A Study of Energy Optimisation of Urban Water Distribution Systems Using Potential Elements

Abstract

:1. Introduction

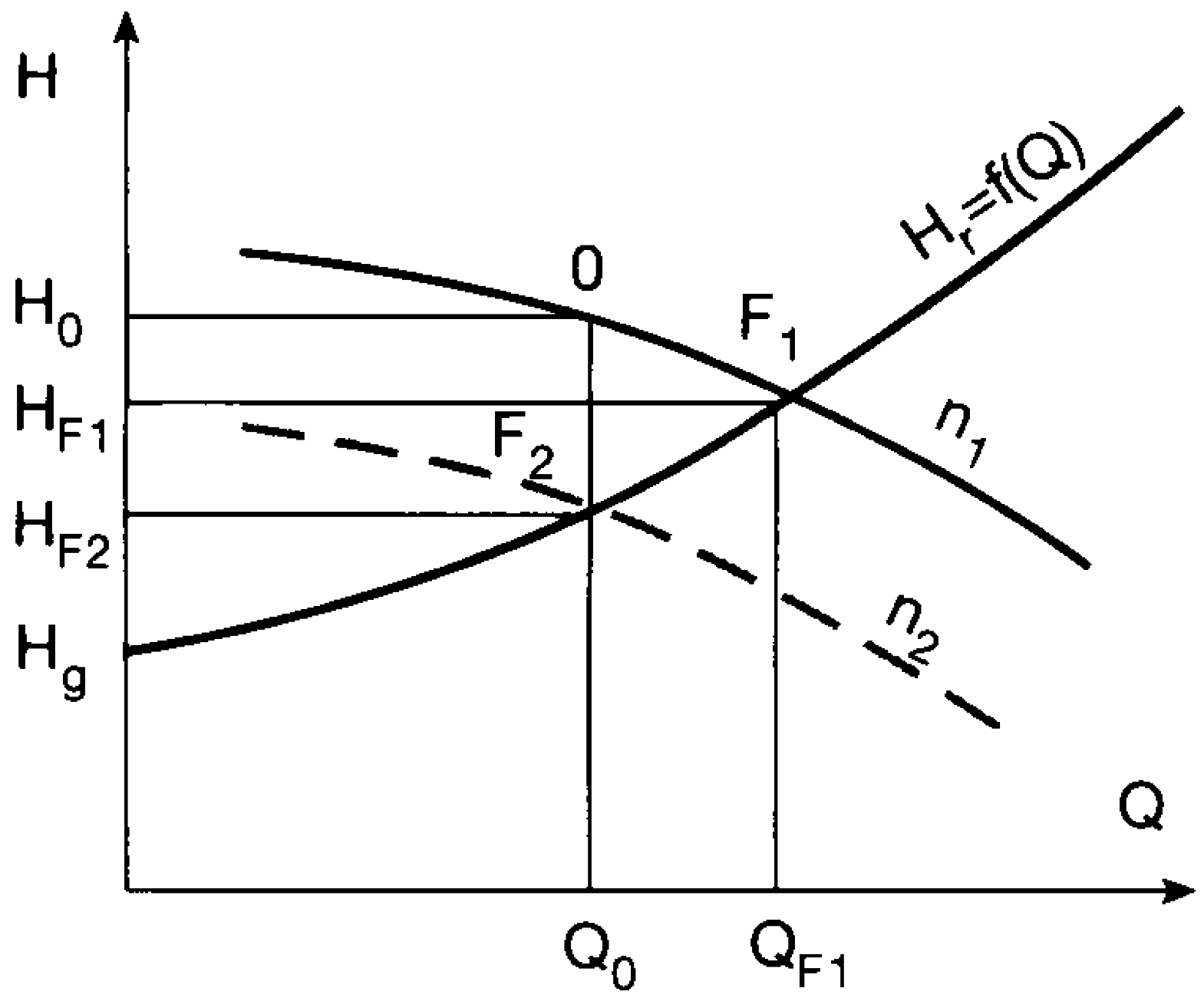

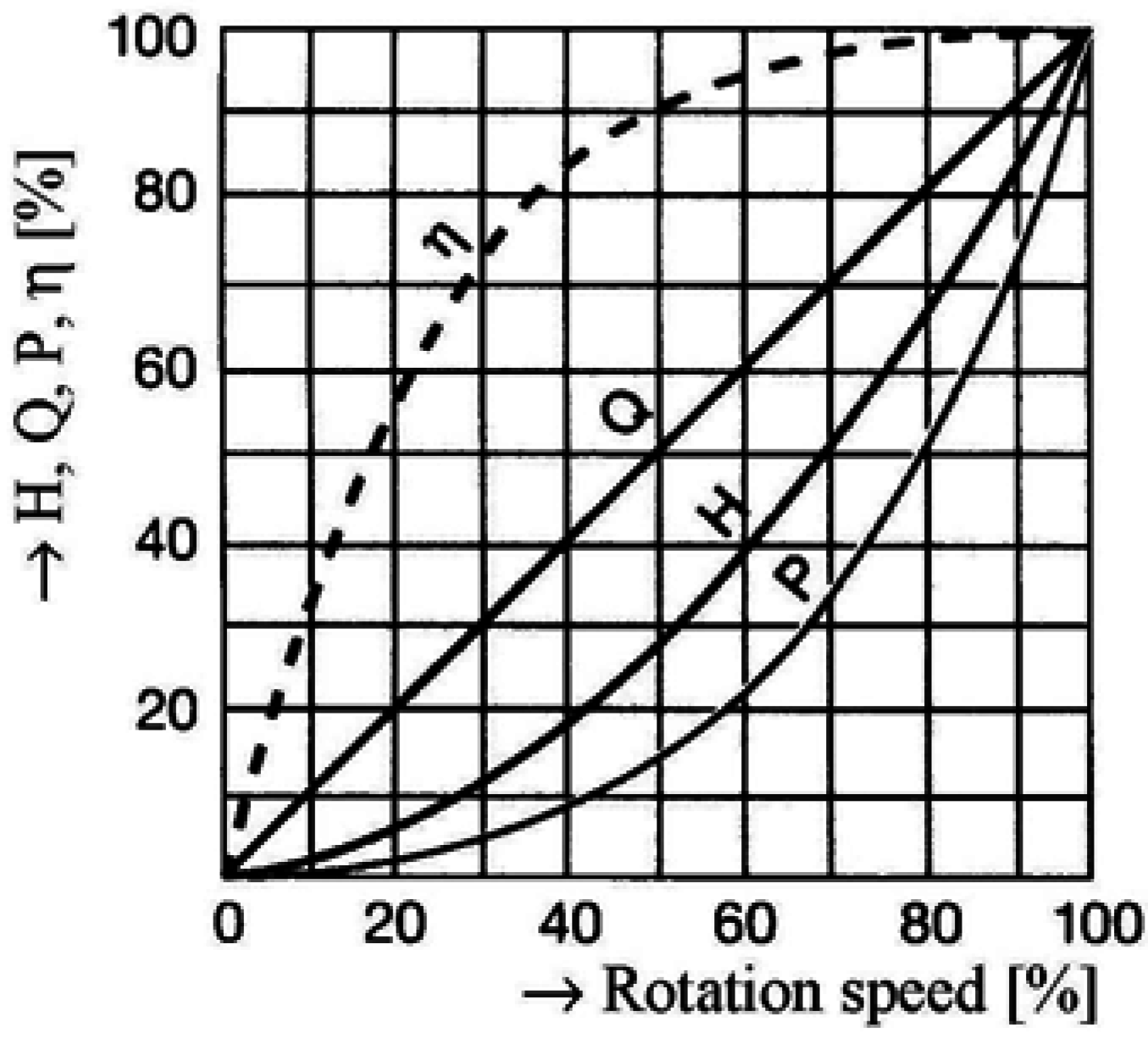

2. Improving Energy Efficiency of Water Pumping

2.1. A Brief Review of Previous Works

- Bypassing part of the water flow rate.

- Introducing a supplementary pressure loss using a control valve [28] that can lead to higher energy efficiency of the water supply system when the nominal pump head is lower than the optimal value. Additionally, valves can be a source of emissions and suffer from corrosion, erosion, plugging, cavitation, and leakage.

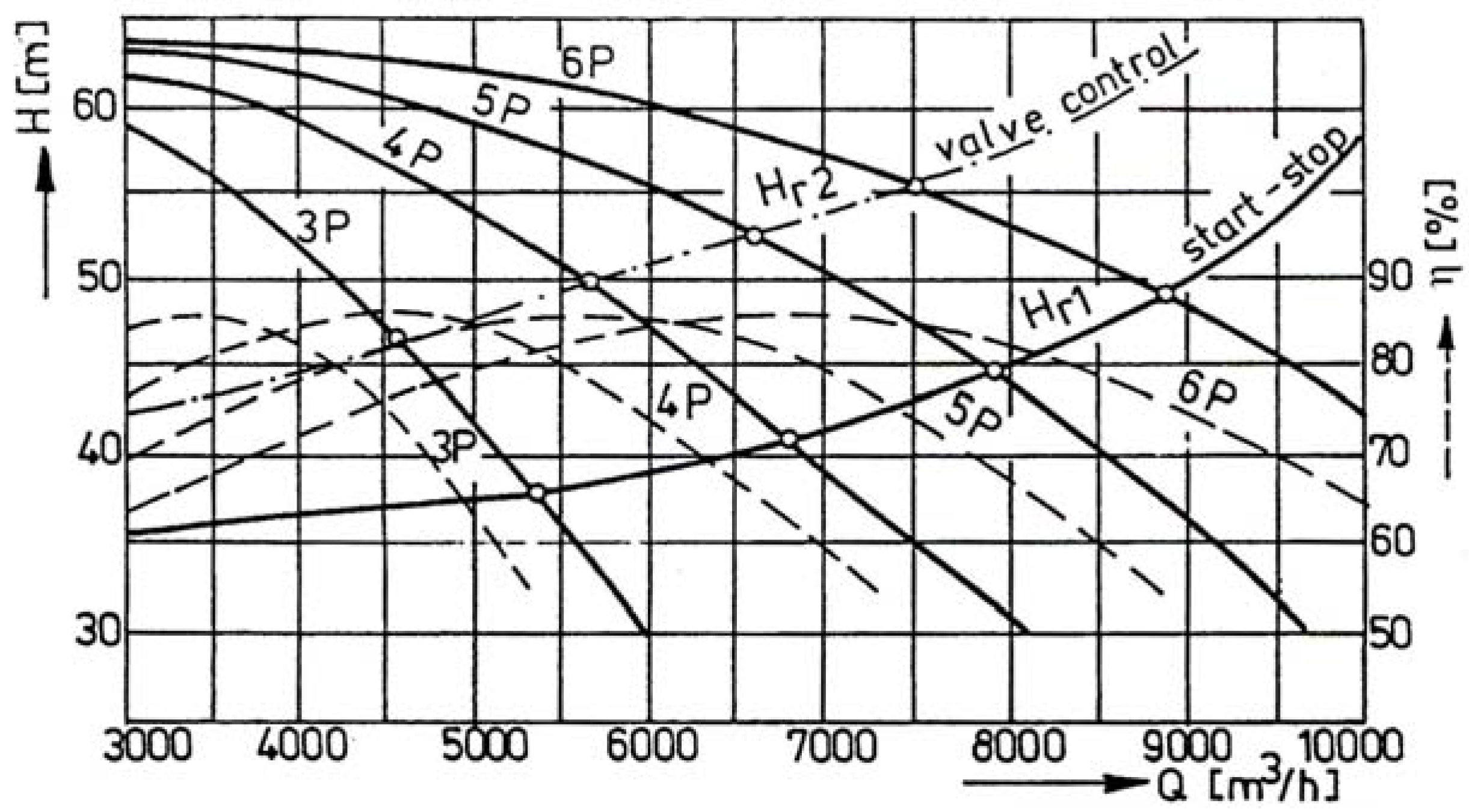

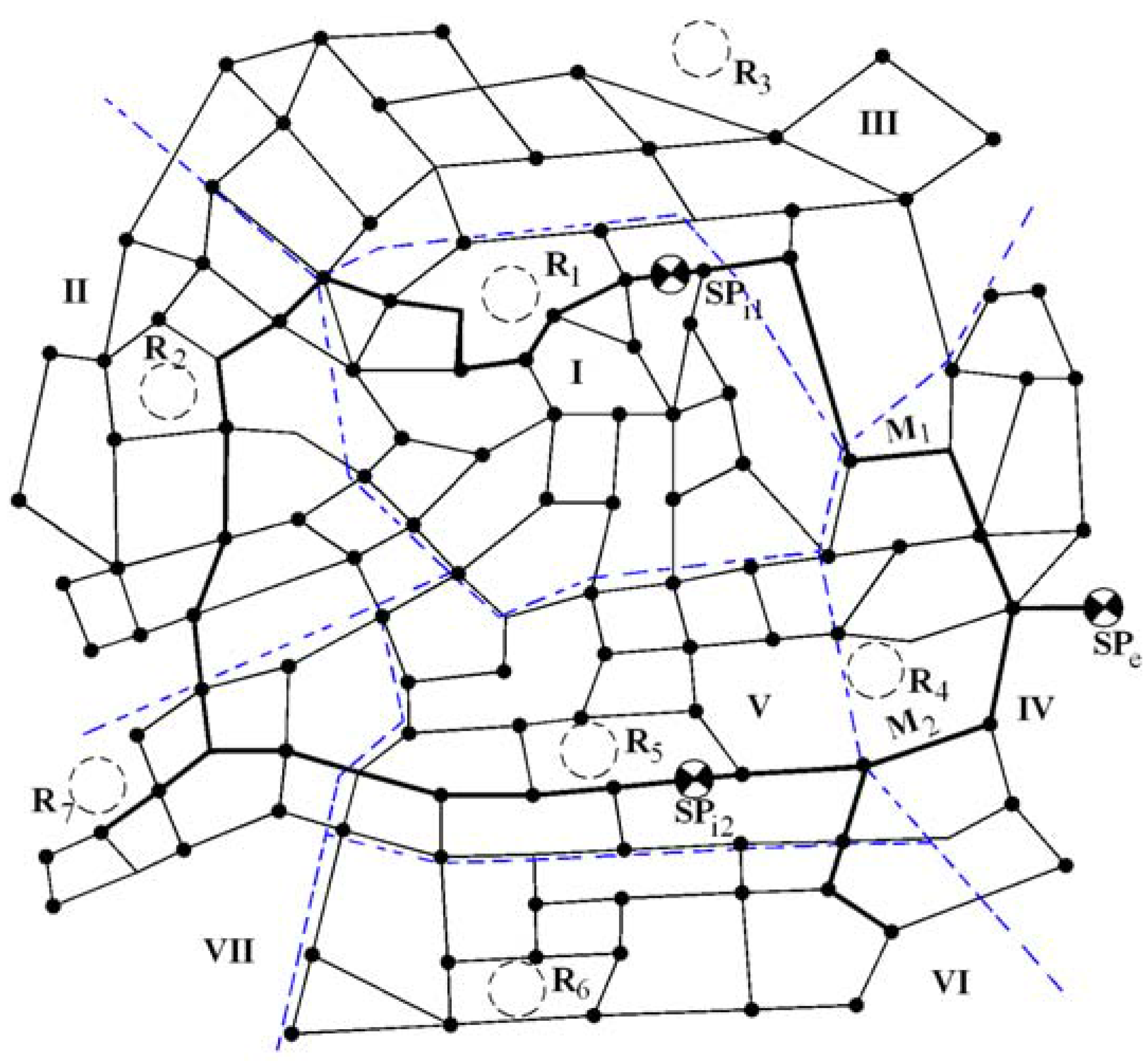

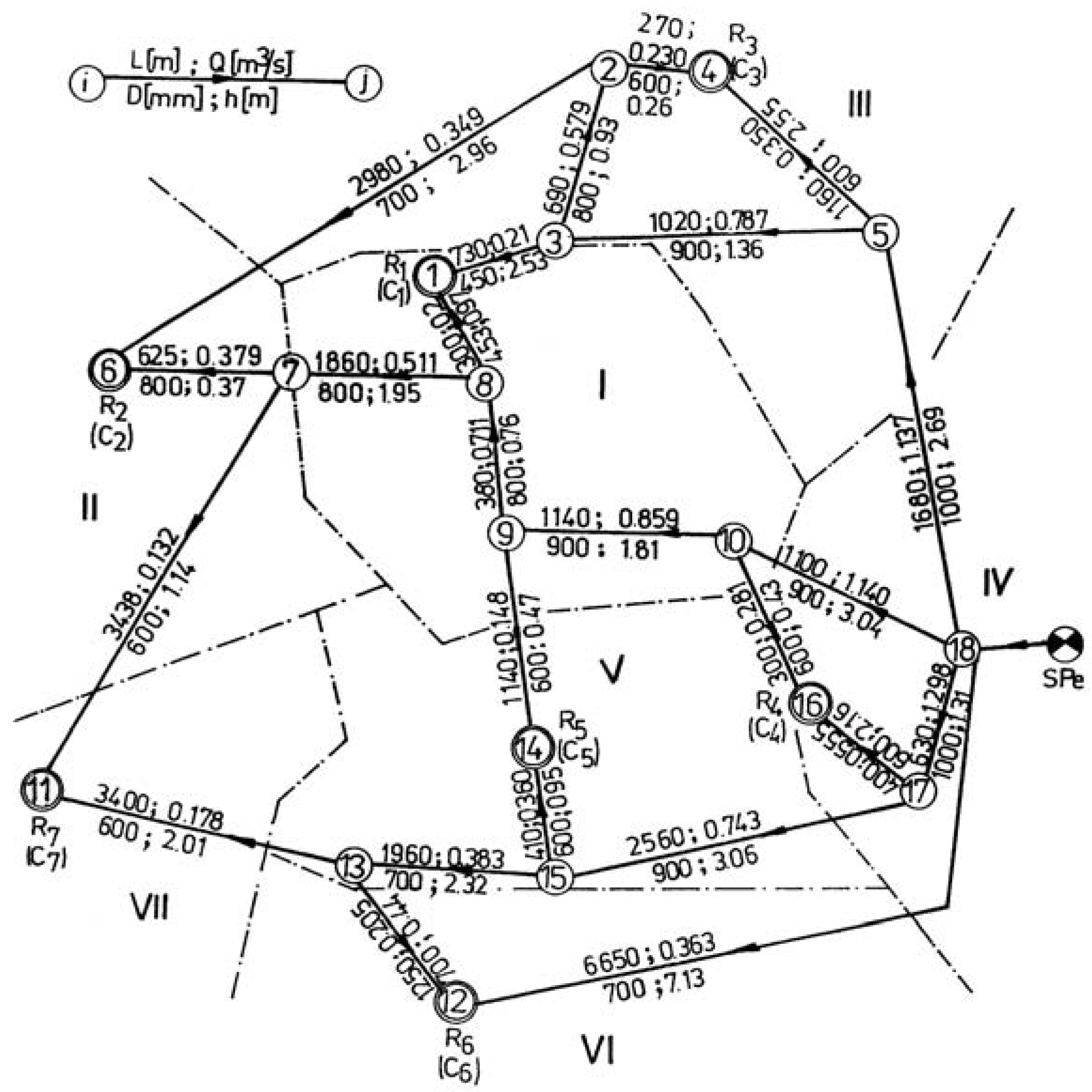

2.2. Case Study

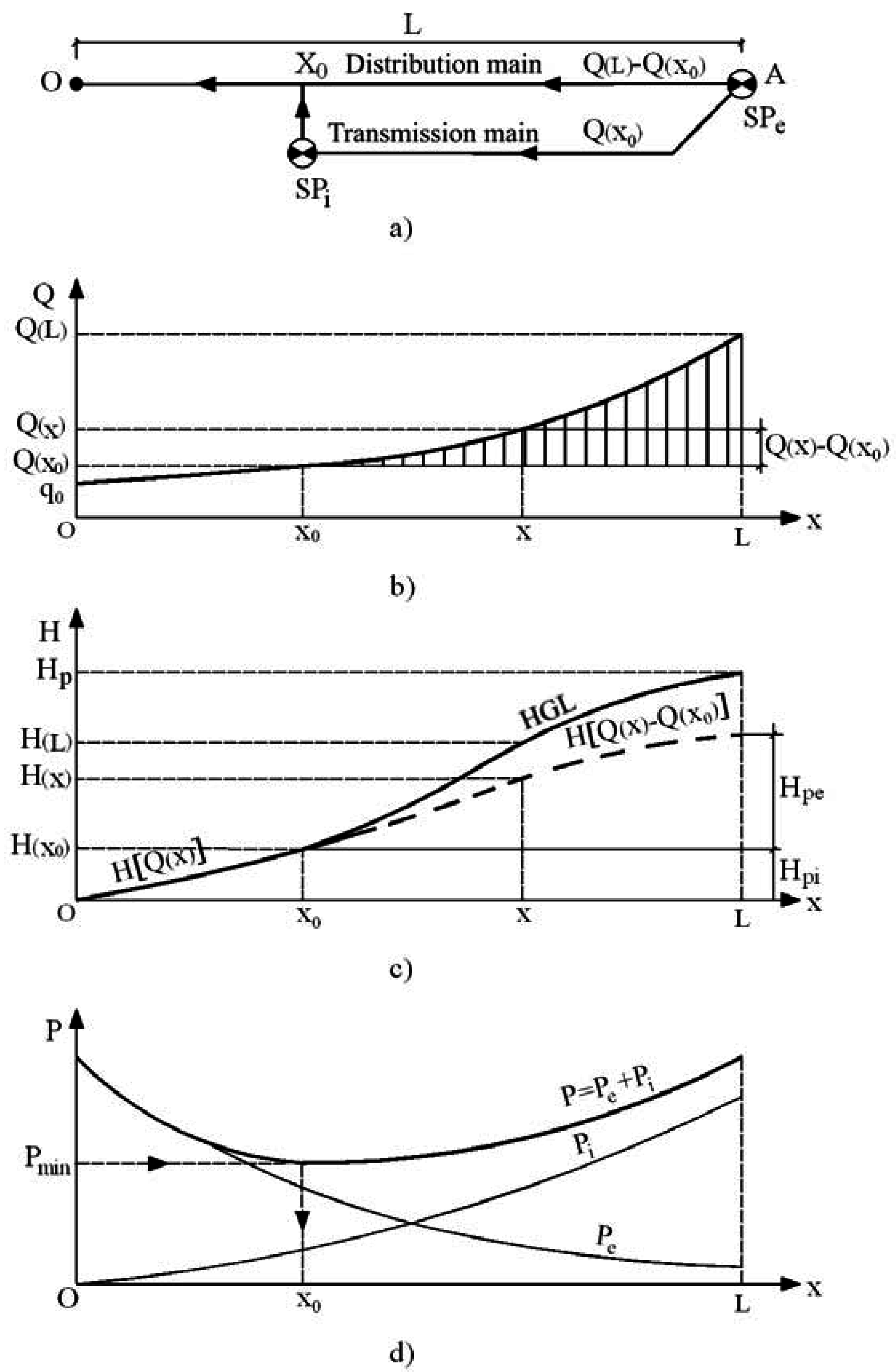

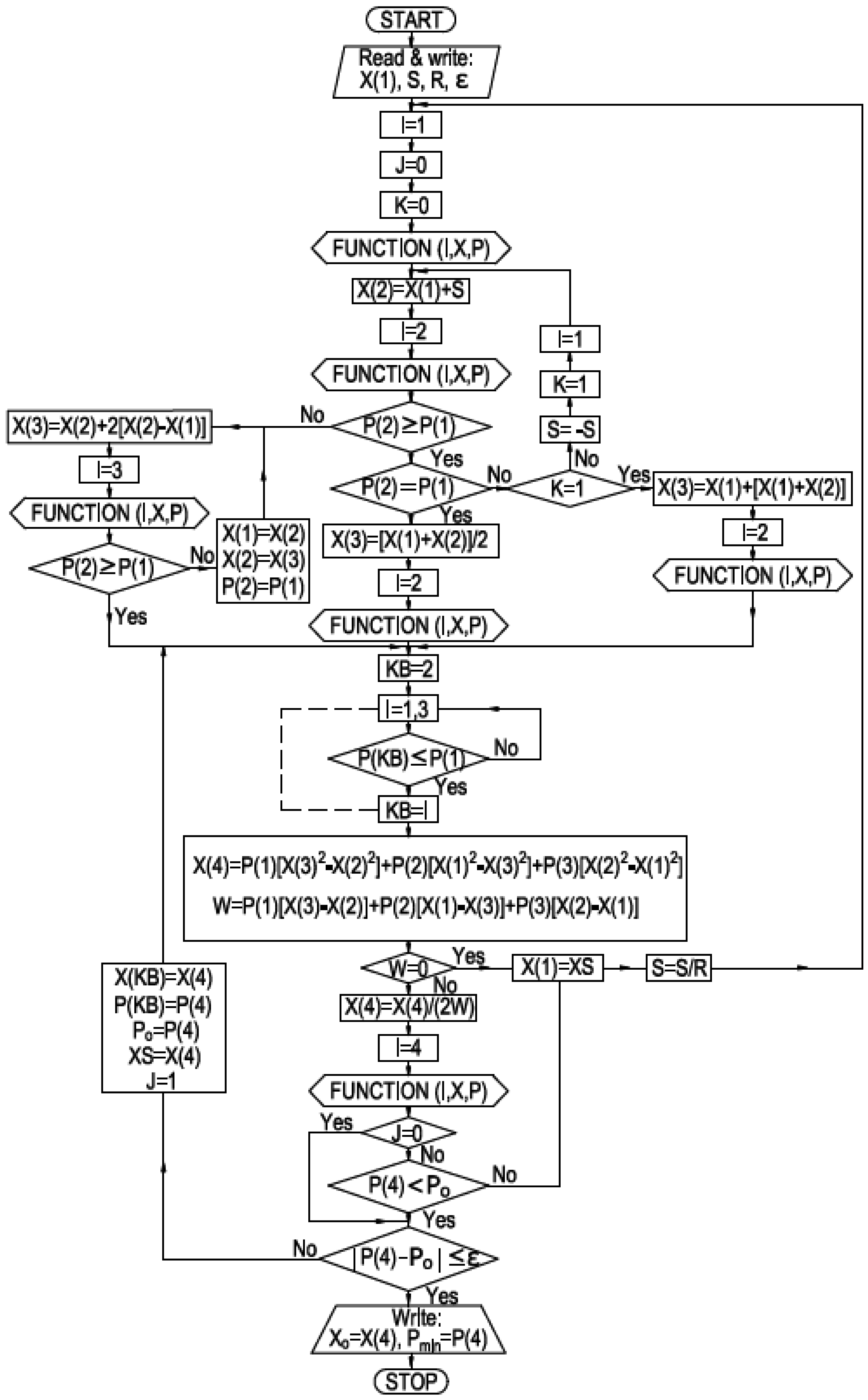

3. Energy Optimisation Methodology

3.1. Pumped Storage Tanks

3.2. Intermediary Pumping Stations Integrated on the Distribution Mains

3.3. Elevated Tanks

3.4. Economic Indicators

4. Case Studies

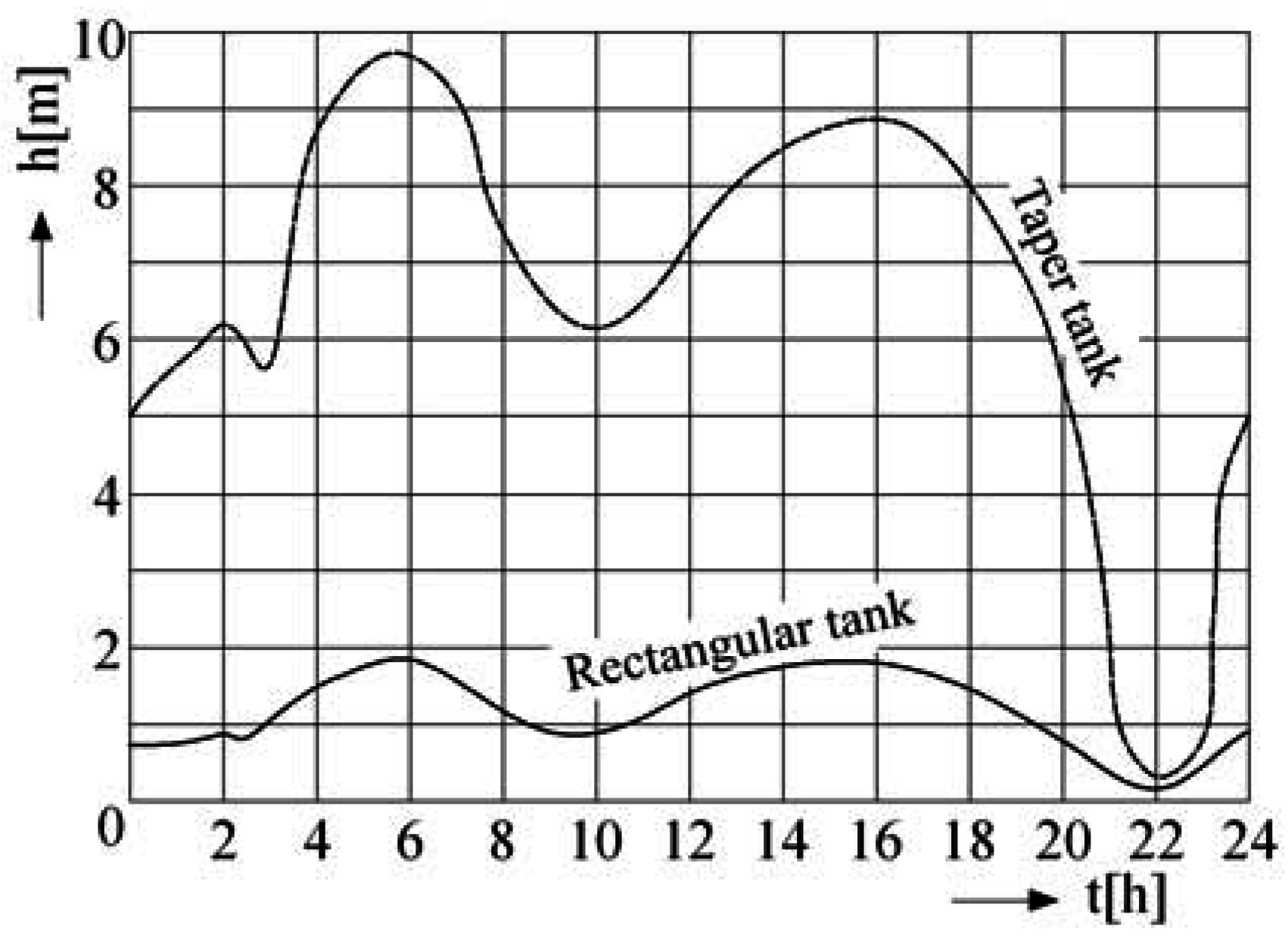

4.1. Potential Characteristics Influence of the Elevated Tanks on Distribution Energy Balance

4.2. Energy–Economic Efficiency of Optimisation Solutions

5. Results and Discussion

6. Conclusions

Conflicts of Interest

Appendix A

References

- Watergy. 2009. Available online: http://www.watergy.net/-overview/why.php (accessed on 5 June 2015).

- Moreira, D.F.; Ramos, H.M. Energy cost optimization in a water supply system case study. J. Energy 2013. [Google Scholar] [CrossRef]

- Coelho, B.; Andrade-Campos, A. Efficiency achievement in water supply systems–A review. Renew. Sustain. Energy Rev. 2014, 30, 59–84. [Google Scholar] [CrossRef]

- Bene, J.G.; Selek, I.; Hös, C. Neutral search technique for short-term pump schedule optimization. J. Water Resour. Plan. Manag. 2010, 136, 133–137. [Google Scholar] [CrossRef]

- Vilanova, M.R.N.; Balestieri, J.A.P. Energy and hydraulic efficiency in conventional water supply systems. Renew. Sustain. Energy Rev. 2014, 30, 701–7014. [Google Scholar] [CrossRef]

- Walski, T.M.; Chase, D.V.; Savic, D.A.; Grayman, W.; Beckwith, S.; Koelle, E. Advanced Water Distribution Modeling and Management; Haestad Press: Waterbury, CT, USA, 2003. [Google Scholar]

- Binder, A. Potentials for energy saving with modern drive technology: A survey. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Ischia, Italy, 11–13 June 2008.

- Pemberton, M.; Bachmann, J. Pump systems performance impacts multiple bottom lines. Eng. Min. J. 2010, 211, 56–59. [Google Scholar]

- Ferreira, F.J.T.E.; Fong, C.; de Almeida, T. Eco-analysis of variable-speed drives for flow regulation in pumping system. IEEE Trans. Ind. Electron. 2011, 58, 2117–2125. [Google Scholar] [CrossRef]

- Zhang, H.; Xia, X.; Zhang, J. Optimal sizing and operation of pumping systems to achieve energy efficiency and load shifting. Electr. Power Syst. Res. 2012, 86, 41–50. [Google Scholar] [CrossRef]

- McCormick, G.; Powell, R.S. Optimal pump scheduling in water supply systems with maximum demand charges. J. Water Resour. Plan. Manag. 2003, 129, 372–379. [Google Scholar] [CrossRef]

- Van Zyl, J.E.; Savic, D.A.; Walters, G.A. Operational optimization of water distribution systems using a hybrid genetic algorithm. J. Water Resour. Plan. Manag. 2004, 130, 160–170. [Google Scholar] [CrossRef]

- Salomons, E.; Goryashko, A.; Shamir, U.; Rao, Z.; Alvisi, S. Optimizing the operation of the Haifa: A water distribution network. J. Hydroinf. 2007, 9, 51–64. [Google Scholar] [CrossRef]

- Lopez-Ibáñez, M.; Prasad, T.D.; Paechter, B. Ant colony optimization for optimal control of pumps in water distribution networks. J. Water Resour. Plan. Manag. 2008, 134, 337–346. [Google Scholar] [CrossRef]

- Broad, D.R.; Maier, H.R.; Dandy, G.C. Optimal operation of complex water distribution systems using metamodels. J. Water Resour. Plan. 2010, 136, 433–443. [Google Scholar] [CrossRef]

- Vogelesang, H. Two approaches to capacity control. World Pumps 2009, 511, 26–29. [Google Scholar] [CrossRef]

- Pemberton, M. Intelligent variable speed pumping. Plant Eng. 2003, 57, 28–30. [Google Scholar]

- Bortoni, E.; Almeida, R.A.; Viana, A.N.C. Optimization of parallel variable-speed-driven centrifugal pumps operation. Energy Effic. 2008, 1, 167–173. [Google Scholar] [CrossRef]

- Yang, Z.; Borsting, H. Energy efficient control of a boosting system with multiple variable-speed pumps in parallel. In Proceedings of the 49th IEEE Conference on Decision and Control, Atlanta, GA, USA, 15–17 December 2010.

- Viholainen, J.; Tamminen, J.; Abhonen, T.; Ahola, J.; Vakkilainen, E.; Soukka, R. Energy-efficient control strategy for variable speed-driven parallel pumping systems. Energy Effic. 2013, 6, 495–509. [Google Scholar] [CrossRef]

- Araujo, L.S.; Ramos, H.; Coelho, S.T. Pressure control for leakage minimisation in water distribution systems management. Water Resour. Manag. 2006, 20, 133–149. [Google Scholar] [CrossRef]

- Carravetta, A.; Del Giudice, G.; Fecarotta, O.; Ramos, H.M. Energy production in water distribution networks: A PAT design strategy. Water Resour. Manag. 2012, 26, 3947–3959. [Google Scholar] [CrossRef]

- Diniz, A.M.F.; Fontes, C.H.; da Costa, C.A.; Costa, G.M.N. Dynamic modeling and simulation of water supply system with applications for improving energy efficiency. Energy. Effic. 2014, 8, 417–432. [Google Scholar] [CrossRef]

- Nazif, S.; Karanouz, M.; Moridi, A. Pressure management model for urban water distribution networks. Water Resour. Manag. 2010, 24, 437–458. [Google Scholar] [CrossRef]

- Lenzi, C.; Bragalli, C.; Bolognesi, A.; Artina, S. From energy balance to energy efficiency indicators including water losses. Water Sci. Technol. Water Supply 2013, 13, 889–895. [Google Scholar] [CrossRef]

- Sarbu, I.; Ostafe, G. Energetically optimization of water distribution systems in large urban centers. Period. Polytech. Mech. Eng. 2008, 52, 93–102. [Google Scholar] [CrossRef]

- Feldman, M. Aspects of energy efficiency in water supply systems. In Proceedings of the 5th IWA Water Loss Reduction Specialist Conference, Cape Town, South Africa, 26–30 April 2009.

- Rishel, J.B. Water Pumps and Pumping Systems; McGraw-Hill: New York, NY, USA, 2002. [Google Scholar]

- Marchi, A.; Simpson, A.R.; Ertugrul, N. Assessing variable speed pump efficiency in water distribution systems. Drink. Water Eng. Sci. 2012, 5, 15–21. [Google Scholar] [CrossRef]

- Sarbu, I.; Borza, I. Energetic optimization of water pumping in distribution systems. Period. Polytech. Mech. Eng. 1998, 42, 141–152. [Google Scholar]

- Hooper, W. Advantages of parallel pumping. Plant Eng. 1999, 31, 4–6. [Google Scholar]

- Volk, M. Pump Characteristics and Applications; Taylor & Francis Group: Boca Raton, FL, USA, 2005. [Google Scholar]

- Kaya, D.; Yagmur, E.A.; Yigit, K.S.; Kilic, F.C.; Eren, A.S.; Celik, C. Energy efficiency in pumps. Energy Convers. Manag. 2008, 49, 1662–1673. [Google Scholar] [CrossRef]

- Gibson, I.H. Variable-speed dives as flow control elements. ISA Trans. 1994, 33, 165–169. [Google Scholar] [CrossRef]

- Sarbu, I. Nodal analysis of urban water distribution networks. Water Resour. Manag. 2014, 28, 3143–3159. [Google Scholar] [CrossRef]

- Sarbu, I. Analysis of looped water supply networks. La Houille Blanche 2001, 3–4, 138–142. [Google Scholar]

- Démidovitch, B.; Maron, I. Elements de Calcul Numerique; Mir: Moscou, Russia, 1979. [Google Scholar]

- Sarbu, I. Energy Optimization of Water Distribution Systems; Romanian Academy Publishing House: Bucharest, Romania, 1997. [Google Scholar]

- Polak, E. Computational Methods in Optimization; Academic Press: New York, NY, USA, 1971. [Google Scholar]

- Walski, T.M. Hydraulic design of water distribution storage tanks. In Water Distribution System Handbook; McGraw Hill: New York, NY, USA, 2000. [Google Scholar]

- Sarbu, I.; Kalmar, F. Optimization of looped water supply networks. Period. Polytech. Mech. Eng. 2002, 46, 75–90. [Google Scholar]

| Adjustment Method | Period (h) | Number of Operating Pumps | Pumped Flow Q (m3/s) | Pump Head Hp (m) | Absorbed Power P (kW) | Consumed Energy W (kWh/Day) | Specific Energy Consumption w (%) |

|---|---|---|---|---|---|---|---|

| 1. Classical (start–stop) | 0:00–4:00 | 3 pf | 1.47 | 38.6 | 696.3 | 31,705.6 | 100 |

| 4:00–10:00 | 6 pf | 2.48 | 49.8 | 1730.8 | |||

| 10:00–14:00 | 4 pf | 1.91 | 42.5 | 995.4 | |||

| 14:00–17:00 | 5 pf | 2.18 | 45.7 | 1303.1 | |||

| 17:00–22:00 | 6 pf | 2.48 | 49.8 | 1730.8 | |||

| 22:00–24:00 | 4 pf | 1.91 | 42.5 | 995.4 | |||

| 2. Throttle valve control | 0:00–5:00 | 3 pf | 1.47 | 38.6 | 696.3 | 27,970.5 | 88 |

| 5:00–6:00 | 6 pf | 2.25 | 53.0 | 1424.0 | |||

| 6:00–7:00 | 6 pf | 2.48 | 49.8 | 1730.8 | |||

| 7:00–8:00 | 6 pf | 2.25 | 53.0 | 1424.0 | |||

| 8:00–10:00 | 5 pf | 2.08 | 47.5 | 1138.2 | |||

| 10:00–12:00 | 4 pf | 1.91 | 42.5 | 995.4 | |||

| 12:00–13:00 | 5 pf | 1.81 | 56.0 | 1181.6 | |||

| 13:00–15:00 | 4 pf | 1.91 | 42.5 | 995.4 | |||

| 15:00–16:00 | 6 pf | 2.08 | 47.5 | 1138.2 | |||

| 16:00–20:00 | 6 pf | 2.25 | 53.0 | 1424.0 | |||

| 20:00–23:00 | 6 pf | 2.46 | 50.0 | 1544.1 | |||

| 23:00–24:00 | 4 pf | 1.81 | 43.0 | 1122.6 | |||

| 3. Rotational speed control | 0:00–5:00 | 2pf + 1pv | 1.42 | 37.6 | 655.2 | 25,375.5 | 80 |

| 5:00–6:00 | 5pf + 1pv | 2.25 | 45.5 | 1222.5 | |||

| 6:00–7:00 | 6 pf | 2.48 | 49.8 | 1730.8 | |||

| 7:00–8:00 | 5pf + 1pv | 2.25 | 45.5 | 1222.5 | |||

| 8:00–10:00 | 5 pf | 2.08 | 43.0 | 1030.3 | |||

| 10:00–12:00 | 4 pf | 1.91 | 42.5 | 995.4 | |||

| 12:00–1:00 | 3pf + 1pv | 1.81 | 40.0 | 708.9 | |||

| 13:00–15:00 | 4 pf | 1.91 | 42.5 | 995.4 | |||

| 15:00–16:00 | 5pf | 2.08 | 43.0 | 1030.3 | |||

| 16:00–20:00 | 5pf + 1pv | 2.25 | 45.5 | 1222.5 | |||

| 20:00–23:00 | 5pf + 1pv | 2.46 | 49.6 | 1534.5 | |||

| 23:00–24:00 | 3pf + 1pv | 1.81 | 40.0 | 708.9 | |||

| Energy saving, ΔW2-1 | (MWh/year) | 1345.0 | |||||

| (%) | 11.6 | ||||||

| Energy saving, ΔW3-1 | (MWh/year) | 2280.0 | |||||

| (%) | 20 | ||||||

| Energy saving, ΔW3-2 | (MWh/year) | 935.0 | |||||

| (%) | 8.4 | ||||||

| Period (h) | Demand Percentage, (%) | Pumping Percentage, (%) | Compensation Percentage, (%) | Compensatory Volume, (%) | |||

|---|---|---|---|---|---|---|---|

| αd | Σαd | αp | Σαp | αc = αp − αd | Σαc | αv | |

| 0:00–1:00 | 3.30 | 3.30 | 4.50 | 4.50 | 1.20 | 1.20 | 2.80 |

| 1:00–2:00 | 3.25 | 6.55 | 4.50 | 9.00 | 1.25 | 2.45 | 4.05 |

| 2:00–3:00 | 3.25 | 9.80 | 4.50 | 13.50 | 1.25 | 3.70 | 5.30 |

| 3:00–4:00 | 3.25 | 13.05 | 4.50 | 18.00 | 1.25 | 4.95 | 6.55 |

| 4:00–5:00 | 3.40 | 16.45 | 4.50 | 22.50 | 1.10 | 6.05 | 7.65 |

| 5:00–6:00 | 3.95 | 20.40 | 4.50 | 27.00 | 0.55 | 6.60 (max) | 8.20 (max) |

| 6:00–7:00 | 4.80 | 25.20 | 4.50 | 31.50 | −0.30 | 6.30 | 7.90 |

| 7:00–8:00 | 5.25 | 30.40 | 2.50 | 34.00 | −2.70 | 3.60 | 5.20 |

| 8:00–9:00 | 4.55 | 34.95 | 3.00 | 37.00 | −1.55 | 2.05 | 3.65 |

| 9:00–10:00 | 4.55 | 39.50 | 4.50 | 40.50 | −0.05 | 2.00 | 3.60 |

| 10:00–11:00 | 4.60 | 44.10 | 5.50 | 47.00 | 0.90 | 2.90 | 4.50 |

| 11:00–12:00 | 4.50 | 48.60 | 5.20 | 52.50 | 1.00 | 3.90 | 5.50 |

| 12:00–13:00 | 4.75 | 53.35 | 5.25 | 57.75 | 0.50 | 4.40 | 6.00 |

| 13:00–14:00 | 4.50 | 57.85 | 5.25 | 63.00 | 0.75 | 5.15 | 6.75 |

| 14:00–15:00 | 4.30 | 62.15 | 5.00 | 68.00 | 0.70 | 5.85 | 7.45 |

| 15:00–16:00 | 4.25 | 66.40 | 4.50 | 72.50 | 0.25 | 6.10 | 7.70 |

| 16:00–17:00 | 4.20 | 70.60 | 4.25 | 76.75 | 0.05 | 6.15 | 7.75 |

| 17:00–18:00 | 4.10 | 74.70 | 2.50 | 79.25 | −1.60 | 4.55 | 6.15 |

| 18:00–19:00 | 4.20 | 78.90 | 2.50 | 81.75 | −1.70 | 2.85 | 4.45 |

| 19:00–20:00 | 4.30 | 83.10 | 2.85 | 84.60 | −1.45 | 1.40 | 3.00 |

| 20:00–21:00 | 5.00 | 88.20 | 3.00 | 87.75 | −2.00 | −0.45 | 1.15 |

| 21:00–22:00 | 4.80 | 93.00 | 3.65 | 91.40 | −1.15 | −1.60 (min) | 0.00 |

| 22:00–23:00 | 3.60 | 96.60 | 4.25 | 95.50 | 0.65 | −1.10 | 0.50 |

| 23:00–24:00 | 3.40 | 100.00 | 4.50 | 100.00 | 1.10 | 0.00 | 1.60 |

| Period (h) | Pumping | Taper Tank | Rectangular Tank | |||||

|---|---|---|---|---|---|---|---|---|

| αp (%) | Qp (m3/s) | Hp (m) | P (kW) | W (kWh/Day) | Hp (m) | P (kW) | W (kWh/Day) | |

| 0:00–1:00 | 4.50 | 4.25 | 53.6 | 2980 | 67,375.0 | 43.7 | 2710 | 59,980.0 |

| 1:00–2:00 | 4.50 | 4.25 | 54.4 | 3025 | 48.8 | 2715 | ||

| 2:00–3:00 | 4.50 | 4.25 | 53.6 | 2980 | 48.7 | 2710 | ||

| 3:00–4:00 | 4.50 | 4.25 | 56.8 | 3160 | 49.0 | 2725 | ||

| 4:00–5:00 | 4.50 | 4.25 | 57.2 | 3180 | 49.5 | 2750 | ||

| 5:00–6:00 | 4.50 | 4.25 | 57.7 | 3205 | 49.8 | 2770 | ||

| 6:00–7:00 | 4.50 | 4.25 | 56.8 | 3155 | 49.8 | 2770 | ||

| 7:00–8:00 | 2.50 | 2.36 | 56.4 | 1740 | 49.3 | 1520 | ||

| 8:00–9:00 | 3.00 | 2.83 | 56.3 | 2085 | 48.9 | 1810 | ||

| 9:00–10:00 | 4.50 | 4.25 | 54.0 | 3000 | 48.8 | 2710 | ||

| 10:00–11:00 | 5.50 | 5.20 | 54.5 | 3705 | 49.0 | 3330 | ||

| 11:00–12:00 | 5.20 | 4.91 | 55.7 | 3580 | 49.2 | 3160 | ||

| 12:00–13:00 | 5.25 | 4.96 | 56.2 | 3645 | 49.3 | 3200 | ||

| 13:00–14:00 | 5.25 | 4.96 | 56.7 | 3680 | 49.4 | 3205 | ||

| 14:00–15:00 | 5.00 | 4.73 | 56.8 | 3515 | 49.5 | 3060 | ||

| 15:00–16:00 | 4.50 | 4.25 | 56.9 | 3160 | 49.9 | 2775 | ||

| 16:00–17:00 | 4.25 | 4.02 | 56.8 | 2985 | 49.7 | 2615 | ||

| 17:00–18:00 | 2.50 | 2.36 | 56.5 | 1745 | 49.6 | 1530 | ||

| 18:00–19:00 | 2.50 | 2.36 | 55.3 | 1705 | 49.3 | 1520 | ||

| 19:00–20:00 | 2.85 | 2.03 | 54.2 | 1440 | 48.9 | 1300 | ||

| 20:00–21:00 | 3.00 | 2.83 | 53.8 | 1990 | 48.4 | 1790 | ||

| 21:00–22:00 | 3.50 | 3.30 | 49.4 | 2130 | 48.1 | 2075 | ||

| 22:00–23:00 | 4.25 | 4.02 | 50.4 | 2650 | 48.1 | 2530 | ||

| 23:00–24:00 | 4.50 | 4.25 | 52.8 | 2935 | 46.8 | 2700 | ||

| Energy saving, ΔW | (MWh/year) | 2662 | ||||||

| (%) | 11 | |||||||

| No. | Indicator | Solution | |||

|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | ||

| 1 | Additional investment, 10−3ΔI [€] | ||||

| – transmissions mains | – | 1240 | 1240 | – | |

| – tanks | – | 157 | 625 | – | |

| – pump stations | – | 52 | – | 63 | |

| Total | – | 1449 | 1865 | 63 | |

| 2 | Average pump head, Hp [m] | ||||

| – external pump station | 60 | 15 | 49 | 40.5 | |

| – internal pump stations | – | 35 | – | 12 | |

| 3 | Consumed energy, W [MWh/year] | ||||

| – external pump station | 25,300 | 6600 | 21,600 | 19,600 | |

| – internal pump stations | – | 13,400 | – | 3600 | |

| Total | 25,300 | 20,000 | 21,600 | 23,200 | |

| Peak | 7300 | 2700 | 3400 | 5400 | |

| 4 | Operation cost, 10−3Cw [€/year] | ||||

| –energy cost difference, 10−3ΔCw | – | 170 | 135 | 67 | |

| –pay-off rate, 10−3rΔI | – | 29 | 38 | 1 | |

| Costs difference, 10−3(ΔCw − pΔI) | – | 141 | 97 | 66 | |

| 5 | SPBT [years] | – | 10 | 19 | 1 |

| 6 | Energy saving, ΔW | (MWh/year) | 5300 | 3700 | 2100 |

| (%) | 21 | 15 | 8 | ||

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarbu, I. A Study of Energy Optimisation of Urban Water Distribution Systems Using Potential Elements. Water 2016, 8, 593. https://doi.org/10.3390/w8120593

Sarbu I. A Study of Energy Optimisation of Urban Water Distribution Systems Using Potential Elements. Water. 2016; 8(12):593. https://doi.org/10.3390/w8120593

Chicago/Turabian StyleSarbu, Ioan. 2016. "A Study of Energy Optimisation of Urban Water Distribution Systems Using Potential Elements" Water 8, no. 12: 593. https://doi.org/10.3390/w8120593

APA StyleSarbu, I. (2016). A Study of Energy Optimisation of Urban Water Distribution Systems Using Potential Elements. Water, 8(12), 593. https://doi.org/10.3390/w8120593