Whether the RA can successfully avoid obstacles, the key is to determine the distance from the RA to the obstacles. Moreover, near the obstacle, it is easy to generate a symmetric path, and the RA needs to quickly optimize it to choose a better trajectory to move. If the modeling is based on the shape of the robot and the obstacle, for checking whether they collide at each moment, it will make the computational complexity much higher and the solution more difficult to obtain. Therefore, this study uses the bounding box detection method to simplify the collision detection object model and reduce the computational complexity.

4.1. Bounding Box Collision Detection

According to the shape characteristics of the bounding box, the bounding box can be classified as CBB, AABB, or SBB, etc. The computational complexity of collision detection decreases with the simplification of the bounding box shape. However, the simple shape may lead to poor envelope sealing to the envelope of the RA, which directly affects the collision detection sensitivity [

24].

4.1.1. Collision Detection Based on Cylinder Bounding Box

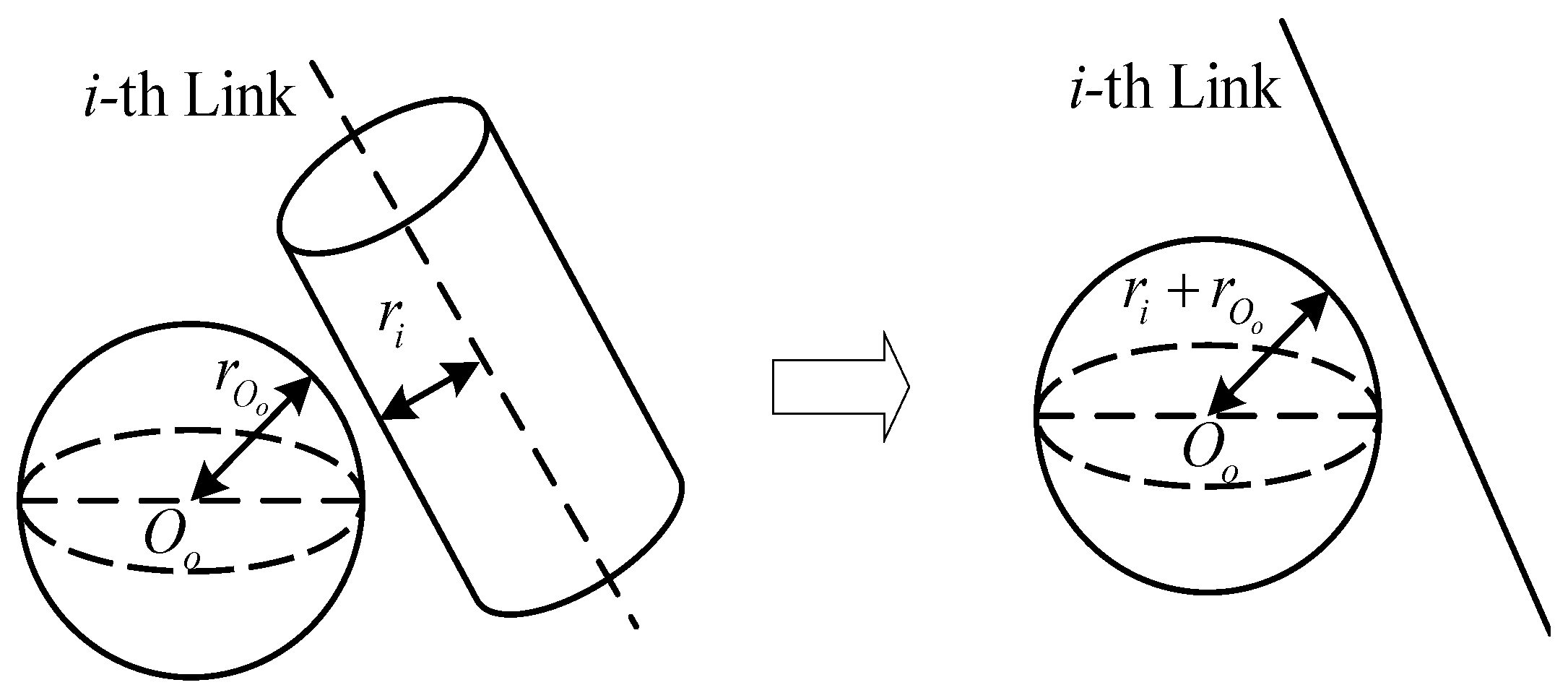

Figure 7 shows the spatial position relationship between the CBB of the

i-th link of the RA and the obstacle. To simplify the calculation, the cylinder can be considered as a line segment, while the radius

of the sphere surrounding the obstacle is increased by the radius

of the cylinder. Thus, the collision detection problem is simplified into an intersection detection problem between a line and a ball in space.

The sphere of the obstacle has a centre of

. The first and last coordinates of the

i-th link of the robot are

,

. From the centre

, a vertical line segment is drawn towards the link

i and intersects the line segment at the point

. Suppose the coordinate of the foot point

is

. We obtain the equation of a straight line in space:

The coordinates of the foot point

can be determined by the proportional coefficient

in the Equation (

17). We will typically want to ensure that the robot has a safety margin

[

25]. Thus, we want to enforce the following constraints at each time step.

4.1.2. Collision Detection Based on Multi-Sphere Bounding Box

The SBB uses a sphere with the smallest radius that can completely enclose the object to approximate the RA. The object is projected onto the coordinate axes, and the two points farthest apart are obtained. Take the midpoint of the line segment connecting the two points as the center of the sphere. The length of the line segment is used as the diameter of the sphere to construct the minimum SBB.

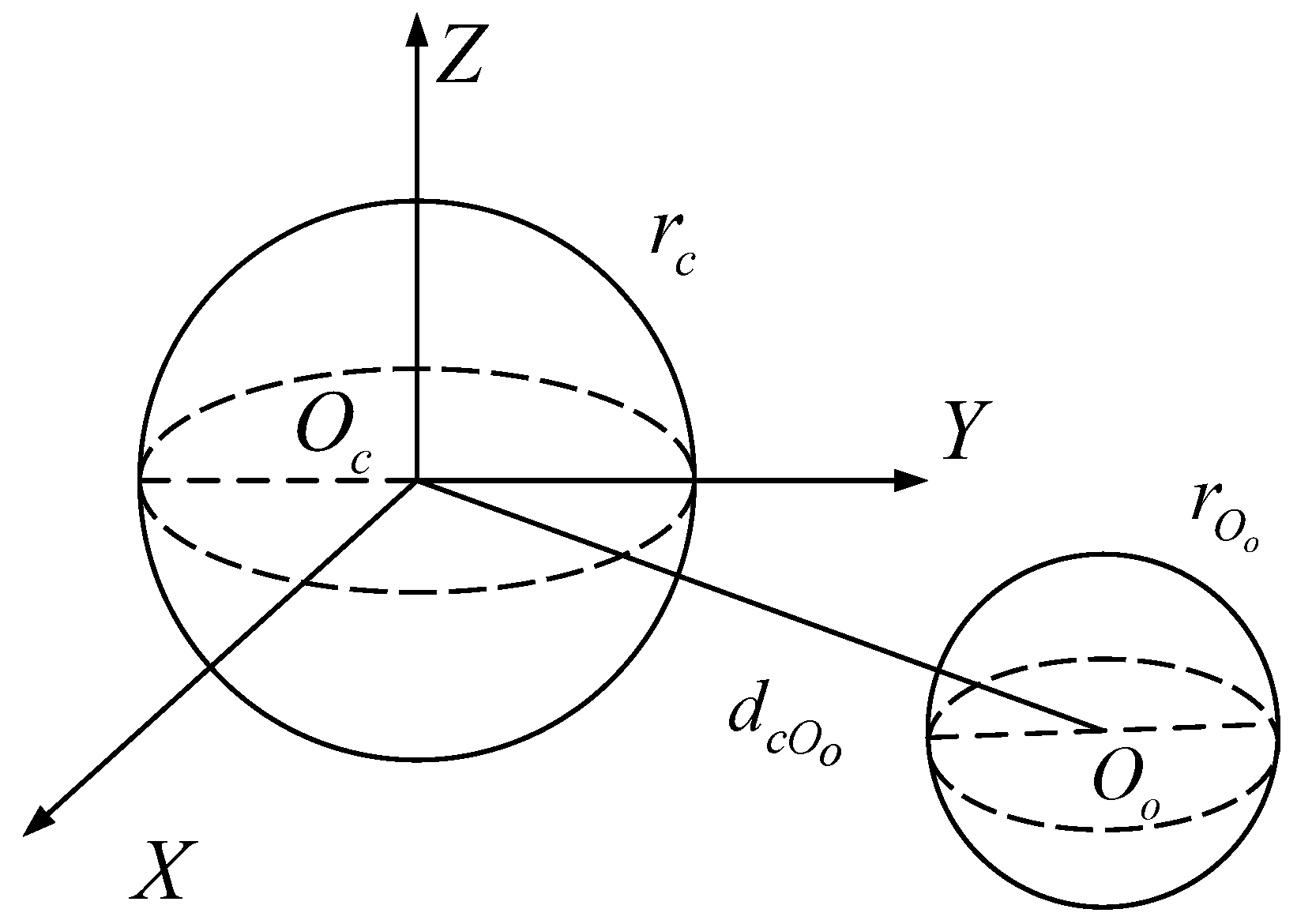

Suppose the coordinates of the center of the sphere are , and the radius of the sphere is . The obstacle enveloped by a SBB, its spherical center and radius are and .

According

Figure 8, the distance

between the centers of the two spheres can be calculated by the spatial expression of the two spheres.

It is simple to check for collisions between R3-RA and obstacles by SBB. However, the distribution of the R3-RA over the three coordinate axes is not uniform. When R3-RA is enveloped by the SBB, there will be a large amount of redundant space inside, which will lead to a decrease in the accuracy of collision detection and a considerable increase in the solution time. After analyzing the shape of the R3-RA, we decided to use multiple spheres of different sizes to envelope the RA, so that it could compensate for the poor compactness.

Select a set of points

on the centre line of the

i-th link as the centre of the bounding sphere, and define the corresponding radius

. Make point

as centre, such that the set

of spheres can fully envelop the

i-th link.

Figure 9 shows the multi-sphere surrounding the RA.

Similarly, we want to enforce the following constraints at each time step.

Hereby,

is the center of the

k-th bounding ball on the

i-th link,

,

is the number of bounding balls on the link.

can be specifically expressed by Equation (

19).

4.2. Numerical Results

In order to more fully test the collision-free trajectory planning based on the two bounding box, we test them under two different task requirements. Task 1: , . The coordinates of the ball centre surrounding the obstacles are , the radius of the ball surrounded by obstacles is and the safety distance is . parse-numbers = false Task 2: , . The coordinates of the ball centre surrounding the obstacles are , the radius of the ball is and the safety distance is .

According to the obstacle positions, it is found that only the third link is likely to collide with the obstacle during the RA running, so the collision-free constraint using CBB in OTP (

8) can be simplified:

With

different spheres enveloping the third link, the collision-free constraint in OTP (

8) can be simplified:

Except for the no-collision constraint, other constraints are shown in the Equation (

16). Set the weighs

. The collision-free OTP is solved by GA-CVP, and the simulation is carried out on MATLAB.

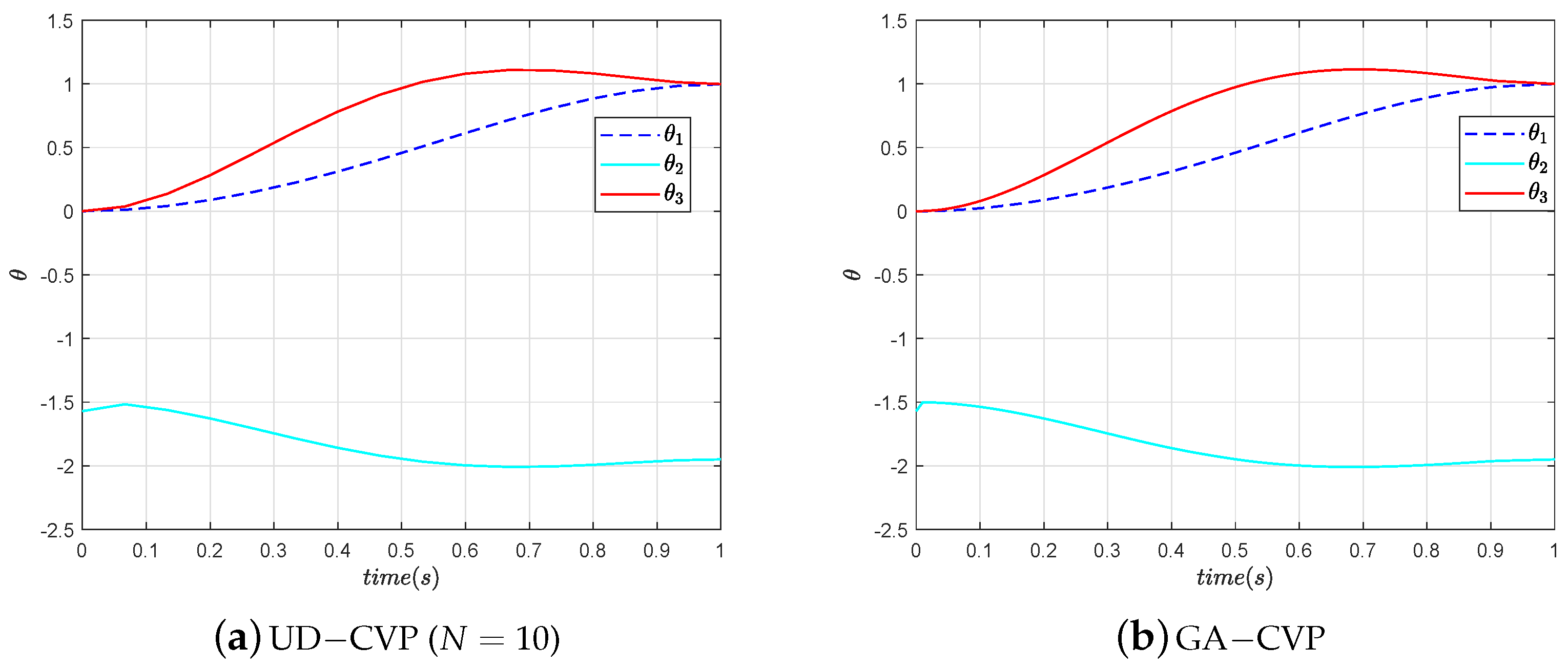

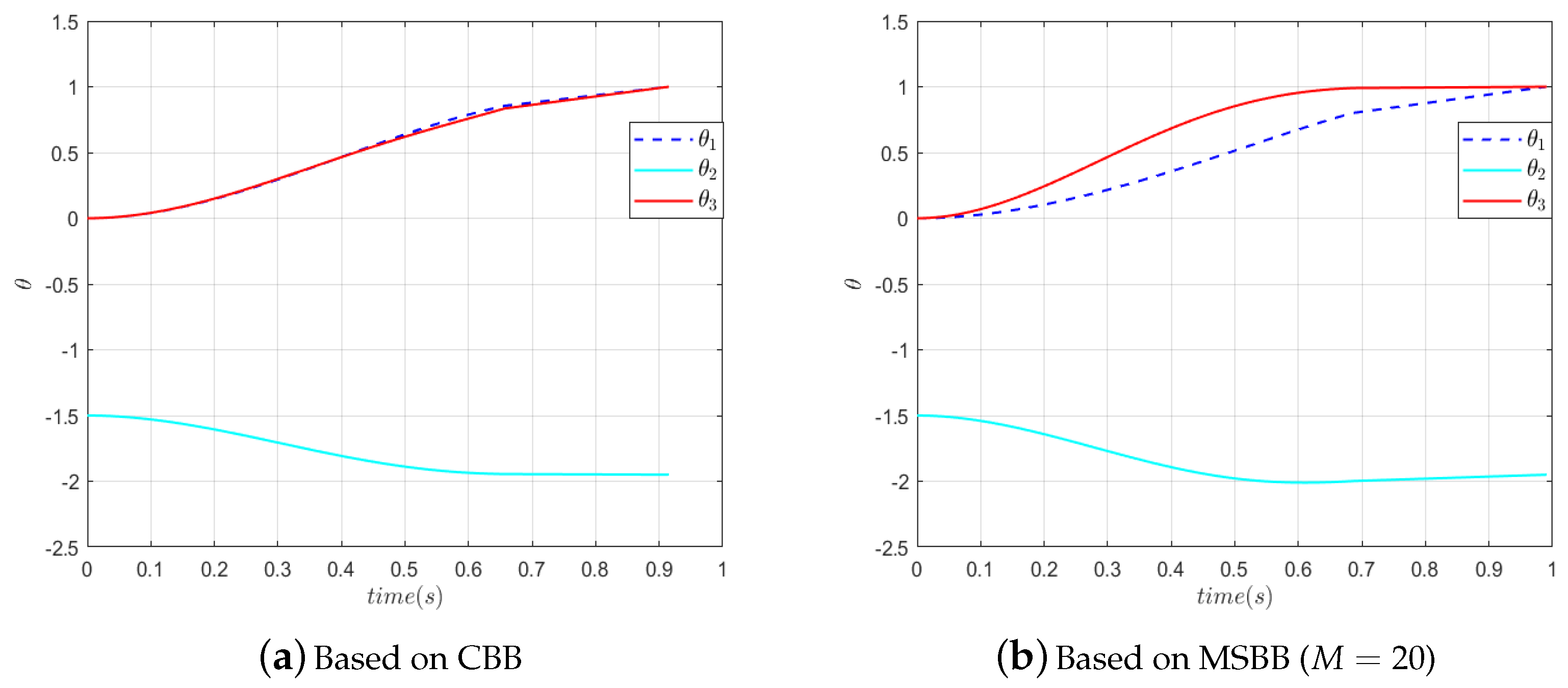

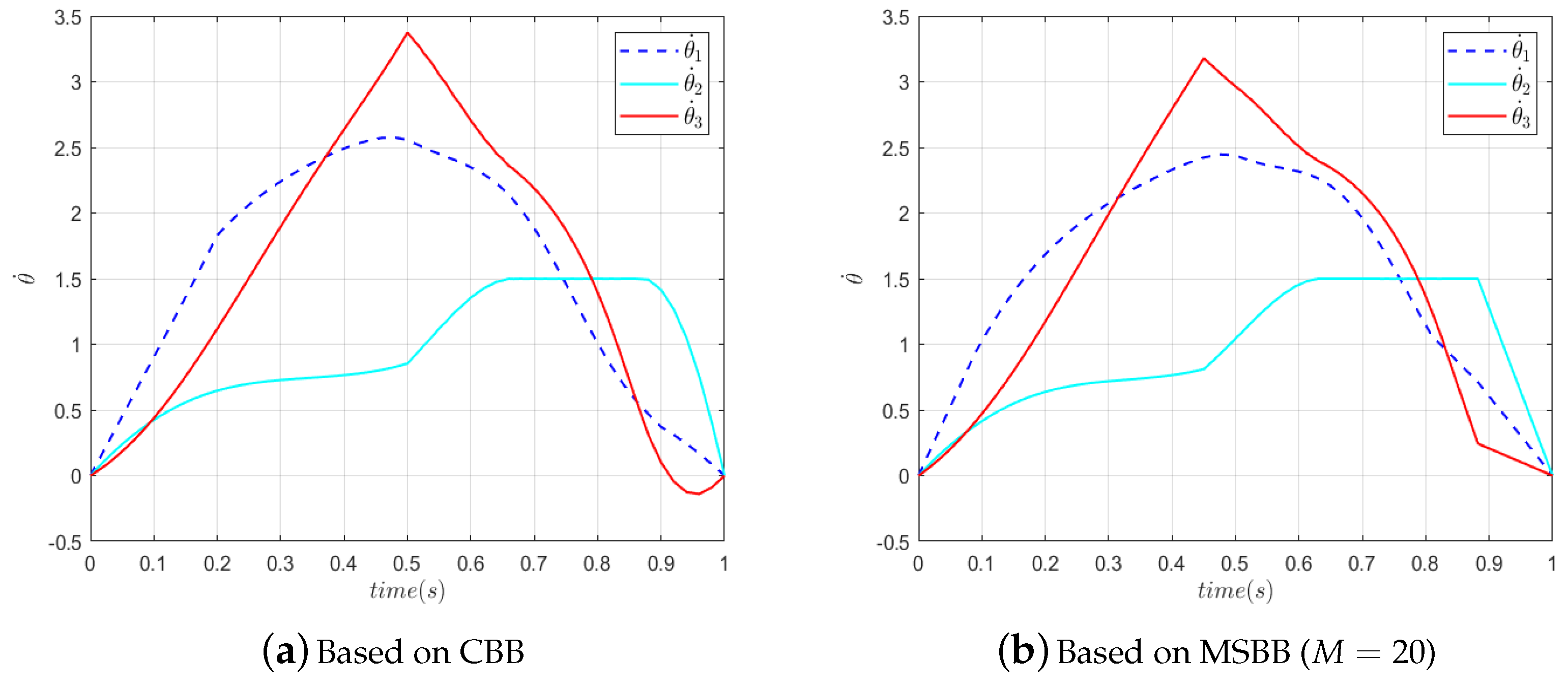

Figure 10 and

Figure 11 show the angular velocity for each joint angle during RA motion.

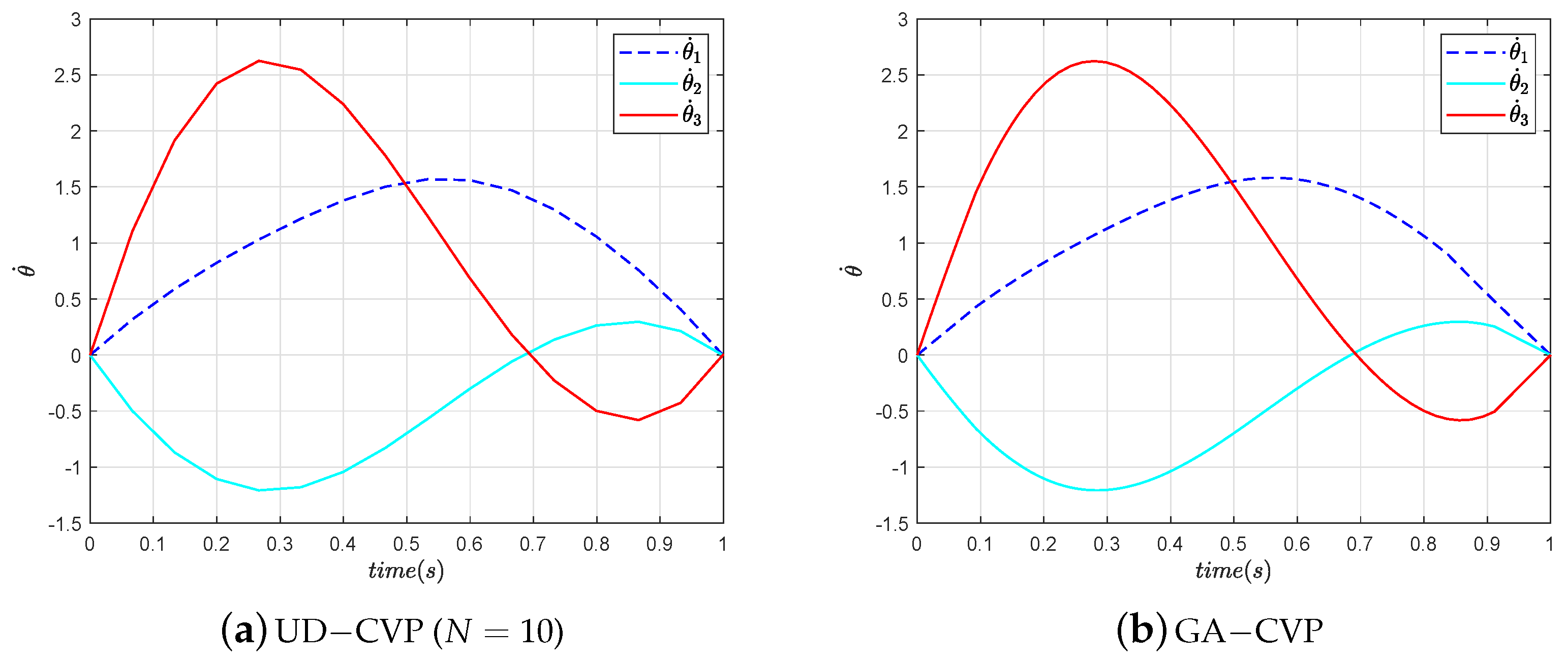

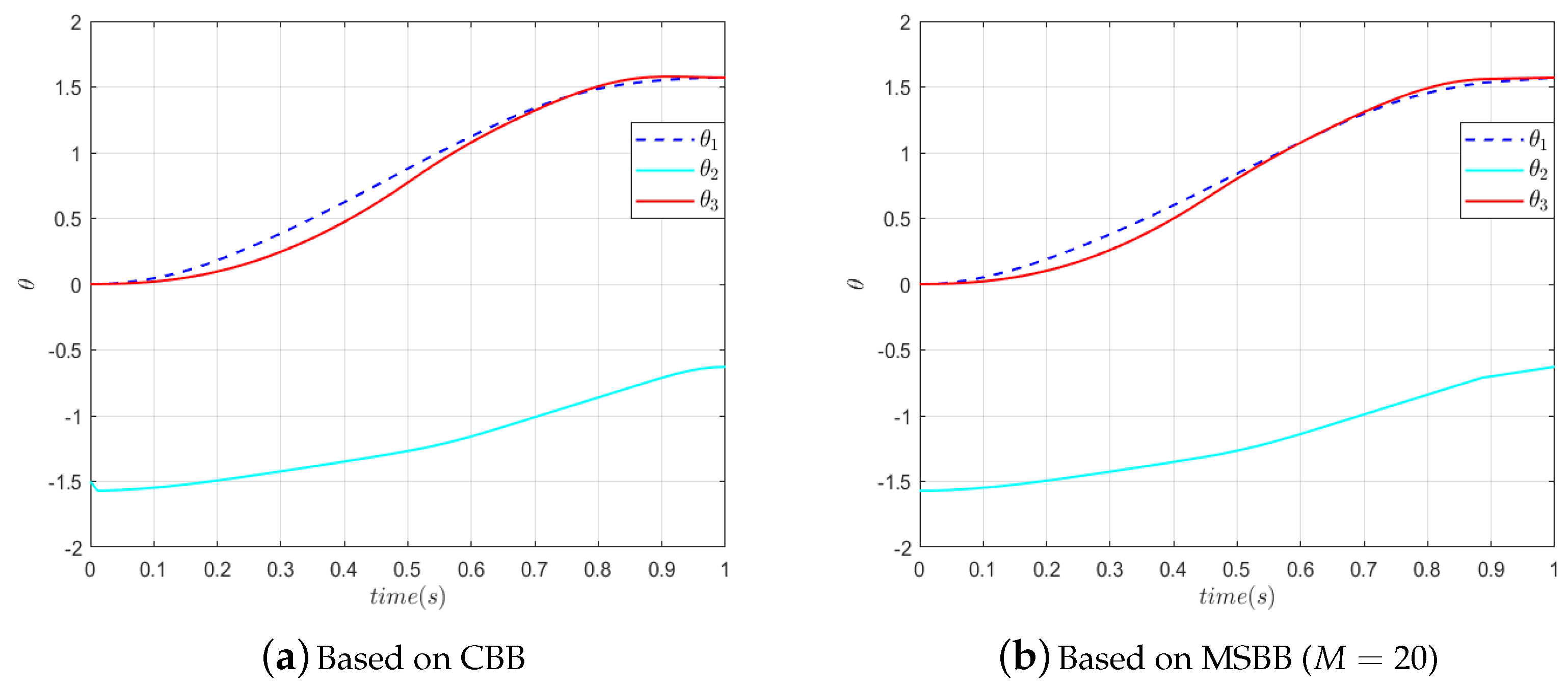

Figure 12 and

Figure 13 show the angular velocity for each joint angle during RA motion.

According to the four curves in

Figure 10 and

Figure 11, the joint angles at the initial and terminal moments of the RA meet the task requirements. The manipulator can move accurately from the initial position to the target position, and each joint rotation is within the range. It is clear that all four curves are smooth. This indicates that the joint angle changes smoothly and that there are no sudden changes in angle. It can be seen from

Figure 12 and

Figure 13 that the angular velocities of the joints are also within the velocity constraints. Both

in

Figure 13a at

and

in

Figure 13b at

reach their maximum angular velocity, indicating that they are constrained by their respective upper line of angular velocities during these periods.

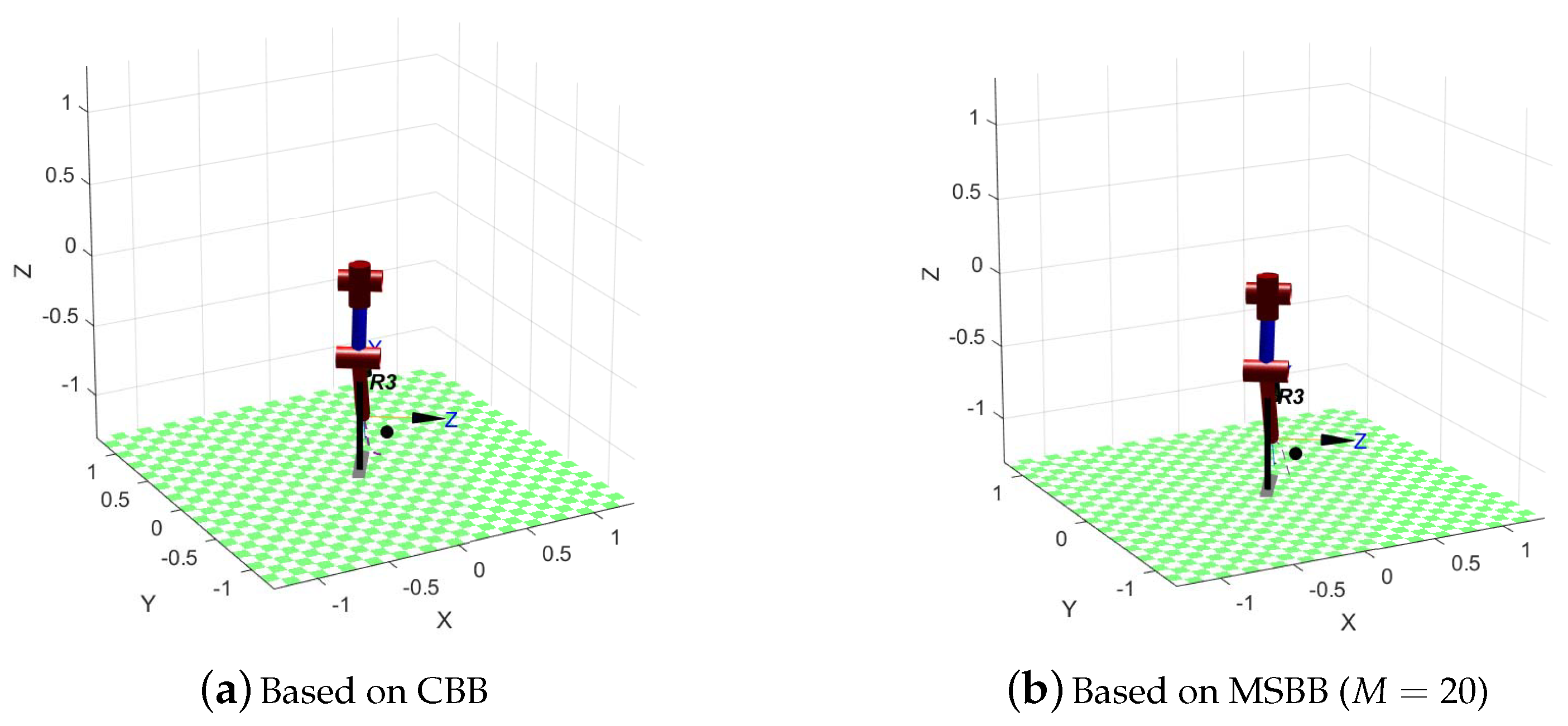

Figure 14 and

Figure 15 show that the trajectory of the manipulator was simulated in MATLAB. Based on the four trajectories in

Figure 14 and

Figure 15, it can be seen that both the trajectories based on the CBB and MSBB are effective in avoiding obstacles. Moreover, the trajectory of the manipulator is smooth for different tasks. By comparing

Figure 14a with

Figure 14b, it can be seen that the trajectory planned based on MSBB is closer to the obstacle. The CD based on MSBB is more sensitive.

To further compare the CD sensitivity and computational complexity of the two bounding boxes, MSBB with a different number of spheres is used to envelop the link. When

, the minimum enclosing sphere radius

of MSBB is slightly larger than the radius

of the CBB, so the number of enclosing spheres

M of MSBB is 20, 15, 10, 6, 5. Based on these conditions, we record the shortest distance

between the manipulator and the obstacle and the calculation time for two different tasks.

Table 6 and

Table 7 show the results.

From

Table 6 and

Table 7, it is seen that the shortest distance is

between the robot arm and the obstacle. It indicates that the collision-free trajectory can be successfully planned under both conditions of Task 1 and Task 2 based on the two different bounding boxes. When the number of enveloping spheres

of MSBB, the shortest distance between the manipulator and the obstacle for both Task 1 and Task 2 is smaller than that based on the CBB. Therefore, MSBB is more sensitive when the minimum enclosing ball radius

is smaller than the cylinder radius

. Moreover, in Task 1, the minimum distance based on MSBB (

) is nearly one half of the minimum distance based on the CBB. However, as the number of envelope spheres

M increases, the calculation time also increases. In real-world applications, it is necessary to take into account the relation between the quantity of envelope spheres and the calculation time. Choose the appropriate number of envelope balls, the requirement of the shortest distance

is met. The real-time requirement of movement is also met.