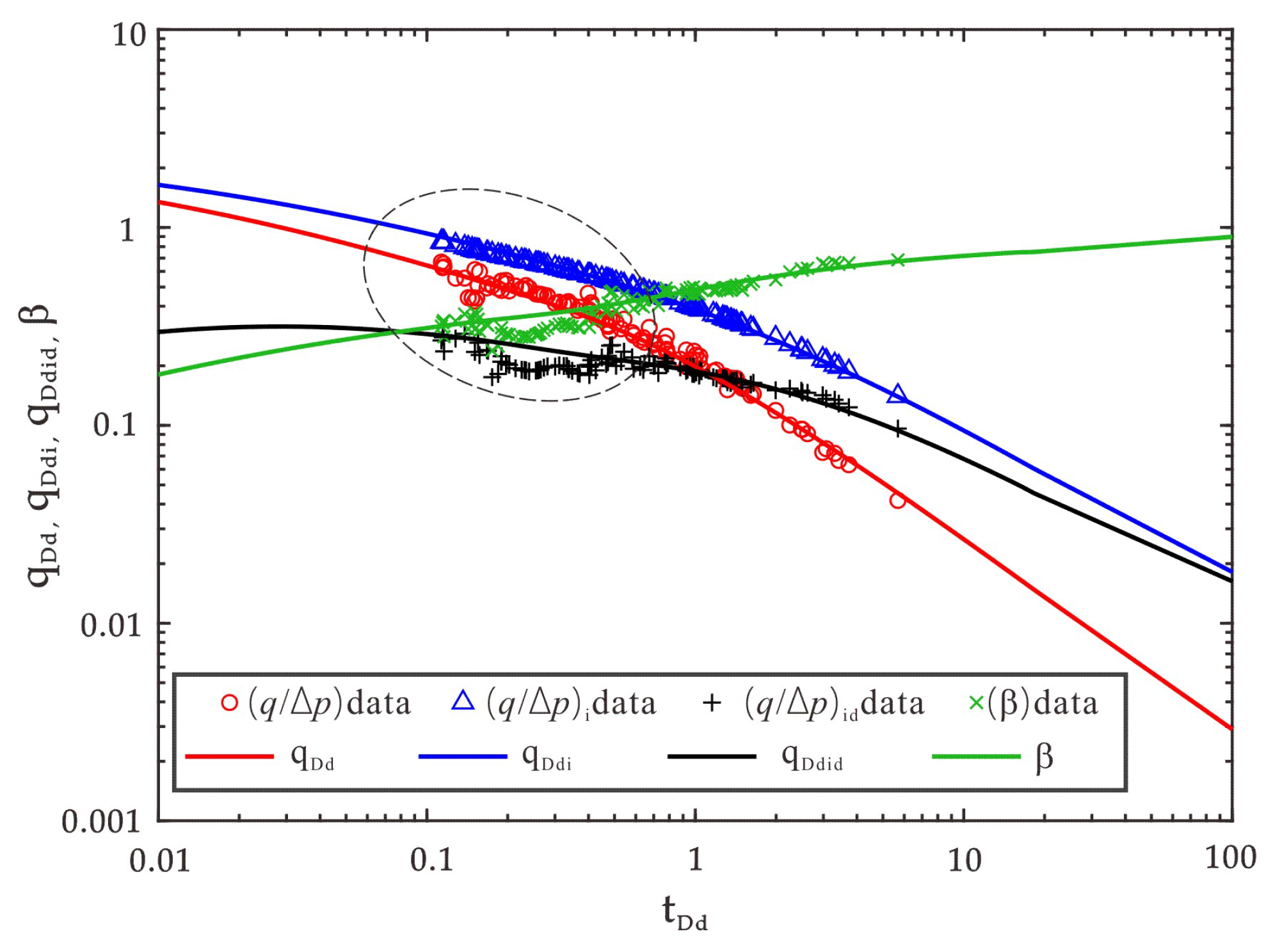

5. Model Application

6. Conclusions

- (1)

- Microseismic monitoring, core experiments, core numerical simulations, etc., have confirmed that the complex fractures can be formed in conglomerate reservoirs. Under this condition, the fractal porosity and fractal permeability models can be used. The core slices have confirmed that the matrix cannot be described by a single-pore model due to the development of gravel–edge fractures. Modeling can be simplified to a pseudo-dual-porosity medium.

- (2)

- The mathematic model of the fractured horizontal well with small well spacing was developed, with the multi-modal pore structure of the tight conglomerate reservoir, the fractal characteristic of the branch fracture network, threshold pressure gradient for fluid flow in the matrix, and stress sensitivity taken, into consideration. The sensitive parameters were analyzed, and it was confirmed that the model conforms to the seepage law.

- (3)

- The field application validated the feasibility and reliability of the developed Blasingame curves for the parameter evaluation of developing tight conglomerate reservoirs using small-spacing horizontal wells. The fitting accuracy is 10% higher than that of the conventional SRV model.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, G.; Qin, J.; Xian, C.; Fan, X.; Zhang, J.; Ding, Y. Theoretical understandings, key technologies and practices of tight conglomerate oilfield efficient development: A case study of the Mahu oilfield, Junggar Basin, NW China. Pet. Explor. Dev. 2020, 47, 1185–1197. [Google Scholar] [CrossRef]

- Qin, J.; Zhang, J.; Jiang, Q.; Feng, Y.; Zhao, Y.; Zhu, J.; Lu, Z.; Wu, S. Sweet spot classifi cation evaluation of tight conglomerate reservoir in Mahu sag and its engineering application. China Pet. Explor. 2020, 25, 110–119. [Google Scholar]

- Yan, Y. Production Decline Analysis on Volumetric Fractured Horizontal Wells in Tight Reservoir. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2017. [Google Scholar]

- Cao, Y. Application of Modern Production Decline Analysis to Prefracture Assessment of Refracturing Technology. Master’s Thesis, Chengdu University of Technology, Chengdu, China, 2016. [Google Scholar]

- Sun, H.; Ouyang, W.; Zhang, M.; Tang, H.; Chen, C.; Ma, X.; Fu, Z. Advanced production decline analysis of tight gas wells with variable fracture conductivity. Pet. Explor. Dev. 2018, 45, 455–463. [Google Scholar] [CrossRef]

- Liu, X.; Zou, C.; Jiang, Y.; Yang, X. Theory and application of modern production decline analysis. Nat. Gas Ind. 2010, 30, 50–54. [Google Scholar]

- Blasingame, T.A.; Johnston, J.L.; Lee, W.J. Type Curve Analysis Using the Pressure Integral Method. In Proceedings of the SPE California Regional Meeting (Society of Petroleum Engineers), Bakersfield, CA, USA, 5 April 1989. [Google Scholar]

- Palacio, J.C.; Blasingame, T.A. Decline Curve Analysis Using Type Curves: Analysis of Gas Well Production Data. In Proceedings of the SPE California Regional Meeting (Society of Petroleum Engineers), Denver, CO, USA, 26–28 April 1993. [Google Scholar]

- Blasingame, T.A.; Iik, D.; Hosseinpour, Z.N. Application of the B-Derivative Function to Production Analysis. In Proceedings of the SPE Annual Technical Conference & Exhibition, Anaheim, CA, USA, 11–14 November 2007. [Google Scholar]

- Wang, J.L.; Yan, C.Z.; Jia, A.L.; He, D.B.; Wei, Y.S.; Qi, Y.D. Rate decline analysis of multiple fractured horizontal well in shale reservoir with triple continuum. J. Cent. South Univ. 2014, 21, 4320–4329. [Google Scholar] [CrossRef]

- Sun, Z. Research on Horizontal Well and Fractured Horizontal Well Advanced Production Dynamics Analysis Method and Software Development. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2015. [Google Scholar]

- Cao, L. Research on Unstable Percolation Theory and Rate Transient Analysis in Tight Gas Reservoirs. Ph.D. Thesis, Southwest Petroleum University, Chengdu, China, 2017. [Google Scholar]

- Li, W. Study on Pressure Production Dynamic Model and Method of Tight Oil Reservoirs with Fractured Horizontal Well. Ph.D. Thesis, China University of Geosciences (Beijing), Beijing, China, 2019. [Google Scholar]

- Wang, M.; Dou, X.; Ming, R.; Li, W.; Zhao, W.; Tan, C. Semi-Analytical rate decline solutions for a refractured horizontal well intercepted by multiple reorientation fractures with fracture face damage in an anisotropic tight reservoir. Energies 2021, 14, 7482. [Google Scholar] [CrossRef]

- Liu, J. An investigation on structure model of conglomeratic reservoir and its evaluation. Pet. Explor. Dev. 1983, 10, 45–56. [Google Scholar]

- Lu, Y. Experimental Studies on Water-Flooding Mechanisms of Glutenite Reservoirs. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2017. [Google Scholar]

- Yin, S.; Chen, G.; Chen, Y.; Wu, X. Mechanism of complex modes of the pore structure of sandstone/conglomerate reservoirs. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2019, 41, 1–17. [Google Scholar]

- Zou, Y.; Shi, S.; Zhang, S.; Yu, T.; Tian, G.; Ma, X.; Zhang, Z. Experimental modeling of sanding fracturing and conductivity of propped fractures in conglomerate: A case study of Mahu tight conglomerate in Junggar Basin, NW China. Pet. Explor. Dev. 2021, 48, 1383–1392. [Google Scholar] [CrossRef]

- Li, L.; Li, G.; Meng, Q.; Wang, Z. Numerical simulation of propagation of hydraulic fractures in glutenite formation. Rock Soil Mech. 2013, 34, 1501–1507. [Google Scholar]

- Chang, J.; Yortsos, Y.C. Pressure-transient analysis of fractal reservoirs. SPE Form. Eval. 1990, 5, 31–38. [Google Scholar] [CrossRef]

- Yang, L.; Ge, H.; Shi, X.; Cheng, Y.; Zhang, K.; Chen, H.; Shen, Y.; Zhang, J.; Qu, X. The effect of microstructure and rock mineralogy on water imbibition characteristics in tight reservoirs. J. Nat. Gas Sci. Eng. 2016, 34, 1461–1471. [Google Scholar] [CrossRef]

- Jia, B.; Xian, C.-G. Permeability measurement of the fracture-matrix system with 3D embedded discrete fracture model. Pet. Sci. 2022, 19, 1757–1765. [Google Scholar] [CrossRef]

- DeSwaan, O.A. Analytic solutions for determining naturally fractured reservoir properties by well testing. Soc. Pet. Eng. J. 1976, 16, 117–122. [Google Scholar] [CrossRef]

- Shao, S.; Tian, S.; Li, G.; He, Z. Fracture spacing optimization for fracture network fracturing in horizontal well. Pet. Drill. Tech. 2014, 42, 86–90. [Google Scholar]

- Pei, Y. Establishment and Application of Seepage Mathematical Model for Fractured Horizontal Wells in Tight Gas Reservoirs. Ph.D. Thesis, China University of Petroleum (Beijing), Beijing, China, 2019. [Google Scholar]

- Zhang, C.; Jiang, R.; Qiao, X.; Cui, Y.; Shen, Z.; Zhang, F.; Yuan, J. Transient pressure analysis of the horizontal well in dual-medium tight fractal gas reservoir. J. Northeast. Pet. Univ. 2018, 42, 95–103. [Google Scholar]

- Gu, D.; Tian, L.; Dong, J. A new percolating model for the SRV horizontal well based on fractal and anomalous diffusion. Pet. Geol. Oilfield Dev. Daqing 2019, 38, 61–69. [Google Scholar]

- Jiang, R.; Zhang, C.; Gao, Y.; Geng, Y.; Hui, Y.; Li, H. Fractal nonlinear seepage model of horizontal wells in fractured-vuggy carbonate reservoirs. Lithologic Reservoirs 2019, 31, 118–126. [Google Scholar]

- Chen, Z. Model of spherical flow through porous media in the homogenous reservoirs and Laplace space solution. J. Chengdu Univ. Technol. (Sci. Technol. Ed.) 2011, 38, 641–644. [Google Scholar]

- Pedrosa, J.R. Pressure Transient Response in Stress-Sensitive Formations. In Proceedings of the SPE California Regional Meeting (Society of Petroleum Engineers), Oakland, CA, USA, 2 April 1986. [Google Scholar]

- Jiang, R.; Liu, X.; Cui, Y.; Zhang, C.; Hao, Y.; Pan, H.; Wang, X. Bottomhole pressure analysis of multistage fractured horizontal well during unsteady crossflow. Pet. Geol. Recovery Effic. 2019, 26, 86–95. [Google Scholar]

- Huang, Y.; Li, X.; Tan, X. Research on rate decline analysis for horizontal well in triple-porosity composite reservoir. Nat. Gas Geosci. 2018, 29, 1190–1197. [Google Scholar]

| Dimensionless Parameters | Definitions |

|---|---|

| Reservoir pressure | |

| Production time | |

| Distance | |

| Fracture width | |

| Permeability modulus | |

| Permeability ratios | |

| Pressure transfer coefficients | |

| Ratio of the pressure transfer coefficients | |

| Cross flow coefficient | |

| Elastic storativity ratios | |

| Less conductivity of main fractures |

| Method | Fracture Half Length (m) | Fracture Conductivity (mD·m) | Skin Factor | Threshold Pressure Gradient (MPa/cm) | Fractal Dimension | Anomalous Diffusion Exponent | Well-Controlled Area (km2) | Well-Controlled Reserve (10,000 tons) |

|---|---|---|---|---|---|---|---|---|

| Software | 52 | 152 | 0.003 | - | - | - | 018 | 8.80 |

| This research | 48 | 256 | 0.01 | 0.21 | 1.73 | 0.30 | 0.17 | 8.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Song, J.; Pan, H.; Gu, K.; Wang, S.; Yang, L.; You, H.; Wang, L.; Wang, X.; Li, S.; et al. Production Decline Analysis of Tight Conglomerate Reservoirs with Small Well Spacing, Based on the Fractal Characteristics of Fracture Networks. Minerals 2022, 12, 1433. https://doi.org/10.3390/min12111433

Li X, Song J, Pan H, Gu K, Wang S, Yang L, You H, Wang L, Wang X, Li S, et al. Production Decline Analysis of Tight Conglomerate Reservoirs with Small Well Spacing, Based on the Fractal Characteristics of Fracture Networks. Minerals. 2022; 12(11):1433. https://doi.org/10.3390/min12111433

Chicago/Turabian StyleLi, Xiaoshan, Junqiang Song, Hong Pan, Kaifang Gu, Shuo Wang, Liu Yang, Haoyu You, Li Wang, Xin Wang, Shihong Li, and et al. 2022. "Production Decline Analysis of Tight Conglomerate Reservoirs with Small Well Spacing, Based on the Fractal Characteristics of Fracture Networks" Minerals 12, no. 11: 1433. https://doi.org/10.3390/min12111433

APA StyleLi, X., Song, J., Pan, H., Gu, K., Wang, S., Yang, L., You, H., Wang, L., Wang, X., Li, S., Li, T., & Luo, G. (2022). Production Decline Analysis of Tight Conglomerate Reservoirs with Small Well Spacing, Based on the Fractal Characteristics of Fracture Networks. Minerals, 12(11), 1433. https://doi.org/10.3390/min12111433