A Multivariate Long Short-Term Memory Neural Network for Coalbed Methane Production Forecasting

Abstract

1. Introduction

2. Data and Methods

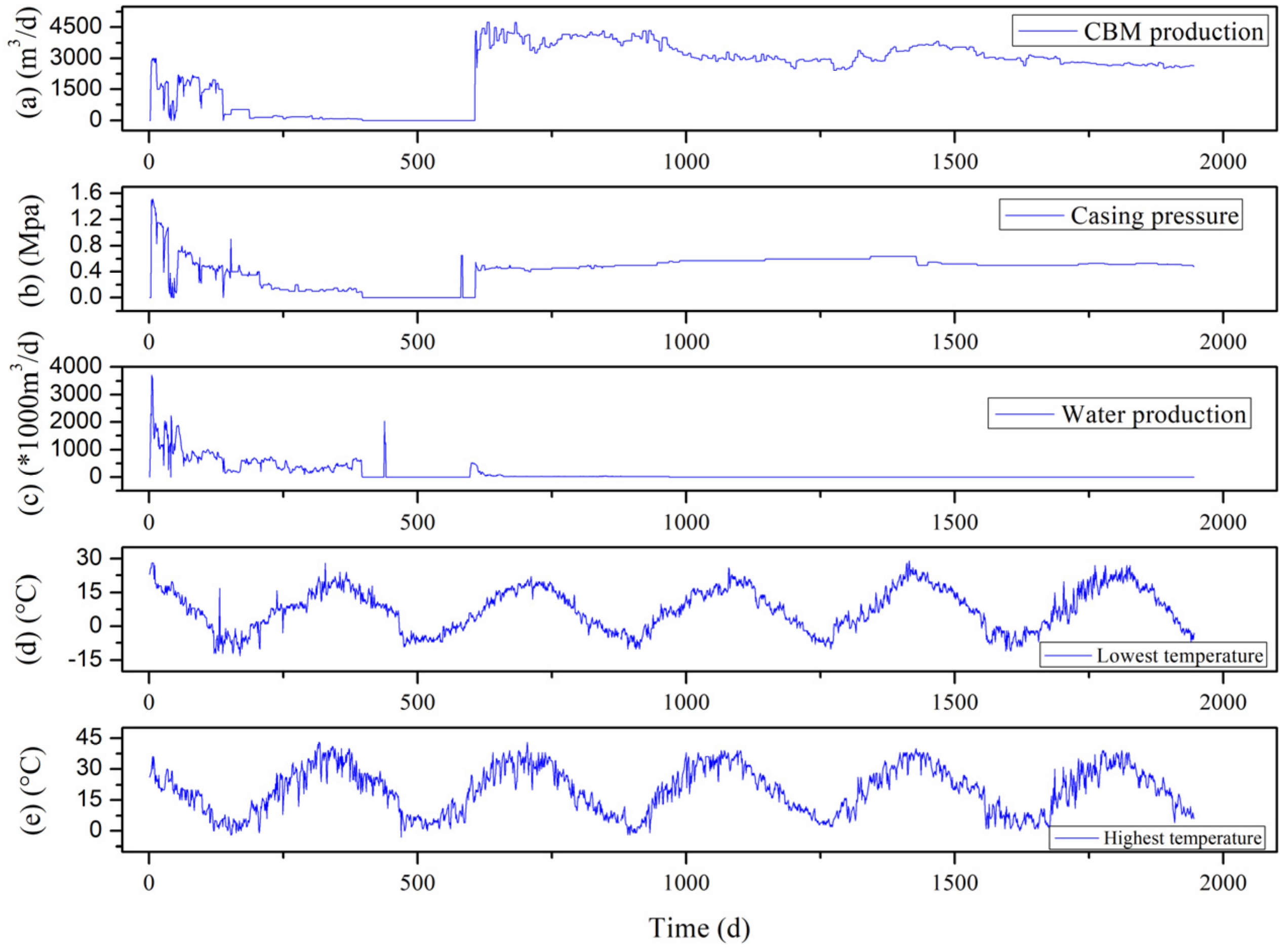

2.1. Data Description

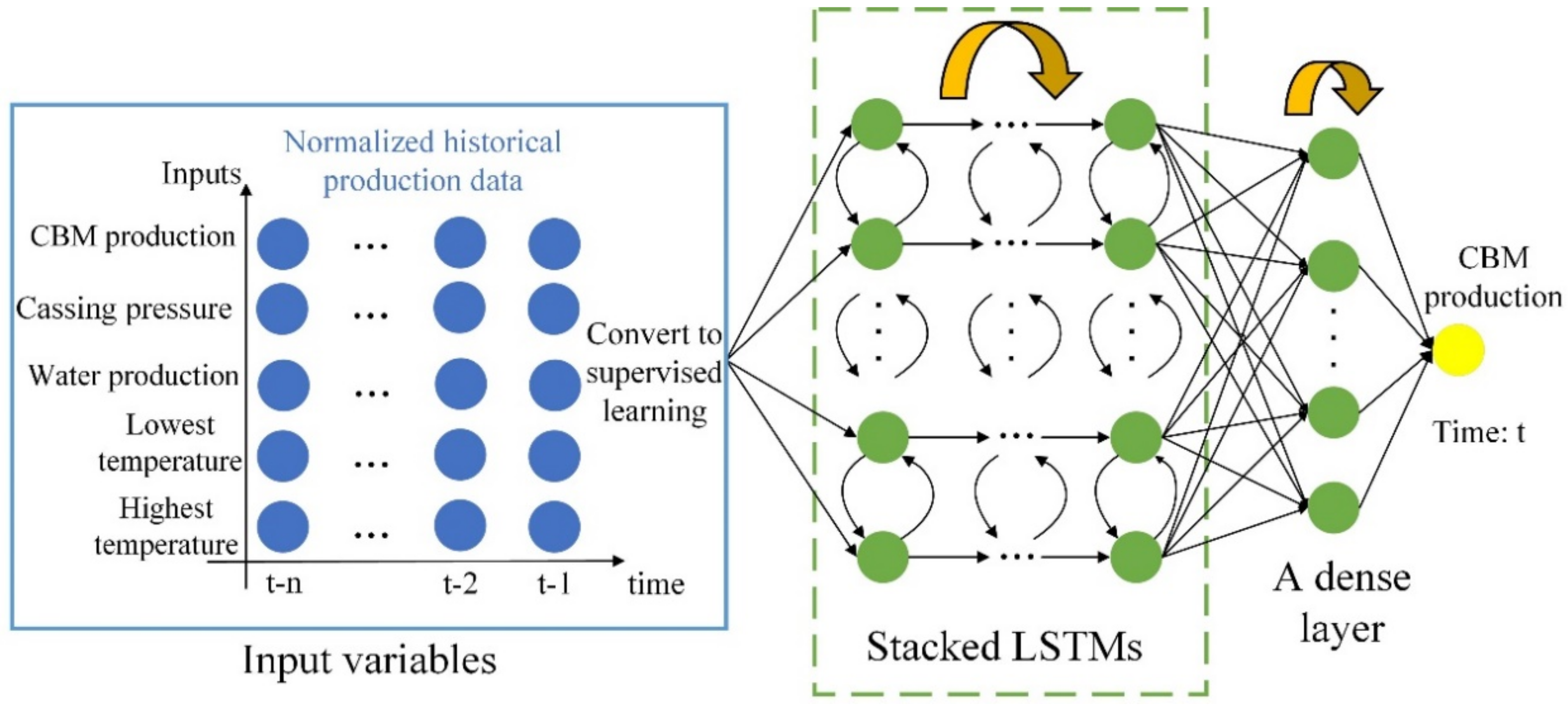

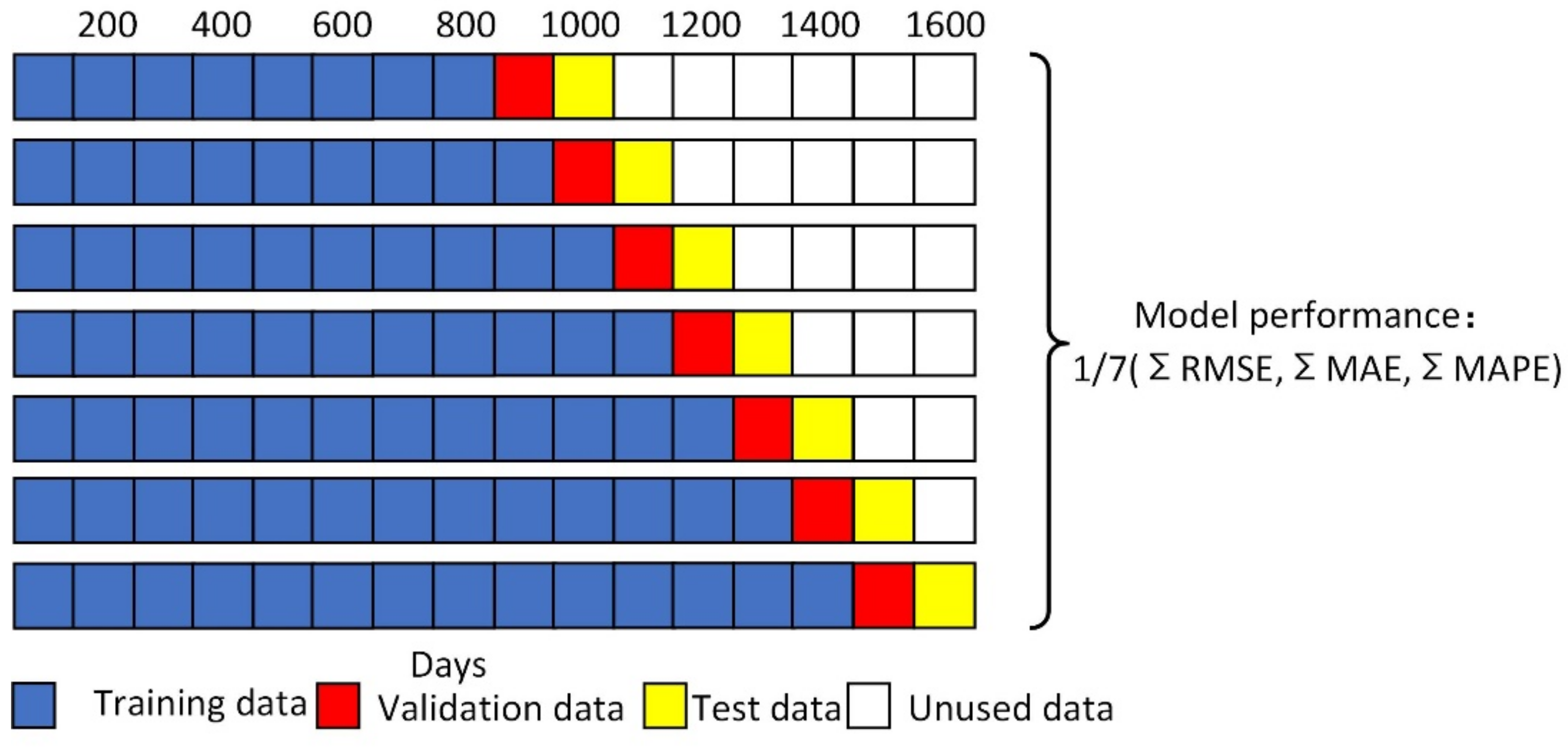

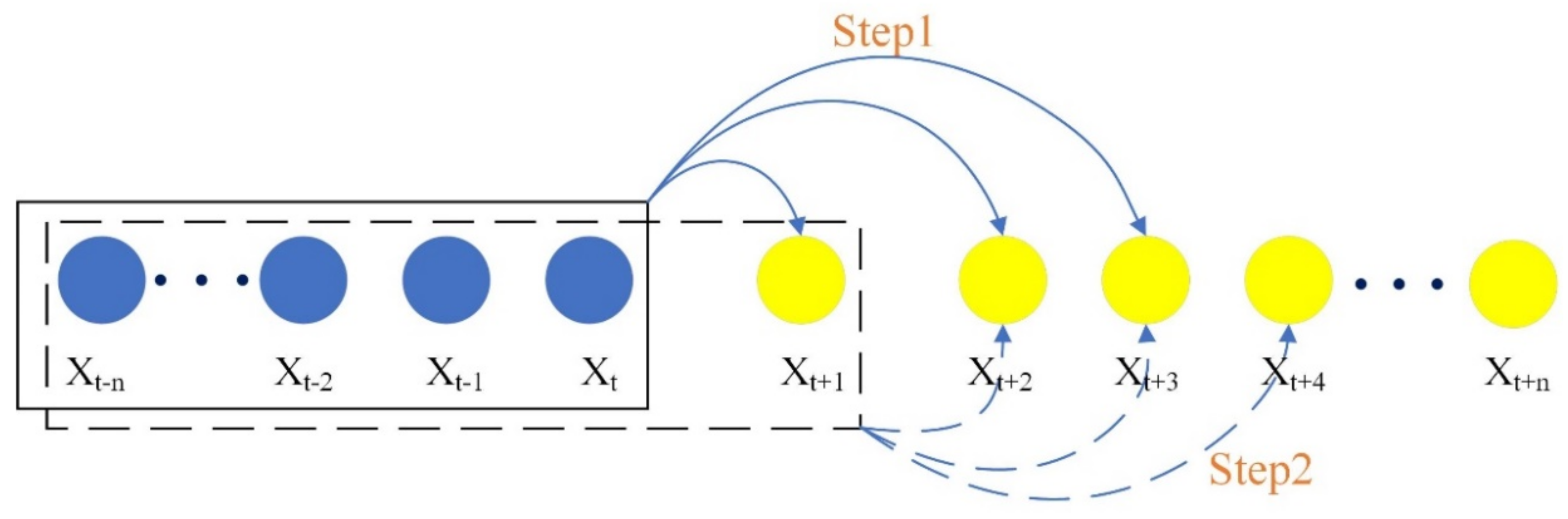

2.2. M-LSTM NN Model

2.3. Evaluation Index

2.4. Network Architecture

3. Results and Discussion

3.1. Prediction Performance

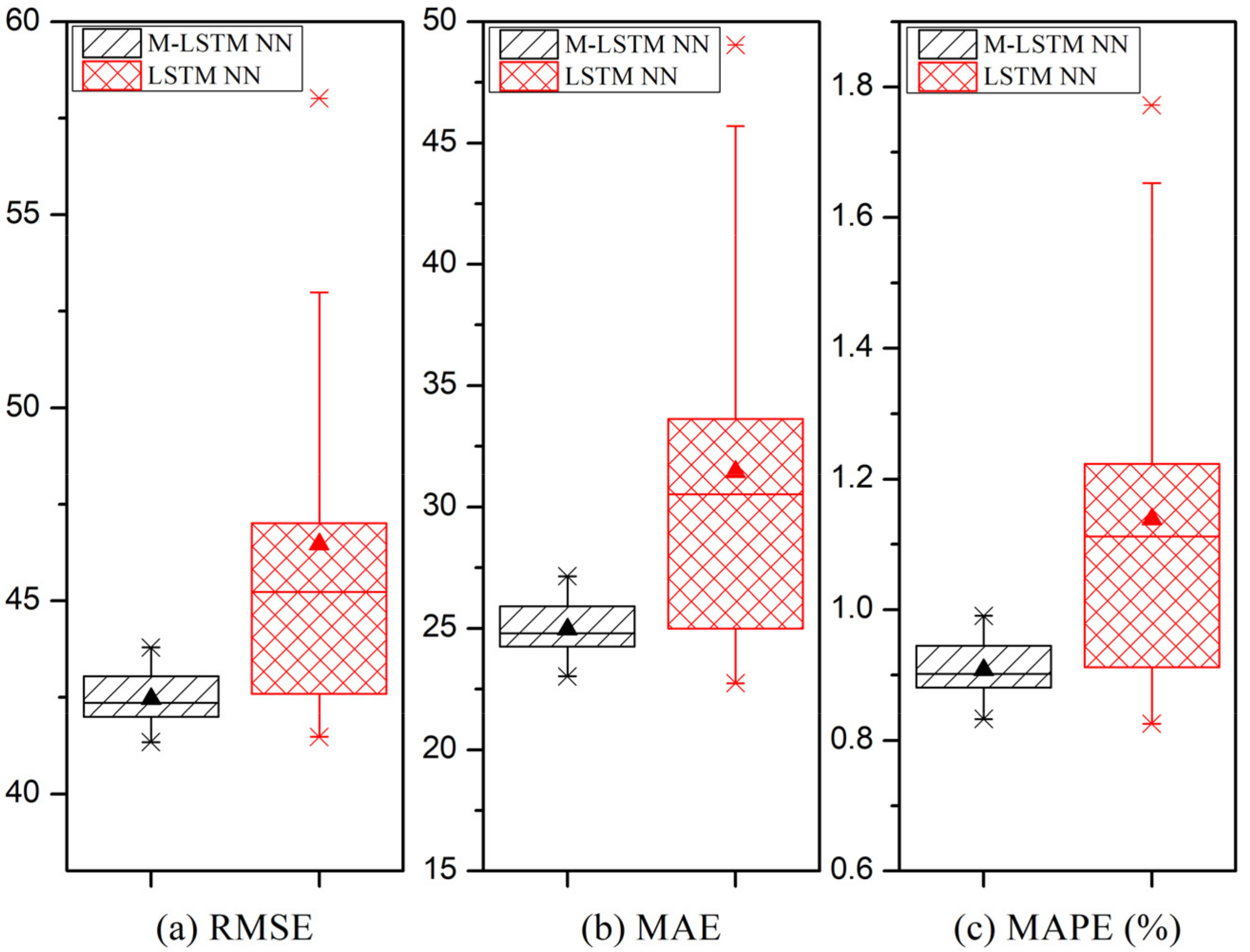

3.2. Comparison with Traditional LSTM NN Model (without Multivariate Inputs)

3.3. Multi-Step Predictions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

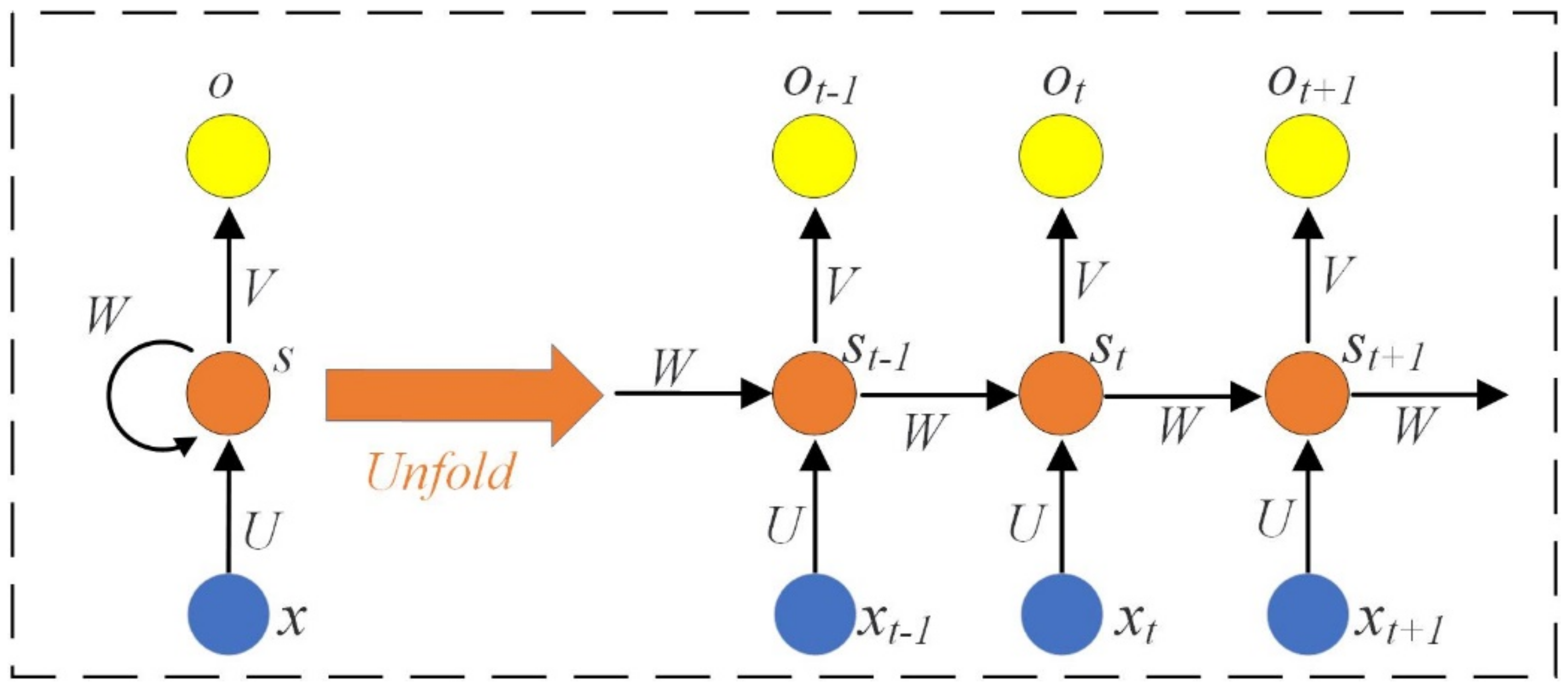

Appendix A. RNN

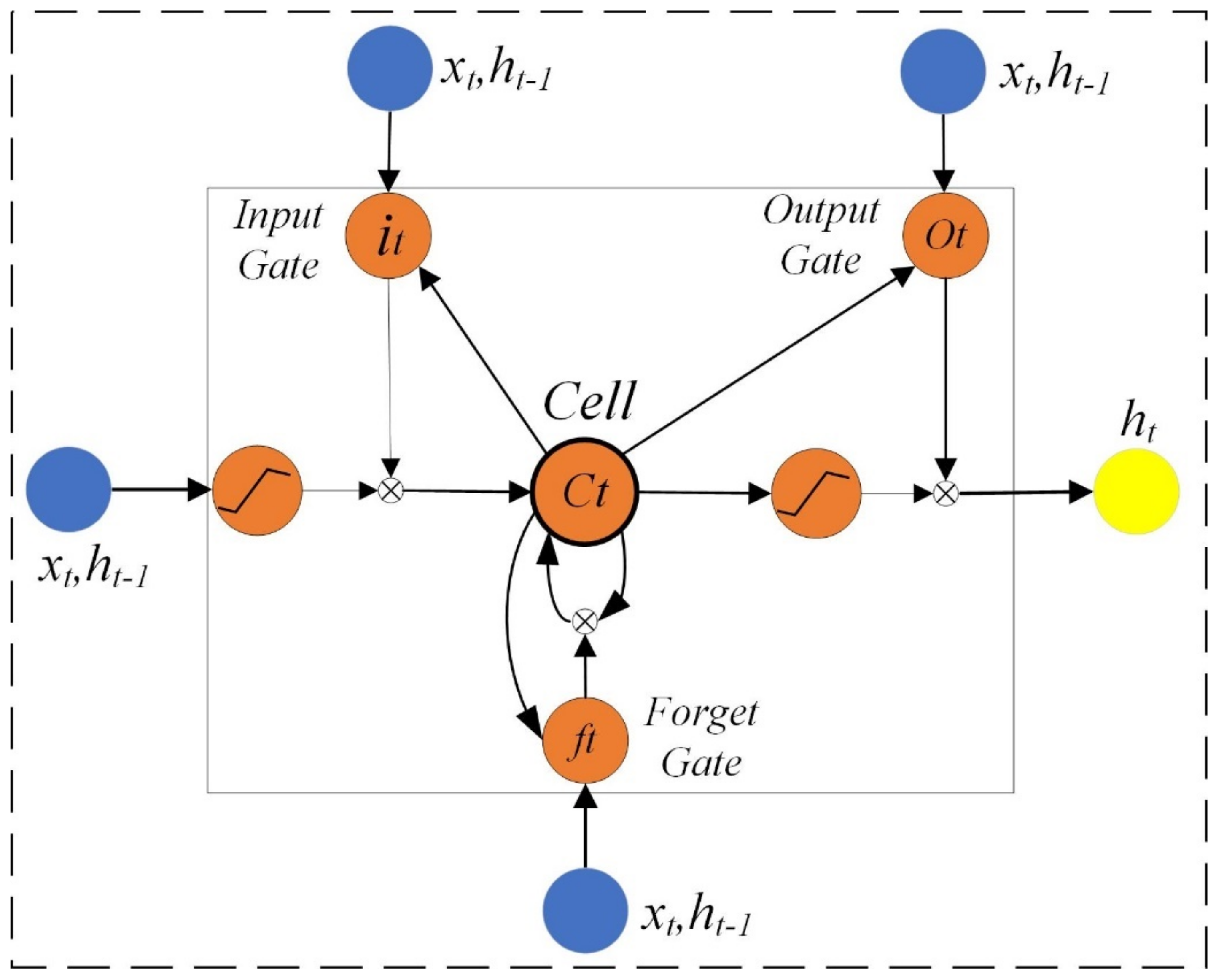

Appendix B. LSTM NN

References

- Stopa, J.; Mikolajczak, E. Empirical modeling of two-phase CBM production using analogy to nature. J. Pet. Sci. Eng. 2018, 171, 1487–1495. [Google Scholar] [CrossRef]

- Aminian, K.; Ameri, S. Predicting production performance of CBM reservoirs. J. Nat. Gas Sci. Eng. 2019, 1, 25–30. [Google Scholar] [CrossRef]

- Clarkson, C.R. Production data analysis of unconventional gas wells: Review of theory and best practices. Int. J. Coal Geol. 2013, 109, 101–146. [Google Scholar] [CrossRef]

- Clarkson, C.R. Production data analysis of unconventional gas wells: Workflow. Int. J. Coal Geol. 2013, 109–110, 147–157. [Google Scholar] [CrossRef]

- King, G.R. Material-balance techniques for coal-seam and devonian shale gas-reservoirs with limited water influx. SPE Reserv. Eng. 1993, 8, 67–72. [Google Scholar] [CrossRef]

- Lue, Y.; Tang, D.; Xu, H.; Tao, S. Productivity matching and quantitative prediction of coalbed methane wells based on BP neural network. Sci. China Technol. Sci. 2011, 54, 1281–1286. [Google Scholar] [CrossRef]

- Huang, X.D.; Wang, S.Q. Prediction of Bottom-Hole Flow Pressure in Coalbed Gas Wells Based on GA Optimization SVM; IEEE: New York, NY, USA, 2018. [Google Scholar]

- Fetkovich, M.J. Decline curve analysis using type curves. J. Pet. Technol. 1980, 32, 1065–1077. [Google Scholar] [CrossRef]

- Jang, H.; Kim, Y.; Park, J.; Lee, J. Prediction of production performance by comprehensive methodology for hydraulically fractured well in coalbed methane reservoirs. Int. J. Oil Gas Coal Technol. 2019, 20, 143–168. [Google Scholar] [CrossRef]

- Li, P.; Hao, M.; Hu, J.; Ru, Z.; Li, Z. A new production decline model for horizontal wells in low-permeability reservoirs. J. Pet. Sci. Eng. 2018, 171, 340–352. [Google Scholar] [CrossRef]

- Cipolla, C.L.; Lolon, E.P.; Erdle, J.C.; Rubin, B. Reservoir Modeling in Shale-Gas Reservoirs. SPE Reserv. Eval. Eng. 2010, 13, 638–653. [Google Scholar] [CrossRef]

- Li, L.C.; Wei, C.T.; Qi, Y.; Cao, J.; Wang, K.Y.; Bao, Y. Coalbed methane reservoir formation history and its geological control at the Shuigonghe Syncline. Arab. J. Geosci. 2015, 8, 619–630. [Google Scholar] [CrossRef]

- Zhou, F.D. History matching and production prediction of a horizontal coalbed methane well. J. Pet. Sci. Eng. 2012, 96–97, 22–36. [Google Scholar] [CrossRef]

- Thararoop, P.; Karpyn, Z.T.; Ertekin, T. Development of a multi-mechanistic, dual-porosity, dual-permeability, numerical flow model for coalbed methane reservoirs. J. Nat. Gas Sci. Eng. 2012, 8, 121–131. [Google Scholar] [CrossRef]

- Yun, M.G.; Rim, M.W.; Han, C.N. A model for pseudo-steady and non-equilibrium sorption in coalbed methane reservoir simulation and its application. J. Nat. Gas Sci. Eng. 2018, 54, 342–348. [Google Scholar] [CrossRef]

- Shi, J.T.; Chang, Y.C.; Wu, S.G.; Xiong, X.Y.; Liu, C.; Feng, K. Development of material balance equations for coalbed methane reservoirs considering dewatering process, gas solubility, pore compressibility and matrix shrinkage. Int. J. Coal Geol. 2018, 195, 200–216. [Google Scholar] [CrossRef]

- Sun, Z.; Shi, J.; Zhang, T.; Wu, K.; Miao, Y.; Feng, D.; Li, X. The modified gas-water two phase version flowing material balance equation for low permeability CBM reservoirs. J. Pet. Sci. Eng. 2018, 165, 726–735. [Google Scholar] [CrossRef]

- Xia, H.M.; Qin, Y.C.; Zhang, L.J.; Cao, Y.P.; Xu, J.X. Forecasting of Coalbed Methane (CBM) Productivity Based on Rough Set and Least Squares Support Vector Machine. In Proceedings of the 2017 25th International Conference on Geoinformatics, Buffalo, NY, USA, 2–4 August 2017. [Google Scholar]

- Zhao, C.; Li, J. Equilibrium Selection under the Bayes-Based Strategy Updating Rules. Symmetry 2020, 12, 739. [Google Scholar] [CrossRef]

- Zhang, B.; Xu, D.; Liu, Y.; Li, F.; Cai, J.; Du, L. Multi-scale evapotranspiration of summer maize and the controlling meteorological factors in north China. Agric. For. Meteorol. 2016, 216, 1–12. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, P. Influence of mine shallow roadway on airflow temperature. Arab. J. Geosci. 2020, 13, 12. [Google Scholar] [CrossRef]

- Bai, Y.; Zeng, B.; Li, C.; Zhang, J. An ensemble long short-term memory neural network for hourly PM2.5 concentration forecasting. Chemosphere 2019, 222, 286–294. [Google Scholar] [CrossRef]

- Li, X.; Peng, L.; Yao, X.; Cui, S.; Hu, Y.; You, C.; Chi, T. Long short-term memory neural network for air pollutant concentration predictions: Method development and evaluation. Environ. Pollut. 2017, 231, 997–1004. [Google Scholar] [CrossRef] [PubMed]

- Wen, C.; Liu, S.; Yao, X.; Peng, L.; Li, X.; Hu, Y.; Chi, T. A novel spatiotemporal convolutional long short-term neural network for air pollution prediction. Sci. Total Environ. 2019, 654, 1091–1099. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Deng, F.; Cai, Y.; Chen, J. Long short-term memory—Fully connected (LSTM-FC) neural network for PM2.5 concentration prediction. Chemosphere 2019, 220, 486–492. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Zheng, Z.; Liu, J.; Chen, P.; Wu, X. LSTM network: A deep learning approach for short-term traffic forecast. IET Intell. Transp. Syst. 2017, 11, 68–75. [Google Scholar]

- Tian, Y.; Zhang, K.; Li, J.; Lin, X.; Yang, B. LSTM-based traffic flow prediction with missing data. Neurocomputing 2018, 318, 297–305. [Google Scholar] [CrossRef]

- Li, Y.; Cao, H. Prediction for Tourism Flow based on LSTM Neural Network. In 2017 International Conference on Identification, Information and Knowledge in the Internet of Things, Qufu, China, 19–21 October 2017; Qufu Normal University, School of Information Science and Engineering: Shandong, China, 2018; Volume 129, pp. 277–283. [Google Scholar]

- Ma, X.; Tao, Z.; Wang, Y.; Yu, H.; Wang, Y. Long short-term memory neural network for traffic speed prediction using remote microwave sensor data. Transp. Res. Part C Emerg. Technol. 2015, 54, 187–197. [Google Scholar] [CrossRef]

- Petersen, N.C.; Rodrigues, F.; Pereira, F.C. Multi-output bus travel time prediction with convolutional LSTM neural network. Expert Syst. Appl. 2019, 120, 426–435. [Google Scholar] [CrossRef]

- Fischer, T.; Krauss, C. Deep learning with long short-term memory networks for financial market predictions. Eur. J. Oper. Res. 2018, 270, 654–669. [Google Scholar] [CrossRef]

- Kim, H.Y.; Won, C.H. Forecasting the volatility of stock price index: A hybrid model integrating LSTM with multiple GARCH-type models. Expert Syst. Appl. 2018, 103, 25–37. [Google Scholar] [CrossRef]

- Vochozka, M.; Vrbka, J.; Suler, P. Bankruptcy or Success? The Effective Prediction of a Company’s Financial Development Using LSTM. Sustainability 2020, 12, 7529. [Google Scholar] [CrossRef]

- Wu, Y.; Mei, Y.; Dong, S.; Li, L.; Liu, Y. Remaining useful life estimation of engineered systems using vanilla LSTM neural networks. Neurocomputing 2018, 167–179. [Google Scholar] [CrossRef]

- Peng, L.; Liu, S.; Liu, R.; Wang, L. Effective long short-term memory with differential evolution algorithm for electricity price prediction. Energy 2018, 162, 1301–1314. [Google Scholar] [CrossRef]

- Sagheer, A.; Kotb, M. Time series forecasting of petroleum production using deep LSTM recurrent networks. Neurocomputing 2019, 323, 203–213. [Google Scholar] [CrossRef]

- Xu, X.X.; Rui, X.P.; Fan, Y.L.; Yu, T.; Ju, Y.W. Forecasting of Coalbed Methane Daily Production Based on T-LSTM Neural Networks. Symmetry 2020, 12, 861. [Google Scholar] [CrossRef]

- Li, C.; Wang, Z.; Rao, M.; Belkin, D.; Song, W.; Jiang, H.; Xia, Q. Long short-term memory networks in memristor crossbar arrays. Nat. Mach. Intell. 2019, 1, 49–57. [Google Scholar] [CrossRef]

- Bergmeir, C.; Benítez, J.M. On the use of cross-validation for time series predictor evaluation. Inf. Sci. 2012, 191, 192–213. [Google Scholar] [CrossRef]

| Nodes | RMSE (m3) | MAE (m3) | MAPE (%) |

|---|---|---|---|

| 32 | 81.84 | 50.11 | 1.50 |

| 64 | 79.30 | 46.85 | 1.41 |

| 128 | 75.77 | 41.41 | 1.24 |

| 256 | 80.81 | 50.02 | 1.53 |

| 512 | 84.46 | 52.62 | 1.58 |

| Learning Rate | RMSE (m3) | MAE (m3) | MAPE (%) |

|---|---|---|---|

| 0.005 | 142.42 | 121.87 | 3.69 |

| 0.001 | 95.37 | 72.60 | 2.22 |

| 0.0005 | 82.27 | 54.08 | 1.66 |

| 0.0001 | 76.24 | 44.68 | 1.35 |

| 0.00005 | 76.59 | 43.18 | 1.30 |

| Model | RMSE (m3) | MAE (m3) | MAPE (%) |

|---|---|---|---|

| LSTM NN | 46.47 | 31.46 | 1.14 |

| M-LSTM NN | 42.46 | 24.98 | 0.91 |

| Variable | RMSE (m3) | MAE (m3) | MAPE (%) |

|---|---|---|---|

| Casing pressure | 44.15 | 31.22 | 1.10 |

| Water production | 42.54 | 28.58 | 1.01 |

| Lowest temperature | 46.64 | 31.45 | 1.14 |

| Highest temperature | 46.63 | 31.08 | 1.15 |

| No auxiliary variables | 46.47 | 31.46 | 1.14 |

| All variables | 42.46 | 24.98 | 0.91 |

| Time Lag (Day) | RMSE (m3) | MAE (m3) | MAPE (%) |

|---|---|---|---|

| t + 1 | 11.55 | 6.42 | 0.24 |

| t + 2 | 17.39 | 12.82 | 0.48 |

| t + 3 | 22.50 | 19.18 | 0.71 |

| t + 4 | 23.77 | 20.66 | 0.77 |

| t + 5 | 25.00 | 22.06 | 0.82 |

| t + 6 | 26.16 | 23.37 | 0.87 |

| t + 7 | 27.28 | 24.61 | 0.92 |

| t + 8 | 38.50 | 35.39 | 1.31 |

| t + 9 | 47.57 | 46.09 | 1.71 |

| t + 10 | 59.51 | 56.74 | 2.09 |

| Time Lag (Month) | RMSE (m3) | MAE (m3) | MAPE (%) |

|---|---|---|---|

| t + 1 | 2410 | 2230 | 2.68 |

| t + 2 | 3380 | 2980 | 3.65 |

| t + 3 | 5140 | 4830 | 5.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Rui, X.; Fan, Y.; Yu, T.; Ju, Y. A Multivariate Long Short-Term Memory Neural Network for Coalbed Methane Production Forecasting. Symmetry 2020, 12, 2045. https://doi.org/10.3390/sym12122045

Xu X, Rui X, Fan Y, Yu T, Ju Y. A Multivariate Long Short-Term Memory Neural Network for Coalbed Methane Production Forecasting. Symmetry. 2020; 12(12):2045. https://doi.org/10.3390/sym12122045

Chicago/Turabian StyleXu, Xijie, Xiaoping Rui, Yonglei Fan, Tian Yu, and Yiwen Ju. 2020. "A Multivariate Long Short-Term Memory Neural Network for Coalbed Methane Production Forecasting" Symmetry 12, no. 12: 2045. https://doi.org/10.3390/sym12122045

APA StyleXu, X., Rui, X., Fan, Y., Yu, T., & Ju, Y. (2020). A Multivariate Long Short-Term Memory Neural Network for Coalbed Methane Production Forecasting. Symmetry, 12(12), 2045. https://doi.org/10.3390/sym12122045