Urban Industrial Carbon Efficiency Measurement and Influencing Factors Analysis in China

Abstract

1. Introduction

2. Literature Review

3. Research Methods

3.1. Accounting for Industrial Carbon Emissions at City Scale

3.2. UICE Measurement Model

3.3. Constructing UICE Measurement Index System

3.4. UICE Factor Analysis Model

3.4.1. Theoretical Framework Construction

3.4.2. Tobit Model

4. Study Areas and Data Sources

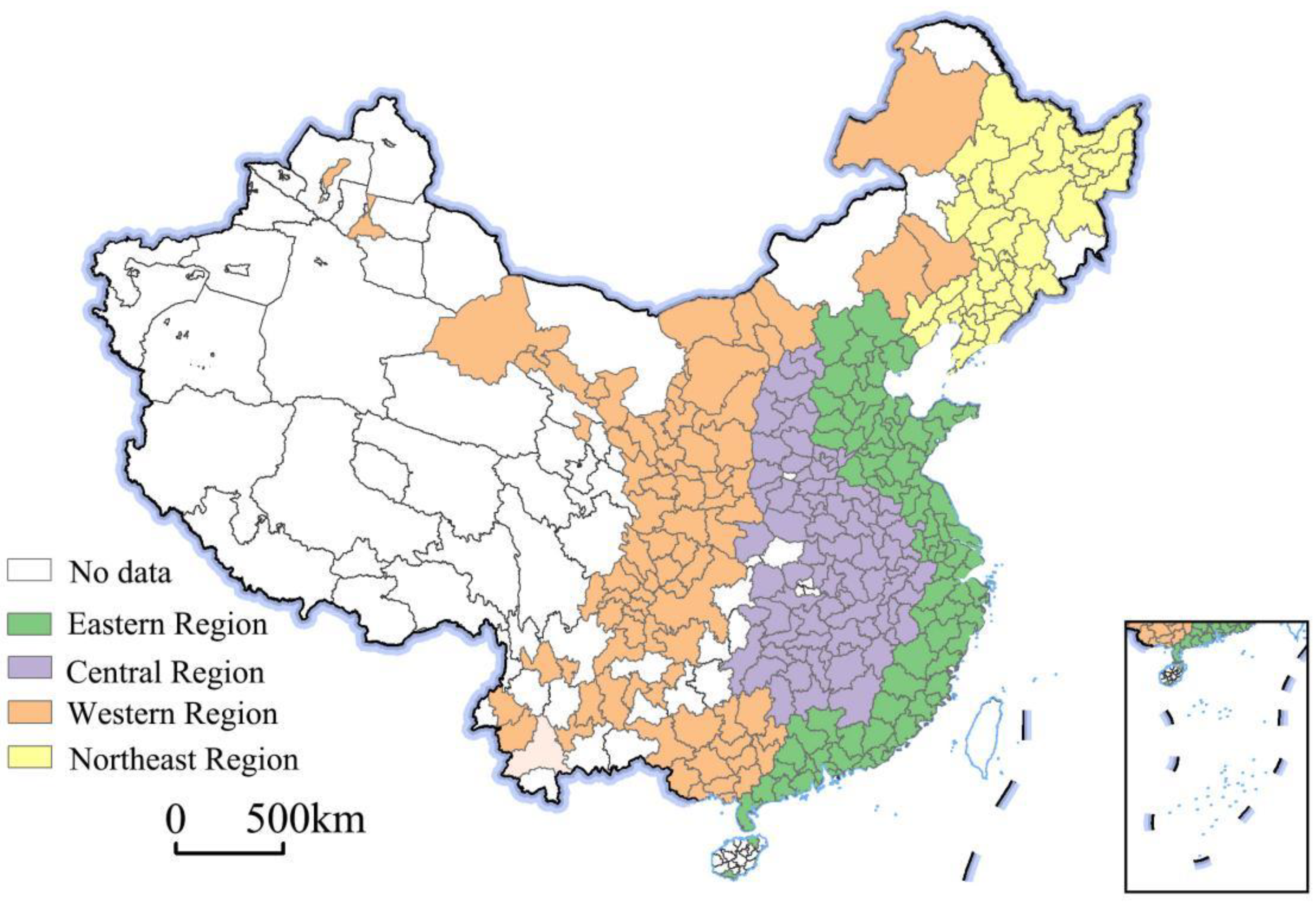

4.1. Study Area

4.2. Data Source

5. Empirical Results

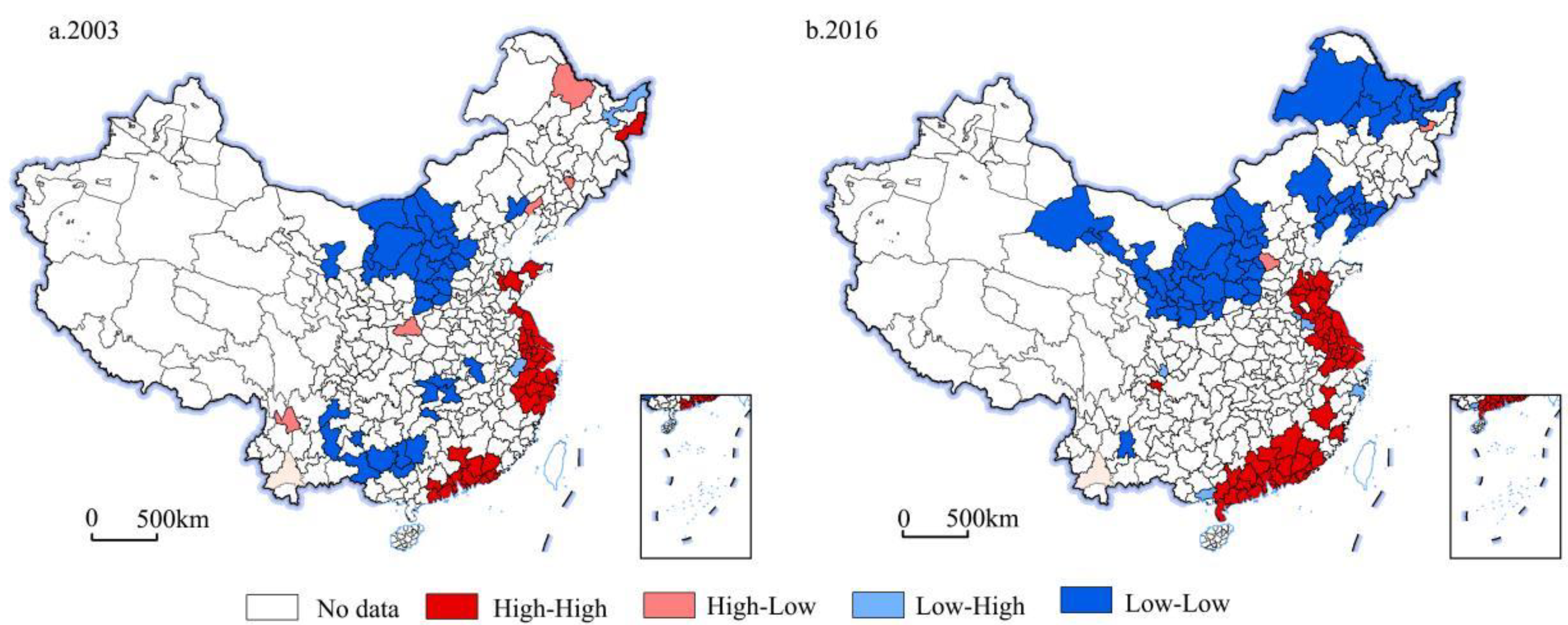

5.1. Spatial Evolution of UICE in China

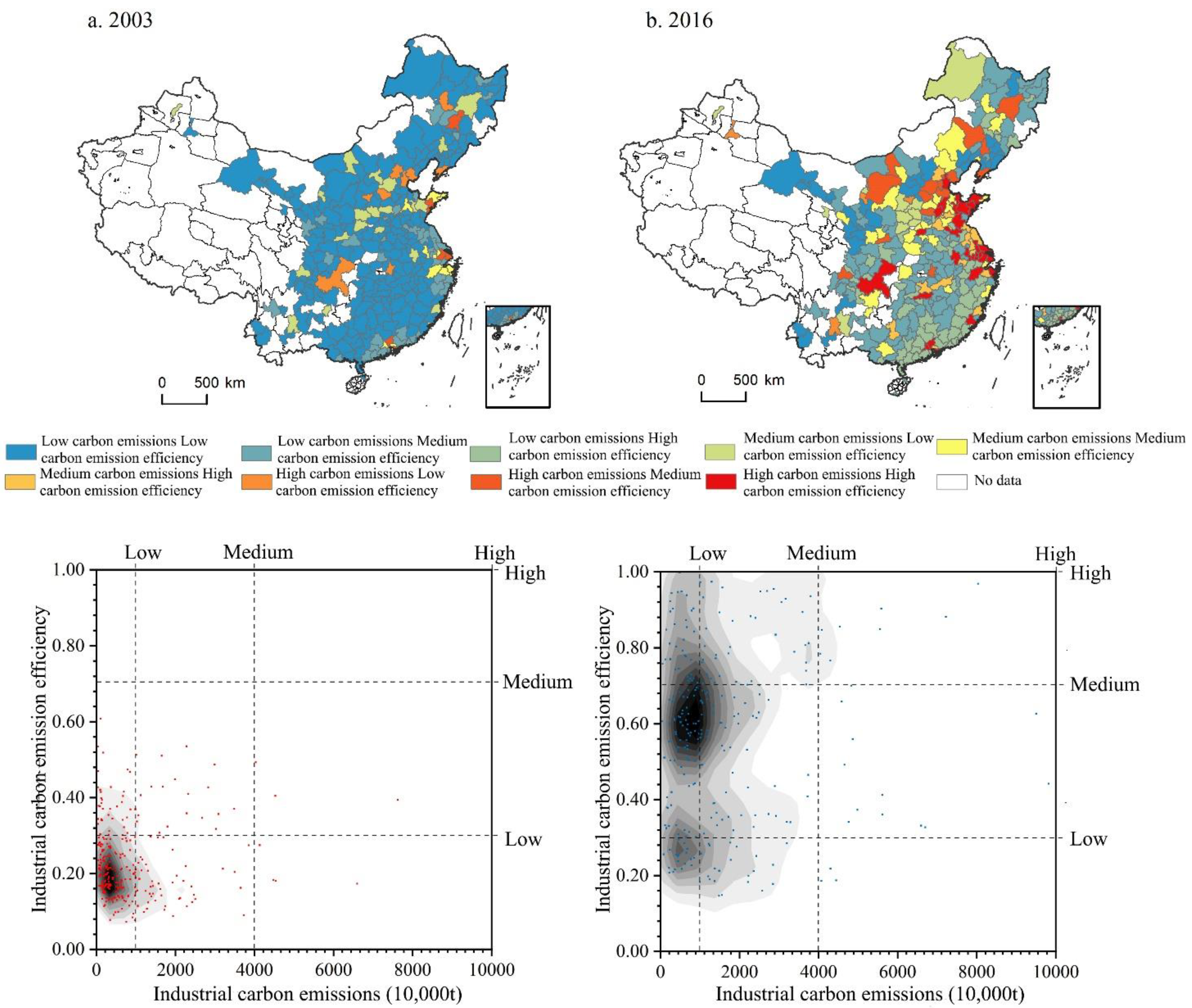

5.2. Spatial Evolution of UICE Types in China

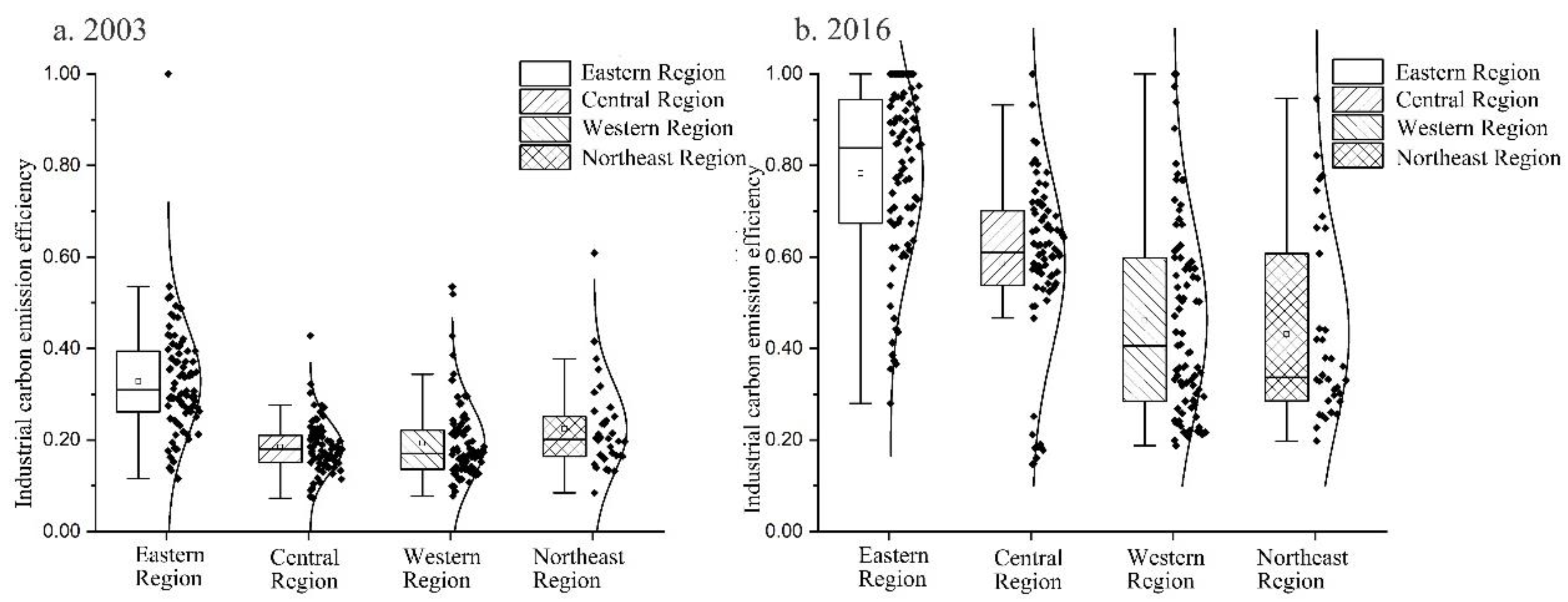

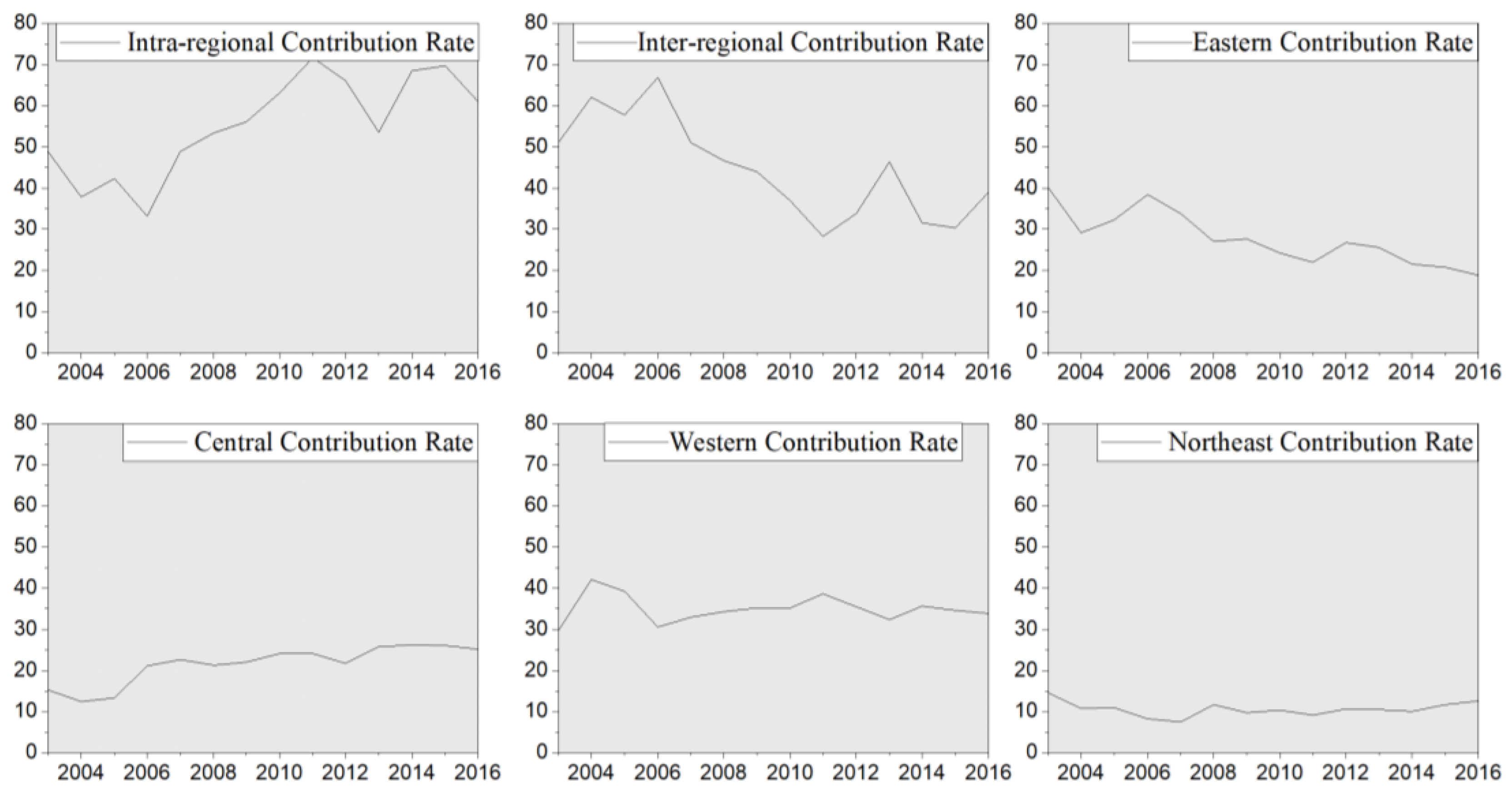

5.3. Characteristics of Regional Differences in UICE in China

5.4. The Relationship between UICE and Economic Development in China

5.5. Influencing Factors of UICE in China

5.5.1. Influencing Factors of China’s UICE

5.5.2. Influencing Factors of UICE in Different Regions

6. Conclusions and Policy Implications

6.1. Conclusions

- (1)

- UICE in China was driven by low efficiency in 2003, while, in 2016, it was dominated by medium and high efficiency, with a decreasing spatial pattern from “east—central—west—northeast.” UICE in China evolved in a “single core-horizontal expansion” pattern in 2003, and a “double core-vertical improvement” pattern in 2016. This indicates that UICE has significant positive spatial correlation properties, and the spatial correlation tends to increase.

- (2)

- The evolutionary pattern of China’s UICE model in 2003 can be summarized as a “single core—horizontal expansion” type, with low carbon emission and low efficiency types as the dominant core and a clear horizontal growth in industrial carbon emissions. The evolutionary pattern of UICE in 2016 can be summarized as a “dual core—vertical growth” type, with two cores of low carbon emission medium efficiency types and low carbon emission low efficiency types formed and showing a clear evolutionary characteristics of UICE’s vertical growth.

- (3)

- China’s UICE was initially at a low level of stability stage, and in 2016, it was in the process of evolving into a high-efficiency steady state, with the eastern and central regions forming a “trailing effect” and the western and northeastern regions forming a “leading effect.” Intra-regional differences have always been the main aspect which affects the overall difference in UICE in China from 2003 to 2016.

- (4)

- The relationship between economic development and UICE is a logistic curve. In the early stage of industrialization, UICE increases rapidly with the growth of GDP per capita; in the middle stage of industrialization, the improvement rate of UICE slows down with the growth in GDP per capita; in the late stage of industrialization, the improvement rate of UICE decreases further with the growth of GDP per capita and shows a steady change at the high efficiency level. From 2003 to 2016, intra-regional variation has consistently been the main aspect which influences the overall change in UICE in China, explaining it to a greater extent, while inter-regional variation has been a secondary aspect which influences the overall change.

- (5)

- In China, the factors that are significantly positively correlated with UICE are industrial agglomeration, local fiscal decentralization, level of economic development, technological progress, average size of industrial enterprises, and industrial diversification. Factors that are significantly negatively correlated with UICE are the level of industrialization, the share of output value of state-owned enterprises in total output value, industrial openness, and environmental regulation. The factors that influence UICE differ depending on the stage of industrialization. The impact of the level of economic development on UICE shows an “inverted U-shaped” change. The impact of industrial agglomeration on UICE is positive, and the positive impact tends to diminish as the level of agglomeration increases.

6.2. Policy Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Xu, X.; Zhu, Q. Carbon emission reduction decisions of supply chain members under cap-and-trade regulations: A differential game analysis. Comput. Ind. Eng. 2021, 162, 107711. [Google Scholar]

- Zhu, R.; Zhao, R.; Sun, J.; Xiao, L.; Jiao, S.; Chuai, X.; Zhang, L.; Yang, Q. Temporospatial pattern of carbon emission efficiency of China’s energy-intensive industries and its policy implications. J. Clean. Prod. 2021, 286, 125507. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, Z.; Xu, X.; Chang, D. Does the transformation of resource-dependent cities promote the realization of the carbon-peaking goal? An analysis based on typical resource-dependent city clusters in China. J. Clean. Prod. 2022, 365, 132731. [Google Scholar] [CrossRef]

- Li, X.F.; Peng, R.; Yang, M.X. Analysis of Industrial Carbon Emissions Assessment and Spatial Distribution. Adv. Mater. Res. 2014, 2745, 1073–1076. [Google Scholar] [CrossRef]

- Chen, L.; Xu, L.; Cai, Y.; Yang, Z. Spatiotemporal patterns of industrial carbon emissions at the city level. Resour. Conserv. Recycl. 2021, 169, 105499. [Google Scholar] [CrossRef]

- Outline of the 14th Five-Year Plan (2021–2025) for National Economic and Social Development and Vision 2035 of the People’s Republic of China, 2021. Available online: http://www.gov.cn/xinwen/2021-03/13/content_5592681.htm. (accessed on 11 December 2022).

- The 14th Five-Year Plan for Green Development of Industry. 2021. Available online: http://www.gov.cn/zhengce/zhengceku/2021-12/03/content_5655701.htm (accessed on 11 December 2022).

- Agras, J.; Chapman, D. A dynamic approach to the Environmental Kuznets Curve hypothesis. Ecol. Econ. 1999, 28, 267–277. [Google Scholar] [CrossRef]

- Gao, M.; Yang, H.; Xiao, Q.; Goh, H. A novel method for carbon emission forecasting based on Gompertz’s law and fractional grey model: Evidence from American industrial sector. Renew. Energy 2022, 181, 803–819. [Google Scholar] [CrossRef]

- Williams, J.H.; Jones, R.A.; Haley, B.; Kwok, G.; Hargreaves, J.; Farbes, J.; Torn, M.S. Carbon-Neutral Pathways for the United States. AGU Adv. 2021, 2, e2020AV000284. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Goto, M. Environmental assessment for corporate sustainability by resource utilization and technology innovation: DEA radial measurement on Japanese industrial sectors. Energy Econ. 2014, 46, 295–307. [Google Scholar] [CrossRef]

- Jung, T.Y.; Park, T.S. Structural Change of the Manufacturing Sector in Korea: Measurement of Real Energy Intensity and CO2 Emissions. Mitig. Adapt. Strat. Glob. Chang. 2000, 5, 221–238. [Google Scholar] [CrossRef]

- Dai, S.; Qian, Y.; He, W.; Wang, C.; Shi, T. The spatial spillover effect of China’s carbon emissions trading policy on industrial carbon intensity: Evidence from a spatial difference-in-difference method. Struct. Change Econ. Dyn. 2022, 63, 139–149. [Google Scholar]

- Wang, Q.; Han, X.; Li, R. Does technical progress curb India’s carbon emissions? A novel approach of combining extended index decomposition analysis and production-theoretical decomposition analysis. J. Environ. Manag. 2022, 310, 114720. [Google Scholar] [CrossRef]

- Yu, X.N.; Yang, Z. The Impact of Digital Economy on Industrial Carbon Emission Efficiency: Evidence from Chinese Provincial Data. Math. Probl. Eng. 2022, 2022, 6583809. [Google Scholar] [CrossRef]

- Lei, H.J.; Zhang, Q.L.; Li, C.J.; Xi, B.D.; Xia, X.F. Factor Analysis on the Industrial Environmental Efficiency and Energy Utilization Efficiency of China by DEA Method. Appl. Mech. Mater. 2012, 209–211, 1620–1626. [Google Scholar] [CrossRef]

- Li, J.; Ding, J.; Zhang, Y.; Li, S. Study on spatial-temporal characteristics and influencing factors of urban environmental resource efficiency in the Yangtze River Basin of China. Front. Environ. Sci. 2022, 1552. [Google Scholar] [CrossRef]

- Zhou, R.; Li, S. A Study on the Development of Low-carbon Economy in Shandong Province-Based on Empirical Analysis on the Influence Factor of Carbon Emission. Energy Procedia 2011, 5, 2152–2159. [Google Scholar] [CrossRef][Green Version]

- Lu, Q.; Yang, H.; Huang, X.; Chuai, X.; Wu, C. Multi-sectoral decomposition in decoupling industrial growth from carbon emissions in the developed Jiangsu Province, China. Energy 2015, 82, 414–425. [Google Scholar] [CrossRef]

- Xepapadeas, A. Chapter 23 Economic growth and the environment. In Handbook of Environmental Economics; Elsevier: Amsterdam, The Netherlands, 2005; Volume 3, pp. 1219–1271. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, C.; Zhou, X. Going carbon-neutral in China: Does the low-carbon city pilot policy improve carbon emission efficiency? Sustain. Prod. Consum. 2022, 33, 312–329. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, L.; Liu, J.; Zhang, H. Total-factor carbon emission efficiency of China′s provincial industrial sector and its dynamic evolution. Renew. Sustain. Energy Rev. 2018, 94, 330–339. [Google Scholar] [CrossRef]

- Jiang, H.; Yin, J.; Qiu, Y.; Zhang, B.; Ding, Y.; Xia, R. Industrial Carbon Emission Efficiency of Cities in the Pearl River Basin: Spatiotemporal Dynamics and Driving Forces. Land 2022, 11, 1129. [Google Scholar] [CrossRef]

- Wang, L.; Wang, H.; Cao, Z.; He, Y.; Dong, Z.; Wang, S. Can industrial intellectualization reduce carbon emissions?—Empirical evidence from the perspective of carbon total factor productivity in China. Technol. Forecast. Soc. Change 2022, 184, 121969. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Tang, Z.; Zhang, K.; Wang, T. Spatial effects of urban expansion on air pollution and eco-efficiency: Evidence from multisource remote sensing and statistical data in China. J. Clean. Prod. 2022, 367, 132973. [Google Scholar] [CrossRef]

- Sun, J.; Du, T.; Sun, W.; Na, H.; He, J.; Qiu, Z.; Yuan, Y.; Li, Y. An evaluation of greenhouse gas emission efficiency in China′s industry based on SFA. Sci. Total Environ. 2019, 690, 1190–1202. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Xu, Y. Evaluation of China’s pilot low-carbon city program: A perspective of industrial carbon emission efficiency. Atmos. Pollut. Res. 2022, 13, 101446. [Google Scholar] [CrossRef]

- Tang, L.; Xue, X.; Jia, M.; Jing, H.; Wang, T.; Zhen, R.; Huang, M.; Tian, J.; Guo, J.; Li, L.; et al. Iron and steel industry emissions and contribution to the air quality in China. Atmospheric Environ. 2020, 237, 117668. [Google Scholar] [CrossRef]

- Ju, Y.; Fujikawa, K. Revealing the impact of a projected emission trading scheme on the production technology upgrading in the cement industry in China: An LCA-RCOT model. Resour. Conserv. Recycl. X 2019, 4, 100019. [Google Scholar] [CrossRef]

- Lin, B.; Wang, M. Dynamic analysis of carbon dioxide emissions in China′s petroleum refining and coking industry. Sci. Total Environ. 2019, 671, 937–947. [Google Scholar] [CrossRef]

- Zhang, Z.; Schoengold, K. Carbon emissions control policies in China’s power generation sector. China Agric. Econ. Rev. 2011, 3. [Google Scholar] [CrossRef]

- Li, A.; Hu, M.; Sun, C.; Li, Z. Optimal CO2 abatement pathway with induced technological progress for chinese coal-fired power industry. Energy Sustain. Dev. 2017, 36, 55–63. [Google Scholar] [CrossRef]

- Garver, G.; Podhora, A. Transboundary environmental impact assessment as part of the North American Agreement on Environmental Cooperation. Impact Assess. Proj. Apprais. 2008, 26, 253–263. [Google Scholar] [CrossRef]

- Grossman, G.M.; Krueger, A.B. Environmental Impacts of a North American Free Trade Agreement. CEPR Discuss. Pap. 1992, 8, 223–250. [Google Scholar]

- Lu, Y.; Li, M. Industrial Carbon Emission Efficiency in the Yangtze River Economic Belt and Its Influencing Factors. Int. J. Des. Nat. Ecodynamics 2020, 15, 25–32. [Google Scholar] [CrossRef]

- Dong, Y.; Jin, G.; Deng, X. Dynamic interactive effects of urban land-use efficiency, industrial transformation, and carbon emissions. J. Clean. Prod. 2020, 270, 122547. [Google Scholar] [CrossRef]

- You, J.; Zhang, W. How heterogeneous technological progress promotes industrial structure upgrading and industrial carbon efficiency? Evidence from China’s industries. Energy 2022, 247, 123386. [Google Scholar] [CrossRef]

- Feng, R.; Lin, P.; Hou, C.; Jia, S. Study of the Effect of China’s Emissions Trading Scheme on Promoting Regional Industrial Carbon Emission Reduction. Front. Environ. Sci. 2022, 10, 947925. [Google Scholar] [CrossRef]

- Kaya, Y. Impact of Carbon Dioxide Emission Control on GNP Growth: Interpretation of Proposed Scenarios IPCC Energy and Industry Subgroup, Response Strategies Working Group. 1990. Available online: https://cir.nii.ac.jp/crid/1570291225678384256#citations_container (accessed on 15 December 2022).

- Yang, G.; Zhang, F.; Zhang, F.; Ma, D.; Gao, L.; Chen, Y.; Luo, Y.; Yang, Q. Spatiotemporal changes in efficiency and influencing factors of China’s industrial carbon emissions. Environ. Sci. Pollut. Res. 2021, 28, 36288–36302. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, Z.; Wang, C. Random forest analysis of factors affecting urban carbon emissions in cities within the Yangtze River Economic Belt. PLoS ONE 2021, 16, e0252337. [Google Scholar]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Tone, K.; Tsutsui, M. An epsilon-based measure of efficiency in DEA—A third pole of technical efficiency. Eur. J. Oper. Res. 2010, 207, 1554–1563. [Google Scholar] [CrossRef]

- Zhou, Z.; Cao, L.; Zhao, K.; Li, D.; Ding, C. Spatio-Temporal Effects of Multi-Dimensional Urbanization on Carbon Emission Efficiency: Analysis Based on Panel Data of 283 Cities in China. Int. J. Environ. Res. Public Health 2021, 18, 12712. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Y.; Gao, Y.; Wang, J. Carbon Emission Trading Policy and Carbon Emission Efficiency: An Empirical Analysis of China’s Prefecture-Level Cities. Front. Energy Res. 2021, 844. [Google Scholar] [CrossRef]

- Tao, F.; Li, L.; Xia, X.H. Industry Efficiency and Total Factor Productivity Growth under Resources and Environmental Constraint in China. Sci. World J. 2012, 2012, 310407. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Wei, Y.D.; Yang, Z. The impact of environmental regulations on the location of pollution-intensive industries in China. J. Clean. Prod. 2017, 148, 785–794. [Google Scholar] [CrossRef]

- Cai, H.; Liu, Q. Competition and Corporate Tax Avoidance: Evidence from Chinese Industrial Firms. Econ. J. 2009, 119, 764–795. [Google Scholar] [CrossRef]

- Wang, J.; Sun, K.; Ni, J.; Xie, D. Evaluation and Factor Analysis of Industrial Carbon Emission Efficiency Based on “Green-Technology Efficiency”—The Case of Yangtze River Basin, China. Land 2021, 10, 1408. [Google Scholar] [CrossRef]

- Gao, P.; Yue, S.; Chen, H. Carbon Emission Efficiency of China’s Industry Sectors: From the Perspective of Embodied Carbon Emissions. J. Clean. Prod. 2020, 283, 124655. [Google Scholar] [CrossRef]

- Li, Y.; Chiu, Y.-H.; Lin, T.-Y. Energy and Environmental Efficiency in Different Chinese Regions. Sustainability 2019, 11, 1216. [Google Scholar] [CrossRef]

- Cai, Y.; Hu, Z. Industrial agglomeration and industrial SO2 emissions in China’s 285 cities: Evidence from multiple agglomeration types. J. Clean. Prod. 2022, 353, 131675. [Google Scholar] [CrossRef]

- Xu, X.; Yang, G.; Tan, Y.; Zhuang, Q.; Tang, X.; Zhao, K.; Wang, S. Factors influencing industrial carbon emissions and strategies for carbon mitigation in the Yangtze River Delta of China. J. Clean. Prod. 2017, 142, 3607–3616. [Google Scholar] [CrossRef]

| Variable Name | Calculation | Unit | Symbol |

|---|---|---|---|

| Economic development level | GDP per capita | Rmb/person | UGP |

| Industrialization level | Secondary industry value added as a proportion of GDP | % | UIC |

| Environmental regulation | Weighted value of industrial SO2, soot, and dust treatment rate in city | % | ER |

| Local fiscal decentralization | Proportion of total fiscal expenditure in GDP | % | DLF |

| Industrial enterprise scale | Average size of industrial enterprises | 10,000/ea | ISC |

| Industrial structure | Proportion of capital- and technology-intensive industrial output value in total industrial output value | % | ST |

| Industrial Technical advancement | Proportion of industrial patent applications in city’s patent applications | % | ITP |

| Industrial opening level | Proportion of foreign-invested industrial output value in total industrial output value | % | OI |

| Industrial agglomeration | Industrial agglomeration using the city’s industrial location quotient | / | IA |

| Industrial diversification | Herfindahl coefficient | / | DIC |

| Industrial Ownership | Share of output of state-owned enterprises in total industrial output | % | IO |

| National | Eastern Region | Central Region | Western Region | Northeast Region | |

|---|---|---|---|---|---|

| UGP | 0.0999 *** (18.44) | 0.129 *** (12.69) | 0.131 *** (15.30) | 0.131 *** (15.30) | 0.0893 *** (6.67) |

| UIC | −0.443 *** (−14.14) | −0.632 *** (−9.35) | −0.590 *** (−12.65) | −0.590 *** (−12.65) | −0.378 *** (−5.93) |

| ER | −0.0293 (−1.81) | 0.156 *** (4.94) | −0.139 *** (−6.44) | −0.139 *** (−6.44) | −0.0454 (−1.12) |

| DLF | 0.201 *** (6.89) | 0.550 *** (5.18) | 0.608 *** (9.55) | 0.608 *** (9.55) | 0.162 * (1.99) |

| ISC | 0.0277 *** (5.58) | 0.0168 (1.74) | −0.0327 *** (−3.59) | −0.0327 *** (−3.59) | 0.0216 (1.93) |

| ST | −0.00302 (−1.22) | 0.00352 (0.67) | 0.0267 *** (6.69) | 0.0267 *** (6.69) | 0.00898 * (2.12) |

| ITP | 0.0307 * (2.01) | −0.129 *** (−4.38) | 0.0470 * (2.45) | 0.0470 * (2.45) | −0.160 ** (−3.23) |

| OI | −0.0386 (−1.41) | −0.178 *** (−4.40) | −0.273 *** (−5.75) | −0.273 *** (−5.75) | −0.00653 (−0.12) |

| IA | 0.186 *** (19.29) | 0.106 *** (6.14) | 0.230 *** (16.29) | 0.230 *** (16.29) | 0.232 *** (11.29) |

| DIC | 0.00462 *** (6.19) | −0.00113 (−0.87) | 0.00520 *** (5.88 | 0.00520 *** (5.88) | 0.00351 * (2.28) |

| IO | −0.247 *** (−19.93) | −0.370 *** (−11.96) | −0.171 *** (−9.18) | −0.171 *** (−9.18) | −0.123 *** (−4.65) |

| cons | −0.707 *** (−18.82) | −0.851 *** (−10.51) | −0.945 *** (−17.53) | −0.945 *** (−17.53) | −0.885 *** (−11.89) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, W.; Lin, X.; Wang, D.; Mi, Y. Urban Industrial Carbon Efficiency Measurement and Influencing Factors Analysis in China. Land 2023, 12, 26. https://doi.org/10.3390/land12010026

Cui W, Lin X, Wang D, Mi Y. Urban Industrial Carbon Efficiency Measurement and Influencing Factors Analysis in China. Land. 2023; 12(1):26. https://doi.org/10.3390/land12010026

Chicago/Turabian StyleCui, Weijia, Xueqin Lin, Dai Wang, and Ying Mi. 2023. "Urban Industrial Carbon Efficiency Measurement and Influencing Factors Analysis in China" Land 12, no. 1: 26. https://doi.org/10.3390/land12010026

APA StyleCui, W., Lin, X., Wang, D., & Mi, Y. (2023). Urban Industrial Carbon Efficiency Measurement and Influencing Factors Analysis in China. Land, 12(1), 26. https://doi.org/10.3390/land12010026