A Failure Modes and Effects Analysis Framework for Assessing Geotechnical Risks of Tailings Dam Closure

Abstract

:1. Introduction

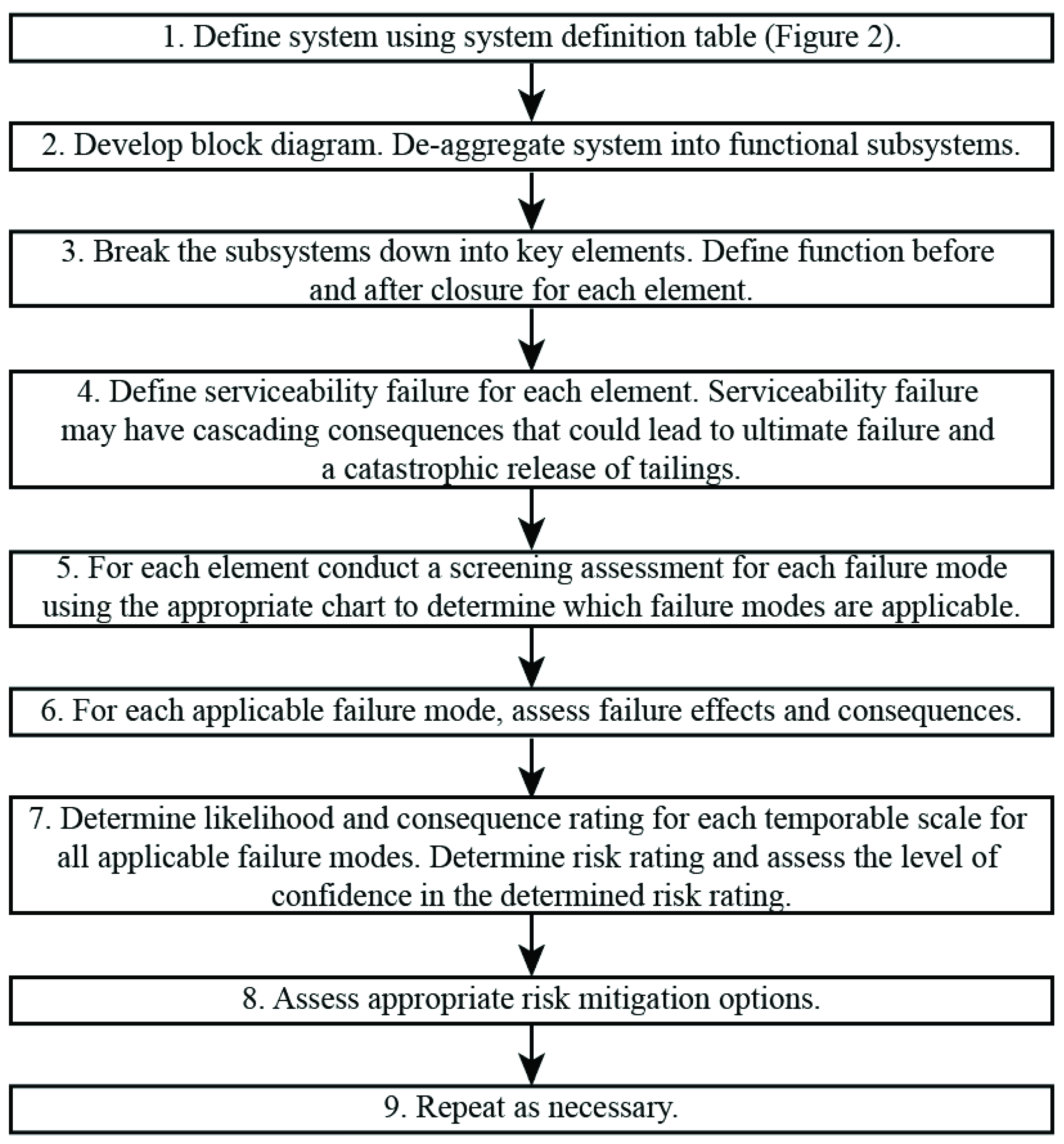

2. FMEA Background

- Define the system, including all components.

- Based on component interaction, de-aggregate the system into functional sub-systems.

- Break the sub-systems down into key elements and functions.

- Analyze the failure modes of the different elements.

- Assess the failure effects and consequences of the various elements.

- Summarize the findings.

- Repeat as necessary.

3. Risk Matrix Background

4. Generalized FMEA Framework

- Ultimate failure: the collapse of a tailings dam leading to catastrophic failure as defined by the Global Tailings Standard [35]:

- ○

- “A tailings facility failure that results in material disruption to social, environmental and local economic systems. Such failures are a function of the interaction between hazard exposure, vulnerability, and the capacity of people and systems to respond. Catastrophic events typically involve numerous adverse impacts, at different scales and over different timeframes, including loss of life, damage to physical infrastructure or natural assets, and disruption to lives, livelihoods, and social order. Operators may be affected by damage to assets, disruption to operations, financial loss, or negative impact to reputation. Catastrophic failures exceed the capacity of affected people to cope using their own resources, triggering the need for outside assistance in emergency response, restoration and recovery efforts.”

- Serviceability failure: failure to perform as intended.

- Literature reviews related to:

- Tailings dam characteristics in the oil sands and coal industries;

- Tailings dam failure modes;

- Risk assessment tools.

- The input from the regulator and industry stakeholders.

4.1. Temporal Scales

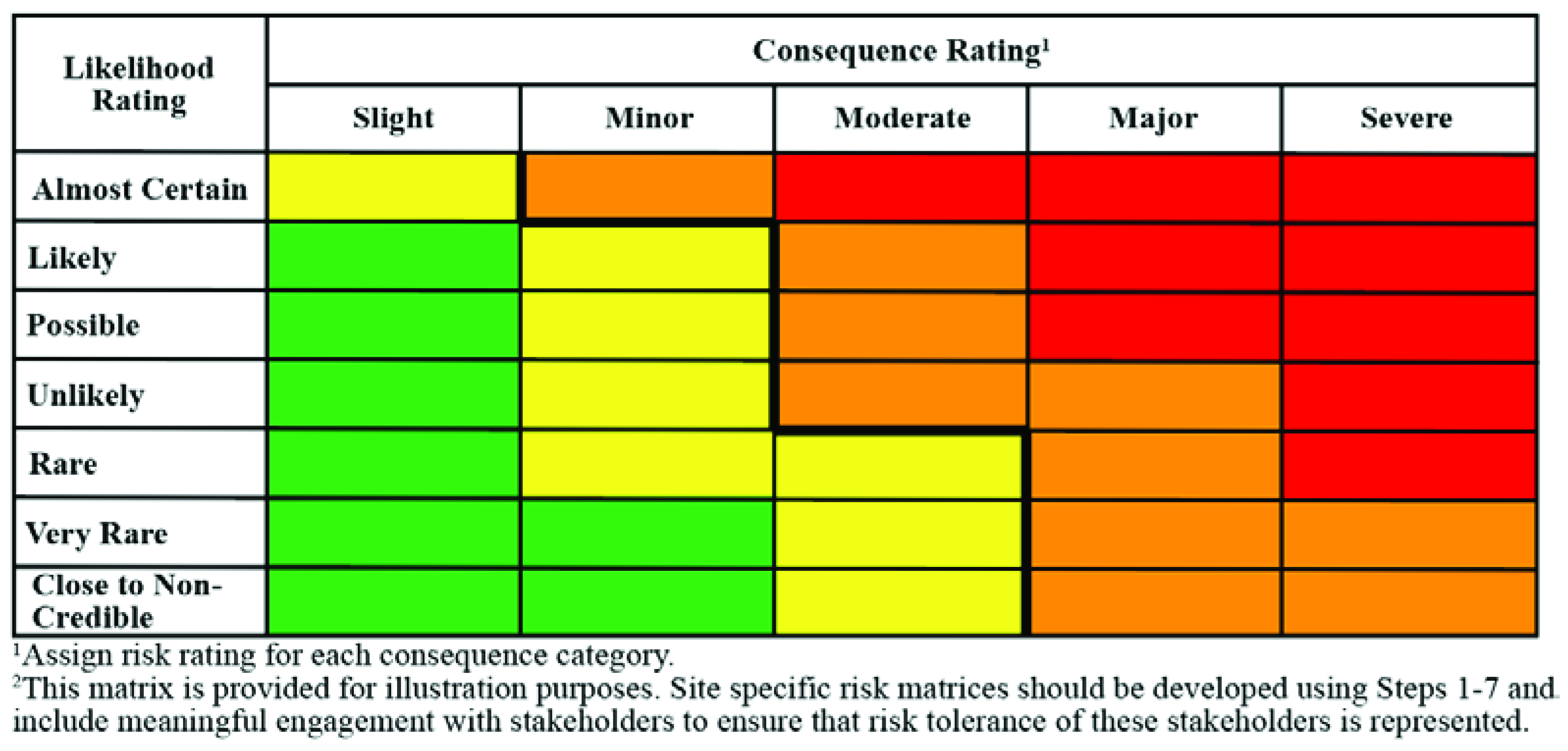

4.2. Risk Matrix Framework

- Clear descriptions of likelihood and consequence ratings are essential. as provided by Griffin and MEND [17,46]. It is common for different risk matrices to use the terms ‘almost certain’, ‘likely’, and ‘possible’ but it is equally common for these to not be accompanied by clear definitions as shown in Brown and Hadjigeorgiou [18,45]. This is problematic as terms such as these are not universally understood to have the same meaning amongst practitioners [47]. This aligns with the critiques in Table 1.

- A level-of-confidence scale (or similar) is recommended to go along with the risk matrix and selected risk rating [17].

- OSTDC determines the consequence rating based on the loss of function of the structure, the degree of human intervention required on the structure after an event occurs, population at risk, and environmental economics [43]. In contrast, a risk matrix designed to assess the risk for an operational facility may consider elements such as health and safety, environment, community, reputation, and legal aspects when assessing the consequences of failure.

- The G-FMEA presented in this research assesses the individual elements of a dam, not the dam as a whole, which is what the OSTDC [43] risk matrix was developed for. The developed risk matrix must be fit for purpose.

- The OSTDC risk matrix was developed to assess if a facility could be deregistered as a dam [43]. The consequence and likelihood ratings reflect this. In contrast, the risk matrix is used here to assess the risk of failure over time and if a closure plan is adequate to prevent failure to support a facility being deregistered as a dam.

4.2.1. Likelihood Rating

4.2.2. Consequence Rating

- The degree of the consequence of failure of an element on the rest of the system.

- ○

- This involves an assessment regarding if the failure will result in cascading consequences to other elements.

- The degree of human intervention (post failure) required.

- ○

- It is important to note the degree of human intervention required in response to a failure as the ultimate goal is to reach a state of minimal or no human intervention. In cases where this is not possible, this may suggest a careful evaluation of the custodial transfer scenario for that facility.

- Community.

- ○

- The impact on the community should be assessed using input from the relevant stakeholders. This is difficult to evaluate in light of the time frames associated with closure. Our ability to predict downstream and upstream populations in the future is limited by our short-term knowledge; however, a consideration can be made of the likelihood that the affected area could be inhabited in the future (i.e., is the mine located in inhospitable terrain or in an area that is desirable for development?). This would allow baseline assumptions to be made about the future community impact. A key step to defining the impact on a community is identifying the community. As defined by the Impact and Benefit Agreement (IBA) Community Toolkit [50], this involves answering the questions: “Who is the community? How is the geographic, ethnic, or scope of community defined? Who legitimately represents the community? Is it simply representatives from local community organizations, or is it necessary to reach out to more diverse groups to ensure all elements are consulted? The definition of “community” should be inclusive enough to promote equity and avoid future conflict resulting from lack of inclusion” [50]. The community consequence rating provided in Table 6 is provided as a guideline only and requires input from the relevant stakeholders to explicitly define the community impact. This should be accomplished using a meaningful engagement as defined by the Global Tailings Standard [35]. Defining the consequence rating for the community may involve a consideration of health (including fatalities), loss of access/destruction of traditional lands, housing, destruction/damage of farmland, harm to livestock, damage to water or soil resources, impacts to trapping and fishing, the loss of animals, overall cultural impact, and employment. It is critical that the impact on all valued components (and their condition following a failure) to the relevant stakeholders are considered. A valued component is that which is considered important by the community [50]. It should be noted that Impact and Benefit Agreements developed between the mining companies and Aboriginal communities may include agreement provisions to account for catastrophic failures and losses and should be consulted when assessing the consequences of a dam failure to the community [50].

- Environment.

- ○

- The environmental impact must be assessed with a consideration of the impacted land (both surrounding the facility and in the facility itself, with respect to its post mining land use) and waterbodies and the toxicity of the tailings. The Canadian Dam Association (CDA) developed a Working Group to revamp their environmental classification system, noting that the existing system lacked a clear scientific basis and used vague criteria that was open to interpretation based on personal beliefs and principles [51]. Nikl et al. provides a summary of the draft environmental consequence classification system [51]. The framework considers three variables: ecological impact, the intrinsic hazards of contents, and the duration of the impact, to determine the consequence category (low, significant, high, and very high) using a matrix and dial combination method approach [51]. The consequence classification is intended to assess the environmental consequences from a global tailings dam failure (i.e., ultimate failure in this case). In contrast, the risk matrix and G-FMEA is intended to assess the failure modes of individual elements; however, the principles and concepts from Nikl et al. can still be used to support the environmental consequence category [51]. As such, the methodology used by Nikl et al. is adapted to fit within the consequence rating framework [51]. The goal of a closure plan is for the facility to remain safe and sustain a particular land use. Consequently, the environment category should be assessed with a consideration of the impact on the post mining land use, in addition to the surrounding environment. It is recognized that post mining land uses may change over time as the closure plan develops [52]. As the agreed post-mining land use changes, hazards should be re-evaluated. The most serious consequence associated with the post mining land use is when the promised land use is destroyed leaving the land sterilized. In such a situation, the facility may be fenced off to prevent all access to the site. This situation may also lead to downstream effects where additional land is sterilized. Ultimately, this would yield a severe consequence rating.

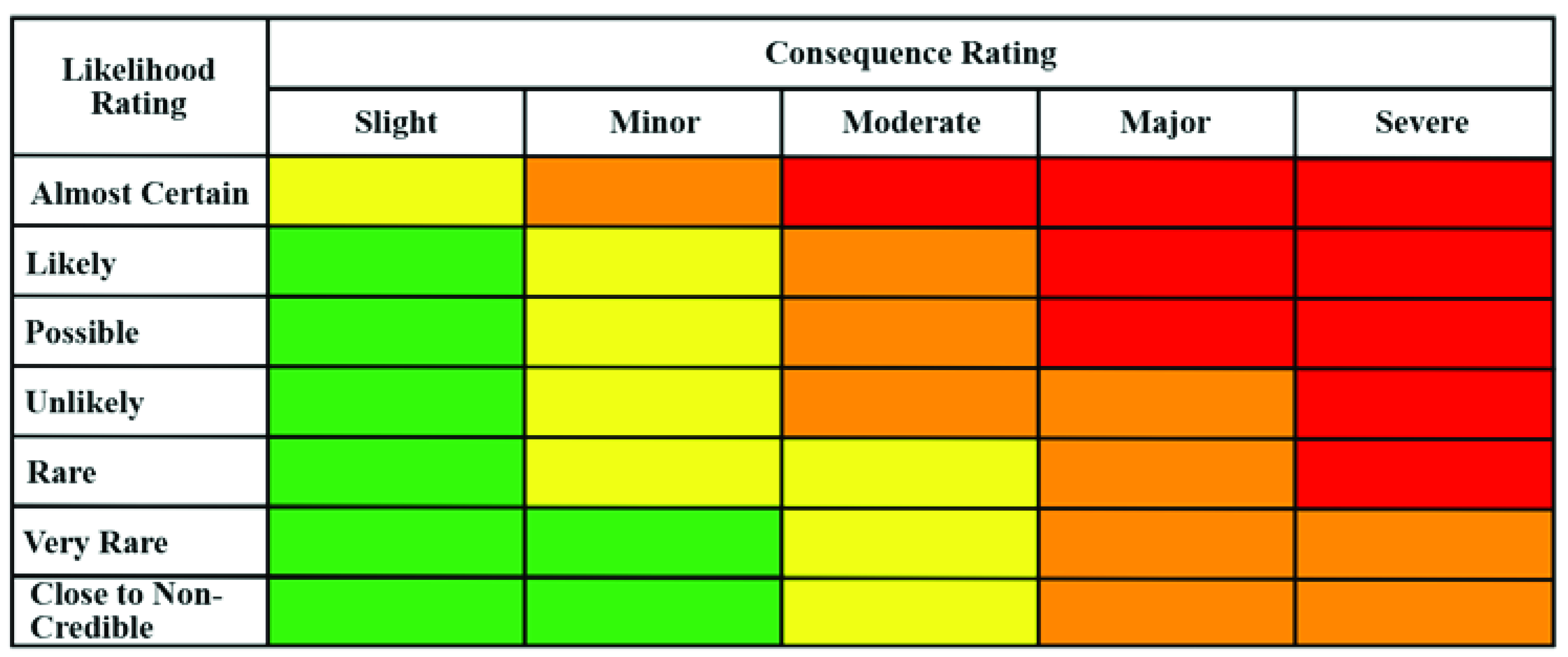

4.2.3. Risk Matrix and Rating

- Develop iso-contours of equal risk based on the estimated quantitative consequence measure and the provided likelihoods (Likelihood = Risk/Consequence). Assuming that the consequence quantitative measure is an order of magnitude between categories, the consequence and likelihood iso-contours should be plotted in log-log space. Plot the iso-contours on the risk matrix. Assign the risk categories to the iso-contours of equal risk and use these to develop an initial colour-coded risk matrix. This step serves as a starting point for colour coding the risk matrix. Any available known acceptance criteria can be used as an initial starting point for this exercise. Decisions will need to be made about the cells that have an iso-contour cutting through them (i.e., do you assign the higher or lower risk category?). This exercise demonstrates a known issue with risk matrices where risk is represented as categorical, rather than on a continuum, and hazards are binned into these categories.

- A note from Baybutt [25]: When consequences and likelihood categories differ by orders of magnitude, they are represented in log-log space. Practically, this means that high consequence-low likelihood events (negatively correlated) have the most uncertain risks in these type of rating schemes. This is especially problematic as these events already have a lot of inherent uncertainty. Ultimately, it is not possible to increase the precision of these events on a risk matrix. This concept of uncertainty related to these types of events supports the idea of using a threshold value on the risk matrix to trigger more extensive risk analysis.

- Assess the initial colour-coded risk matrix against the Cox axioms for a well-defined risk matrix [19]. This step is simply a logical ‘check’. Duijm recommends that a key to using the risk matrix is to recognize that the colouring of the risk matrix is a risk definition in its own right (and cannot be separately and stringently defined as Risk = probability × consequence) as it expresses a subjective risk perception (i.e., major hazard aversion), which is an important element of risk decisions [31]. Duijm notes that, when no reference is made to an external risk definition, then “the colouring of the matrix itself is the only relevant risk definition, then the axioms of weak consistency and consistent colouring are trivial” [31]. If a quantitative definition of risk is desired by stakeholders, then the Cox axioms should be satisfied [19]. Cox axioms can be summarized as [19]:

- Weak consistency, where each hazard in the red category represents a higher risk than the hazards in the green category.

- Betweenness, where every positively sloped line segment that starts in a green cell and ends in a red cell must pass through an intermediate risk category.

- Consistent colouring, where hazards with an approximately equal risk have the same colour.

- Assess if the Levine lettering scheme is more appropriate for your risk analysis goals [29]. In the study by Levine, logarithmic axes are used for the consequence and likelihood axes [29]. Straight line iso-contours of equal risk are drawn. Instead of using colours, the different areas are labelled A, B, C, D, E, F, and G (each line represents a new letter). This method results in a matrix that is somewhat unintuitive, but this prevents risk matrix users from making assumptions about the risks based on the colouring scheme. When a risk matrix is constructed in this manner, the following conclusions can be drawn:

- Risks in one letter category can only be distinguished from risks in another category if they are more than one letter apart (i.e., C > A, D > B).

- Risks in categories that are zero or one letter apart are not able to be distinguished from one another (i.e., it is not known if C > B or B > C).

- As noted by Duijm, another way to develop risk scores and colouring is by using basic arithmetic (multiplication and addition) based on ordinal numbers assigned to each consequence and probability category [31]. When the categories are essentially linearly spaced, then the multiplication of the ordinal numbers is an appropriate way of defining the risk score. When the categories are essentially logarithmically spaced, the addition of the ordinal numbers is desired. Apply the appropriate mathematical operations and compare to the risk matrix developed in Step 3.

- Assess if major hazard aversion is required and apply as necessary. Hazard aversion is the concept of low-probability–high-consequence events being assigned a higher risk than a high-probability–low-consequence event, even if the expected loss is mathematically the same [31]. This concept is used in scenarios where low-probability–high-consequence events are of greater concern and may require different decisions [25].

- Conduct “logic checks” by stress testing the risk matrix with different scenarios. Focus on what the risk matrix is telling the user. Adjust the colour scheme as needed and repeat. This is an important step as the risk matrix may be developed using one quantitative measure. As such, it must be assessed to determine if it is applicable across the different consequence categories.

4.2.4. Limitations of the Risk Matrix Framework

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. G-FMEA Charts

| Element | Failure Mode Description | Potential Trigger/Cause | Screening Assessment of Failure Mode | Failure Effects |

|---|---|---|---|---|

| Perimeter ditch | Blockage (partial or full) | Sedimentation, sloughing/slope failure of walls, beaver dam, continuous build up of ice (icing) | Is there erosion protection in place? What is the slope of the ditch? Is it sufficient to keep particles suspended? What is the slope of the side slopes? What is the strength of the material? Have there been failures in this material before? Are there beavers in the area? Is the mine located in an area that could experience icing? | Rise in phreatic surface, increase in seepage, pond on reclamation surface, internal erosion, global instability, flooding, blockage of drain outlets, toe erosion, discharge of process affected water to the environment |

| Reduction in cross-sectional area | Sloughing/slope failure of walls, excessive vegetation | What is the slope of the side slopes? What is the strength of the material? Have there been failures in this material before? Will the ditch regularly have water running through it or will it stay dry for a portion of the year? Are there deterrents in place to prevent the growth of vegetation? | Rise in phreatic surface, increase in seepage, pond on reclamation surface, internal erosion, global instability, reduced capacity, erosion, potential flooding, blockage of drain outlets, toe erosion, discharge of process affected water to the environment | |

| Change in slope | Erosion, differential settlement | Is there erosion protection in place? Does the material have the potential to consolidate or settle over time? Is it a cut into natural ground or is the material placed? | Change to water discharge velocity, creation of secondary channels, localized areas of erosion, instability of dam | |

| Sand channel buoyancy | Freezing conditions in channels composed of sand | Are the drainage channels constructed of sand? Could the channel experience freezing? | Rise in phreatic surface, increase in seepage, pond on reclamation surface, internal erosion, global instability, reduced capacity, erosion, potential flooding, blockage of drain outlets, toe erosion, discharge of process affected water to the environment | |

| Pipes (perforated and non perforated) | Breakage of pipe | Break in pipe, buckling, physical degradation | Is the pipe capable of breaking, buckling, and/or physically degrading over time? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope |

| Pipe clogging | Biological, chemical, particulate clogging | Is chemical, biological, or sediment clogging possible? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope | |

| Clogging surround (woven sock or sand and gravel bed) | Biological, chemical, or particulate clogging | Is it possible for the material surrounding the pipe to become clogged? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope | |

| Blockage at outlet | Blockage from perimeter channel or other (snow, debris, etc.) | Is the pipe outlet close enough to the base of the perimeter channel that it could become blocked? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability | |

| Breakage of connection between a drain and outlet pipe | Overloading, degradation of connection, poor installation | How are the drain and outtake connected? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope | |

| Granular materials | Erosion from flowing water | Increase in seepage gradients, development of preferential flow paths adjacent to drain (i.e., burrowing from animals, cracks) | Could cracks develop along drains? Is the site known for having issues with burrowing animals? Is the material erodible? | Decreased capacity of drain resulting in failure, lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, erosion on downstream slope |

| Clogging | Biological, chemical, particulate clogging | Is chemical, biological, or sediment clogging possible? What is the grain size distribution? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope | |

| Failure to meet drain criteria | Change in material properties, including permeability due to aging, change in gradation due to movement with seepage, weathering/degradation | To what extent is aging and weathering/degradation of the material possible? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope | |

| Obstruction of drainage at outlet | Snow and ice blocking outlet | Will an obstruction prevent the drain from performing as intended? Is the outlet protected from a blockage? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope | |

| Deformation leading to reduction in drain capacity | Slow and continuous deformation under long-lasting shear and pressure forces from consolidation of overlying material | How much deformation is expected over time as the materials above the drain consolidate and settle? Has the impact on the drain been considered? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope | |

| Crushing/breakage of granular drain | Overloading drain, settlement of the dam | How much settlement is expected to occur over time? Was settlement accounted for in the design? Will the drain continued to be loaded? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope | |

| Geosynthetics | Aging | Degradation of geosynthetic over time (temperature, oxidation, hydrolytic, chemical, biological, radioactive, etc.) | Is the geosynthetic capable of aging in the given time frame? Have sufficient tests been performed to investigate this? | Brittle rupture of geosynthetic, lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope |

| Creep deformation | Slow and continuous deformation under long-lasting shear and pressure forces from consolidation of overlying material | How much deformation is expected over time as the materials above the geotextile consolidate and settle? Has the impact on the geosynthetic been considered? | Reduction in thickness leading to reduction in drain capacity or shear failure of drain if in-place deformation reaches a critical value, lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope | |

| Clogging | Biological, chemical, particulate clogging | Are there dispersive soils present? Are there ferrous soils? Does the permeant contain oily waters or sludge? Is there turbid water with high suspended solids? Is there potential for chemical precipitation or biological growth? What is the end land use (does it involve agriculture or sewage systems that could result in clogging)? Is sediment capable of clogging the drain? What is the grain size distribution? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope | |

| Blockage | Intrusion of adjacent materials (i.e., geotextile), blockage of downstream or exit surface caused by sedimentation, vegetation, etc. | Does the downstream or exit surface of the geosynthetic have the potential to be blocked and prevent drainage from sediment, vegetation, ice, snow, etc.? Could adjacent materials impede movement of water to the geosynthetic? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope | |

| Blinding where fine-grained soils are prevented from entering the geotextile, which creates a filter cake | Formation of a filter cake at the interface of the geosynthetic from coarse particles being retained by the geotextile and intercepting fine particles migrating from the soil | Is the geosynthetic in intimate contact with the soil? Have all appropriate filter criterion been followed during design? | Lack of control of phreatic surface (potential rise in phreatic surface), increase in seepage, pond on reclamation surface, internal erosion, global instability, release of water into downstream shell, erosion on downstream slope | |

| Low permeability cores | Hydraulic fracture | Decrease in total stress (i.e., differential settlement, arching in narrow cores), increase in porewater pressure | Is there a narrow core? Is there the potential for excessive differential settlement that could lead to a decrease in total stress? Is there the potential for an increase in porewater pressure? Is there an effective downstream filter to prevent internal erosion of the core? | Cracking, internal erosion, global instability |

| Internal erosion in dam from suffusion | High hydraulic gradients, design/construction defect, presence of widely gap-graded or non-plastic gap-graded soils | Is the material widely gap-graded or gap-graded non plastic? Is there an effective downstream filter to prevent internal erosion of the core? | Global instability, seepage on the downstream slope, settlement of the crest, permeability may increase as erosion progresses or decrease if clogging occurs | |

| Internal erosion in dam from concentrated leak | Cracks from vertical deformation in foundation, starter dyke, or other tailings materials or differential settlement; tunnels created by burrowing animals; hydraulic fracture; high hydraulic gradient; design/construction defects | Is there a crack or gap that could allow for a concentrated leak to develop? Is there an effective downstream filter to prevent internal erosion of the core? | Global instability, development of a pipe | |

| Internal erosion in dam from contact erosion | Parallel flow in coarser layer to the interface between the coarse-grained and fine-grained soil, high hydraulic gradients, design/construction defects | Is there a contact between a coarse and fine-grained soil? Is there a filter in place? Is there an effective downstream filter to prevent internal erosion of the core? Is there an effective downstream filter to prevent internal erosion of the core? | Global instability, static liquefaction, settlement of the crest, loss of stability or unravelling, eroded material can clog the permeable layer and increase the porewater pressure (could result in hydraulic fracture and uplift of the downstream toe or a rise in the phreatic surface), development of a pipe | |

| Shear failure from changing shear strength | Degradation/weathering, porewater pressure change, change in permeability over time, failure of drains, progressive failure of strain softening materials, brittle failure of contractive materials | Is there potential for weathering or degradation of materials? Does the porewater pressure rely on drain performance? Could drains fail over time? Are the materials strain softening or brittle? Is there an effective downstream filter to prevent internal erosion of the core? | Slumping of downstream slope, translational slide, rotational slide | |

| Shear failure from changing shear stress | Loading/unloading crest, toe, upstream, or downstream; surface erosion of downstream slope; excessive and uncontrolled seepage through foundation resulting in erosion of toe; subsurface stress changes (geothermal development, in situ oil or gas production, wastewater injection, etc.) | Is there potential for anthropogenic contributions (i.e., excavations or construction)? Erodibility of material? Is there an effective downstream filter to prevent internal erosion of the core? | Slumping of downstream slope, translational slide, rotational slide | |

| Vertical deformation (differential or otherwise) from consolidation | Consolidation/settlement | Does the material have the potential to consolidate? How much consolidation has occurred already? How much is expected to occur? Is there an effective downstream filter to prevent internal erosion of the core? | Release of pore water and loss of height (potential for pond to develop on reclamation surface), development of cracks above starter dyke, internal erosion, overtopping |

| Failure Mode Description | Potential Trigger/Cause | Screening Assessment of Failure Mode | Failure Effects |

|---|---|---|---|

| Heave (seepage forces create zero effective stress condition) | Embankment loading, excessive rainfall, embankment seepage | What are the current hydraulic gradients and maximum possible due to geometry? What are the materials present? Are there cohesionless soils confined by an overlying lower permeability layer? | Global instability |

| Vertical deformation from collapse of karst formation | Collapse of karst formation | Is there karst present in the foundation? | Cracking (transverse cracks - perpendicular to dam crest are larger problems than longitudinal cracks) in dam, internal erosion in dam, crest subsidence |

| Vertical deformation caused by settlement of material | Consolidation | Will the materials in the foundation consolidate over time? How much consolidation has already occurred? Does the material have the potential to collapse? | Cracking (transverse cracks - perpendicular to dam crest are larger problems than longitudinal cracks) in dam, internal erosion in dam, crest subsidence |

| Excessive/uncontrolled seepage through foundation or foundation/dam contact | Excessive rainfall | Is there potential for seepage through the foundation? What is the permeability of the materials? | Erosion of downstream toe, increase in porewater pressure in dam, global instability |

| Shear failure along pre-existing shear plane from changing shear stress | Loading/unloading of foundation, earthquake, subsurface stress changes (geothermal development, in situ oil or gas production, wastewater injection, etc.) | Are there pre-existing shear planes? Is there the potential for anthropogenic loading or unloading events? Is the material erodible? | Slumping of downstream slope, translational slide, rotational slide, static liquefaction |

| Shear failure along new shear plane from changing shear stress | Loading/unloading of foundation, earthquake, subsurface stress changes (geothermal development, in situ oil or gas production, wastewater injection, etc.) | Is there the potential for anthropogenic loading or unloading events? Is the material erodible? | Slumping of downstream slope, translational slide, rotational slide, static liquefaction |

| Shear failure along pre-existing shear plane from changing shear strength | Degradation/weathering, porewater pressure change, progressive failure of strain softening materials, brittle failure of contractive materials | Are there pre-existing shear planes? Is there the potential for degradation or weathering of the material? Is the material strain softening or brittle? | Slumping of downstream slope, translational slide, rotational slide, static liquefaction |

| Shear failure along new shear plane from changing shear strength | Degradation/weathering, porewater pressure change, progressive failure of strain softening materials, brittle failure of contractive materials | Is there the potential for degradation or weathering of the material? Is the material strain softening or brittle? | Slumping of downstream slope, translational slide, rotational slide, static liquefaction |

| Internal erosion in foundation or dam/foundation contact from global backward erosion | Failure of soil above or around a backward erosion pipe to hold a roof, heave, high hydraulic gradients, design/construction defect, presence of non-plastic soils in the foundation | Are there non-plastic soils in the foundation? | Static liquefaction, global instability, unravelling/sloughing of downstream face, sub vertical cavities |

| Internal erosion in foundation or dam/foundation contact from backward erosion piping | Heave, high hydraulic gradients, design/construction defect, presence of non-plastic soils that are capable of holding a roof | Are there non-plastic soils in the foundation and soils capable of ’holding a roof’? | Enlargement of pipe, global instability, static liquefaction |

| Internal erosion in foundation or dam/foundation contact from contact erosion | Parallel flow in coarser layer to the interface between the coarse-grained and fine-grained soil, high hydraulic gradients, design/construction defect | Is there a contact between a coarse-grained and a fine-grained soil? Is the geometrical and hydraulic condition for contact erosion met? | Global instability, static liquefaction, settlement of the crest, loss of stability or unravelling, eroded material can clog the permeable layer and increase the porewater pressure (could result in hydraulic fracture and uplift of the downstream toe or a rise in the phreatic surface), development of a pipe |

| Internal erosion in foundation or dam/foundation contact from suffusion | High hydraulic gradients, design/construction defect, presence of widely gap-graded or non-plastic gap-graded soils | Is the material widely gap-graded or gap-graded non plastic? | Global instability, seepage on the downstream slope, settlement of the crest, permeability may increase as erosion progresses or decrease if clogging occurs |

| Internal erosion in foundation or dam/foundation contact from concentrated leak | Fracture in foundation soil, hydraulic fracture, high hydraulic gradient, cracks at dam/foundation contact from vertical deformation in foundation or poor construction practices or differential settlement, design/construction defects | Is there a crack or gap that could allow for a concentrated leak to develop? | Global instability, development of a pipe |

| Thawing of foundation permafrost | Climate change | Is there permafrost in the foundation? | Cracking (transverse cracks - perpendicular to dam crest are larger problems than longitudinal cracks) in dam, piping in dam, crest subsidence |

| Failure Mode Description | Potential Trigger/Cause | Screening Assessment of Failure Mode | Failure Effects |

|---|---|---|---|

| Destruction of vegetation | Suffocation by eroded material, forest fires, pests and disease, climate change, large storm event, anthropogenic contributions, surface erosion on downstream slope, evolution of vegetation over time due to climate change | Does the resistance to erosion rely on the vegetation? Is the area susceptible to forest fires? Are there pests/disease that could lead to vegetation destruction? What is the downstream slope? Is the area remote? Are there surrounding communities that could lead to destruction of vegetation (i.e., recreational vehicles)? | Increase in surface erosion, instability of downstream slope, global instability, change in overall evapotranspiration and water balance impacts (infiltration versus runoff) |

| Internal erosion in dam from suffusion | High hydraulic gradients, design/construction defect, presence of widely gap-graded or non-plastic, gap-graded soils | Is the material widely gap-graded or gap-graded non plastic? | Global instability, seepage on the downstream slope, settlement of the crest, permeability may increase as erosion progresses or decrease if clogging occurs |

| Internal erosion in dam from concentrated leak | Cracks from vertical deformation in foundation, starter dyke, or other tailings materials or differential settlement; tunnels created by burrowing animals; hydraulic fracture; high hydraulic gradient; design/construction defects | Is there a crack or gap that could allow for a concentrated leak to develop? | Global instability, development of a pipe |

| Internal erosion in dam from contact erosion | Parallel flow in coarser layer to the interface between the coarse-grained and fine-grained soil, high hydraulic gradients, design/construction defects | Is there a contact between a coarse and fine-grained soil? Is there a filter in place? | Global instability, static liquefaction, settlement of the crest, loss of stability or unravelling, eroded material can clog the permeable layer and increase the porewater pressure (could result in hydraulic fracture and uplift of the downstream toe or a rise in the phreatic surface), development of a pipe |

| Dynamic liquefaction | Earthquakes, induced seismicity, construction traffic, blasting | Seismic events in area? Induced seismicity? Density of material (contractive or dilative)? Saturated or unsaturated? Hydraulically placed or compacted? | Global instability, local slumps, crest drops |

| Shear failure from changing shear strength | Degradation/weathering, porewater pressure change, change in permeability over time, failure of drains, progressive failure of strain softening materials, brittle failure of contractive materials | Is there potential for weathering or degradation of materials? Does the porewater pressure rely on drain performance? Could drains fail over time? Are the materials strain softening or brittle? | Slumping of downstream slope, translational slide, rotational slide |

| Shear failure from changing shear stress | Loading/unloading crest, toe, upstream, or downstream; surface erosion of downstream slope; excessive and uncontrolled seepage through foundation resulting in erosion of toe; earthquake; subsurface stress changes (geothermal development, in situ oil or gas production, wastewater injection, etc.) | Is there potential for anthropogenic contributions (i.e., excavations or construction)? Erodibility of material? | Slumping of downstream slope, translational slide, rotational slide |

| Static liquefaction from changing mean effective stress | Change in pore pressures caused by a phreatic surface change (i.e., failure of drainage system) | Density of material (contractive or dilative)? Saturated or unsaturated? Hydraulically placed or compacted? Does control of the phreatic surface rely on drain function? Could drains become clogged or fail in the future? | Global instability |

| Static liquefaction from changing shear stress | Loading/unloading; overloading, including increasing the load, construction activities at the crest, fill placement at toe; over steepening of downstream slope or toe (slumping of downstream slope from shear failure), including erosion or excavation of toe; foundation shear; shear in starter dyke; shear in other tailings materials; excessive and uncontrolled seepage through foundation resulting in erosion of toe; subsurface stress changes (geothermal development, in situ oil or gas production, wastewater injection, etc.) | Density of material (contractive or dilative)? Hydraulically placed or compacted? Saturated or unsaturated? Is there a likelihood for anthropogenic contributions in the future (i.e., unexpected construction)? Is the site remote? What is the material of the downstream slope? Is there a nearby river? | Global instability |

| Static liquefaction from changing shear stress and mean effective stress | Lateral extrusion | Density of material (contractive or dilative)? Hydraulically placed or compacted? Saturated or unsaturated? Weak layers interbedded in tailings? Could the tailings ’squish’ out like toothpaste during loading? | Global instability |

| Static liquefaction from long-term change in material properties resulting in changing shear strength | Changing shear strength caused by degradation/weathering, progressive failure, porewater pressure change, failure of drains | Density of material (contractive or dilative)? Hydraulically placed or compacted? Saturated or unsaturated? To what extent could weathering or degradation of the material occur? Will it result in an increase or decrease in strength? Will a change in the phreatic surface impact the strength of the material? | Global instability |

| Surface erosion from spring sapping (headward erosion of gullies due to concentration of seepage forces at the locus of the gully which accentuates erosion) | Destruction of vegetation, increased seepage on downstream slope from failure of drainage system, increased seepage from internal erosion of starter dyke or tailings deposits) | Is the material susceptible to erosion? Is there a vegetative cover or erosion protection? Will seepage daylight on the downstream slope? | Slope failures (shallow surficial movement, slumps), change in downstream slope angle, blockage in perimeter channel with sediment, development of negative drainage, development of large erosion scarps |

| Surface erosion from wind and overland flow resulting in rills, gullies, or sheet erosion | Destruction of vegetation, rainfall, melting of snow, wind, increased seepage on downstream slope from failure of drainage system, increased seepage from internal erosion in embankment | Is the material susceptible to erosion? Is there a vegetative cover or erosion protection? | Slope failures (shallow surficial movement, slumps), change in downstream slope angle, blockage in perimeter channel with sediment, development of negative drainage, development of large erosion scarps |

| Toe erosion | Flow action from perimeter ditch or nearby river, release of a dam from a beaver, flood event, river changing course over time, destruction of vegetation, excessive and uncontrolled seepage through foundation, excessive erosion from internal erosion | Is the material susceptible to erosion? Is there a vegetative cover or erosion protection? Is there a nearby perimeter ditch or river? Is there known animal activity in the area? | Slope failures (shallow surficial movement, slumps), change in downstream slope angle, blockage in perimeter channel with sediment, development of negative drainage, development of large erosion scarps, beaver bafflers |

| Vertical deformation (differential or otherwise) from consolidation | Consolidation/settlement | Does the material have the potential to consolidate? How much consolidation has occurred already? How much is expected to occur? | Release of pore water and loss of height (potential for pond to develop on reclamation surface), development of cracks above starter dyke, internal erosion, overtopping |

| Item/Functional Identification | Failure Mode Description | Potential Trigger/Cause | Screening Assessment of Failure Mode | Failure Effects-End Effects |

|---|---|---|---|---|

| Cap | Excessive settlement | Consolidation | Does the material have the potential to settle over time? | Formation of ponds on reclamation surface, overtopping, piping (increase in seepage forces and gradients), infiltration of previously unsaturated tailings that could increase vulnerability to liquefaction for materials previously considered "not flowable" |

| Differential settlement | Consolidation, poor construction practices | Does the material have the potential to settle over time? Are there areas that have the potential to settle more that others? | Formation of ponds on reclamation surface, failure to direct surface water runoff towards drainage channels, development of cracks, formation of preferential flow paths, localized depressions, infiltration of previously unsaturated tailings that could increase vulnerability to liquefaction for materials previously considered "not flowable" | |

| Infilled material | Excessive settlement | Consolidation | Does the material have the potential to settle over time? | Formation of ponds on reclamation surface, overtopping, piping (increase in seepage forces and gradients) |

| Differential settlement | Consolidation, poor construction practices | Are there areas that have the potential to settle more than others? | Formation of ponds on reclamation surface, overtopping, piping (increase in seepage forces and gradients), failure of drainage channels to behave as intended, localized depressions | |

| Hummocks | Shear failure from changing shear stress | Loading/unloading crest, toe, slopes; surface erosion; failure of underlying underlying material to support hummock | Is there potential for anthropogenic contributions (i.e., excavations or construction)? Erodibility of material? | Slumping, translational slide, rotational slide, blockage of drainage channels |

| Shear failure from changing shear strength | Degradation/weathering, porewater pressure change, change in permeability over time, failure of drains, progressive failure of strain softening materials, brittle failure of contractive materials | Is there potential for weathering or degradation of materials? Are the materials strain softening or brittle? | Slumping of slopes, translational slide, rotational slide, blockage of drainage channels | |

| Surface erosion from wind and overland flow resulting in rills, gullies, or sheet erosion | Destruction of vegetation, rainfall, melting of snow, wind | Is the material susceptible to erosion? Is there a vegetative cover or erosion protection? | Slope failures (shallow surficial movement, slumps), change in downstream slope angle, blockage in drainage channel with sediment, development of negative drainage, development of large erosion scarps | |

| Drainage channels | Washout of erosion protection (riprap) | Precipitation event larger than design events (including extreme or repeat events) | What precipitation event are the channels designed for? What is the chance of exceedance over 1000 years? How susceptible are the underlying materials to erosion? Was the erosion protection properly designed and constructed? | Excessive erosion (erosion gullies, etc.), change in slope of drainage channels, erosion and release of materials underlying drainage channels |

| Blockage (complete or partial) | Debris, beaver dam, icing, sedimentation, slumping from slope failure, ingress of vegetation, slope failure/excessive erosion from nearby hummock | Are there beavers in the area? Is there a chance for a slope failure? Could debris be carried downstream and deposited in the channels resulting in a complete or partial blockage? Is the mine located in an area that could experience icing? | Formation of a pond upstream of the drainage channel, blockage breakthrough resulting in flooding, overtopping from pond formation, revert back to a pond, piping through dam (increase in seepage forces and gradient) | |

| Sand channel buoyancy | Freezing conditions in channels composed of sand | Are the drainage channels constructed of sand? Could the channel experience freezing? | Flooding | |

| Erosion control failure | Improper design/construction, differential settlement | Do the drainage channels rely on erosion control for stability? Is there the chance for differential settlement of the channel? | Excessive erosion (erosion gullies, etc.), change in slope of drainage channel, erosion and release of materials underlying drainage channel, formation of secondary channel | |

| Outlet | Washout of erosion protection (riprap) | Precipitation event larger than design event (including extreme or repeat events), flood following sand channel buoyancy event in drainage channel | What precipitation event is the outlet designed for? What is the chance of exceedance over 1000 years? How susceptible are the underlying materials to erosion? Was the erosion protection properly designed and constructed? | Excessive erosion (erosion gullies, etc.), change in slope of outlet, erosion and release of materials underlying outlet |

| Blockage (complete or partial) | Debris, beaver dam, icing, sedimentation, slumping from slope failure, ingress of vegetation, increase in depositional material due to failure of erosion protection in drainage channels upstream | Are there beavers in the area? Is there a chance for a slope failure? Could debris be carried downstream and deposited in the outlet resulting in a complete or partial blockage? Is the mine located in an area that could experience icing? | Formation of a pond upstream of the outlet, blockage breakthrough resulting in flooding, overtopping from pond formation, revert back to a pond, piping through dam (increase in seepage forces and gradient) | |

| Sand channel buoyancy | Freezing conditions in channels composed of sand | Is the outlet constructed of sand? Could the channel experience freezing? | Flooding | |

| Erosion control failure | Improper design/construction, differential settlement | Does the outlet rely on erosion control for stability? Is there the chance for differential settlement of the channel? | Excessive erosion (erosion gullies, etc.), change in slope of outlet, erosion and release of materials underlying outlet, formation of secondary channel | |

| Vegetative cover | Destruction of vegetation | Suffocation by eroded material, forest fires, pests and disease, climate change, large storm event, anthropogenic contributions | Does the resistance to erosion rely on the vegetation? Is the area susceptible to forest fires? Are there pests/disease that could lead to vegetation destruction? Is the area remote? Are there surrounding communities that could lead to destruction of vegetation (i.e., recreational vehicles)? | Increase in surface erosion, deposition of material in drainage channels that could lead to a blockage via sedimentation, development of negative drainage on reclamation surface, ponding of water near dam crest, internal erosion (increase in seepage forces and hydraulic gradient) |

| Tailings | Excessive settlement | Consolidation | Does the material have the potential to settle over time? | Formation of ponds on reclamation surface, overtopping, piping (increase in seepage forces and gradients) |

| Differential settlement | Consolidation, different material properties/infilling techniques, etc. | Are there areas that have the potential to settle more than others? | Formation of ponds on reclamation surface, overtopping, piping (increase in seepage forces and gradients), failure of drainage channels to behave as intended, localized depressions |

Appendix B. FMEA Worksheet

| Element | Failure mode identification | Failure mode description | Potential trigger/cause | Screening assessment of failure mode | Is this failure mode applicable? | If yes, is there sufficient data to evaluate the risk? List any resource gaps. | Failure effects | Immediate-term/Short-term/Medium-term/Long-term Assessment * | ||||||||||||||

| Likelihood | Consequences | Risk Rating | Level of Confidence | Controls | Remarks | |||||||||||||||||

| Element failure consequence | Human intervention | Environment | Community | Element failure consequence | Human intervention | Environment | Community | Element failure consequence | Human intervention | Environment | Community | |||||||||||

Appendix C. Risk Matrix Development

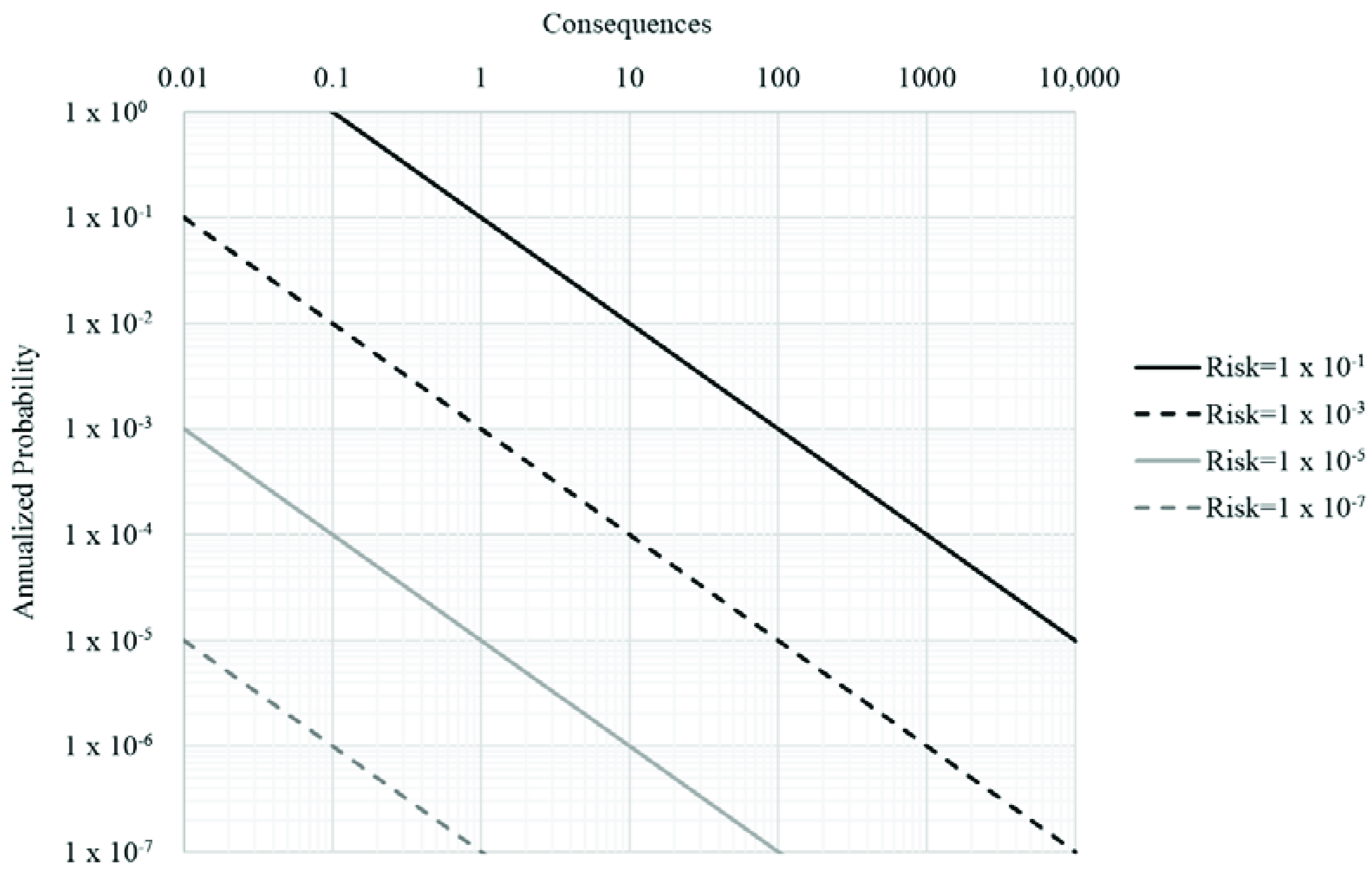

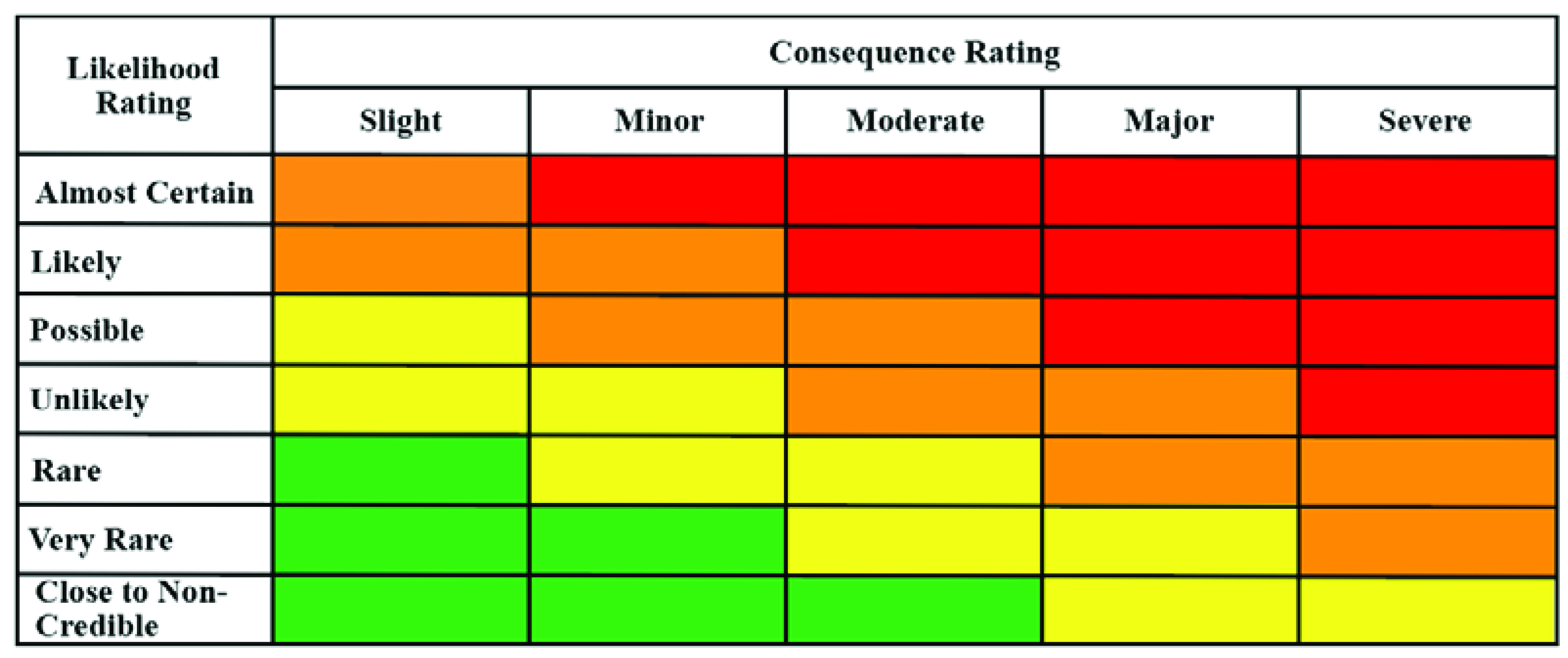

- In order to develop the iso-contours of equal risk, quantitative values from 0.01 to 10,000 were assigned to the consequence categories and assumed to have an order of magnitude increase between the categories. For individual projects, site-specific consequences could be considered here where there are known magnitudes of the consequences (i.e., financial impacts of environmental consequences). Iso-contours of equal risk were developed based on the estimated quantitative consequence measure and the provided likelihoods using the definition (Likelihood = Risk/Consequence). The iso-contours are shown in Figure A1, which show the annualized probability plotted against the consequences. It is important to remember that this is an estimation technique only and serves as a first-order step for colour coding the matrix. It is desirable to use quantitative measures of the consequences that extend across the full range of categories. Risk categories were then assigned to the iso-contours of equal risk (Table A6). This was used to colour code the initial risk matrix shown in Figure A2. Cells that had an iso-contour cutting through them were assigned to the higher risk category.

| Risk Category | Risk Level |

|---|---|

| Red | >1 × 10−1 |

| Orange | >1 × 10−3 |

| Yellow | >1 × 10−5 |

| Green | >1 × 10−7 |

- 3.

- The initial colour-coded risk matrix was assessed to determine if it satisfied the Cox axioms (weak consistency, betweenness, and consistent colouring).

- 4.

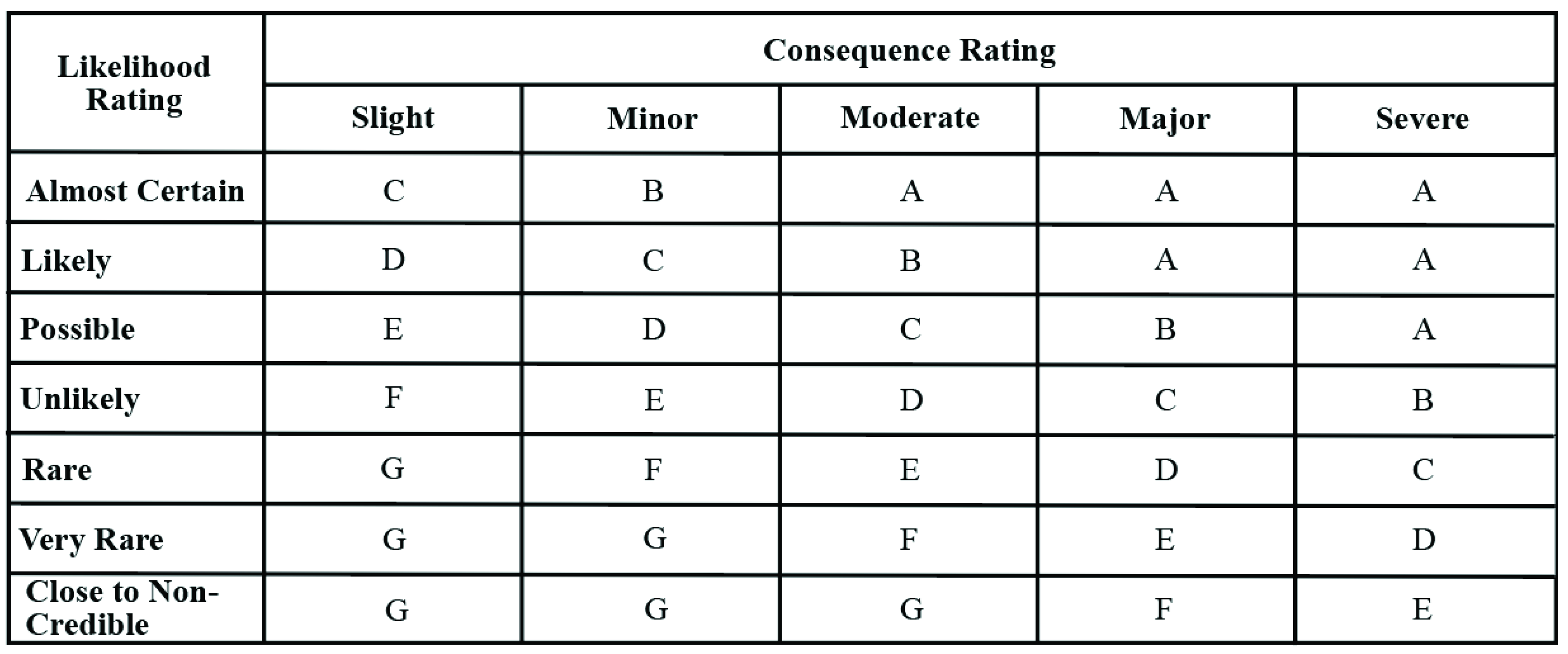

- The risk matrix was assessed using the Levine lettering scheme [29]. For this, logarithmic axes were used for the consequence and likelihood axes and straight-line iso-contours of equal risk were drawn (similar to Figure A1). Following this, each area was labelled with a letter as opposed to a colour, as shown in Figure A3 (each line represents a new letter). Levines method results in a matrix that is somewhat unintuitive, but this prevents risk matrix users from making assumptions about risks based on the colouring scheme. When a risk matrix is constructed in this manner, the following conclusions can be drawn:

- Risks in one letter category can only be distinguished from risks in another category if they are more than one letter apart (i.e., C > A, D > B).

- Risks in categories that are zero or one letter distant are not able to be distinguished from another (i.e., it is not known if C > B or B > C).

- 5.

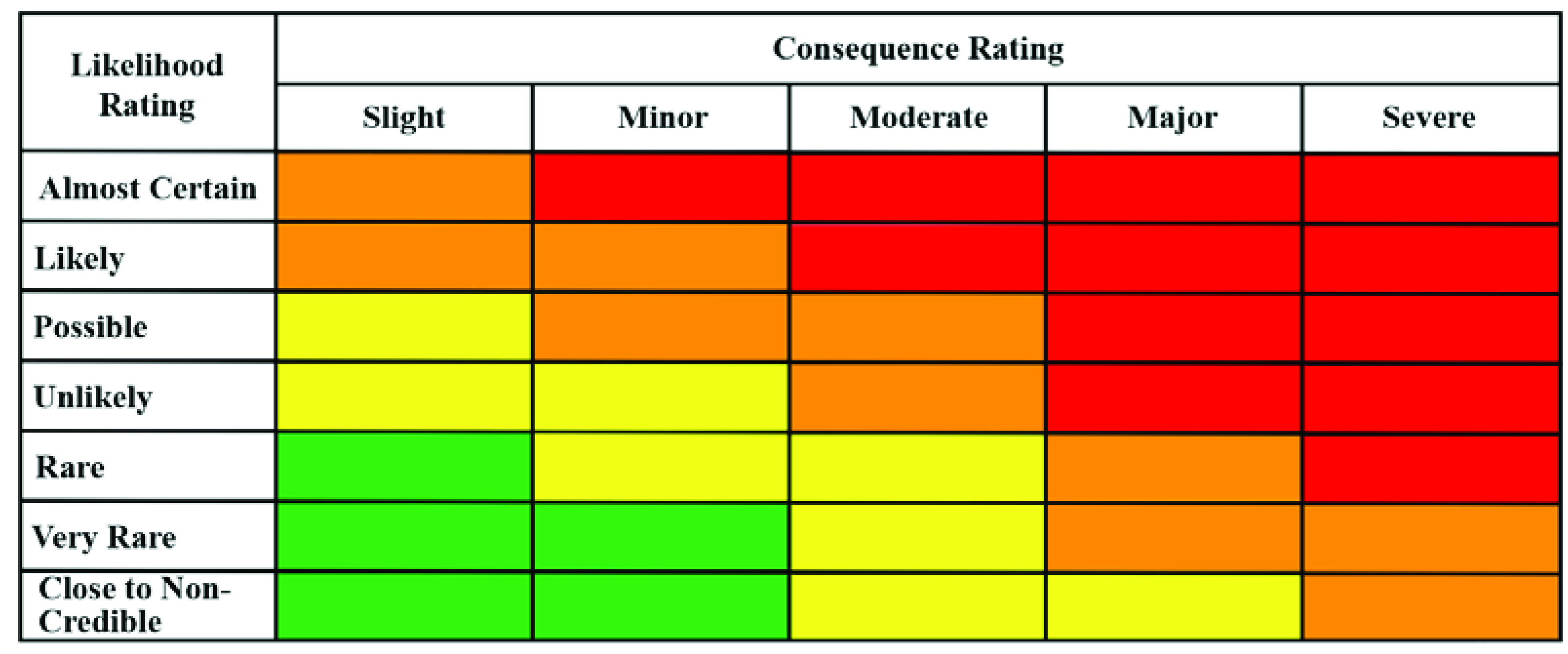

- As noted by Duijm, another way to develop risk scores and colouring is by using basic arithmetic (multiplication and addition) based on ordinal numbers assigned to each consequence and probability category [31]. As the categories were logarithmically spaced, the addition of the ordinal numbers was used, as shown in Figure A4. For this example, this results in a risk matrix that is colour-coded in the same way as Figure A2.

- 6.

- 7.

- Following the application of major hazard aversion, the risk matrix was stress tested by evaluating its performance in different scenarios and evaluating what the risk matrix told the user. The evaluation showed that the yielded risk ratings from Figure A5 for the ‘Slight’ and ‘Minor’ consequence rating columns were too high. Some amendments were made to the risk matrix and it was stress tested again. This resulted in the final example risk matrix in Figure A6.

References

- Baker, F.; Cook, D.; Deem, J.; Letient, H.; Walsh, H. Matachewan Mines Tailings Dam from Failure to Rehabilitation. In Proceedings of the 1996 CDA Annual Conference, Niagra Falls, ON, Canada, 6–10 October 1996. [Google Scholar]

- Provincial Court of Alberta. Agreed Statement of Facts, Docket No, Agreed Statement of Facts, Docket No. 151258456P1 &160061354P1; Provincial Court of Alberta, 2017; Available online: http://www1.aer.ca/compliancedashboard/enforcement/201706-04_AgreedStatementofFacts_PrairieMines_Obed_2013-006.pdf (accessed on 6 November 2021).

- LDI. Mining with the End in Mind: Landform Design for Sustainable Mining. Position Paper 2021-01; Landform Design Institute (LDI): Delta, BC, Canada, 2021. [Google Scholar]

- Government of Alberta. Alberta Dam and Canal Safety Directive, AEP Water Conservation 2018 No.3; Government of Alberta: Edmonton, AB, Canada, 2018.

- AER. Manual 019 Decommissioning, Closure, and Abandonment of Dams at Energy Projects; Alberta Energy Regulator (AER): Calgary, AB, Canada, 2020. [Google Scholar]

- Ghahramani, N.; Mitchell, A.; Rana, N.M.; McDougall, S.; Evans, S.G.; Take, W.A. Tailings-flow runout analysis: Examining the applicability of a semi-physical area–volume relationship using a novel database. Nat. Hazards Earth Syst. Sci. 2020, 20, 3425–3438. [Google Scholar] [CrossRef]

- Al-Mamun, M.; Small, A. Revision of Guidance of Landforms in CDA Minings Dams Bulletin-A Companion Paper with Additional Details. In Proceedings of the 2018 CDA Annual Conference, Quebec City, QC, Canada, 13–19 October 2018. [Google Scholar]

- Ayyub, B.M. Risk Analysis in Engineering and Economics, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2014; ISBN 978-1-4665-1826-1. [Google Scholar]

- Robertson, A.; Shaw, S. Mine Closure; Info Mine E-Book: Vancouver, BC, Canada, 2006. [Google Scholar]

- Valis, D.; Koucky, M. Selected Overview of Risk Assessment Techniques. Probl. Eksploat. 2009, 4, 19–32. [Google Scholar]

- Hartford, D.N.D.; Baecher, G.B. Risk and Uncertainty in Dam Safety; Thomas Telford Publishing: London, UK, 2004; ISBN 9780727740397. [Google Scholar]

- Kupper, A.G.; Hurndall, B.; Morgenstern, N.; Sobkowicz, J.; Abeda, W.; Baldwin, G.; Cameron, R.; Eenkooren, N.; Grapel, C.; Martens, S.; et al. De-Licensing Oil Sands Tailings Dams-When Is a Dam No Longer a Dam? In Proceedings of the 17th International Conference on Tailings and Mine Waste, Banff, AB, Canada, 3–6 November 2013. [Google Scholar]

- Dos Santos, R.N.C.; Caldeira, L.M.M.S.; Serra, J.P.B.; Dos Santos, R.C. FMEA of a tailings dam. Georisk: Assess. Manag. Risk Eng. Syst. Geohazards 2012, 6, 89–104. [Google Scholar] [CrossRef]

- Schafer, H.L.; Macciotta, R.; Beier, N.A. Tailings dam closure scenarios, risk communication, monitoring, and surveillance in Alberta. CIM J. 2020, 11, 80–90. [Google Scholar] [CrossRef]

- Schafer, H.L.; Beier, N.A.; Macciotta, R. Closure and the Long-Term Behaviour of Tailings Dams: Using Industry Experience to Fill in the Gaps. In Proceedings of the 72nd Canadian Geotechnical Conference, St. John’s, NL, Canada, 29 September–2 October 2019. [Google Scholar]

- Porter, M.; Lato, M.; Quinn, P.; Whittall, J. Challenges with Use of Risk Matrices for Geohazard Risk Management for Resource Development Projects. In Proceedings of the First International Conference on Mining Geomechanical Risk, Perth, WA, Australia, 9–11 April 2019; Australian Centre for Geomechanics: Crawley, WA, Australian; pp. 71–84. [Google Scholar]

- MEND. Cold Regions Cover System Design Technical Guidance Document, MEND Report 1.61.5c; Mine Environment Neutral Drainage (MEND) Program: 2012. Available online: http://mend-nedem.org/wp-content/uploads/2013/01/1.61.5c.pdf (accessed on 6 November 2021).

- Brown, B.S. What Are the Real Risks for Tailings Facilities? In Proceedings of the First International Conference on Mining Geomechanical Risk, Perth, WA, Australia, 9–11 April 2019; Australian Centre for Geomechanics: Crawley, WA, Australia; pp. 21–30. [Google Scholar]

- (Tony)Cox, L.A. What’s Wrong with Risk Matrices? Risk Anal. 2008, 28, 497–512. [Google Scholar] [CrossRef]

- Pickering, A.; Cowley, S.P. Risk Matrices: Implied Accuracy and False Assumptions. J. Health Saf. Res. Pract. 2010, 2, 11–18. [Google Scholar]

- Ball, D.J.; Watt, J. Further Thoughts on the Utility of Risk Matrices. Risk Anal. 2013, 33, 2068–2078. [Google Scholar] [CrossRef]

- Monat, J.P.; Doremus, S. Alternatives to Heat Map Risk Matrices for Project Risk Prioritization. J. Mod. Proj. Manag. 2018, 6, 104–113. [Google Scholar] [CrossRef]

- IEC. IEC/ISO 31010 Risk Management-Risk Assessment Techniques; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2009. [Google Scholar]

- Center for Security Studies. Visualizing Risk: The Use of Graphical Elements in Risk Analysis and Communications; Center for Security Studies: Zurich, Switzerland, 2012. [Google Scholar]

- Baybutt, P. Guidelines for designing risk matrices. Process. Saf. Prog. 2017, 37, 49–55. [Google Scholar] [CrossRef]

- Thomas, P.; Bratvold, R.B.; Eric, B.J. The Risk of Using Risk Matrices. SPE Econ. Manag. 2014, 6, 56–66. [Google Scholar] [CrossRef]

- Baybutt, P. Designing risk matrices to avoid risk ranking reversal errors. Process. Saf. Prog. 2015, 35, 41–46. [Google Scholar] [CrossRef]

- Oboni, C.; Oboni, F. Is It True that PIGs Fly When Evaluating Risks of Tailings Management Systems? In Proceedings of the 16th International Conference on Tailings and Mine Waste, Keystone, CO, USA, 14–17 October 2012; pp. 95–105. [Google Scholar]

- Levine, E. Improving risk matrices: The advantages of logarithmically scaled axes. J. Risk Res. 2012, 15, 209–222. [Google Scholar] [CrossRef]

- Smith, E.D.; Siefert, W.T.; Drain, D. Risk matrix input data biases. Syst. Eng. 2008, 12, 344–360. [Google Scholar] [CrossRef]

- Duijm, N.J. Recommendations on the use and design of risk matrices. Saf. Sci. 2015, 76, 21–31. [Google Scholar] [CrossRef] [Green Version]

- Bao, C.; Li, J.; Wu, D. A fuzzy mapping framework for risk aggregation based on risk matrices. J. Risk Res. 2016, 21, 539–561. [Google Scholar] [CrossRef]

- Oboni, F.; Oboni, C. Tailings Dam Management for the Twenty-First Century; Springer Nature Switzerland AG: Cham, Switzerland, 2020; ISBN 978-3-030-19447-5. [Google Scholar]

- Canadian Geotechnical Society. Canadian Foundation Engineering Manual, 4th ed.; Canadian Geotechnical Society: Richmond, BC, Canada, 2006; ISBN 9780920505281. [Google Scholar]

- Global Tailings Review. Global Industry Standard on Tailings Management; International Council on Mining and Metals: London, UK; United Nations Environment Programme: Nairobi, Kenya; Principles of Responsible Investment: London, UK, 2020. [Google Scholar]

- ICOLD. Internal Erosion of Existing Dams, Levees and Dikes, and Their Foundations; International Commission on Large Dams (ICOLD): Paris, France, 2017; Volume Bulletin 164. [Google Scholar]

- Task Committee on Low-Level Radioactive Waste Management of the Technical Committee on Nuclear Effects Management of Inactive Uranium Mill Tailings. J. Environ. Eng. 1986, 112, 490–537. [CrossRef]

- DOE Lakeview Oregon Final Completion Report Volume 1; Department of Energy (DOE) Albuquerque Operations Office: Albuquerque, NM, USA, 1991.

- Mathes, D.E. Lessons-Learned from the 20-Year Uranium Mill Tailings Remedial Action Surface Project. In Proceedings of the Waste Management, Tuscon, AZ, USA, 28 February–4 March 1999. [Google Scholar]

- IAEA. The Long Term Stabilization of Uranium Mill Tailings; International Atomic Energy Agency (IAEA): Vienna, Austria, 2004. [Google Scholar]

- ICOLD. Tailings Dam Committee Sustainable Design and Post-Closure Performance of Tailings Dams; International Committee on Large Dams (ICOLD): Paris, France, 2013; Volume Bulletin 153. [Google Scholar]

- CDA. Application of Dam Safety Guidelines to Mining Dams; Canadian Dam Association (CDA): Markham, ON, Canada, 2014. [Google Scholar]

- OSTDC. De-Licensing of Oil Sands Tailings Dams. In Technical Guidance Document; Oil Sands Tailings Dam Committee (OSTDC). 2014. Available online: https://era.library.ualberta.ca/items/8131d11c-4402-4bed-b0ab-0d3833b95af6/view/7165e9fb-e003-4ce6-8a92-efaf8355ec2b/2014-2003-2028-20--20Report-20--20Oil-20Sands-20Dams-20De-Licensing-20Technical-20Guide.pdf (accessed on 6 November 2021).

- INAP. Global Cover System Design Technical Guidance Document; International Network for Acid Prevention (INAP). 2017. Available online: https://www.inap.com.au/wp-content/uploads/global-cover-system-design.pdf (accessed on 6 November 2021).

- Hadjigeorgiou, J. Understanding, Managing and Communicating Geomechanical Mining Risk. In Proceedings of the First International Conference on Mining Geomechanical Risk, Australian Centre for Geomechanics, Perth, WA, Australia, 9–11 April 2019; pp. 3–20. [Google Scholar]

- Griffin, B. Risk Assessment. In Guidelines for Mine Waste Dump and Stockpile Design; Hawley, M., Cunning, J., Eds.; CSIRO Publishing: Clayton South, VIC, Australia, 2017; pp. 187–195. [Google Scholar]

- Reagan, R.T.; Mosteller, F.; Youtz, C. Quantitative meanings of verbal probability expressions. J. Appl. Psychol. 1989, 74, 433–442. [Google Scholar] [CrossRef] [PubMed]

- NOAMI. The Policy Framework in Canada for Mine Closure and Management of Long-Term Liabilities: A Guidance Document; National Orphaned/Abandoned Mines Initiative (NOAMI): Ottawa, ON, Canada, 2010. [Google Scholar]

- Slovic, P.; Weber, E.U. Perception of Risk Posed by Extreme Events. In Proceedings of the Risk Management Strategies in an Uncertain World, Palisades, New York, NY, USA, 12–13 April 2002. [Google Scholar]

- Gibson, G.; O’Faircheallaigh, C. IBA Community Toolkit: Negotiation and Implementation of Impact and Benefit Agreements; Walter & Duncan Gordon Foundation: Toronto, ON, Canada, 2015. [Google Scholar]

- Nikl, L.; Steele, J.; Robertson, L.; Davidson, S.; Schryburt, R. Environmental Consequence Classification of Mine Dam Failures: Updating the Canadian Classification System. In Proceedings of the ASDSO 2018 Dam Safety Conference, Association of State Dam Safety Officials, Seattle, Washington, DC, USA, 9–13 September 2018. [Google Scholar]

- Department of Mines and Petroleum. Environmental Protection Authority Guidelines for Preparing Mine Closure Plans; Government of Western Australia: Perth, WA, Australia, 2015.

- Aven, T. Risk assessment and risk management: Review of recent advances on their foundation. Eur. J. Oper. Res. 2016, 253, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Oboni, F.; Oboni, C. The Long Shadow of Human-Generated Geohazards: Risks and Crises. In Geohazards Caused by Human Activity; Faris, A., Ed.; InTech: Rijeka, Croatia, 2016; pp. 107–140. ISBN 978-953-51-2802-1. [Google Scholar]

| Issue | References | Comments related to the G-FMEA |

|---|---|---|

| Subjective nature (not as simple and transparent as it would seem). | [8,19,20,21,22,23] | Quantitative data should be used as often as possible with supporting verbal descriptions and quantitative descriptors (ranges or anchor points to the definition of categories). The risk assessment should be accompanied by a description of the risk assessor, including their risk tolerances. |

| Can lead to incorrect risk prioritization. | [21,22,24,25] | The risk matrix does not focus on risk prioritization, but is intended as a screening tool to assess the closure design. |

| Can shut down conversations about risk instead of opening them up due to the pre-defined colour coding scheme determining risk prioritization. | [24] | The risk matrix is designed to determine if a closure design is adequate and is a screening tool. It involves input from stakeholders to determine the consequence ratings and is intended to open up dialogue. |

| Ranking reversal: where quantitatively smaller risks are assigned qualitatively higher rating levels than some quantitatively larger risks due to incorrect risk prioritization. | [19,20,26,27] | The risk matrix does not focus on risk prioritization, but is intended as a screening tool to assess the closure design. |

| Does not account for different risk tolerances of the individual conducting the risk assessment. | [22,28] | The risk assessor‘s background should be listed with the completed risk assessment. |

| Range compression where risks with very different likelihoods and consequences are grouped together. Risk matrices with too many categories may give false resolutions. | [19,26,28,29] | The number of risk categories should be developed with consideration of range compression. |

| Centering bias can be an issue where individuals have the tendency to avoid extreme values or statements when presented with a choice. This can exacerbate range compression. | [26,30] | An extra category can be added to both sides of the expected range for the consequences and likelihoods, as suggested by Duijm [31]. |

| Category definition bias where different definitions exist for a given likelihood or consequence descriptor. | [26,31] | Clear definitions must be provided for the consequences and likelihoods categories. |

| Risk matrix can be misleading as it implies that risk is categorical as opposed to a position on a risk continuum. | [20] | The risk matrix should be accompanied by a clear definition of risk and associated discussion on the risk continuum. |

| Ambiguity of the consequence definition. There are different definitions used in practice for the consequence which can lead to issues if not clearly defined (worst case, most likely, a number of alternate discrete outcomes). | [31] | The consequence category must be clearly defined. |

| Risk matrices cannot provide aggregate measures of risk (i.e., total risk). | [23,27,32] | The goal of this risk matrix is to serve as a screening tool and is not intended to provide an indication of total risk. |

| Risk matrices are unable to aggregate risk from multiple consequence dimensions. This means that different types of consequences should not be directly compared (i.e., impact on the environment, human life). In practice, a hazard is often assigned a risk level based on the most severe consequence. This is misleading. | [23,31,33] | A risk rating should be assigned for each consequence category for a hazard. |

| Corporate-wide risk matrices are intended to be used as a way of standardizing risk assessment and risk acceptance criteria across a company. This is problematic as risk tolerance may vary throughout a company. | [31] | Corporate-wide risk matrices should not be used with the Generalized FMEA. |

| Element | Failure Mode Description | Potential Trigger/Cause | Screening Assessment of Failure Mode | Failure Effects |

|---|---|---|---|---|

| Perimeter Ditch | Blockage (partial or full) | Sedimentation, sloughing/slope failure of walls, beaver dam, continuous build up of ice (icing) | Is there erosion protection in place? What is the slope of the ditch? Is it sufficient to keep particles suspended? What is the slope of the side slopes? What is the strength of material? Have there been failures in this material before? Are there beavers in the area? Is the mine located in an area that could experience icing? | Rise in phreatic surface, increase in seepage, pond on reclamation surface, internal erosion, global instability, flooding, blockage of drain outlets, toe erosion, discharge of process affected water to the environment |

| Reduction in cross-sectional area | Sloughing/slope failure of walls, excessive vegetation | What is the slope of the side slopes? What is the strength of material? Have there been failures in this material before? Will the ditch regularly have water running through it or will it stay dry for a portion of the year? Are there deterrents in place to prevent the growth of vegetation? | Rise in phreatic surface, increase in seepage, pond on reclamation surface, internal erosion, global instability, reduced capacity, erosion, potential flooding, blockage of drain outlets, toe erosion, discharge of process affected water to the environment | |

| Change in slope | Erosion, differential settlement | Is there erosion protection in place? Does the material have the potential to consolidate or settle over time? Is it a cut into natural ground or is the material placed? | Change to water discharge velocity, creation of secondary channels, localized areas of erosion, instability of dam |

| Assessment Period | Definition |

|---|---|

| Adaptive Management | Occurs following closure activities when the closed facility may be at its greatest risk of failure prior to reaching equilibrium. The operator has the greatest capacity to respond. This period may be defined explicitly by the regulator, using accumulated knowledge, or using a site-specific scientific basis. |

| Proactive Management | Occurs as personnel and equipment are reduced. Involves a regular fixed frequency monitoring and maintenance schedule to confirm that the landform is trending along the designed trajectory. It is expected that the frequency will be less than during the adaptive management period. |

| Reactive Management | Issues are rectified strictly on a reaction basis, once a trigger event occurs. There should be a clear plan in place that outlines what the trigger events are and how they will be managed. Monitoring may occur in response to events such as fires, floods, earthquakes, and other extreme events. |

| Risk Assessment | Conditions | Approximate Assessment Period 1 |

|---|---|---|

| Immediate-term | Should fall within the projected adaptive management period | 0–10 years |

| Short-term | Should fall within the projected adaptive or proactive management period | 10–50 years |

| Medium-term | Should fall within the projected reactive management period | 50–200 years |

| Long-term | - | 1000 years |

| Likelihood Rating | Qualitative Interpretation Guidance 1 | Quantitative Interpretation Guidance | Annualized Probability of Occurrence |

|---|---|---|---|

| Almost certain | Almost certain that an incident will occur given the circumstances. Very high probability of one or more occurrences per year. | Higher than 10% probability in a year | p ≥ 0.1 |

| Likely | High likelihood. Commonly observed at similar facilities. | Higher than 10% probability in 10 years | p ≥ 0.01 |

| Possible | Has occurred a number of times within the industry and at least once at the site (or similar facilities in the region). | Higher than 1% probability in 10 years | p ≥ 0.001 |

| Unlikely | Has occurred before within the industry, but not at the site. | Less than a 1% probability in 10 years | p < 0.001 |

| Rare | Low likelihood of occurrence, but not impossible. Has not occurred at the site but has occurred in industry. | Less than a 1% probability in 100 years | p < 0.0001 |

| Very rare | Very low likelihood of occurrence, but not impossible. Occurrence cannot be deemed non-credible | Less than a 1% probability in 1000 years | p < 0.00001 |

| Close to non-credible | Extremely remote likelihood of occurrence. Although the mechanisms are technically plausible for the occurrence, it is seen as near non-credible. | Less than a 1% probability in 10,000 years | p < 0.000001 |

| Consequence Rating 1 | Consequence of Failure of Element on the Rest of the System | Degree of Human Intervention Required | Environment | Community |

|---|---|---|---|---|

| Slight | Failure of element does not have cascading consequences. | Structural integrity maintained. No intervention or maintenance required. | No movement of tailings beyond the structure footprint. | No impact on local community. |

| Minor | Failure of element may have cascading consequences that do not result in global failure. | Structural integrity maintained. Minor or localized intervention or maintenance required. | Released tailings are not toxic 2, and/or minimal loss of habitat (<5%) of species of special interest 3, and/or acceptable restoration of water bodies and environment feasible in a short time frame (<5 years). | Impact 4 on local community for less than 1 year. |

| Moderate | Failure of element has cascading consequences that do not result in global failure. | Intervention or maintenance required to limit impact of cascading consequences. | Released tailings are not toxic 2, and/or moderate loss of habitat (5–20%) of species of special interest 3, and/or acceptable restoration of water bodies and environment feasible in a short time frame (<5 years). | Short-term (<5 years) impact 4 on local community. |

| Major | Global failure of tailings dam with minor release of tailings. | Intervention or maintenance required to maintain function of structure as a whole. | Released tailings are toxic 2, and/or significant loss of habitat (20–50%) of species of special interest 3, and/or acceptable restoration of water bodies and environment feasible in a moderate time frame (5–25 years). | Medium-term (5–25 years) impact 4 on local community. |

| Severe | Global failure of tailings dam with catastrophic release of tailings. | Structural repair not possible. | Released tailings are toxic 2, and/or very significant loss of habitat (>50%) of species of special interest 3, and/or acceptable restoration of water bodies and environment unlikely within an extended time frame (>25 years). | Long-term (>25 years) impact 4 on local community. Fatalities. |

| Risk Category | Description of Risk Category |

|---|---|

| Low | Risk minimal. Monitor risks. Acceptable closure plan. |

| Moderate | Risk tolerable with controls. Assess risk mitigation options and monitor these risks. Minor re-design of closure plan may be required to accommodate risk mitigation. |

| High | Risk undesirable. Risk mitigation should be employed to ALARP to reduce risk category. Closure plan may require alteration to accommodate risk mitigation. |

| Extreme | Risk intolerable. Risk mitigation required immediately to reduce risk category. Requires more detailed risk analysis. Closure plan requires alteration. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schafer, H.L.; Beier, N.A.; Macciotta, R. A Failure Modes and Effects Analysis Framework for Assessing Geotechnical Risks of Tailings Dam Closure. Minerals 2021, 11, 1234. https://doi.org/10.3390/min11111234

Schafer HL, Beier NA, Macciotta R. A Failure Modes and Effects Analysis Framework for Assessing Geotechnical Risks of Tailings Dam Closure. Minerals. 2021; 11(11):1234. https://doi.org/10.3390/min11111234

Chicago/Turabian StyleSchafer, Haley L., Nicholas A. Beier, and Renato Macciotta. 2021. "A Failure Modes and Effects Analysis Framework for Assessing Geotechnical Risks of Tailings Dam Closure" Minerals 11, no. 11: 1234. https://doi.org/10.3390/min11111234

APA StyleSchafer, H. L., Beier, N. A., & Macciotta, R. (2021). A Failure Modes and Effects Analysis Framework for Assessing Geotechnical Risks of Tailings Dam Closure. Minerals, 11(11), 1234. https://doi.org/10.3390/min11111234