The Improved Motion Model of Particles in the Cone Crusher Considering the Spatial Compound Motion of the Mantle

Abstract

:1. Introduction

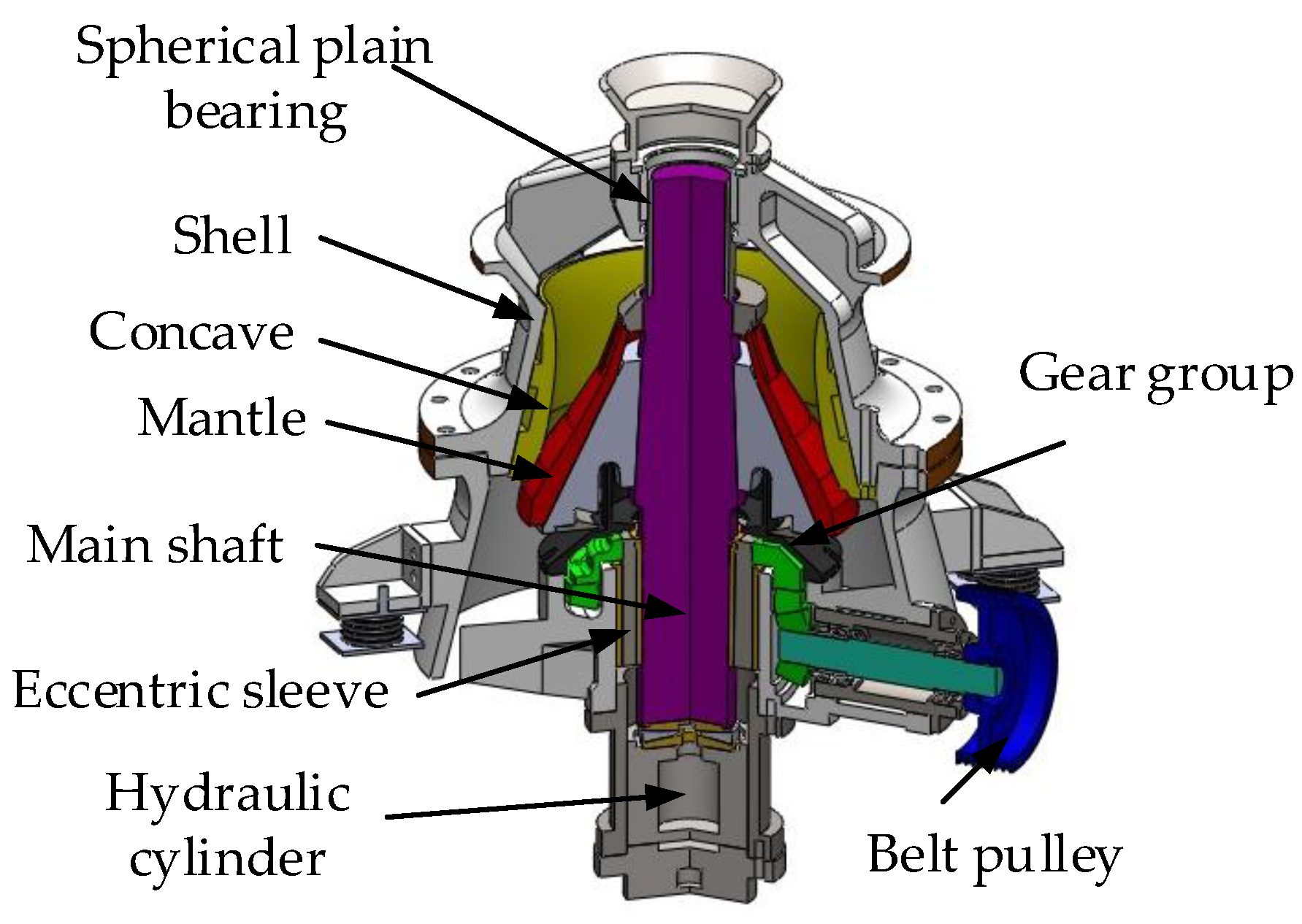

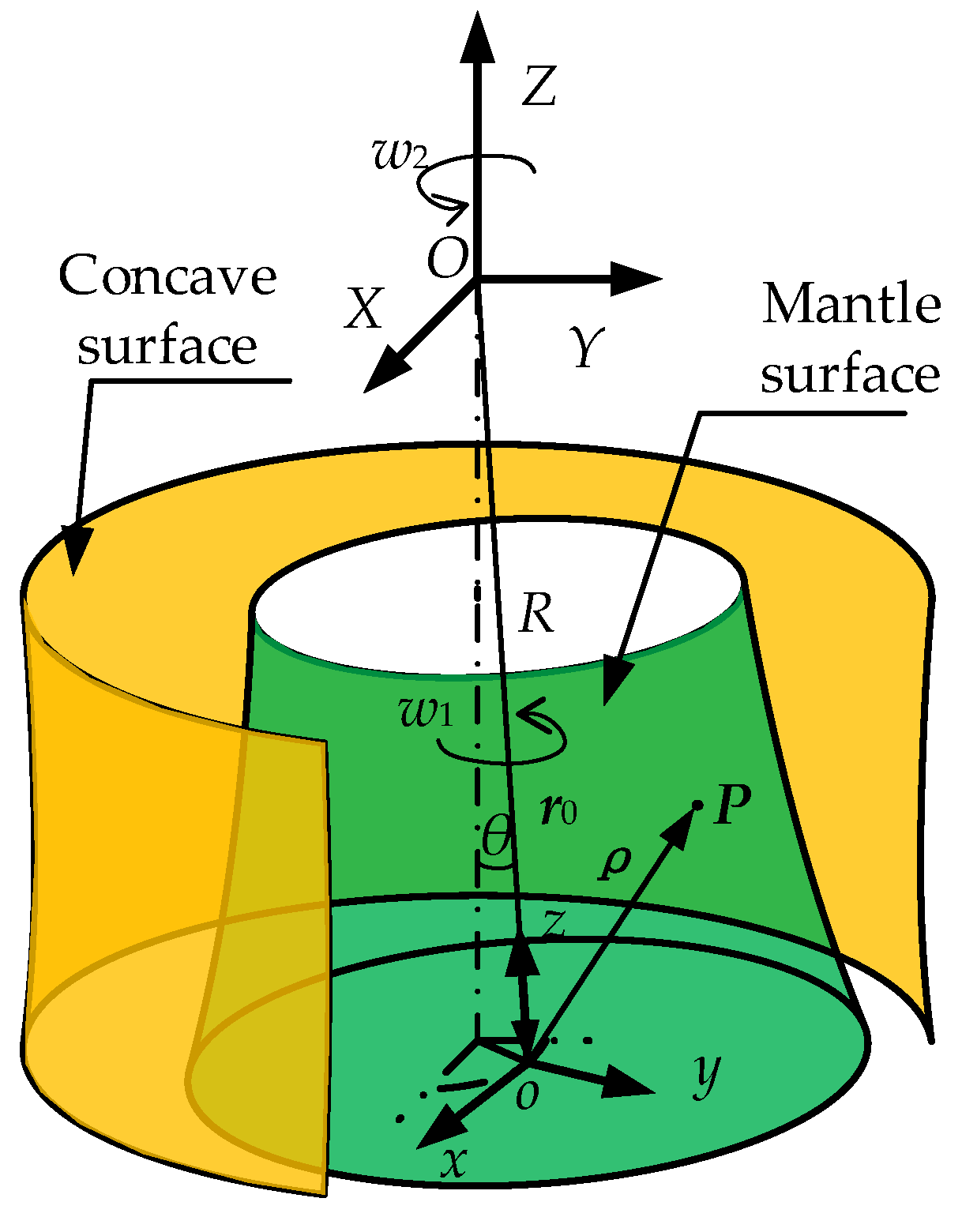

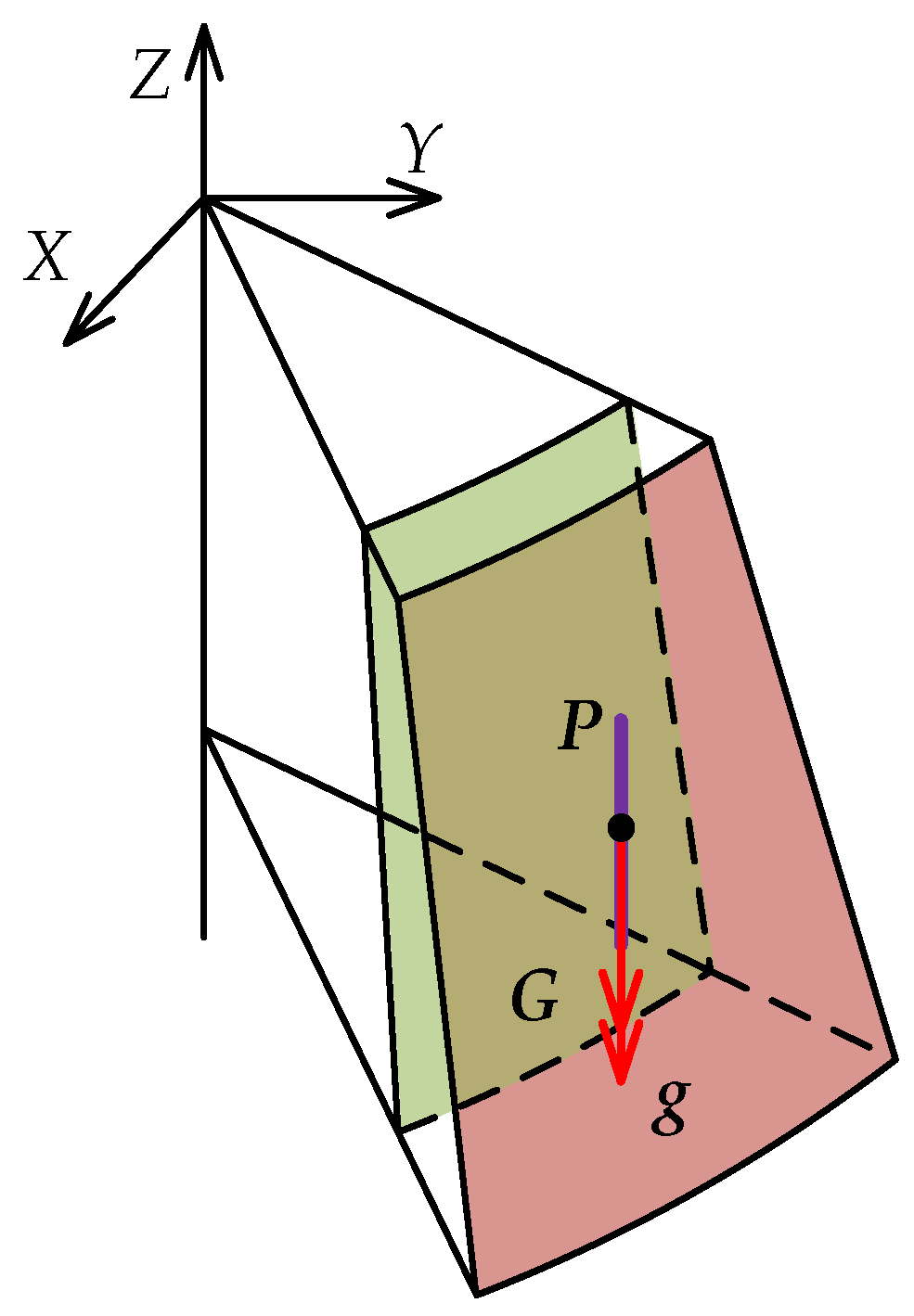

2. The Spatial Compound Motion of the Mantle

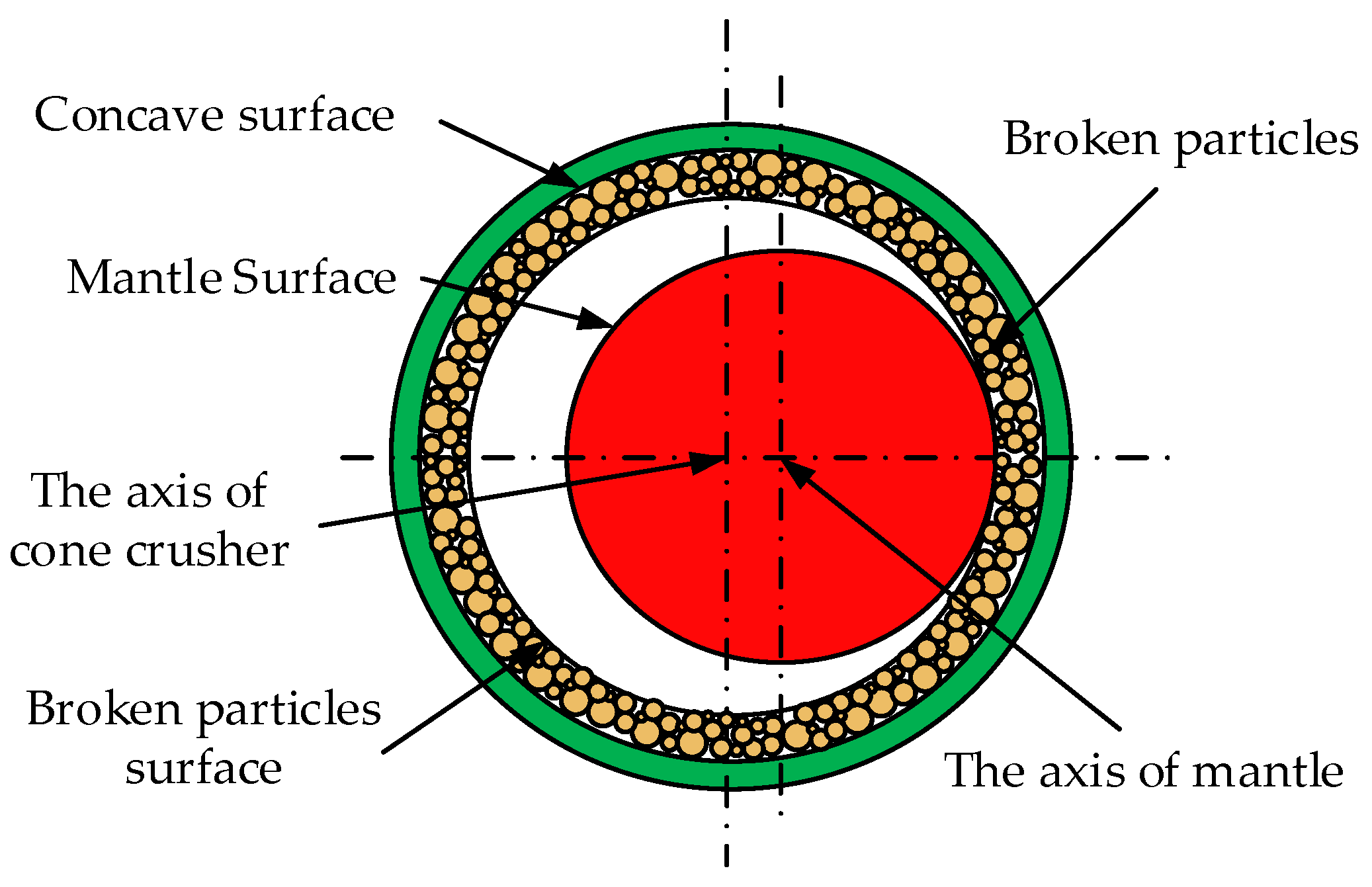

3. The Motion Characteristics of Particles in Crushing Chamber

3.1. The Coordinate System Transformation Matrix of Cone Crusher

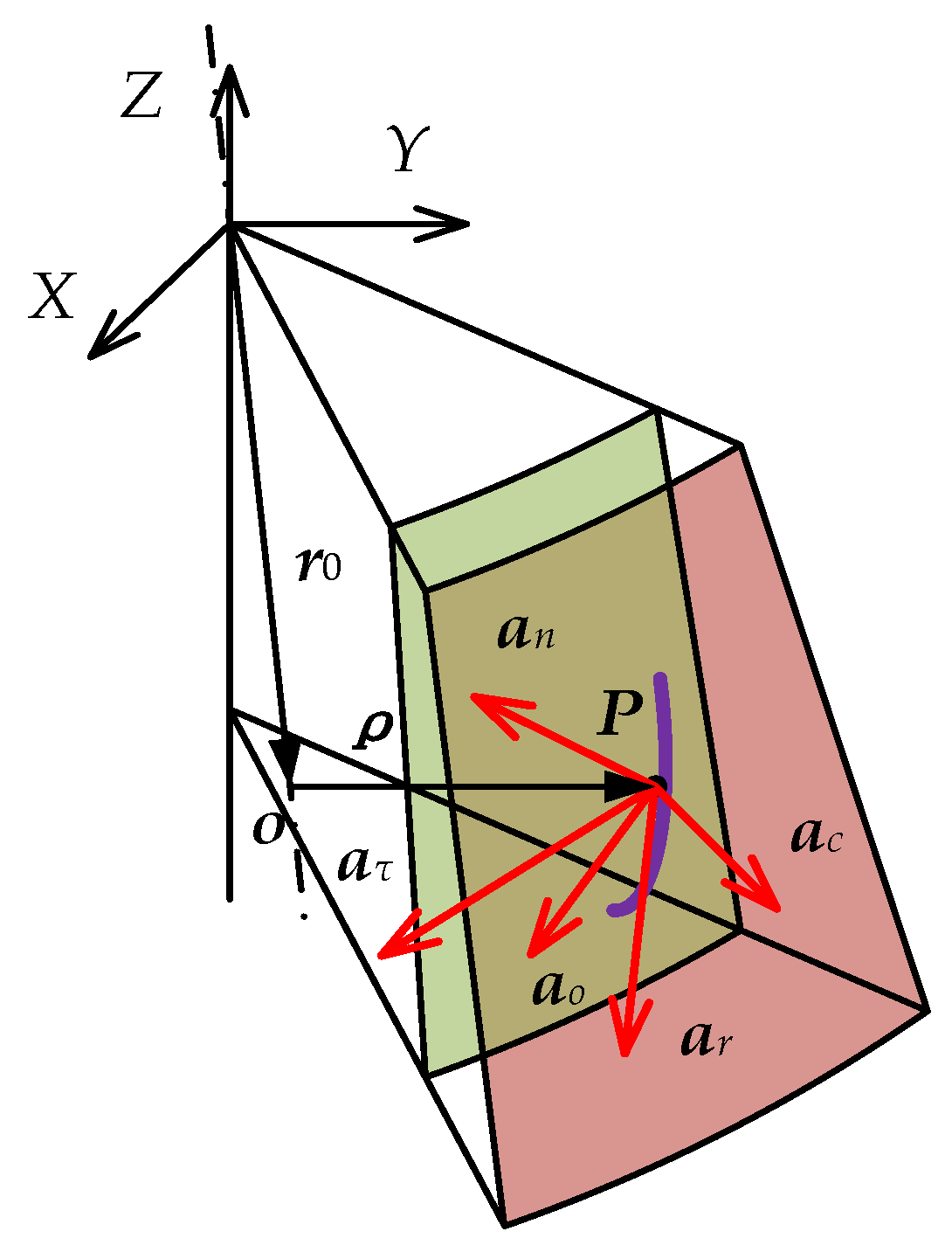

3.2. Analysis of Motion Characteristics of Particles in Crushing Chamber

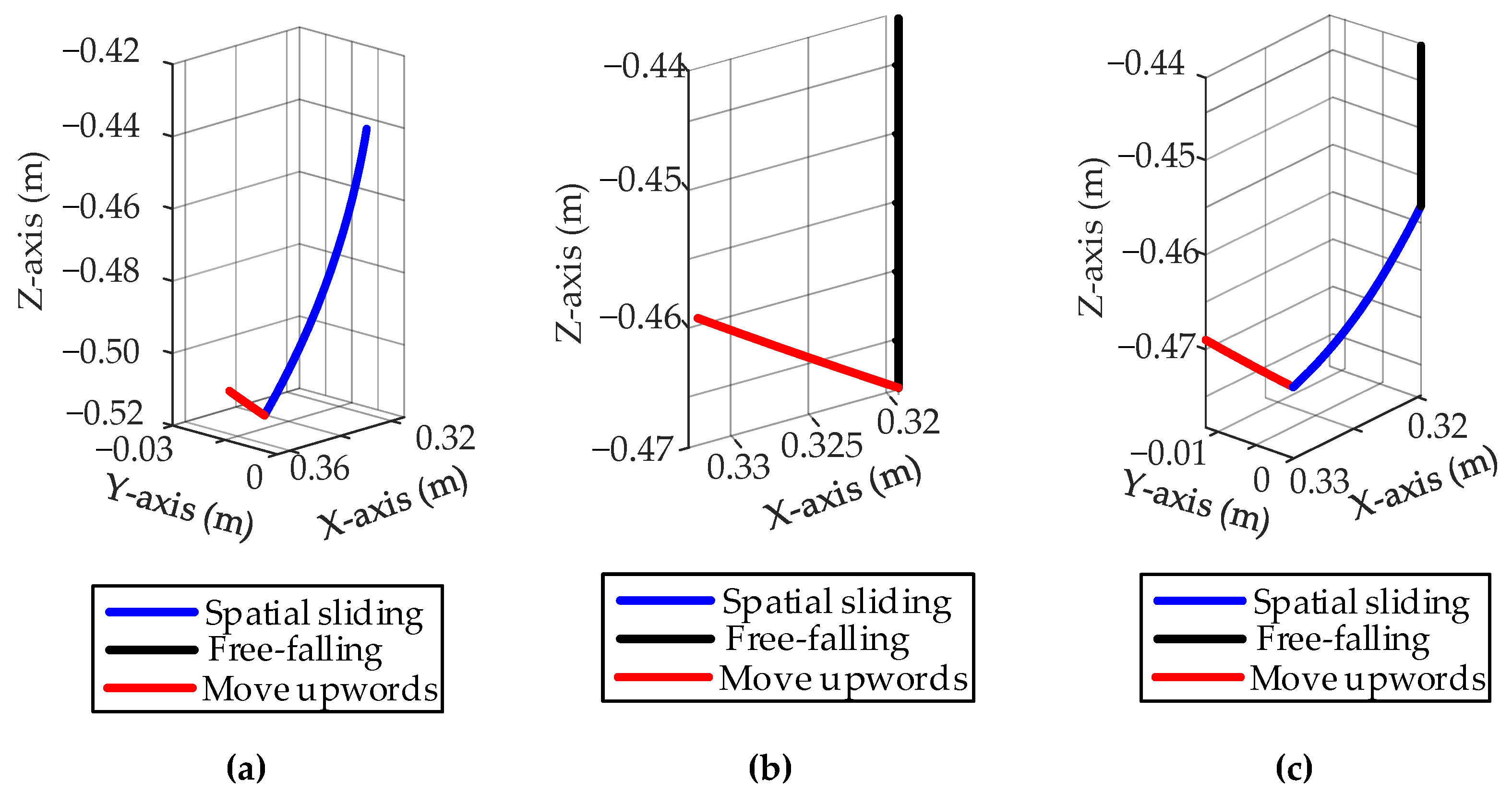

3.2.1. The Motion Characteristics of Spatial Sliding

3.2.2. The Motion Characteristics of Free-Falling

3.2.3. The Motion Characteristics of Spatial Compound Falling

3.2.4. The Simulation of Motion Characteristics of Particle

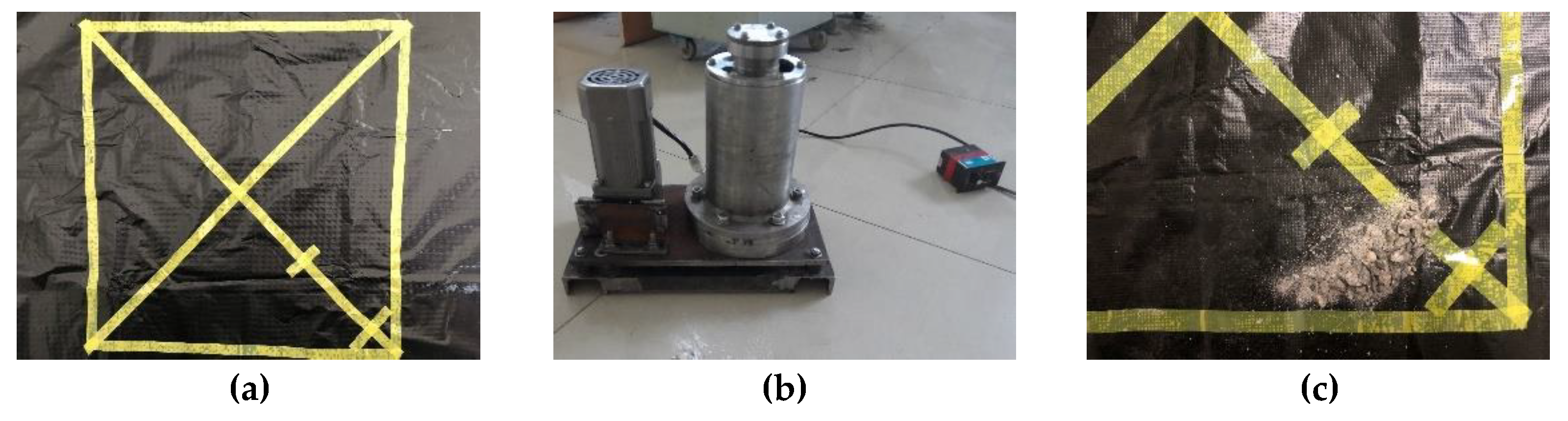

4. The Experiment of Particles Breaking in Cone Crusher

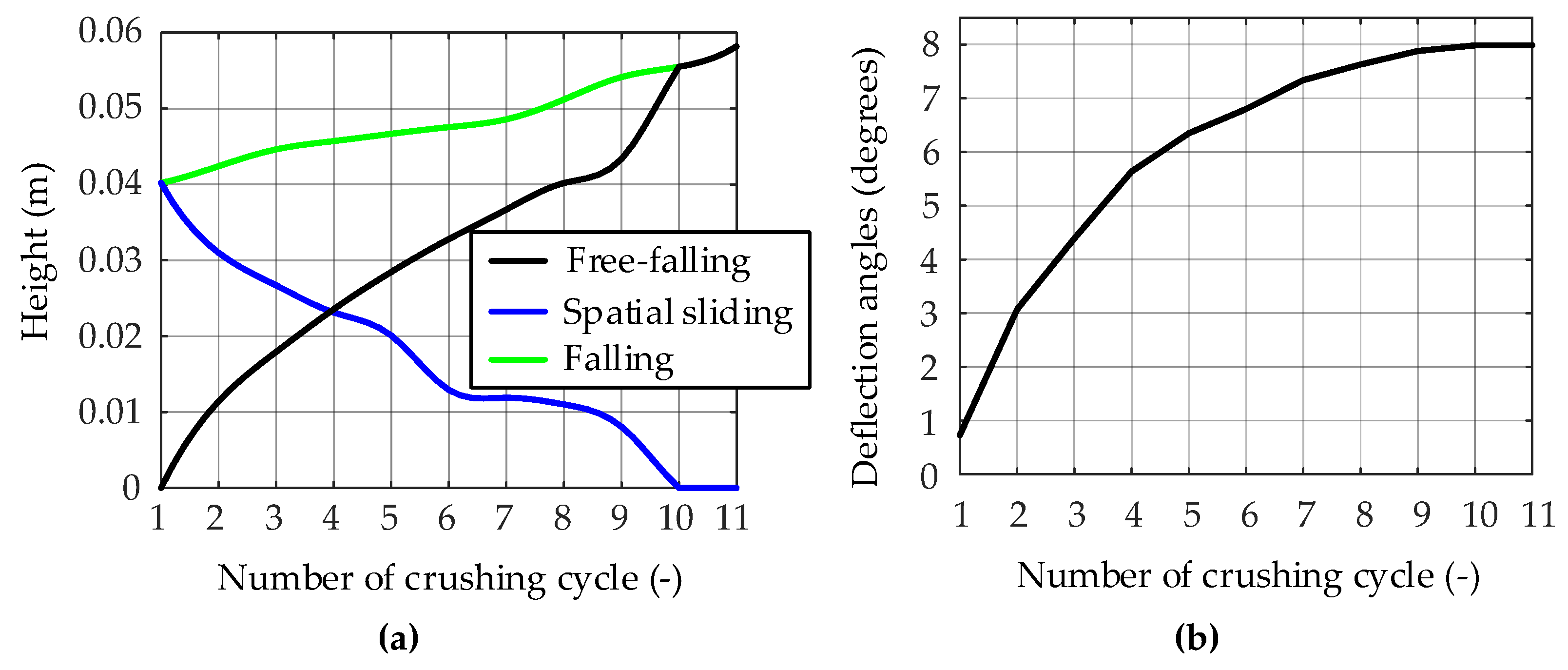

5. The Analysis of Particles Motion Characteristics in the CF11 Hydraulic Cone Crusher Based on the Improved Model

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.L.; Ren, T.Z.; Cheng, J.Y.; Jin, X. The improved model of inter-particle breakage considering the transformation of particle shape for cone crusher. Miner. Eng. 2017, 112, 11–18. [Google Scholar] [CrossRef]

- Gauldie, K. The output of gyratory crushers. Engineering 1954, 4, 557–559. [Google Scholar]

- Gauldie, K. Performance of jaw crushers. Engineering 1953, 10, 456–458. [Google Scholar]

- Briggs, C.A. Fundamental Model of a Cone Crusher. Ph.D. Thesis, University of Queensland, Queensland, Australia, 1997. [Google Scholar]

- Evertsson, C.M. Output prediction of cone crushers. Miner. Eng. 1998, 11, 215–232. [Google Scholar] [CrossRef]

- Evertsson, C.M. Modelling of flow in cone crushers. Miner. Eng. 1999, 12, 1479–1499. [Google Scholar] [CrossRef]

- Pierre, J.; Yoël, F.; Olivier, P. A constitutive law for dense granular flows. Nature 2006, 441, 727–730. [Google Scholar]

- Oliver, B.; John, B.; Paul, H.; Ian, L. Flows of granular material in two-dimensional channels. J. Eng. Math. 2016, 98, 49–70. [Google Scholar]

- Cleary, P.W.; Sinnott, M.D. Simulation of particle flows and breakage in crushers using DEM: Part 1–Compression crushers. Miner. Eng. 2015, 74, 178–197. [Google Scholar] [CrossRef]

- Weerasekara, N.S.; Powell, M.S.; Cleary, P.W.; Tavares, L.M.; Evertsson, M.; Morrison, R.D.; Quist, J.; Carvalho, R.M. The contribution of DEM to the science of comminution. Powder Technol. 2013, 248, 3–24. [Google Scholar] [CrossRef]

- Cleary, P.W.; Delaney, G.W.; Sinnott, M.D.; Cummins, S.J.; Morrison, R.D. Advanced comminution modelling: Part 1–crushers. Appl. Math. Model. 2020, 88, 238–265. [Google Scholar] [CrossRef]

- Herbst, J.A.; Potapov, A.V. Making a discrete grain breakage model practical for comminution equipment performance simulation. Powder Technol. 2004, 143, 144–150. [Google Scholar] [CrossRef]

- Li, H.; McDowell, G.R.; Lowndes, I.S. A laboratory investigation and discrete element modeling of rock flow in a chute. Powder Technol. 2012, 229, 199–205. [Google Scholar] [CrossRef]

- Delaney, G.W.; Morrison, R.D.; Sinnott, M.D.; Cumminsa, S.; Cleary, P.W. DEM modelling of non-spherical particle breakage and flow in an industrial scale cone crusher. Miner. Eng. 2015, 74, 112–122. [Google Scholar] [CrossRef]

- Quist, J.; Evertsson, C.M. Cone crusher modelling and simulation using DEM. Miner. Eng. 2016, 85, 92–105. [Google Scholar] [CrossRef]

- Johansson, M.; Quist, J.; Evertsson, M.; Hulthén, E. Cone crusher performance evaluation using DEM simulations and laboratory experiments for model validation. Miner. Eng. 2017, 103, 93–101. [Google Scholar] [CrossRef]

- Meriam, J.L.; Kraige, L.G. Engineering Mechanics, Dynamics; John Wiley and Sons: New York, NY, USA, 1987; pp. 154–196. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| Inlet size | 52 | mm |

| Feeding size | 10–15 | mm |

| CSS | 11 | mm |

| Stroke | 9 | mm |

| Eccentric angle | 0.81 | deg |

| Main shaft rotating speed | 30–500 | rpm |

| Rotating Speed | Experiment I | Experiment II | Experiment III | Experiment IV | ||||

|---|---|---|---|---|---|---|---|---|

| 164 rpm | 6.8° | 4.1° | 7.4° | 4.6° | 6.0° | 4.0° | 7.1° | 3.2° |

| 224 rpm | 7.4° | 6.2° | 8.0° | 6.1° | 7.9° | 6.5° | 7.5° | 5.3° |

| 272 rpm | 12.5° | 9.7° | 14.7° | 7.8° | 11.2° | 8.9° | 10.9° | 10.4° |

| 321 rpm | 7.2° | 5.9° | 6.9° | 3.2° | 7.1° | 5.7° | 6.6° | 4.3° |

| 369 rpm | 3.8° | 2.2° | 4.0° | 2.0° | 4.7° | 1.0° | 3.1° | 2.0° |

| 406 rpm | 0.1° | −0.4° | 2.1° | 0.2° | 0.4° | −0.5° | 0.3° | −0.1° |

| 453 rpm | 0.8° | −0.2° | 3.3° | 1.4° | 0.1° | −0.7° | 2.2° | 1.1° |

| 501 rpm | 2.9° | 1.0° | 0.2° | −0.3° | 2.1° | 0.6° | 1.1° | 0° |

| Parameter | Value | Unit |

|---|---|---|

| Inlet size | 230 | mm |

| Feeding size | 90 | mm |

| CSS | 24 | mm |

| Stroke | 22 | mm |

| Base diameter of mental | 1050 | mm |

| Base angle of mental | 49.5 | deg |

| Eccentric angle | 0.7 | deg |

| Main shaft rotating speed | 317 | rpm |

| Capacity | 85–152 | t/h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Ren, T.; Cheng, J. The Improved Motion Model of Particles in the Cone Crusher Considering the Spatial Compound Motion of the Mantle. Minerals 2022, 12, 16. https://doi.org/10.3390/min12010016

Zhang Z, Ren T, Cheng J. The Improved Motion Model of Particles in the Cone Crusher Considering the Spatial Compound Motion of the Mantle. Minerals. 2022; 12(1):16. https://doi.org/10.3390/min12010016

Chicago/Turabian StyleZhang, Zilong, Tingzhi Ren, and Jiayuan Cheng. 2022. "The Improved Motion Model of Particles in the Cone Crusher Considering the Spatial Compound Motion of the Mantle" Minerals 12, no. 1: 16. https://doi.org/10.3390/min12010016

APA StyleZhang, Z., Ren, T., & Cheng, J. (2022). The Improved Motion Model of Particles in the Cone Crusher Considering the Spatial Compound Motion of the Mantle. Minerals, 12(1), 16. https://doi.org/10.3390/min12010016