Optimization of Airflow Field for Pneumatic Drum Magnetic Separator to Improve the Separation Efficiency

Abstract

:1. Introduction

2. Experimental Section

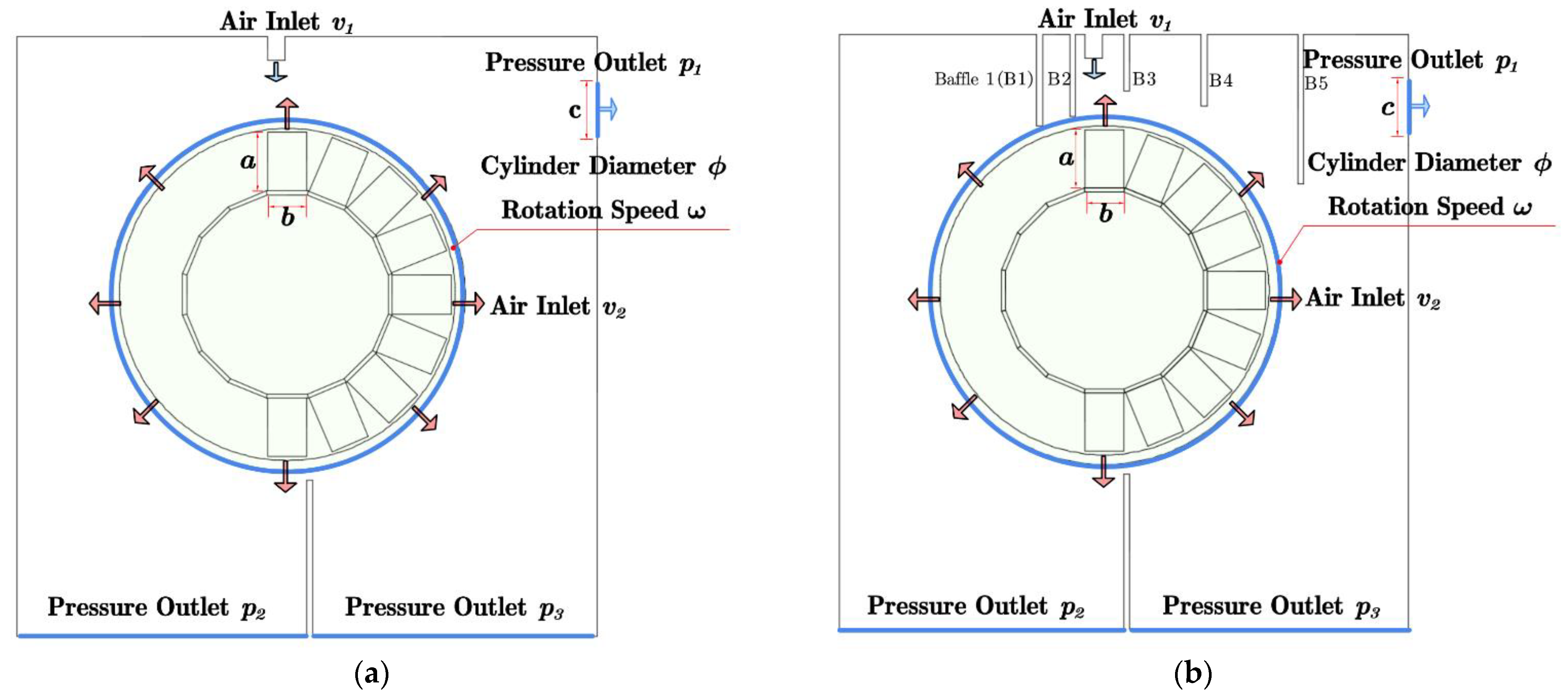

2.1. Configuration Improvement of Pneumatic Drum Magnetic Separator

2.2. Materials

2.3. Experimental and Evaluation Methods

2.4. Simulation Method and Conditions

3. Results and Discussions

3.1. Airflow Field Simulation and Analysis

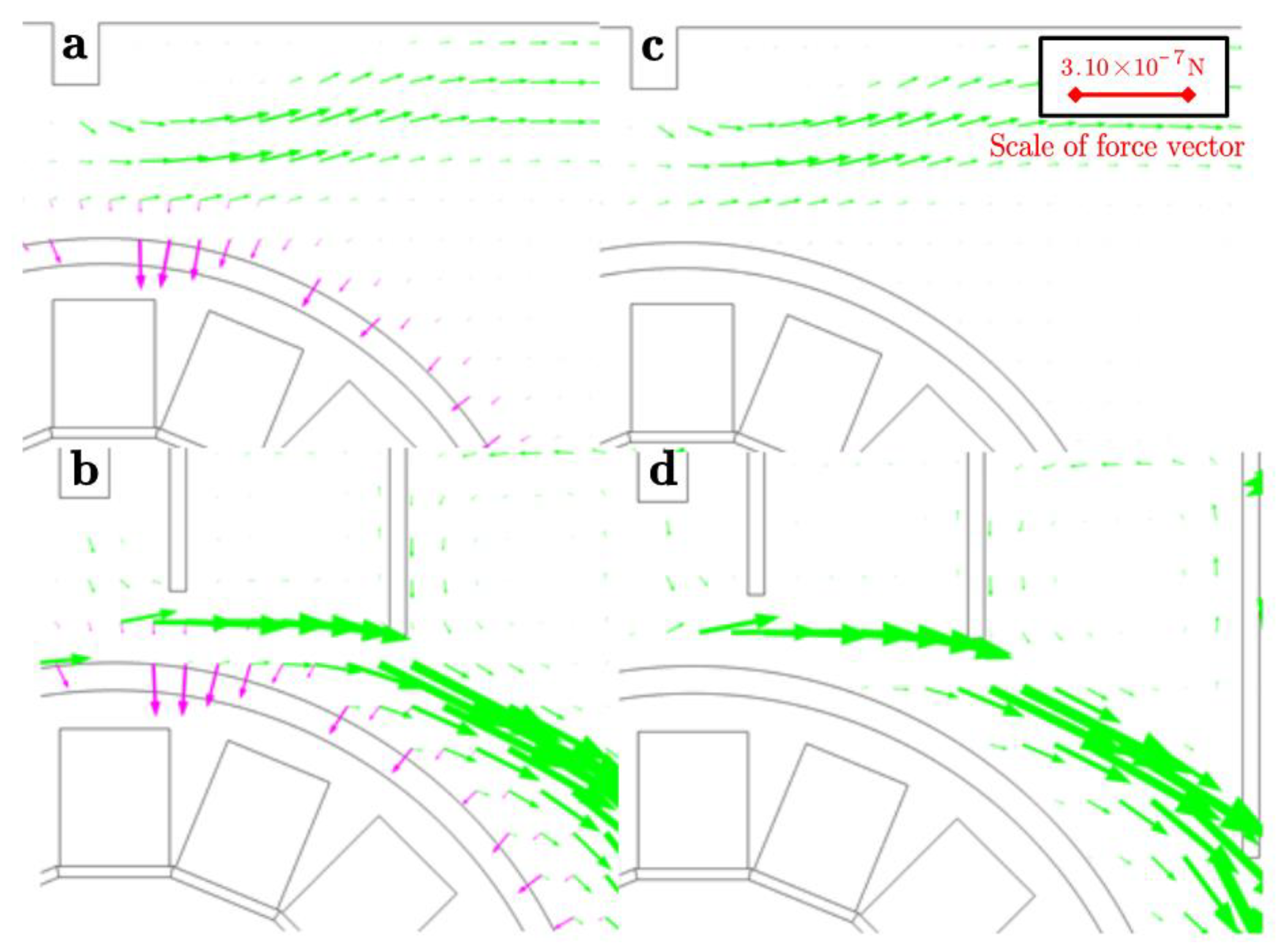

3.2. Particle Force Analysis in Separation Zone

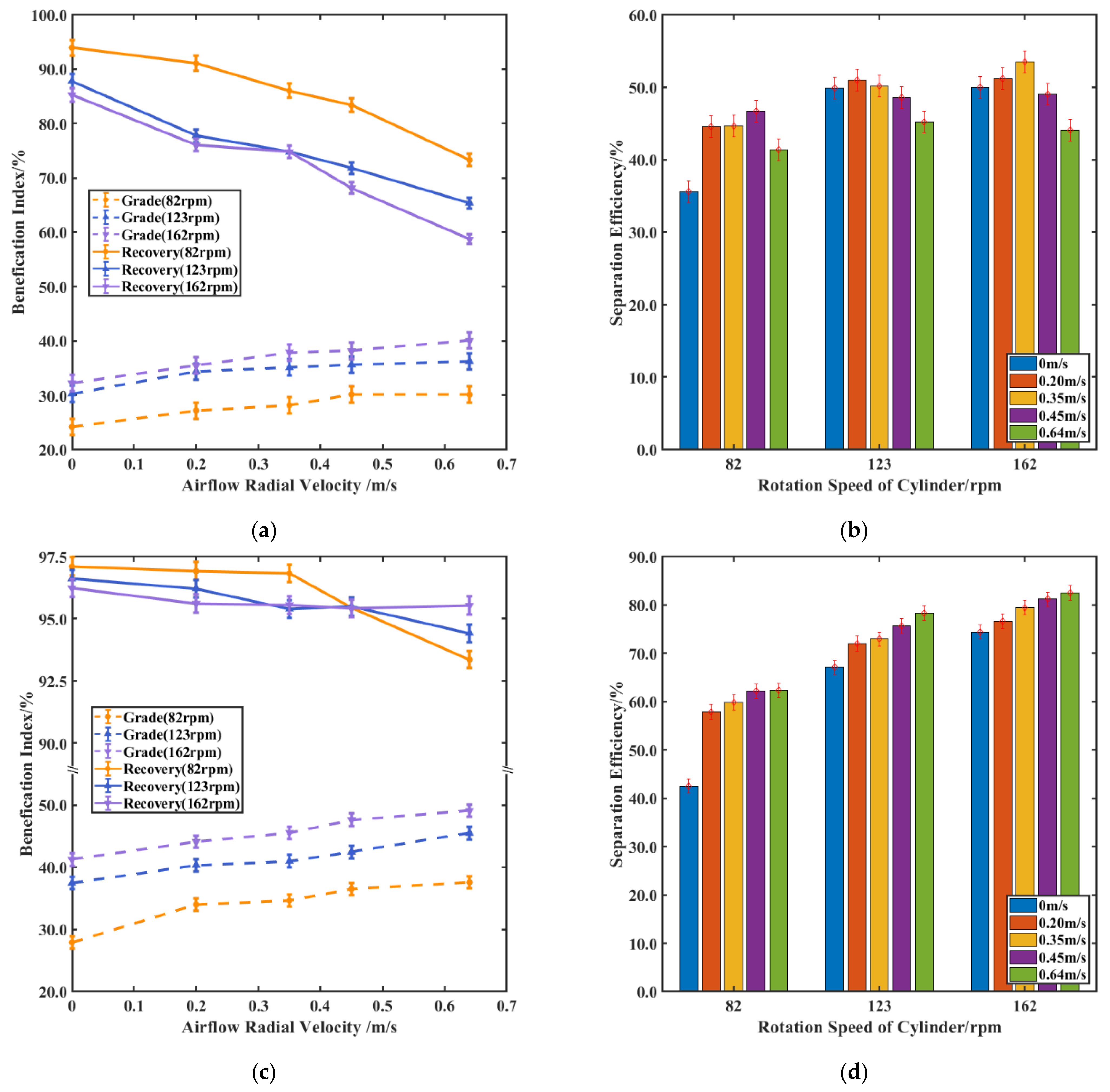

3.3. Experimental Verification

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Oberteuffer, J. Magnetic Separation: A Review of Principles, Devices, and Applications. IEEE Trans. Magn. 1974, 10, 223–238. [Google Scholar] [CrossRef]

- Parker, M.R. The Physics of Magnetic Separation. Contemp. Phys. 1977, 18, 279–306. [Google Scholar] [CrossRef]

- Tripathy, S.K.; Banerjee, P.K.; Suresh, N.; Murthy, Y.R.; Singh, V. Dry High-Intensity Magnetic Separation in Mineral Industry—A Review of Present Status and Future Prospects. Miner. Process. Extr. Metall. Rev. 2017, 38, 339–365. [Google Scholar] [CrossRef]

- Verkhoturov, M.V.; Emel’yashin, Y.M.; Tarasenko, V.P. Moisture of Air and Efficiency of Dry Magnetic Separation. Sov. Min. Sci. 1986, 22, 508–511. [Google Scholar] [CrossRef]

- Nakai, Y.; Senkawa, K.; Mishima, F.; Akiyama, Y.; Nishijima, S. Study on Interparticle Interaction for Dry HGMS System Using Pneumatic Conveyance. Phys. C Supercond. Its Appl. 2011, 471, 1533–1537. [Google Scholar] [CrossRef]

- Senkawa, K.; Nakai, Y.; Mishima, F.; Akiyama, Y.; Nishijima, S. Research on High Gradient Magnetic Separation of Pneumatic Conveyed Powder Products: Investigation from the Viewpoint of Interparticle Interactions. Phys. C Supercond. 2013, 484, 329–332. [Google Scholar] [CrossRef]

- Peng, Y.; Shuyi, L.; Jin, C. The Separation Performance of the Pulsating High–Gradient Magnetic Separator. Magn. Electr. Sep. 1993, 4, 211–221. [Google Scholar] [CrossRef]

- Chen, Z.; Li, B.; Zhao, R.; Zhang, B. An experimental probe on high gradient magnetic separation assisted by ultrasonic wave vibration. J. Inn. Mong. Univ. Sci. Technol. 2010, 29, 14–18. [Google Scholar]

- Demidov, I.V.; Vaisberg, L.A.; Blekhman, I.I. Vibrational Dynamics of Paramagnetic Particles and Processes of Separation of Granular Materials. Int. J. Eng. Sci. 2019, 141, 141–156. [Google Scholar] [CrossRef]

- Huang, Z.; Lin, M.; Qiu, R.; Zhu, J.; Ruan, J.; Qiu, R. A Novel Technology of Recovering Magnetic Micro Particles from Spent Lithium-Ion Batteries by Ultrasonic Dispersion and Waterflow-Magnetic Separation. Resour. Conserv. Recycl. 2021, 164, 105172. [Google Scholar] [CrossRef]

- Xu, J.; Chen, J.; Ren, X.; Xiong, T.; Liu, K.; Song, S. A Novel Dry Vibrating HGMS Separator for Purification of Potash Feldspar Ore. Sep. Sci. Technol. 2021, 56, 1–8. [Google Scholar] [CrossRef]

- Read, A.D.; Whitehead, A.; Grainger-Allen, T.J.N. Pre-Treatment of Feed for Dry Magnetic Separation of Fine Materials. Int. J. Miner. Process. 1976, 3, 343–355. [Google Scholar] [CrossRef]

- Dobbins, M.; Dunn, P.; Sherrell, I. Recent Advances in Magnetic Separator Designs and Applications. In Proceedings of the 7th International Heavy Minerals Conference ‘What Next’, Drakensberg, South Africa, 20–23 September 2009; pp. 63–70. [Google Scholar]

- Xiong, D.; Lu, L.; Holmes, R.J. 9–Developments in the Physical Separation of Iron Ore: Magnetic Separation; Iron, O., Lu, L., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 283–307. ISBN 978-1-78242-156-6. [Google Scholar]

- Brandner, E.D.; Jamison, R.E. VacuMag Magnetic Separator and Process. U.S. Patent US20,100,661,478, 18 March 2010. [Google Scholar]

- Rosensweig, R.E.; Lee, W.K.; Siegell, J.H. Magnetically Stabilized Fluidized Beds for Solids Separation by Density. Sep. Sci. Technol. 1987, 22, 25–45. [Google Scholar] [CrossRef]

- Mishima, F.; Yamazaki, S.; Yoshida, K.; Nakane, H.; Yoshizawa, S.; Takeda, S.; Izumi, Y.; Nishijima, S. A Study on the Development of an Open-Gradient Magnetic Separator under Dry Condition. IEEE Trans. Appl. Supercond. 2004, 14, 1561–1564. [Google Scholar] [CrossRef]

- Siadaty, M.; Kheradmand, S.; Ghadiri, F. Improvement of the Cyclone Separation Efficiency with a Magnetic Field. J. Aerosol Sci. 2017, 114, 219–232. [Google Scholar] [CrossRef]

- Song, S.; Zhang, G.; Luo, Z.; Lv, B. Development of a Fluidized Dry Magnetic Separator and Its Separation Performance Tests. Miner. Process. Extr. Metall. Rev. 2019, 40, 307–313. [Google Scholar] [CrossRef]

- Safikhani, H.; Allahdadi, S. The Effect of Magnetic Field on the Performance of New Design Cyclone Separators. Adv. Powder Technol. 2020, 31, 2541–2554. [Google Scholar] [CrossRef]

- Tang, D.; Wang, F.; Dai, H. Dynamic Behavior of Fine Particles in Dry Medium-Intensity Magnetic Separator Based on k–ε Turbulence Model and Low Reynolds Number k–ε Turbulence Model. Sep. Sci. Technol. 2020, 56, 1383–1396. [Google Scholar] [CrossRef]

- Baawuah, E.; Kelsey, C.; Addai-Mensah, J.; Skinner, W. Assessing the Performance of a Novel Pneumatic Magnetic Separator for the Beneficiation of Magnetite Ore. Miner. Eng. 2020, 156, 106483. [Google Scholar] [CrossRef]

- Kozlova, E.V.; Skrypnikov, A.V.; Kozlov, V.G. Air Magnetic Separator for the Preparation of Forestry Seed Material and Its Theoretical Justification. Mater. Sci. Eng. 2019, 560, 012070. [Google Scholar] [CrossRef]

- Lu, D.; Liu, J.; Cheng, Z.; Li, X.; Xue, Z.; Li, S.; Zheng, X.; Wang, Y. Development of an Open-Gradient Magnetic Separator in the Aerodynamic Field. Physicochem. Probl. Miner. Process. 2020, 56, 325–337. [Google Scholar]

- Svoboda, J. Magnetic Techniques for the Treatment of Materials; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2004; ISBN 978-1-4020-2038-4. [Google Scholar]

- Bagchi, P.; Balachandar, S. Inertial and Viscous Forces on a Rigid Sphere in Straining Flows at Moderate Reynolds Numbers. J. Fluid Mech. 2003, 481, 105–148. [Google Scholar] [CrossRef]

- Guan, X.; Li, X.; Yang, N.; Liu, M. CFD Simulation of Gas-Liquid Flow in Stirred Tanks: Effect of Drag Models. Chem. Eng. J. 2020, 386, 121554. [Google Scholar] [CrossRef]

| Parameters | Original | Improved |

|---|---|---|

| a | 25 mm | 25 mm |

| b | 20 mm | 20 mm |

| c | 25 mm | 25 mm |

| φ | 180 mm | 180 mm |

| ω | variable | variable |

| Air Inlet v1 | 2.8 m/s | 2.8 m/s |

| Air Inlet v2 | variable | variable |

| Pressure Outlet p1 | 0 | 20 kpa |

| Pressure Outlet p2 | 0 | 0 |

| Pressure Outlet p3 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Wang, Y.; Lu, D.; Zheng, X.; Gao, X. Optimization of Airflow Field for Pneumatic Drum Magnetic Separator to Improve the Separation Efficiency. Minerals 2021, 11, 1228. https://doi.org/10.3390/min11111228

Li X, Wang Y, Lu D, Zheng X, Gao X. Optimization of Airflow Field for Pneumatic Drum Magnetic Separator to Improve the Separation Efficiency. Minerals. 2021; 11(11):1228. https://doi.org/10.3390/min11111228

Chicago/Turabian StyleLi, Xudong, Yuhua Wang, Dongfang Lu, Xiayu Zheng, and Xuesong Gao. 2021. "Optimization of Airflow Field for Pneumatic Drum Magnetic Separator to Improve the Separation Efficiency" Minerals 11, no. 11: 1228. https://doi.org/10.3390/min11111228

APA StyleLi, X., Wang, Y., Lu, D., Zheng, X., & Gao, X. (2021). Optimization of Airflow Field for Pneumatic Drum Magnetic Separator to Improve the Separation Efficiency. Minerals, 11(11), 1228. https://doi.org/10.3390/min11111228