Impact of Grinding of Printed Circuit Boards on the Efficiency of Metal Recovery by Means of Electrostatic Separation

Abstract

1. Introduction

2. Materials and Methods

2.1. Grinding Materials and Methods

- option 1—1 mm screen perforation, mill load (capacity of feeding the material to the mill): 5 g/min;

- option 2—1 mm screen perforation, cooling the feed with liquid nitrogen, mill load: 20 g/min;

- option 3—2 mm screen perforation, mill load: 10 g/min;

- option 4—3 mm screen perforation, mill load: 10 g/min.

- rotator speed: 2815 min−1;

- gap between the knives in the mill: 0.5 mm.

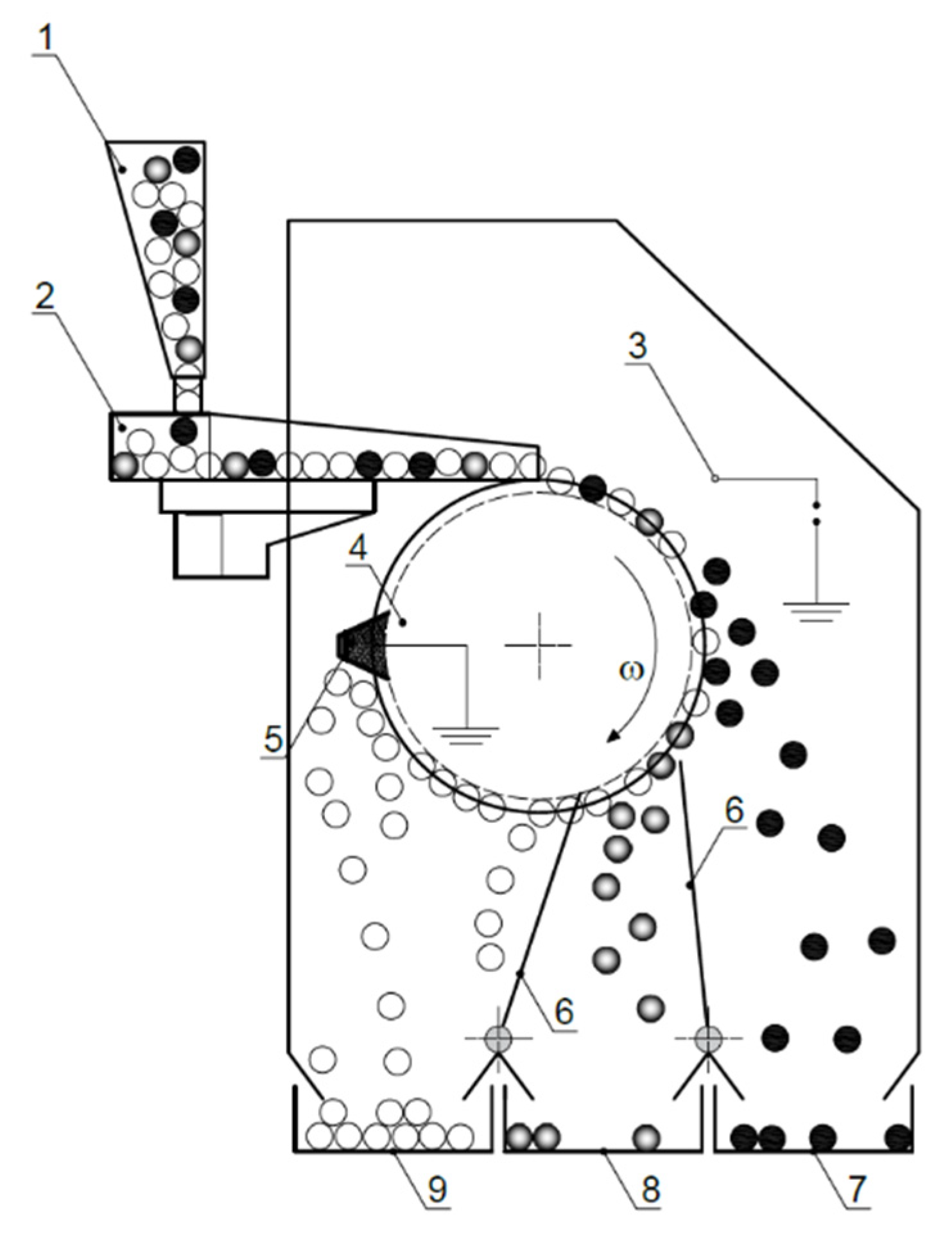

2.2. Electrostatic Separation

2.3. Product Analysis

- Fritsch screens with mesh sizes of 2 mm, 1.4 mm, 1 mm, 710 μm, 500 μm, 355 μm, 250 μm, 180 μm, 125 μm, and 90 μm.

- ANALYSETTE 22 MicroTec Plus Laser Particle Sizer (Fritsch, Idar-Oberstein, Germany)—the measurement was not carried out on material obtained from grinding in a mill with a screen with 2 and 3 mm perforation due to limitations in the measurement of grain size.

- ICP-AES—using the JY2000 Optical Emission Spectrometer (by Jobin Yvon) in order to assess the content of elements in products. The source of the induction was a plasma torch coupled with a 40.68 MHz frequency generator; the products were previously dissolved.

- Specific density analysis—using Gay-Lussac pycnometers on the basis of PN-EN 1097-7:2001 with the use of ethyl alcohol with a density of 0.7893 g/cm3.

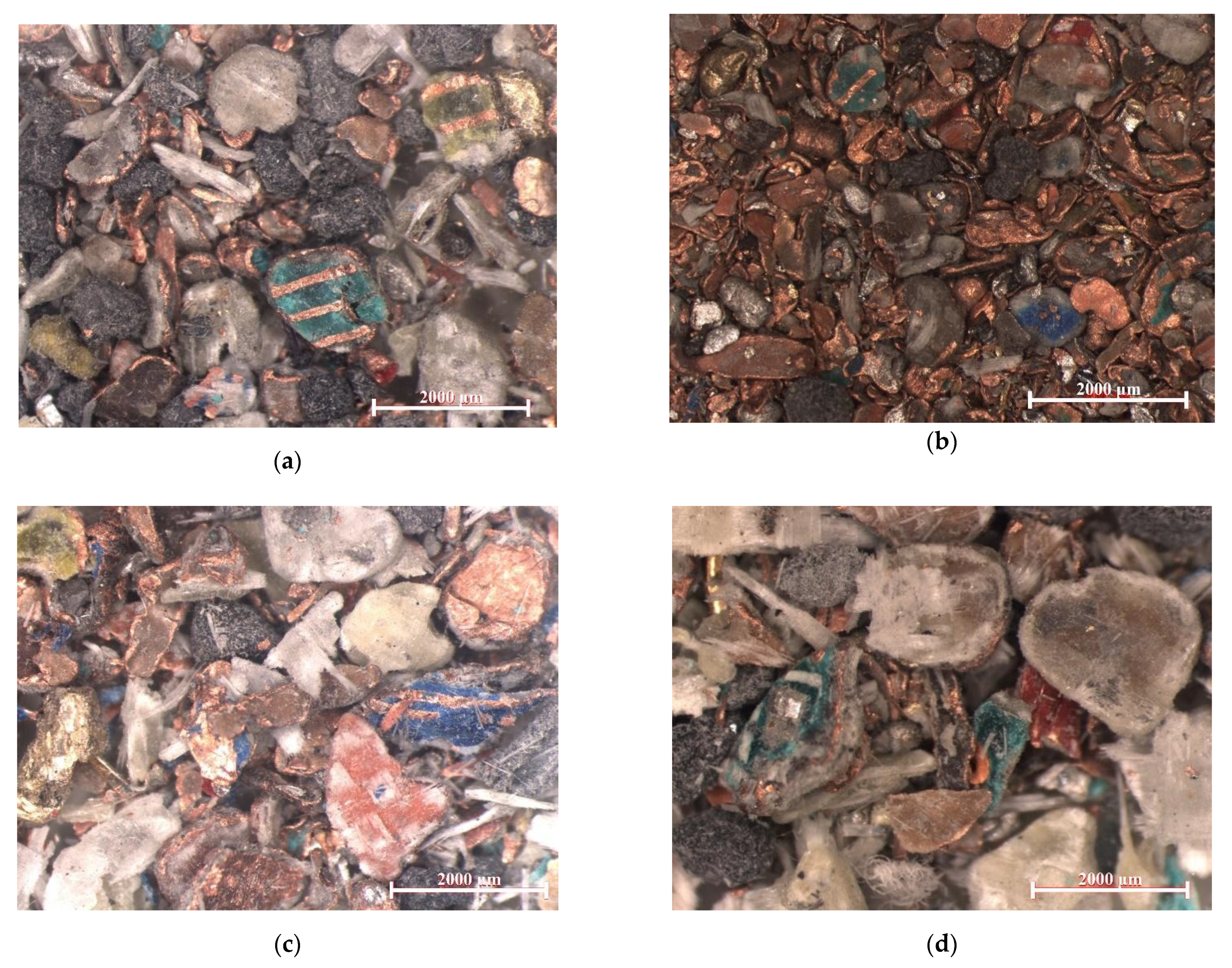

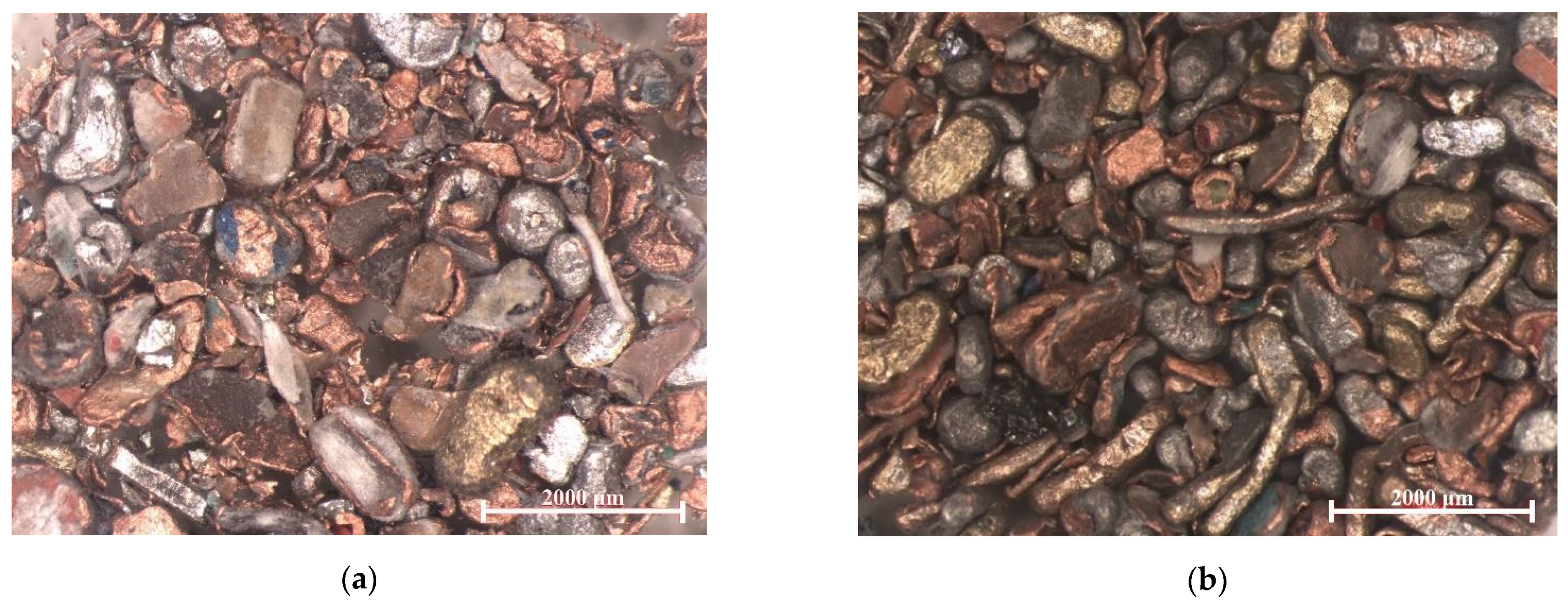

- Microscope analysis with Zeiss SteREO Discovery Modular Stereo Microscope (Carl Zeiss AG, Jena, Germany).

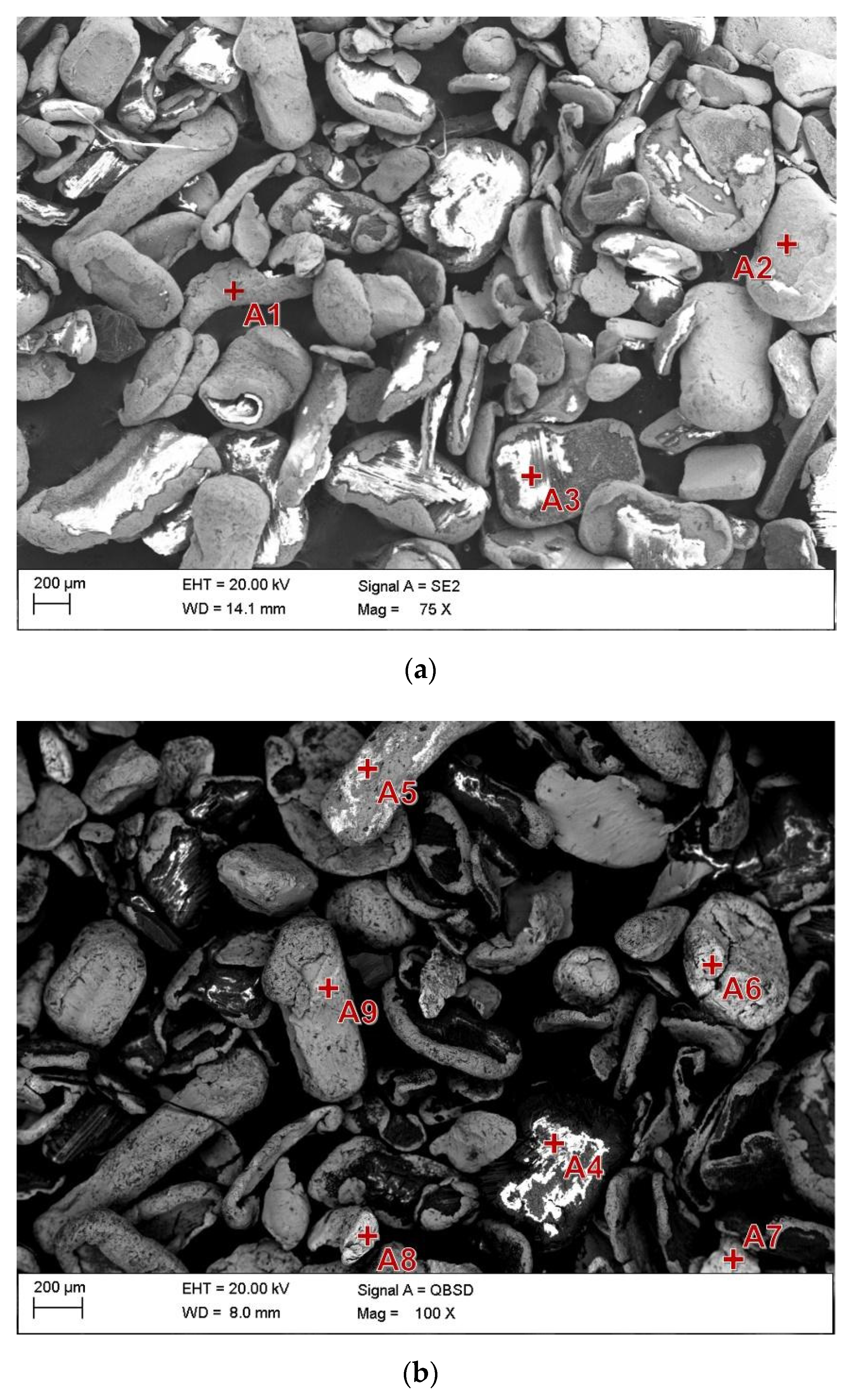

- High-resolution Zeiss SUPRA 35 scanning electron microscope (Carl Zeiss AG, Germany), equipped with EDAX energy dispersive X-ray spectroscopy (EDS) chemical analysis system (EDAX, Mahwah, NJ, USA).

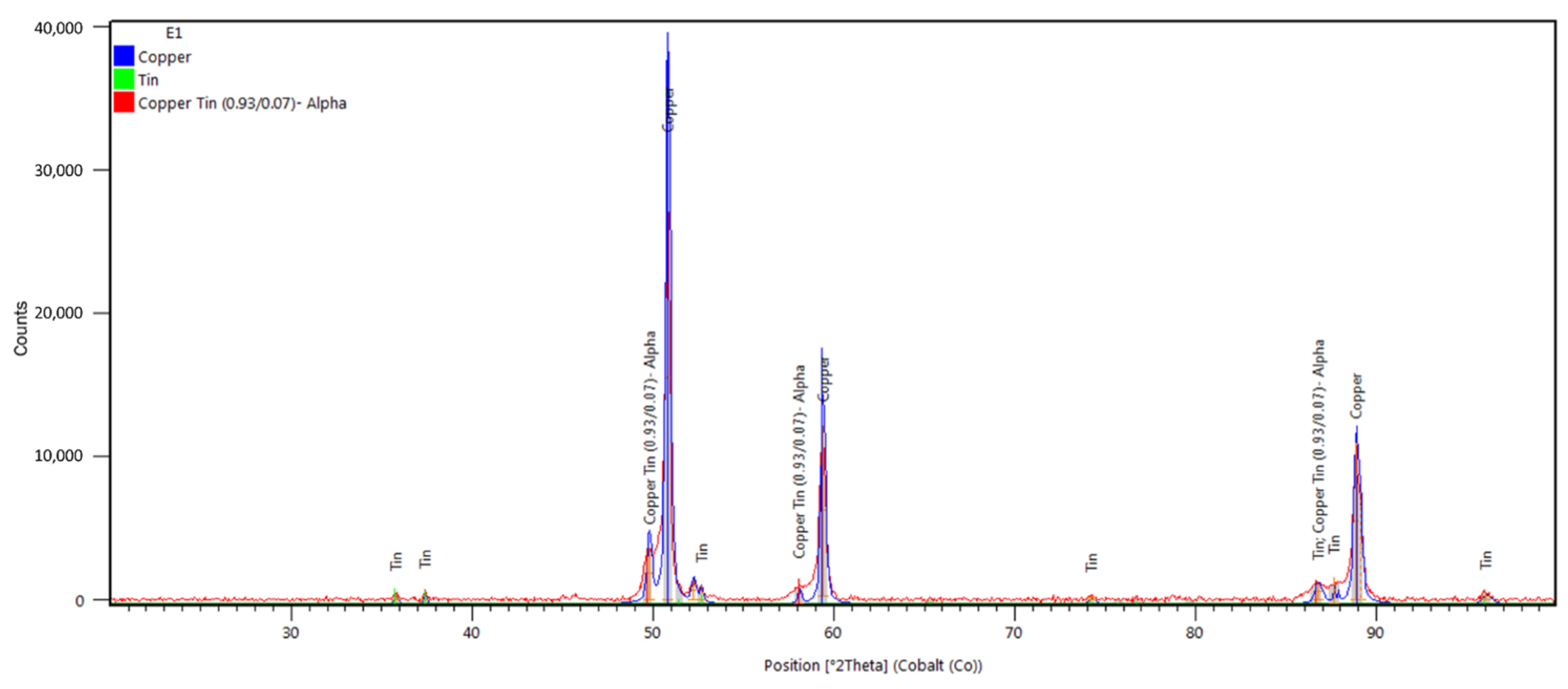

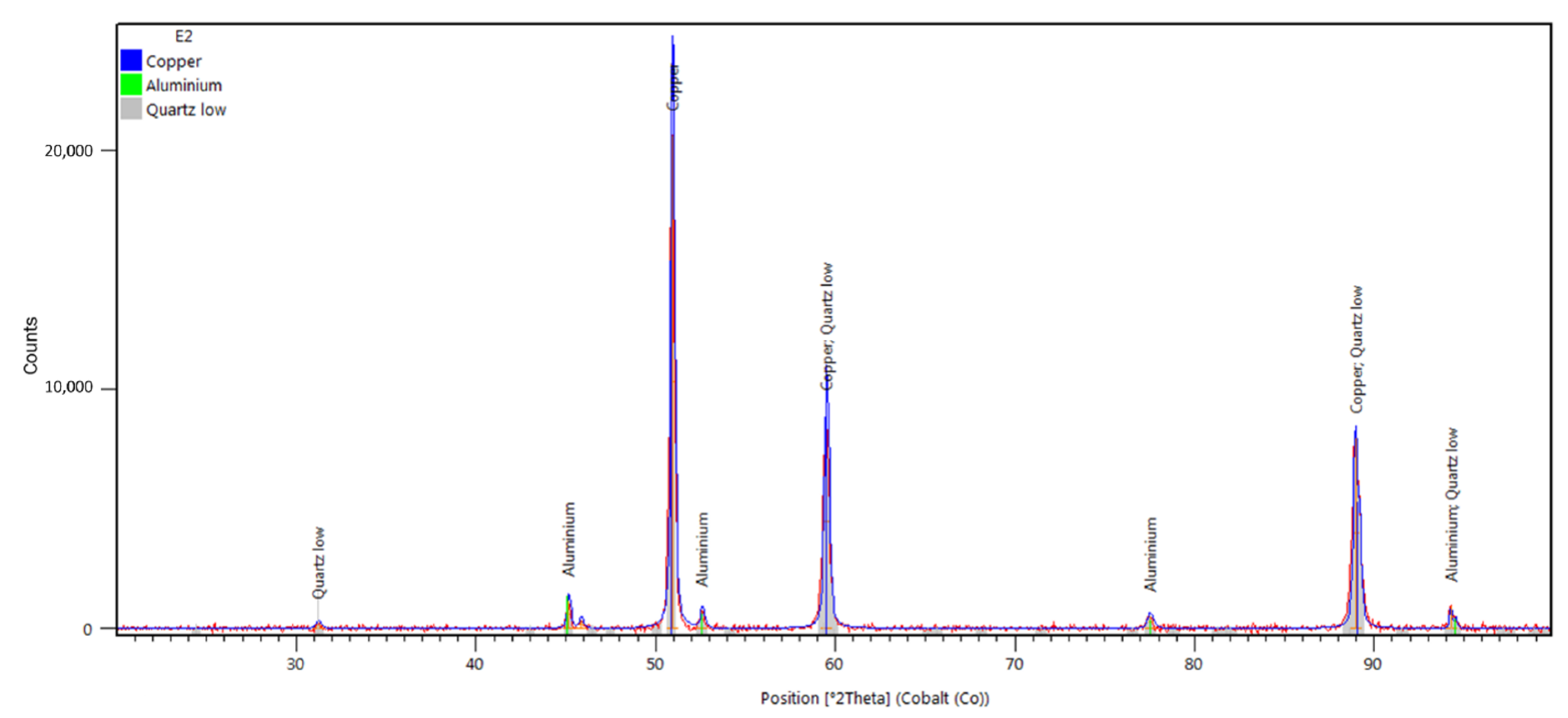

- Qualitative phase analysis was performed with the use of a Panalytical X’Pert Pro MPD diffractometer (Panalytical, Almelo, The Netherlands), utilising filtered radiation of a cobalt anode lamp (λKα = 0.179 nm). The diffraction lines were recorded in the Bragg–Brentano geometry, using the step-scanning method by means of a PIXcell 3D detector on the diffracted beam axis, in the angle range of 20°–100° [2θ] (step, 0.05°; count time per step, 200 s). The obtained diffractograms were analysed with the use of Panalytical HighScore Plus (v. 3.0e) software with the PAN-ICSD database.

3. Results

3.1. Grinding

3.2. Analysis of the Electrostatic Separation Efficiency

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vermeșan, H.; Tiuc, A.-E.; Purcar, M. Advanced Recovery Techniques for Waste Materials from IT and Telecommunication Equipment Printed Circuit Boards. Sustainability 2019, 12, 74. [Google Scholar] [CrossRef]

- Kumar, V.; Lee, J.; Jeong, J.; Jha, M.K.; Kim, B.; Singh, R. Recycling of Printed Circuit Boards (PCBs) to Generate Enriched Rare Metal Concentrate. J. Ind. Eng. Chem. 2015, 21, 805–813. [Google Scholar] [CrossRef]

- Sohaili, J.; Muniyandi, S.K.; Mohamad, S.S. A Review on Printed Circuit Board Recycling Technology. J. Emerg. Trends Eng. Appl. Sci. 2012, 3, 12–18. [Google Scholar]

- Tsydenova, O.; Bengtsson, M. Chemical Hazards Associated with Treatment of Waste Electrical and Electronic Equipment. Waste Manag. 2011, 31, 45–58. [Google Scholar] [CrossRef]

- Johnson, J.; Harper, E.M.; Lifset, R.; Graedel, T.E. Supporting Information for “Dining at the Periodic Table: Metals”Concentrations as They Relate to Recycling. Environ. Sci. Technol. 2007, 41, 1759–1765. [Google Scholar] [CrossRef] [PubMed]

- Tuncuk, A.; Stazi, V.; Akcil, A.; Yazici, E.Y.; Deveci, H. Aqueous Metal Recovery Techniques from E-Scrap: Hydrometallurgy in Recycling. Miner. Eng. 2012, 25, 28–37. [Google Scholar] [CrossRef]

- Li, J.; Lu, H.; Guo, J.; Xu, Z.; Zhou, Y. Recycle Technology for Recovering Resources and Products from Waste Printed Circuit Boards. Environ. Sci. Technol. 2007, 41, 1995–2000. [Google Scholar] [CrossRef]

- Dascalescu, L.; Iuga, A.; Morar, R. Corona–Electrostatic Separation: An Efficient Technique for the Recovery of Metals and Plastics From Industrial Wastes. Magn. Electr. Sep. 1900, 4, 059037. [Google Scholar] [CrossRef]

- Huang, K.; Guo, J.; Xu, Z. Recycling of Waste Printed Circuit Boards: A Review of Current Technologies and Treatment Status in China. J. Hazard. Mater. 2009, 164, 399–408. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Holuszko, M.E.; Janke, T. Characterization of the Non-Metal Fraction of the Processed Waste Printed Circuit Boards. Waste Manag. 2018, 75, 94–102. [Google Scholar] [CrossRef] [PubMed]

- Weil, E.D.; Levchik, S. A Review of Current Flame Retardant Systems for Epoxy Resins. J. Fire Sci. 2004, 22, 25–40. [Google Scholar] [CrossRef]

- Muniyandi, S.K.; Sohaili, J.; Hassan, A. Encapsulation of Nonmetallic Fractions Recovered from Printed Circuit Boards Waste with Thermoplastic. J. Air Waste Manag. Assoc. 2014, 64, 1085–1092. [Google Scholar] [CrossRef]

- Duan, H.; Hu, J.; Yuan, W.; Wang, Y.; Yu, D.; Song, Q.; Li, J. Characterizing the Environmental Implications of the Recycling of Non-Metallic Fractions from Waste Printed Circuit Boards. J. Clean. Prod. 2016, 137, 546–554. [Google Scholar] [CrossRef]

- Bizzo, W.; Figueiredo, R.; de Andrade, V. Characterization of Printed Circuit Boards for Metal and Energy Recovery after Milling and Mechanical Separation. Materials 2014, 7, 4555–4566. [Google Scholar] [CrossRef]

- Charles, R.G.; Douglas, P.; Hallin, I.L.; Matthews, I.; Liversage, G. An Investigation of Trends in Precious Metal and Copper Content of RAM Modules in WEEE: Implications for Long Term Recycling Potential. Waste Manag. 2017, 60, 505–520. [Google Scholar] [CrossRef] [PubMed]

- Cayumil, R.; Khanna, R.; Rajarao, R.; Mukherjee, P.S.; Sahajwalla, V. Concentration of Precious Metals during Their Recovery from Electronic Waste. Waste Manag. 2016, 57, 121–130. [Google Scholar] [CrossRef] [PubMed]

- Schluep, M.; Hagelueken, C.; Kuehr, R.; Magalini, F.; Maurer, C. Recycling—from e-Waste to Resources. In Sustainable Innovation and Technology Transfer Industrial Sector Studies; UNEP and STeP: Nairobi, Kenya; Bonn, Germany, 2006. [Google Scholar]

- Mao, S.; Kang, Y.; Zhang, Y.; Xiao, X.; Zhu, H. Fractional Grey Model Based on Non-Singular Exponential Kernel and Its Application in the Prediction of Electronic Waste Precious Metal Content. ISA Trans. 2020, 107, 12–26. [Google Scholar] [CrossRef] [PubMed]

- Hagelüken, C. Recycling of Electronic Scrap at Umicore’s Integrated Metals Smelter and Refinery. World Metall. Erzmetall 2006, 59, 152–161. [Google Scholar]

- Song, Q.; Zeng, X.; Li, J.; Duan, H.; Yuan, W. Environmental Risk Assessment of CRT and PCB Workshops in a Mobile E-Waste Recycling Plant. Environ. Sci. Pollut. Res. 2015, 22, 12366–12373. [Google Scholar] [CrossRef]

- Dervišević, I.; Minić, D.; Kamberović, Ž.; Ćosović, V.; Ristić, M. Characterization of PCBs from Computers and Mobile Phones, and the Proposal of Newly Developed Materials for Substitution of Gold, Lead and Arsenic. Environ. Sci. Pollut. Res. 2013, 20, 4278–4292. [Google Scholar] [CrossRef] [PubMed]

- Niu, Q.; Xiang, D.; Liu, X.; Duan, G.; Shi, C. The Recycle Model of Printed Circuit Board and Its Economy Evaluation. In Proceedings of the 2007 IEEE International Symposium on Electronics and the Environment, Orlando, FL, USA, 7–10 May 2007; IEEE: Orlando, FL, USA, 2007; pp. 106–111. [Google Scholar]

- Guo, C.; Wang, H.; Liang, W.; Fu, J.; Yi, X. Liberation Characteristic and Physical Separation of Printed Circuit Board (PCB). Waste Manag. 2011, 31, 2161–2166. [Google Scholar] [CrossRef]

- Kaya, M. Recovery of Metals and Nonmetals from Electronic Waste by Physical and Chemical Recycling Processes. Waste Manag. 2016, 57, 64–90. [Google Scholar] [CrossRef]

- Leung, A.O.W.; Luksemburg, W.J.; Wong, A.S.; Wong, M.H. Spatial Distribution of Polybrominated Diphenyl Ethers and Polychlorinated Dibenzo-p-Dioxins and Dibenzofurans in Soil and Combusted Residue at Guiyu, an Electronic Waste Recycling Site in Southeast China. Environ. Sci. Technol. 2007, 41, 2730–2737. [Google Scholar] [CrossRef]

- Qiu, R.; Lin, M.; Ruan, J.; Fu, Y.; Hu, J.; Deng, M.; Tang, Y.; Qiu, R. Recovering Full Metallic Resources from Waste Printed Circuit Boards: A Refined Review. J. Clean. Prod. 2020, 244, 118690. [Google Scholar] [CrossRef]

- Xiang, D.; Mou, P.; Wang, J.; Duan, G.; Zhang, H.C. Printed Circuit Board Recycling Process and Its Environmental Impact Assessment. Int. J. Adv. Manuf. Technol. 2007, 34, 1030–1036. [Google Scholar] [CrossRef]

- Argumedo-Delira, R.; Gómez-Martínez, M.J.; Soto, B.J. Gold Bioleaching from Printed Circuit Boards of Mobile Phones by Aspergillus Niger in a Culture without Agitation and with Glucose as a Carbon Source. Metals 2019, 9, 521. [Google Scholar] [CrossRef]

- Drzymała, J.; Swatek, A. Mineral Processing: Foundations of Theory and Practice of Minerallurgy; University of Technology: Wroclaw, Poland, 2007; ISBN 978-83-7493-362-9. [Google Scholar]

- Tatariants, M.; Yousef, S.; Sidaraviciute, R.; Denafas, G.; Bendikiene, R. Characterization of Waste Printed Circuit Boards Recycled Using a Dissolution Approach and Ultrasonic Treatment at Low Temperatures. RSC Adv. 2017, 7, 37729–37738. [Google Scholar] [CrossRef]

- Forti, V.; Baldé, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential; United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR)—Co-Hosted SCYCLE Programme, International Telecommunication Union (ITU) & International Solid Waste Association (ISWA): Bonn, Germany; Geneva, Switzerland; Rotterdam, The Netherlands, 2020; p. 120. [Google Scholar]

- Bidini, G.; Fantozzi, F.; Bartocci, P.; D’Alessandro, B.; D’Amico, M.; Laranci, P.; Scozza, E.; Zagaroli, M. Recovery of Precious Metals from Scrap Printed Circuit Boards through Pyrolysis. J. Anal. Appl. Pyrolysis 2015, 111, 140–147. [Google Scholar] [CrossRef]

- LaDou, J. Printed Circuit Board Industry. Int. J. Hyg. Environ. Health 2006, 209, 211–219. [Google Scholar] [CrossRef]

- Ernst, T.; Popp, R.; Wolf, M.; van Eldik, R. Analysis of Eco-Relevant Elements and Noble Metals in Printed Wiring Boards Using AAS, ICP–AES and EDXRF. Anal. Bioanal. Chem. 2003, 375, 805–814. [Google Scholar] [CrossRef]

- Koyanaka, S.; Endoh, S.; Ohya, H. Effect of Impact Velocity Control on Selective Grinding of Waste Printed Circuit Boards. Adv. Powder Technol. 2006, 17, 113–126. [Google Scholar] [CrossRef]

- Li, J.; Xu, Z.; Zhou, Y. Application of Corona Discharge and Electrostatic Force to Separate Metals and Nonmetals from Crushed Particles of Waste Printed Circuit Boards. J. Electrost. 2007, 65, 233–238. [Google Scholar] [CrossRef]

- Khaliq, A.; Rhamdhani, M.; Brooks, G.; Masood, S. Metal Extraction Processes for Electronic Waste and Existing Industrial Routes: A Review and Australian Perspective. Resources 2014, 3, 152–179. [Google Scholar] [CrossRef]

- Dascalescu, L.; Tilmatine, A.; Aman, F.; Mihailescu, M. Optimization of Electrostatic Separation Processes Using Response Surface Modeling. IEEE Trans. Ind. Applicat. 2004, 40, 53–59. [Google Scholar] [CrossRef]

- Zenkiewicz, M.; Zuk, T. Physical basis of tribocharging and electrostatic separation of plastics. Polimery 2014, 59, 314–323. [Google Scholar] [CrossRef]

- Wu, J.; Li, J.; Xu, Z. Electrostatic Separation for Recovering Metals and Nonmetals from Waste Printed Circuit Board: Problems and Improvements. Environ. Sci. Technol. 2008, 42, 5272–5276. [Google Scholar] [CrossRef]

- Wei, J.; Realff, M.J. Design and Optimization of Free-Fall Electrostatic Separators for Plastics Recycling. AIChE J. 2003, 49, 3138–3149. [Google Scholar] [CrossRef]

- Tilmatine, A.; Medles, K.; Bendimerad, S.-E.; Boukholda, F.; Dascalescu, L. Electrostatic Separators of Particles: Application to Plastic/Metal, Metal/Metal and Plastic/Plastic Mixtures. Waste Manag. 2009, 29, 228–232. [Google Scholar] [CrossRef] [PubMed]

- Hou, S.; Wu, J.; Qin, Y.; Xu, Z. Electrostatic Separation for Recycling Waste Printed Circuit Board: A Study on External Factor and a Robust Design for Optimization. Environ. Sci. Technol. 2010, 44, 5177–5181. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Li, J.; Guo, J.; Xu, Z. Movement Behavior in Electrostatic Separation: Recycling of Metal Materials from Waste Printed Circuit Board. J. Mater. Process. Technol. 2008, 197, 101–108. [Google Scholar] [CrossRef]

- Li, J.; Zhou, Q.; Xu, Z. Real-Time Monitoring System for Improving Corona Electrostatic Separation in the Process of Recovering Waste Printed Circuit Boards. Waste Manag. Res. 2014, 32, 1227–1234. [Google Scholar] [CrossRef] [PubMed]

- Sanapala, R. Characterization of FR-4 Printed Circuit Board Laminates Before and After Exposure to Lead-Free Soldering Conditions. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2008. [Google Scholar]

- Franke, D.; Suponik, T. Metals Recovery from E-Scrap Using Gravity, Electrostatic and Magnetic Separations. IOP Conf. Ser. Mater. Sci. Eng. 2019, 545, 012016. [Google Scholar] [CrossRef]

- Lee, J.; Kim, Y.; Lee, J. Disassembly and Physical Separation of Electric/Electronic Components Layered in Printed Circuit Boards (PCB). J. Hazard. Mater. 2012, 241–242, 387–394. [Google Scholar] [CrossRef] [PubMed]

- Available online: www.testchem.pl/en/testchem-products/sample-preparing/grinders-and-crushers/knife-lab-grinders/ (accessed on 4 December 2020).

- Franke, D.; Suponik, T.; Nuckowski, P.M.; Gołombek, K.; Hyra, K. Recovery of Metals from Printed Circuit Boards By Means of Electrostatic Separation. Manag. Syst. Prod. Eng. 2020, 28, 213–219. [Google Scholar] [CrossRef]

- Suponik, T.; Franke, D.; Nuckowski, P. Electrostatic and Magnetic Separations for the Recovery of Metals from Electronic Waste. IOP Conf. Ser. Mater. Sci. Eng. 2019, 641, 012017. [Google Scholar] [CrossRef]

- Wu, W.; Liu, X.; Zhang, X.; Zhu, M.; Tan, W. Bioleaching of Copper from Waste Printed Circuit Boards by Bacteria-Free Cultural Supernatant of Iron–Sulfur-Oxidizing Bacteria. Bioresour. Bioprocess. 2018, 5, 10. [Google Scholar] [CrossRef]

- Pham, H.Q.; Marks, M.J. Epoxy Resins. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA, Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005; pp. 155–244. ISBN 978-3-527-30673-2. [Google Scholar]

- Sood, B.; Sanapala, R.; Das, D.; Pecht, M.; Huang, C.Y.; Tsai, M.Y. Comparison of Printed Circuit Board Property Variations in Response to Simulated Lead-Free Soldering. IEEE Trans. Electron. Packag. Manufact. 2010, 33, 98–111. [Google Scholar] [CrossRef]

- Sood, B.; Pecht, M. The Effect of Epoxy/Glass Interfaces on CAF Failures in Printed Circuit Boards. Microelectron. Reliab. 2018, 82, 235–243. [Google Scholar] [CrossRef]

- Wu, J.; Qin, Y.; Zhou, Q.; Xu, Z. Impact of Nonconductive Powder on Electrostatic Separation for Recycling Crushed Waste Printed Circuit Board. J. Hazard. Mater. 2009, 164, 1352–1358. [Google Scholar] [CrossRef] [PubMed]

| Grain Class, mm | Yield of Product, % | |||||

|---|---|---|---|---|---|---|

| Option 1 a | Option 1 b | Option 2 a | Option 2 b | Option 3 a | Option 4 a | |

| >2.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.2 |

| 2.0–1.4 | 0.0 | 0.0 | 0.0 | 0.0 | 0.4 | 13.7 |

| 1.4–1.0 | 0.3 | 0.0 | 0.4 | 0.0 | 11.1 | 24.6 |

| 1.0–0.71 | 5.7 | 5.2 | 3.6 | 1.6 | 25.6 | 16.8 |

| 0.71–0.50 | 14.1 | 14.8 | 13.0 | 10.4 | 15.6 | 10.7 |

| 0.50–0.36 | 19.3 | 22.0 | 19.5 | 22.1 | 11.6 | 8.4 |

| 0.36–0.25 | 17.0 | 10.4 | 17.0 | 14.2 | 8.6 | 6.3 |

| 0.25–0.18 | 9.6 | 5.6 | 10.6 | 6.5 | 5.0 | 4.1 |

| 0.18–0.13 | 8.5 | 4.9 | 10.8 | 5.3 | 4.5 | 4.5 |

| 0.13–0.09 | 9.1 | 3.8 | 8.5 | 4.3 | 3.6 | 4.2 |

| <0.09 | 16.3 | 33.3 | 16.6 | 35.6 | 13.9 | 6.5 |

| Grinding Option | Yield of Product, % | Density, g/cc | ||||

|---|---|---|---|---|---|---|

| Waste | Intermediate | Concentrate | Waste | Intermediate | Concentrate | |

| Option 1 | 71.5 | 2.8 | 25.8 | 2.61 | 5.98 | 8.78 |

| Option 2 | 71.0 | 2.8 | 26.2 | 2.29 | 5.33 | 8.87 |

| Option 3 | 66.7 | 6.1 | 27.2 | 2.92 | 3.76 | 7.32 |

| Option 4 | 50.4 | 6.3 | 43.2 | 3.35 | 3.5 | 5.51 |

| Element | Content of the Element, %, in | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Feed | Concentrate | Intermediate | Waste | |||||||||||

| Option 1 | Option 2 | Option 3 | Option 4 | Option 1 | Option 2 | Option 3 | Option 4 | Option 1 | Option 2 | Option 3 | Option 4 | |||

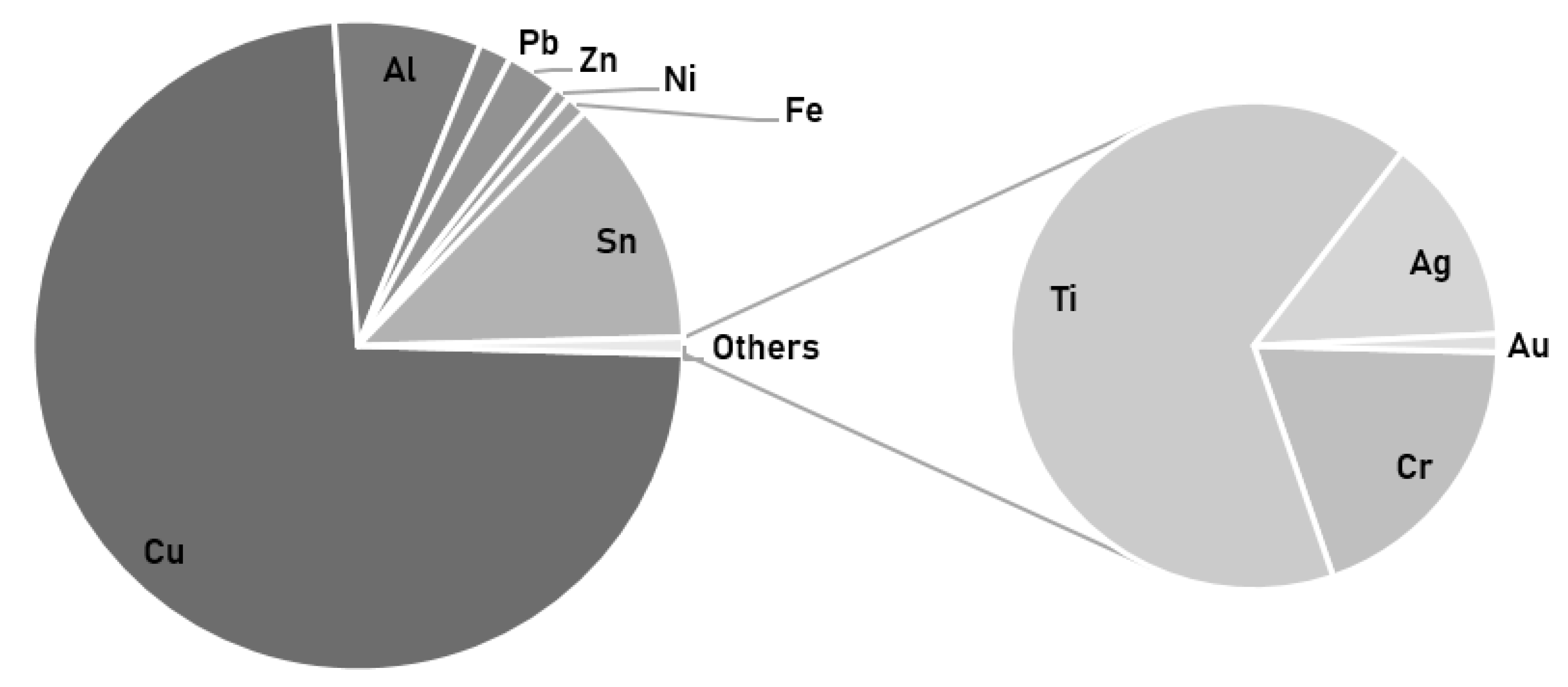

| Valuable elements | Cu | 17.70 ± 1.77 | 64.17 ± 6.42 | 68.50 ± 6.85 | 54.29 ± 5.43 | 38.45 ± 3.85 | 5.14 ± 0.51 | 6.68 ± 0.67 | 6.42 ± 0.64 | 7.47 ± 0.75 | 1.24 ± 0.12 | 0.17 ± 0.02 | 3.20 ± 0.32 | 3.89 ± 0.39 |

| Al | 1.95 ± 0.20 | 5.28 ± 0.53 | 6.82 ± 0.68 | 4.58 ± 0.46 | 4.08 ± 0.41 | 1.18 ± 0.12 | 1.34 ± 0.13 | 0.84 ± 0.08 | 0.54 ± 0.05 | 0.2 ± 0.02 | 0.07 ± 0.01 | 0.48 ± 0.05 | 0.29 ± 0.03 | |

| Pb | 0.39 ± 0.04 | 2.04 ± 0.20 | 1.5 ± 0.15 | 2.54 ± 0.25 | 1.74 ± 0.17 | 1.28 ± 0.13 | 0.74 ± 0.07 | 0.47 ± 0.04 | 0.08 ± 0.01 | BDL * | 0.001 ± 0.0001 | BDL * | 0.02 ± 0.002 | |

| Zn | 0.69 ± 0.07 | 1.22 ± 0.12 | 2.5 ± 0.25 | 1.87 ± 0.19 | 0.87 ± 0.09 | 0.74 ± 0.07 | 0.94 ± 0.09 | 0.40 ± 0.04 | 0.94 ± 0.09 | 0.14 ± 0.01 | BDL * | 0.08 ± 0.01 | BDL * | |

| Ni | 0.19 ± 0.02 | 1.28 ± 0.13 | 0.75 ± 0.08 | 0.49 ± 0.05 | 0.34 ± 0.03 | 0.75 ± 0.07 | 0.31 ± 0.03 | 0.41 ± 0.04 | 0.21 ± 0.02 | BDL * | BDL * | 0.18 ± 0.02 | BDL * | |

| Fe | 0.38 ± 0.04 | 2.42 ± 0.24 | 0.95 ± 0.10 | 1.87 ± 0.19 | 1.11 ± 0.11 | 0.61 ± 0.06 | 1.50 ± 0.15 | 1.64 ± 0.16 | 0.84 ± 0.08 | 0.04 ± 0.004 | 0.09 ± 0.01 | 0.15 ± 0.02 | 0.40 ± 0.04 | |

| Sn | 2.92 ± 0.29 | 9.54 ± 0.95 | 11.5 ± 1.15 | 9.78 ± 0.98 | 7.21 ± 0.72 | 2.57 ± 0.26 | 1.18 ± 0.12 | 1.88 ± 0.19 | 0.58 ± 0.06 | 0.15 ± 0.02 | 0.02 ± 0.002 | 1.14 ± 0.11 | 1.19 ± 0.12 | |

| Cr | 0.06 ± 0.06 | 0.18 ± 0.02 | 0.15 ± 0.02 | 0.09 ± 0.01 | 0.04 ± 0.004 | 0.02 ± 0.002 | 0.04 ± 0.004 | 0.47 ± 0.05 | 0.27 ± 0.03 | 0.001 ± 0.0001 | 0.001 ± 0.0001 | BDL * | 0.04 ± 0.004 | |

| Ti | 0.26 ± 0.03 | 0.39 ± 0.04 | 0.51 ± 0.05 | 0.51 ± 0.05 | 0.51 ± 0.05 | BDL * | 0.39 ± 0.04 | 0.40 ± 0.04 | 0.22 ± 0.02 | 0.21 ± 0.02 | 0.18 ± 0.02 | 0.28 ± 0.03 | BDL * | |

| Ag | 0.030 ± 0.003 | 0.0647 ± 0.0067 | 0.1074 ± 0.0011 | 0.0221 ± 0.0022 | 0.0054 ± 0.0005 | BDL * | BDL * | 0.0007 ± 0.0001 | BDL * | BDL * | BDL * | BDL * | 0.0002 ± 0.00002 | |

| Au | 0.0029 ± 0.0003 | 0.0010 ± 0.0001 | 0.0092 ± 0.0009 | 0.0005 ± 0.0001 | 0.0007 ± 0.0001 | BDL * | BDL * | BDL * | BDL * | BDL * | BDL * | BDL * | BDL * | |

| Sum | 24.57 | 86.58 | 93.30 | 76.04 | 54.36 | 12.29 | 13.12 | 12.93 | 11.15 | 1.99 | 0.54 | 5.51 | 5.83 | |

| Nonvaluable elements | Sb | 0.22 ± 0.02 | 0.27 ± 0.03 | 0.61 ± 0.06 | 0.19 ± 0.02 | 0.08 ± 0.01 | BDL * | 0.18 ± 0.02 | 0.18 ± 0.02 | 0.12 ± 0.01 | 0.21 ± 0.02 | 0.01 ± 0.001 | 0.27 ± 0.03 | 0.33 ± 0.03 |

| Ca | 6.56 ± 0.66 | 0.98 ± 0.10 | 0.92 ± 0.09 | 1.12 ± 0.11 | 2.24 ± 0.22 | 2.81 ± 0.28 | 2.41 ± 0.24 | 4.78 ± 0.48 | 3.91 ± 0.39 | 8.43 ± 0.84 | 7.51 ± 0.75 | 6.93 ± 0.70 | 9.05 ± 0.91 | |

| Br | 1.64 ± 0.08 | 0.08 ± 0.01 | 0.03 ± 0.003 | 0.35 ± 0.04 | 0.78 ± 0.08 | 0.78 ± 0.08 | 1.12 ± 0.12 | 1.49 ± 0.15 | 1.21 ± 0.12 | 2.11 ± 0.21 | 1.28 ± 0.13 | 1.69 ± 0.17 | 1.41 ± 0.14 | |

| Ba | 0.31 ± 0.03 | 0.10 ± 0.01 | BDL * | 0.2 ± 0.02 | 0.15 ± 0.02 | BDL * | 0.41 ± 0.04 | 0.12 ± 0.01 | 0.32 ± 0.03 | 0.64 ± 0.06 | 0.77 ± 0.08 | 0.59 ± 0.06 | 0.59 ± 0.06 | |

| Mg | 0.57 ± 0.06 | 0.05 ± 0.01 | 0.05 ± 0.01 | 0.28 ± 0.03 | 0.43 ± 0.04 | 0.95 ± 0.09 | 1.51 ± 0.15 | 0.64 ± 0.06 | 0.44 ± 0.04 | 2.01 ± 0.20 | 2.50 ± 0.25 | 2.10 ± 0.21 | 1.48 ± 0.15 | |

| Si | 12.00 ± 1.20 | 1.21 ± 0.12 | 0.40 ± 0.04 | 7.45 ± 0.75 | 6.15 ± 0.62 | 5.68 ± 0.57 | 3.19 ± 0.32 | 6.78 ± 0.68 | 7.28 ± 0.73 | 14.48 ± 1.45 | 13.92 ± 1.39 | 11.21 ± 1.12 | 12.1 ± 1.21 | |

| Mn | 0.01 ± 0.001 | 0.03 ± 0.003 | 0.03 ± 0.003 | 0.03 ± 0.003 | 0.03 ± 0.003 | BDL * | BDL * | BDL * | BDL * | BDL * | BDL * | BDL * | BDL * | |

| Sum | 21.26 | 2.69 | 2.01 | 9.59 | 9.83 | 10.22 | 8.82 | 13.99 | 13.28 | 27.88 | 26.00 | 22.79 | 24.93 | |

| Element | Point of Analysis | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | |

| Mg | - | - | - | 6.2 | - | - | - | - | - |

| Al | 1.4 | 2.3 | 19.0 | 93.8 | 22.4 | 4.1 | 5.5 | 34.9 | 4.0 |

| Si | - | 1.0 | 46.8 | - | - | - | - | 3.6 | 1.7 |

| Sc | - | - | - | - | - | - | 0.2 | - | 0.2 |

| Fe | - | - | - | - | 3.2 | - | - | - | - |

| Ni | - | - | - | - | 26.4 | - | - | - | 37.0 |

| Cu | 98.6 | 96.8 | 5.0 | - | 12 | - | 3.1 | 50.9 | 45.8 |

| Sn | - | - | - | - | - | 95.9 | 89.7 | 10.7 | 10.6 |

| Sb | - | - | - | - | - | - | 1.6 | - | 0.7 |

| Au | - | - | - | - | 36 | - | - | - | - |

| Na | - | - | 1.0 | - | - | - | - | - | - |

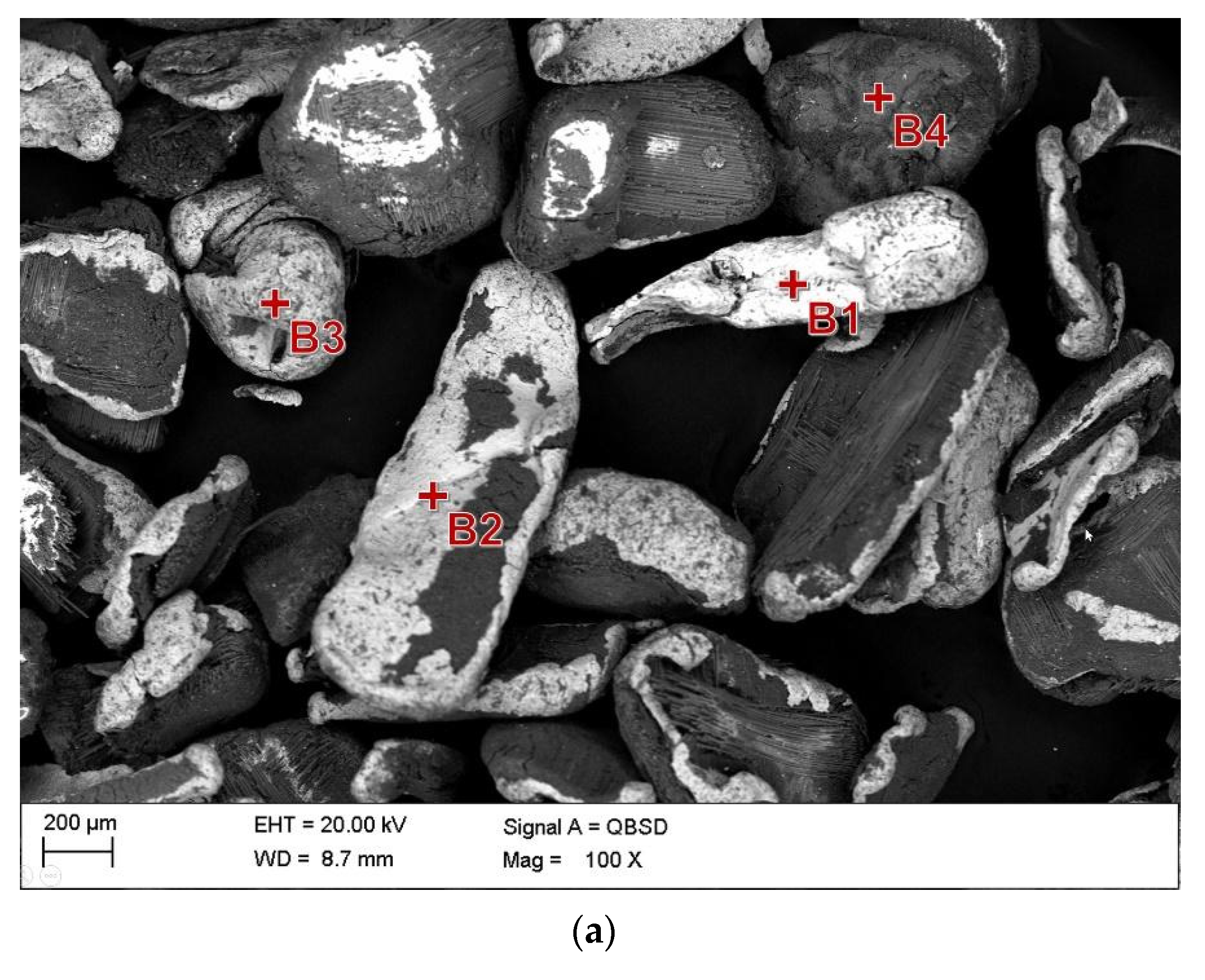

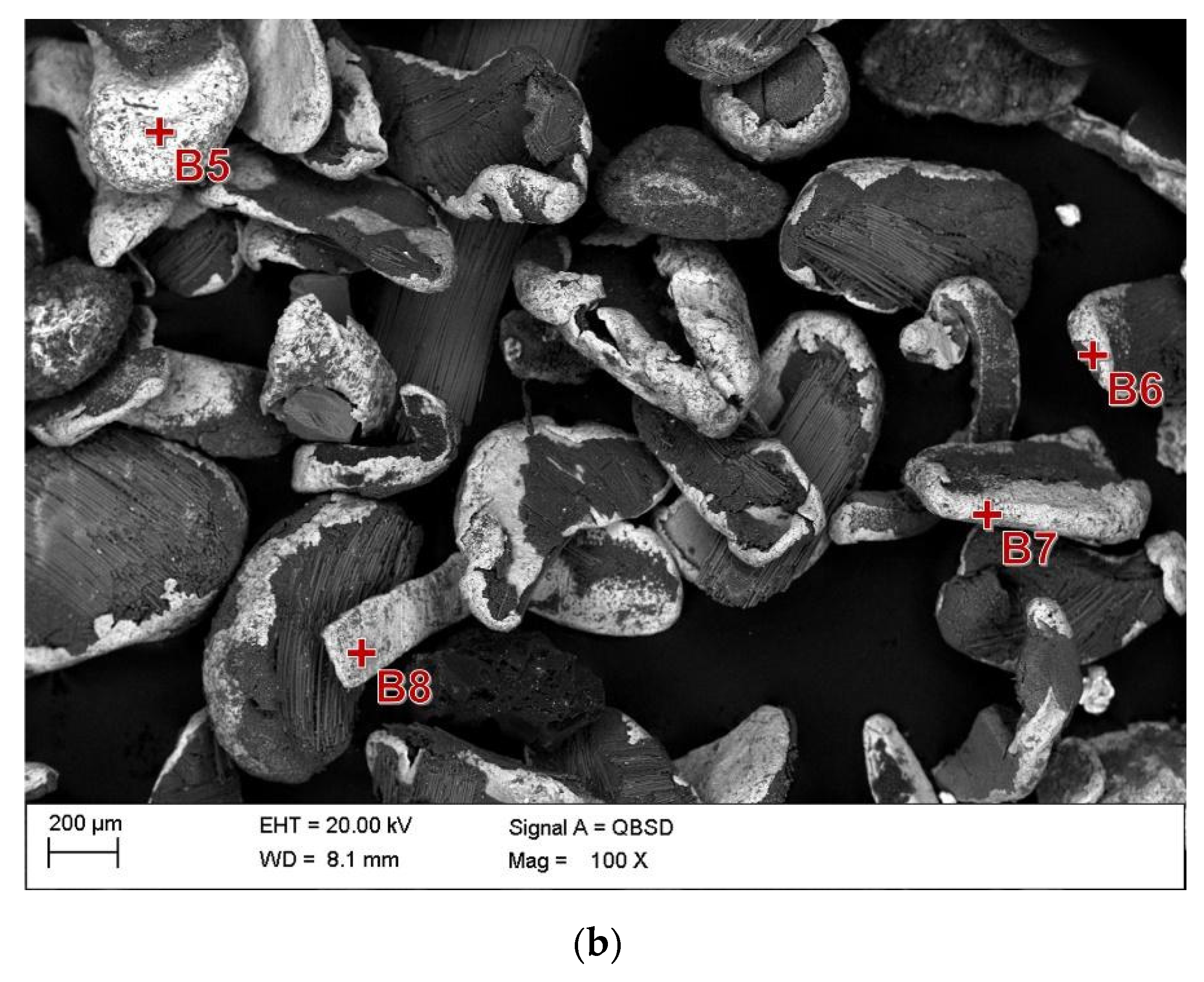

| Element | Point of Analysis | |||||||

|---|---|---|---|---|---|---|---|---|

| B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 | |

| Mg | - | - | 1.5 | - | - | - | 1.8 | - |

| Al | 3.4 | 4.6 | 13.7 | 74.8 | 6.8 | 2.4 | 8.5 | 9.9 |

| Si | - | - | 20.4 | 4.6 | - | 1.2 | - | 1.2 |

| Sc | - | - | - | - | 0.3 | - | - | - |

| Fe | - | - | 23.1 | 1.7 | - | - | - | - |

| Ni | 4.3 | - | 2.0 | - | - | - | - | - |

| Cu | 17.2 | 95.4 | 26.9 | 10.6 | 5.9 | 96.4 | 89.7 | 87.3 |

| Ag | 1.2 | - | - | - | 2.5 | - | - | - |

| Sn | 73.9 | - | - | 6.6 | 83.6 | - | - | - |

| Sb | - | - | - | - | 0.8 | - | - | - |

| Ca | - | - | 4.7 | 1.3 | - | - | - | - |

| Mn | - | - | 0.2 | - | - | - | - | - |

| S | - | - | 0.5 | - | - | - | - | - |

| Cl | - | - | - | 0.3 | - | - | - | 1.6 |

| Cr | - | - | 6.7 | - | - | - | - | - |

| Ba | - | - | 0.2 | - | - | - | - | - |

| Metal | Price *, ($/Mg) | Metal Content in the Concentrate (Data from Table 3), % | Metal Recovery Level Related to the Initial PCB Mass (after Dismantling), % | Prices of Metals Obtained from 100 g of PCB, $ |

|---|---|---|---|---|

| Cu | 7635 | 68.5 | 17.95 | 1.4 |

| Al | 1986 | 6.82 | 1.79 | 0.035 |

| Pb | 2063 | 1.5 | 0.39 | 0.008 |

| Zn | 2762 | 2,5 | 0.66 | 0.018 |

| Ni | 16,390 | 0.75 | 0.20 | 0.032 |

| Fe | 553 | 0.95 | 0.25 | 0.001 |

| Sn | 19,128 | 11.5 | 3.01 | 0.576 |

| Ag | 7.91 × 105 | 0.1074 | 0.0281 | 0.223 |

| Au | 6.01 × 107 | 0.0092 | 0.0024 | 1.4 |

| Suma, $ | 3.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suponik, T.; Franke, D.M.; Nuckowski, P.M.; Matusiak, P.; Kowol, D.; Tora, B. Impact of Grinding of Printed Circuit Boards on the Efficiency of Metal Recovery by Means of Electrostatic Separation. Minerals 2021, 11, 281. https://doi.org/10.3390/min11030281

Suponik T, Franke DM, Nuckowski PM, Matusiak P, Kowol D, Tora B. Impact of Grinding of Printed Circuit Boards on the Efficiency of Metal Recovery by Means of Electrostatic Separation. Minerals. 2021; 11(3):281. https://doi.org/10.3390/min11030281

Chicago/Turabian StyleSuponik, Tomasz, Dawid M. Franke, Paweł M. Nuckowski, Piotr Matusiak, Daniel Kowol, and Barbara Tora. 2021. "Impact of Grinding of Printed Circuit Boards on the Efficiency of Metal Recovery by Means of Electrostatic Separation" Minerals 11, no. 3: 281. https://doi.org/10.3390/min11030281

APA StyleSuponik, T., Franke, D. M., Nuckowski, P. M., Matusiak, P., Kowol, D., & Tora, B. (2021). Impact of Grinding of Printed Circuit Boards on the Efficiency of Metal Recovery by Means of Electrostatic Separation. Minerals, 11(3), 281. https://doi.org/10.3390/min11030281