Picosecond Acoustics Technique to Measure the Sound Velocities of Fe-Si Alloys and Si Single-Crystals at High Pressure

Abstract

1. Introduction

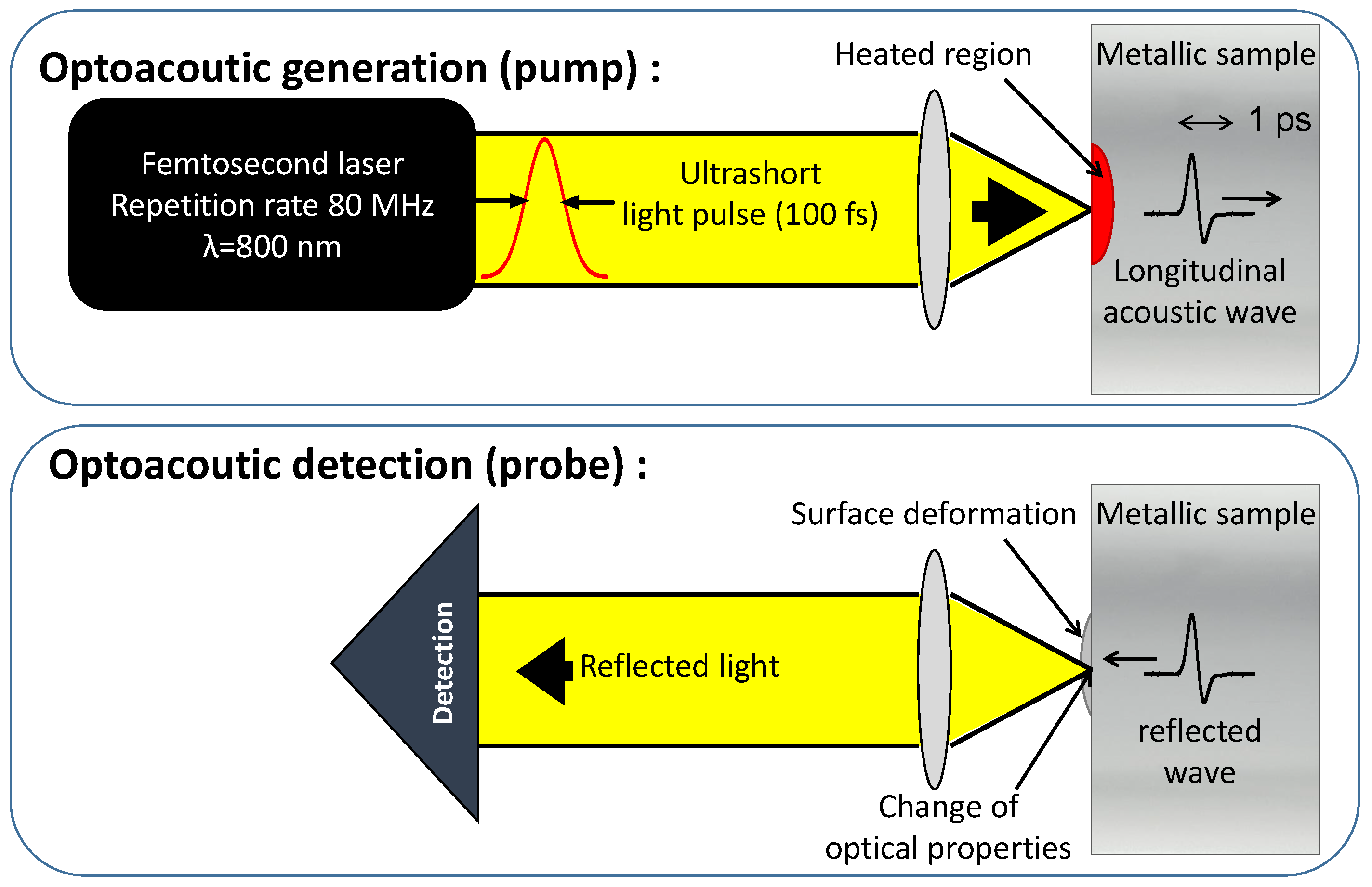

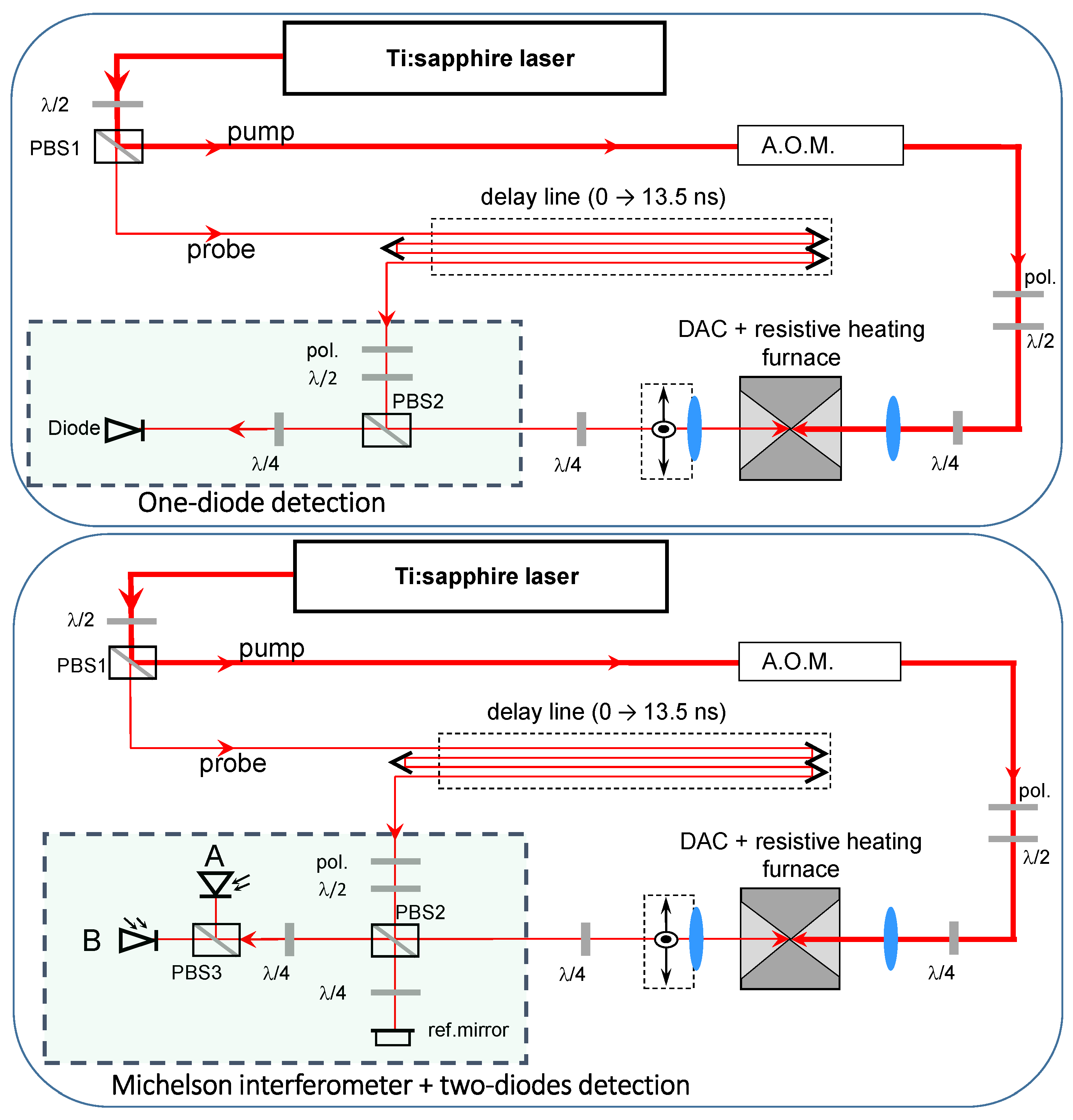

2. Measuring Techniques

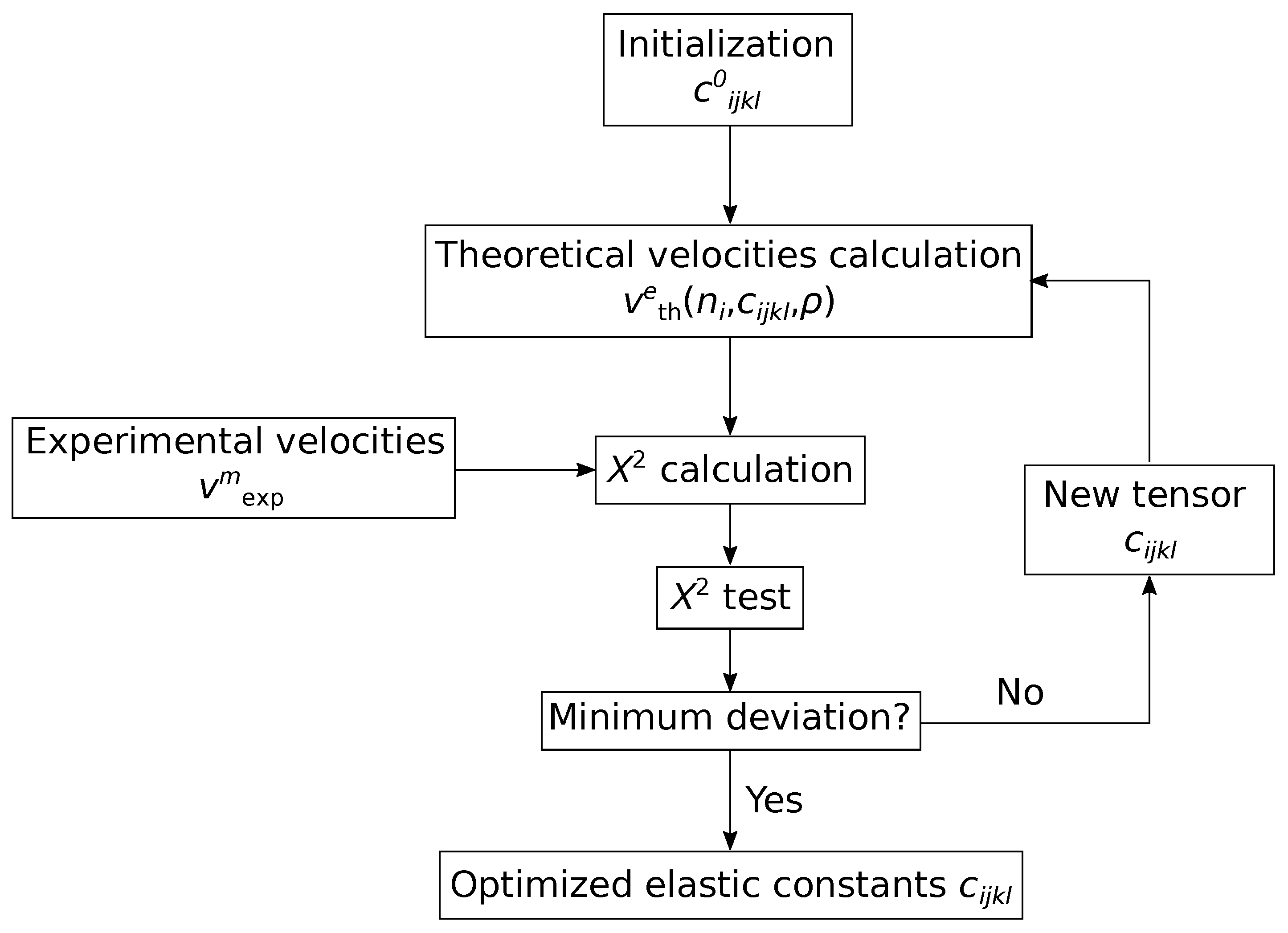

Picosecond Acoustics in Diamond Anvil Cells: A Complementary Acoustic Technique for Sound Velocity Measurements at High Pressure and Temperature

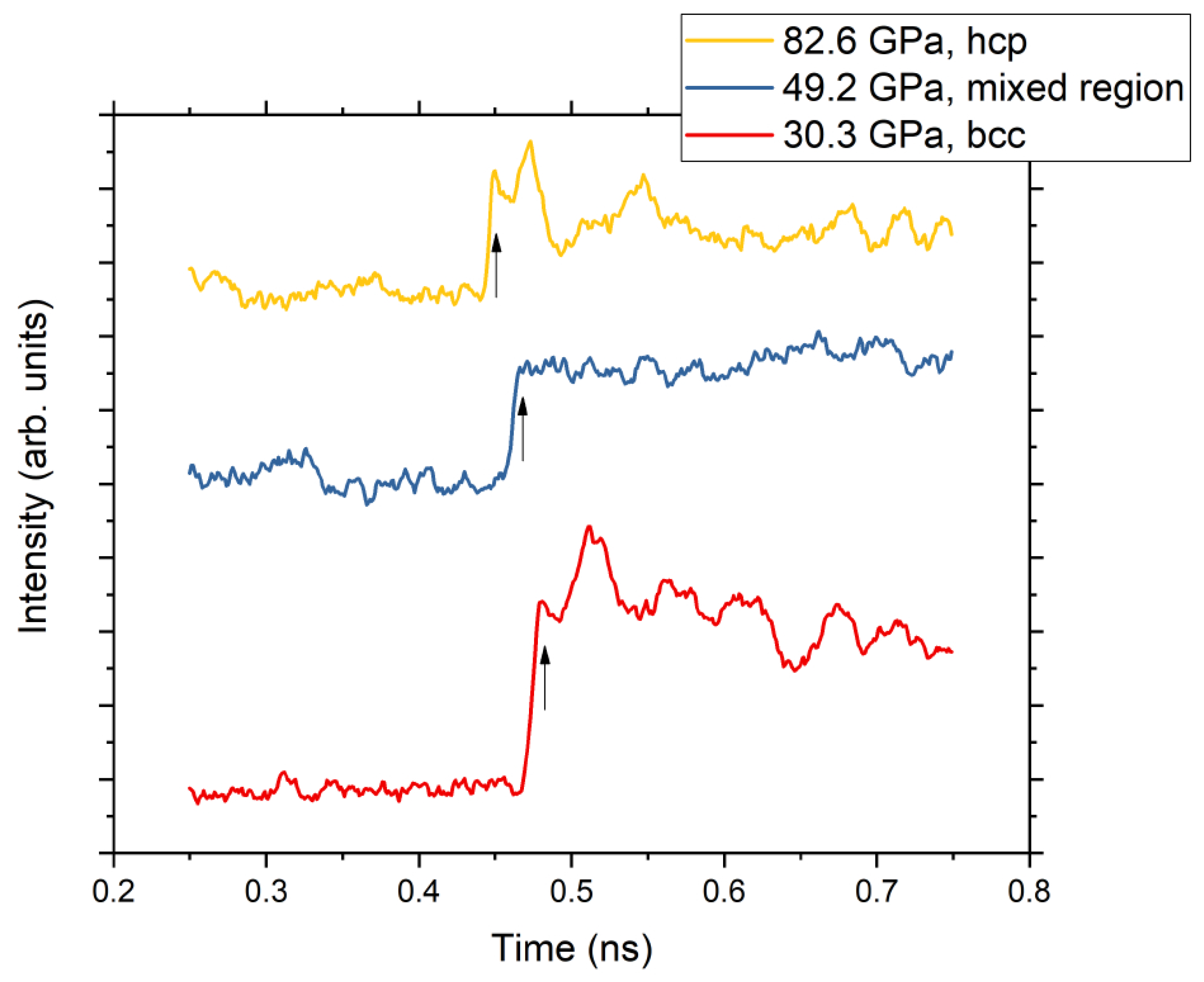

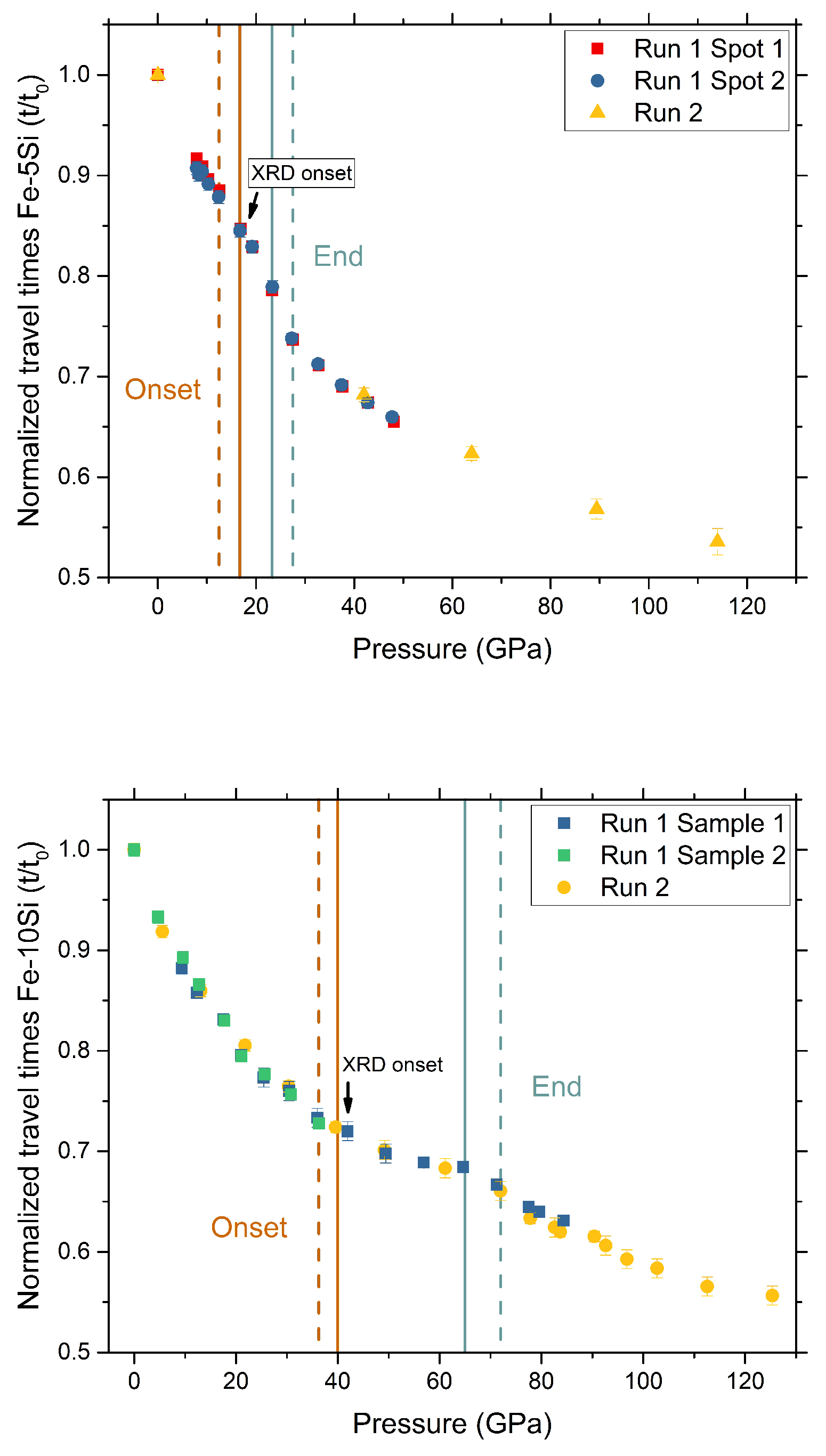

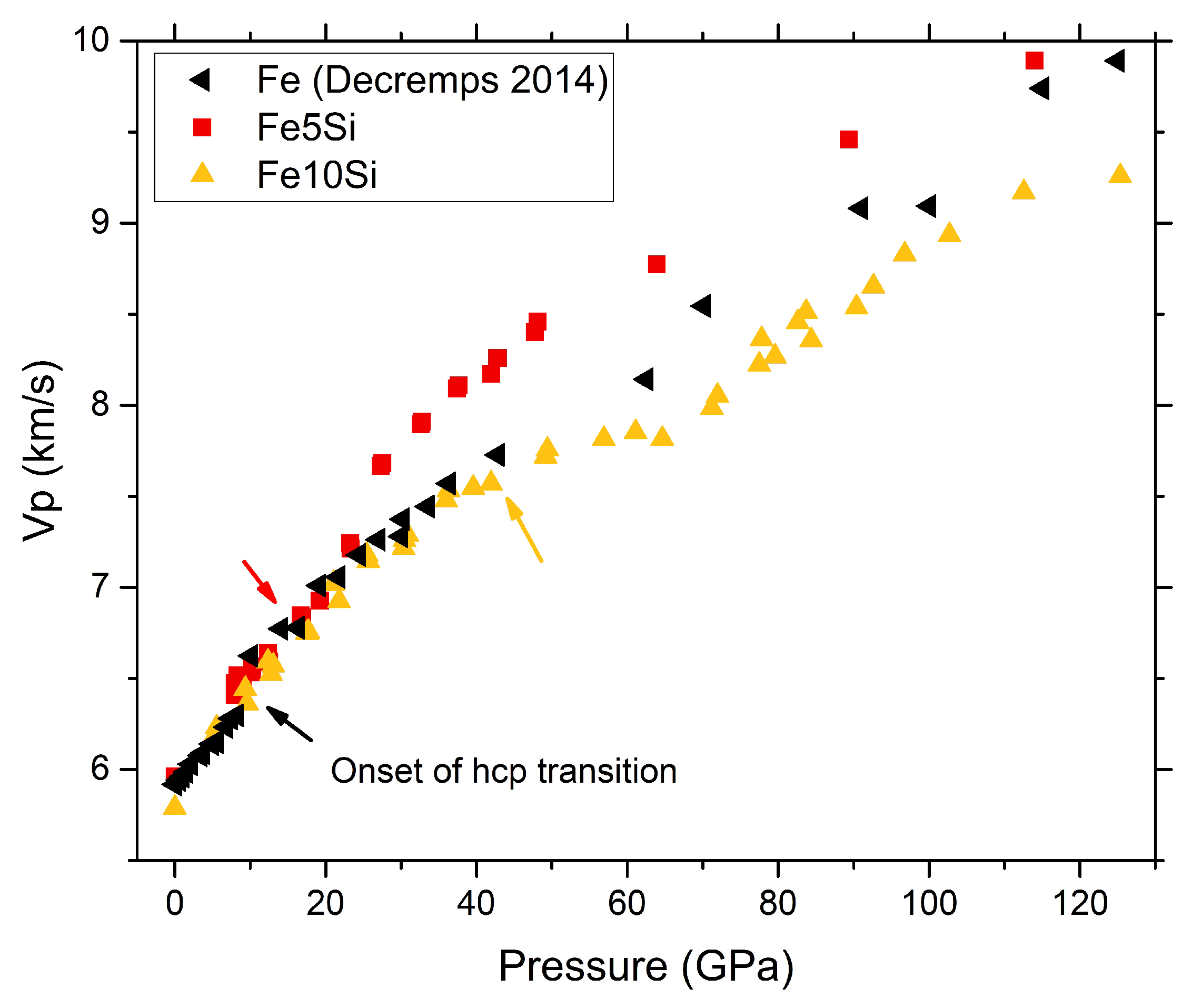

3. Measurement of the Sound Velocities of Polycrystalline Fe-Si Alloys at Mbar Pressures

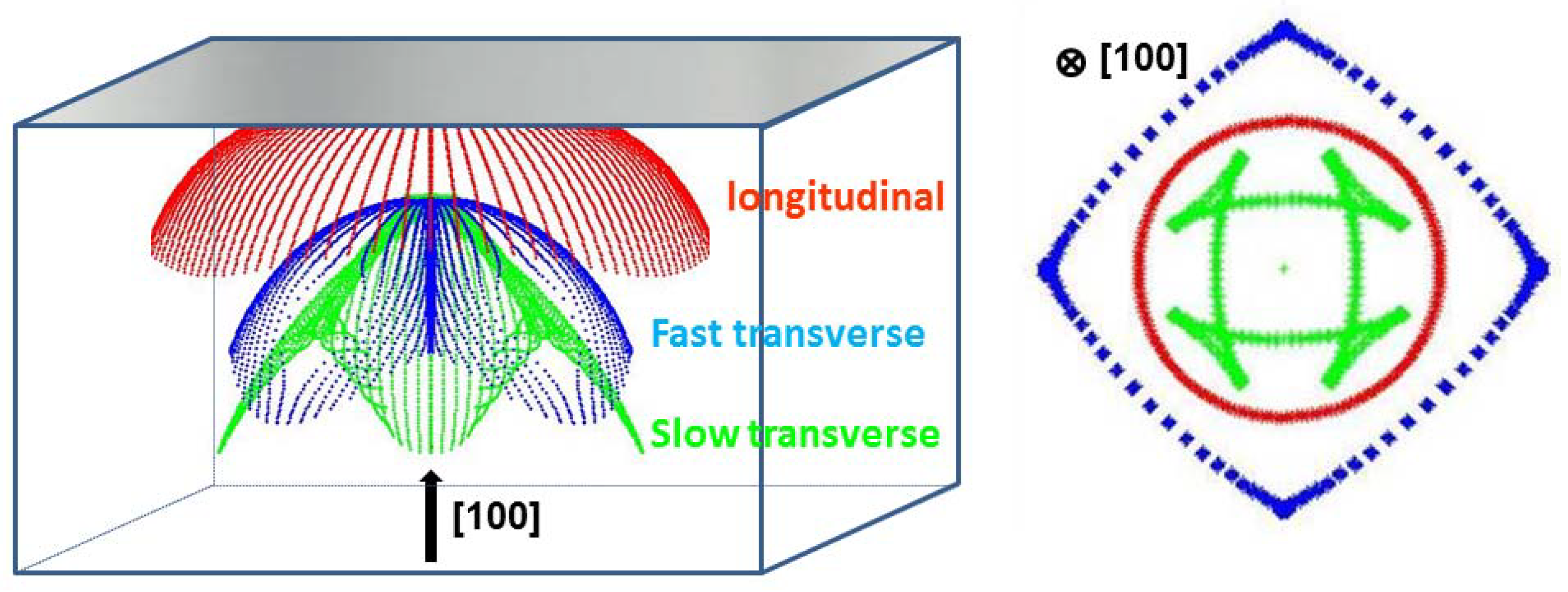

4. Propagation of the Acoustic Energy in a Silicon Single Crystal at High Pressure

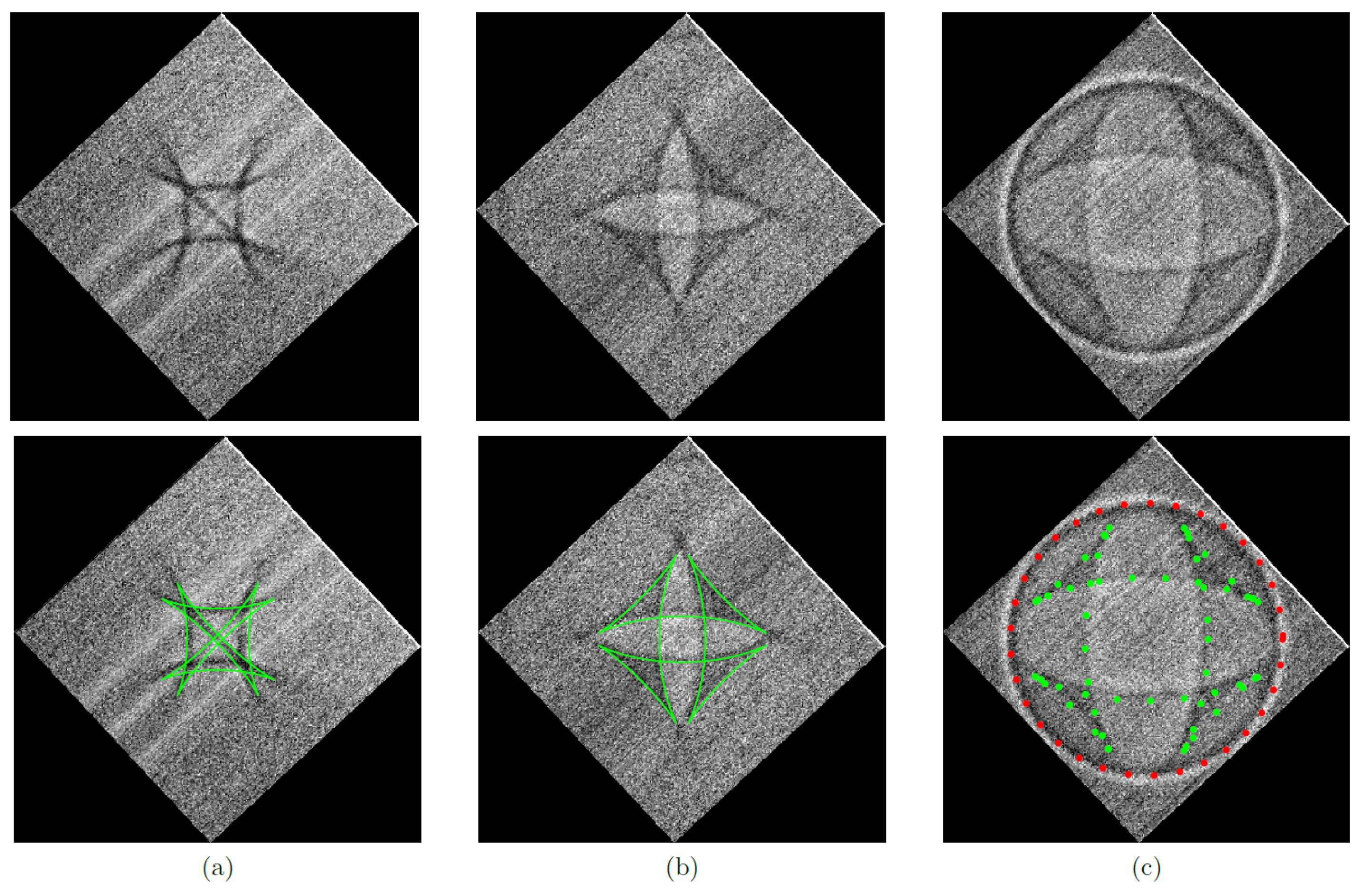

4.1. “Phonon Focusing” at High Pressure: Experimental Principles and Data Analysis

4.2. Ambient Conditions Elastic Constants

4.3. High Pressure Dependence of the Complete Set of Elastic Constants

- C(P) = 165.7 + 4.73P − 0.09P;

- C(P) = 63.60 + 5.78P − 0.12P;

- C (P) = 80 GPa (constant)

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Anderson, O.; Isaak, D. Another look at the core density deficit of Earth’s outer core. Phys. Earth Planet. Int. 2002, 131, 19–27. [Google Scholar] [CrossRef]

- Kong, Y.; Dolgov, O.; Jepsen, O.; Andersen, O. Electron-phonon interaction in the normal and superconducting states of MgB2. Phys. Rev. B 2001, 64. [Google Scholar] [CrossRef]

- Gregoryanz, E.; Degtyareva, O.; Somayazulu, M.; Hemley, R.J.; Mao, H.K. Melting of Dense Sodium. Phys. Rev. Lett. 2005, 94, 185502. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Zhao, H.; Li, G.; Aluru, N.R. Finite-temperature quasicontinuum method for multiscale analysis of silicon nanostructures. Phys. Rev. B 2006, 74, 064110. [Google Scholar] [CrossRef]

- Decremps, F.; Datchi, F.; Polian, A. Hypersonic velocity measurement using Brillouin scattering technique. Application to water under high pressure and temperature. Ultrasonics 2006, 44, E1495–E1498. [Google Scholar] [CrossRef]

- McSkimin, H.; Andreacht, P. Elastic moduli of silicon vs hydrostatic pressure at 25 degrees C and −195.8 degrees C. J. Appl. Phys. 1964, 35, 2161. [Google Scholar] [CrossRef]

- Li, B.; Gwanmesia, G.D.; Liebermann, R.C. Sound velocities of olivine and beta polymorphs of Mg2SiO4 at Earth’s transition zone pressures. Geophys. Res. Lett. 1996, 23, 2259–2262. [Google Scholar] [CrossRef]

- Gauthier, M.; Lheureux, D.; Decremps, F.; Fischer, M.; Itié, J.P.; Syfosse, G.; Polian, A. High-pressure ultrasonic setup using the Paris–Edinburgh press: Elastic properties of single crystalline germanium up to 6 GPa. Rev. Sci. Instrum. 2003, 74, 3712–3716. [Google Scholar] [CrossRef]

- Krisch, M.; Loubeyre, P.; Ruocco, G.; Sette, F.; Cunsolo, A.; D’Astuto, M.; LeToullec, R.; Lorenzen, M.; Mermet, A.; Monaco, G.; et al. Pressure evolution of the high-frequency sound velocity in liquid water. Phys. Rev. Lett. 2002, 89. [Google Scholar] [CrossRef]

- Antonangeli, D.; Occelli, F.; Requardt, H.; Badro, J.; Fiquet, G.; Krisch, M. Elastic anisotropy in textured hcp-iron to 112 GPa from sound wave propagation measurements. Earth Planet. Sci. Lett. 2004, 225, 243–251. [Google Scholar] [CrossRef]

- Decremps, F.; Fischer, M.; Polian, A.; Sieskind, M. Elasticity of BaFCl single crystal under hydrostatic pressure. Eur. Phys. J. B 1998, 5, 7–13. [Google Scholar] [CrossRef]

- Jacobsen, S.D.; Reichmann, H.J.; Spetzler, H. Advances in High-Pressure Technology for Geophysical Applications; Chen, J., Wang, Y., Duffy, T.S., Shen, G., Dobrzhinetskaya, L., Eds.; Cambridge University Press: Cambridge, UK, 2005; p. 25. [Google Scholar]

- Maris, H. Picosecond ultrasonics. Sci. Am. 1998, 278, 86–89. [Google Scholar] [CrossRef]

- Matsuda, O.; Larciprete, M.C.; Li Voti, R.; Wright, O.B. Fundamentals of picosecond laser ultrasonics. Ultrasonics 2015, 56, 3–20. [Google Scholar] [CrossRef] [PubMed]

- Wright, O.B.; Perrin, B.; Matsuda, O.; Gusev, V.E. Optical excitation and detection of picosecond acoustic pulses in liquid mercury. Phys. Rev. B 2008, 78, 024303. [Google Scholar] [CrossRef]

- Decremps, F.; Belliard, L.; Gauthier, M.; Perrin, B. Equation of state, stability, anisotropy and nonlinear elasticity of diamond-cubic (ZB) silicon by phonon imaging at high pressure. Phys. Rev. B 2010, 82. [Google Scholar] [CrossRef]

- Decremps, F.; Belliard, L.; Couzinet, B.; Vincent, S.; Munsch, P.; Le Marchand, G.; Perrin, B. Liquid mercury sound velocity measurements under high pressure and high temperature by picosecond acoustics in a diamond anvils cell. Rev. Sci. Instrum. 2009, 80. [Google Scholar] [CrossRef] [PubMed]

- Decremps, F.; Belliard, L.; Perrin, B.; Gauthier, M. Sound velocity and absorption measurements under high pressure using picosecond ultrasonics in a diamond anvil cell: Application to the stability study of AlPdMn. Phys. Rev. Lett. 2008, 100. [Google Scholar] [CrossRef]

- Decremps, F.; Gauthier, M.; Ayrinhac, S.; Bove, L.; Belliard, L.; Perrin, B.; Morand, M.; Le Marchand, G.; Bergame, F.; Philippe, J. Picosecond acoustics method for measuring the thermodynamical properties of solids and liquids at high pressure and high temperature. Ultrasonics 2015, 56, 129–140. [Google Scholar] [CrossRef]

- Ayrinhac, S.; Gauthier, M.; Le Marchand, G.; Morand, M.; Bergame, F.; Decremps, F. Thermodynamic properties of liquid gallium from picosecond acoustic velocity measurements. J. Phys. Condens. Matter 2015, 27, 275103. [Google Scholar] [CrossRef]

- Ayrinhac, S.; Gauthier, M.; Bove, L.E.; Morand, M.; Le Marchand, G.; Bergame, F.; Philippe, J.; Decremps, F. Equation of state of liquid mercury to 520 K and 7 GPa from acoustic velocity measurements. J. Chem. Phys. 2014, 140, 244201. [Google Scholar] [CrossRef]

- Dziewonski, A.M.; Anderson, D.L. Preliminary reference Earth model. Phys. Earth Planet. Int. 1981, 25, 297–356. [Google Scholar] [CrossRef]

- Mao, H.K.; Hu, Q.; Yang, L.; Liu, J.; Kim, D.Y.; Meng, Y.; Zhang, L.; Prakapenka, V.B.; Yang, W.; Mao, W.L. When water meets iron at Earth’s core–mantle boundary. Natl. Sci. Rev. 2017, 4, 870–878. [Google Scholar] [CrossRef]

- Dasgupta, R.; Hirschmann, M.M. The deep carbon cycle and melting in Earth’s interior. Earth Planet. Sci. Lett. 2010, 298, 1–13. [Google Scholar] [CrossRef]

- Siebert, J.; Badro, J.; Antonangeli, D.; Ryerson, F.J. Terrestrial Accretion Under Oxidizing Conditions. Science 2013, 339, 1194–1197. [Google Scholar] [CrossRef] [PubMed]

- Fischer, R.A.; Nakajima, Y.; Campbell, A.J.; Frost, D.J.; Harries, D.; Langenhorst, F.; Miyajima, N.; Pollok, K.; Rubie, D.C. High pressure metal-silicate partitioning of Ni, Co, V, Cr, Si, and O. Geochim. Cosmochim. Acta 2015, 167, 177–194. [Google Scholar] [CrossRef]

- Edmund, E.; Antonangeli, D.; Decremps, F.; Morard, G.; Ayrinhac, S.; Gauthier, M.; Boulard, E.; Mezouar, M.; Hanfland, M.; Guignot, N. Structure and elasticity of cubic Fe-Si alloys at high pressures. Phys. Rev. B 2019, 100, 134105. [Google Scholar] [CrossRef]

- Edmund, E.; Antonangeli, D.; Decremps, F.; Miozzi, F.; Morard, G.; Boulard, E.; Clark, A.N.; Ayrinhac, S.; Gauthier, M.; Morand, M.; et al. Velocity-Density Systematics of Fe-5wt%Si: Constraints on Si Content in the Earth’s Inner Core. J. Geophys. Res. Solid Earth 2019, 124, 3436–3447. [Google Scholar] [CrossRef]

- Antonangeli, D.; Morard, G.; Paolasini, L.; Garbarino, G.; Murphy, C.A.; Edmund, E.; Decremps, F.; Fiquet, G.; Bosak, A.; Mezouar, M.; et al. Sound velocities and density measurements of solid hcp-Fe and hcp-Fe-Si (9 wt.%) alloy at high pressure: Constraints on the Si abundance in the Earth’s inner core. Earth Planet. Sci. Lett. 2018, 482, 446–453. [Google Scholar] [CrossRef]

- Takemura, K. Evaluation of the hydrostaticity of a helium-pressure medium with powder X-ray diffraction techniques. J. Appl. Phys. 2001, 89, 662. [Google Scholar] [CrossRef]

- Finger, L.W.; Hazen, R.M.; Zou, G.; Mao, H.K.; Bell, P.M. Structure and compression of crystalline argon and neon at high pressure and room temperature. Appl. Phys. Lett. 1981, 39, 892. [Google Scholar] [CrossRef]

- Loubeyre, P.; Besson, J.M.; Pinceaux, J.P.; Hansen, J.P. High-Pressure Melting Curve of 4He. Phys. Rev. Lett. 1982, 49, 1172. [Google Scholar] [CrossRef]

- Klotz, S.; Chervin, J.C.; Munsch, P.; Marchand, G.L. Hydrostatic limits of 11 pressure transmitting media. J. Phys. D Appl. Phys. 2009, 42, 075413. [Google Scholar] [CrossRef]

- Dorfman, S.M.; Prakapenka, V.B.; Meng, Y.; Duffy, T.S. Intercomparison of pressure standards (Au, Pt, Mo, MgO, NaCl and Ne) to 2.5 Mbar. J. Geophys. Res. Solid Earth 2012, 117, B08210. [Google Scholar] [CrossRef]

- Decremps, F.; Antonangeli, D.; Gauthier, M.; Ayrinhac, S.; Morand, M.; Le Marchand, G.; Bergame, F.; Philippe, J. Sound velocity of iron up to 152 GPa by picosecond acoustics in diamond anvil cell. Geophys. Res. Lett. 2014, 41, 1459–1464. [Google Scholar] [CrossRef]

- Mao, H.K.; Badro, J.; Shu, J.; Hemley, R.J.; Singh, A.K. Strength, anisotropy, and preferred orientation of solid argon at high pressures. J. Phys. Condens. Matter 2006, 18, 963. [Google Scholar] [CrossRef]

- Marquardt, H.; Speziale, S.; Gleason, A.; Sinogeikin, S.; Kantor, I.; Prakapenka, V.B. Brillouin scattering and X-ray diffraction of solid argon to 65 GPa and 700 K: Shear strength of Argon at HP/HT. J. Appl. Phys. 2013, 114, 093517. [Google Scholar] [CrossRef]

- Martorell, B.; Wood, I.G.; Brodholt, J.; Vocadlo, L. The elastic properties of hcp-Fe1-xSix at Earth’s inner-core conditions. Earth Planet. Sci. Lett. 2016, 451, 89–96. [Google Scholar] [CrossRef]

- Mao, Z.; Lin, J.F.; Liu, J.; Alatas, A.; Gao, L.; Zhao, J.; Mao, H.K. Sound velocities of Fe and Fe-Si alloy in the Earth’s core. Proc. Natl. Acad. Sci. USA 2012, 109, 10239–10244. [Google Scholar] [CrossRef]

- Sakairi, T.; Sakamaki, T.; Ohtani, E.; Fukui, H.; Kamada, S.; Tsutsui, S.; Uchiyama, H.; Baron, A.Q. Sound velocity measurements of hcp Fe-Si alloy at high pressure and high temperature by inelastic X-ray scattering. Am. Mineral. 2018, 103, 85. [Google Scholar] [CrossRef]

- Lin, J.F.; Struzhkin, V.V.; Sturhahn, W.; Huang, E.; Zhao, J.; Hu, M.Y.; Alp, E.E.; Mao, H.k.; Boctor, N.; Hemley, R.J. Sound velocities of iron-nickel and iron-silicon alloys at high pressures. Geophys. Res. Lett. 2003, 30, 2112. [Google Scholar] [CrossRef]

- Decremps, F.; Belliard, L.; Perrin, B. Structure and elasticity of single-crystals by phonon imaging at high pressure. Acta Crystallogr. A Found. Adv. 2011, 67, C111–C112. [Google Scholar] [CrossRef]

- Hurley, D.; Wolfe, J. Phonon Focusing in Cubic-Crystals. Phys. Rev. B 1985, 32, 2568–2587. [Google Scholar] [CrossRef] [PubMed]

- Buchwald, V.; Davis, A. Surface waves in anisotropic elastic media. Nature 1961, 191, 899. [Google Scholar] [CrossRef]

- Audoin, B.; Bescond, C.; Deschamps, M. Measurement of stiffness coefficients of anisotropic materials from pointlike generation and detection of acoustic waves. J. Appl. Phys. 1996, 80, 3760–3771. [Google Scholar] [CrossRef]

- Rossignol, C.; Rampnoux, J.M.; Perton, M.; Audoin, B.; Dilhaire, S. Generation and Detection of Shear Acoustic Waves in Metal Submicrometric Films with Ultrashort Laser Pulses. Phys. Rev. Lett. 2005, 94, 166106. [Google Scholar] [CrossRef] [PubMed]

- Auld, B.A. Acoustic Fields and Waves in Solids; Malabar, F.L., Ed.; R.E. Krieger Publishing Company: Malabar, FL, USA, 1990; Volume I. [Google Scholar]

- McSkimin, H.; Andreacht, P. Measurement of 3-order moduli of silicon and germmanium. J. Appl. Phys. 1964, 35, 3312. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Edmund, E.; Gauthier, M.; Antonangeli, D.; Ayrinhac, S.; Boccato, S.; Deletang, T.; Morand, M.; Garino, Y.; Parisiades, P.; Decremps, F. Picosecond Acoustics Technique to Measure the Sound Velocities of Fe-Si Alloys and Si Single-Crystals at High Pressure. Minerals 2020, 10, 214. https://doi.org/10.3390/min10030214

Edmund E, Gauthier M, Antonangeli D, Ayrinhac S, Boccato S, Deletang T, Morand M, Garino Y, Parisiades P, Decremps F. Picosecond Acoustics Technique to Measure the Sound Velocities of Fe-Si Alloys and Si Single-Crystals at High Pressure. Minerals. 2020; 10(3):214. https://doi.org/10.3390/min10030214

Chicago/Turabian StyleEdmund, Eric, Michel Gauthier, Daniele Antonangeli, Simon Ayrinhac, Silvia Boccato, Thibault Deletang, Marc Morand, Yiuri Garino, Paraskevas Parisiades, and Frédéric Decremps. 2020. "Picosecond Acoustics Technique to Measure the Sound Velocities of Fe-Si Alloys and Si Single-Crystals at High Pressure" Minerals 10, no. 3: 214. https://doi.org/10.3390/min10030214

APA StyleEdmund, E., Gauthier, M., Antonangeli, D., Ayrinhac, S., Boccato, S., Deletang, T., Morand, M., Garino, Y., Parisiades, P., & Decremps, F. (2020). Picosecond Acoustics Technique to Measure the Sound Velocities of Fe-Si Alloys and Si Single-Crystals at High Pressure. Minerals, 10(3), 214. https://doi.org/10.3390/min10030214