Production of a Phosphate Concentrate from the Tailings of a Niobium Ore Concentrator

Abstract

1. Introduction

2. Materials and Methods

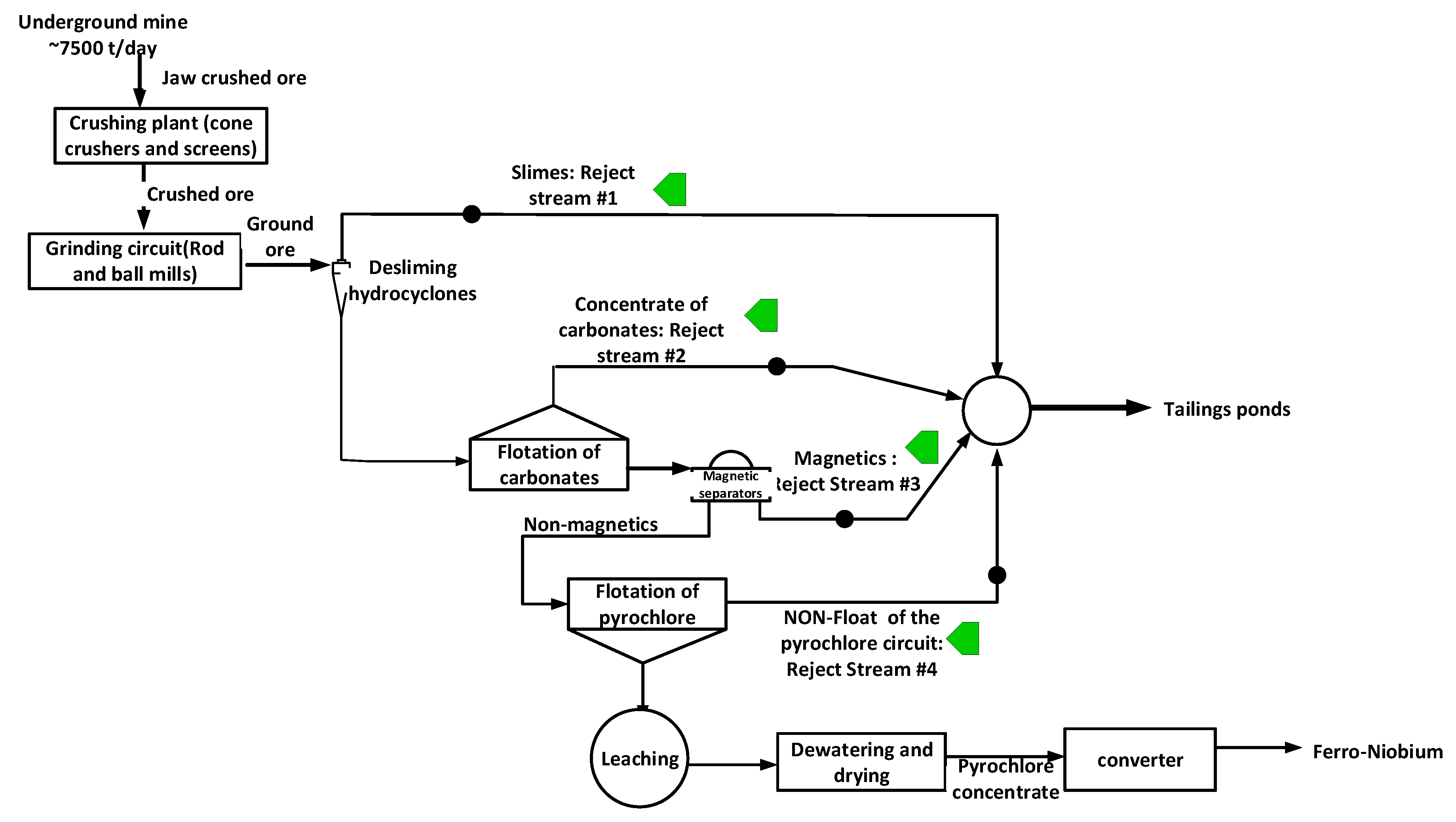

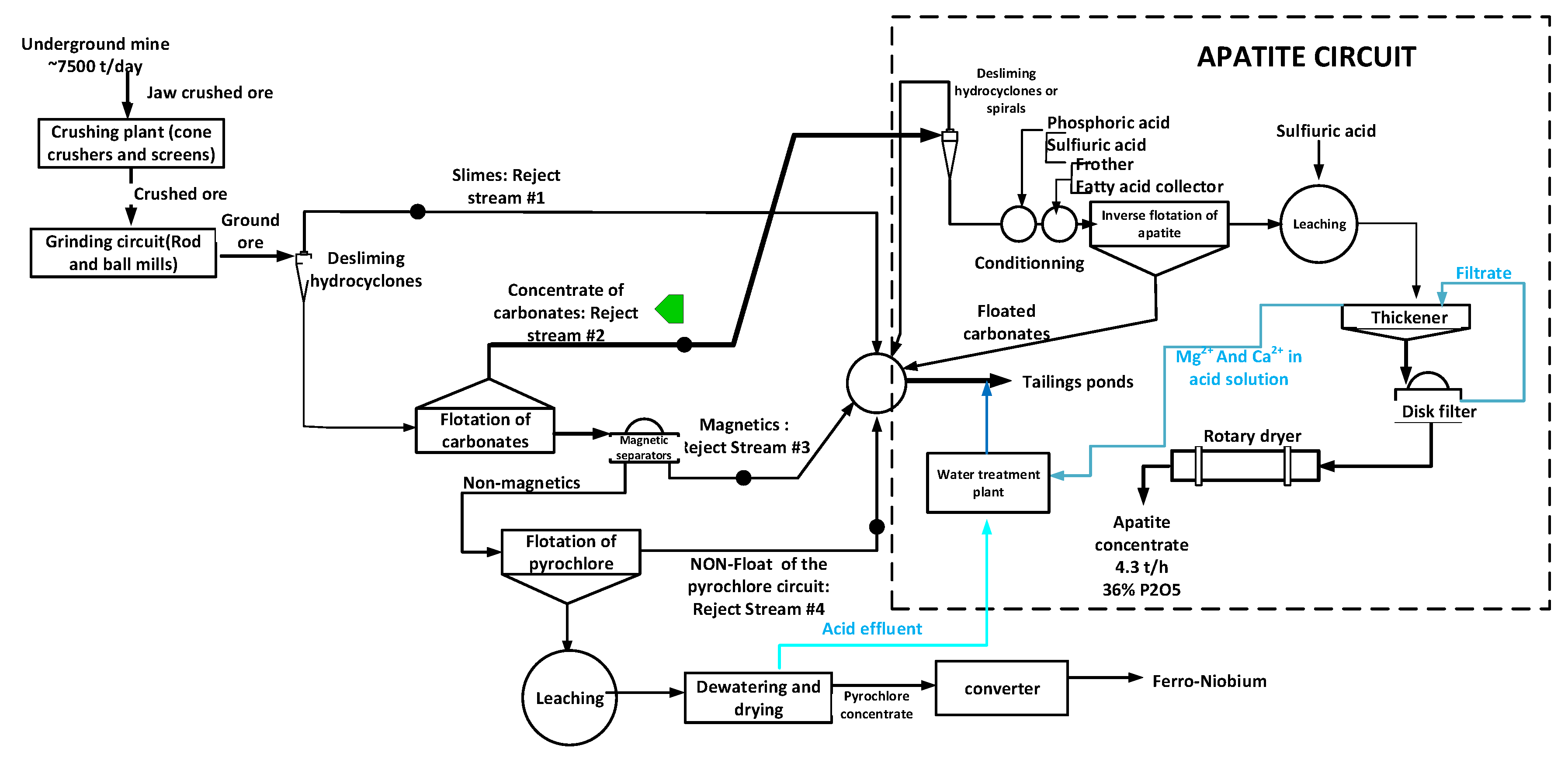

2.1. Source of the Tailings for the Beneficiation of Apatite

- To produce a phosphate concentrate to be spread directly on top of the agricultural fields [13].

- To maximize the plus-value of the product by producing a phosphate concentrate for the market of chemical fertilizers.

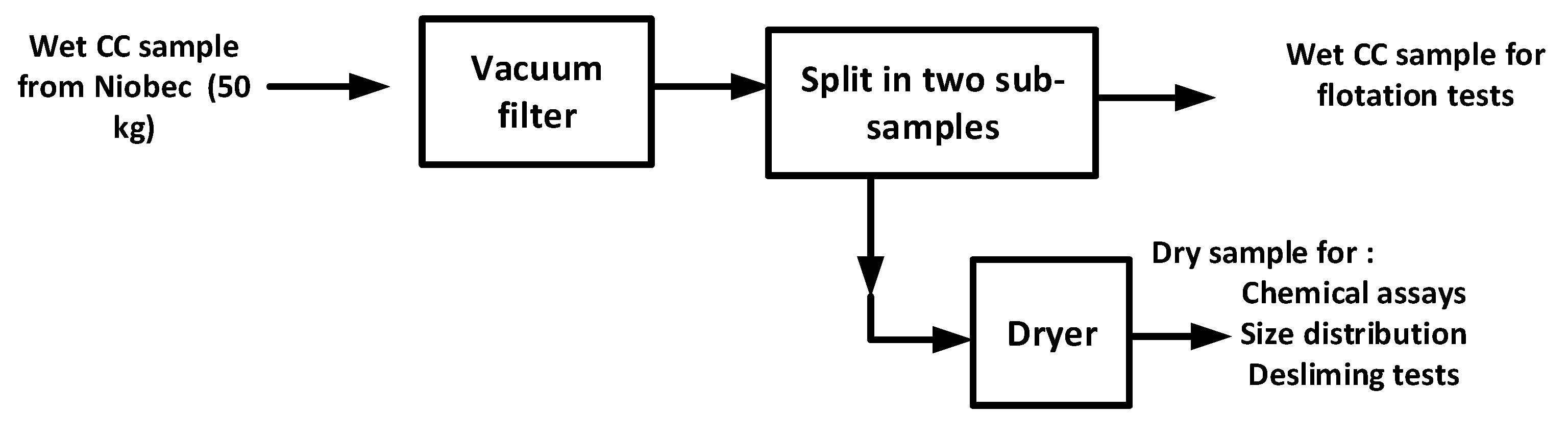

2.2. Sample Preparation and Characterization, Methods of Analysis

2.2.1. Sample Characterization

2.2.2. Analysis Instruments

2.2.3. Flotation Equipment

2.3. Mineral Composition and Phosphate Content as a Function of Particle Size

3. Experimentation and Results

3.1. Pre-Concentration of Apatite

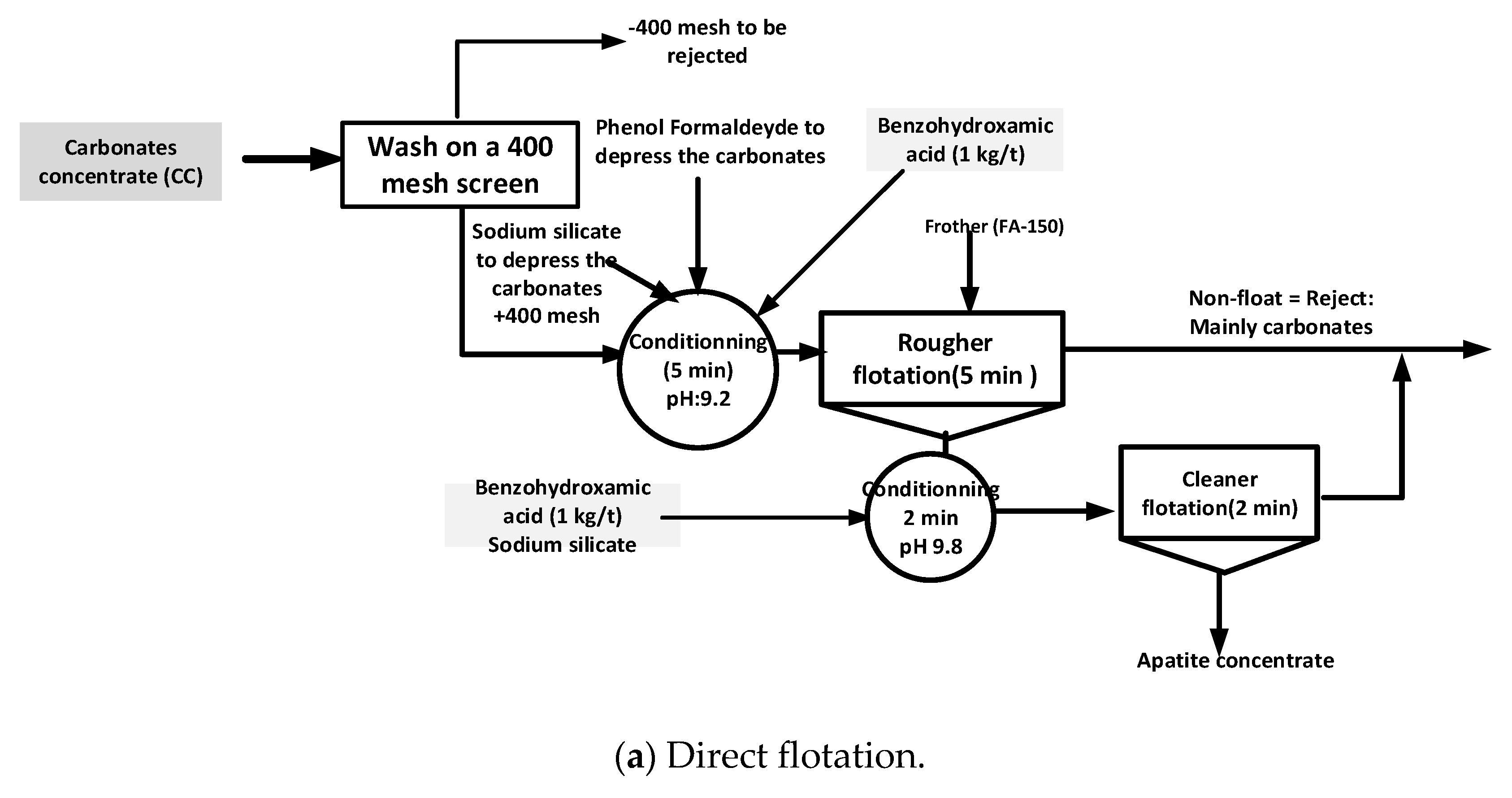

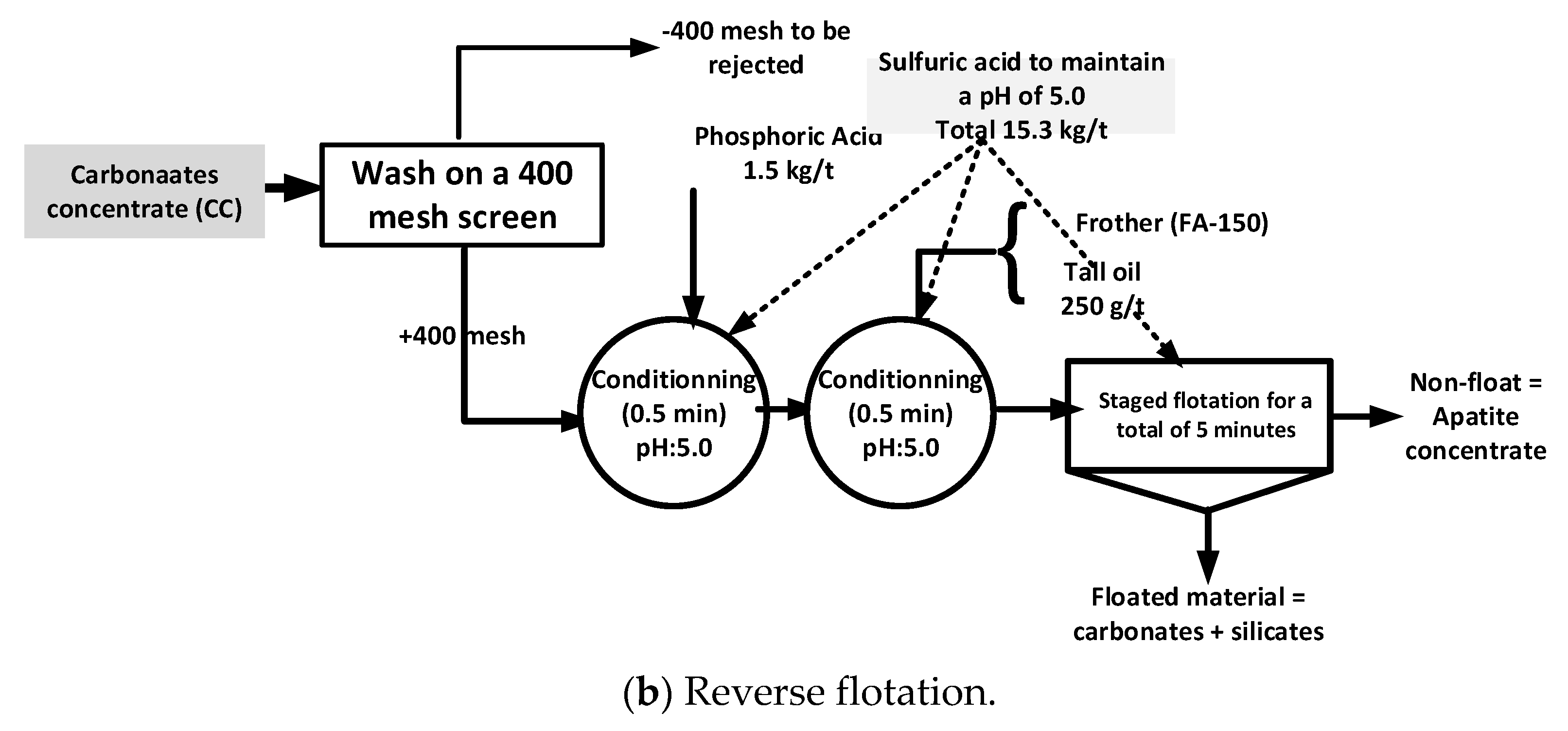

3.2. Apatite Concentration by Flotation

- Reverse flotation for which apatite is depressed and the gangue minerals are floated [23].

3.2.1. Direct Flotation of Apatite

3.2.2. Reverse Flotation of Apatite

- A lower demand and cost for the flotation reagents, particularly the collector used (i.e., benzohydroxamic acid) for the direct flotation of apatite.

- A better rejection of MgO from the apatite concentrate.

- A simple flowsheet (lower Capex) with only one flotation stage.

3.3. Leaching of the Apatite Concentrate

3.4. Overall Process for the Production of a Phosphate Concentrate

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nielsson, F.T. Manual of Fertilizer Processing, (vol. Fertilizer Science and Technology Series); Marcel Dekker: New York, NY, USA, 1987. [Google Scholar]

- Houot, R. Beneficiation of phosphatic ores through flotation: Review of industrial applications and potential developments. Int. J. Miner. Proc. 1982, 9, 352–384. [Google Scholar] [CrossRef]

- Feng, D.; Aldrich, C. Influence of operating parameters on the flotation of apatite. Miner. Eng. 2004, 17, 453–455. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Y.; Liu, T.; Cai, Z.; Sun, K. Characterization and separation studies of a fine sedimentary phosphate ore slime. Minerals 2017, 7, 94–102. [Google Scholar] [CrossRef]

- Matiolo, E.; Bianquini Couto, H.J.; de Lira Teixeira, M.F.; de Almeida, R.N.; de Freitas, A.S. A comparative study of different columns sizes for ultrafine apatite flotation. Minerals 2019, 9, 391. [Google Scholar] [CrossRef]

- Dehghani, A.; Azizi, A.; Moitshedzadeh, S.H.; Gharibi, K. Optimizing rougher flotation parameters of the Esfordi Phosphate ore. Miner. Process. Extr. Metall. Rev. 2012, 33, 260–268. [Google Scholar] [CrossRef]

- Ripley, E.A.; Redmann, R.E.; Crowder, A.A. Environmental Effects of Mining; St-Lucie Press: Delry Beach, FL, USA, 1996. [Google Scholar]

- Oliveira, M.S.; Santana, R.C.; Ataide, C.H.; BArrazo, M.A. Recovery of apatite from flotation tailings. Sep. Purif. Technol. 2011, 79, 79–84. [Google Scholar] [CrossRef]

- Paiement, J.-P.; Gagné, J.; Duplessis, C.; Rousseau, G.; Gagnon, G.; Dagbert, M.; SGS Canada Inc. Pre-Feasibility Study; Mine Arnaud Inc.: Blainville, QC, Canada, 2013; 377p. [Google Scholar]

- Sis, H.; Chander, S. Reagents used in the flotation of phosphate ores, a critical review. Miner. Eng. 2003, 16, 577–585. [Google Scholar] [CrossRef]

- Rabi, R.; Gendron, L.A.; Robert, M.; Gagnon, G.; Pichette, M.; Lafrenière, G. The Niobec conentrator. In Milling Practice in Canada; Pickett, D.E., Ed.; The Canadian Institute of Mining and Metallurgy: Westmount, QC, Canada, 1978; Volume 16, pp. 329–332. [Google Scholar]

- Ni, X.; Parent, M.; Cao, M.; Huang, L.; Bouagila, A.; Liu, Q. Developing flotation reagents for niobium oxide recovery from carbonatite Nb ores. Miner. Eng. 2012, 36–38, 111–118. [Google Scholar] [CrossRef]

- Savard, J.Y. Étude de Mise en Valeur de rejets de Carbonate-Apatite de la Mine Niobec dans le but d’une Utilisation Comme Engrais en Agriculture. Ph.D. Thesis, Université du Québec à Chicoutimi, Chicoutimi, QC, Canada, 1981. [Google Scholar]

- Kawatra, K.S.; Carlson, J.T. Beneficiation of Phosphate Ore; SME: New York, NY, USA, 2013. [Google Scholar]

- Hignett, T.P. Fertilizer Manual, Dordrecht. In Fertilizer Development Center, and Organización de las Naciones Unidas para Desarrollo Industrial (Unido & IFDC); Klumer Academic Publishers: Berlin, Germany, 1998. [Google Scholar]

- Hodouin, D.; Everell, M.D. A hierarchical procedure for adjustment and material balancing of mineral processes data. Int. J. Miner. Process. 1980, 7, 91–116. [Google Scholar] [CrossRef]

- Whiten, B. Calculation of mineral composition from chemical assays. Miner. Process. Extr. Metall. Rev. 2008, 29, 83–97. [Google Scholar] [CrossRef]

- Clapperton, A. Valorisation des Résidus de la Mine Niobec. Master’s Thesis, Université Laval, Québec, QC, Canada, 2018. [Google Scholar]

- Sadeghi, M.; Bazin, C.; Renaud, M. Effect of wash water on the mineral size recovery curves in a spiral concentrator used for iron ore processing. Int. J. Miner. Process. 2014, 129, 22–26. [Google Scholar] [CrossRef]

- Bazin, C.; Sadeghi, M.; Bourassa, M.; Roy, P.; Lavoie, F.; Cataford, D.; Gosselin, C. Size recovery curves of minerals in industrial spirals for processing iron oxide ores. Miner. Eng. 2014, 65, 115–123. [Google Scholar] [CrossRef]

- Tripathy, S.K.; Murthy, Y.R. Multi objective optimisation of spiral concentrator for separation of ultrafine chromite. Int. J. Min. Miner. Eng. 2012, 4, 151–162. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Y.; Liu, T.; Cai, Z.; Chen, T.; Sun, K. Beneficiation of a sedimentary phosphate ore by a combination of spiral gravity and direct-reverse flotation. Minerals 2016, 6, 38. [Google Scholar] [CrossRef]

- Mohammadkhani, M.; Noaparast, M.; Shafaei, S.Z.; Amini, A.; Amini, E.; Abdollahi, H. Double reverse flotation of very low grade sedimentary phosphate rock, rich in carbonate and silicate. Int. J. Miner. Process. 2011, 100, 157–165. [Google Scholar] [CrossRef]

- Bulatovic, S.M. Handbook of Flotation Reagents: Chemistry, Theory and Practice; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Abu-Eishah, S.I.; Muthraker, M.; Touqan, N. A new technique for the beneficiation of low carbonate-rich phosphate rocks by digestion with dilute acetic acid solutions: Pilot plant testing results. Miner. Eng. 1991, 4, 573–586. [Google Scholar] [CrossRef]

- Dalencourt, C.; Michaud, A.; Habibi, A.; Leblanc, A.; Larivière, D. Rapid, versatile and sensitive method for the quantification of radium in environmental samples through cationic extraction and inductively coupled plasma mass spectrometry. J. Anal. At. Spectrom. 2018, 33, 1031–1040. [Google Scholar] [CrossRef]

- Rock Phosphate Monthly Price. Available online: www.indexmundi.com/commodities/?commodity=rock-phosphate&months=60 (accessed on 3 August 2020).

| Stream | Reject Stream # | Weight Distribution from Mill Feed (%) | Apatite Distribution from Mill Feed (%) | P2O5 Content * (%) |

|---|---|---|---|---|

| Slimes | 1 | 13 | 10 | 2.3 |

| CC | 2 | 25 | 42.5 | 5.1 |

| Magnetic concentrate | 3 | 3 | 0.4 | 0.43 |

| Reject of the pyrochlore circuit | 4 | 58 | 45.5 | 2.3 |

| Species | Acceptable Range |

|---|---|

| P2O5 | >30% |

| %CaO/%P2O5 | <1.6 |

| MgO | <1.0% |

| Al2O3 | <5.0% |

| Fe2O3 | ~2–3% |

| SiO2 | ~2.0% |

| Cl | <0.1% |

| Na-K | 0.1–0.8% |

| Mineral | % |

|---|---|

| Calcite | 36 ± 5 |

| Dolomite | 39 ± 8 |

| Ankerite | 9 ± 5 |

| Total carbonates | 84 ± 15 |

| Apatite | 12 ± 3 |

| Silicates | 2 ± 0.7 |

| Other | 2 ± 1.5 |

| Particle Size (μm) | % Retained | % P2O5 | Cumulative % P2O5 | Distribution % |

|---|---|---|---|---|

| Head | 100 | 5.0 ± 1.2 | ||

| 106/150 | 1 ± 0.4 | 25.5 ± 3.2 | 25.5 ± 3.2 | 5 ± 1 |

| 75/106 | 3.3 ± 1.1 | 17.7 ± 1.6 | 19.9 ± 2.9 | 11 ± 2 |

| 54/75 | 9.5 ± 1.2 | 7.9 ± 1.1 | 11.4 ± 2.1 | 15 ± 4 |

| 38/54 | 29 ± 3.1 | 4.3 ± 0.9 | 6.6 ± 1.8 | 25 ± 7 |

| <38 | 57.4 ± 5.2 | 3.8 ± 0.8 |

| Flux | Hydrocyclone Desliming * (Statistics on 4 Replicate) | Spiral Desliming ** (Statistics on 4 Replicates) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Weight (%) | %P2O5 | P2O5 Distribution (%) | %MgO | MgO Distribution (%) | Weight (%) | %P2O5 | P2O5 Distribution (%) | %MgO | MgO Distribution (%) | |

| Feed | 100 | 5.1 ± 0.8 | 100.0 | 12.3 ± 1.2 | 100.0 | 100.0 | 5.62 ± 0.5 | 100.0 | 12.5 | 100.0 |

| Reject | 85.8 | 5.0 ± 1.0 | 83.6 ± 0.4 | 12.5 ± 1.3 | 87.2 ± 0.9 | 84.7 | 5.4 ± 0.5 | 81.7 ± 2 | 12.7 ± 0.8 | 85.9 ± 1.1 |

| Pre concentrate | 14.2 | 5.9 ± 0.8 | 16.4 ± 3.0 | 11.1 ± 0.9 | 12.82 ± 0.7 | 15.3 | 6.7 ± 0.7 | 18.3 ± 0.7 | 11.5 ± 0.9 | 14.1 ± 0.5 |

| Content (%w/w) | Distribution (%) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stream | mass (g) | MgO | Al2O3 | SiO2 | P2O5 | CaO | Fe2O3 | wt.% | MgO | Al2O3 | SiO2 | P2O5 | CaO | Fe2O3 |

| Feed | 450.0 | 10.75 | 0.04 | 0.07 | 7.74 | 35.6 | 4.4 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Rougher concentrate | 173.3 | 8.73 | 0.06 | 0.01 | 17.13 | 35.3 | 3.07 | 38.5 | 31.3 | 57.8 | 5.5 | 85.2 | 38.2 | 26.9 |

| Cleaner concentrate | 49.5 | 8.18 | 0.07 | 0.01 | 21.43 | 35.5 | 2.75 | 11.0 | 8.4 | 19.3 | 1.6 | 30.5 | 11.0 | 6.9 |

| Rougher taillings | 276.8 | 12.01 | 0.02 | 0.1 | 1.86 | 35.8 | 5.23 | 61.5 | 68.7 | 30.8 | 87.9 | 14.8 | 61.8 | 73.1 |

| Cleaner taillings | 123.8 | 8.95 | 0.06 | 0.01 | 15.42 | 35.2 | 3.2 | 27.5 | 22.9 | 41.3 | 3.9 | 54.8 | 27.2 | 20.0 |

| Content (%) | Distribution (%) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stream | mass (g) | MgO | Al2O3 | SiO2 | P2O5 | CaO | Fe2O3 | wt.% | MgO | Al2O3 | SiO2 | P2O5 | CaO | Fe2O3 |

| Feed | 525 | 11.46 | 0.05 | 0.15 | 8.62 | 33.38 | 4.45 | 100 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Rougher floated material | 370 | 14.86 | 0.01 | 0.09 | 0.75 | 33.95 | 5.46 | 70.5 | 91.4 | 14.1 | 42.3 | 6.1 | 71.7 | 86.5 |

| Rougher non-floated material | 155 | 3.33 | 0.15 | 0.29 | 27.43 | 32.02 | 2.04 | 29.5 | 8.6 | 85.9 | 57.7 | 93.9 | 28.3 | 13.5 |

| Species | Reverse Flotation Concentrate | Final Phosphate Concentrate | Target for a Commercial Concentrate |

|---|---|---|---|

| Weight % | 100 | 74.4 | |

| %MgO | 3.63 ± 0.6 | 0.45 ± 0.05 | <1% |

| %Al2O3 | 0.19 ± 0.05 | 0.21 ± 0.03 | <2% |

| %P2O5 | 27.32 ± 2.3 | 36.4 ± 2.9 | >30% |

| %SiO2 | 0.35 ± 0.05 | 0.4 ± 0.05 | <2% |

| %CaO | 32.4 ± 3.1 | 31.7 ± 2.9 | |

| %Fe2O3 | 2.12 ± 0.9 | 0.96 ± 0.10 | <2% |

| %CaO/%P2O5 | 1.2 ± 0.4 | 0.9 ± 0.2 | <1.6 |

| Content (%) | ||

|---|---|---|

| Species | Reverse Flotation Concentrate | Final Phosphate Concentrate |

| Apatite | 65 ± 4 | 86 ± 3.7 |

| Dolomite | 16 ± 3 | 2 ± 0.9 |

| Ankerite | 9 ± 2 | 5 ± 1.5 |

| Calcite | <1 | <1 |

| Processing Step | Condition | Alternative | Remark |

|---|---|---|---|

| Desliming | Hydrocyclone 5 cm diameter 0.5 cm apex Feed% solids: 15% Pressure: 140 kPa. | Spiral WWWPlus 70 cm diameter 20 L/min wash water Feed% solids: 15% | Lot of room for optimizing the process |

| Flotation | Inverse pH: 4.5 Depressant: 1.5 kg/t of H3PO4 pH modifier: H2SO4 Collector: 450 g/t of tall oil (Sylfat FA-2) Frother; 15 g/t of MIBC Flotation time (7 min) | Important consumption of H2SO4 due to the carbonates | |

| Leaching | Acid: H2SO4 Maintain a pH of 3.0 during 30 min |

| Item | $ US/ton Concentrate | % |

|---|---|---|

| Pre-concentration | 1.83 $ | 1.3 |

| Reagents | 103.86 $ | 72.3 |

| Energy | 8.38 $ | 5.8 |

| Working capital | 2.65 $ | 1.8 |

| Salaries | 21.97 $ | 15.3 |

| Concentrate dewatering & shipping | 4.95 $ | 3.4 |

| Total | 143.63 $ | 100 |

| Revenues per ton | 151.20 $ | |

| UnItary profit | 7.57 $ |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Clapperton, A.; Bazin, C.; Downey, D.; Marois, J.-S. Production of a Phosphate Concentrate from the Tailings of a Niobium Ore Concentrator. Minerals 2020, 10, 692. https://doi.org/10.3390/min10080692

Clapperton A, Bazin C, Downey D, Marois J-S. Production of a Phosphate Concentrate from the Tailings of a Niobium Ore Concentrator. Minerals. 2020; 10(8):692. https://doi.org/10.3390/min10080692

Chicago/Turabian StyleClapperton, Anthony, Claude Bazin, Dominic Downey, and Jean-Sébastien Marois. 2020. "Production of a Phosphate Concentrate from the Tailings of a Niobium Ore Concentrator" Minerals 10, no. 8: 692. https://doi.org/10.3390/min10080692

APA StyleClapperton, A., Bazin, C., Downey, D., & Marois, J.-S. (2020). Production of a Phosphate Concentrate from the Tailings of a Niobium Ore Concentrator. Minerals, 10(8), 692. https://doi.org/10.3390/min10080692