1. Introduction

Different sorts of rotating machines are used in the industry that are equipped with bearings as a fundamental rotating element. These rotating machines include industrial motors, compressors, fans, turbines, and so on [

1,

2,

3,

4]. It is crucial for the rotating machines to work smoothly in the industrial environment, without which a sudden switch-off could occur in the entire industrial processing. To avoid this situation, predictive maintenance of the rotating machines is required. Vibration signals from the rotating element bearings possess efficient information about the rotating machine conditions. Vibration signals from rotating machines are evaluated using different digital signal processing (DSP) techniques and machine learning (ML) technologies to detect the condition of the machine. The symmetrical behavior of these signals provides valuable insights into the functioning and condition of the bearings. When a fault occurs in the bearings, deviations from their symmetrical behavior can be indicative of potential issues or faults. Therefore, by examining the symmetrical characteristics of the vibration signals, it becomes possible to identify and diagnose faults accurately, allowing for timely maintenance and prevention of sudden shutdowns or damages to the entire industrial process.

DSP methods are employed to extract relevant information from vibration signals. The vibration signals acquired from a rotating machine possess background noise and unwanted signals, which cause a low signal-to-noise ratio, and, consequently, it is challenging to diagnose the condition of the rotating machines [

5]. To solve this issue, filtering is used to reduce noise or isolate certain frequency ranges of interest. Envelope analysis using power spectrum density (PSD) is also widely employed to determine the faults in rotating machines [

6], but the vibration signals must have a high signal-to-noise ratio. Alternatively, kurtosis is an excellent statistical index to determine the transient in the vibration signal. Spectral Kurtosis (SK) [

7,

8,

9] computes kurtosis over each frequency band in the vibration signal. In the literature, different results are presented for the fault diagnosis in vibration signals using kurtosis and SK [

5,

9,

10,

11]. However, it is challenging to determine the faults and machine conditions because of the non-ideal vibration signals.

ML technologies, on the other hand, are employed to train algorithms on labeled data to categorize the condition of the machine as normal or abnormal based on vibration patterns. Clustering, decision trees, neural networks, and support vector machines are some of the approaches that are used in ML techniques [

12,

13,

14,

15,

16,

17,

18]. Furthermore, intelligent health diagnosis efficiently detects the faults in the rotating machine and generates results on its own using ML methods [

19,

20]. These intelligent methods are usually composed of two main steps: the first one is feature learning using a neural network or signal processing, and the second one is classification using pattern reorganization methods [

21].

Moreover, deep learning methods have shown better performance in many fields including image classification, object detection, segmentation, and speech precogitation [

22]. Deep learning methods can handle high-dimensional complex data and learn features because of their multi-layer neural networks [

23,

24,

25]. Deep learning is a form of ML that includes training multiple-layer artificial neural networks to discover complicated patterns and correlations in data. Deep learning approaches come in a variety of flavors, including [

26]:

Autoencoders: These are neural networks that have been trained to learn a compressed representation of input data. The network is initially trained to encode the input data into a lower-dimensional representation before decoding it back into its original format. Autoencoders are frequently used to extract features and reduce dimensionality.

Deep belief networks: These are generative models with numerous layers of hidden units. Deep belief networks are trained through unsupervised learning and may be utilized for image and voice recognition.

Deep Boltzmann machines: These are similar to deep belief networks, but they employ a different form of model known as a Boltzmann machine. Deep Boltzmann machines are also learned via unsupervised learning and may be utilized for tasks such as collaborative filtering and anomaly detection.

Recurrent neural networks (RNNs) are neural networks that are designed to process sequential input, such as text or time series data. RNNs include loops in their network design that allow them to recall prior inputs and learn dependencies over time. RNNs are frequently used for language modeling and speech recognition.

Convolutional neural networks (CNNs): These are neural networks that employ convolutional layers to learn spatial patterns in a picture or audio input. CNNs are frequently used for object identification and speech recognition.

Many researchers have combined CNN with other methods to improve the performance of fault diagnosis in rotating machines. For example, CNN is combined with a hierarchical convolution network [

27] and hierarchical symbolic analysis [

28,

29], respectively, for bearing fault diagnosis. In [

30], vibration signals are preprocessed using continuous wavelet transform and then CNN is applied to diagnose the condition. Feature alignment method is used in [

31] with multiscale CNN and multivariate encoder information-based CNN is applied in [

32] for gearbox fault diagnosis. In [

33], normalized deep CNN (DCNN) is applied for imbalanced fault diagnosis, and in [

23], DCNN is applied to a noisy environment under different working loads.

Each of these deep learning approaches has advantages and disadvantages, and the methods used are determined by the goals and data at hand. Among these methods, DCNN is one of the most efficient methods for vibration fault diagnosis and prognosis in rotating machines because of two reasons [

21,

34]. The first reason is that raw vibration data can directly be applied to DCNN without manually extracting features because DCNN has the ability to extract the features automatically from raw data. The second reason for DCNN’s popularity is that it has better performance with less training data compared to other neural network architectures [

21,

35]. However, the performance of DCNN is affected by raw vibration datasets from variable-speed rotating machines and variations in fault depths.

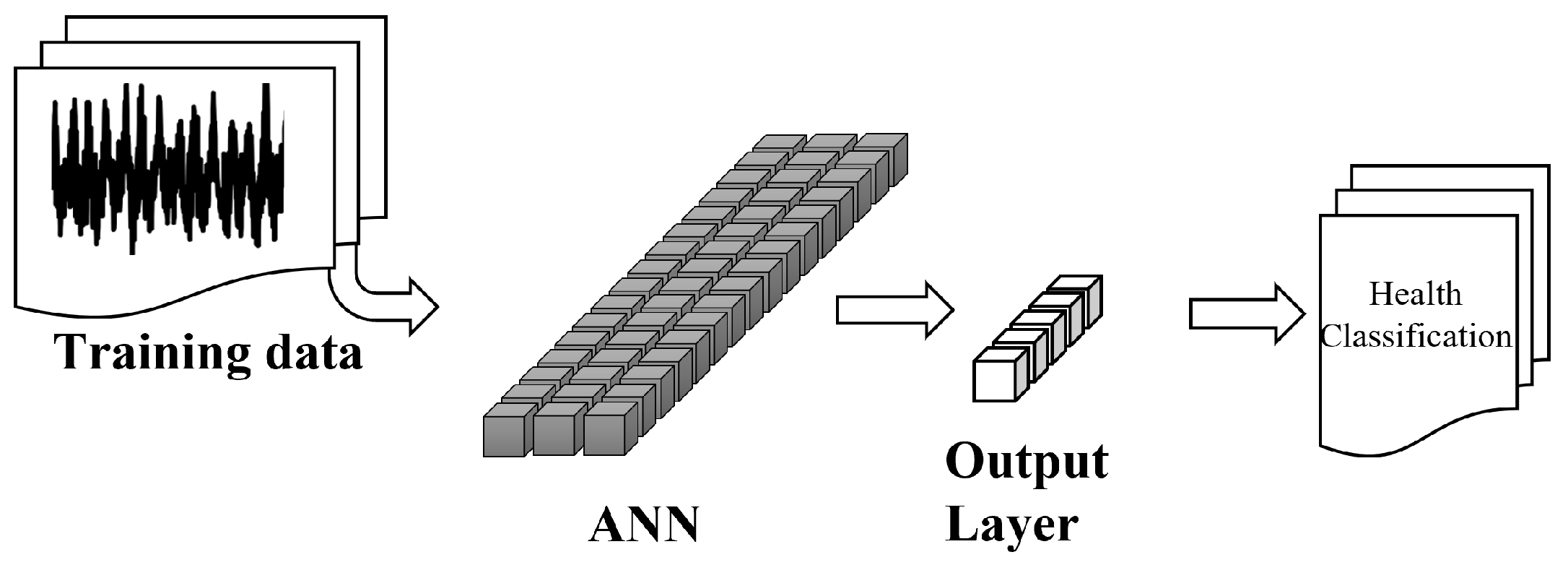

To improve the performance of DCNN, different sorts of classifiers are reported in the literature, including the Bayesian classifier, Artificial Neural Network (ANN), and Support Vector Machine (SVM) [

14,

36,

37,

38]. The Bayesian classifier is a statistical classifier that uses Bayes’ theorem to assess the likelihood of a data point belonging to a certain class based on the likelihood of the attributes associated with that class. It is a simple and effective classifier, but it implies that the characteristics are independent of one another and that the feature distribution is known. ANNs are a type of machine learning model that is inspired by the structure and function of the human brain. ANNs are made up of linked nodes or neurons that execute mathematical operations on input data to anticipate output. Since they can learn complicated patterns and correlations in data, ANNs are frequently employed for categorization jobs. SVMs are a sort of supervised learning algorithm that is used for classification and regression analysis. SVMs seek a hyperplane that best separates the distinct classes in the input space. SVMs are frequently used for fault classification because they are good at managing high-dimensional data and can manage non-linear correlations between features.

Other classifiers that are commonly used for fault classification include decision trees, random forests, and k-nearest neighbors (KNN). The choice of the classifier will depend on the specific requirements of the task, such as the size and complexity of the dataset, the number of classes, and the desired level of accuracy and interpretability. The first two classifiers work efficiently if enough training data are available; otherwise, their performance is poor. On the other hand, SVM works efficiently with less training data because of its efficient network generalization capability and high classification accuracy [

39]. However, if the data are redundant, the performance of SVM decreases because of its shallow structure [

40].

Recently, researchers have been working on new techniques in order to analyze the rotating machine conditions; however, the accuracy and sensitivity of vibration analysis techniques, including digital signal processing and machine learning, can be affected by changes in working conditions or by constraints such as limited sensor data, high levels of noise, and complex vibration patterns. Furthermore, the above-mentioned literature review relies on huge training data, which is challenging for rotating machines in real industrial fault diagnosis environments. Moreover, there is little literature on condition diagnosis for variable speed vibration data using CNN, and even less has been researched about intelligent fault diagnosis for variable speed vibration data using DCNN.

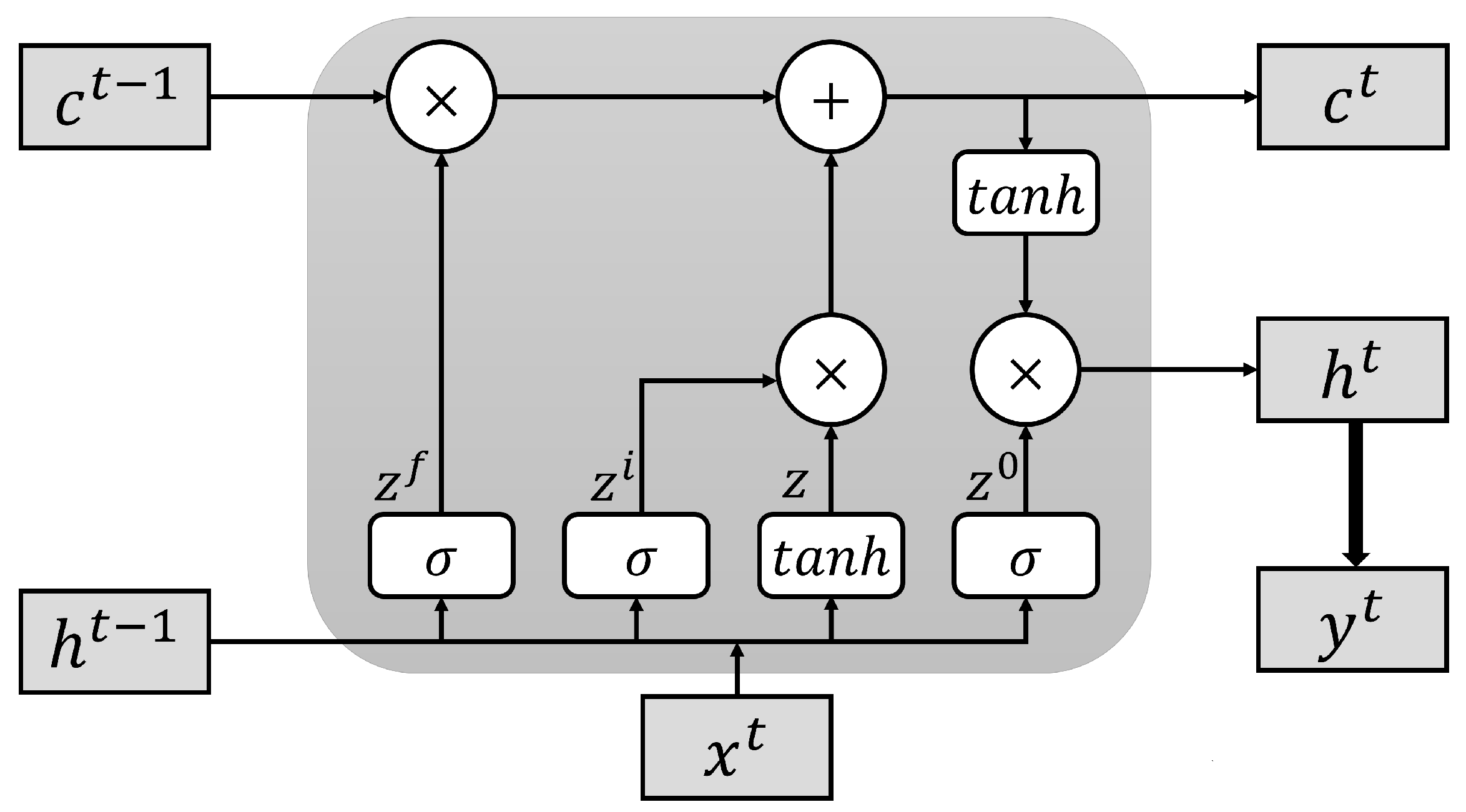

The Long Short-Term Memory (LSTM) architecture excels at capturing and modeling long-term dependencies, which is crucial for fault classification in variable-speed rotating machines. The following are how LSTM addresses specific requirements in this context:

Variable-speed rotating machines generate sequential data where each time step is influenced by the preceding ones. LSTM’s recurrent connections allow for the capture of temporal dependencies in the data. By retaining information from previous time steps in its memory cell, LSTM can learn and exploit the patterns and relationships that exist across different speed regimes and time periods.

Variable-speed machines produce data sequences of varying lengths depending on the duration of operation or the occurrence of faults. LSTM is designed to handle variable-length sequences as it processes data in a step-by-step manner, adapting to the varying time lengths. This flexibility makes LSTM well-suited for accommodating the dynamic nature of variable-speed rotating machines.

LSTM’s ability to recognize and learn speed-dependent features is crucial for fault classification in variable-speed rotating machines. By training on historical data that include speed information, LSTM can capture the relationships between speed and fault characteristics. It can then leverage these learned associations to make accurate fault predictions and classifications when new data are presented, considering the specific speed regime of the machine.

Faults in rotating machines can exhibit complex patterns that may be difficult to detect using traditional techniques. LSTM’s architecture allows it to learn and model complex relationships within the data. It can automatically extract relevant features, recognize subtle fault patterns, and capture the interactions between speed variations and fault signatures. This enables LSTM to provide accurate fault classifications even in challenging scenarios.

By utilizing LSTM’s architecture, operators can leverage its ability to handle temporal dependencies, accommodate variable-length sequences, recognize speed-dependent features, and learn complex fault patterns. This makes LSTM a suitable choice for fault classification in variable-speed rotating machines. It can enhance the accuracy and reliability of fault diagnosis, enabling timely maintenance actions and improving the overall performance and longevity of the machines.

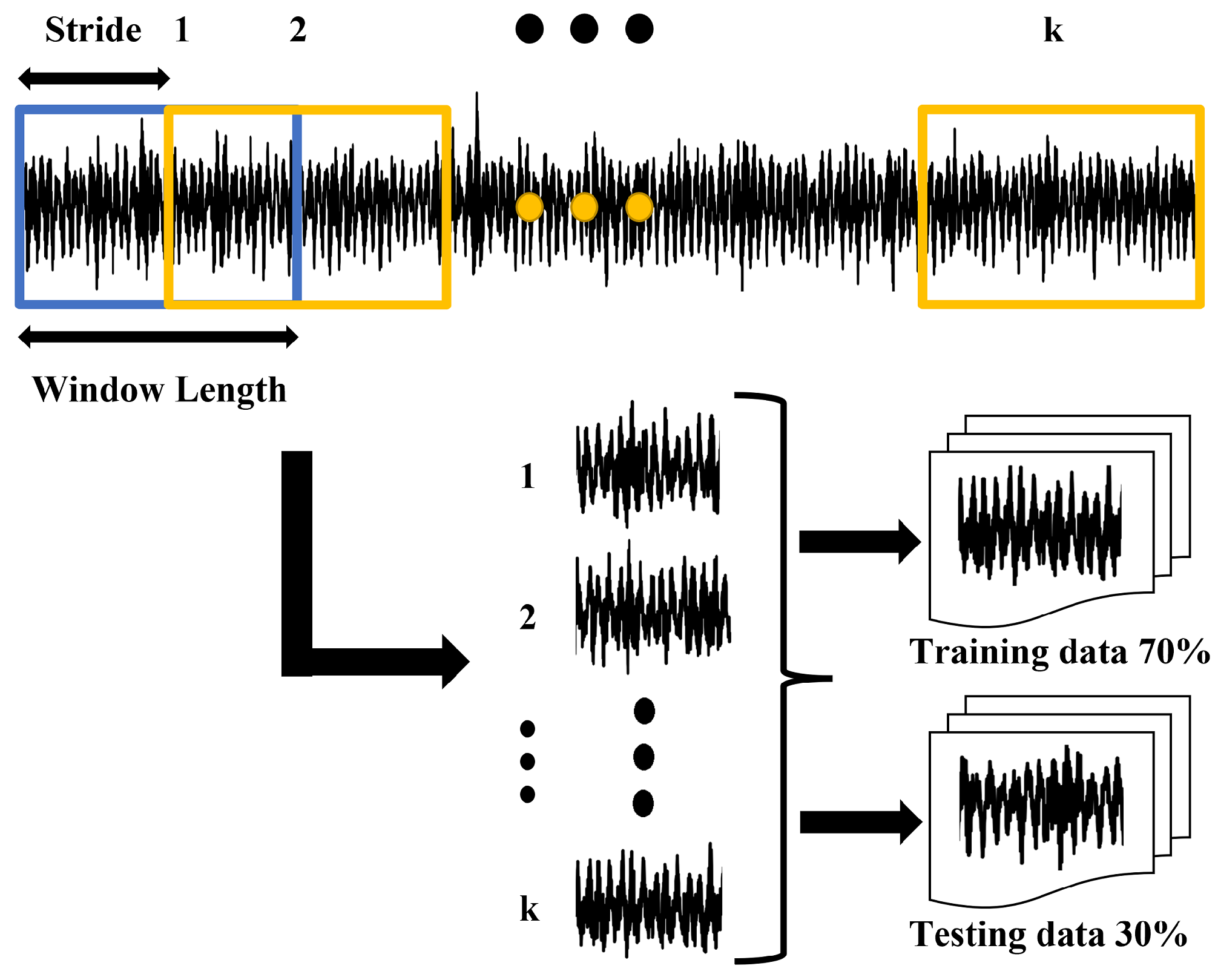

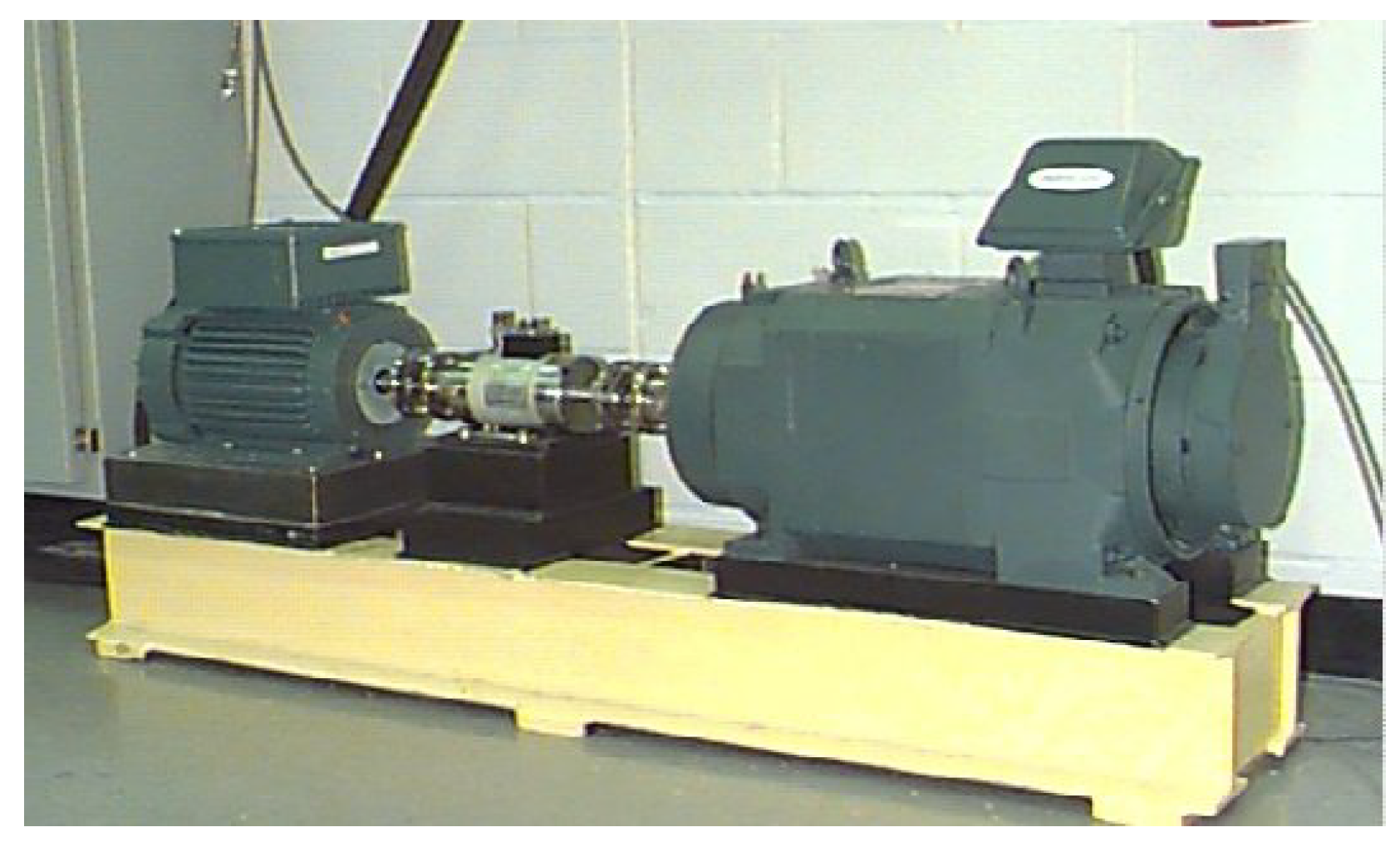

Motivated by the aforementioned literature, this paper proposes an efficient model consisting of DCNN-LSTM with SoftMax classifier to diagnose the faults in raw vibration signals. The proposed model is efficient for multiple fault diagnoses such as outer race fault, inner race fault, ball fault, and mixed faults in vibration signals acquired from variable speed rotating machines and diverse fault depths datasets. Different from the existing DCNN models, the proposed model consists of DCNN and LSTM with SoftMax classifier for multiple faults diagnosis and is efficient for both (1) variable speed rotating machines where the vibration data were recorded when the speed of the rotating machine was first increased and then decreased, and (2) a diverse fault depths dataset that consists of healthy bearings, inner race faults, outer race faults, and ball faults with different fault depths. The experimental results driven using the proposed model are compared with the existing models in the literature, and it is concluded that, for both datasets, the proposed model is more efficient in terms of accuracy to diagnose the different fault conditions.

The rest of the paper is arranged as follows.

Section 2 includes the materials and methods that describe the proposed model and experimental setups used to record the vibration datasets. This section includes two different datasets utilized to validate the proposed model. In

Section 3, the simulation results are presented for both datasets. This section also compares the results concluded for the proposed DCNN-LSTM model with the existing models in the literature and the ANN model with SoftMax classifier to illustrate the superiority of the proposed model over the existing models in the literature. Finally, the conclusion of this research work is presented at the end.

4. Conclusions

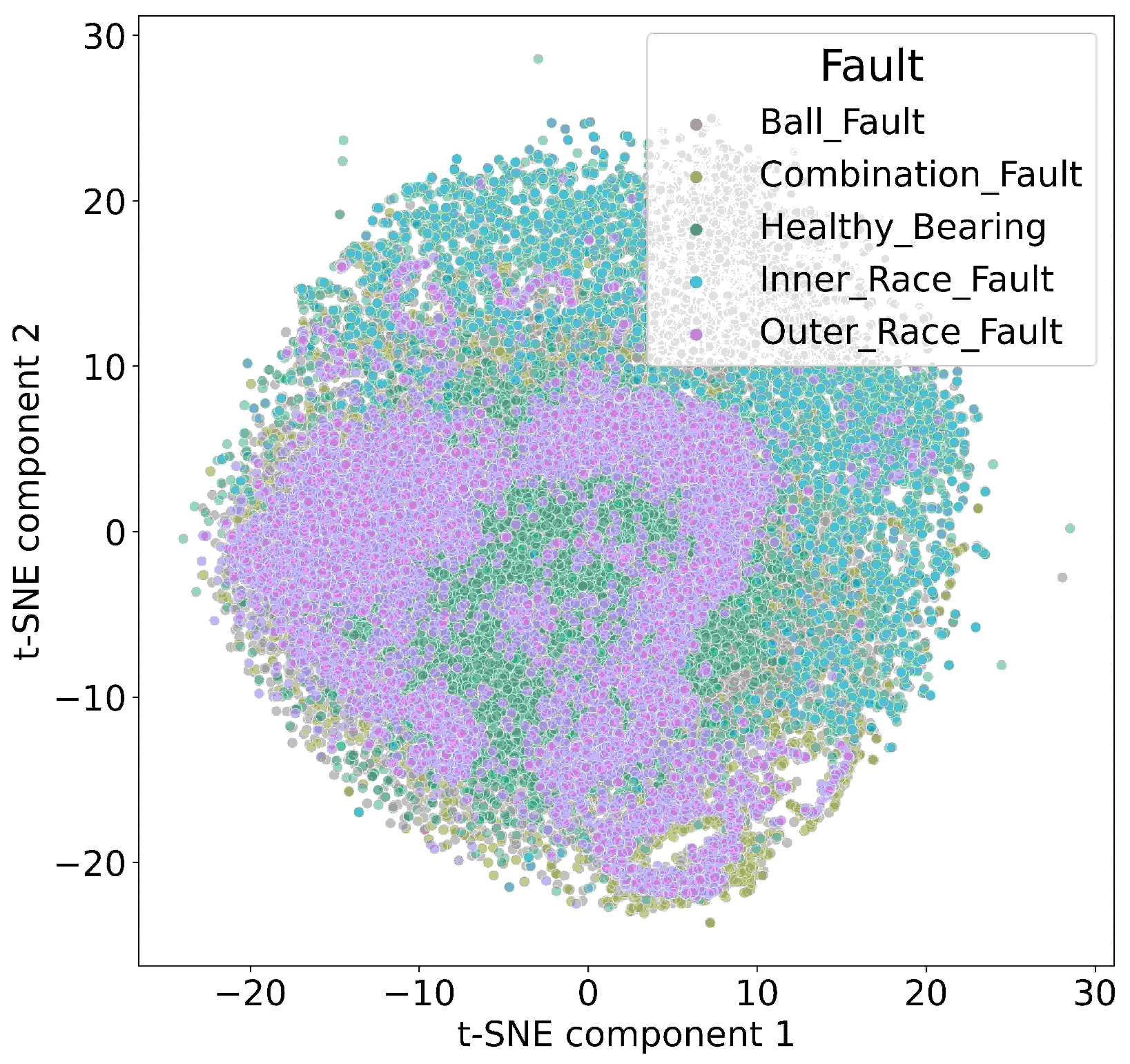

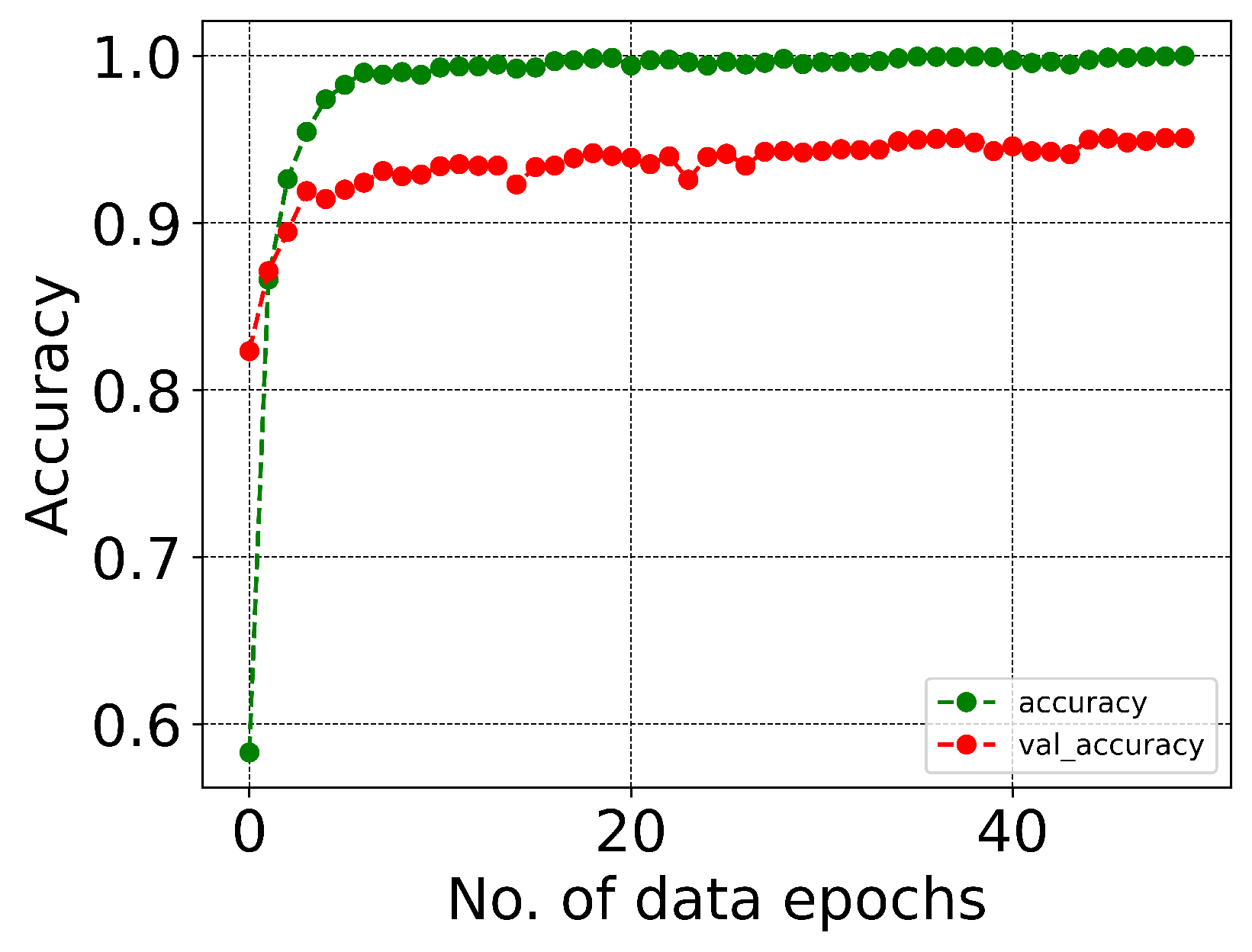

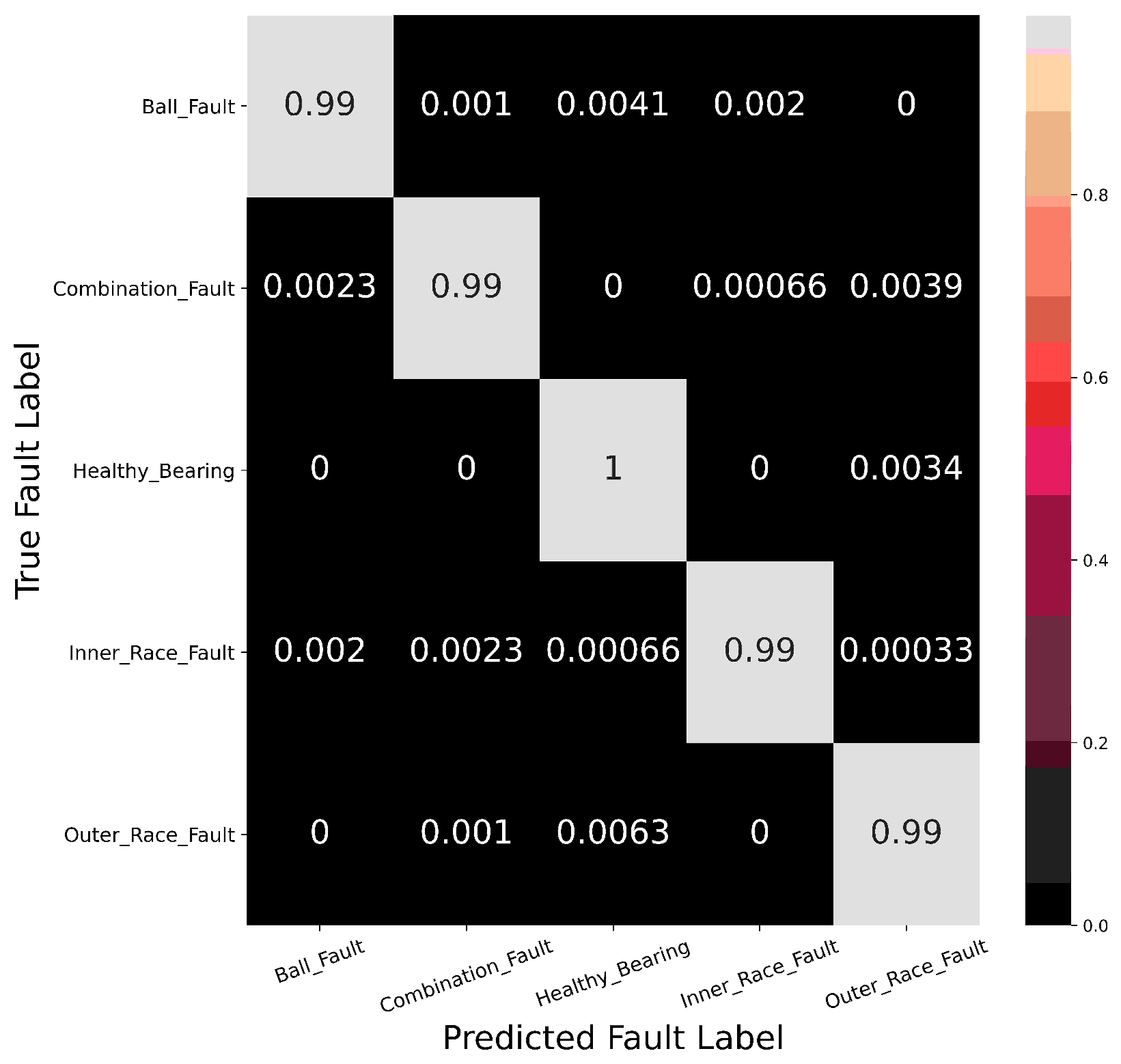

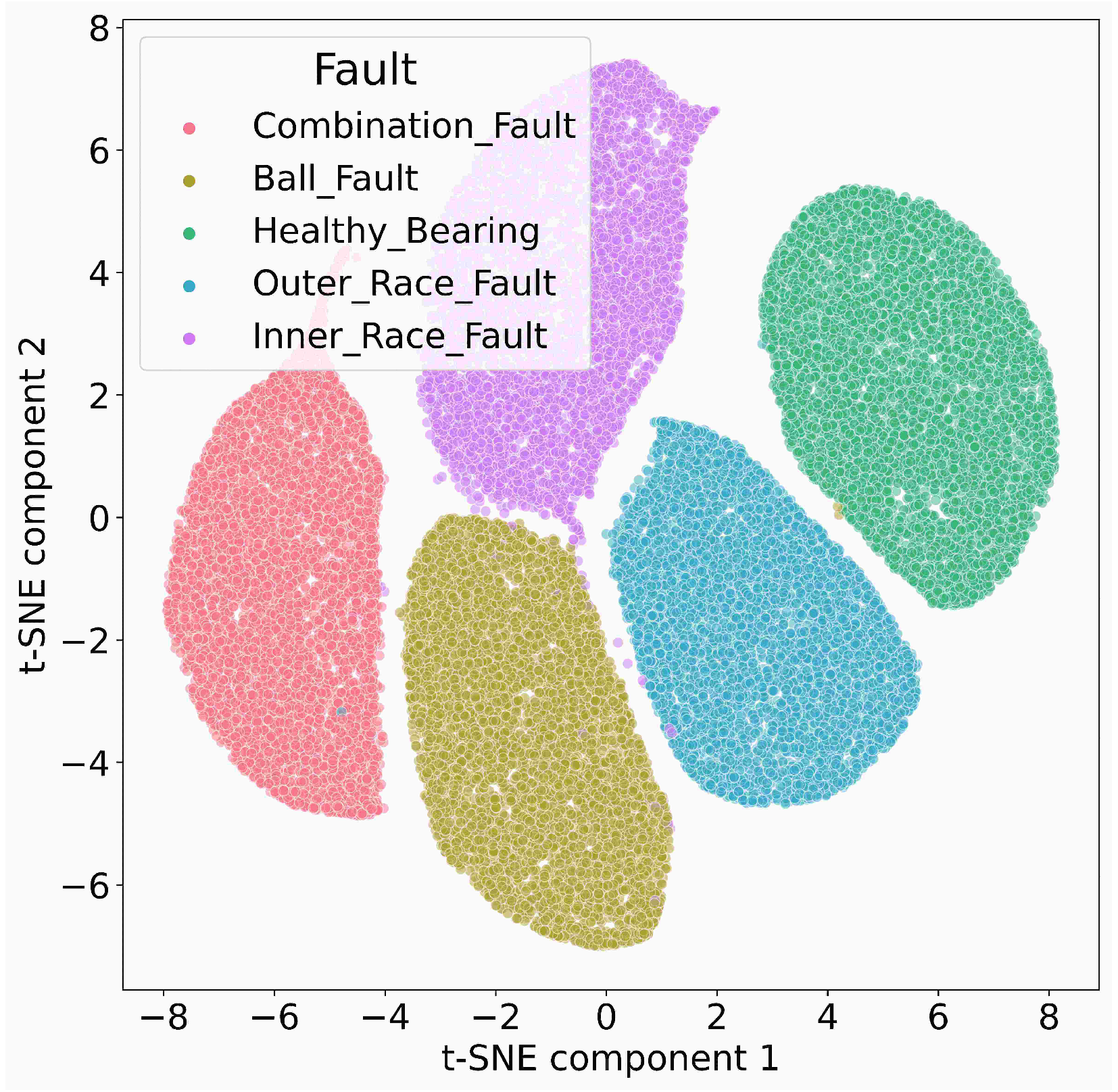

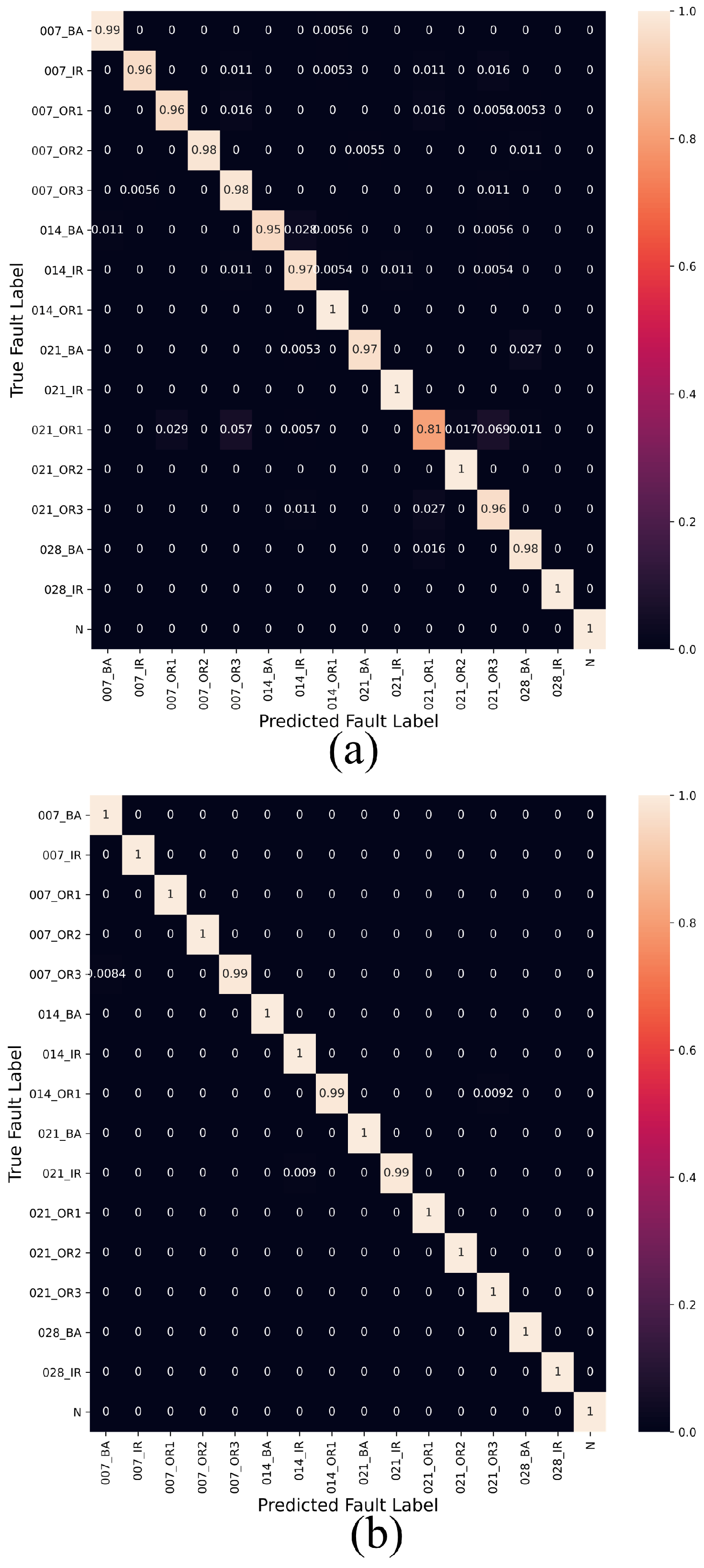

This paper proposes an efficient model of the DCNN-LSTM model with SoftMax classifier for diagnosing faults in rotating machines, capable of diagnosing faults in both variable speed and diverse fault depths datasets. In contrast to the current DCNN-LSTM models, the novel model presented in this study exhibits enhanced efficacy in two distinct scenarios. Firstly, it demonstrates efficiency in analyzing vibration data obtained from variable-speed rotating machines. The recorded data encompass instances where the rotational speed of the machine undergoes a sequential increase and subsequent decrease. This characteristic sets it apart from prior DCNN-LSTM models that primarily focus on constant-speed operating conditions. The proposed DCNN-LSTM model achieved an impressive overall condition prediction accuracy of 99.40% for variable-speed rotating machines. In addition, when compared to the existing literature, it was found that the proposed model outperformed the other approaches in terms of prediction accuracy.

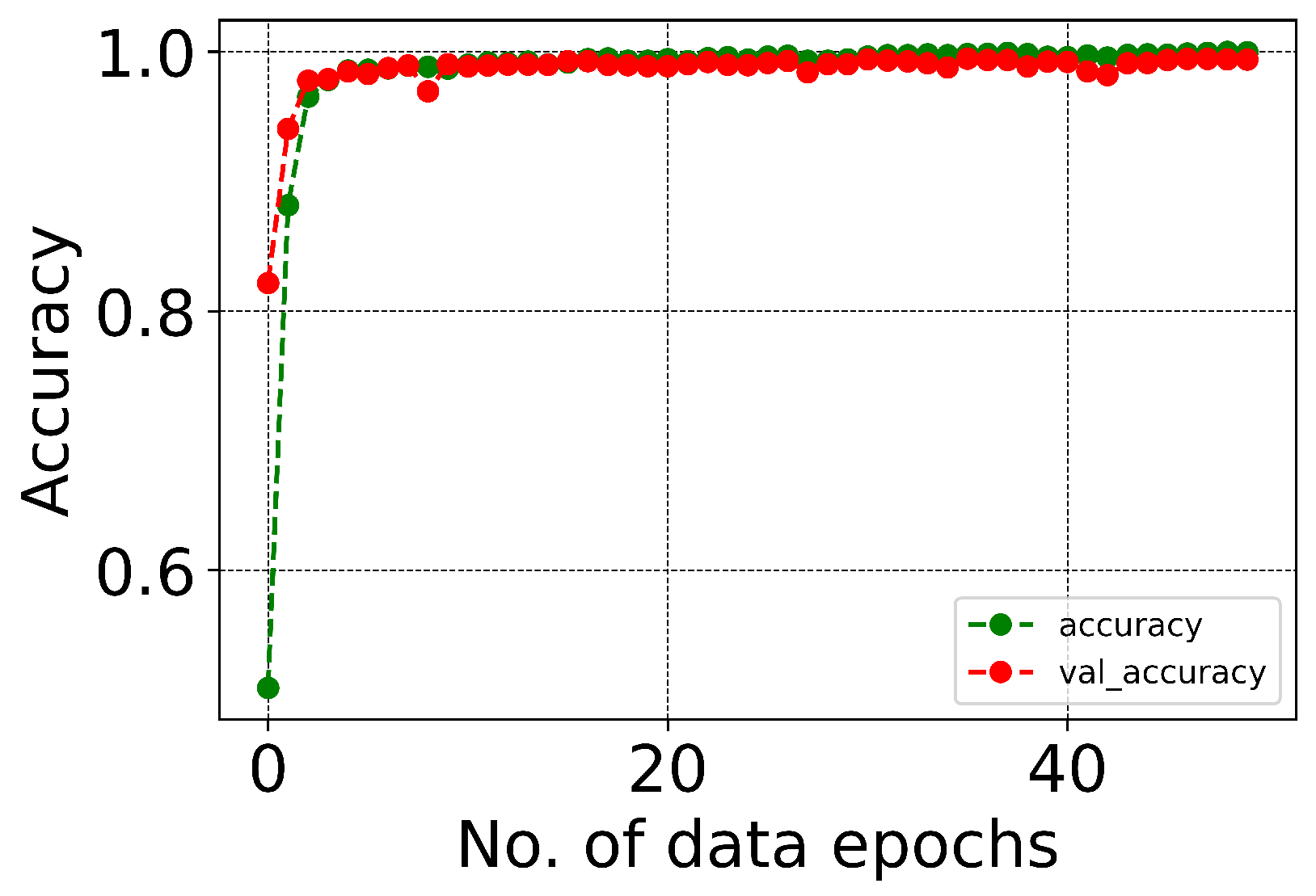

Secondly, the proposed model showcases its effectiveness in handling a diverse fault depths dataset. This dataset comprises various fault categories, including healthy bearings, inner race faults, outer race faults, and ball faults. Notably, each fault category incorporates fault instances with different levels or depths of damage to the machinery. This aspect distinguishes the proposed model from existing approaches, which often concentrate on specific fault types or do not explicitly consider varying fault depths. The DCNN-LSTM model proposed in this study demonstrated an outstanding overall condition prediction accuracy of 99.87% when applied to a diverse fault depths dataset. Furthermore, when compared to existing literature, it is evident that the proposed model surpasses other approaches in terms of prediction accuracy.

Moreover, the proposed model eliminates the need for manual feature extraction from the vibration datasets. This examination of symmetrical characteristics enables accurate identification and diagnosis of faults, leading to timely maintenance and the prevention of sudden shutdowns or damages to the entire industrial process. It streamlines the analysis process by directly feeding the raw vibration signals into the model. This feature circumvents the laborious task of manually identifying and extracting relevant features, thus enhancing the efficiency and simplicity of the diagnostic process.

The performance of the proposed model was compared with an ANN model for both datasets, and it was found that the proposed DCNN-LSTM model with the SoftMax classifier is more efficient in diagnosing fault conditions. Additionally, the results of the proposed model were compared with existing models in the literature, demonstrating its ability to effectively diagnose faults in both variable speed and diverse fault depths datasets with a load. Overall, it was concluded that the proposed DCNN-LSTM model with SoftMax classifier is a promising tool for fault diagnosis in rotating machines with raw vibration datasets.