Combined Mining and Pulp-Lifting of Ferromanganese Nodules and Rare-Earth Element-Rich Mud around Minamitorishima Island in the Western North Pacific: A Prefeasibility Study

Abstract

1. Introduction

2. FN and Research and Development Approaches to Mining

3. Previous Economic Evaluation of REE-Rich Mud Mining

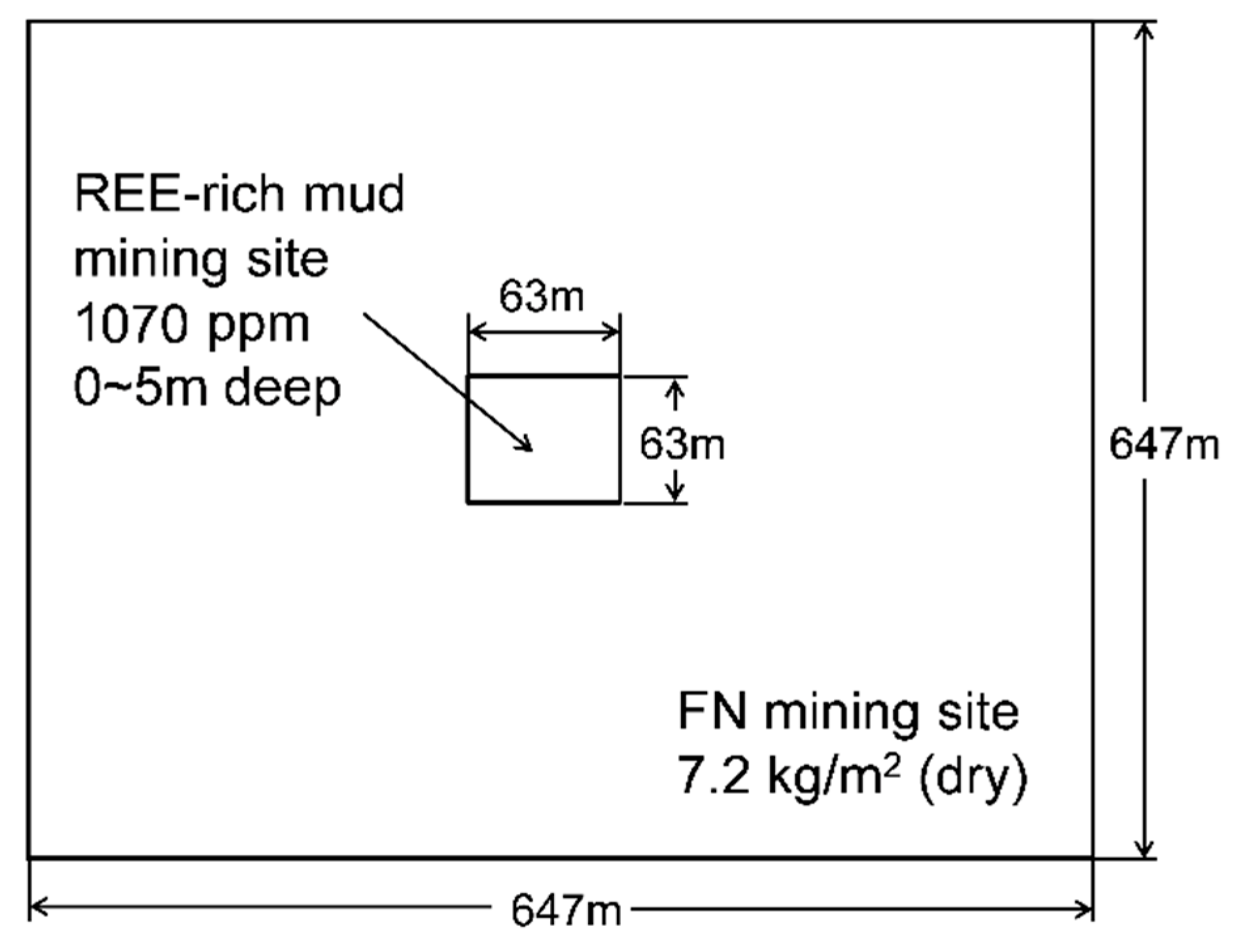

4. Mining Model: Combined Mining of REE-Rich Mud and FN by Pulp-Lifting

- Production rate of 6000 t/d in dry conditions in REE-rich mud and 3000 t/d in dry conditions in FN;

- Hydraulic cut and suction for REE-rich mud excavation;

- Hydraulic suction for FN collection then crushing;

- Mixing and pulp-making then feeding to a piston pump;

- Pumping up through a riser;

- Solid volumetric concentration of 55% and seawater concentration of 45% in pulp;

- Water depth of 5800 m;

- Drying lifted pulp then transferring it to carrier vessels;

- Transportation distance of 2000 km from Minamitorishima Island EEZ to the leaching and processing location in Japan’s mainland;

- Separation of REE-rich mud and crushed FN;

- Leaching by HCl and solvent extraction with recovery ratios of 24% for Ce and 92% for other rare-earth elements in REE-rich mud [3];

- Brick making by adding cement powder to the leached mud after neutralization and desalting then providing it for construction material free of charge;

- Processing by SCL with recovery ratios of 80% for Mn and 94% for the other three metals in FN [56];

- Processed slag sales as concrete aggregate in 100 $/t;

- Calculating the CAPEX and OPEX of the mining model except for the brick-making and processing using an equation based on ones in the previous study [8]:where CA = the value in this study; CB = the value in the previous study; aA = the total mass in this study; aB = the total mass in the previous study; n = 0.6 scale factor [70].

- Calculating the CAPEX and OPEX of the brick-making on the basis of Tsuji et al. [71];

5. Economic Feasibility of the Combined Mining of REE-Rich Mud and FN by Pulp-Lifting

5.1. Results of Basic Condition

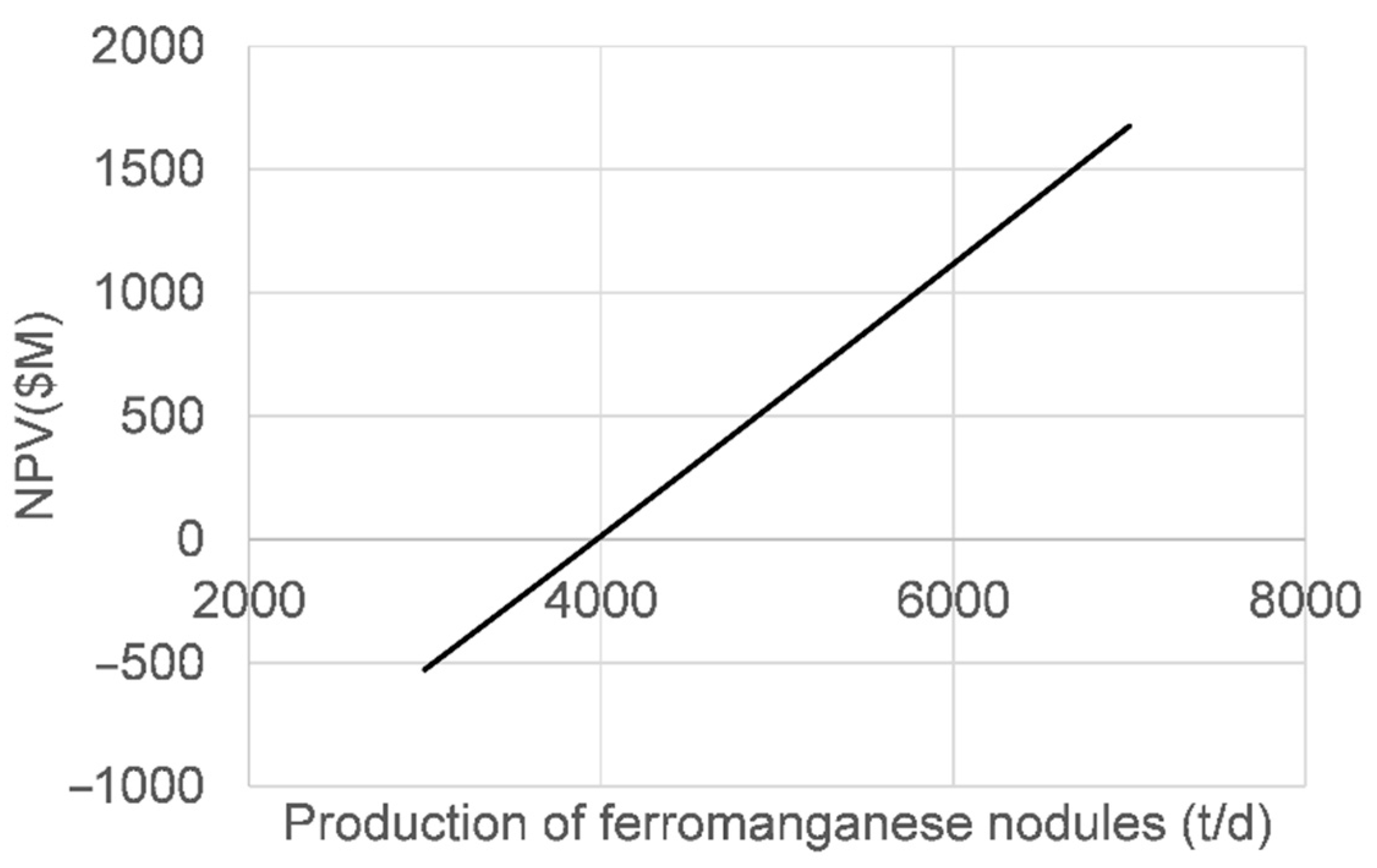

5.2. Sensitivity Analyses by FN Production Rate

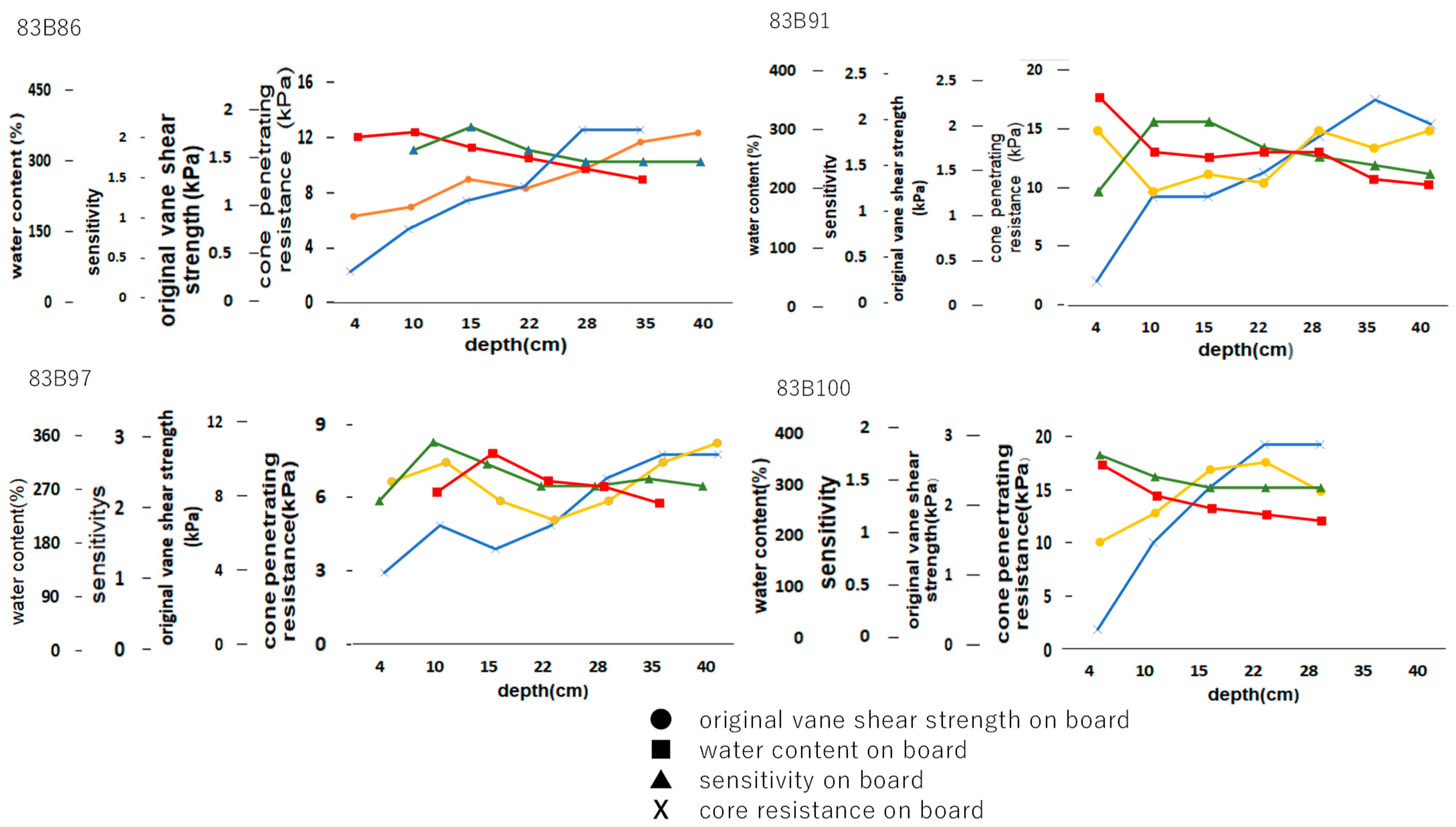

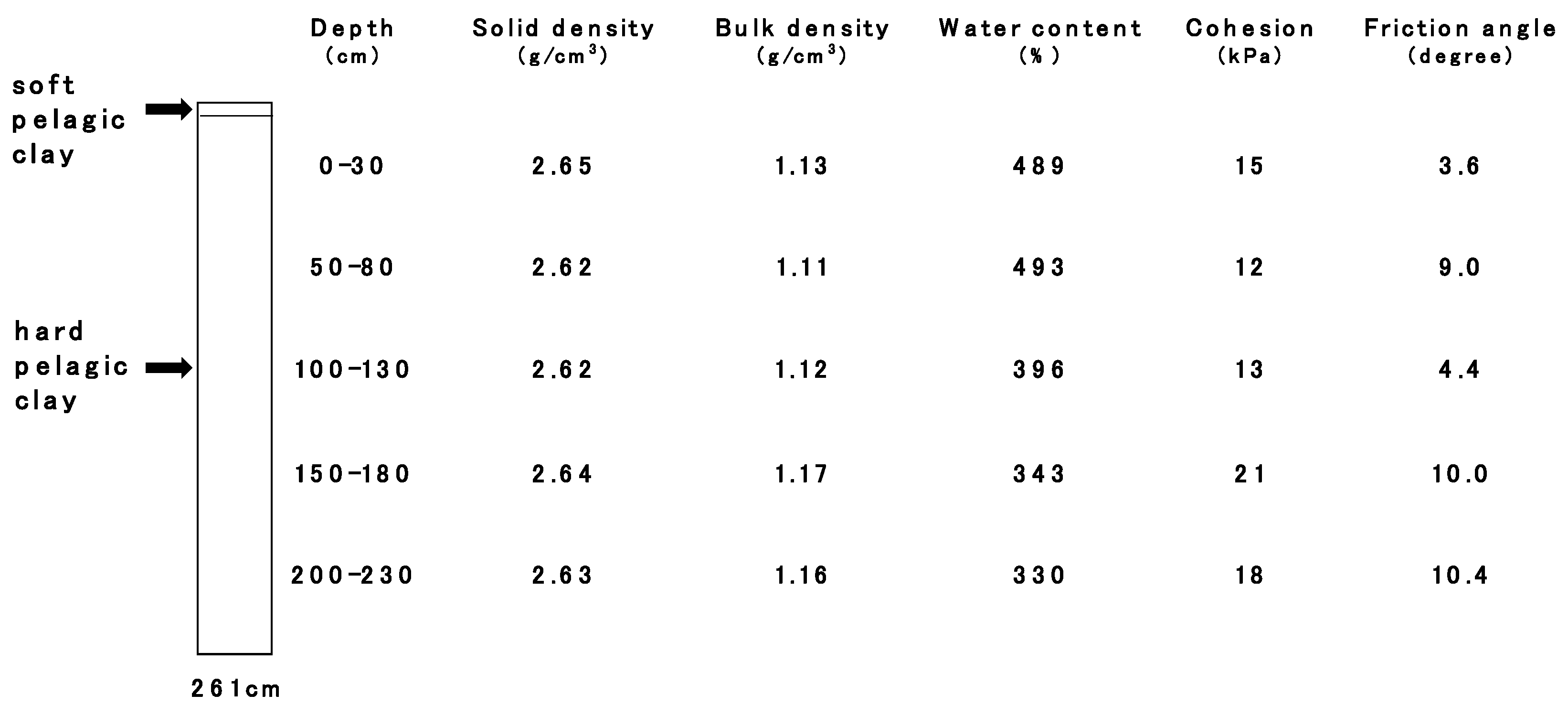

6. Expected Geotechnical Characteristics of REE-Rich Mud

7. Technical Considerations

8. Mining Area Management Plan

9. Concluding Remarks

- Combined mining with REE-rich mud and FN;

- Pulp-lifting;

- Reuse of waste mud and processed slag as construction materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kato, Y.; Fujinaga, K.; Nakamura, K.; Takaya, Y.; Kitamura, K.; Ohta, J.; Toda, R.; Nakashima, T.; Iwamori, H. Deep-sea mud in the Pacific Ocean as a potential resource for rare-earth elements. Nat. Geosci. 2011, 4, 535–539. [Google Scholar] [CrossRef]

- Bashir, M.B.; Kim, S.H.; Kiosidou, E.; Wolgamot, H.; Zhang, W. A Concept for Seabed Rare Earth Mining in the Eastern South Pacific; LRET Collegium 2012 Series; University Southampton: Southampton, UK, 2012; Volume 1, p. 121. [Google Scholar]

- Abe, K.; Watanabe, D.; Fujinaga, K.; Kato, Y.; Nakamura, T.; Yamazaki, T. Technical and Economic Feasibility Study on Rare-earth Elements and Yttrium-rich Mud. In Proceedings of the 23rd Ocean Engineering Symposium, Tokyo, Japan, 2–3 August 2012. JFOES & JASNAOE, OES23-089 (In Japanese with English Abstract). [Google Scholar]

- Wolgamot, H.; Zhang, W.; Kiosidou, E.; Kim, S.H.; Bashir, M. Considerations for Seabed Rare Earth Mining in the Pacific. In Proceedings of the 32nd International Conference on Ocean, Offshore and Arctic Engineering, Nantes, France, 9–14 June 2013. OMAE2013-10844. [Google Scholar]

- JAMSTEC Press Releases. Available online: http://www.jamstec.go.jp/e/about/press_release/20130321/ (accessed on 26 October 2020).

- Iijima, K.; Yasukawa, K.; Fujinaga, K.; Nakamura, K.; Machida, S.; Takaya, Y.; Ohta, J.; Haraguchi, S.; Nishio, Y.; Usui, Y.; et al. Discovery of extremely REY-rich mud in the western North Pacific Ocean. Geochem. J. 2016, 50, 557–573. [Google Scholar] [CrossRef]

- Takaya, Y.; Yasukawa, K.; Kawasaki, T.; Fujinaga, K.; Ohta, J.; Usui, Y.; Nakamura, K.; Kimura, J.-I.; Chang, Q.; Hamada, M.; et al. The tremendous potential of deepsea mud as a source of rare-earth elements. Sci. Rep. 2018, 8, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Yamazaki, T.; Yamamoto, Y.; Nakatani, N.; Arai, R. Preliminary Economic Evaluation of Deep-sea REE Mud Mining. In Proceedings of the 33rd International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. OMAE2014-23141. [Google Scholar]

- Mero, J.L. The Mineral Resources of the Sea; Oceanography Series, 1; Elsevier: Amsterdam, The Netherlands, 1965; p. 312. [Google Scholar]

- Cronan, D.S. Underwater Minerals; Academic Press: London, UK, 1980; p. 362. [Google Scholar]

- Craig, J.D.; Andrews, J.E. A Factor Analysis Study of Deep Sea Ferromanganese Deposits in the Equatorial North Pacific Ocean. Mar. Min. 1978, 1, 305–326. [Google Scholar]

- Andrews, J.E.; Friedrich, G.H.W. Distribution Patterns of Manganese Nodule Deposits in the Northeast Equatorial Pacific. Mar. Min. 1979, 2, 1–43. [Google Scholar]

- Friedrich, G.; Glasby, G.P.; Thijssen, T.; Plüger, W.L. Morphological and Geochemical Characteristics of Manganese Nodules Collected from Three Areas on an Equatorial Pacific Transect by RV Sonne. Mar. Min. 1983, 4, 167–253. [Google Scholar]

- Von Stackelberg, U.; Beiersdorf, H. The Formation of Manganese Nodules between the Clarion Clipperton Fracture Zones Southeast of Hawaii. Mar. Geol. 1991, 98, 411–423. [Google Scholar] [CrossRef]

- Morgan, C.L.; Nichols, J.A.; Selk, B.W.; Toth, J.R.; Wallin, C. Preliminary Analysis of Exploration Data from Pacific Deposits of Manganese Nodules. Mar. Georesour. Geotechnol. 1993, 11, 1–25. [Google Scholar] [CrossRef]

- ISA. POLYDAT: Polymetallic nodule database. In Proceedings of the Workshop on Proposed Technologies for Mining Deep-Seabed Polymetallic Nodules, International Seabed Authority, Kingston, Jamaica, 3–6 August 1999; pp. 447–456. [Google Scholar]

- Padan, J.W. Commercial Recovery of Deep—Seabed Manganese Nodules: Twenty Years of Accomplishments. Mar. Min. 1990, 9, 87–103. [Google Scholar]

- ISA. Plans of Work for Exploration of Government of India, IFREMER/AFERNOD, DORD, Yuzhmorgeologiya, COMRA, IOM, Republic of Korea; Report of the Secretary General No. ISBA/4/A/1/Rev.2; International Seabed Authority: Kingston, Jamaica, 1998; p. 47. [Google Scholar]

- Andrews, B.V.; Flipse, J.E.; Brown, F.C. The Economic Viability of a Four-Metal Pioneer Deep Ocean Mining Venture; PB84-122563; US Dept. of Commerce: Washington, DC, USA, 1983; p. 201. [Google Scholar]

- Hillman, C.T.; Gosling, B.B. Mining Deep Ocean Manganese Nodules: Description and Economic Analysis of a Potential Venture; IC 9015; US Bureau of Mines: Washington, DC, USA, 1985; p. 19. [Google Scholar]

- Charles, C.; Herrouin, G.; Mauviel, F.; Bernard, J. Views on Future Nodule Technologies Based on IFREMER-GEMONOD Studies. Mater. Soc. 1990, 14, 299–326. [Google Scholar]

- Søreide, F.; Lund, T.; Markussen, J.M. Deep Ocean Mining Reconsidered a Study of the Manganese Nodule Deposits in Cook Island. In Proceedings of the 4th ISOPE Ocean Mining Symposium, Szczecin, Poland, 23–27 September 2001; pp. 88–93. [Google Scholar]

- Honkawa Data Tribune. Available online: https://honkawa2.sakura.ne.jp/5500.html (accessed on 26 December 2020). (In Japanese).

- Welling, C.G. An advanced design deep sea mining system. In Proceedings of the 13th Offshore Technology Conference, Houston, TX, USA, 4–7 May 1981. [Google Scholar]

- Kaufman, R.; Latimer, J.P.; Tolefson, D.C. The design and operation of a Pacific Ocean deep ocean mining test ship: R/V Deepsea Miner II. In Proceedings of the 17th Offshore Technology Conference, Houston, TX, USA, 6–9 May 1985. [Google Scholar]

- Bath, A.R. Deep sea mining technology: Recent developments and future projects. In Proceedings of the 21st Offshore Technology Conference, Houston, TX, USA, 1–4 May 1989. [Google Scholar]

- Heine, O.R.; Suh, S.L. An Experimental Nodule Collection Vehicle Design and Testing. In Proceedings of the 10th Offshore Technology Conference, Houston, TX, USA, 8–11 May 1978. [Google Scholar]

- Clauss, G. Hydraulic Lifting in Deep-Sea Mining. Mar. Min. 1978, 1, 189–208. [Google Scholar]

- Burns, J.Q.; Suh, S.L. Design and Analysis of Hydraulic Lift Systems for Deep Ocean Mining. In Proceedings of the 11th Offshore Technology Conference, Houston, TX, USA, 30 April 1979. [Google Scholar]

- Grote, P.B.; Burns, J.Q. System Design Considerations in Deep Ocean Mining Lift System. Mar. Min. 1981, 2, 357–383. [Google Scholar]

- Chung, J.S.; Whitney, A.K.; Loden, W.A. Nonlinear Transient Motion of Deep Ocean Mining Pipe. J. Energy Resour. Technol. 1981, 103, 2–10. [Google Scholar] [CrossRef]

- Kollwentz, W. Lessons Learned in the Development of Nodule Mining Technology. Mater. Soc. 1990, 14, 285–298. [Google Scholar]

- Kotlinski, R. InterOceanMetal Joint Organization: Achievements and Challenges. In Proceedings of the 1st ISOPE Ocean Mining Symposium, Tsukuba, Japan, 21–22 November 1995; pp. 5–7. [Google Scholar]

- Yang, N.; Wang, M. New Era for China Manganese Nodules Mining: Summary of Last Five Years’ Research Activities and Prospective. In Proceedings of the 2nd ISOPE Ocean Mining Symposium, Seoul, Korea, 24–26 November 1997; pp. 8–11. [Google Scholar]

- Yamada, H.; Yamazaki, T. Japan’s Ocean Test of the Nodule Mining System. In Proceedings of the 8th International Offshore and Polar Engineering Conference, Montreal, QC, Canada, 24–29 May 1998; pp. 13–19. [Google Scholar]

- Hong, S.; Kim, K.-H. Research and Development of Deep Seabed Mining Technologies for Polymetallic Nodules in Korea. In Proceedings of the Proposed Technologies for Deep Seabed Mining of Polymetallic Nodules, International Seabed Authority, Kingston, Jamaica, 3–6 August 1999; pp. 261–283. [Google Scholar]

- Muthunayagam, A.E.; Das, S.K. Indian polymetallic nodule program. In Proceedings of the 3rd ISOPE Ocean Mining Symposium, Goa, India, 8–11 November 1999; pp. 1–5. [Google Scholar]

- Li, L.; Zhang, J. The China’s Manganese Nodules Miner. In Proceedings of the 2nd ISOPE Ocean Mining Symposium, Seoul, Korea, 24–26 November 1997; pp. 95–99. [Google Scholar]

- Yasukawa, H.; Ikegami, K.; Minami, T. Motion Analysis of a Towed Collector for Manganese Nodule Mining in Ocean Test. In Proceedings of the 9th International Offshore and Polar Engineering Conference, Brest, France, 30 May–4 June 1999; pp. 100–107. [Google Scholar]

- Hong, S.; Choi, J.-S.; Kim, J.-H.; Yang, C.-H. Experimental Study on Hydraulic Performance of Hybrid Pickup Device of Manganese Nodule Collector. In Proceedings of the 3rd ISOPE Ocean Mining Symposium, Goa, India, 8–11 November 1999; pp. 69–77. [Google Scholar]

- Yamazaki, T.; Kuboki, E.; Yoshida, H. Tracing Collector Passes and Preliminary Analysis of Collector Operation. In Proceedings of the 3rd ISOPE Ocean Mining Symposium, Goa, India, 8–11 November 1999; pp. 55–62. [Google Scholar]

- Deepak, C.R.; Shajahan, M.A.; Atmanand, M.A.; Annamalai, K.; Jeyamani, R.; Ravindran, M.; Schulte, E.; Handschuh, R.; Panthel, J.; Grebe, H.; et al. Developmental Test on the Underwater Mining System Using Flexible Riser Concept. In Proceedings of the 4th ISOPE Ocean Mining Symposium, Szczecin, Poland, 23–27 September 2001; pp. 94–98. [Google Scholar]

- Bernard, J.; Bath, A.R.; Greger, B. Analysis and comparison of nodule hydraulic transport systems. In Proceedings of the 9th Offshore Technology Conference, Houston, TX, USA, 27–30 April 1987; p. 5476. [Google Scholar]

- Saito, T.; Usami, T.; Yamazaki, T.; Tomishima, Y.; Kiyono, F. Lifting Characteristics of Manganese Nodules by Air-Lift-Pump on 200m Vertical Test Plant. In Proceedings of the OCEANS’89, Seattle, WA, USA, 8–21 September 1989; pp. 48–53. [Google Scholar]

- Xia, J.; Xia, L.; Zau, W.; Tang, D.; Huang, J.; Wang, S. Studies on Reasonable Hydraulic Lifting Parameters of Manganese Nodules. In Proceedings of the 2nd ISOPE Ocean Mining Symposium, Seoul, Korea, 24–26 November 1997; pp. 112–116. [Google Scholar]

- Yoon, C.-H.; Kwon, K.-S.; Kwon, O.-K.; Kwon, S.-K.; Kim, I.-K.; Lee, D.-K.; Lee, H.-S. An Experimental Study on Lab Scale Air-Lift Pump Flowing Solid-Liquid-Air Three-Phase Mixture. In Proceedings of the 10th International Offshore and Polar Engineering Conference, Seattle, WA, USA, 27 May–2 June 2000; pp. 515–521. [Google Scholar]

- Chung, J.S.; Lee, K.; Tischler, A.; Yarim, G. Effect of Particle Size and Concentration on Pressure Gradient in Two-Phase Vertically Upward Transport. In Proceedings of the 4th ISOPE Ocean Mining Symposium, Szczecin, Poland, 23–27 September 2001; pp. 132–138. [Google Scholar]

- Aso, K.; Kan, K.; Doki, H.; Ohkoshi, T. The Effect of Vibration Absorbers on the Longitudinal Vibration of a Pipe String in the Deep Sea—Part 2: A Case of Mining Manganese Nodules. Int. J. Offshore Polar Eng. 1994, 4, 62–67. [Google Scholar]

- Chung, J.S.; Cheng, B.-R.; Huttelmaier, H.P. Three-Dimensional Coupled Responses of a Vertical Deep-Ocean Pipe: Part II. Excitation at Pipe Top and External Torsion. Int. J. Offshore Polar Eng. 1994, 4, 321–339. [Google Scholar]

- Cheng, B.-R.; Chung, J.S. Effects of Axial Dampers and Elastic Joints on 3-D Dynamic Responses of a Deep-Ocean Pipe with Torsional Coupling. Int. J. Offshore Polar Eng. 1997, 7, 36–43. [Google Scholar]

- Ohta, T.; Morikawa, M. Bending Strength of Lifting Pipes Handling of Pipe Connection in Manganese Mining System. In Proceedings of the 2nd ISOPE Ocean Mining Symposium, Seoul, Korea, 24–26 November 1997; pp. 68–74. [Google Scholar]

- Handschuh, R.; Grebe, H.; Panthel, J.; Schulte, E.; Wenzlawski, B.; Schwarz, W.; Atmanand, M.A.; Jeyamani, R.; Shajahan, M.; Deepak, R.; et al. Innovative Deep-Ocean Mining Concept Based on Flexible Riser and Self-propelled Mining Machine. In Proceedings of the 4th ISOPE Ocean Mining Symposium, Szczecin, Poland, 23–27 September 2001; pp. 99–107. [Google Scholar]

- Agarwal, J.C.; Beecher, N.; Davies, D.S.; Hubred, G.L.; Kakaria, V.K.; Moslen, J.H. Comparative Economics of Recovery of Metals from Ocean Nodules. Mar. Min. 1979, 2, 119–130. [Google Scholar]

- Hubred, G.L. Manganese Nodule Extractive Metallurgy Review 1973–1978. Mar. Min. 1980, 2, 191–212. [Google Scholar]

- Black, J.R.H. Metals Recovery from Manganese Nodules: A Review of Processing Schemes. In Marine Mining: A New Beginning; Humphrey, P.B., Ed.; Hawaii Department of Planning and Economic Development: Honolulu, HI, USA, 1982; pp. 93–107. [Google Scholar]

- Kojima, K. Review of Studies on Manganese Nodules Processing. In Proceedings of the 2nd ISOPE Ocean Mining Symposium, Seoul, Korea, 24–26 November 1997; pp. 19–22. [Google Scholar]

- Kim, D.-J.; Park, K.-H. Study on the Leaching Mechanism of Cu and Ni from Deep-sea Manganese Nodules with Hydrochloric Acid. In Proceedings of the 2nd ISOPE Ocean Mining Symposium, Seoul, Korea, 24–27 November 1997; pp. 172–176. [Google Scholar]

- Xiang, Z.; Zequan, H.; Yujun, S.; Yongjun, M.; Shuguang, Q.; Xianbai, L. The Smelting-Rusting-Solvent Extraction Process to Recover Valuable Metals from Polymetallic Nodules. In Proceedings of the 3rd ISOPE Ocean Mining Symposium, Goa, India, 8–11 November 1999; pp. 227–231. [Google Scholar]

- Das, R.P. India’s Demonstration Metallurgical Plant to Treat Ocean Nodule. In Proceedings of the 4th ISOPE Ocean Mining Symposium, Szczecin, Poland, 23–27 September 2001; pp. 163–166. [Google Scholar]

- ISA. Polymetallic Nodule Mining Technology: Current Status and Challenges Ahead. In Proceedings of the Executive Summary of ISA workshop, Chennai, India, 18–22 February 2008. [Google Scholar]

- ISA. Report on the International Seabed Authority’s Workshop on Polymetallic Nodule Mining Technology: Current status and Challenges Ahead. Available online: https://www.isa.org.jm/files/documents/EN/14Sess/LTC/ISBA-14LTC-3.pdf (accessed on 26 October 2020).

- ISA. A Geological MODEL of Polymetallic Nodule Deposits in the Clarion-Clipperton Fracture Zone; ISA Technical Study: No. 6; International Seabed Authority: Kingston, Jamaica, 2010; p. 211. [Google Scholar]

- ISA. Polymetallic Nodules Resource Classification -Report of an International Workshop Held in 2014-, ISA Technical Study: No. 19; International Seabed Authority: Kingston, Jamaica, 2017; p. 79. [Google Scholar]

- Yamazaki, T.; Kuboki, E.; Yoshida, H.; Suzuki, T. A Consideration on Size Distribution of Resuspended Deep-sea Sediments. In Proceedings of the 10th International Offshore and Polar Engineering Conference, Seattle, WA, USA, 27 May–2 June 2000; pp. 507–514. [Google Scholar]

- JAMSTEC Press Releases. Available online: http://www.jamstec.go.jp/e/about/press_release/20160826/ (accessed on 26 October 2020).

- Machida, S.; Sato, T.; Yasukawa, K.; Nakamura, K.; Iijima, K.; Nozaki, T.; Kato, Y. Visualisation method for the broad distribution of seafloor ferromanganese deposits. Mar. Georesour. Geotechnol. 2021, 39, 267–279. [Google Scholar] [CrossRef]

- Machida, S.; Fujinaga, K.; Ishii, T.; Nakamura, K.; Hirano, N.; Kato, Y. Geology and geochemistry of ferromanganese nodules in the Japanese Exclusive Economic Zone around Minamitorishima Island. Geochem. J. 2016, 50, 539–555. [Google Scholar] [CrossRef]

- ISA. Available online: https://www.isa.org.jm/exploration-contracts/beijing-pioneer-hi-tech-development-corporation and https://www.isa.org.jm/map/beijing-pioneer-hi-tech-development-corporation (accessed on 26 October 2020).

- Ogawa, J.; Shibata, K. Production Technology of COM and CWM. J. Fuel Soc. Jpn. 1990, 69, 828–832, (In Japanese with English Abstract). [Google Scholar] [CrossRef]

- Japan Coal Development Technology Cooperation Center. Mine Investment Analysis, Overseas Coal Development Technical Guide; Japan Coal Development Technology Cooperation Center: Tokyo, Japan, 1993; Volume 2, p. 55. (In Japanese) [Google Scholar]

- Tsuji, T.; Tanaka, Y.; Nakagawa, M.; Nonaka, S.; Nagao, K.; Akashi, Y.; Kiso, E.; Tasaki, T. Materials Properties and Production Technology of Artificial Stone Using the Dredged Soil. J. Jpn. Soc. Civ. Eng. Ser. B3 (Ocean Eng.) 2015, 71, I_1173–I_1178, (In Japanese with English Abstract). [Google Scholar]

- Park, S.; Yamazaki, T.; Shimada, S.; Yamamoto, T. Development Potential Examination Method for Cobalt-rich Manganese Crusts. J. Min. Mater. Process. Inst. Jpn. 2002, 118, 641–649, (In Japanese with English Abstract). [Google Scholar]

- SMM Information & Technology. Available online: https://www.metal.com/ (accessed on 7 February 2021).

- MetalPrices. Available online: https://mineralprices.com/ (accessed on 7 February 2021).

- Dataset of World Economy. Available online: https://ecodb.net/commodity/metal/ (accessed on 26 October 2020). (In Japanese).

- Yamazaki, T.; Tsurusaki, K.; Handa, K.; Inagaki, T. Geotechnical Properties of Deep Ocean Sediment Layer. J. Min. Mater. Process. Inst. Jpn. 1995, 110, 309–315, (In Japanese with English Abstract). [Google Scholar]

- Yamazaki, T.; Komine, T.; Kawakami, T. Geotechnical Properties of Deep-sea Sediments and the In-situ Measurement Techniques. In Proceedings of the 6th ISOPE Ocean Mining Symposium, Changsha, China, 9–13 October 2005; pp. 48–55. [Google Scholar]

- Abuhajar, O.; El Naggar, M.H.; Newson, T. Review of Available Methods for Evaluation of Soil Sensitivity for Seismic Design. In Proceedings of the International Conference Recent Advances in Geotechnology, Earthquake Engineering and Soil Dynamics, San Diego, CA, USA, 24–29 May 2010. Paper No. 1.32b. [Google Scholar]

- Yamashita, S.; Kawaguchi, T.; Ohshima, H. Design of handy cone penetration tester and its application. Jpn. Geotech. J. 2016, 11, 193–200, (In Japanese with English Abstract). [Google Scholar] [CrossRef]

- Yamazaki, T.; Tomishima, Y.; Handa, K.; Saito, T. Studies on Characteristics of Friability of Manganese Nodules and on their Friability in the On-Board Facilities. Shigen; National Research Institute of Resources and Environment: Tsukuba, Japan, 1990; Volume 2, pp. 339–350, (In Japanese with English Abstract). [Google Scholar]

- Stanton, P.; Yu, A. Interim Use of API Codes for Design of Dynamic Riser Systems for Deepsea Mining Industry. In Proceedings of the 29th International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010. OMAE2010-20189. [Google Scholar]

- Ohta, J.; Ysukawa, K.; Machida, S.; Fujinaga, K.; Nakamura, K.; Takaya, Y.; Iijima, K.; Suzuki, K.; Kato, Y. Geological factors responsible for REY-rich mud in the western North Pacific Ocean: Implications from mineralogy and grain size distributions. Geochem. J. 2016, 50, 591–603. [Google Scholar] [CrossRef]

- Yasukawa, K.; Kino, S.; Azuma, K.; Tanaka, E.; Miura, K.; Ohta, J.; Fujinaga, K.; Nakamura, K.; Kato, Y. Geochemical features of Fe-Mn micronodules in deep-sea sediments of the western North Pacific Ocean: Potential for co-product metal extraction from REY-rich mud. Ore Geol. Rev. 2020, 127, 103805. [Google Scholar] [CrossRef]

- Tanaka, E.; Nakamura, K.; Yasukawa, K.; Miura, K.; Fujinaga, K.; Ohta, J.; Iijima, K.; Nozaki, T.; Machida, S.; Kato, Y. Chemostratigraphy of deep-sea sediments in the western North Pacific Ocean: Implications for genesis of mud highly enriched in rare-earth elements and yttrium. Ore Geol. Rev. 2020, 119, 103392. [Google Scholar] [CrossRef]

- Tanaka, E.; Nakamura, K.; Yasukawa, K.; Miura, K.; Fujinaga, K.; Ohta, J.; Iijima, K.; Nozaki, T.; Machida, S.; Kato, Y. Chemostratigraphic Correlations of Deep-Sea Sediments in the Western North Pacific Ocean: A New Constraint on the Distribution of Mud Highly Enriched in Rare-Earth Elements. Minerals 2020, 10, 575. [Google Scholar] [CrossRef]

| Authors Processing method | Andrews et al. [19] Reduction and Hydrochloric Acid Leach Process | Hillman and Gosling [20] Cuprion Ammoniacal Leach Process | Charles et al. [21] Reduction and Hydrochloric Acid Leach Process | Søreide et al. [22] High-Temperature & High-Pressure Sulfuric Acid Leach Process | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Subsystem | Mining | Trans. | Process. | Mining | Trans. | Process. | Mining | Trans. | Process. | Mining | Trans. | Process. |

| (condition) | (wet) | (dry) | (dry) | (wet) | (dry) | (dry) | (wet) | (dry) | (dry) | (wet) | (dry) | (dry) |

| Production (t/y) | 2.3 M | 1.5 M | 1.5 M | 4.2 M | 3.0 M | 3.0 M | 2.3 M | 1.5 M | 1.5 M | 1.1 M | 0.7 M | 0.7 M |

| Operation days | 300 d/y | 300 d/y | 330 d/y | 300 d/y | 300 d/y | 330 d/y | 250 d/y | |||||

| Capital expenditure (CAPEX) | $180M | $176M | $513M | $590M | $310M | $727M | $282M | $188M | $470M | $127M | $93M | $271M |

| CAPEX ratio | 21% | 20% | 59% | 36% | 19% | 45% | 30% | 20% | 50% | 26% | 19% | 55% |

| Equity/Loan | 100/0 | 100/0 | 50/50 | 30/70 | ||||||||

| Operating expenditure (OPEX) | $45M | $25M | $165M | $77M | $37M | $111M | $48M | $36M | $156M | $21.8M | $13.5M | $22.9M |

| Loan interest | 0% | 0% | 8% | |||||||||

| Survey cost | $6M | $3M | $1.9M | |||||||||

| OPEX ratio | 19% | 11% | 70% | 34% | 16% | 50% | 20% | 15% | 65% | 38% | 23% | 39% |

| Metal | Price | Recovery | Product | Price | Recovery | Product | Price | Recovery | Product | Price | Recovery | Product |

| Co | $5.5/lb | 85% | 3375 t/y | $8.53/lb | 65% | 5070 t/y | $6.8/lb | 85% | 3525 t/y | $20/lb | 83% | 2652 t/y |

| Ni | $3.75/lb | 95% | 18,525 t/y | $3.62/lb | 92% | 36,708 t/y | $3.6/lb | 95% | 19,730 t/y | $3.33/lb | 98% | 2548 t/y |

| Cu | $1.25/lb | 95% | 15,675 t/y | $1.17/lb | 92% | 28,704 t/y | $0.95/lb | 95% | 17,810 t/y | $1/lb | 97% | 1890 t/y |

| Mn | $0.4/lb | 93% | 404,550 t/y | $0.3/lb | 93% | 382,500 t/y | ||||||

| Taxes | 46% | Total 29% | 10% | |||||||||

| NPV | −81M | |||||||||||

| IRR | 6.4% | 7.4% | 12% | 9.6% | ||||||||

| Item | REE-Rich Mud | FN |

|---|---|---|

| Water depth | 5600–5800 m | about 5000 m |

| Seafloor excavation | Hydraulic cut and suction | Hydraulic suction |

| Lift | Pump hydraulic in riser | Pump hydraulic in riser |

| Dewatering | Settlement and dry-up | Separation and dry-up |

| Transport | 2000 km by cargo carrier to Japan’s main land | 2000–5000 km by cargo carrier to North America |

| Processing | Acid leach and solvent separation | Hydro-metallurgy |

| CAPEX ($M) | OPEX ($M) | |

|---|---|---|

| Mining | 179.7 | 80.7 |

| Transportation | 223.8 | 33.7 |

| Leaching (REE-mud) | 198.3 | 261.9 |

| Brock making | 155.6 | 226.0 |

| Processing (FN) | 863.6 | 110.8 |

| Total | 1621.0 | 713.1 |

| Element | Content (ppm) |

|---|---|

| Ce | 177.9 |

| La | 154.0 |

| Pr | 46.2 |

| Nd | 192.6 |

| Sm | 44.9 |

| Eu | 11.1 |

| Gd | 49.0 |

| Tb | 7.3 |

| Dy | 45.4 |

| Y | 277.2 |

| Metal | Content (%) |

|---|---|

| Ni | 0.4 |

| Cu | 0.2 |

| Co | 0.5 |

| Mn | 20.0 |

| Element and Metal | Price ($/t) | Yearly Revenue ($M) |

|---|---|---|

| Ce | 15,000 | 1.2 |

| La | 15,000 | 3.8 |

| Pr | 125,833 | 9.6 |

| Nd | 83,333 | 26.6 |

| Sm | 35,000 | 2.6 |

| Eu | 1,500,000 | 27.6 |

| Gd | 100,000 | 8.1 |

| Tb | 1,033,333 | 12.5 |

| Dy | 508,333 | 38.2 |

| Y | 56,666 | 26.0 |

| Ni | 16,121 | 51.8 |

| Cu | 6678 | 11.3 |

| Co | 34,698 | 155.6 |

| Mn | 2463 | 354.7 |

| Total | 729.6 |

| NPV ($M) | IRR (%) | PP (year) |

|---|---|---|

| −526.7 | 3.66 | 15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamazaki, T.; Nakatani, N.; Arai, R.; Sekimoto, T.; Katayama, H. Combined Mining and Pulp-Lifting of Ferromanganese Nodules and Rare-Earth Element-Rich Mud around Minamitorishima Island in the Western North Pacific: A Prefeasibility Study. Minerals 2021, 11, 310. https://doi.org/10.3390/min11030310

Yamazaki T, Nakatani N, Arai R, Sekimoto T, Katayama H. Combined Mining and Pulp-Lifting of Ferromanganese Nodules and Rare-Earth Element-Rich Mud around Minamitorishima Island in the Western North Pacific: A Prefeasibility Study. Minerals. 2021; 11(3):310. https://doi.org/10.3390/min11030310

Chicago/Turabian StyleYamazaki, Tetsuo, Naoki Nakatani, Rei Arai, Tsunehiro Sekimoto, and Hiroyuki Katayama. 2021. "Combined Mining and Pulp-Lifting of Ferromanganese Nodules and Rare-Earth Element-Rich Mud around Minamitorishima Island in the Western North Pacific: A Prefeasibility Study" Minerals 11, no. 3: 310. https://doi.org/10.3390/min11030310

APA StyleYamazaki, T., Nakatani, N., Arai, R., Sekimoto, T., & Katayama, H. (2021). Combined Mining and Pulp-Lifting of Ferromanganese Nodules and Rare-Earth Element-Rich Mud around Minamitorishima Island in the Western North Pacific: A Prefeasibility Study. Minerals, 11(3), 310. https://doi.org/10.3390/min11030310