Durable, Low-Cost, and Efficient Heat Spreader Design from Scrap Aramid Fibers and Hexagonal Boron Nitride

Abstract

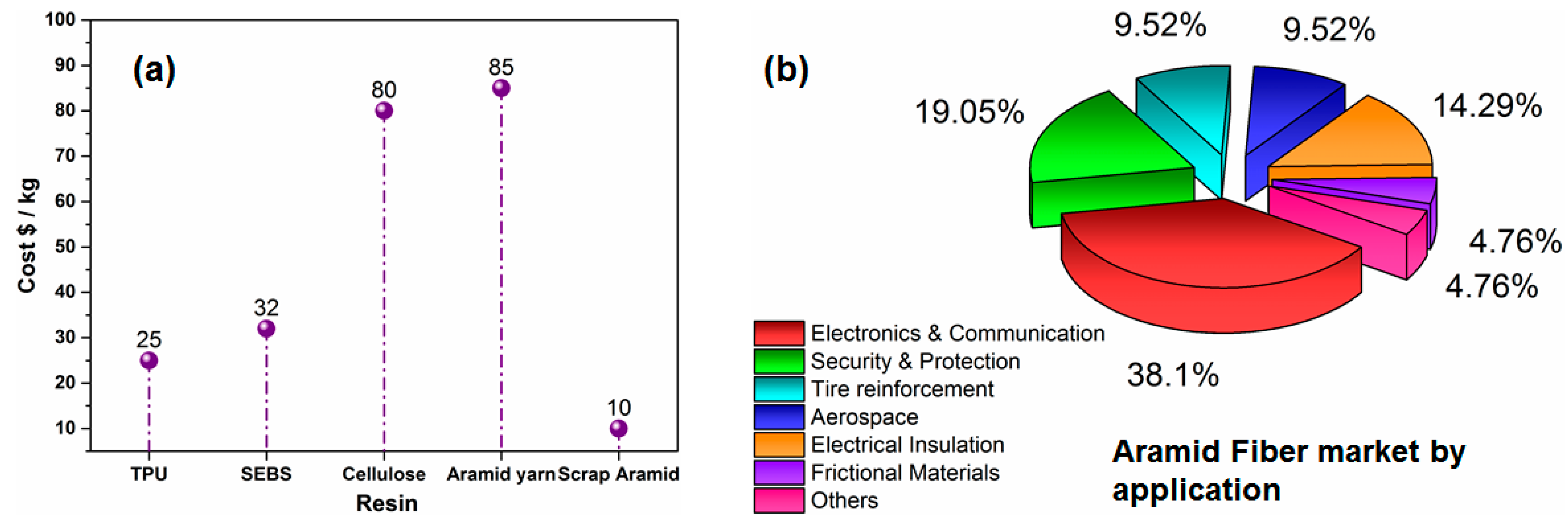

1. Introduction

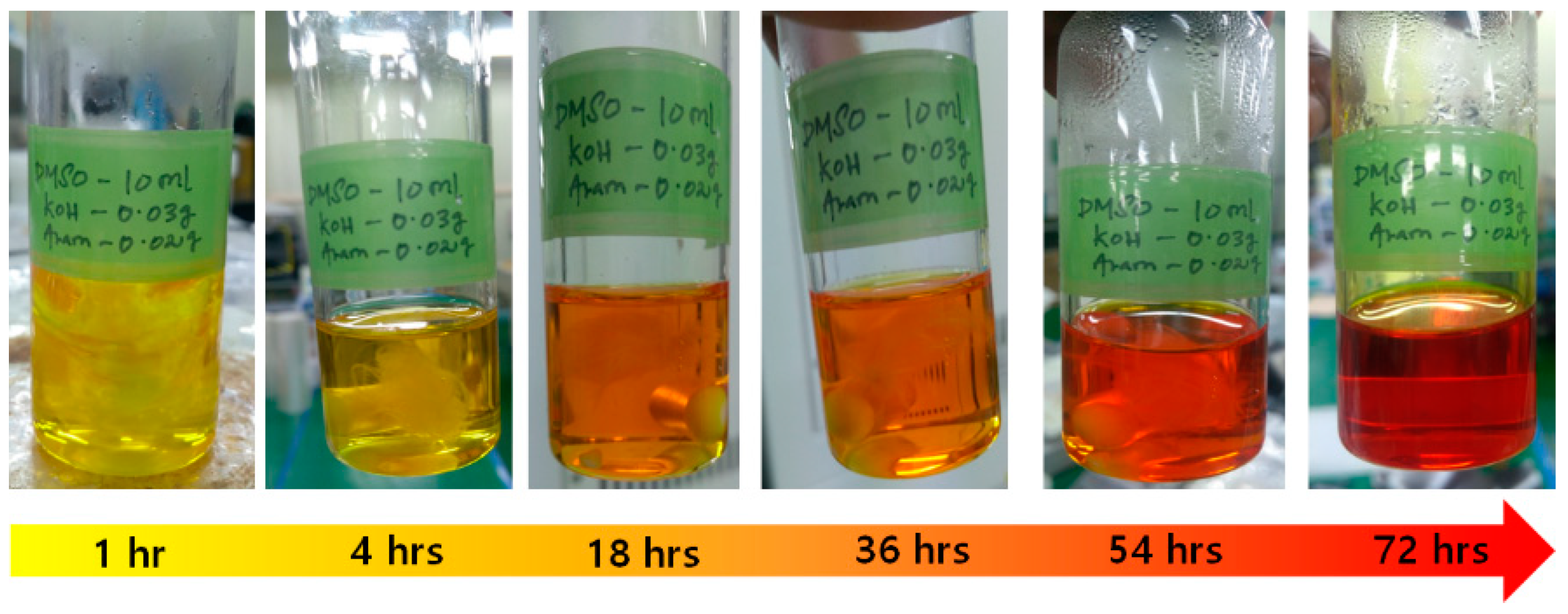

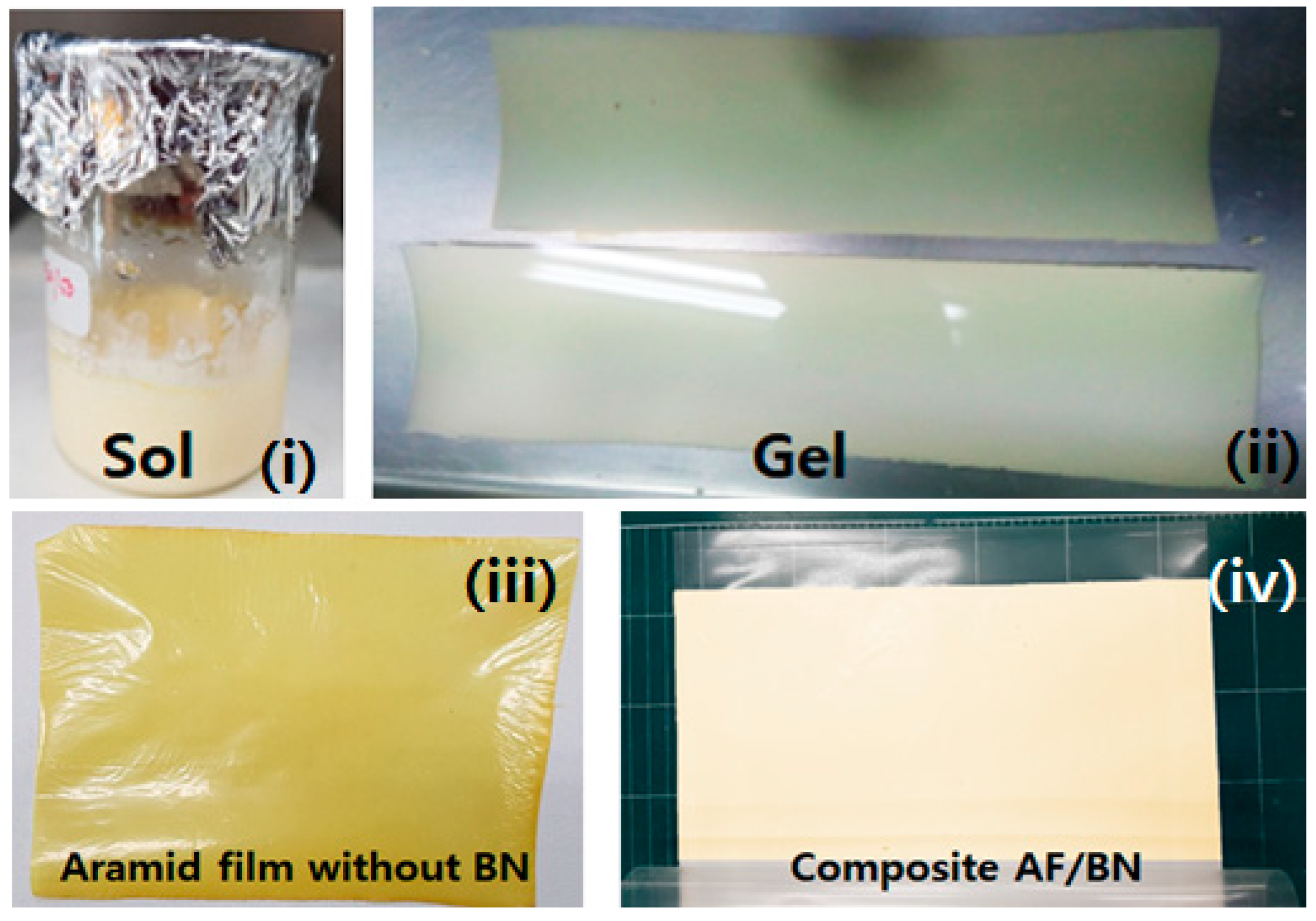

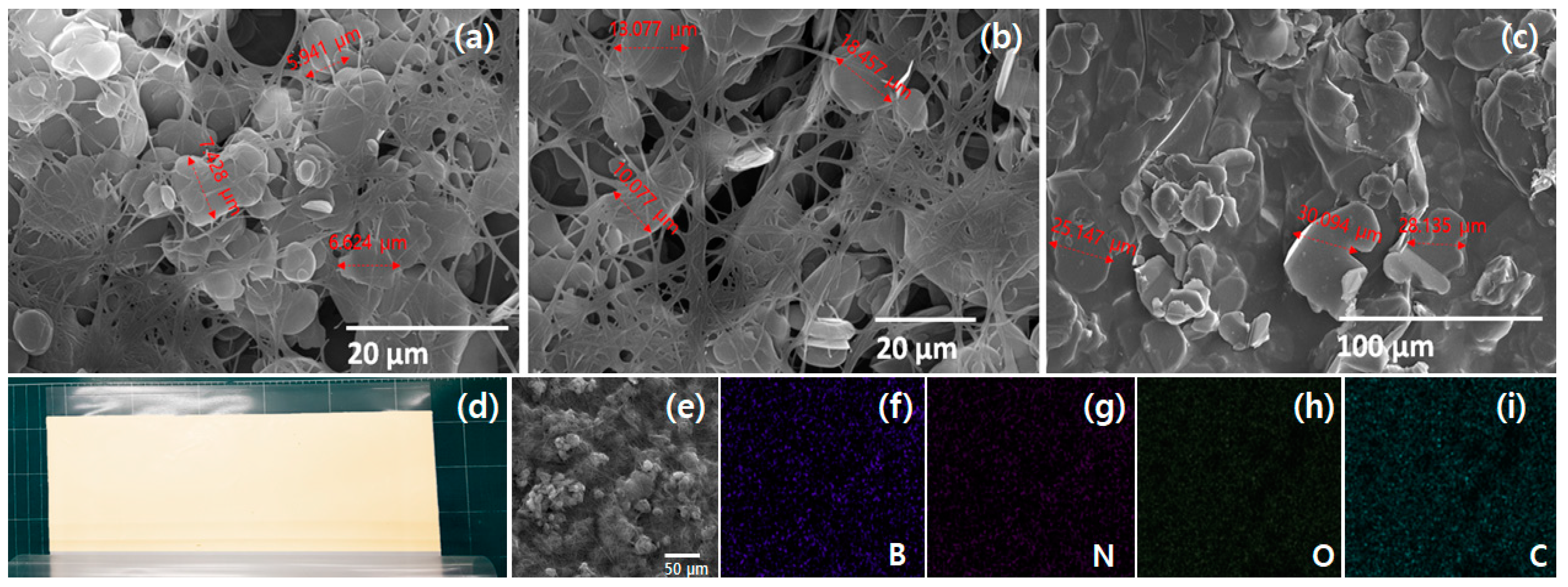

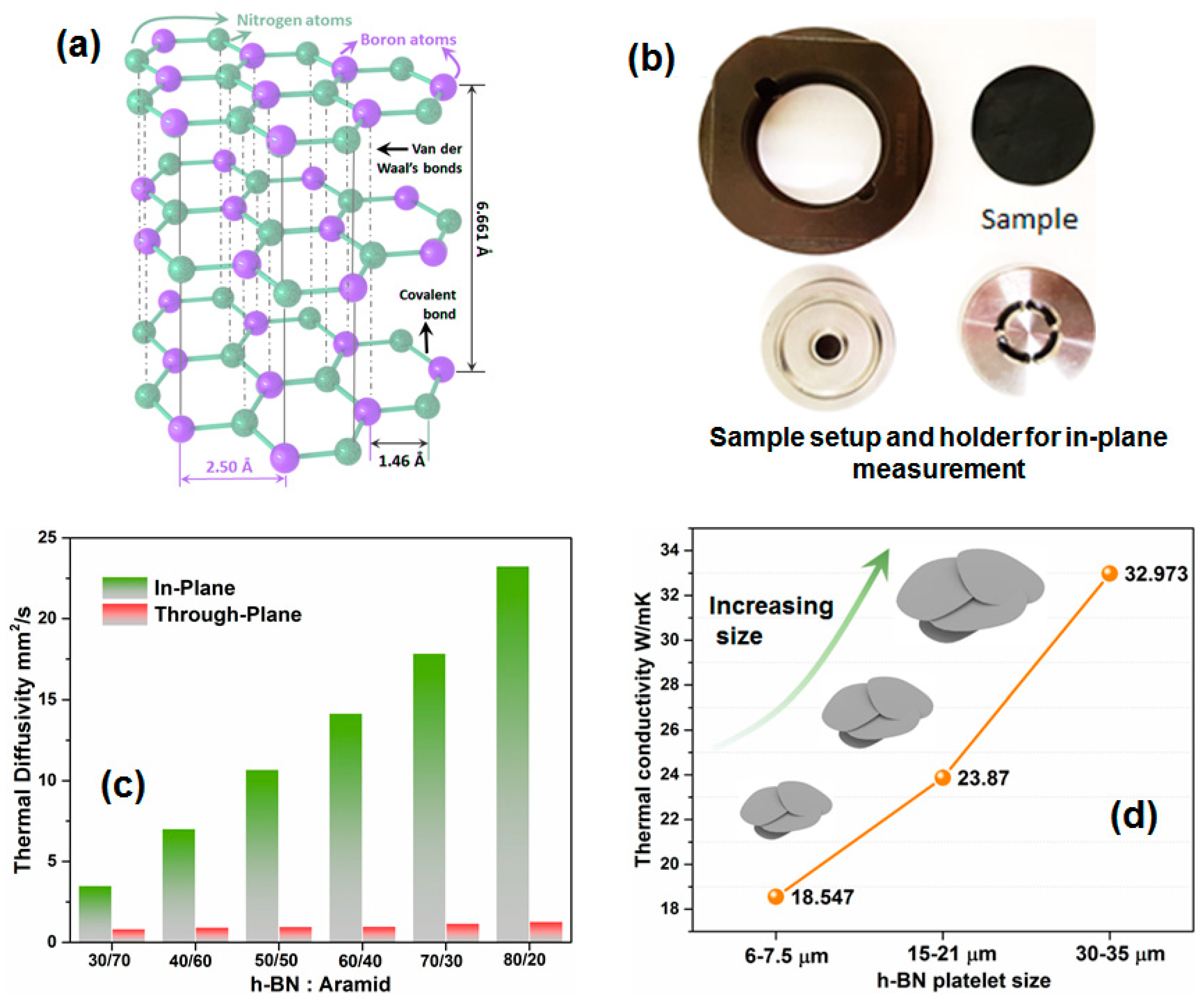

2. Materials and Method

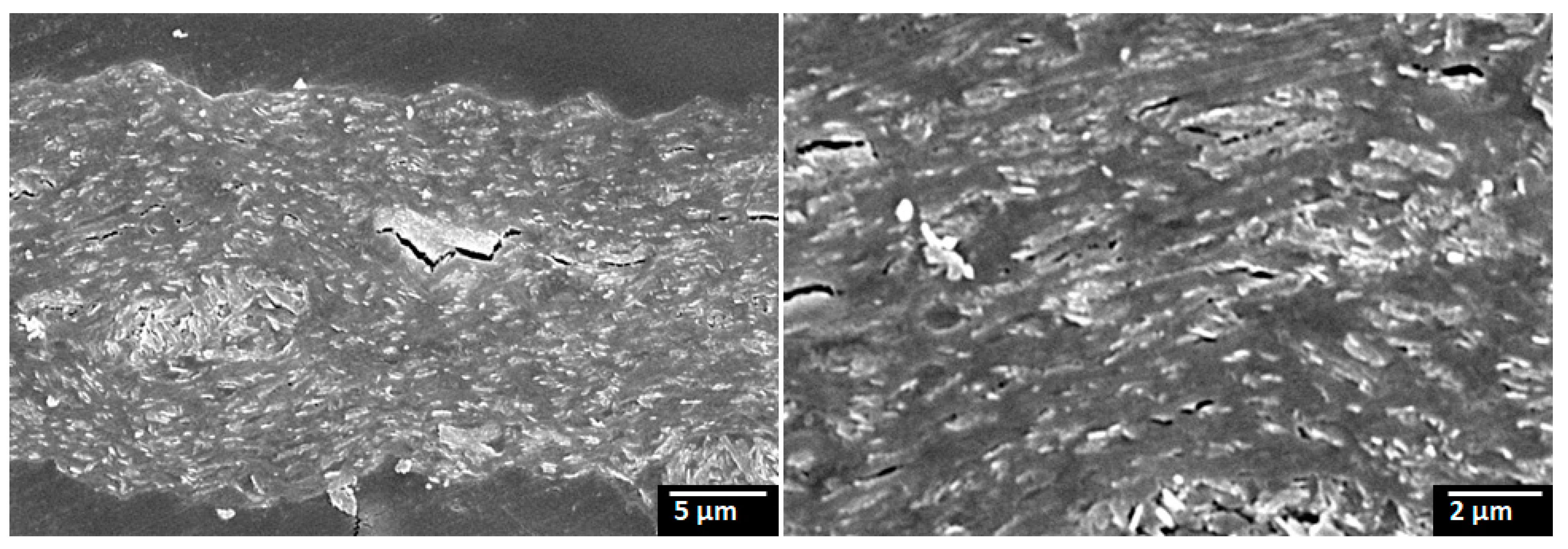

3. Characterization

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kitahara, H.; Oku, T. Nanostructures and electronic properties of carbon and boron nitride nanocapsules. J. Ceram. Process. Res. 2004, 5, 89–93. [Google Scholar]

- Alazzam, M.B.; Hajjej, F.; AlGhamdi, A.S.; Ayouni, S.; Rahman, M.A. Mechanics of materials natural fibers technology on thermal properties of polymer. Adv. Mater. Sci. Eng. 2022, 2022, 1–5. [Google Scholar] [CrossRef]

- Kugimoto, H.; Uehara, M.; Enomoto, N.; Hojo, J. Rod-like Si3N4 grain growth in the sintered body of amorphous Si3N4-BN composite powder with sintering additives. J. Ceram. Process. Res. 2003, 4, 6–9. [Google Scholar]

- Kim, D.; Lee, Y.; Chacón, A.; Kim, D.-E. Effect of interlayer coupling and symmetry on high-order harmonic generation from monolayer and bilayer hexagonal boron nitride. Symmetry 2022, 14, 84. [Google Scholar] [CrossRef]

- Besisa, D.H.; Hagras, M.A.; Ewais, E.M.; Ahmed, Y.M.; Zaki, Z.I.; Ahmed, A.J. Low temperature synthesis of nano-crystalline h-boron nitride from boric acid/urea precursors. J. Ceram. Process. Researc 2016, 17, 1219–1225. [Google Scholar]

- Fu, L.; Wang, T.; Yu, J.; Dai, W.; Sun, H.; Liu, Z.; Sun, R.; Jiang, N.; Yu, A.; Lin, C.-T. An ultrathin high-performance heat spreader fabricated with hydroxylated boron nitride nanosheets. J. 2D Mater. 2017, 4, 025047. [Google Scholar] [CrossRef]

- Chen, H.; Ginzburg, V.V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal conductivity of polymer-based composites: Fundamentals and applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

- Lim, C.S.; Ryu, J.H.; Kim, D.-H.; Cho, S.-Y.; Oh, W.-C. Reaction morphology and the effect of pH on the preparation of TiO2 nanoparticles by a sol-gel method. J. Ceram. Process. Res. 2010, 11, 736–741. [Google Scholar]

- Wang, Y.; Xia, S.; Xiao, G.; Di, J.; Wang, J. High-loading boron nitride-based bio-inspired paper with plastic-like ductility and metal-like thermal conductivity. ACS Appl. Mater. Interfaces 2020, 12, 13156–13164. [Google Scholar] [CrossRef]

- Švec, P.J. Microstructure and mechanical properties of B4C-TiB2 ceramic composites hot pressed with in-situ reaction. J. Ceram. Process. Res. 2019, 20, 113–120. [Google Scholar] [CrossRef]

- Zhong, J.; Feng, Y.; Wang, H.; Hu, D. Fabrication and characterization of hexagonal boron nitride powder by a precursor conversion method. J. Ceram. Process. Res. 2013, 14, 269–273. [Google Scholar]

- Ning, Z.; Huan, L.; Tianwen, Z.; Hongmin, K.; Xiaoyang, W.; Xingyu, C. Effects of boron source composition ratio on the microstructure and adsorption performance of hexagonal boron nitride prepared by template method. J. Ceram. Process. Res. 2016, 17, 181–185. [Google Scholar]

- Liu, L.; Shen, S.; Wang, Y. Enhanced thermal conductivity of flexible h-BN/polyimide composites films with ethyl cellulose. e-Polymers 2019, 19, 305–312. [Google Scholar] [CrossRef]

- Chen, L.; Xu, H.-F.; He, S.-J.; Du, Y.-H.; Yu, N.-J.; Du, X.-Z.; Lin, J.; Nazarenko, S. Thermal conductivity performance of polypropylene composites filled with polydopamine-functionalized hexagonal boron nitride. PLoS ONE 2017, 12, e0170523. [Google Scholar] [CrossRef] [PubMed]

- Sayam, A.; Rahman, A.; Rahman, M.; Smriti, S.A.; Ahmed, F.; Rabbi, M.; Hossain, M.; Faruque, M. A review on carbon fiber-reinforced hierarchical composites: Mechanical performance, manufacturing process, structural applications and allied challenges. Carbon Lett. 2022, 32, 1–33. [Google Scholar] [CrossRef]

- Li, T.-L.; Hsu, S.L.-C. Enhanced thermal conductivity of polyimide films via a hybrid of micro-and nano-sized boron nitride. J. Phys. Chem. B 2010, 114, 6825–6829. [Google Scholar] [CrossRef]

- Moradi, S.; Román, F.; Calventus, Y.; Hutchinson, J. Remarkable Thermal Conductivity of Epoxy Composites Filled with Boron Nitride and Cured under Pressure. Polymers 2021, 13, 955. [Google Scholar] [CrossRef]

- Pramono, A.E.; Nura, M.Z.; Soedarsonob, J.; Indayaningsih, N. Properties of wear rate and electrical conductivity of carbon ceramic composites. J. Ceram. Process. Res. 2019, 20, 1–7. [Google Scholar] [CrossRef]

- Antunes, M.; Realinho, V.; Velasco, J.I.; Solórzano, E.; Rodríguez-Pérez, M.-Á.; de Saja, J.A. Thermal conductivity anisotropy in polypropylene foams prepared by supercritical CO2 dissolution. Mater. Chem. Phys. 2012, 136, 268–276. [Google Scholar] [CrossRef]

- Ferreira, F.; Franceschi, W.; Menezes, B.; Brito, F.; Lozano, K.; Coutinho, A.; Cividanes, L.; Thim, G. Dodecylamine functionalization of carbon nanotubes to improve dispersion, thermal and mechanical properties of polyethylene based nanocomposites. Appl. Surf. Sci. 2017, 410, 267–277. [Google Scholar] [CrossRef]

- Muratov, D.; Kuznetsov, D.; Il’Inykh, I.; Mazov, I.; Stepashkin, A.; Tcherdyntsev, V. Thermal conductivity of polypropylene filled with inorganic particles. J. Alloy. Compd. 2014, 586, S451–S454. [Google Scholar] [CrossRef]

- Yang, C.; Navarro, M.; Zhao, B.; Leng, G.; Xu, G.; Wang, L.; Jin, Y.; Ding, Y. Thermal conductivity enhancement of recycled high density polyethylene as a storage media for latent heat thermal energy storage. Sol. Energy Mater. Sol. Cells 2016, 152, 103–110. [Google Scholar] [CrossRef]

- Cao, J.-P.; Zhao, J.; Zhao, X.; You, F.; Yu, H.; Hu, G.-H.; Dang, Z.-M. High thermal conductivity and high electrical resistivity of poly (vinylidene fluoride)/polystyrene blends by controlling the localization of hybrid fillers. Compos. Sci. Technol. 2013, 89, 142–148. [Google Scholar] [CrossRef]

- Guo, Y.; Ruan, K.; Shi, X.; Yang, X.; Gu, J. Factors affecting thermal conductivities of the polymers and polymer composites: A review. Compos. Sci. Technol. 2020, 193, 108134. [Google Scholar] [CrossRef]

- Kiran, V.; Gaur, B. Curing and thermal behavior of epoxy resins of hexafluoro-bisphenol–A and bisphenol-A. Polímeros 2016, 26, 11–20. [Google Scholar] [CrossRef]

- Messina, E.; Leone, N.; Foti, A.; Di Marco, G.; Riccucci, C.; Di Carlo, G.; Di Maggio, F.; Cassata, A.; Gargano, L.; D’Andrea, C. Double-wall nanotubes and graphene nanoplatelets for hybrid conductive adhesives with enhanced thermal and electrical conductivity. ACS Appl. Mater. Interfaces 2016, 8, 23244–23259. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Panda, B.P.; Mohanty, S.; Nayak, S.K.; Gupta, M.K. Recent developments on epoxy-based thermally conductive adhesives (TCA): A review. Polym.-Plast. Technol. Eng. 2018, 57, 903–934. [Google Scholar] [CrossRef]

- Liu, B.; Li, Y.; Fei, T.; Han, S.; Xia, C.; Shan, Z.; Jiang, J. Highly thermally conductive polystyrene/polypropylene/boron nitride composites with 3D segregated structure prepared by solution-mixing and hot-pressing method. Chem. Eng. J. 2020, 385, 123829. [Google Scholar] [CrossRef]

- Mrajji, O.; El Wazna, M.; Ouhaibi, S.; Sair, S.; El Bouari, A.; Cherkaoui, O.; Belouaggadia, N. Thermal Performance of Building Materials Based on Feather and Polystyrene Wastes; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; p. 012010. [Google Scholar]

- Souza, M.K.; Lima, E.P.; Nascimento, I.V.; Montazerian, M.; Baino, F.; Fook, M.V. Development, characterization and optimization of a new bone cement based on calcium–Strontium aluminates and chitosan-glycerin solution. Ceram. Int. 2022, 48, 31866–31879. [Google Scholar] [CrossRef]

- Uher, C. Thermal conductivity of high-T c superconductors. J. Supercond. 1990, 3, 337–389. [Google Scholar] [CrossRef]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Zhai, S.; Zhang, P.; Xian, Y.; Zeng, J.; Shi, B. Effective thermal conductivity of polymer composites: Theoretical models and simulation models. Int. J. Heat Mass Transf. 2018, 117, 358–374. [Google Scholar] [CrossRef]

- Shimizu, Y.; Ishii, J.; Shinzato, K.; Baba, T. A novel method for determination of the thermal diffusivity of thin films using a modulated CO2 laser. Int. J. Thermophys. 2005, 26, 203–211. [Google Scholar] [CrossRef]

- Yang, M.; Cao, K.; Sui, L.; Qi, Y.; Zhu, J.; Waas, A.; Arruda, E.M.; Kieffer, J.; Thouless, M.; Kotov, N.A. Dispersions of aramid nanofibers: A new nanoscale building block. ACS Nano 2011, 5, 6945–6954. [Google Scholar] [CrossRef]

- Hammer, C. Cooperative molecular motion in blends of poly (vinyl chloride) with ethylene-vinyl acetate copolymers. Macromolecules 1971, 4, 69–71. [Google Scholar] [CrossRef]

- ATALA, M.; GÜL AYGÜN, E.; Doğan, A. Evaluation of the crack formation of feldspathic ceramic reinforced with bor chemicals. J. Ceram. Process. Res. 2020, 21, 407–415. [Google Scholar]

- Liu, Z.; Li, J.; Liu, X. Novel functionalized BN nanosheets/epoxy composites with advanced thermal conductivity and mechanical properties. ACS Appl. Mater. Interfaces 2020, 12, 6503–6515. [Google Scholar] [CrossRef]

- Kim, H.; Jeon, D.-Y.; Jang, S.G.; Lee, M.W. Synergetic effect of BN for the electrical conductivity of CNT/PAN composite fiber. J. Mech. Sci. Technol. 2022, 36, 3103–3107. [Google Scholar] [CrossRef]

- Yoo, J.-H.; Maiyalagan, T.; Yi, S.C. Thermal conductive thin, flexible composite sheet of boron nitride aggregates and alumina for enhanced through plane conductivity. Ceram. Int. 2022, 48, 29183–29189. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, H.; Chen, J.; Guo, Y.; Jiang, P.; Gao, F.; Bao, H.; Huang, X. Thermally Conductive but Electrically Insulating Polybenzazole Nanofiber/Boron Nitride Nanosheets Nanocomposite Paper for Heat Dissipation of 5G Base Stations and Transformers. ACS Nano 2022, 16, 14323–14333. [Google Scholar] [CrossRef]

- Yin, C.-G.; Liu, Z.-J.; Mo, R.; Fan, J.-C.; Shi, P.-H.; Xu, Q.-J.; Min, Y.-L. Copper nanowires embedded in boron nitride nanosheet-polymer composites with enhanced thermal conductivities for thermal management. Polymer 2020, 195, 122455. [Google Scholar] [CrossRef]

- Wu, K.; Fang, J.; Ma, J.; Huang, R.; Chai, S.; Chen, F.; Fu, Q. Achieving a Collapsible, Strong, and Highly Thermally Conductive Film Based on Oriented Functionalized Boron Nitride Nanosheets and Cellulose Nanofiber. ACS Appl. Mater. Interfaces 2017, 9, 30035–30045. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Zeng, X.; Wang, F.; Sun, R.; Xu, J.-b.; Wong, C.-P. Significant Enhancement of Thermal Conductivity in Bioinspired Freestanding Boron Nitride Papers Filled with Graphene Oxide. Chem. Mater. 2016, 28, 1049–1057. [Google Scholar] [CrossRef]

- Li, P.; Shen, H.; Qian, Z.; Yang, X.; Zhao, N.; Zhu, C.; Xu, J. Facile fabrication of flexible layered GO/BNNS composite films with high thermal conductivity. J. Mater. Sci. 2018, 53, 4189–4198. [Google Scholar] [CrossRef]

- Rahman, M.M.; Puthirath, A.B.; Adumbumkulath, A.; Tsafack, T.; Robatjazi, H.; Barnes, M.; Wang, Z.; Kommandur, S.; Susarla, S.; Sajadi, S.M.; et al. Fiber reinforced layered dielectric nanocomposite. Adv. Funct. Mater. 2019, 29, 1900056. [Google Scholar] [CrossRef]

| Parameters | Through Plane | In-Plane |

|---|---|---|

| Detection size | 12.5 mm | 24.80 mm |

| Sample coating | Graphite | Graphite |

| Voltage | 260 V | 250 V |

| Duration | 2000 ms | 4000 ms |

| Pulse width | 30 μs | 50 μs |

| Main gain | 5087 | 5087 |

| Composite | k (W/mK) | Reference |

|---|---|---|

| f-BNNS/PVA 90/10 | 4.5 | [41] |

| BN/PVA 57/43 | 7.47 | [42] |

| f-BNNS/CNF 70/30 | 30.25 | [43] |

| BNNS/GO 95/5 | 29.8 | [44] |

| BNNS/GO | 11.9 | [45] |

| ANF/BNNS 90/10 | 2.4 | [46] |

| AF/BN | 32.973 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, J.-H.; Yi, S.C. Durable, Low-Cost, and Efficient Heat Spreader Design from Scrap Aramid Fibers and Hexagonal Boron Nitride. Symmetry 2022, 14, 2597. https://doi.org/10.3390/sym14122597

Yoo J-H, Yi SC. Durable, Low-Cost, and Efficient Heat Spreader Design from Scrap Aramid Fibers and Hexagonal Boron Nitride. Symmetry. 2022; 14(12):2597. https://doi.org/10.3390/sym14122597

Chicago/Turabian StyleYoo, Jung-Hun, and Sung Chul Yi. 2022. "Durable, Low-Cost, and Efficient Heat Spreader Design from Scrap Aramid Fibers and Hexagonal Boron Nitride" Symmetry 14, no. 12: 2597. https://doi.org/10.3390/sym14122597

APA StyleYoo, J.-H., & Yi, S. C. (2022). Durable, Low-Cost, and Efficient Heat Spreader Design from Scrap Aramid Fibers and Hexagonal Boron Nitride. Symmetry, 14(12), 2597. https://doi.org/10.3390/sym14122597