Sulfate-Dependent Shear Behavior of Cementing Fiber-Reinforced Tailings and Rock

Abstract

1. Introduction

- (1)

- To study the effect of the initial sulfate concentration on the behavior of a 1-day-old FR-CPB and rock interface;

- (2)

- To evaluate the effect of treatment time and the initial sulfate concentration on the behavior of the FR-CPB and rock interface (1-, 3-, 7-, and 28-day-old interface);

- (3)

- To compare the effect of the initial sulfate concentration on the interface behavior of FR-CPB material with various fiber contents (after 7 days of curing);

- (4)

- To develop a basic understanding of the shear behavior of the FR-CPB/rock interface under sulfate attack.

2. Experimental Program

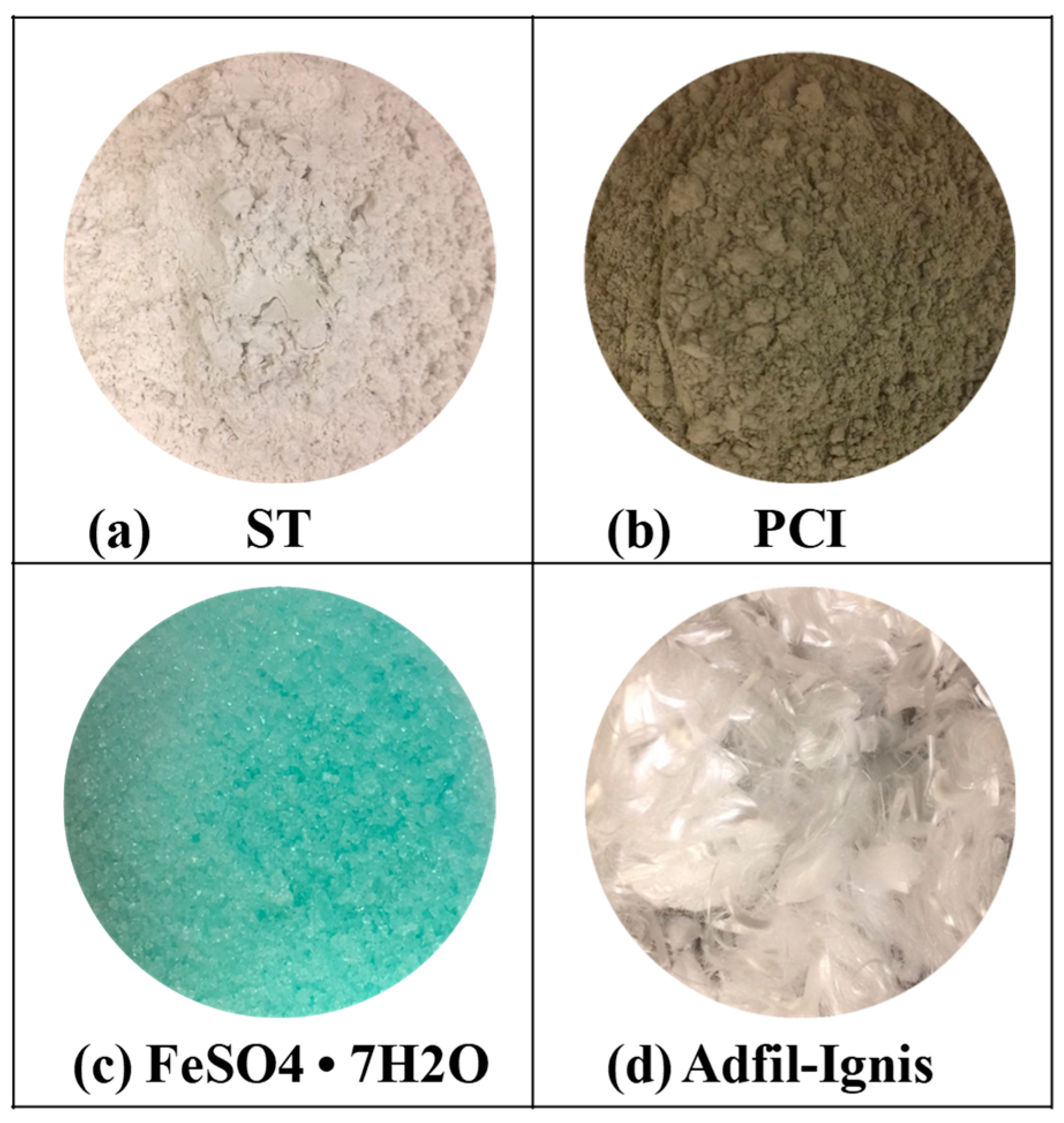

2.1. Materials

2.1.1. Tailings

2.1.2. Binder

2.1.3. Rock Specimens

2.1.4. Mixing Water

2.1.5. Fibers

2.2. Sample Preparation

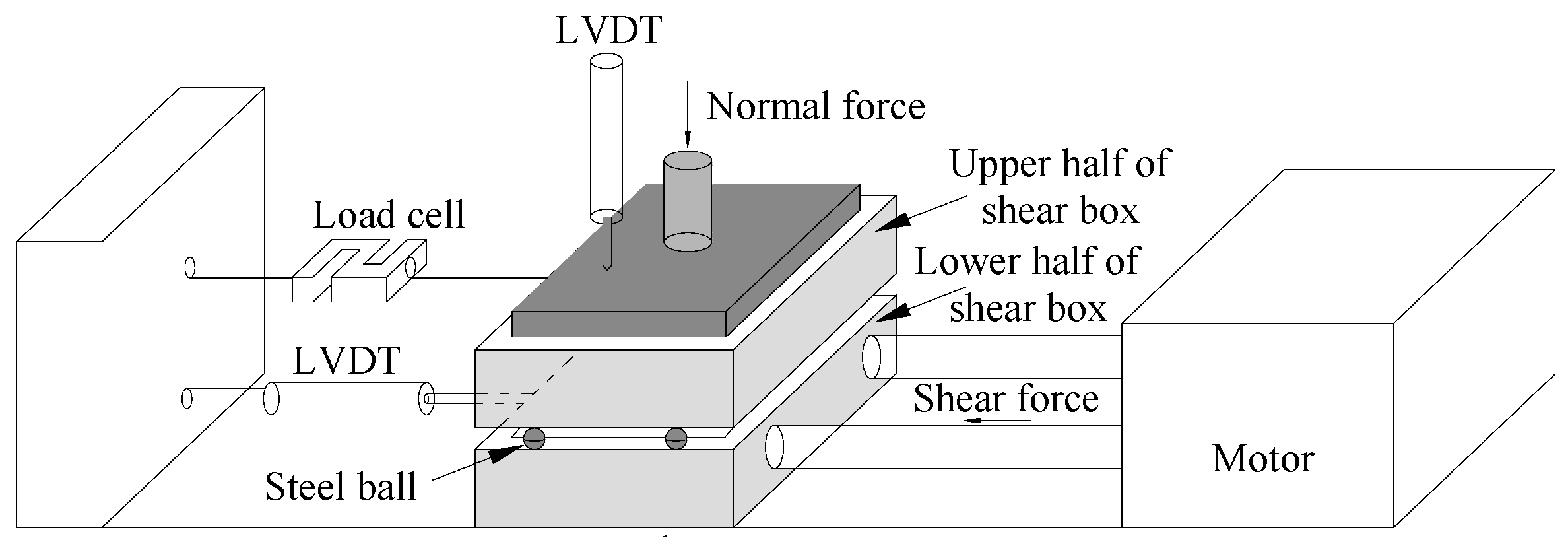

2.3. Interface Shear Tests

2.4. Microstructural Analyses

3. Results and Discussion

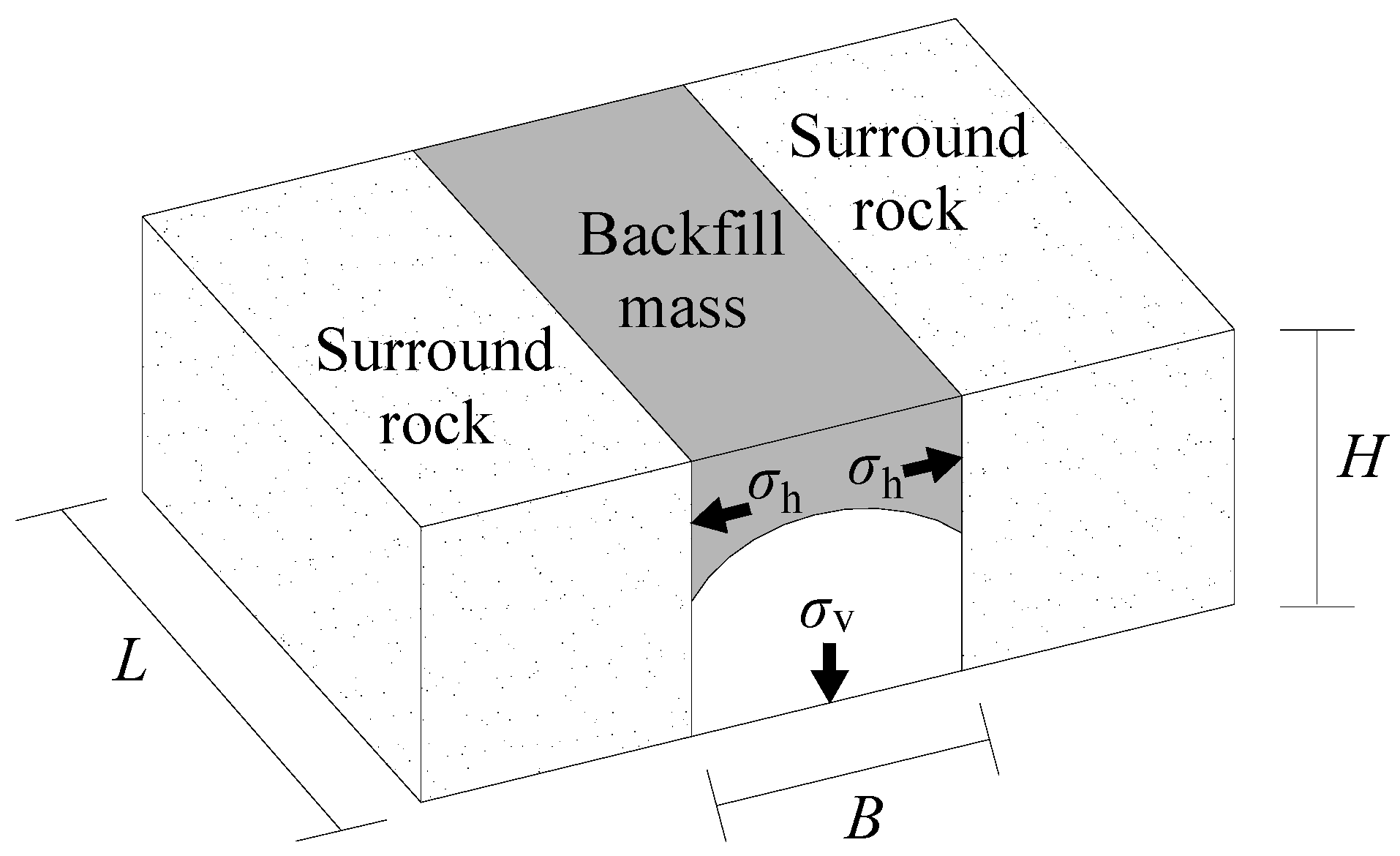

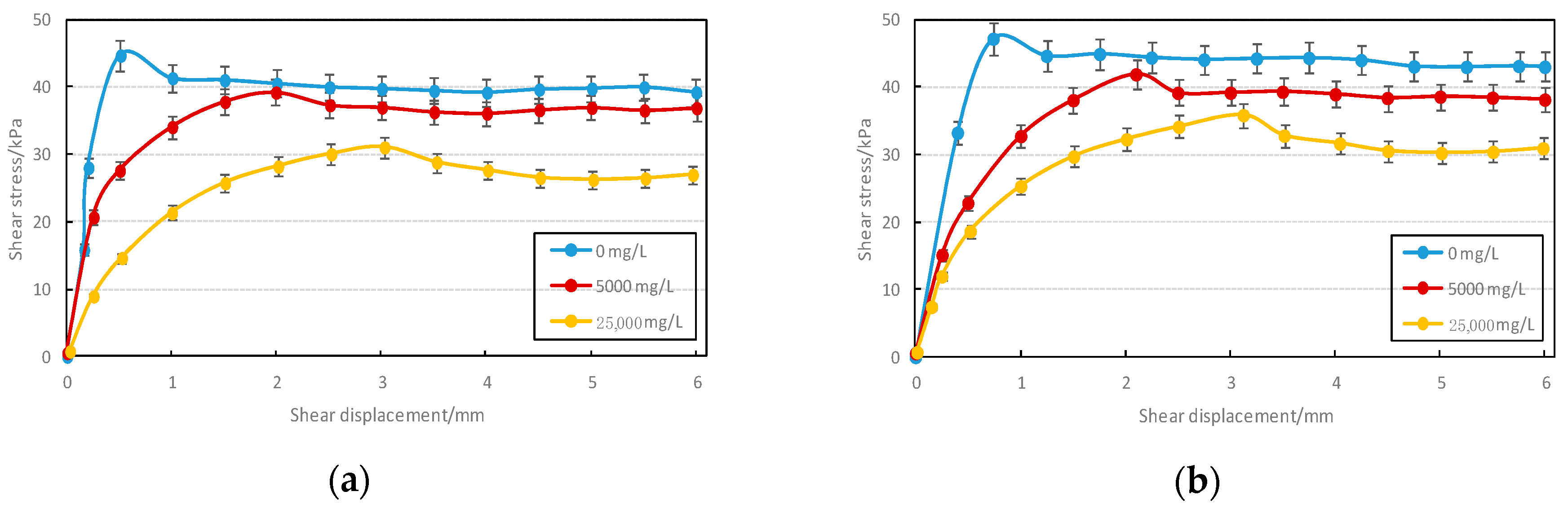

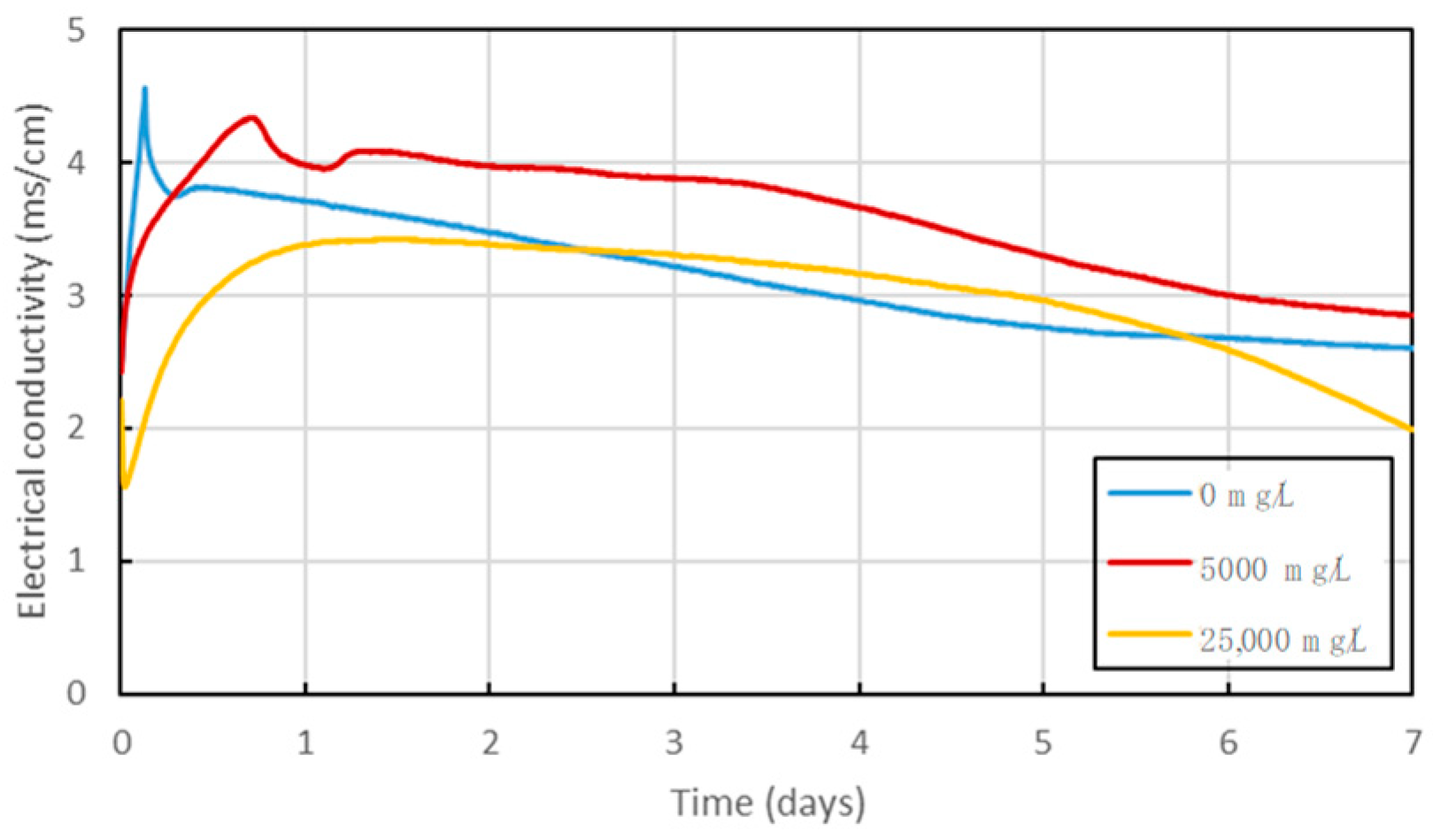

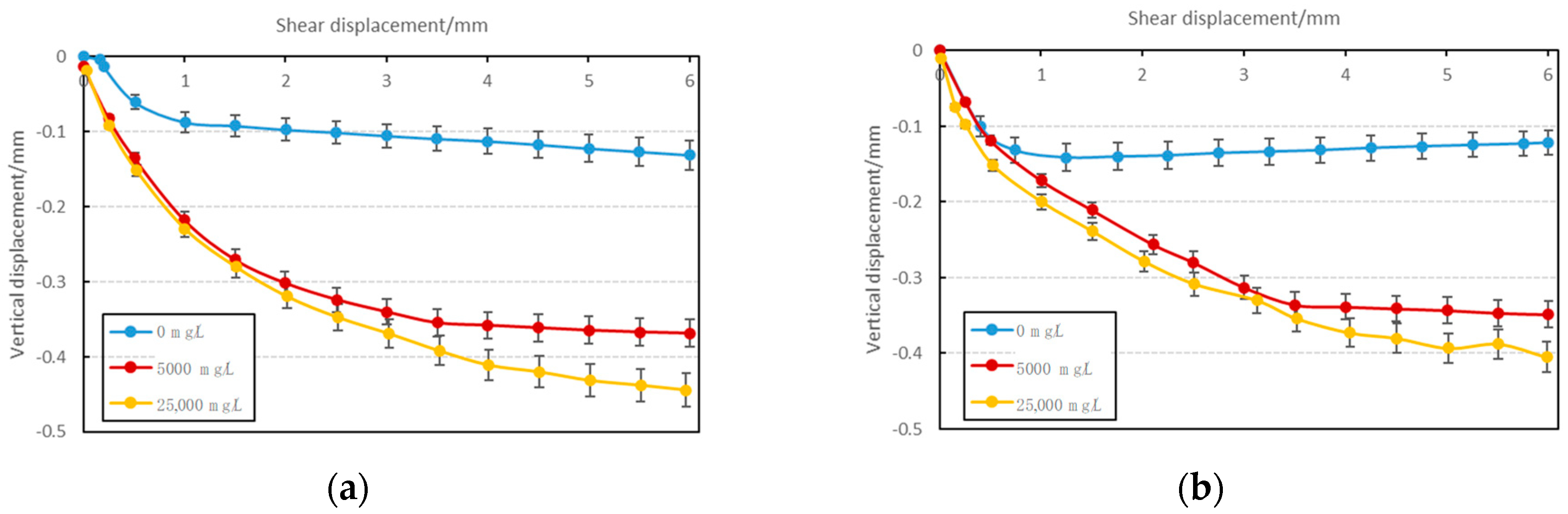

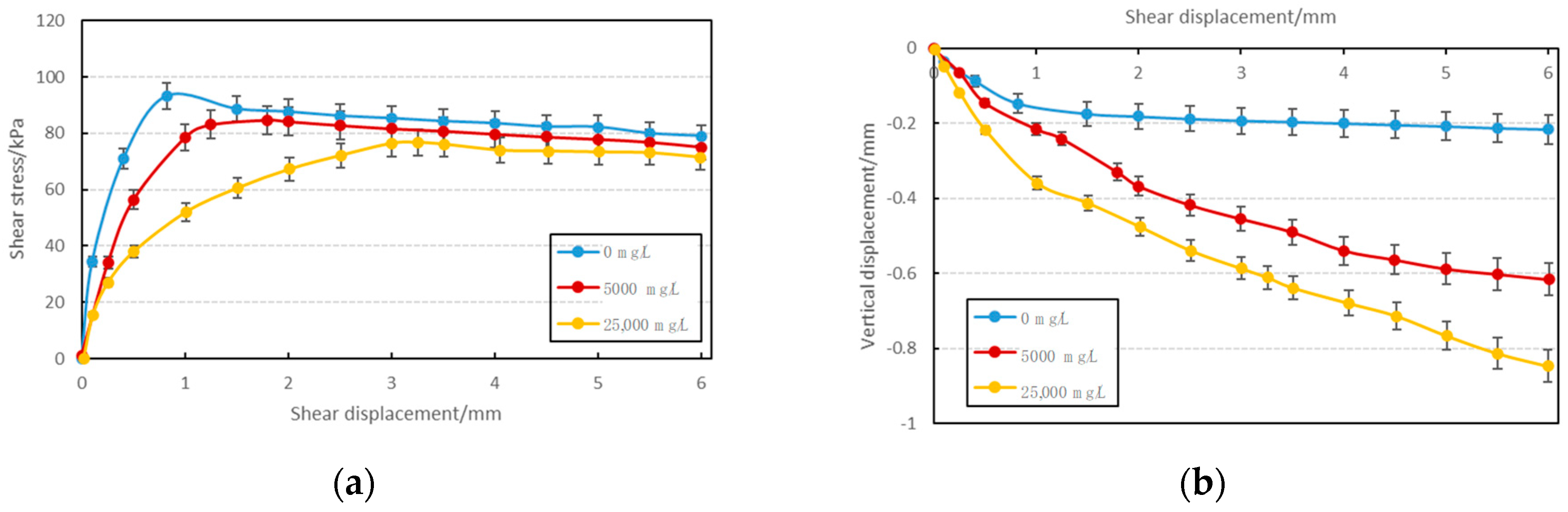

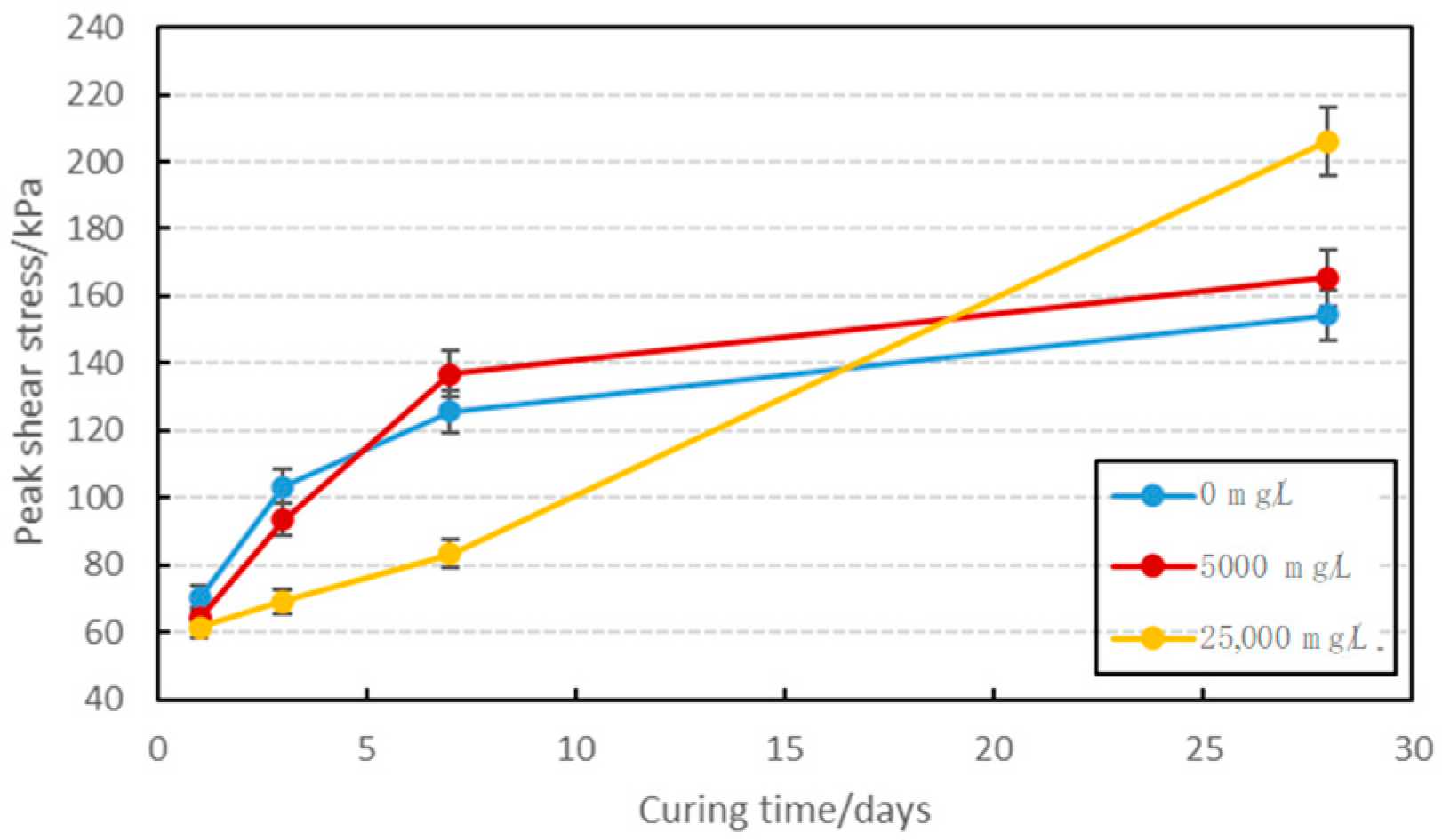

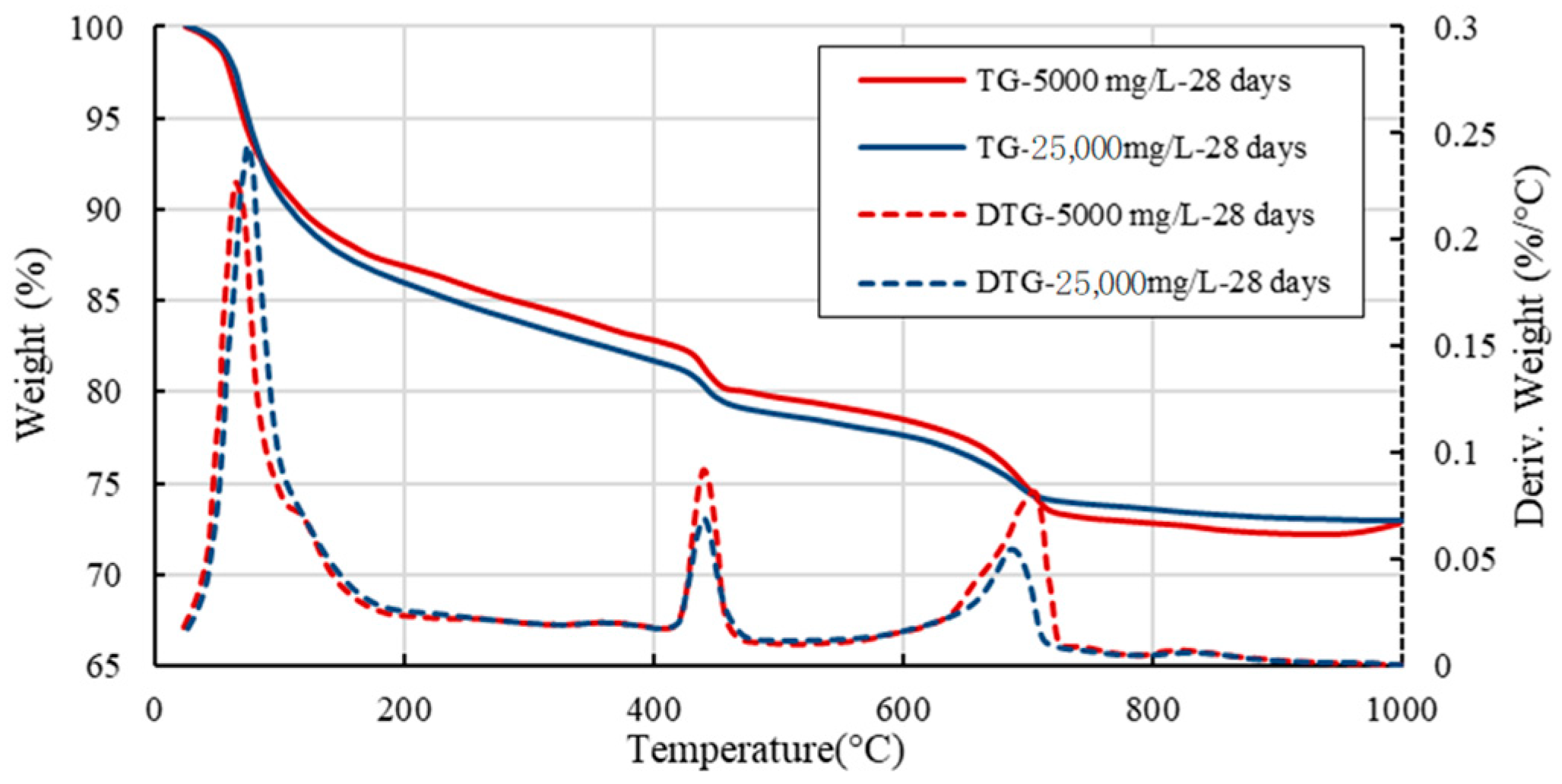

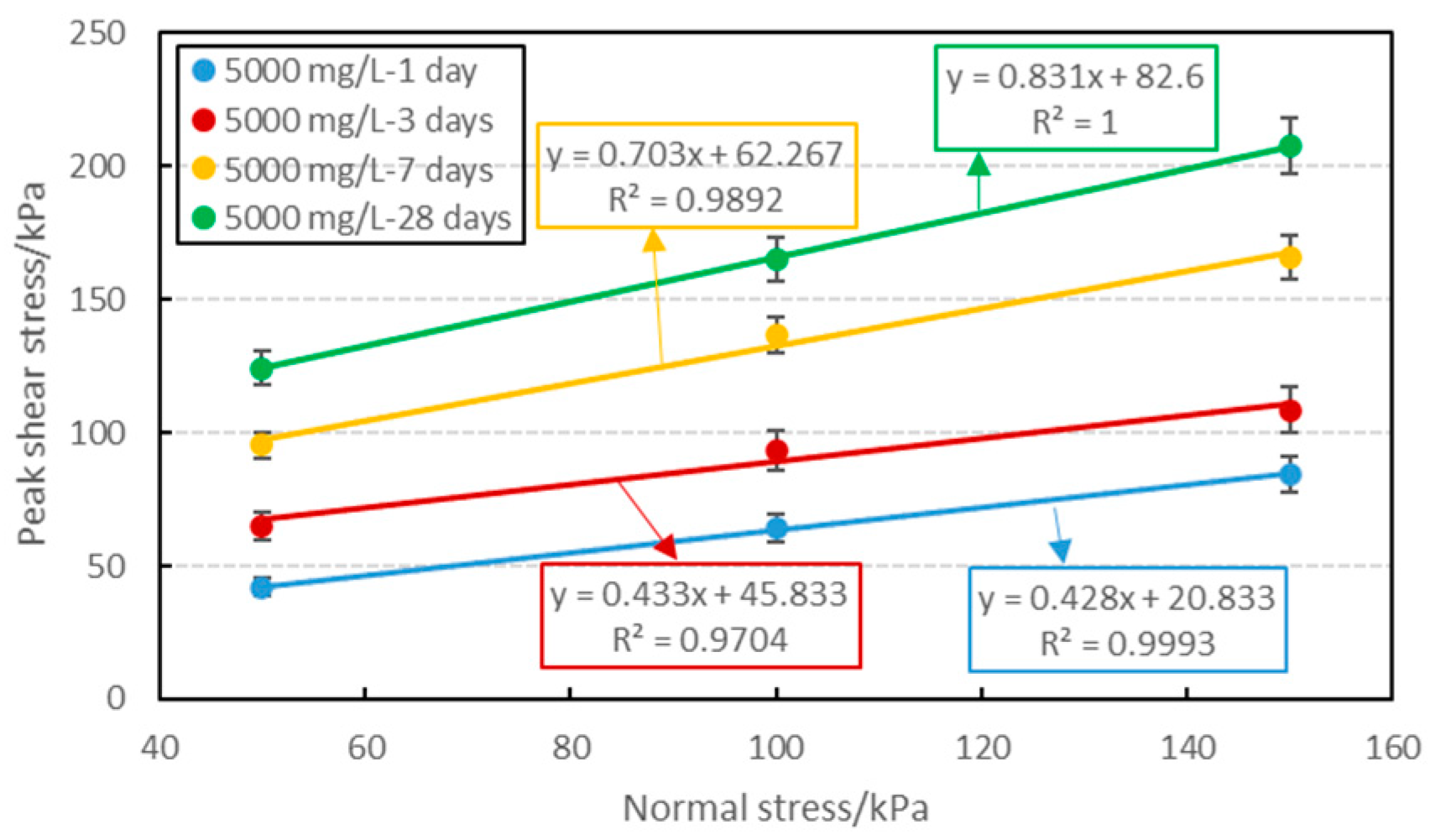

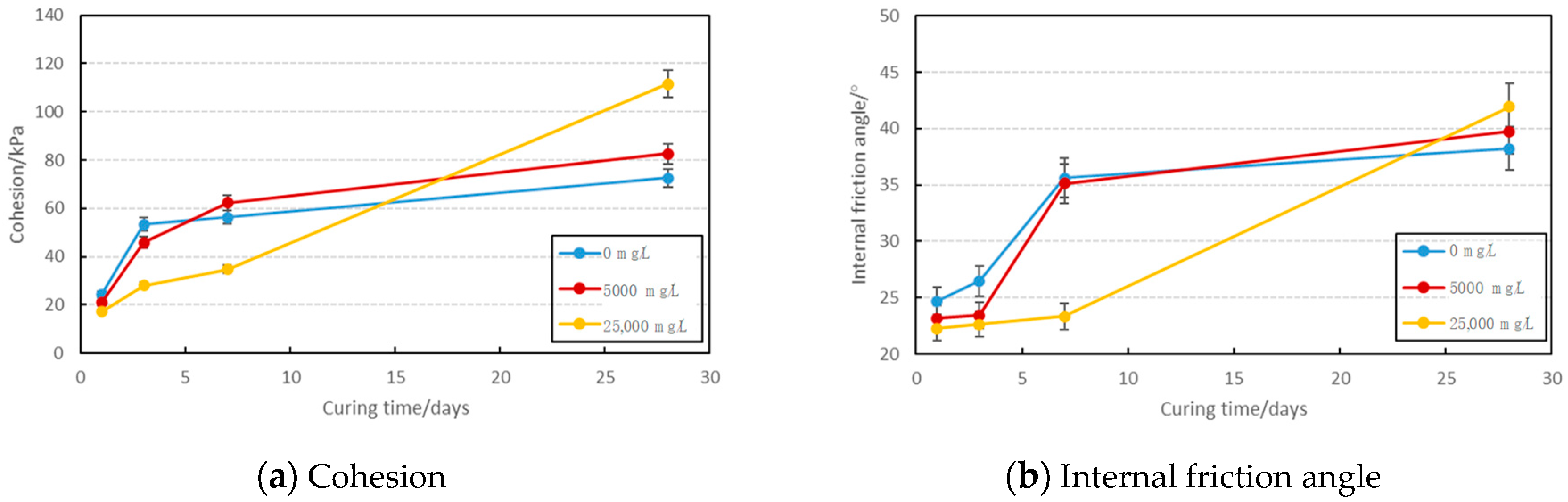

3.1. Effects of Sulfate Concentration on the Shear Behavior of the Fiber-Reinforced Cemented Paste Backfill (FR-CPB)/Rock Interface

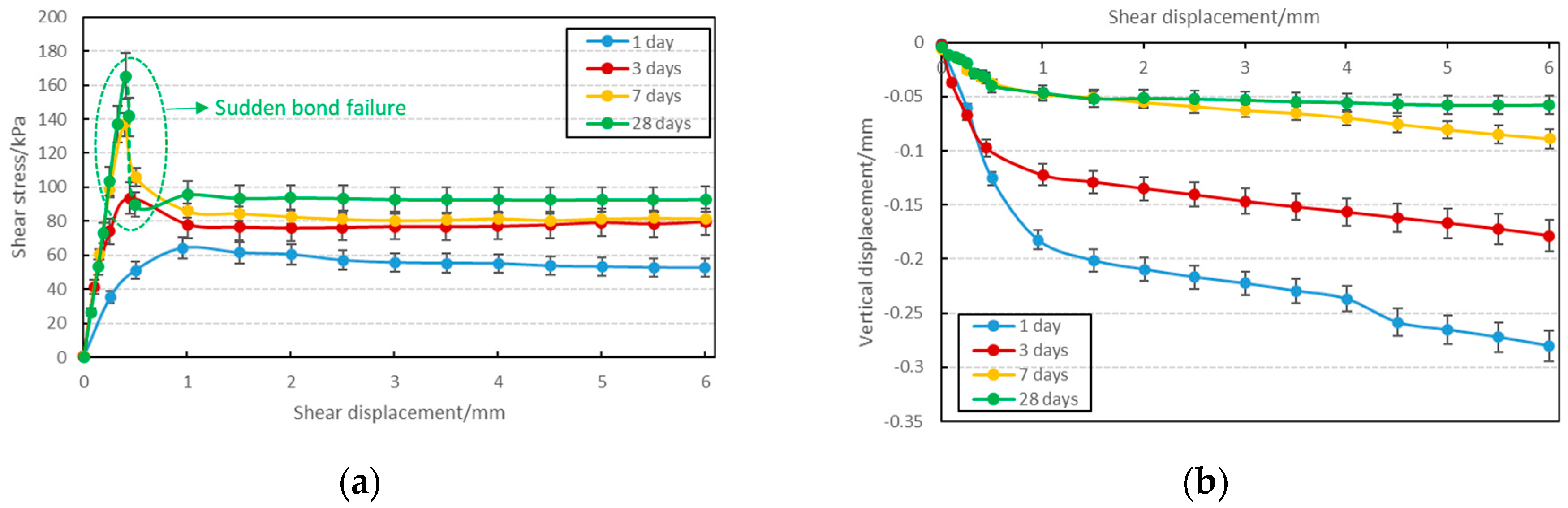

3.2. Combined Effects of the Curing Time and the Initial Sulfate Concentration on the Shear Behavior of the FR-CPB/Rock Interface

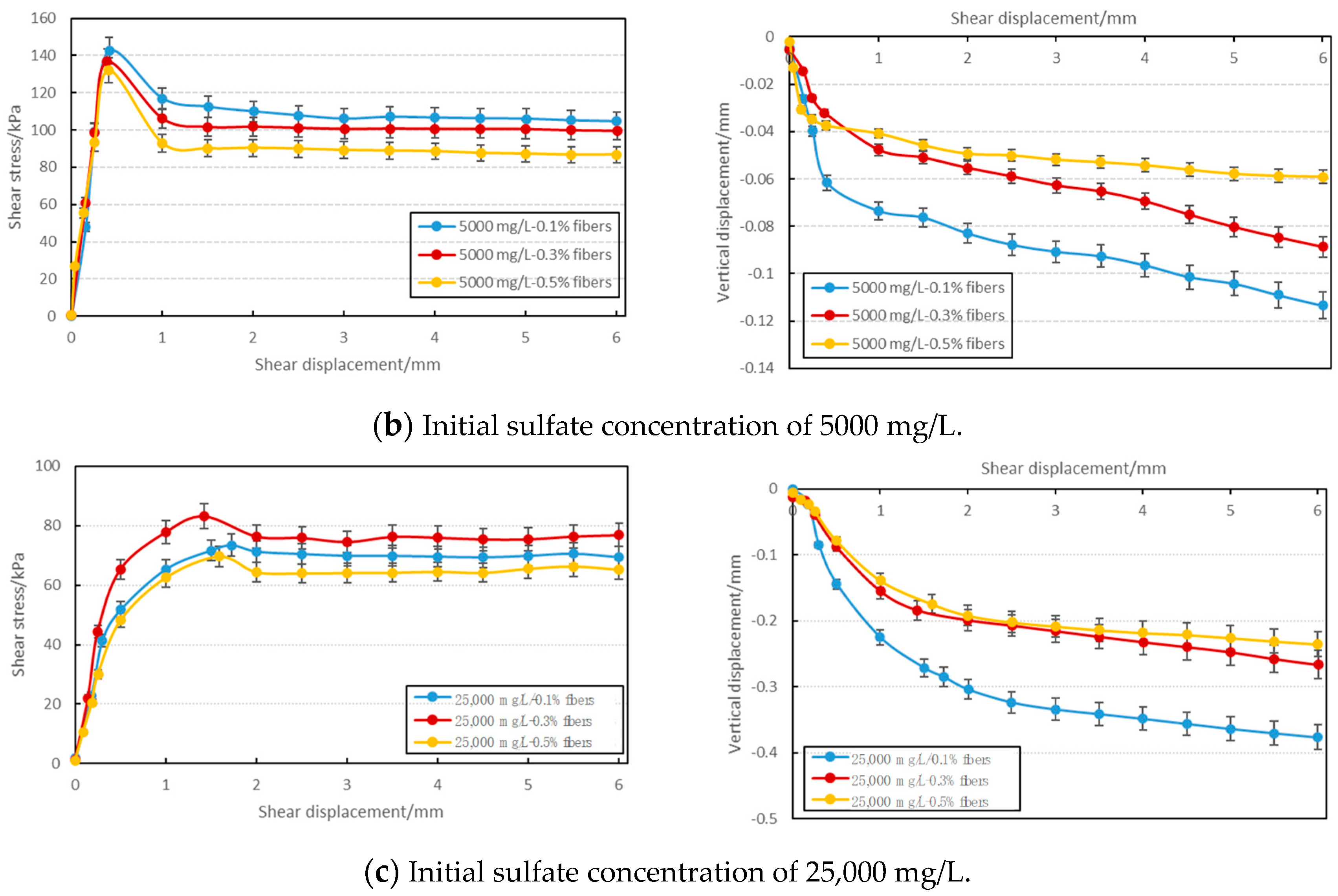

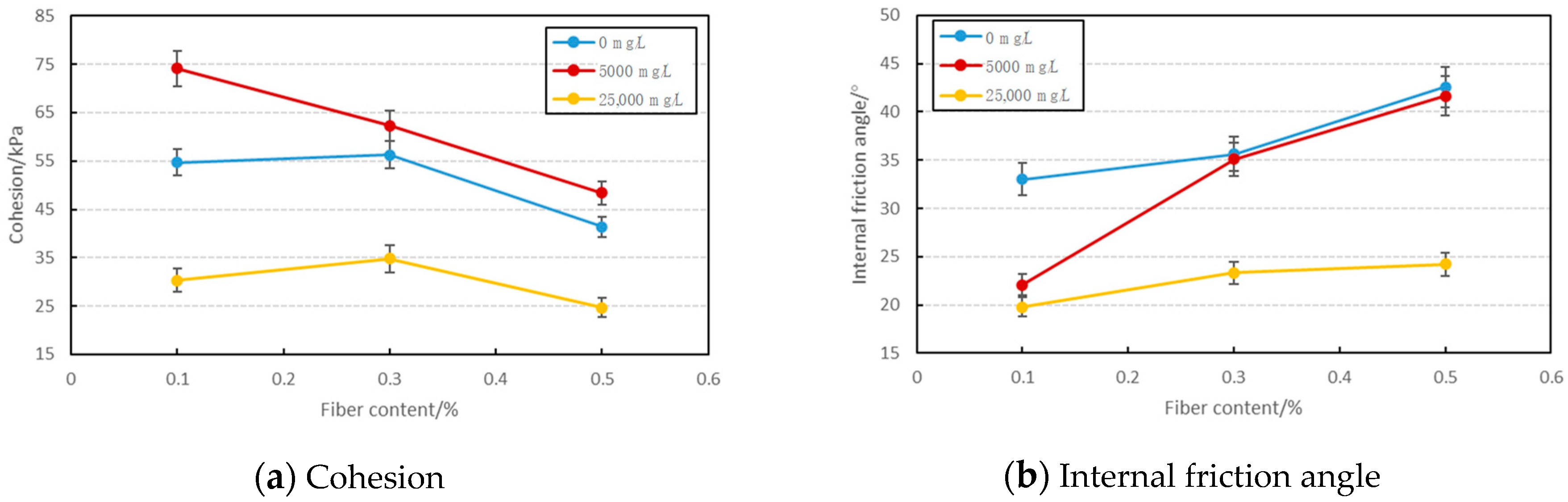

3.3. Combined Effects of the Fiber Content and the Initial Sulfate Concentration on the Shear Behavior of the FR-CPB/Rock Interface

4. Summary and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yilmaz, E. Advances in reducing large volumes of environmentally harmful mine waste rocks and tailings Introduction. Gospod. Surowcami Miner. Miner. Resour. Manag. 2011, 27, 89–112. [Google Scholar]

- Swedish Waste Research Council. Svensk Gruvavfallsforskning: Seminar 15 December 1998; AFR Rapport 194, AFR-R-194-SE; AFN, Naturvårdsverket, Swedish Environmental Protection Agency: Stockholm, Sweden, 1998; ISSN 1102-6944. (In Swedish) [Google Scholar]

- Current Situation of China’s Large and Medium Municipal Solid Waste Pollution. Recycling of Bulk Industrial Solid Waste. 2020. Available online: http://www.chyxx.com/industry/202007/882981.html (accessed on 9 October 2020). (In Chinese).

- Nabassé, J.F.; Koupouli, B.T.; Rivard, P.; Effenguet, H. Direct shear tests on cemented paste backfill–rock wall and cemented paste backfill–backfill interfaces. J. Rock Mech. Geotech. Eng. 2016, 8, 472–479. [Google Scholar]

- Belem, T.; Benzaazoua, M. Design and application of underground mine paste backfill technology. Geotech. Geol. Eng. 2008, 26, 147–174. [Google Scholar] [CrossRef]

- Orejarena, L.; Fall, M. Mechanical response of a mine composite material to extreme heat. Bull. Eng. Geol. Environ. 2008, 67, 387–396. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M. Modeling the effect of sulphate on strength development of paste backfill and binder mixture optimization. Cem. Concr. Res. 2005, 35, 301–314. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Coupled thermo-hydro-mechanical–chemical behaviour of cemented paste backfill in column experiments. Part I: Physical, hydraulic and thermal processes and characteristics. Eng. Geol. 2013, 164, 195–207. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Belem, T.; Bussière, B. Chemical factors that influence the performance of mine sulphidic paste backfill. Cem. Concr. Res. 2002, 32, 1133–1144. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Marion, P.; Picquet, I.; Bussière, B. The use of pastefill as a solidification and stabilization process for the control of acid mine drainage. Miner. Eng. 2004, 17, 233–243. [Google Scholar] [CrossRef]

- Guo, G.L.; Zhu, X.J.; Zha, J.F.; Qiang, W. Subsidence prediction method based on equivalent mining height theory for solid backfilling mining. Trans. Nonferr. Met. Soc. China 2014, 24, 3302–3308. [Google Scholar] [CrossRef]

- Mitchell, R.J.; Olsen, R.S.; Smith, J.D. Model studies on cemented tailings used in mine backfill. Can. Geotech. J. 1982, 19, 14–28. [Google Scholar] [CrossRef]

- Cui, L.; Fall, M. Multiphysics modeling and simulation of strength development and distribution in cemented tailings backfill structures. Int. J. Concr. Struct. Mater. 2018, 12, 25. [Google Scholar] [CrossRef]

- Lu, G.; Fall, M.; Yang, Z. An evolutive bounding surface plasticity model for early-age cemented tailings backfill under cyclic loading. Soil Dyn. Earthq. Eng. 2019, 117, 339–356. [Google Scholar] [CrossRef]

- Wang, Y.; Fall, M.; Wu, A. Initial temperature-dependence of strength development and self-desiccation in cemented paste backfill that contains sodium silicate. Cem. Concr. Compos. 2016, 67, 101–110. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Benzaazoua, M. Effects of curing and stress conditions on hydromechanical, geotechnical and geochemical properties of cemented paste backfill. Eng. Geol. 2014, 168, 23–37. [Google Scholar] [CrossRef]

- Pokharel, M.; Fall, M. Combined influence of sulphate and temperature on the saturated hydraulic conductivity of hardened cemented paste backfill. Cem. Concr. Compos. 2013, 38, 21–28. [Google Scholar] [CrossRef]

- Cui, L.; Fall, M. Multiphysics modeling of arching effects in fill mass. Comput. Geotech. 2017, 83, 114–131. [Google Scholar] [CrossRef]

- Shui, Z.H.; Zhang, R.; Chen, W.; Xuan, D.X. Effects of mineral admixtures on the thermal expansion properties of hardened cement paste. Constr. Build. Mater. 2010, 24, 1761–1767. [Google Scholar] [CrossRef]

- Nasir, O.; Fall, M. Shear behaviour of cemented pastefill-rock interfaces. Eng. Geol. 2008, 101, 146–153. [Google Scholar] [CrossRef]

- Tsai, J.S.; Chang, J.C. Three-dimensional stability analysis for slurry-filled trench wall in cohesionless soil. Can. Geotech. J. 1996, 33, 798–808. [Google Scholar] [CrossRef]

- Take, W.A.; Valsangkar, A.J. Earth pressures on unyielding retaining walls of narrow backfill width. Can. Geotech. J. 2001, 38, 1220–1230. [Google Scholar] [CrossRef]

- Pain, A.; Chen, Q.S.; Nimbalkar, S.; Zhou, Y. Evaluation of seismic passive earth pressure of inclined rigid retaining wall considering soil arching effect. Soil Dyn. Earthq. Eng. 2017, 100, 286–295. [Google Scholar] [CrossRef]

- Wu, A.X.; Shen, H.; Jiang, L. Arching effect of long-narrow cemented paste backfill body and its effect on target strength. Trans. Nonferr. Met. Soc. China 2016, 26, 648–654. [Google Scholar]

- Grice, T. Recent mine developments in Australia. In Proceedings of the 7th International Symposium on Mining with Backfill (MINEFILL), Seattle, WA, USA, 17–19 September 2001; pp. 351–357. [Google Scholar]

- Fall, M.; Nasir, O. Mechanical behaviour of the interface between cemented tailings backfill and retaining structures under shear loads. Geotech. Geol. Eng. 2010, 28, 779–790. [Google Scholar] [CrossRef]

- Fang, K.; Fall, M. Effects of curing temperature on shear behaviour of cemented paste backfill-rock interface. Int. J. Rock Mech. Min. Sci. 2018, 112, 184–192. [Google Scholar] [CrossRef]

- Fang, K.; Fall, M. Chemically induced changes in the shear behaviour of the interface between rock and tailings backfill undergoing cementation. Rock Mech. Rock Eng. 2019, 52, 3047–3062. [Google Scholar] [CrossRef]

- Fang, K.; Fall, M. Shear behavior of the interface between rock and cemented backfill: Effect of curing stress, drainage condition and backfilling rate. Rock Mech. Rock Eng. 2020, 53, 325–336. [Google Scholar] [CrossRef]

- Hassani, F.P.; Mortazavi, A.; Shabani, M. An investigation of mechanisms involved in backfill-rock mass behaviour in narrow vein mining. J. S. Afr. Inst. Min. Metall. 2008, 108, 463–472. [Google Scholar]

- Ling, T.C.; Kaliyavaradhan, S.K.; Poon, C.S. Global perspective on application of controlled low-strength material (CLSM) for trench backfilling—An overview. Constr. Build. Mater. 2018, 158, 535–548. [Google Scholar] [CrossRef]

- Xu, W.; Li, Q.; Liu, B. Coupled effect of curing temperature and age on compressive behavior, microstructure and ultrasonic properties of cemented tailings backfill. Constr. Build. Mater. 2020, 237, 117738. [Google Scholar] [CrossRef]

- Han, B.; Wu, A.X.; Deng, J.; Wang, X.L. Backfill technical analysis based on reliability theory in the underhand drift cut-and-filling stoping. J. Cent. South Univ. 2006, 37, 583–587. [Google Scholar]

- Yu, C.; Zhu, M.; Shong, X.; Chen, Y. Study on dyeable polypropylene fiber and its properties. J. Appl. Polym. Sci. 2010, 82, 3172–3176. [Google Scholar] [CrossRef]

- Song, P.; Hwang, S.; Sheu, B. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Ma, Y.; Qiu, J.; Wang, P.; Yang, Q.B.; Sun, Z.P.; Jiang, Z.W. Effect of polypropylene fiber on the plastic shrinkage stress and plastic shrinkage ratio of mortar. J. Build. Mater. 2005, 8, 499–507. [Google Scholar]

- Zeiml, M.; Leithner, D.; Lackner, R.; Mang, H.A. How do polypropylene fibers improve the spalling behavior of in-situ concrete. Cem. Concr. Res. 2006, 36, 929–942. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.; Zhang, H. Combined effect of polypropylene fiber and silica fume on mechanical properties of concrete composite containing fly ash. J. Reinf. Plast. Compos. 2011, 30, 1349–1358. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Fall, M.; Belem, T. A contribution to understanding the hardening process of cemented pastefill. Miner. Eng. 2004, 17, 141–152. [Google Scholar] [CrossRef]

- Alexander, M.G. Effects of aging on mechanical properties of the interfacial zone between cement paste and rock. Cem. Concr. Res. 1994, 24, 1277–1285. [Google Scholar] [CrossRef]

- Yi, X.W.; Ma, G.W.; Fourie, A. Compressive behaviour of fibre-reinforced cemented paste backfill. Geotext. Geomembr. 2015, 43, 207–215. [Google Scholar] [CrossRef]

- Consoli, N.C.; Zortea, F.; Souza, M.D.; Festugato, L. Studies on the dosage of fiber-reinforced cemented soils. J. Mater. Civ. Eng. 2011, 23, 1624–1632. [Google Scholar] [CrossRef]

- Zaimoglu, A.S.; Yetimoglu, T. Strength behavior of fine grained soil reinforced with randomly distributed polypropylene fibers. Geotech. Geol. Eng. 2012, 30, 197–203. [Google Scholar] [CrossRef]

- Miller, G.A.; Hamid, T.B. Interface direct shear testing of unsaturated soil. Geotech. Test. J. 2006, 30, 182–191. [Google Scholar]

- Fall, M.; Pokharel, M. Coupled effects of sulphate and temperature on the strength development of cemented tailings backfills: Portland cement-paste backfill. Cem. Concr. Compos. 2010, 32, 819–828. [Google Scholar] [CrossRef]

- Tzouvalas, G.; Dermatas, N.; Tsimas, S. Alternative calcium sulfate-bearing materials as cement retarders: Part I. Anhydrite. Cem. Concr. Res. 2004, 34, 2113–2118. [Google Scholar] [CrossRef]

- Orejarena, L.; Fall, M. Artificial neural network based modeling of the coupled effect of sulphate and temperature on the strength of cemented paste backfill. Rev. Can. Génie Civ. 2011, 38, 100–109. [Google Scholar] [CrossRef]

- Gani, M.S.J. Cement and Concrete; Chapman and Hall: London, UK, 1997. [Google Scholar]

- Kyungsu, H.; Habeun, C.; Moochul, S.; Park, K. On the size effect of interfacial fracture between concrete and fiber reinforced polymer. Cem. Concr. Compos. 2018, 93, 99–106. [Google Scholar]

- Karthik, M.P.; Maruthachalam, D. Experimental study on shear behaviour of hybrid Fibre Reinforced Concrete beams. KSCE J. Civ. Eng. 2015, 19, 259–264. [Google Scholar] [CrossRef]

- Correia, A.A.S.; Venda Oliveira, P.J.; Custodio, D.G. Effect of polypropylene fibres on the compressive and tensile strength of a soft soil, artificially stabilised with binders. Geotext. Geomembr. 2015, 43, 97–106. [Google Scholar] [CrossRef]

- Li, W.; Fall, M. Sulphate effect on the early age strength and self-desiccation of cemented paste backfill. Constr. Build. Mater. 2016, 106, 296–604. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Yu, Z. Influence of polypropylene fiber reinforcement on tensile behavior and failure mode of tailings cemented paste backfill. IEEE Access 2019, 7, 69015–69026. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Xu, X.; Fall, M.; Alainachi, I.; Fang, K. Characterization of fiber-reinforced backfill/rock interface through direct shear Tests. Geotech. Res. 2020, 7, 11–25. [Google Scholar] [CrossRef]

- Ercikdi, B.; Kesimal, A.; Cihangir, F.; Deveci, H.; Alp, İ. Cemented paste backfill of sulphide-rich tailings: Importance of binder type and dosage. Cem. Concr. Compos. 2009, 31, 268–274. [Google Scholar] [CrossRef]

- Saiang, D.; Malmgren, L.; Nordlund, E. Laboratory tests on shotcrete-rock joints in direct shear, tension and compression. Rock Mech. Rock Eng. 2005, 38, 275–297. [Google Scholar] [CrossRef]

- Tian, H.; Chen, W.; Yang, D.; Yang, J.P. Experimental and numerical analysis of the shear behaviour of cemented concrete–rock joints. Rock Mech. Rock Eng. 2015, 48, 213–222. [Google Scholar] [CrossRef]

- Pane, I.; Hansen, W. Investigation of blended cement hydration by isothermal calorimetry and thermal analysis. Cem. Concr. Res. 2005, 35, 1155–1164. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Ouellet, S. Experimental characterization of the influence of tailings fineness and density on the quality of cemented paste backfill. Miner. Eng. 2005, 18, 41–44. [Google Scholar] [CrossRef]

- Fall, M.; Pokharel, M. Strength development and sorptivity of tailings shotcrete under various thermal and chemical loads. Can. J. Civ. Eng. 2011, 38, 772–784. [Google Scholar]

- Mota, B.; Matschei, T.; Scrivener, K. The influence of sodium salts and gypsum on alite hydration. Cem. Concr. Res. 2015, 75, 53–65. [Google Scholar] [CrossRef]

- Bentur, A. Effect of gypsum on the hydration and strength of C3S Pastes. Cheminform 1976, 59, 210–214. [Google Scholar] [CrossRef]

- Pelisser, F.; Gleize, P.J.P.; Mikowski, A. Effect of the Ca/Si molar ratio on the micro/nanomechanical properties of synthetic C-S-H measured by nanoindentation. J. Phys. Chem. C 2012, 116, 17219–17227. [Google Scholar] [CrossRef]

- Xu, W.; Cao, P.; Tian, M. Strength Development and Microstructure Evolution of Cemented Tailings Backfill Containing Different Binder Types and Contents. Minerals 2018, 8, 167. [Google Scholar] [CrossRef]

- Hou, D.; Zhang, J.; Li, Z.; Zhu, Y. Uniaxial tension study of calcium silicate hydrate (C–S–H): Structure, dynamics and mechanical properties. Mater. Struct. 2015, 48, 3811–3824. [Google Scholar] [CrossRef]

- Kantro, D.L.; Brunauer, S.; Weise, C.H. Development of surface in the hydration of calcium silicate in solid surfaces and the gas-solid interface. Adv. Chem. 1961, 33, 199–219. [Google Scholar]

- Li, W.; Fall, M. Strength and self-desiccation of slag-cemented paste backfill at early ages: Link to initial sulphate concentration. Cem. Concr. Compos. 2018, 89, 160–168. [Google Scholar] [CrossRef]

- Prabakar, J.; Sridhar, R.S. Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr. Build. Mater. 2002, 16, 123–131. [Google Scholar] [CrossRef]

- Consoli, N.C.; Bassani, M.A.A.; Festugato, L. Effect of fiber reinforcement on the strength of cemented soils. Geotext. Geomembr. 2010, 28, 344–351. [Google Scholar] [CrossRef]

- Xu, W.; Li, Q.; Zhang, Y. Influence of temperature on compressive strength, microstructure properties and failure pattern of fiber-reinforced cemented tailings backfill. Constr. Build. Mater. 2019, 222, 776–785. [Google Scholar] [CrossRef]

- Cao, S.; Zheng, D.; Yilmaz, E.; Yin, Z.; Xue, G.; Yang, F. Strength development and microstructure characteristics of artificial concrete pillar considering fiber type and content effects. Constr. Build. Mater. 2020, 256, 119408. [Google Scholar] [CrossRef]

- Starcher, R.D.; Liu, C. Mechanical behavior of cement- and cement-fiber-improved soft soils. In Geo-Congress 2013: Stability and Performance of Slopes and Embankments III; Meehan, C., Pradel, D., Pando, M.A., Labuz, J.F., Eds.; American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 2048–2057. [Google Scholar]

| List of Symbols | Complete Terms |

|---|---|

| CPB | Cemented Paste Backfill |

| FR-CPB | Fiber-reinforced CPB |

| FR-CPB/rock interface | Interface between the FR-CPB and the rock. |

| UCS | Unconfined compressive strength |

| LVDT | Linear Variable Differential Transformer |

| ST | Silica tailings |

| TG | Thermal gravity |

| DTG | Differential thermal gravimetric |

| EC | Electrical conductivity |

| SEM | Scanning electron microscopy |

| C3A | 3CaO·Al2O3 |

| C-S-H | Calcium silicate hydrate |

| Element | GS | D10 | D30 | D50 | D60 | CU | CC | SS |

|---|---|---|---|---|---|---|---|---|

| Unit | - | (μm) | (μm) | (μm) | (μm) | - | - | (cm2/g) |

| ST | 2.7 | 1.9 | 9.0 | 22.5 | 31.5 | 16.6 | 1.3 | 3600 |

| Average properties of 9 types of tailings in eastern Canada | - | 1.8 | 9.1 | 20.0 | 30.8 | 17.1 | 1.7 | - |

| Binder | MgO (wt.%) | CaO (wt.%) | SiO2 (wt.%) | Al2O3 (wt.%) | Fe2O3 (wt.%) | SO3 (wt.%) | Gs | SS (cm2/g) |

|---|---|---|---|---|---|---|---|---|

| PCI | 2.65 | 62.86 | 18.03 | 4.53 | 2.70 | 3.82 | 3.15 | 1300 |

| Specimen Type | Tailings | Binder Content (%) | W/C | Fiber Content (%) | Initial Sulfate Concentration (mg/L) | Treatment Time (Days) |

|---|---|---|---|---|---|---|

| FR-CPB/granite | ST | 4.5 | 7.35 | 0 | 0, 5000, 25,000 | 1 |

| FR-CPB/granite | ST | 4.5 | 7.35 | 0.1 | 0, 5000, 25,000 | 7 |

| FR-CPB/granite | ST | 4.5 | 7.35 | 0.3 | 0, 5000, 25,000 | 1, 3, 7, 28 |

| FR-CPB/granite | ST | 4.5 | 7.35 | 0.5 | 0, 5000, 25,000 | 7 |

| Sample Number | Interface Type | Fiber Content (%) | Sulfate Concentration (mg/L) | Interface Shear Strength Parameters | |

|---|---|---|---|---|---|

| Cohesion, c (kPa) | Internal Friction Angle, φ (°) | ||||

| 1 | FR-CPB/rock | 0.0 | 0 | 22.2 | 24.2 |

| 2 | FR-CPB/rock | 0.0 | 5000 | 17.9 | 23.1 |

| 3 | FR-CPB/rock | 0.0 | 25,000 | 12.1 | 22.1 |

| 4 | FR-CPB/rock | 0.3 | 0 | 24.2 | 24.7 |

| 5 | FR-CPB/rock | 0.3 | 5000 | 20.8 | 23.2 |

| 6 | FR-CPB/rock | 0.3 | 25,000 | 17.2 | 22.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Wu, W.; Xu, W. Sulfate-Dependent Shear Behavior of Cementing Fiber-Reinforced Tailings and Rock. Minerals 2020, 10, 1032. https://doi.org/10.3390/min10111032

Xu X, Wu W, Xu W. Sulfate-Dependent Shear Behavior of Cementing Fiber-Reinforced Tailings and Rock. Minerals. 2020; 10(11):1032. https://doi.org/10.3390/min10111032

Chicago/Turabian StyleXu, Xiangqian, Weilv Wu, and Wenbin Xu. 2020. "Sulfate-Dependent Shear Behavior of Cementing Fiber-Reinforced Tailings and Rock" Minerals 10, no. 11: 1032. https://doi.org/10.3390/min10111032

APA StyleXu, X., Wu, W., & Xu, W. (2020). Sulfate-Dependent Shear Behavior of Cementing Fiber-Reinforced Tailings and Rock. Minerals, 10(11), 1032. https://doi.org/10.3390/min10111032