Optimization of Transport Performance and Strength of the Filling Slurry in Tailings Reservoir Waste by Adding Air Entraining Agent

Abstract

:1. Introduction

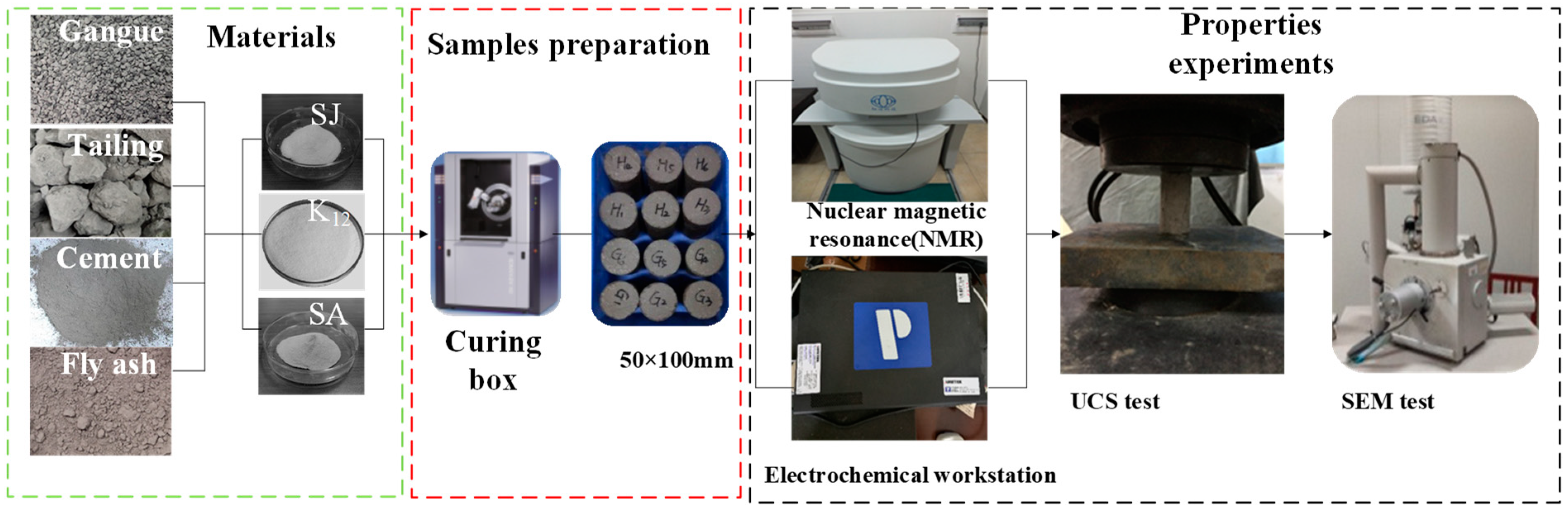

2. Experimental

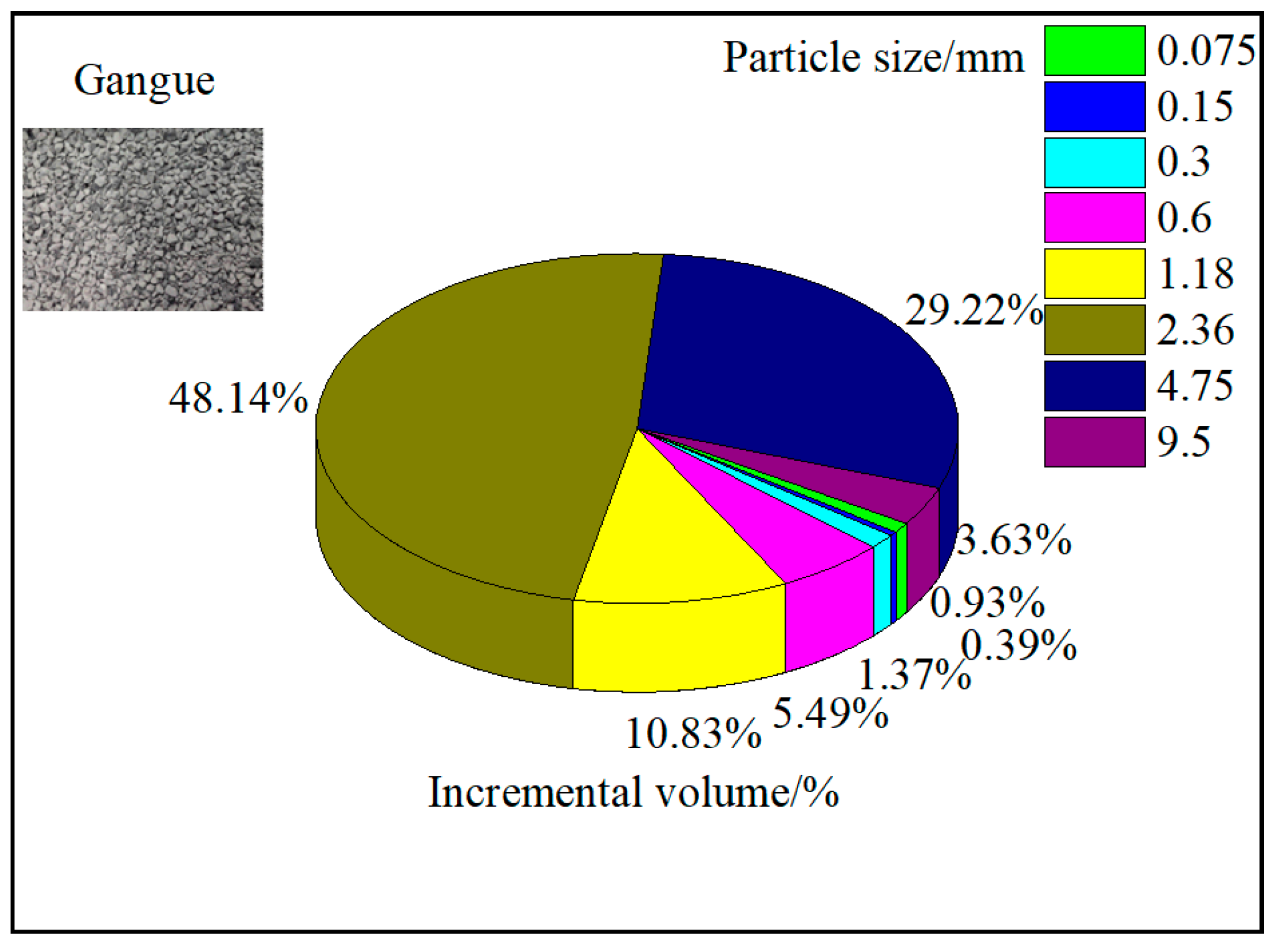

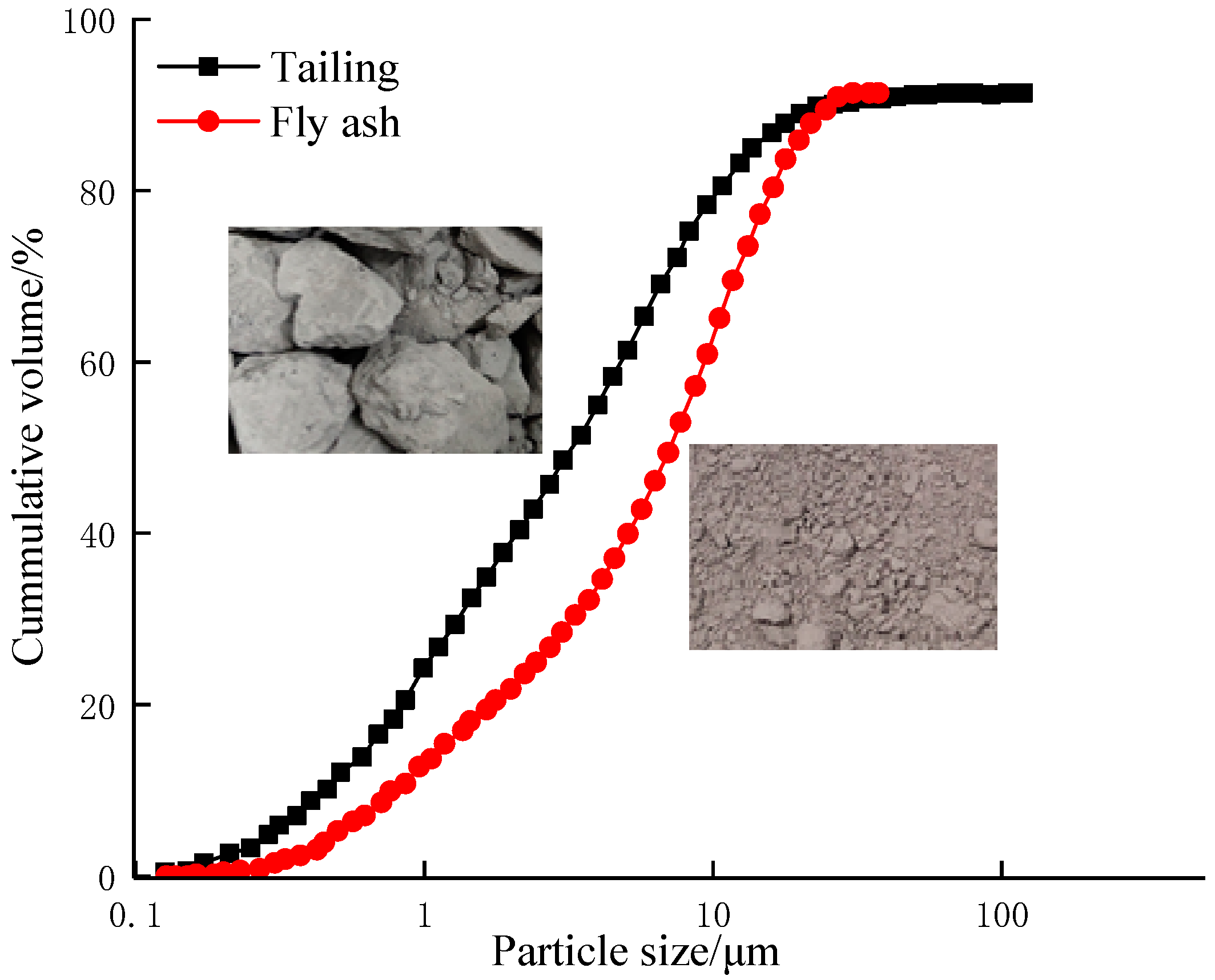

2.1. Materials

2.2. Methods

3. Results and Discussion

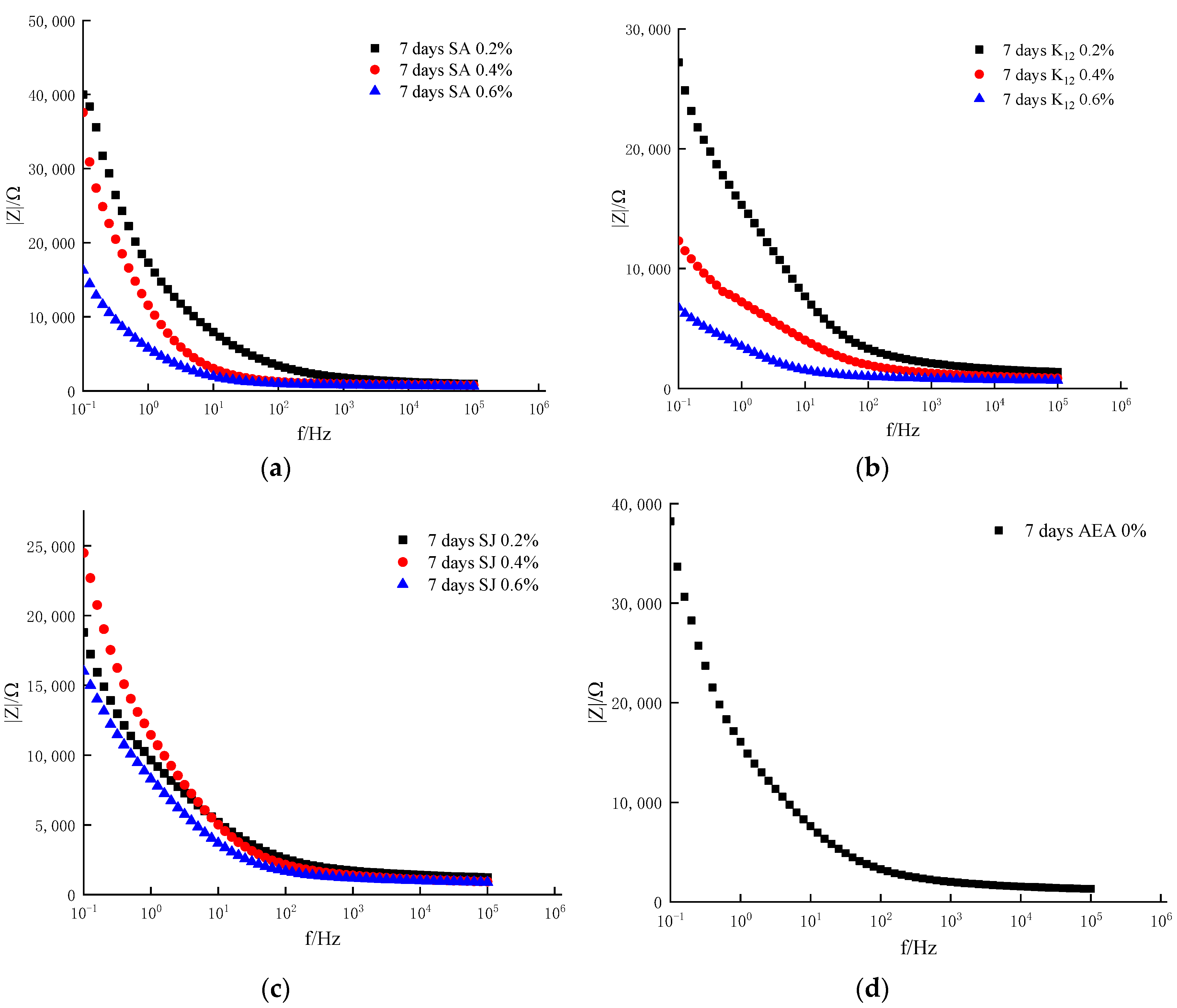

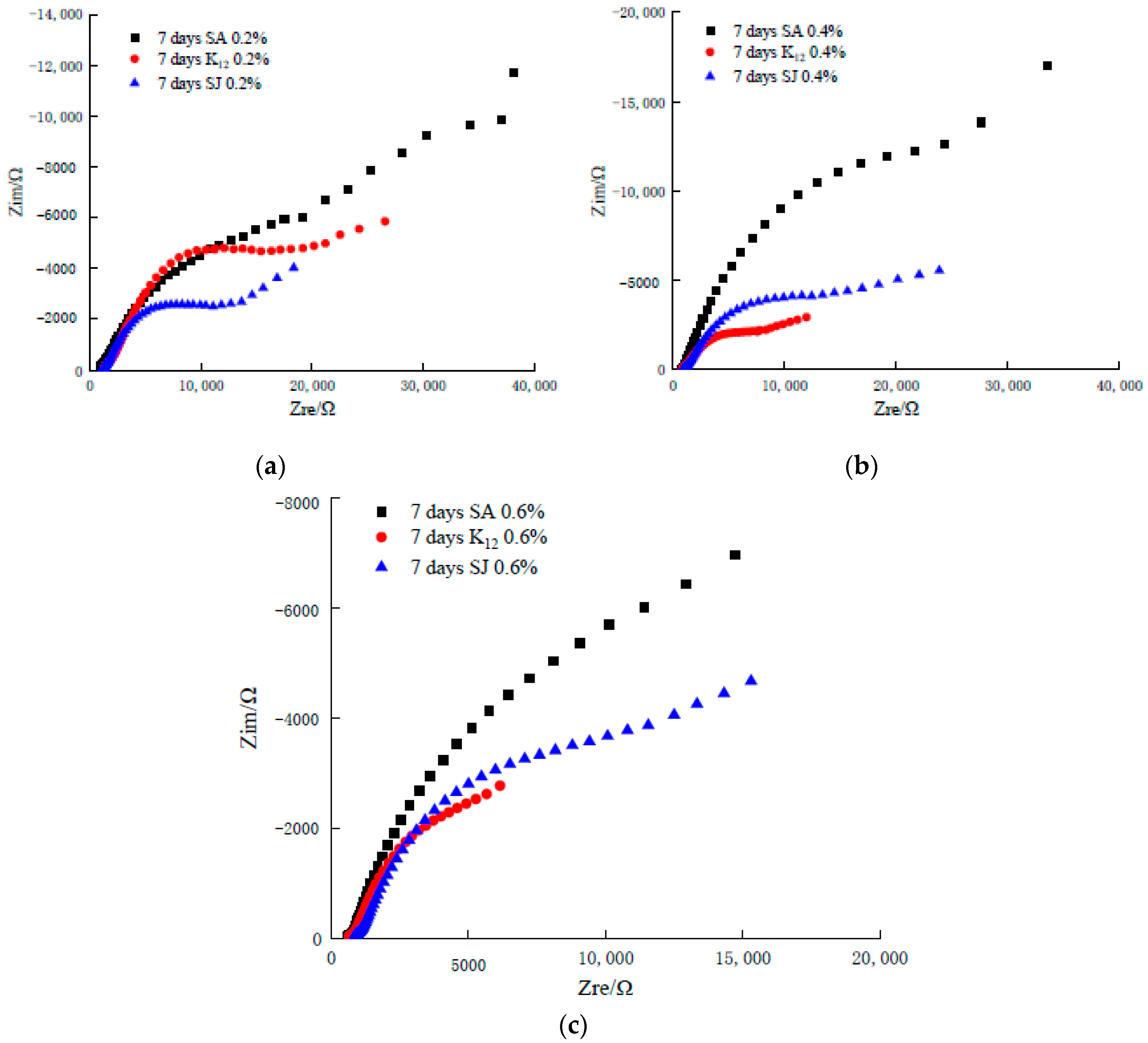

3.1. AC Impedance of the Filling Body after 7 Days of Curing

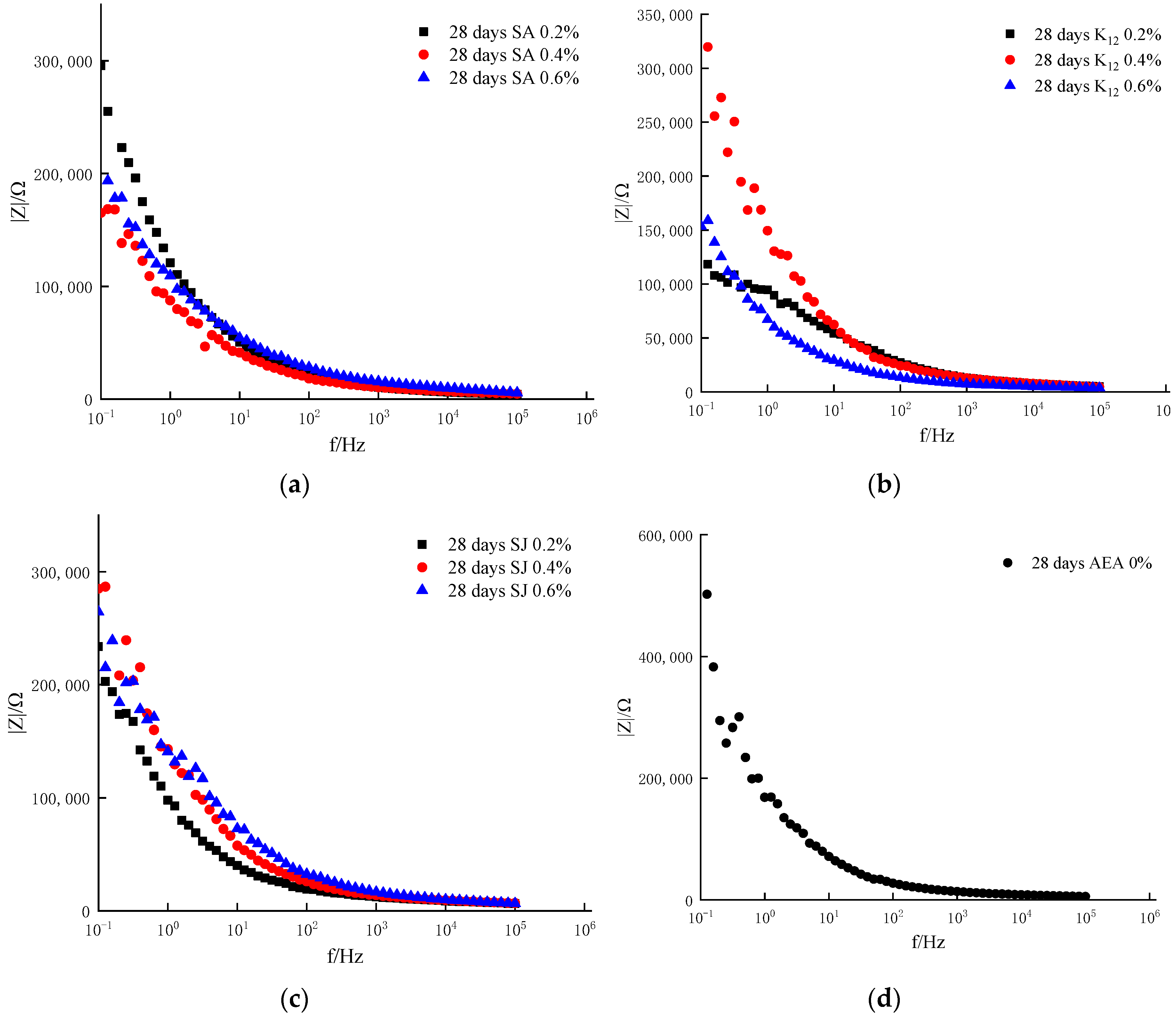

3.2. AC Impedance of the Filling Body for 28 Days of Curing

3.3. Effect of Equivalent Amount of Air-Entraining Agent on AC Impedance

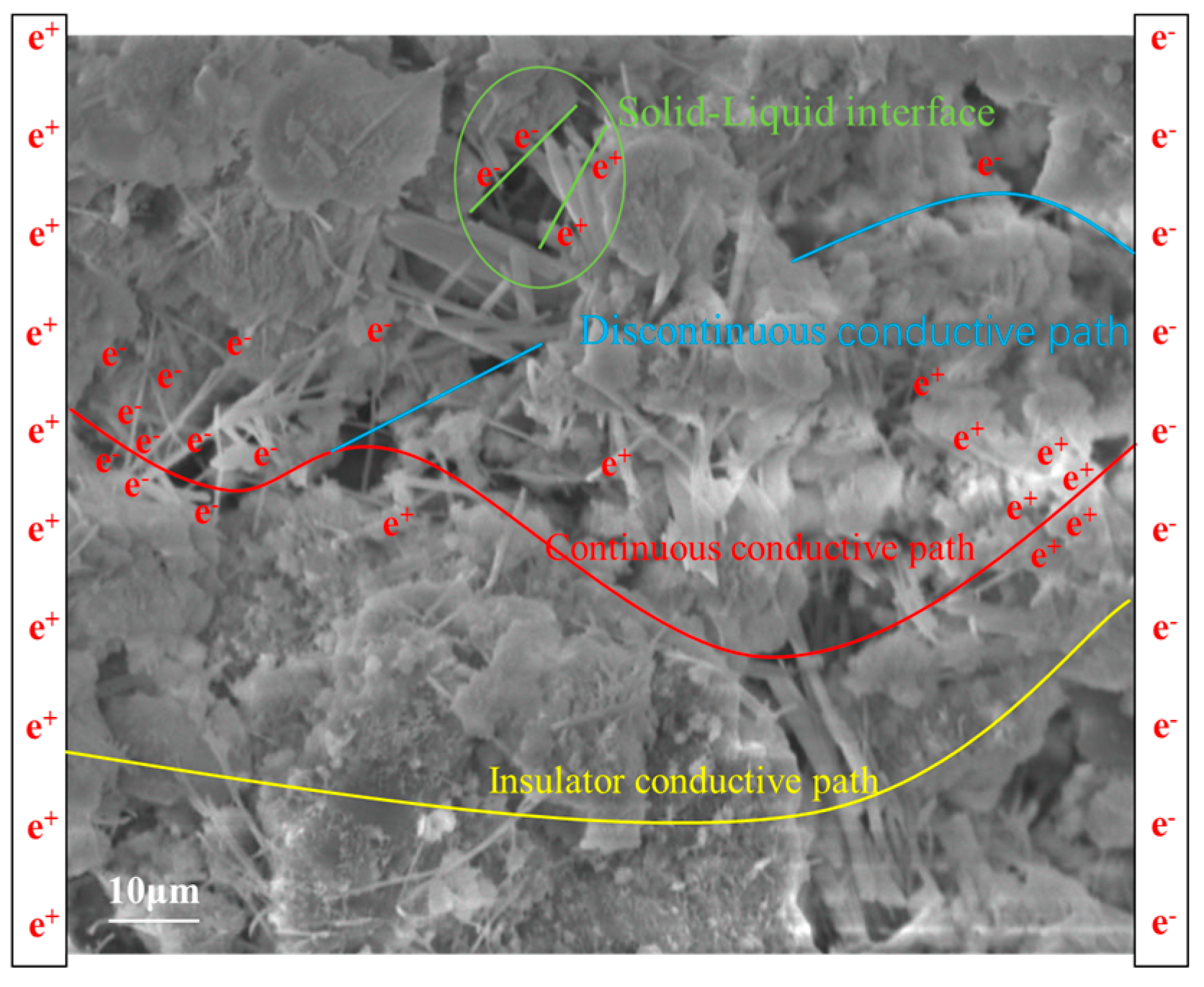

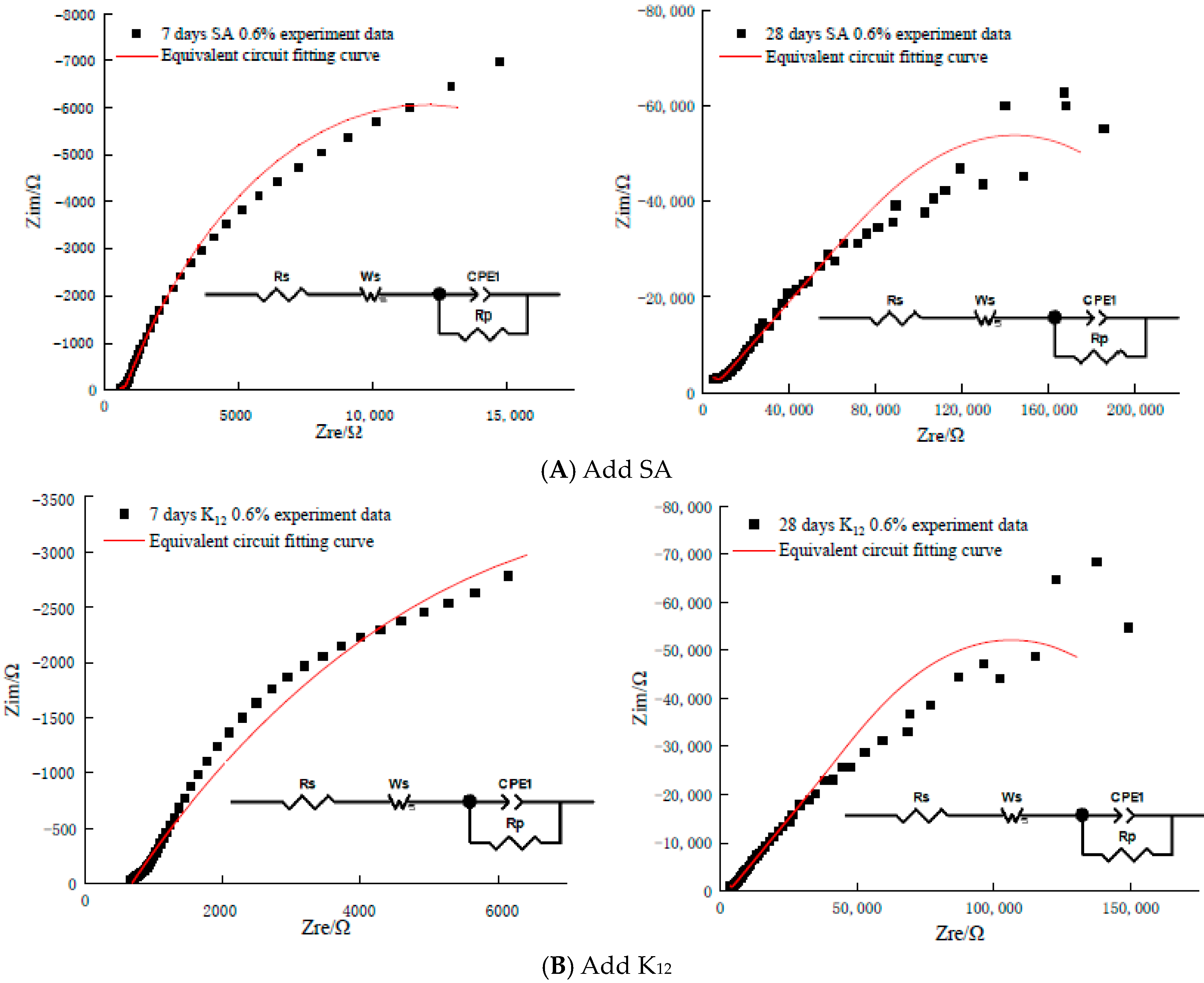

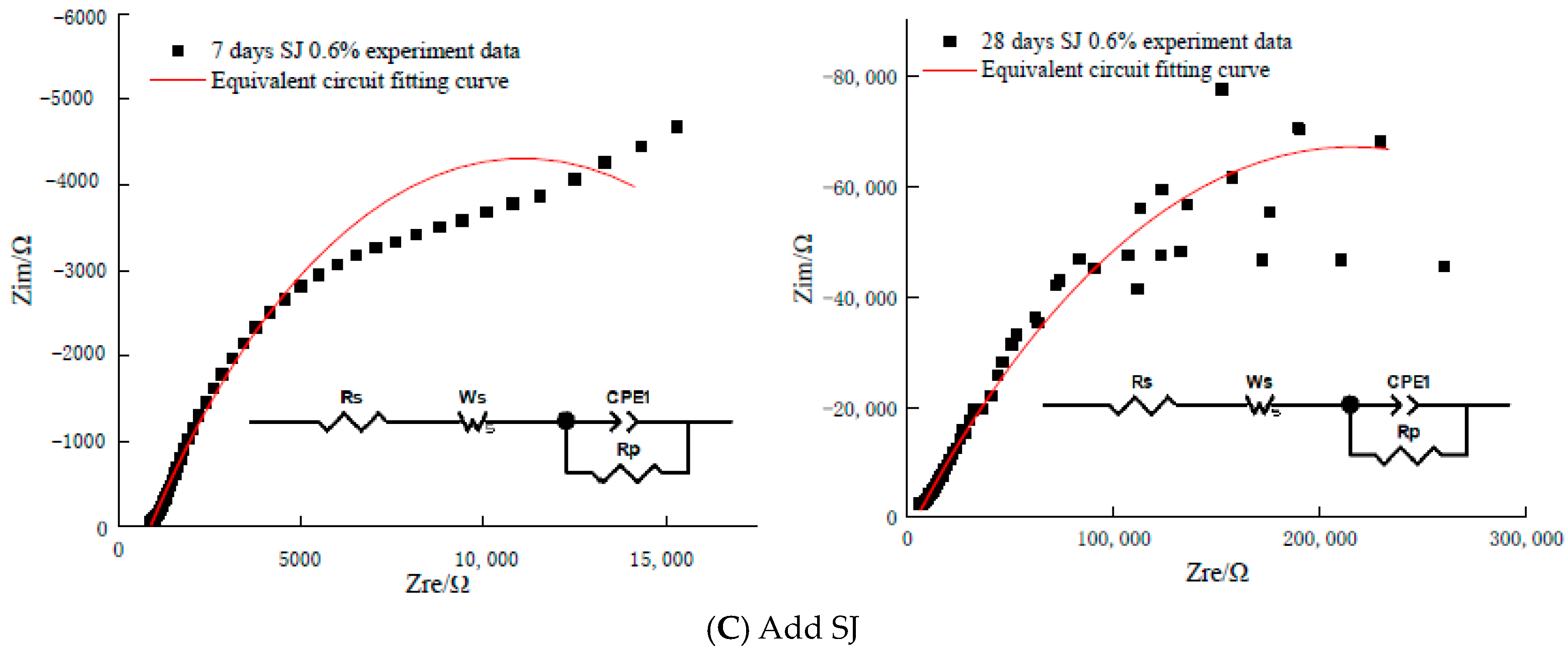

3.4. Equivalent Circuit Analysis of the AC Impedance

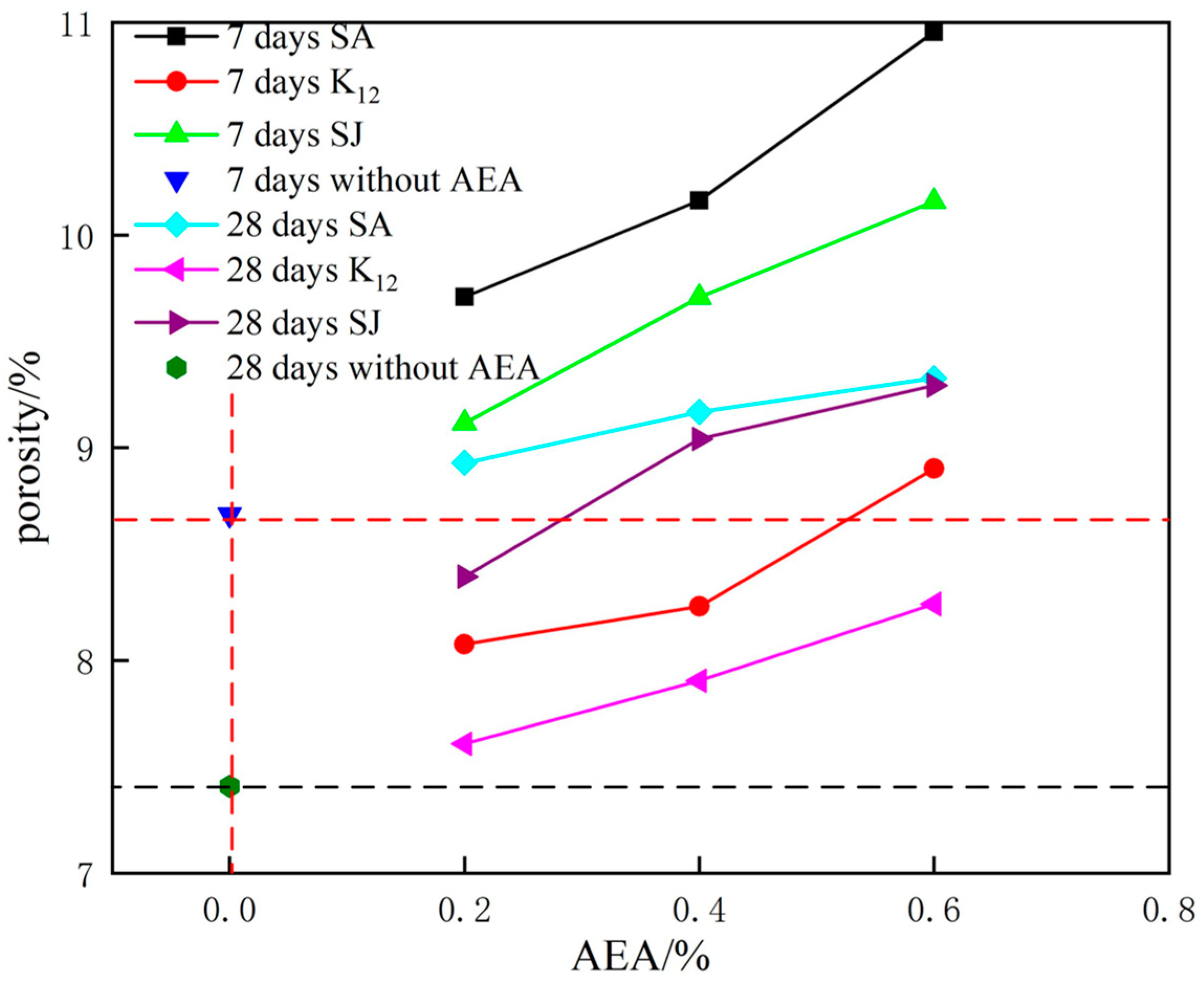

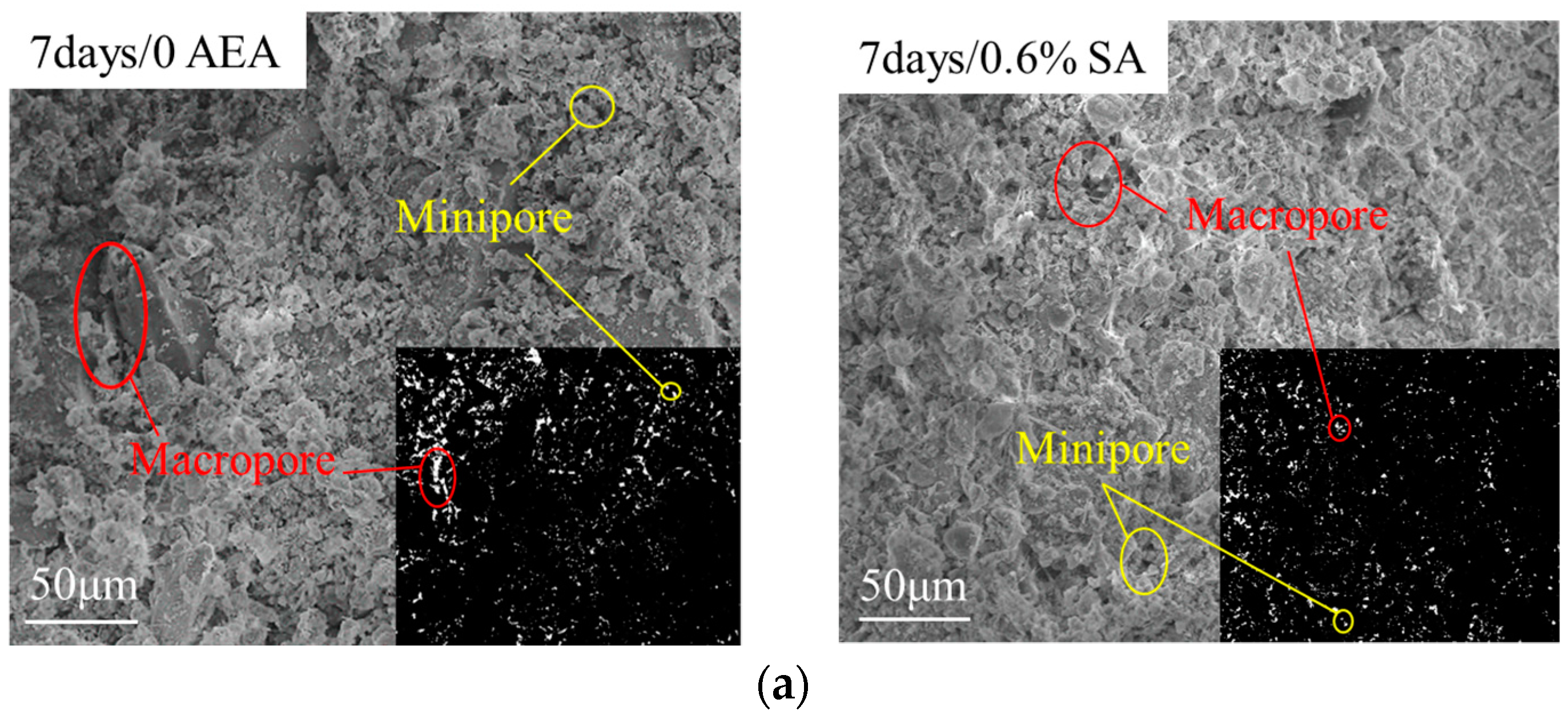

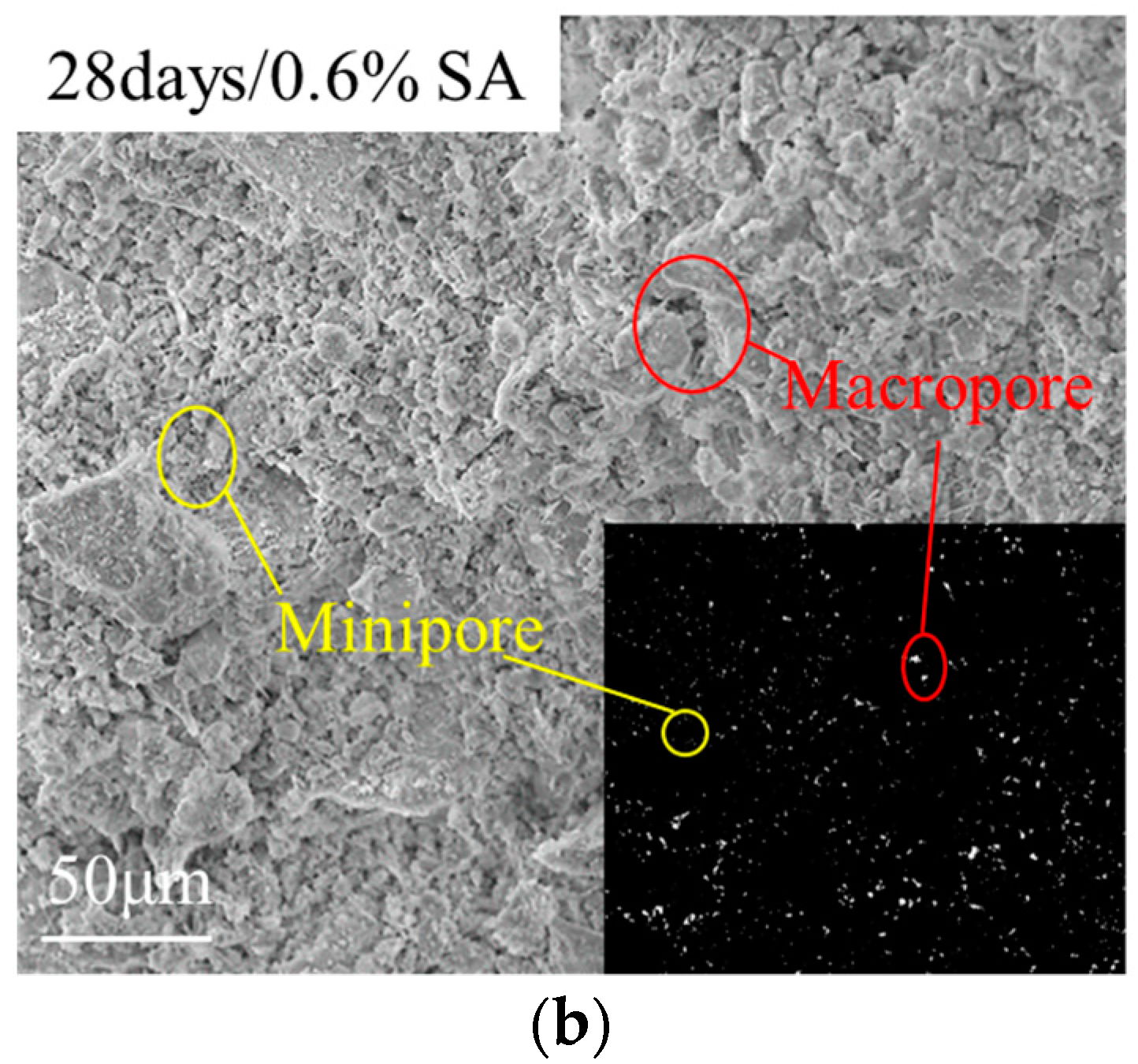

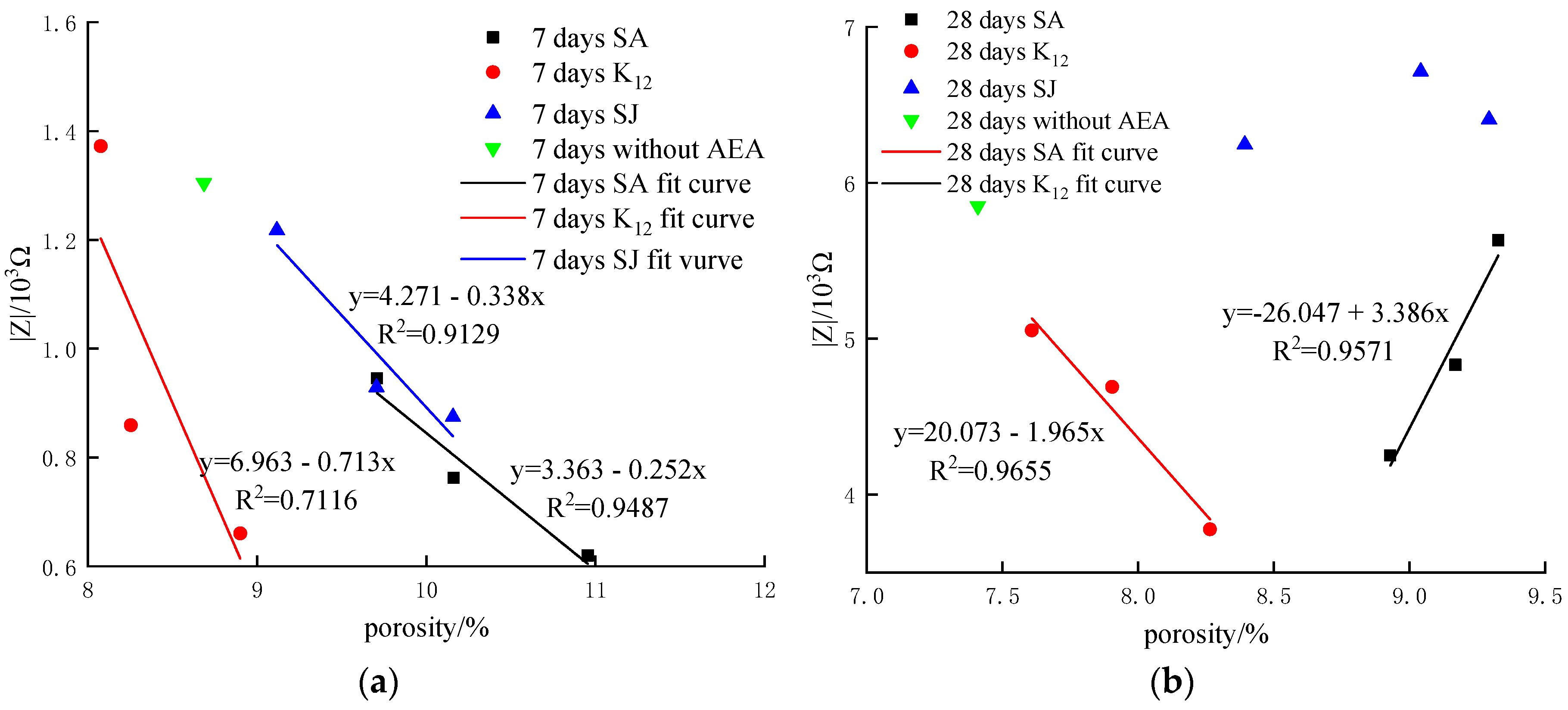

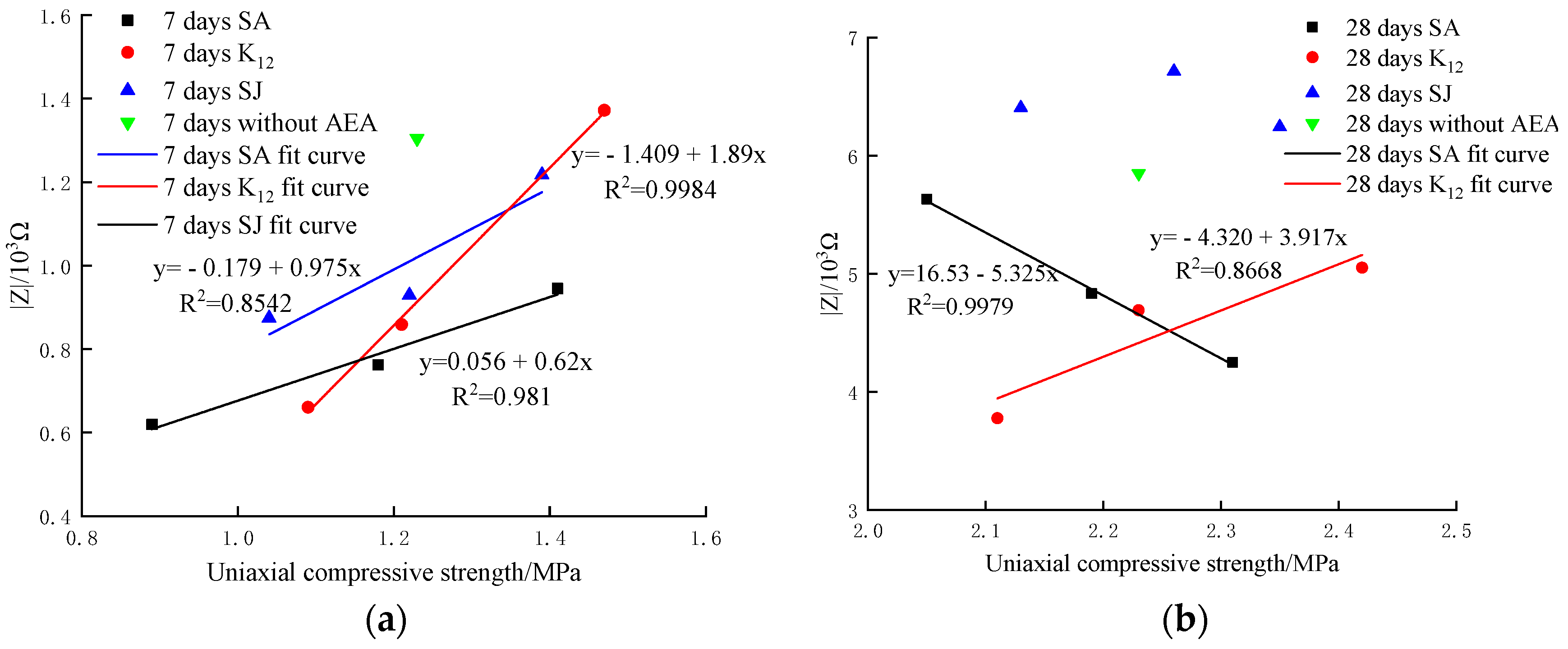

3.5. Analysis of the Porosity of the Filling Body

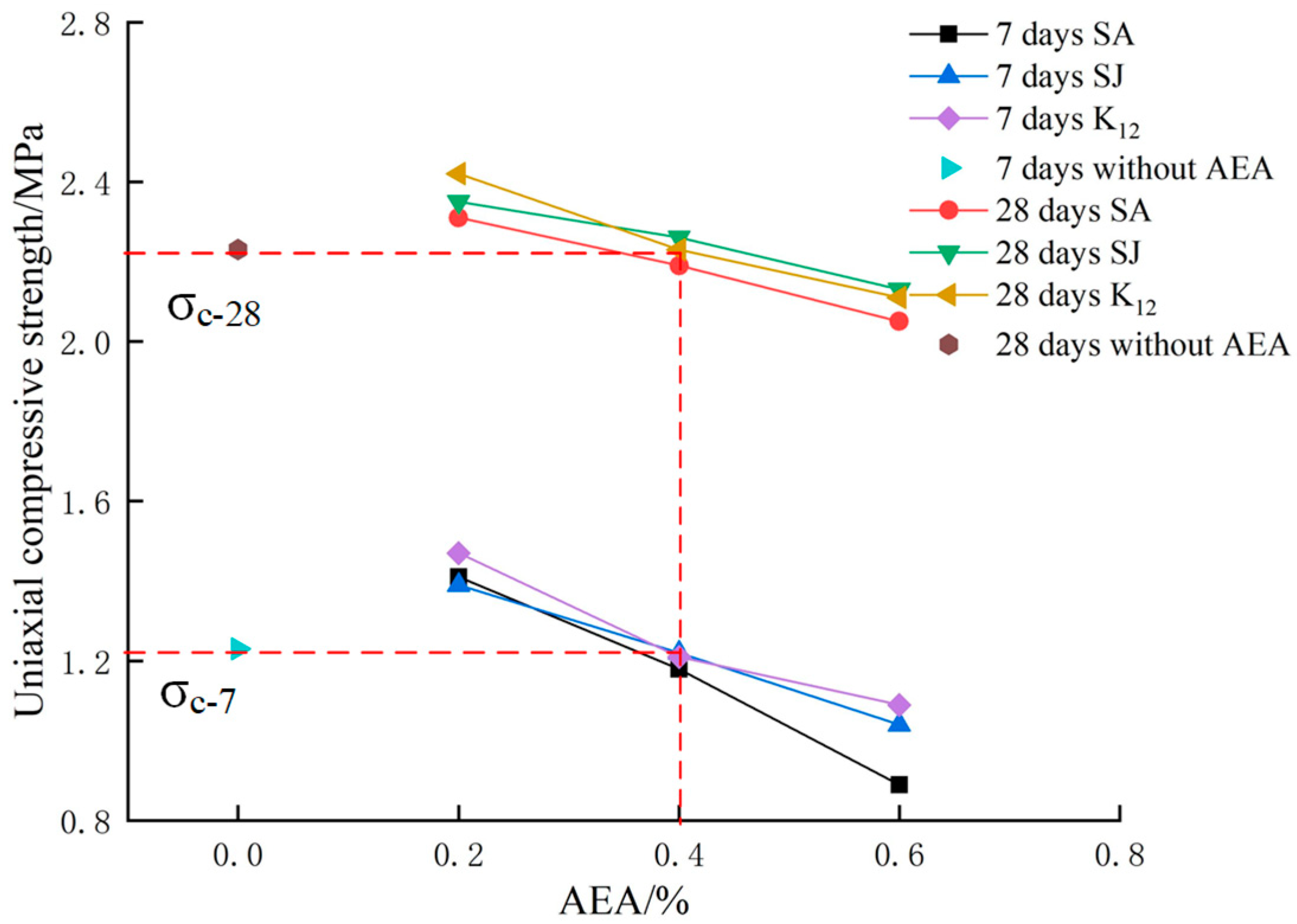

3.6. Analysis of the Strength of the Filling Body

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- McCarter, W.; Garvin, S.; Bouzid, N. Impedance measurements on cement paste. Mater. Sci. Lett. 1988, 7, 1056–1057. [Google Scholar] [CrossRef]

- Bruce, J.C.; Tate, C.; Rudolf, A.O.; Steven, J.F.; Edward, J.G.; Hamlin, M.J.; Thomas, O.M. Impedance spectroscopy of hydrating cement-based materials: Measurement, interpretation, and application. J. Am. Ceram. Soc. 2005, 77, 2789–2804. [Google Scholar]

- Keddam, M.; Takenouti, H.; Novoa, X.; Andrade, C.; Alonso, C. Impedance measurements on cement paste. Cem. Concr. Res. 1997, 27, 1191–1201. [Google Scholar] [CrossRef]

- Song, G. Equivalent circuit model for AC electrochemical impedance spectroscopy of concrete. Cem. Concr. Res. 2000, 30, 1723–1730. [Google Scholar] [CrossRef]

- Woo, L.; Wansom, S.; Hixson, A.; Campo, M.; Mason, T. A universal equivalent circuit model for the impedance response of composites. J. Mater. Sci. 2003, 38, 2265–2270. [Google Scholar] [CrossRef]

- Cruz, J.; Fita, I.; Soriano, L.; Payá, J.; Borrachero, M. The use of electrical impedance spectroscopy for monitoring the hydration products of Portland cement mortars with high percentage of pozzolans. Cem. Concr. Res. 2013, 50, 51–61. [Google Scholar] [CrossRef]

- Sánchez, I.; XNóvoa Vera, G.D.; Climent, M. Microstructural modifications in Portland cement concrete due to forced ionic migration tests. Study by impedance spectroscopy. Cem. Concr. Res. 2008, 38, 1015–1025. [Google Scholar] [CrossRef]

- Shi, C.; Stegeman, J.A.; Cadwell, R.J. Effect of supplementary cementing materials on the specific conductivity of pore solution and its implications on the rapid chloride permeability test (AASHTO T277and ASTM C1202) results. ACI Mater. J. 1998, 95, 389–394. [Google Scholar]

- Zhang, Y.; Shi, M.L. Study of the hydration process of cement-based materials by ac impedance technique. Chin. J. Build. Mater. 2000, 3, 109–112. [Google Scholar]

- Liu, C.S.; Shen, W.; Zheng, H.Y. AC impedance spectroscopy in the hydration process of calcium phosphate cement. J. Chin. Ceram. Soc. 1998, 26, 437–442. [Google Scholar] [CrossRef]

- Andrade, C.; Blanco, V.M.; Collazo, A.; Keddam, M.; Novoa, X.R.; Takenouti, H. Cement paste hardening process studied by impedance spectroscopy. Electrochim. Acta 1999, 44, 4313–4318. [Google Scholar] [CrossRef]

- Wansom, S.; Janjaturaphan, S. Evaluation of fiber orientation in plant fiber-cement composites using AC-impedance spectroscopy. Cem. Concr. Res. 2013, 45, 37–44. [Google Scholar] [CrossRef]

- Wu, L.; Dai, P.; Li, Y. Determination of the transport properties of structural concrete using AC impedance spectroscopy techniques. J. Eng. 2016, 10, 1–8. [Google Scholar] [CrossRef] [Green Version]

- McCarter, W.J.; Chrisp, T.M.; Starrs, G.; Adamson, A.; Basheer, P.A.M.; Nanukuttan, S.V.; Srinivasan, S.; Green, C. Characterization of physio-chemical processes and hydration kinetics in concretes containing supplementary cementitious materials using electrical property measurements. Cem. Concr. Res. 2013, 50, 26–33. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, Z.; Li, Y.; Li, Z. Effect of air entraining agent on uniaxial tensile properties of PVA-ECC. In Proceedings of the 3rd International Conference on Manufacturing, Material and Metallurgical Engineering, Kuala Lumpur, Malaysia, 17–19 March 2018; Volume 409, pp. 12–29. [Google Scholar]

- Şahin, R.; Polat, R.; İçelli, O.; Çelik, C. Determination of transmission factors of concretes with different water/cement ratio, curing condition, and dosage of cement and air entraining agent. Ann. Nucl. Energy 2011, 38, 1505–1511. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.; Taheri, A.; Deng, J.; Ke, B. Effects of superplasticizer on the hydration, consistency, and strength development of cemented paste backfill. Minerals 2018, 8, 381. [Google Scholar] [CrossRef] [Green Version]

- Shang, J.; Hu, J.; Zhou, K.; Luo, X.; Aliyu, M.M. Porosity increment and strength degradation of low-porosity sedimentary rocks under different loading conditions. Int. J. Rock Mech. Min. Sci. 2015, 75, 216–223. [Google Scholar] [CrossRef]

- GB/T 14685-2011. Pebble and Crushed Stone for Construction; National Standardization Administration of China: Beijing, China, 2011. [Google Scholar]

| Class | Apparent Density (kg/m3) | Packing Density (kg/m3) | Surface Moisture Content (%) |

|---|---|---|---|

| Gangue | 2626 | 1464 | 0.120 |

| Tailing | 2653 | 923 | 0.974 |

| Fly ash | 1990 | 650 | 0.049 |

| Sample | Hydroxyllapatite | Quartz | Hematite | Albite | Plagioclase | Muscovite | Illite | Dolomite |

|---|---|---|---|---|---|---|---|---|

| Gangue | 10.15 | 6.91 | 12.75 | - | - | - | - | 69.65 |

| Tailing | 60.94 | 2.24 | - | 8.38 | 11.42 | - | 9.76 | 6.30 |

| Fly Ash | - | 61.55 | 1.46 | 15.99 | - | 20.99 | - | - |

| Cement | 3CaO·SiO2 | 2CaO·SiO2 | 3CaO·Al2O3 | 4CaO·Al2O3·Fe2O3 | ||||

| 52.8 | 20.7 | 11.5 | 8.8 | |||||

| Chemical Agent | Appearance | PH |

|---|---|---|

| SA | White Powder | 10 |

| SJ | Pale yellow powder | 6 |

| K12 | White Powder | 6.5 |

| Code | Gangue | Tailing | Fly Ash | Cement | Water | SA | SJ | K12 |

|---|---|---|---|---|---|---|---|---|

| kg/m3 | % | |||||||

| 0%AEA | 1500 | 400 | 200 | 150 | 562 | - | - | - |

| SA | 1500 | 400 | 200 | 150 | 562 | 0.2 | - | - |

| SA | 1500 | 400 | 200 | 150 | 562 | 0.4 | - | - |

| SA | 1500 | 400 | 200 | 150 | 562 | 0.6 | - | - |

| SJ | 1500 | 400 | 200 | 150 | 562 | - | 0.2 | - |

| SJ | 1500 | 400 | 200 | 150 | 562 | - | 0.4 | - |

| SJ | 1500 | 400 | 200 | 150 | 562 | - | 0.6 | - |

| K12 | 1500 | 400 | 200 | 150 | 562 | - | - | 0.2 |

| K12 | 1500 | 400 | 200 | 150 | 562 | - | - | 0.4 |

| K12 | 1500 | 400 | 200 | 150 | 562 | - | - | 0.6 |

| Group | Time | Rs | W1-R | W1-T | W1-P | CPE1-T | CPE1-P | Rp | Chi-Squre Test/% |

|---|---|---|---|---|---|---|---|---|---|

| SA | 7day | 560.2 | 196.6 | 4.48 × 10−4 | 0.322 | 5.05 × 10−5 | 0.629 | 22466 | 0.22 |

| K12 | 7day | 637.1 | 151.2 | 1.48 × 10−4 | 0.357 | 1.07 × 10−4 | 0.556 | 10882 | 0.43 |

| SJ | 7day | 652 | 346.5 | 9.07 × 10−6 | 0.1938 | 3.22 × 10−5 | 0.549 | 18127 | 0.33 |

| SA | 28day | 2365 | 5206 | 9.76 × 10−6 | 0.329 | 3.63 × 10−6 | 0.388 | 3.66 × 105 | 0.15 |

| K12 | 28day | 2043 | 3498 | 2.76 × 10−6 | 0.235 | 5.72 × 10−6 | 0.449 | 3.489 × 105 | 0.34 |

| SJ | 28day | 2688 | 2.92 × 105 | 4.933 | 0.292 | 1.21 × 10−6 | 0.836 | 40155 | 0.46 |

| Parameter/% | Porosity/% | |Z|/Ω | |

|---|---|---|---|

| 104 HZ | 105 HZ | ||

| 0 | 8.686 | 1538.2 | 1304.5 |

| 0.2 | 9.708 | 1218.3 | 945.42 |

| 0.4 | 10.161 | 841.84 | 762.33 |

| 0.6 | 10.955 | 701.21 | 619.86 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Y.; Hu, J.; Yang, D.; Kuang, Y.; Zhao, F.; Zhou, T. Optimization of Transport Performance and Strength of the Filling Slurry in Tailings Reservoir Waste by Adding Air Entraining Agent. Minerals 2020, 10, 730. https://doi.org/10.3390/min10090730

Qin Y, Hu J, Yang D, Kuang Y, Zhao F, Zhou T. Optimization of Transport Performance and Strength of the Filling Slurry in Tailings Reservoir Waste by Adding Air Entraining Agent. Minerals. 2020; 10(9):730. https://doi.org/10.3390/min10090730

Chicago/Turabian StyleQin, Yaguang, Jianhua Hu, Dongjie Yang, Ye Kuang, Fengwen Zhao, and Tan Zhou. 2020. "Optimization of Transport Performance and Strength of the Filling Slurry in Tailings Reservoir Waste by Adding Air Entraining Agent" Minerals 10, no. 9: 730. https://doi.org/10.3390/min10090730

APA StyleQin, Y., Hu, J., Yang, D., Kuang, Y., Zhao, F., & Zhou, T. (2020). Optimization of Transport Performance and Strength of the Filling Slurry in Tailings Reservoir Waste by Adding Air Entraining Agent. Minerals, 10(9), 730. https://doi.org/10.3390/min10090730