Abstract

Military uniforms serve as an essential symbol for servicemen and an important image of national and military dignity. The current military uniform size system in Taiwan, which features various types of military uniforms based on the body sizes of servicemen, was formulated in 1986. This size classification system includes numerous groups and is too complex, leading to inventory overstock, increased inventory cost and warehouse staff workload, and a waste of national defense resources. This study used support vector clustering (SVC) with genetic algorithm (GA) models to improve the upper garment size system for uniforms. The SVC technique was employed to classify sizes, and the GA technique was used to determine optimal parameter values for the SVC model. This paper developed an upper garment size system that can increase the fit of uniforms to servicemen’s body sizes and reduce the number of size groups, thereby alleviating warehouse staff workload and inventory cost.

1. Introduction

Military uniforms serve as a crucial symbol to servicemen and an essential factor for setting the national image. Therefore, it is critical to produce suitable military uniforms for large groups of servicemen. Different sets of military uniforms vary with the seasons and the various types of terrain in most countries. A standard uniform size system can help reduce production time and cost by facilitating mass manufacturing and promoting economies of scale. Burns and Bryant [1] developed a standard size system that predicts the number of items and ratio of size to be produced, resulting in accurate inventory control and production planning. The current military uniform standard size system in Taiwan, which was established in 1986 (Army Headquarters [2]), has never been properly revised. Uniforms that do not fit servicemen are often supplied because of numerous and complex classifications of uniform size. This causes overstocking, increased stock cost, increased warehouse staff workload, and wasted defense resources. A size system of military uniforms should, therefore, be established to estimate purchase proportions for all sizes and reduce problems regarding the size and number of uniforms that do not fit. This should consequently decrease inventory, stock cost, and financial overstock.

The size of Taiwan soldiers’ uniforms is modified from the folk size specifications nowadays. However, if the soldiers’ body types do not conform to the regulations they will be eliminated by medical examination before enlisting. It cannot meet the current situation, because we lack a uniform system for soldiers, which focuses on their body type. In particular, the wave of big data has swept the world and brought amazing profits to enterprises. Although the purpose of the military sector is not for profit, we cannot ignore the agility and innovation that big data brings. This study was expected to apply anthropometric data effectively, and let the military make quick, sensible decisions as much as possible. We have the following two goals to reach in this paper:

- (1)

- Use the soldiers’ body type data to re-establish the soldiers’ uniform size system, and make the military uniform more suitable for their body.

- (2)

- Avoid excessive storage to reduce storage costs and achieve the goal of agile production.

Modern military science and technology policies are moving toward integrated research and development while taking into account commercial interests and reducing the development costs of national defense science and technology. Therefore, the introduction of relevant assessment methods into military research has emerged. Yang et al. [3] used an operation loop with realistic link rules to model the cooperation relationships among weapons in the defense system. Wan et al. [4] proposed a lookahead behavior model examining simulations. Lu and You [5] employed a new model with a route map and evaluated driven forces improvement of new technology to study real environment of defense skills. In the literature on size systems, Tryfos [6] suggested an integer programming method for optimizing the number of sizes or minimizing an aggregate index to maximize expected sales. McCulloch et al. [7] constructed a size system using a nonlinear optimization approach to maximize the quality of fit. Laing et al. [8] used the K-means cluster analysis method to establish size charts for protective clothing used by firemen in New Zealand. Moon and Nam [9] used the same method to classify the lower body shapes of senior women into a few figure types and subsequently employed a control dimension and size interval to establish a lower garment size system. Gupta and Gangadhar [10] applied multivariate analysis to develop size charts for young females in India. Hsu and Wang [11] utilized a decision tree-based data mining method to develop size systems for the pants of Taiwanese soldiers. Gupta et al. [12] adopted a linear programming approach to classify size groups. Hsu et al. [13] proposed a two-stage cluster analysis approach to classify the anthropometric data of adult females in Taiwan and develop size charts. Chung et al. [14] employed data mining to establish size systems for elementary and high school students. Zakaria et al. [15] used multivariate statistical analysis to explore anthropometric data and develop a size system. They surveyed 629 schoolgirls aged between 7 to 12 years belonging to three major ethnic groups, namely, Malays, Chinese, and Indians. Mason et al. [16] used analysis of variance (ANOVA) to identify unique body shapes based on anthropometric data from female teachers in Africa. Vinue et al. [17] proposed two algorithms based on a new hierarchical partitioning around medoids (HIPAM) clustering method originally developed for defining optimal prototypes for apparel design. Recent scholars used statistical analysis or 3D body scanning for different groups to develop sizing systems appropriate to particular groups of people. Maria et al. [18] developed a new approach to examine anthropometric data through statistical analysis to obtain a customization model and evaluate satisfaction performance. The approach of Bagherzadeh et al. [19] consists of three phases: factor analysis, two-step cluster analysis, and decision tree analysis. Esfandarani and Shahrabi [20] used principal component analysis to cut sizing variables to partition a heterogeneous population into a homogeneous community such that the resulting size chart is estimated by the aggregate loss of the fitness method. Xia and Istook [21] considered the sizing system creation process including natural log-transformation, principle component analysis, multivariate linear regression, size range determination, and measurements calculation. Hamad et al. [22] defined an exhaustive methodology to obtain a clustering of human morphology shapes representative of a population and to extract the most significant morphotype of each class. The method of Lee and Ko [23] also defined three misfit measures: landmark point misfit, landmark line misfit, and circumferential misfit. Some researchers proposed a neural network data mining framework to generate useful patterns for developing standard size charts to improve manufacturing competitiveness. Hsu [24] proposed an Artificial Neural Network (ANN)-based data mining framework to generate useful patterns for developing standard size charts. For Iranian male suits, Vadood et al. [25] presented a novel sizing chart by artificial neural network approaches. To cluster different body sizes, the Kohonen neural network was adopted with ten sizing parameters. Most researchers have used methods of statistical analysis, including principal component analysis. They have determined body size from several measurement variables and subsequently made classifications by one-way ANOVA, multivariate statistical analysis, cluster analysis, or optimal technology. However, these methods yield inferior results when the sample is large or when it has irregular cluster types or when examined under many classes. To address this problem, Ben-Hur et al. [26] have recently developed support vector clustering (SVC), a new and excellent clustering and classification method. SVC is an unmonitored support vector machine (SVM) and a clustering analysis method for kernels. It requires few parameters and no assignment of cluster quantity, makes derivations by quadratic programming, and manages all types of clusters and extreme points (Ben-Hur et al. [27]). In addition, it has been widely applied in several studies to solve problems in the fields of classification, regression, and new knowledge. For example, Chih [28] demonstrated that kernel based Eigen-decomposition can integrate spatial statistics and support vector clustering can evaluate the number of deficiency clusters to divide convex and non-convex deficiency clusters at the same time. Through Garcia and Moreno [29], accurate surface representations distributed in its volume of the objects from data can be obtained. The advantage of their approach can be applied for medical imaging, because it is noise robust and without complex partitions. Gianfranco and Ilie [30] employed an SVC-based approach to integrate several support vectors by the traditional method of the Gaussian kernel where the clusters are packed together by a deterministic algorithm. Pei et al. [31] constructed a new hierarchical classification algorithm to construct support vector machine learning by developing mirrors of the class hierarchy. The SVC model is valuable for reducing the time consumed in SVM training, developing the matrix of performance, and determining proper parameter values (C and q). It also determines cluster quantity (Wang and Chiang [32]). Ben-Hur et al. [26] did not locate the optimal parameter. There are three related papers: Cho and Seo [33], Park et al. [34], and Geem and Kim [35] that are worth mentioning. In this manuscript we apply a genetic algorithm (GA) to search for the optimal parameter such that we can reach the best effect for non-audit training. Samples were first processed by principal component analysis to determine the crucial size variable. The GA was subsequently used to determine the optimal parameters for the SVC model. The proposed calculation process can be used to determine optimal parameter values for the SVC model and thereby alleviate calculation complexity and reduce the time required for training. For completeness, we provide a detailed description of the GA used in this paper.

- [Step 1]

- We set the constant parameter and initial population. We apply the binary coding to code C and q such that they become chromosomes and then we randomly define the first generation of chromosomes as the initial group with the range for parameter C as [0, 1] (where 1 denotes an extremely not allowed value). The range of q is assumed as [1, 200], since when q is greater than 200, the partition outcomes are the same as q = 200. The initial number of groups is 30, which is the present uniform category number.

- [Step 2]

- We assume the adopted function and calculation adopted value: In our paper, we compute the total loss as the adopted value. The formula is denoted as follows:where aj is the assigning value in the j body type, bj is the actual value in the j body type, and p is the total number of body types. A smaller DAB value indicates a more optimal degree of fitness.

- [Step 3]

- The terminal condition: When the following conditions are satisfied then the GA will be stopped, if the terminal conditions are not satisfied, then execute Step 4.

- Condition (1)

- For five consecutive generations, the adopted values are identical.

- Condition (2)

- The iterative process reaches the pre-designed number. In our paper, the pre-designed number is 100.

- [Step 4]

- Duplication: The selection is adopted by the wheel method that depends on the adopted value to decide the duplicated ratio. Those chromosomes with high adopted values have an increased chance to be selected in producing the next generation.

- [Step 5]

- Crossover: We apply the single point crossover method. That is, we randomly select two chromosomes as initial generations and randomly select a mating position among several genes. We replace the right-hand side gene to produce a new chromosome. In our paper, after simulation, we found that the crossover rate of 0.5 reaches the optimal adopted value.

- [Step 6]

- Mutation: We randomly select a chromosome to mutate such that we randomly select genes to switch between 0 and 1. In this paper, after simulation, we find that the mutation ratio of 0.3 will reach the optimal adopted value.

- [Step 7]

- We have gone through the algorithm after duplication; crossover and mutation produce new generations and then we return back to the second step.

We adopt the GA from Zhou et al. [36] and Zhou et al. [37].

In this paper, 1500 male anthropometric data samples on sleeve length, height, collar size, chest perimeter, and chest front horizon were collected from a military supply unit. We applied SVC on 1000 samples to classify military uniform sizes and verified such classification using 500 samples. To reduce inventory, decrease cost, and ease warehouse staff workload, we established an improved military uniform size system for males which uses total loss as a fitness function and alleviates the complexity of the current uniform size system. In the future, if female data is provided, we will reapply our methodology and update our results and techniques if necessary.

2. Methodology

In this paper, primary data was simplified, and five anthropometric parameters (sleeve length, height, collar size, chest front horizon, and chest perimeter) were analyzed by factor analysis to assess their interrelations and determine representative parameters. Second, the least total loss function was obtained by GA. The best parameter values were then used to pick out extreme values. Finally, SVC was employed again to establish the best cluster for constructing a new military uniform size system.

2.1. Current Military Uniform Size System in Taiwan

Taiwan’s current military uniform size system, with 30 size groups (Table 1), was instituted based on public clothing standards. At present, the demand quantity for military uniforms is computed based on the demand quantity during the preceding year in addition to a fixed proportion of safe stock. However, there is excess stock for some sizes primarily because the size system focuses on the body type of the majority of military personnel and is different from other clothing size systems. We referred to historical data on the demand forecast for the quantity and size proportions of military uniforms to evaluate the demand for a more accurate forecast and reduce manufacturing and inventory costs.

Table 1.

Current military uniform size system in Taiwan.

2.2. Factor Analysis

This paper analyzed anthropometric data to establish a military uniform size system for males. In structuring the size system of uniforms, not all anthropometric parameters need to be considered because these parameters are very highly related. In the analytic approach, we assess different anthropometric parameters and select representative main parameters. Factors with characteristic values greater than one are retained based on the Kaiser criterion, and the number of decisive factors are obtained (Hair et al. [28]). The analysis results are shown in Table 2 and Table 3.

Table 2.

Table of characteristic values.

Table 3.

Factor loadings of anthropometric parameters.

In the analysis, Factors 1 and 2 are first selected as the main factors because they have characteristic values greater than 1 (1.97 and 1.16, respectively). After that, anthropometric parameters with factor loadings greater than 0.5 are identified (Table 3). The main anthropometric parameters in Factor 1 are height and sleeve length, comprising the length factor. Meanwhile, those in Factor 2 are collar size, chest perimeter, and chest front horizon, comprising the enclosing factor. Subsequently, anthropometric parameters with the highest factor loadings are determined for both the length factor (sleeve length with a factor loading of 0.90) and enclosing factor (collar size with a factor loading of 0.76).

2.3. Hybrid SVC with GA

Ben-Hur et al. [26] originally constructed the SVC algorithm to deal with nonparametric clustering to derive the clustering number automatically, which was based on the SVM algorithm of (Boser et al. [38], Cortes and Vapnik [39]). Owing to robustness for noise, excellent generalization performance, and fast convergence, SVM is assumed as an outstanding clustering method. SVM is considered a well-defined clustering technique such thatprovided data labels are supposed to be corrected. However, in real-world situations this assumption may be valid. Consequently, a transformation of SVM to a not well-defined algorithm, as the SVM, has become a popular method. The SVM algorithm has a distinct advantage of arbitrary contours of cluster boundaries since inherited from the SVM algorithm. There are two stages in the SVC algorithm. During the first stage, the input data from the provided domain will be projected by a nonlinear kernel function into a high-dimensional feature space. Among kernel functions, the most popular used kernel functions are Gaussian functions. The smallest radius of spheres to contain all data is denoted as support vectors in the high-dimensional feature space. The derived sphere is shifted back to the input data space to constitute several contours in the second stage (Ben-Hur et al. [40]). A description of the operations of SVM training and clustering validity is illustrated in the paper.

2.3.1. SVM Training

With centroid a and radius R, a hypersphere is constructed in the featured space to obtain a closed circumference around data such that the volume of this hypersphere must be minimized to reduce the possibility to contain outliers. The distance between the majority data to the centroid, a, should be less than the radius R.

However, a number of data points outside the sphere are allowed by introducing a slack variable . We assume x is an n-dimensional input space in the n-dimensional rectangular space that consists of n sample points for the training set. We apply non-linear transformation mapping to project to a characteristic space to search the minimum sphere containing all sample points with the relax factor , and the relation is expressed as

where ‖·‖ is the Euclidean norm, a is the center of the sphere, R is the radius, C is a constant (penalty factor), is the penal term, is the data point xi transformed into a high-dimensional feature space, and the parameter C controls the tradeoff between the hypersphere volume and the errors.

By incorporating the above constraints into Equation (2), the Lagrangian can be constructed as

where and are Lagrange multipliers, C is a constant, and is a penalty term. Setting the derivative of L to zero with respect to R, a, and leads to

The Karush–Kuhn–Tucker (KKT) complementary conditions further result in the following:

The hypersphere can be searched in the feature space. Based on Equation (8), the image of those points with positive and will lie outside in the hypersphere. By Equation (7), we derive that those points have and then we conclude that by Equation (6). Those points are referred to as bounded support vectors (BSVs). A point satisfying is transferred to the interior or to the surface of the feature hypersphere. When , based on Equation (8), we derive that its image residues on the surface of the feature hypersphere. Those points are denoted as support vectors (SVs). We summarize as follows: SVs reside on the cluster circumference, BSVs reside outside the boundaries, and all other points reside inside the boundaries.

There will be no BSV, if , due to the constraint in Equation (4). Applying those relations, we can simplify the expression to cancel out variables , and to shift the Lagrangian into the Wolfe dual form in variable :

We apply the SV approach where the inner product of and are represented by the kernel K(xi, xj). Within this paper, we adopt the following Gaussian kernel:

where is the width parameter. Tax and Duin [41] pointed out that polynomial kernels do not imply tight contour representations for clusters. Therefore, we can rewrite the Lagrangian W as follows:

At each point x, we define the distance of the image in the feature space from the center of the sphere:

Considering Equation (5) and the definition of the kernel, we derive

The radius of the sphere is

R = {R(xi)| xi is a support vector}.

The contours that enclose the points in the data space are defined by the set

They are interpreted as forming cluster boundaries. Considering Equation (15), as we discussed before, SVs reside on the cluster circumference, BSVs reside outside, and all other points reside insider the clusters.

2.3.2. Cluster Validity

Points from different clusters will not be separated by the cluster description algorithm. Therefore, we applied a geometric method containing that was dependent on observation for a pair of data points coming from two different clusters such that any route connecting these two points must leave the sphere in the feature space. For those points, with , there exists a path containing a segment of . The adjacency matrix is defined for points and based on the above observation for images reside in or on the sphere of the feature sphere, as follows:

The set A is denoted as collections of clusters for connected components. In this paper, 10 to 20 points were selected as the sampling number to implement for line segments in numerical examples. Those BSVs were not categorized during the above-mentioned process, owing to images of their feature space reside outside the circumference.

When performing training by SVC, parameters C and q must be provided because their values influence the classification results. Therefore, this paper uses the GA to search for optimal parameter values for the SVC model. The GA searching mechanism uses binary codes to encode parameters C and q. The current military uniform size system includes 30 size groups, and the calculating total loss is regarded as a fitness function. The equation is as Equation (1).

Based on the fitness function in Equation (1), parents with higher fitness values will have a better possibility to be selected to produce next offspring. We adopt the roulette wheel selection principle (Holland [42]) to choose parents to generate new generations. We apply crossover and mutation operations to produce new offspring. A shift between 1 and 0 is operated to execute mutation operation. Moreover, we apply the single-point crossover principle for crossover operation.

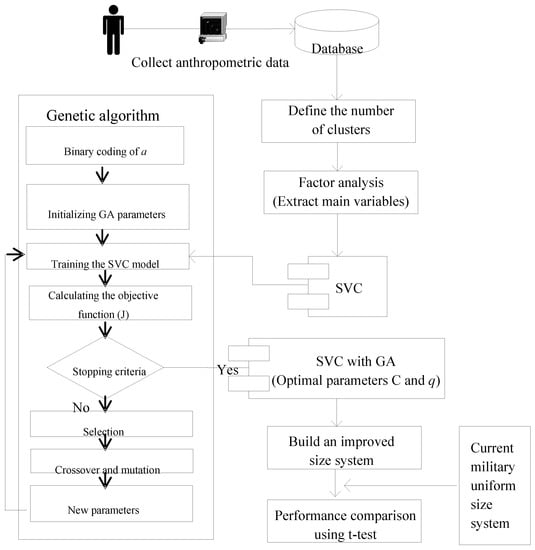

Segments of paired chromosomes between two determined breakpoints are exchanged. The probabilities of crossover and mutation are set to 0.5 and 0.3, respectively. The GA stops when the generation arrives at 100 or when the same fitness value occurs in five generations. Figure 1 shows the flowchart of the hybrid SVC with GA.

Figure 1.

The flowchart of hybrid support vector clustering (SVC) and genetic algorithm (GA).

This paper employs the GA to obtain optimal parameters values (C and q) for the SVC model. The degree of fitness can be improved, and the number of size groups can be reduced to improve the performance of the current size system. Therefore, total loss is considered the fitness function value of the GA. Additionally, less than 30 size groups were included in the SVC model, whereas there are 30 size groups in the current size system. The parameter searching operations continue until one group of parameters (C and q), that can yield total loss, is determined. We inserted the parameters into the SVC model to perform clustering and to construct an appropriate uniform size system for male soldiers.

3. Numerical Example and Discussion

By factor analysis, we extract the main anthropometric parameters (sleeve length and collar size) from the training sample, and then employ GA to search optimal parameter values for the SVC model. With this process, we can obtain the initial cluster, derive extreme values, and gain the size range of the main anthropometric parameters. Furthermore, we determine an appropriate interval distance for classifying body types into various uniform sizes and calculate the total loss function for measuring fitness.

3.1. Analysis by SVC with GA Given Extreme Values

The fitness function value is influenced by the number of sizes and sample coverage, that is, the lower the number of sizes, the lower the sample coverage is and the lower the fitness function value (total loss) is. The conditions for our coverage are based on the GA that are stated as follows:(a) Five consecutive iterations must imply the same result and(b) the number of iterations must reach the pre-designed number. In our research, the pre-designed number was 100 times. To construct a size system with fewer sizes and higher coverage, we focused on two levels of coverage (100% and 92%) and allowed some extreme values to find parameter values leading to a minimum fitness function value. We inputted the SVC model and subsequently constructed the size system based on the clustering results. Extreme values, including least sample points, were selected according to clustering results from the SVC model.

Situation 1.

Sample coverage is 100% (extreme values are not allowed).

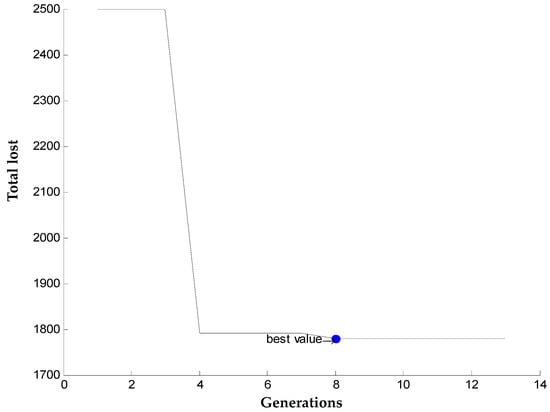

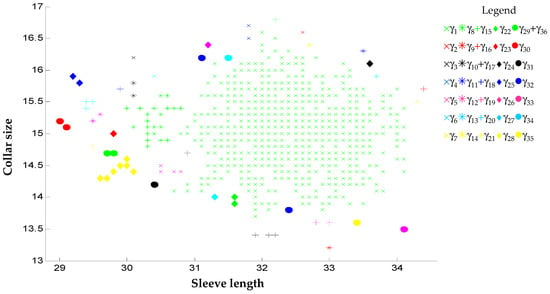

The GA was employed to search for optimal parameter values. The minimum fitness function value was 1078.1, and its relative parameter values were C = 1 and (Figure 2). Subsequently, we inputted the parameter values into the SVC model. The clustering results in Figure 3 show no extreme values such that there is no cluster in Figure 3.

Figure 2.

Calculation results obtained by GA (sample coverage = 100%). Note:  is the minimum fitness value.

is the minimum fitness value.

Figure 3.

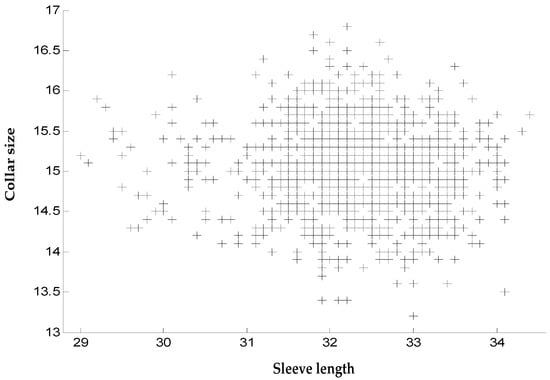

SVC cluster size scatter diagram (q = 1, C = 1). Note: Different colors and shapes represent different γi cluster categories.

Situation 2.

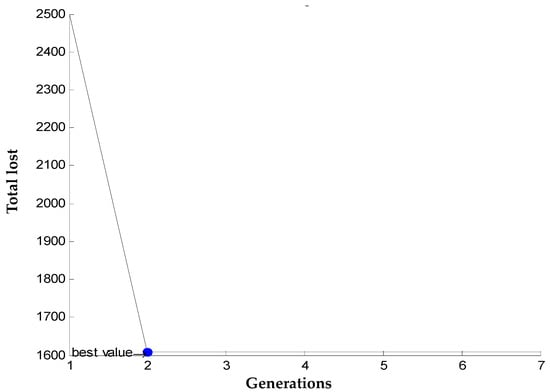

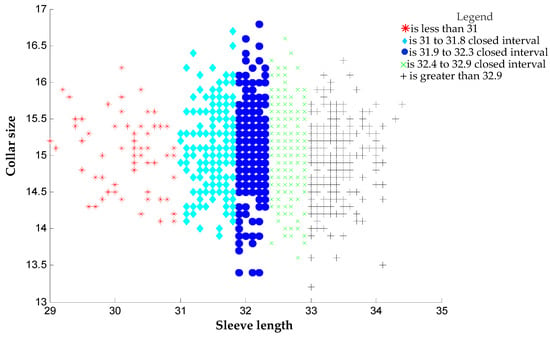

Sample coverage is up to 92% (allowed extreme values ≤ 8%).

Using clustering results from the SVC model, we selected 80 extreme values. The principle for selecting extreme values is to include 17 or more sample points in its group to obtain a sample coverage of 92%. Subsequently, we used the GA to search for optimal parameter values. The results are shown in Figure 4. The minimum fitness value was 1608.2, and the optimal parameter values were C = 0.7 and . We inputted the parameter values into the SVC model, and the clustering results divided into 37 clusters are shown in Figure 5. In the figure, 36 clusters with extreme values are neglected.

Figure 4.

Statistical diagram of calculation results obtained by the GA (sample coverage = 92%). Note:  is the minimum fitness value.

is the minimum fitness value.

Figure 5.

SVC cluster size scatter diagram (q = 163, C = 0.7). Note: Different colors and shapes represent different γi cluster categories.

3.2. Construction of the Improved Size System

According to clustering results obtained in Section 3.1, we computed the maximum, average, and minimum values for sleeve length and collar size for the main clusters. In order to derive appreciated size allowances and construct an improved size system, we started with the average and ended in the maximum and minimum, respectively. According to Eberle and Kilgus [43], a characteristic size interval of 4 to 6 cm is appropriate. Meanwhile, a suitable length characteristic interval of 5 to 10 cm is proposed by the International Organization for Standardization/Technical Report (ISO/TR) 10652 [44]. In this study, we limited the number of size groups to under 30 and analyzed the total loss function. In general, the size parameters include height, chest perimeter, and chest front horizon. Thus, the sample points are classified according to both sleeve length and collar size, and the mean of sample points is calculated for height, chest perimeter, and chest front horizon for purposes of making size allowances. The size system is constructed using two levels of sample coverage.

Situation 1.

Sample coverage is 100% (extreme values are not allowed).

In Table 4, sleeve length is divided into seven sizes and collar size is divided into three sizes (total loss amount = 1780.1). In Table 3, the sample includes the majority; 25.3% of the sample has a sleeve length of 32.3 inches and collar size of 15.1 inches. Based on Table 4 and a sample coverage of 100%, we establish an improved size system with 20 size clusters as shown in Table 5. Size numbers represent collar size, and English letters represent sleeve length.

Table 4.

Various size proportions (q = 1).

Table 5.

Size system after improvement (sample coverage = 100%).

Situation 2.

Sample coverage is 92% (allowed extreme values ≤ 8%).

Using clustering results from the SVC model, we selected 80 extreme values. The principle for selecting extreme values is to include 23 or fewer sample points in its group to obtain a sample coverage of 92%. Subsequently, we used the GA to search for optimal parameter values. The results are shown in Table 6. Sleeve length is divided into five sizes, and collar size is divided into four sizes (total loss amount = 1608.2). The sample includes the majority; 15.9% of the sample has a sleeve length of 32.4 inches and collar size of 15.1 inches. Based on Table 6 and a sample coverage of 92%, we obtain an improved size system with 15 size clusters as shown in Table 7.

Table 6.

Varioussize proportions (q = 163).

Table 7.

Size system after improvement (sample coverage 92%).

3.3. Discussion

An improved size system was developed based on anthropometric data obtained from military personnel. We aimed to reduce the size interval and the number of size groups in the current military uniform size system to make it more suitable to the body types of military personnel. There are few extreme values, which may cause overstock. In determining purchase quantity for every size, we can refer to the size sample proportion statistics in Table 4 and Table 6. This should also reduce inventory cost and warehouse staff workload. It should also realize positive economic effects. We used statistical tests to assess whether the new system presents a significant improvement on the current one.

3.3.1. Comparison between the Improved and Current Military Uniform Size Systems

Table 8 compares the improved size system with the current military uniform size system for males. The current system has 30 size groups whereas the improved system has 20 size groups (a 33.3% difference). In addition, the current system has a total loss of 2171, whereas the improved size system has a total loss of 1780.1. The total loss range is 18%, meaning that the total degree of fitness is improved by 18%.

Table 8.

Comparison between the improved and current military uniform size systems.

Using the t-test, we compare the improved and current size systems to determine the improvement in the total degree of fitness. The mean system size (standard deviation) is 2.17 (1.222) before improvement, whereas it is 1.78 (0.928) after improvement (Table 9). There is a significant difference (t = 12.068, p = 0.000), indicating that the new size system represents an improvement over the current one.

Table 9.

The t-test results for the size system before and after improvement.

3.3.2. Comparison between the Improved Size System with 100% and 92% Sample Coverage

Table 10 presents a comparison between the improved size system with 100% and 92% sample coverage. A total of 20 size groups are found at 100% sample coverage compared with 15 size groups found at 92% sample coverage (reduction by 25%). In addition, total loss is 1780 at 100% sample coverage, whereas it is 1608.2 at 92% sample coverage (reduction by 9.7%).

Table 10.

Comparison between the improved size system with 100% and 92% sample coverage.

Using the paired t-test, we determined whether the improved size system enhances the degree of fitness under two levels of sample coverage (Table 11). The size system with 92% sample coverage can better promote the degree of fitness compared with the size system with 100% sample coverage (t = 3.872, p = 0.000). The degree of fitness is enhanced when extreme values are allowed to comprise up to 8% of the sample (sample coverage of 92%).

Table 11.

The t-test results for the improved size systems under two levels of sample coverage.

4. Testing and Verification

The testing process included two parts. In the first part the improved size system established by SVC with the GA was tested. We compared it with the current military size system to determine whether it fits the body size of servicemen. We placed 500 new samples into the improved size system (Situation 1) and compared it with the current military size system. In the second part, a model test with 1000 identical samples was conducted using the SVC with the GA model developed in this paper and the traditional K-means model.

4.1. Testing with 500 New Samples

We put 500 new samples into the improved size system with 20 size groups and compared such a system with the current military size system having 30 size groups. Using a paired t-test, we tested for a significant difference in fitness (Table 12). The total loss (standard deviation) of the current size system was 2.12 (1.150), whereas that of the improved size system was 1.77 (0.629). The statistically significant difference (t = 6.795, p = 0.000) suggests that the improved size system is superior to the current size system; it can improve integral fitness considerably. The improved size system developed with 100% data coverage provides superior fit to the body size of military servicemen.

Table 12.

The t-test results for the improved and current size systems given 500 new samples.

4.2. Comparison by K-means

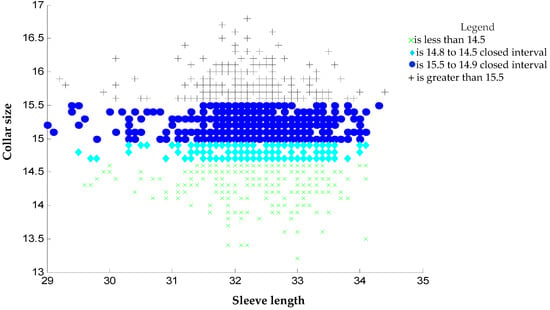

The K-means function developed by Matlab 2009 is used to classify military uniform sizes based on sleeve length and collar size. In this study, five variables of sleeve length and four variables of collar size are assumed. Alternatively, four variables of sleeve length and five variables of collar size are assumed. We calculate total loss to determine the minimum value for each variable. We are limited to constructing 20 groups for purposes of comparison with the improved size system with 100% sample coverage (Situation 1). We determine the minimum values after summing up the total loss; the optimal size classification group has five sleeve length variables and four collar size variables. The results are shown in Figure 6 and Figure 7.

Figure 6.

K-means size cluster scatter chart (clustered by sleeve length). Note: Colors and shapes represent different clusters.

Figure 7.

K-means size cluster scatter chart (clustered by collar length). Note: Colors and shapes represent different clusters.

From the cluster results in Figure 6, we compute the mean sleeve length and height for every cluster, and utilize the results to construct the size system. Similarly, from the cluster results in Figure 7, we compute the mean collar size, chest perimeter, and chest front horizon for every cluster. We utilize the results to construct the size system. As shown in Table 13, the size system constructed by K-means has a total loss of 1810.9 (higher than the total loss of 1780.1 for the improved size system in Situation 1), indicating that the size system constructed by SVC with the GA is superior to that constructed by K-means in terms of integral fitness.

Table 13.

Improved size system developed by K-means.

We compare the performance by three methods: (a) the present system, (b) the K-means approach, and (c) our approach with three criteria: (i) sample coverage, (ii) size clusters, and (iii) total loss. We list the comparison in Table 14.

Table 14.

Comparisons with three different methods.

Based on the findings of Table 14, our improved method not only revised the current system, but it also obtains a better result than the most popular method: K-means.

The results successfully show that the method proposed shows that we can provide a better fit while decreasing the number of categories. However, it has not proved that a reduction in the number of categories and better fitness can reduce warehouse staff workload, alleviate warehouse management problems, prevent overstocking, and decrease inventory cost. Number of categories does not dictate the production volume for each category, how they were stored, or the number of staff employed. Such metrics were never tested against the current statistics. These are good hypotheses and are worthy of further evaluation based on the results presented. That will be the scope of future research. Big data has the energy to generate social change. This research provides support vector clustering with the GA, which can process big data quickly and mine valuable information. In the future, the military can continuously manage, process, analyze, and optimize the data from different sources to provide feedback and update the above applications. It was expected to develop the military’s size system continuously and extend to other types of clothing. We can foresee that it will generate huge economic value in the future.

5. Conclusions

We collected anthropometric data required in making uniforms for male military personnel and cluster the data using SVC with the GA to improve the current military uniform size system in Taiwan. The SVC model can manage any type of clusters and does not require the pre-assignment of cluster quantity. Optimal parameter values for the SVC model are determined by the GA to establish an improved size system that features fewer size groups and better fit to the body types of servicemen. At 100% sample coverage, the improved uniform size system promotes integral fitness by 18% and reduces the number of size groups by 33.3%, thus making it superior to the current size system. The SVC with the GA model proposed in this paper can be applied effectively for size systems. The improved size system ensures the superior fit of uniforms to the body size of servicemen, reduces warehouse staff workload, alleviates warehouse management problems, prevents overstocking, and decreases inventory cost by enhancing room utilization rates.

Author Contributions

Conceptualization, J.C.H.C., G.K.Y. and C.-W.C.; methodology, G.K.Y. and C.-W.C.; software, C.-W.C.; validation, J.C.H.C., G.K.Y. and C.-W.C.; formal analysis, G.K.Y. and C.-W.C.; investigation, G.K.Y. and C.-W.C.; resources, T.-C.H. and J.C.H.C.; data curation, T.-C.H., G.K.Y. and C.-W.C.; writing—original draft preparation, G.K.Y. and C.-W.C.; writing—review and editing, J.C.H.C. and G.K.Y.; visualization, G.K.Y. and C.-W.C.; supervision, T.-C.H. and J.C.H.C.; project administration, T.-C.H. and J.C.H.C.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Burns, L.D.; Bryant, N.O. The Business of Fashion: Designing, Marketing, and Manufacturing; Fairchild Books: New York, NY, USA, 2001. [Google Scholar]

- Army Headquarter. Army Uniform Supply Management Professional Manual; Taipei, Taiwan, 1996. [Google Scholar]

- Wan, C.; Zhang, X.; Zhao, Q.; Yang, K. Operation loop-based optimization model for resource allocation to military countermeasures versus probabilistic threat. Appl. Sci. 2018, 8, 214. [Google Scholar] [CrossRef]

- Yang, M.; Peng, Y.; Ju, R.S.; Xu, X.; Yin, Q.J.; Huang, K.D. A lookahead behavior model for multi-agent hybrid simulation. Appl. Sci. 2017, 7, 1095. [Google Scholar] [CrossRef]

- Lu, H.; You, H. Roadmap modeling and assessment approach for defense technology system of systems. Appl. Sci. 2018, 8, 908. [Google Scholar] [CrossRef]

- Tryfos, P. An integer programming approach to the apparel sizing problem. J. Oper. Res. Soc. 1986, 37, 1001–1006. [Google Scholar] [CrossRef]

- McCulloch, C.E.; Paal, B.; Ashdown, S.P. An optimal approach to apparel sizing. J. Oper. Res. Soc. 1988, 49, 492–499. [Google Scholar]

- Laing, R.M.; Holland, E.J.; Wilson, C.A.; Niven, B.E. Development of sizing system for protective clothing for adult male. Ergonomics 1999, 42, 1249–1257. [Google Scholar] [CrossRef]

- Moon, J.Y.; Nam, Y.J. A study the elderly women’s lower body type classification and lower garment sizing systems. In Proceedings of the International Ergonomics Association Conference, Seoul, Korea, 24–29 August 2003. [Google Scholar]

- Gupta, D.; Gangadhar, B.R. A statistical model for developing body size charts for garments. Int. J. Cloth. Sci. Technol. 2004, 16, 458–469. [Google Scholar] [CrossRef]

- Hsu, C.H.; Wang, M.J. Using decision tree based data mining to establish a sizing system for the manufacture of garments. Int. J. Adv. Manuf. Technol. 2005, 26, 669–674. [Google Scholar] [CrossRef]

- Gupta, D.; Garg, N.; Arora, K.; Priyadarshini, N. Developing body measurement charts for garments manufacture based on a linear programming approach. J. Text Apparel Technol. Mngt. 2006, 5, 1–13. [Google Scholar]

- Hsu, C.H.; Lin, H.F.; Wang, C.H. Developing female size charts for facilitating garment production by using data mining. J. Chin. Inst. Ind. Eng. 2007, 24, 245–251. [Google Scholar] [CrossRef]

- Chung, M.J.; Lin, H.F.; Wang, M.J. The development of sizing systems for Taiwanese elementary and high school students. Int. J. Ind. Ergon. 2007, 37, 707–716. [Google Scholar] [CrossRef]

- Zakaria, N.; Mohd, J.S.; Taib, N.; Tan, Y.Y.; Wah, Y.B. Using data mining technique to explore anthropometric data towards the development of sizing system. In Proceedings of the 2008 International Symposium on Information Technology Proceedings, Kuala Lumpur, Malaysia, 26–28 August 2008. [Google Scholar]

- Mason, A.M.; Klerk, H.M.; Ashdown, S. Sizing and fit research at grassroots level: A methodology for the identification of unique body shapes in African developing countries. J. Fam. Ecol. Consum. Sci. 2008, 36, 9–21. [Google Scholar]

- Vinué, G.; León, T.; Alemany, S.; Ayala, G. Looking for representative fit models for apparel sizing. Decis. Support Syst. 2014, 57, 22–33. [Google Scholar] [CrossRef]

- Maria, L.M.; Philip, N.A.; Nickolas, S.S. A new methodology for the development of sizing systems for the mass customization of garments. Int. J. Cloth. Sci. Technol. 2010, 22, 49–68. [Google Scholar]

- Bagherzadeh, R.; Latifi, M.; Faramarzi, A.R. Employing a three-stage data mining procedure to develop sizing system. World Appl. Sci. J. 2010, 8, 923–929. [Google Scholar]

- Esfandarani, M.S.; Shahrabi, J. Developing a new suit sizing system using data optimization techniques. Int. J. Cloth. Sci. Technol. 2012, 24, 27–36. [Google Scholar] [CrossRef]

- Xia, S.; Istook, C. A Method to Create Body Sizing Systems. Cloth. Text. Res. J. 2017, 35, 235–248. [Google Scholar] [CrossRef]

- Hamad, M.; Thomassey, S.; Bruniaux, P. A new sizing system based on 3D shape descriptor for morphology clustering. Comput. Ind. Eng. 2017, 113, 683–692. [Google Scholar] [CrossRef]

- Lee, W.; Ko, H.S. Heuristic misfit reduction: A programmable approach for 3D garment fit customization. Comput. Graph. 2018, 71, 1–13. [Google Scholar] [CrossRef]

- Tsai, C.Y.; Hsu, C.H. Developing standard elderly aged female size charts based on anthropometric data to improve manufacturing artificial neural network-based data mining. Theor. Issues Ergon. Sci. 2013, 14, 258–272. [Google Scholar] [CrossRef]

- Vadood, M.; Esfandarani, M.S.; Johari, M.S. Developing a new suit sizing system using neural network. J. Eng. FibersFabr. 2015, 10, 108–112. [Google Scholar] [CrossRef]

- Ben-Hur, A.; Horn, D.; Siegelmann, H.T.; Vapnik, V. A support vector clustering method. In Proceedings of the 15th International Conference on Pattern Recognition, Barcelona, Spain, 3–7 September 2000. [Google Scholar]

- Wang, C.H. Separation of composite defect patterns on wafer bin map using support vector clustering. Expert Syst. Appl. 2009, 36, 2554–2561. [Google Scholar] [CrossRef]

- Hair, J.F.; Anderson, R.E.; Tatham, R.L.; Black, W.C. Multivariate Data Analysis; Prentice Hall: Upper Saddle River, NJ, USA, 1998. [Google Scholar]

- Garcia, C.; Moreno, J.A. Application of support vector clustering to the visualization of medical images. In Proceedings of the 2004 2nd IEEE International Symposium on Biomedical Imaging: Nano to Macro (IEEE Cat No. 04EX821), Arlington, VA, USA, 18 April 2004; Volume 2, pp. 1553–1556. [Google Scholar]

- Gianfranco, C.; Ilie, I.S. Support vector clustering of electrical load pattern data. IEEE Trans. Power Syst. 2009, 24, 1619–1628. [Google Scholar]

- Pei, Y.H.; Jung, H.C.; Yi, K.T. Hierarchically SVM classification based on support vector clustering method and its application to document categorization. Expert. Syst. Appl. 2007, 33, 627–635. [Google Scholar]

- Wang, J.S.; Chiang, J.C. A cluster validity measure with outlier detection for support vector clustering. IEEE Trans. Syst. Man Cybern. Part B Cybern. 2008, 38, 78–89. [Google Scholar] [CrossRef]

- Cho, Y.; Seo, K. Building a HOG Descriptor Model of Pedestrian Images Using GA and GP Learning. Int. J. Fuzzy Logic Intell. Syst. 2018, 18, 111–119. [Google Scholar] [CrossRef]

- Park, J.H.; Yu, J.S.; Geem, Z.W. Genetic Algorithm-based Optimal Investment Scheduling for Public Rental Housing Projects in South Korea. Int. J. Fuzzy Logic Intell. Syst. 2018, 18, 135–145. [Google Scholar] [CrossRef]

- Geem, Z.W.; Kim, J.H. Application of Computational Intelligence Techniques to an Environmental Flow Formula. Int. J. Fuzzy Logic Intell. Syst. 2018, 18, 237–244. [Google Scholar] [CrossRef]

- Zhou, T.; Lu, H.; Wang, W.; Yong, X. GA-SVM based feature selection and parameter optimization in hospitalization expense modeling. Appl. Soft Comput. 2019, 75, 323–332. [Google Scholar]

- Zhou, X.; Gao, H.; Zhao, B.; Zhao, L. A GA-based parameters tuning method for an ADRC controller of ISP for aerial remote sensing applications. ISA Trans. 2018, 81, 318–328. [Google Scholar] [CrossRef] [PubMed]

- Boser, B.; Guyon, I.; Vapnik, V. A training algorithm for optimal margin classifiers. In Proceedings of the Fifth Annual Workshop on Computational Learning Theory, Pittsburgh, PA, USA, 27–29 July 1992. [Google Scholar]

- Cortes, C.; Vapnik, V. Support vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Ben-Hur, A.; Horn, D.; Siegelmann, H.T.; Vapnik, V. Support vector clustering. J. Mach. Learn Res. 2001, 2, 125–137. [Google Scholar] [CrossRef]

- Tax, D.; Duin, R. Support vector domain description. Pattern Recogn. Lett. 1999, 20, 1991–1999. [Google Scholar] [CrossRef]

- Holland, J.H. Adaptation in Natural and Artificial System; University of Michigan Press: Ann Arbor, MI, USA, 1975. [Google Scholar]

- Eberle, H.; Kilgus, R. Clothing Technology: From Fiber to Fashion; Haan-Gruiten: Europa-Lehrmittel, Nourney, Vollmer, Germany, 1996. [Google Scholar]

- ISO/TR 10652. Standard Sizing Systems for Clothes; Technical Report; International Organization for Standardization: Geneva, Switzerland, 1991. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).