Improved Oil/Water Separation by Employing Packed-Bed Filtration of Modified Quartz Particles

Abstract

1. Introduction

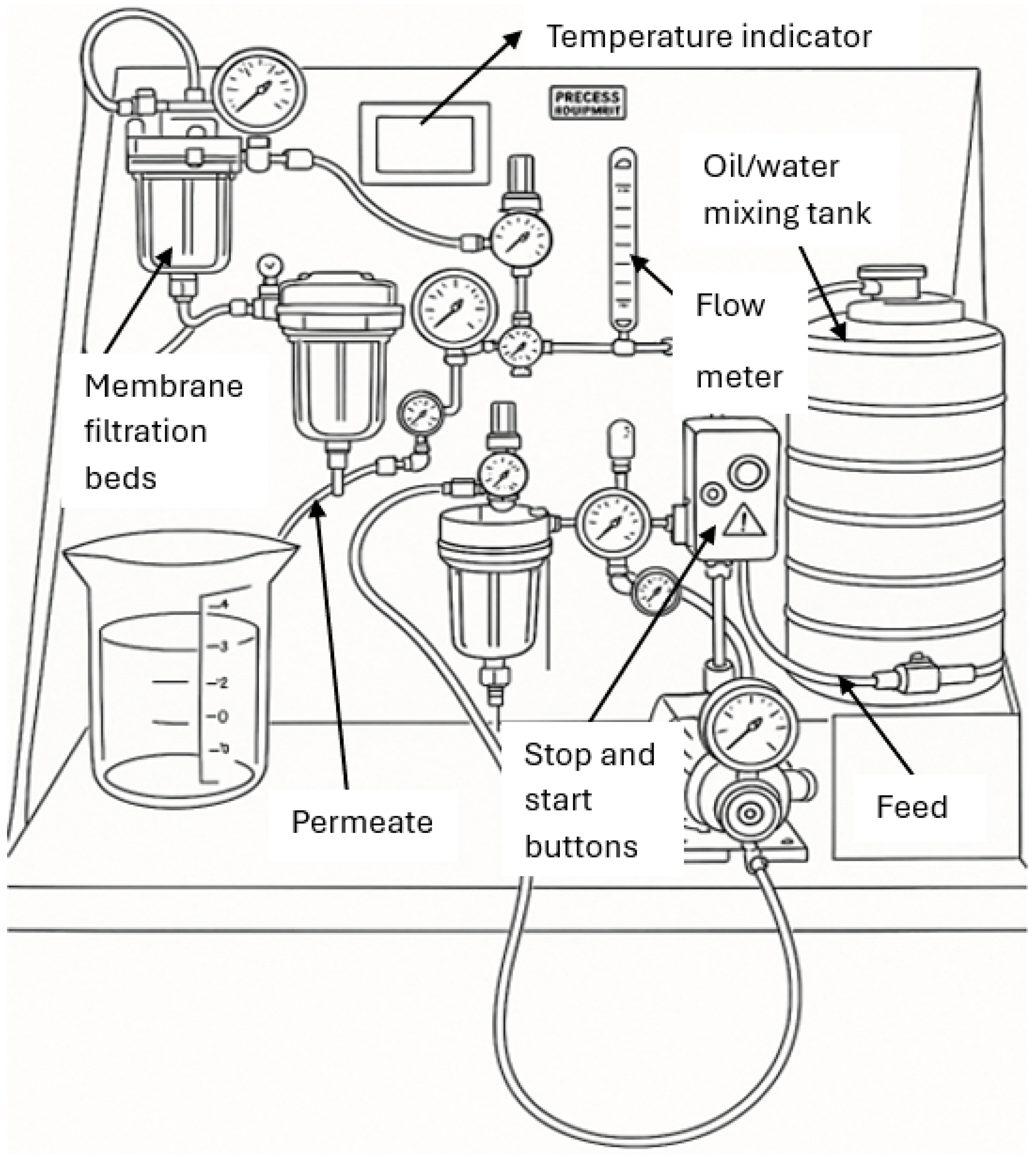

2. Materials and Methods

2.1. Key Mathematical Equations Developed for Modeling the Performance of Quartz Packed-Bed Filtration in Oil-Water Separation

- The importance of pressure control in maintaining oil rejection,

- The trade-offs between hydrophilic enhancement and pore blockage,

- The influence of feed oil concentration on required pressure and flux decline.

2.2. Comparative Analysis of Quartz Packed-Bed Filtration Performance Models Versus Conventional Technologies for Oil/Water Separation

3. Results

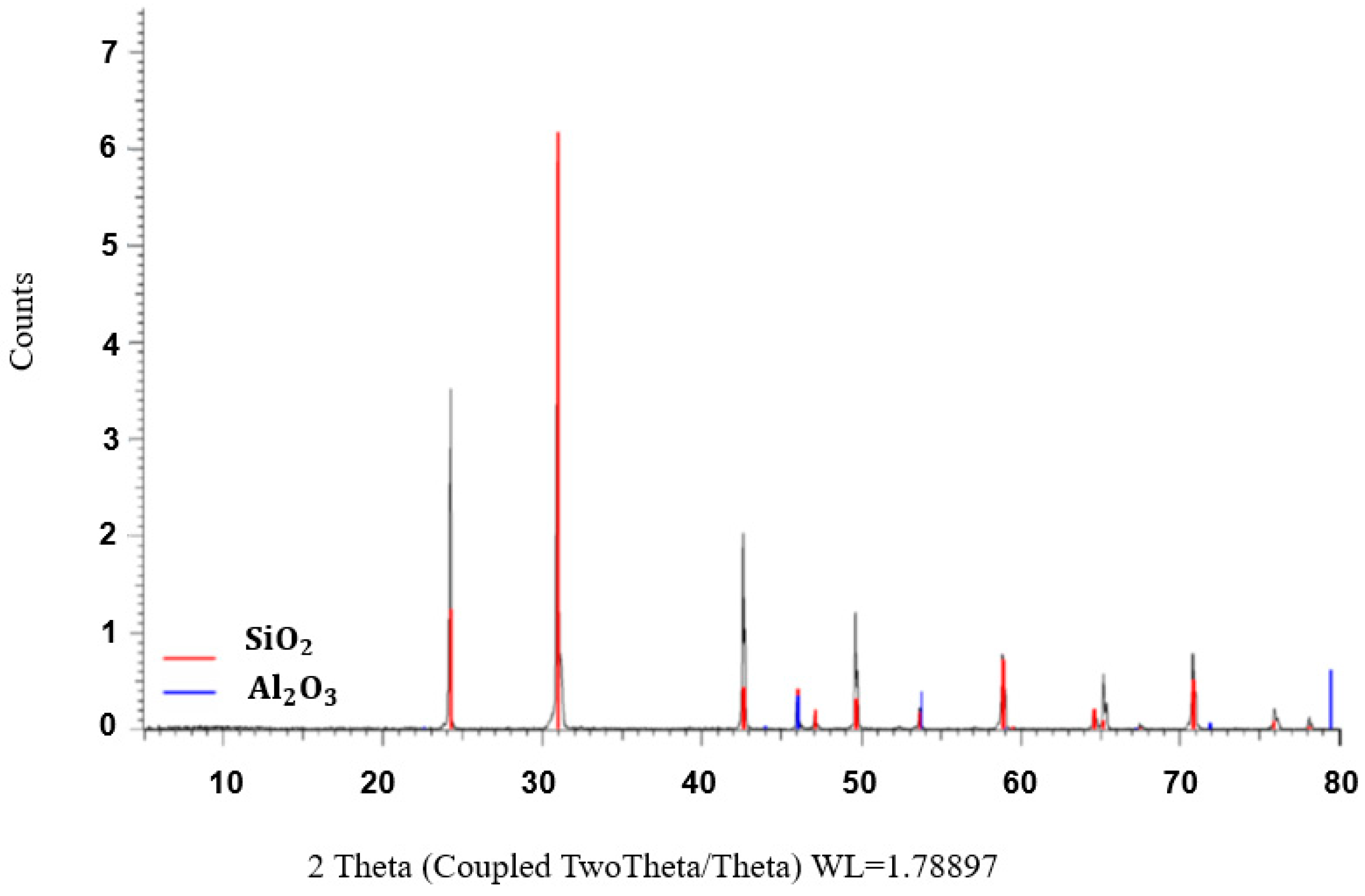

3.1. Structural and Phase Characterization of Quartz via X-ray Diffraction (XRD)

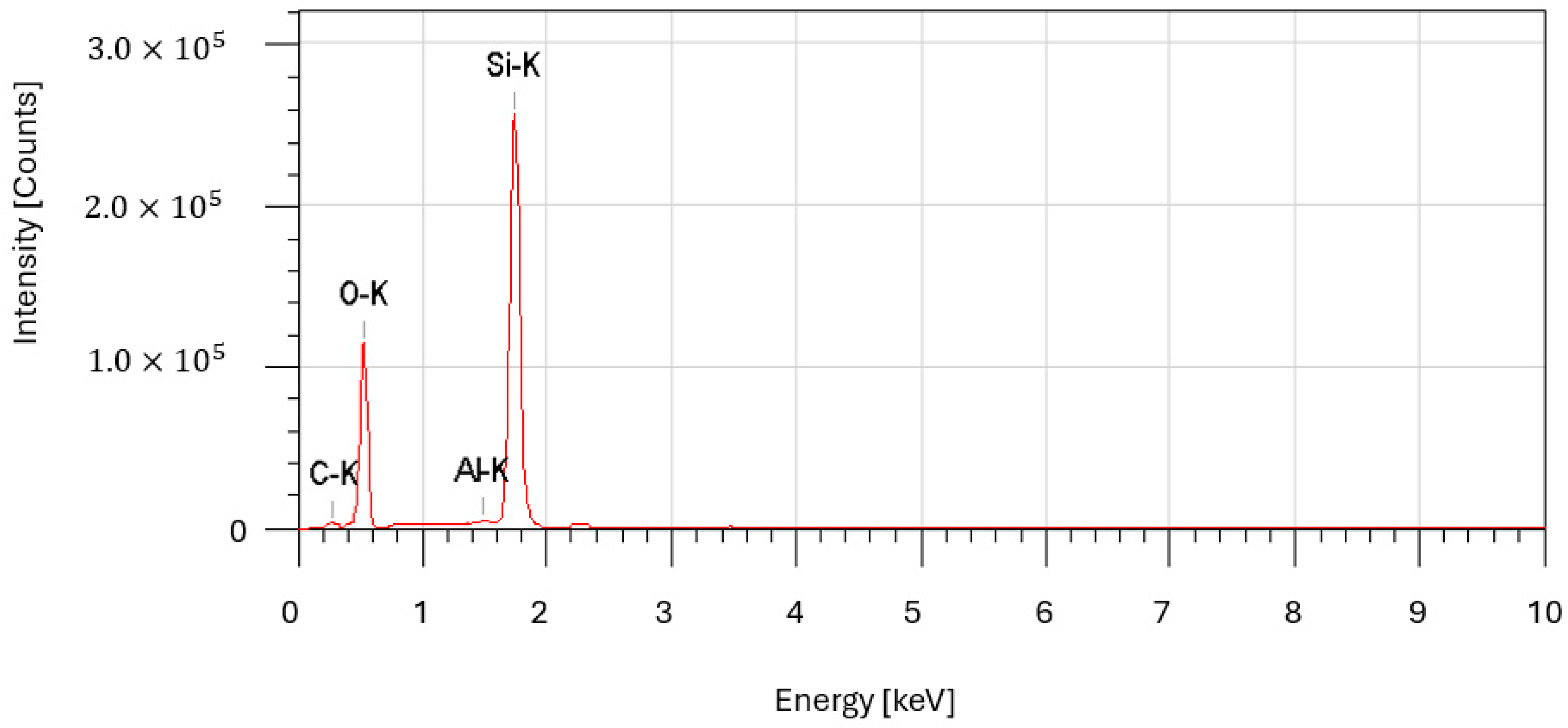

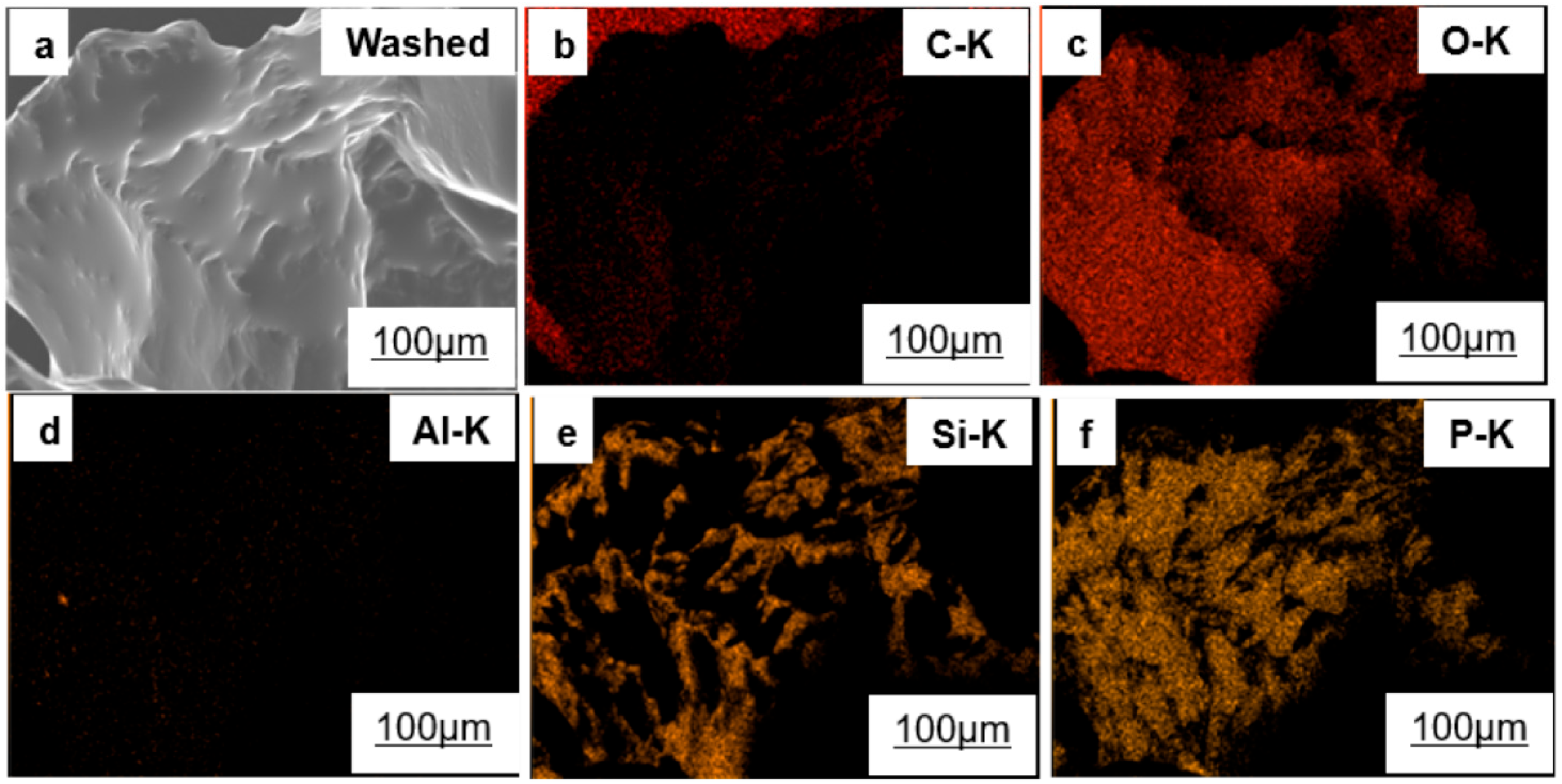

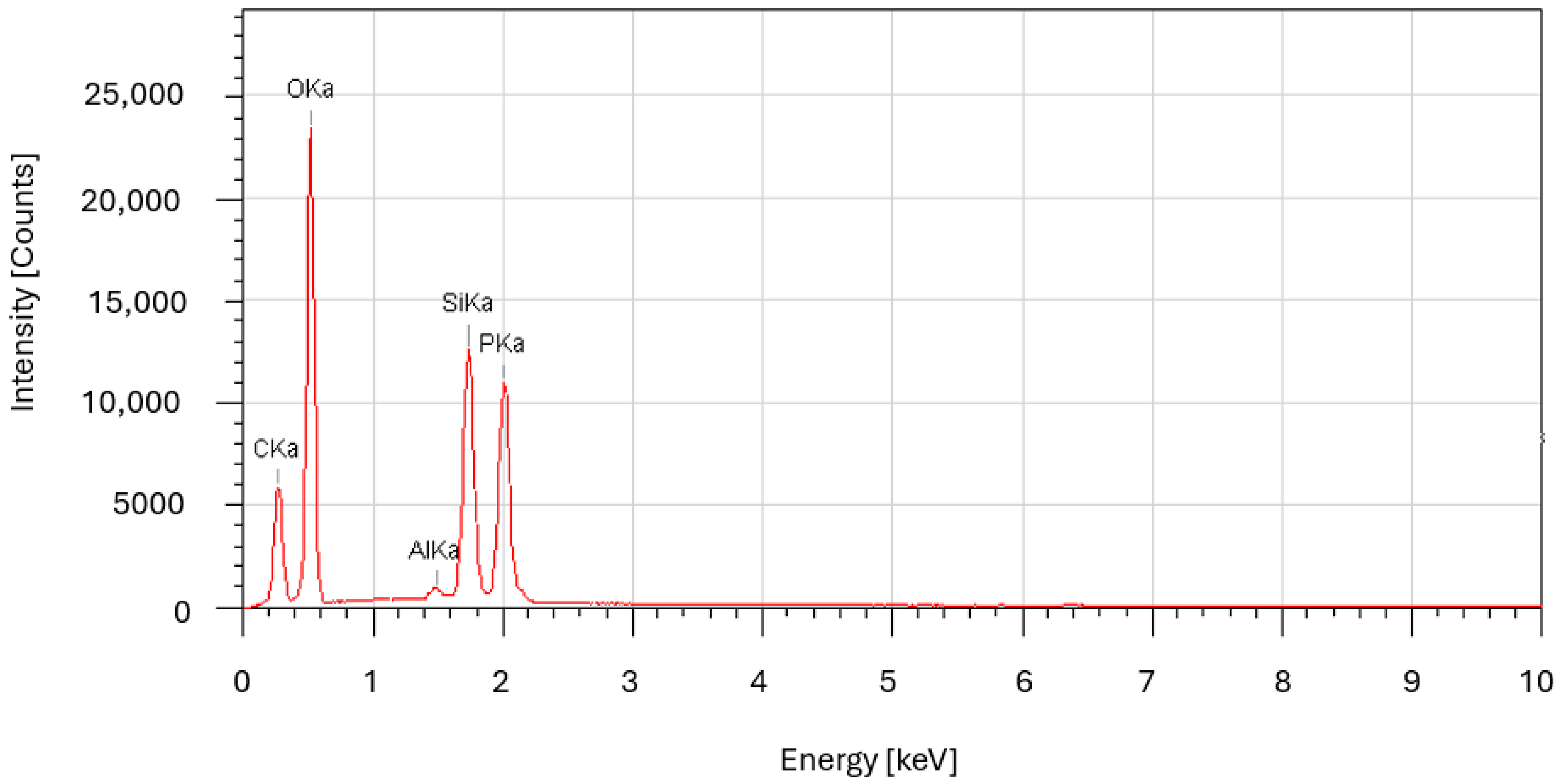

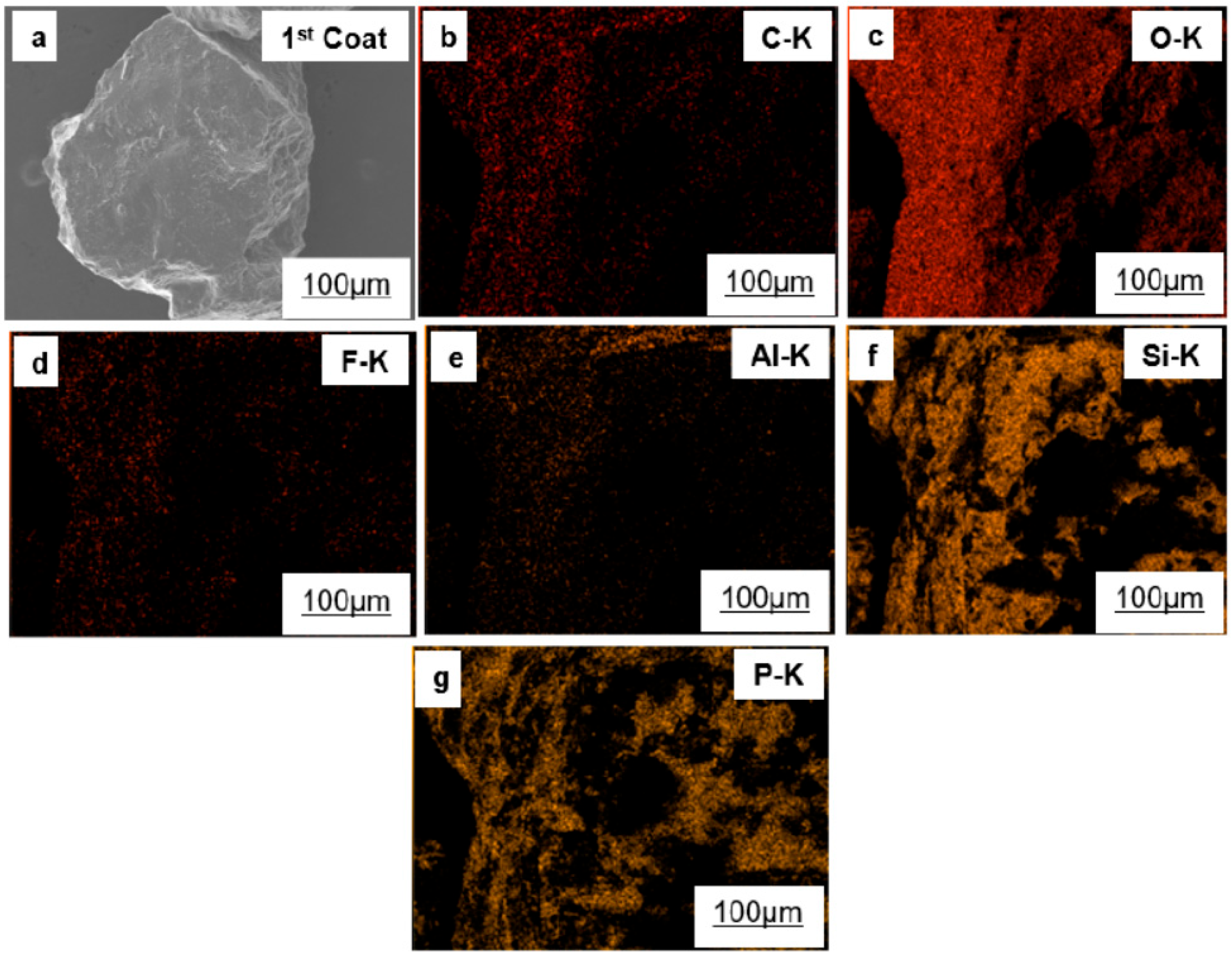

3.2. Surface Morphology and Elemental Composition Analysis via SEM and EDS Findings

3.3. Oil and Grease Analysis Findings

3.4. Statistical Optimization and Performance Assessment of Quartz Packed-Bed Filtration (Raw, Washed, and First Coated) Using Minitab: Taguchi Method and Regression Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salerno, C.; Berardi, G.; Casale, B.; Pollice, A. Comparison of fine bubble scouring, backwash, and mass air load supply for dynamic membrane maintenance and steady operation in SFD MBR for wastewater treatment. J. Water Process Eng. 2023, 53, 103846. [Google Scholar] [CrossRef]

- Purnima, M.; Paul, T.; Pakshirajan, K.; Pugazhenthi, G. Onshore oilfield produced water treatment by hybrid microfiltration-biological process using kaolin based ceramic membrane and oleaginous Rhodococcus opacus. Chem. Eng. J. 2023, 453, 139850. [Google Scholar] [CrossRef]

- Francis, L.; Mohammed, S.; Hashaikeh, R.; Hilal, N. Fabrication and characterization of superhydrophilic graphene-based electrospun membranes for efficient oil-water separation. J. Water Process Eng. 2023, 54, 104066. [Google Scholar] [CrossRef]

- Yuan, C.; Zhou, K.; Wang, Y.; Xie, Y.; Jing, W.; Xing, W. Enhanced micro-explosion to improve the yield of light oil in catalytic cracking of water-in-heavy oil emulsion prepared by continuous membrane emulsification. Fuel 2024, 358, 130122. [Google Scholar] [CrossRef]

- Ma, F.X.; Hao, B.; Xi, X.Y.; Wang, R.; Ma, P.C. Aggregation-induced demulsification technology for the separation of highly emulsified oily wastewater produced in the petrochemical industry. J. Clean. Prod. 2022, 374, 134017. [Google Scholar] [CrossRef]

- Ağtaş, M.; Dilaver, M.; Koyuncu, İ. Ceramic membrane overview and applications in textile industry: A review. Water Sci. Technol. 2021, 84, 1059–1078. [Google Scholar] [CrossRef] [PubMed]

- Ren, Z.; Qi, Y.; Zhao, M.; Li, B.; Jing, W.; Wei, X. A composite structure pressure sensor based on quartz DETF resonator. Sensors Actuators A Phys. 2022, 346, 113883. [Google Scholar] [CrossRef]

- Abuhantash, F.; Abuhasheesh, Y.H.; Hegab, H.M.; Aljundi, I.H.; Al Marzooqi, F.; Hasan, S.W. Hydrophilic, oleophilic and switchable Janus mixed matrix membranes for oily wastewater treatment: A review. J. Water Process Eng. 2023, 56, 104310. [Google Scholar] [CrossRef]

- Zhao, Y.; He, J.; He, T.; Chen, L.; Lai, L.; Yan, X.; Yu, W.; Mi, Y. Synthesis of cyclodextrin-based demulsifier for treatment of oily wastewater through hydrophobic modification strategy. J. Mol. Liq. 2024, 402, 124783. [Google Scholar] [CrossRef]

- Li, K.; Feng, G.; Li, G.; Zhang, Z.; Xiang, J.; Jiao, F.; Chen, T.; Zhao, H. Structurally integrated janus polylactic acid fibrous membranes for oil-water separation. J. Water Process Eng. 2024, 68, 106525. [Google Scholar] [CrossRef]

- Akoumeh, R.; Idoudi, S.; El-Din, L.A.N.; Rekik, H.; Al-Ejji, M.; Ponnama, D.; Sharma, A.; Shamsabadi, A.A.; Alamgir, K.; Song, K.; et al. Advances in fabrication techniques and performance optimization of polymer membranes for enhanced industrial oil-water separation: A critical review. J. Environ. Chem. Eng. 2024, 12, 114411. [Google Scholar] [CrossRef]

- Sun, L.; Wang, Z.; Gao, B. Ceramic membranes originated from cost-effective and abundant natural minerals and industrial wastes for broad applications—A review. Desalin. Water Treat. 2020, 201, 121–138. [Google Scholar] [CrossRef]

- Anggraeni, V.S.; Sutrisna, P.D.; Goh, P.S.; Chan, E.W.C.; Wong, C.W. Development of antifouling membrane film for treatment of oil-rich industrial waste. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Yin, Z.; Li, Z.; Deng, Y.; Xue, M.; Chen, Y.; Ou, J.; Xie, Y.; Luo, Y.; Xie, C.; Hong, Z. Multifunctional CeO2-coated pulp/cellulose nanofibers (CNFs) membrane for wastewater treatment: Effective oil/water separation, organic contaminants photodegradation, and anti-bioadhesion activity. Ind. Crops Prod. 2023, 197, 116672. [Google Scholar] [CrossRef]

- Pei, F.; Jia, H.; Xu, S.; Zhang, M.; Qu, Y. Preparation of superhydrophilic polyimide fibrous membranes by electrostatic spinning fabrication for the efficient separation of oil-in-water emulsions. Sep. Purif. Technol. 2023, 322, 124342. [Google Scholar] [CrossRef]

- Usha, Z.R.; Babiker, D.M.; Zhao, Y.; Chen, X.; Li, L. Advanced super-wetting biaxial polypropylene membrane with hierarchical rough surface for multipollutant removal from oily wastewater. J. Environ. Chem. Eng. 2023, 11, 110775. [Google Scholar] [CrossRef]

- Stoffel, D.; Derlon, N.; Traber, J.; Staaks, C.; Heijnen, M.; Morgenroth, E. Gravity-driven membrane filtration with compact second-life modules daily backwashed: An alternative to conventional ultrafiltration for centralized facilities. Water Res. X 2023, 18, 100178. [Google Scholar] [CrossRef]

- Gan, C.; Luo, Z.; Su, C.; Tong, L.; Liu, H. Mechanism of reactive co-transport of Fe2+ and antibiotics in hyporheic zone simulated by quartz sand column. J. Hydrol. 2023, 621, 129641. [Google Scholar] [CrossRef]

- Whitby, C. A Microbial Solution to Oil Sand Pollution: Understanding the Microbiomes, Metabolic Pathways and Mechanisms Involved in Naphthenic Acid (NA) Biodegradation, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Poli, A.; Sfeir, R.; Santos, A.F.; Jacob, M.; Andrey, P.; Batiot-Dupeyrat, C.; Teychene, B. Backwashable dynamic membrane made of anchored CNT on SiC microfiltration membranes applied to oil in water emulsion filtration. Sep. Purif. Technol. 2022, 278, 119566. [Google Scholar] [CrossRef]

- Ramanamane, N.J.; Sob, P.B.; Alugongo, A.A.; Tengen, T.B. Transmembrane Pressure Modeling for Optimal Integrated Membrane System Performance. Int. J. Emerg. Technol. Adv. Eng. 2022, 12, 168–174. [Google Scholar] [CrossRef]

- Wang, X.; Sun, K.; Zhang, G.; Yang, F.; Lin, S.; Dong, Y. Robust zirconia ceramic membrane with exceptional performance for purifying nano-emulsion oily wastewater. Water Res. 2022, 208, 117859. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhang, J.; Shao, Y.; Cui, Z.; Zhao, Y.; Zhang, Y. Bi-functional Janus mesh membrane with selective spontaneous directional liquids transport for efficient on-demand separation of oil-in-water and water-in-oil emulsions. Sep. Purif. Technol. 2025, 360, 130932. [Google Scholar] [CrossRef]

- Baig, U.; Usman, J.; Abba, S.I.; Yogarathinam, L.T.; Waheed, A.; Bafaqeer, A.; Aljundi, I.H. Insight into soft chemometric computational learning for modelling oily-wastewater separation efficiency and permeate flux of polypyrrole-decorated ceramic-polymeric membranes. J. Chromatogr. A 2024, 1725, 464897. [Google Scholar] [CrossRef]

- Baig, U.; Waheed, A. An efficient and simple strategy for fabricating a polypyrrole decorated ceramic-polymeric porous membrane for purification of a variety of oily wastewater streams. Environ. Res. 2022, 219, 114959. [Google Scholar] [CrossRef] [PubMed]

- Baig, U.; Waheed, A. Facile fabrication of ceramic-polymeric nanocomposite membrane with special surface wettability using amino decorated NH2-SiO2@SiC nanopowder for production of clean water from oily wastewater. Process Saf. Environ. Prot. 2023, 171, 694–704. [Google Scholar] [CrossRef]

- Muslimova, I.B.; Zhumanazar, N.; Melnikova, G.B.; Yeszhanov, A.B.; Zhatkanbayeva, Z.K.; Chizhik, S.A.; Zdorovets, M.V.; Güven, O.; Korolkov, I.V. Preparation and application of stimuli-responsive PET TeMs: RAFT graft block copolymerisation of styrene and acrylic acid for the separation of water-oil emulsions. RSC Adv. 2024, 14, 14425–14437. [Google Scholar] [CrossRef]

- Chai, J.; Wang, G.; Zhang, A.; Zhao, G.; Park, C.B. Superhydrophobic nanofibrous polytetrafluoroethylene and composite membranes with tunable adhesion for micro-droplet manipulation, self-cleaning and oil/water separation. J. Environ. Chem. Eng. 2024, 12, 112355. [Google Scholar] [CrossRef]

- Sun, A.; Zhan, Y.; Chen, X.; Jia, H.; Zhu, F.; Zhao, C.; Li, Y.; He, H.; Wu, Y.; He, T.; et al. Design of photocatalytic self-cleaning poly (arylene ether nitrile)/nitrogen-doped Bi2O2CO3 composite membrane for emulsified oily wastewater purification. J. Environ. Chem. Eng. 2023, 11, 110810. [Google Scholar] [CrossRef]

- Dong, Z.; Qu, N.; Jiang, Q.; Zhang, T.; Han, Z.; Li, J.; Zhang, R.; Cheng, Z. Preparation of polystyrene and silane-modified nano-silica superhydrophobic and superoleophilic three-dimensional composite fiber membranes for efficient oil absorption and oil-water separation. J. Environ. Chem. Eng. 2024, 12, 112690. [Google Scholar] [CrossRef]

- Zhang, Y.; Yi, A.; Ren, Y.; Chen, Q.; Jiang, J.; Sun, H.; Zhu, Z.; Li, A. CMPs membranes prepared using electrostatic spinning as a template for efficient oil-water separation. J. Environ. Chem. Eng. 2024, 12, 113704. [Google Scholar] [CrossRef]

- Pei, Y.; Wu, X.; Lv, Y.; Liang, N.; Lv, S.; Guo, J.; Jia, D. A direct electrospinning strategy prepared series of coal-derived nanofibers for efficient oil-water separation. Appl. Surf. Sci. 2024, 645, 158815. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, X.; Dong, Y.; Li, J.; Yang, X.Y. Effective separation of water-in-oil emulsions using an under-medium superlyophilic membrane with hierarchical pores. J. Hazard. Mater. 2024, 465, 133305. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Tian, Q.; Xu, J.; Qiu, F.; Zhang, T. Enhanced separation of dual pollutants from wastewater containing Cr (Ⅵ) and oil via Fe-doped sludge derived membrane. Chem. Eng. Sci. 2024, 292, 120020. [Google Scholar] [CrossRef]

- He, P.; Zhang, F.; Zhang, Y.; Chen, H. Multifunctional fly ash-based GO/geopolymer composite membrane for efficient oil-water separation and dye degradation. Ceram. Int. 2023, 49, 1855–1864. [Google Scholar] [CrossRef]

- Zhu, B.; Duke, M.; Dumée, L.F.; Merenda, A.; Ligneris, E.D.; Kong, L.; Hodgson, P.D.; Gray, S. Short review on porous metal membranes—Fabrication, commercial products, and applications. Membranes 2018, 8, 83. [Google Scholar] [CrossRef]

- Omar, N.M.A.; Othman, M.H.D.; Tai, Z.S.; Jaafar, J.; Rahman, A.M.; Puteh, M.H.; Abu Bakar, S.; Kurniawan, T.A.; Li, T. Fabrication and characterization of a novel mullite-stainless steel composed hollow fibre membrane for oil/water separation. Ain Shams Eng. J. 2023, 15, 102260. [Google Scholar] [CrossRef]

- Zhong, J.; Xin, Y. Preparation, compatibility and barrier properties of attapulgite/poly (lactic acid)/thermoplastic starch composites. Int. J. Biol. Macromol. 2023, 242, 124727. [Google Scholar] [CrossRef]

- Wang, K.; Liu, X.; Dong, Y.; Zhang, S.; Li, J. A biomimetic Janus delignified wood membrane with asymmetric wettability prepared by thiol-ol chemistry for unidirectional water transport and selective oil/water separation. Colloids Surf. A Physicochem. Eng. Asp. 2022, 652, 129793. [Google Scholar] [CrossRef]

- Liu, H.; Wang, D.; Huang, H.; Zhou, W.; Chu, Z. Cysteine-based antifouling superhydrophilic membranes prepared via facile thiol-ene click chemistry for efficient oil-water separation. J. Environ. Chem. Eng. 2024, 12, 112654. [Google Scholar] [CrossRef]

- Gholamifard, H.; Rasul, M.G.; Rahideh, H.; Azari, A.; Abbasi, M.; Karami, R. Experimental and numerical analysis of oily wastewater treatment using low-cost mineral adsorbent in a single and multi-fixed bed column. Chem. Eng. J. Adv. 2023, 16, 100551. [Google Scholar] [CrossRef]

- Aloulou, W.; Aloulou, H.; Romdhani, M.; Dammak, L.; Amar, R.B. Effectiveness evaluation of a flat smectite membrane for wastewaters purification: Characterization, cost and energy estimation. Desalin. Water Treat. 2024, 318, 100390. [Google Scholar] [CrossRef]

- Dos Santos Barbosa, A.A.A.; Rodrigues, M.G.F. Low cost membrane used in oil/water removal. Desalin. Water Treat. 2024, 317, 100029. [Google Scholar] [CrossRef]

- Basak, S.; Barma, S.; Majumdar, S.; Ghosh, S. Role of silane grafting in the development of a superhydrophobic clay-alumina composite membrane for separation of water in oil emulsion. Ceram. Int. 2022, 48, 26638–26650. [Google Scholar] [CrossRef]

- Avornyo, A.; Chrysikopoulos, C.V. Applications of graphene oxide (GO) in oily wastewater treatment: Recent developments, challenges, and opportunities. J. Environ. Manag. 2024, 353, 120178. [Google Scholar] [CrossRef]

- Hioki, M.; Nakagawa, Y.; Sato, T. Presence of Bicontinuous Microemulsion-Type Domains and Dielectrically Inert Interfacial Water Layers in Lamellar Gel-Stabilized Oil-in-Water Emulsions; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Xu, J.; Xie, A.; Sun, H.; Wu, Y.; Li, C.; Xue, C.; Cui, J.; Pan, J. Construction of tannic acid-Fe complex coated PVDF membrane via simple spraying method for oil/water emulsion separation. Colloids Surf. A Physicochem. Eng. Asp. 2023, 671, 131621. [Google Scholar] [CrossRef]

- Pan, J.; Ge, Y. Low-cost and high-stability superhydrophilic/underwater superoleophobic NaA zeolite/copper mesh composite membranes for oil/water separation. Surf. Interfaces 2023, 37, 102703. [Google Scholar] [CrossRef]

- Abbas, S.M.; Al-Jubouri, S.M. High performance and antifouling zeolite@polyethersulfone/cellulose acetate asymmetric membrane for efficient separation of oily wastewater. J. Environ. Chem. Eng. 2024, 12, 112775. [Google Scholar] [CrossRef]

- Chen, J.Y.; Li, N.; Wang, S.; Wu, T.Y.; Meng, X.; Ye, H.M. Boosting solvent resistance and structure stability of degradable polyester through extended-chain crystal structure: A preliminary case of oil/water separation membrane. J. Environ. Chem. Eng. 2024, 12, 113507. [Google Scholar] [CrossRef]

- Zhang, E.; Liu, L.; Jin, S.; Zhao, P.; Wang, X.Z.; Xu, G. Preparation of corundum ceramic membrane with high permeability and corrosion resistance for oil in water separation. Ceram. Int. 2025, 51, 15512–15520. [Google Scholar] [CrossRef]

- Xiang, B.; Gong, J.; Sun, Y.; Yan, W.; Jin, R.; Li, J. High permeability PEG/MXene@MOF membrane with stable interlayer spacing and efficient fouling resistance for continuous oily wastewater purification. J. Memb. Sci. 2024, 691, 122247. [Google Scholar] [CrossRef]

- Ma, J.; Chen, W.; Qian, J.; Shui, A.; Du, B.; He, C. Co-pressing and co-sintering preparation of cost-effective and high-performance asymmetric ceramic membrane for oily wastewater treatment. Sep. Purif. Technol. 2023, 323, 124373. [Google Scholar] [CrossRef]

- Mao, H.; Shi, H.; Zhang, Z.; Zhou, S.; Qiu, M.; Jia, M.; Li, M.; Zhao, Y.; Xia, S.; Wu, Z. Lower-temperature preparation of porous Al2O3 supports for O/W separation membranes by recycling mixed-dimensional attapulgite clay as sintering aid. J. Environ. Chem. Eng. 2023, 11, 110399. [Google Scholar] [CrossRef]

- Jiang, Q.; Lin, B.; Zhong, Z.; Fan, Y.; Xing, W. Ultra-low temperature co-sintering of water glass (WG)-bonded silicon carbide ceramic membranes for oil-water separation. J. Memb. Sci. 2024, 692, 122311. [Google Scholar] [CrossRef]

- Kallem, P.; Pandey, R.P.; Hegab, H.M.; Gaur, R.; Hasan, S.W.; Banat, F. High-performance thin-film composite forward osmosis membranes with hydrophilic PDA@TiO2 nanocomposite substrate for the treatment of oily wastewater under PRO mode. J. Environ. Chem. Eng. 2022, 10, 107454. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Y.; Yuan, Y.; Jiang, L.; Wu, H.; Dong, Y. Biomimetic hydrophilic modification of poly (vinylidene fluoride) membrane for efficient oil-in-water emulsions separation. Sep. Purif. Technol. 2024, 329, 125227. [Google Scholar] [CrossRef]

- Pan, Y.; Zhu, Z.; Li, M.; Cheng, C.; Wang, M.; Jiao, R.; Sun, H.; Li, A. Preparation of halloysite-based PVDF membrane for effective oil/water separation and dyes removal. Sep. Purif. Technol. 2025, 359, 130595. [Google Scholar] [CrossRef]

- Yang, X.; Bai, R.; Cao, X.; Song, C.; Xu, D. Modification of polyacrylonitrile (PAN) membrane with anchored long and short anionic chains for highly effective anti-fouling performance in oil/water separation. Sep. Purif. Technol. 2023, 316, 123769. [Google Scholar] [CrossRef]

- Ding, J.; Zhang, X.; Chen, H. Fabrication and oil-water separation properties of cerium oxide coated zirconium oxide composite membranes. Colloids Surf. A Physicochem. Eng. Asp. 2024, 683, 133069. [Google Scholar] [CrossRef]

- Mulinari, J.; Ambrosi, A.; Feng, Y.; He, Z.; Huang, X.; Li, Q.; Di Luccio, M.; Hotza, D.; Oliveira, J.V. Polydopamine-assisted one-step immobilization of lipase on α-alumina membrane for fouling control in the treatment of oily wastewater. Chem. Eng. J. 2023, 459, 141516. [Google Scholar] [CrossRef]

- Khebli, Z.; Bouzerara, F.; Brihi, N.; Figoli, A.; Russo, F.; Galiano, F.; Chahredine, S. Fabrication of a Zircon Microfiltration Membrane for Culture Medium Sterilization. Membranes 2023, 13, 399. [Google Scholar] [CrossRef]

- Marino, T.; Russo, F.; Rezzouk, L.; Bouzid, A.; Figoli, A. PES-kaolin mixed matrix membranes for arsenic removal from water. Membranes 2017, 7, 57. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Guo, Z. Natural polymers-based separation membrane for high-efficient separation of oil water mixture. Nano Today 2024, 57, 102367. [Google Scholar] [CrossRef]

- Hu, Y.; Lin, X.; Liu, D.; Liang, L.; Pang, C.; Pan, X.; Wang, H. Electrospun polymethyl methacrylate fibers-based membrane with heterogeneous structure achieving a full-particle size separation of oil-water emulsion. J. Memb. Sci. 2023, 680, 121716. [Google Scholar] [CrossRef]

- Yue, R.Y.; Yuan, P.C.; Zhang, C.M.; Wan, Z.H.; Wang, S.G.; Sun, X. Robust self-cleaning membrane with superhydrophilicity and underwater superoleophobicity for oil-in-water separation. Chemosphere 2023, 330, 138706. [Google Scholar] [CrossRef] [PubMed]

- Baig, U.; Al-Kuhaili, M.F.; Dastageer, M.A. Solar-light active tungsten oxide coated ceramic membrane with unique surface wettability fabricated by RF magnetron sputtering: Remediation of oily wastewater and photo-catalytic self-cleaning. Sustain. Mater. Technol. 2024, 39, e00837. [Google Scholar] [CrossRef]

- Wu, H.; Sun, C.; Huang, Y.; Zheng, X.; Zhao, M.; Gray, S.; Dong, Y. Treatment of oily wastewaters by highly porous whisker-constructed ceramic membranes: Separation performance and fouling models. Water Res. 2022, 211, 118042. [Google Scholar] [CrossRef]

- Li, X.; Xu, S.; Zeng, X.; Yan, Y.; Zhang, M.; Luo, J.; Pi, P.; Wen, X. Enhancing demulsification efficiency and sustaining constant separation flux in oil/water emulsions via Janus membrane inspired by spider silk. J. Environ. Chem. Eng. 2024, 12, 114016. [Google Scholar] [CrossRef]

- Neto, G.L.O.; Oliveira, N.G.N.; Delgado, J.M.P.Q.; Nascimento, L.P.C.; Gomez, R.S.; Cabral, A.S.; Cavalcante, D.C.M.; Miranda, V.A.M.; Neto, S.R.F.; Lima, A.G.B. A new design of tubular ceramic membrane module for oily water treatment: Multiphase flow behavior and performance evaluation. Membranes 2020, 10, 403. [Google Scholar] [CrossRef]

- Bonyadi, E.; Ashtiani, F.Z.; Ghorabi, S.; Niknejad, A.S. Bio-inspired hybrid coating of microporous polyethersulfone membranes by one-step deposition of polydopamine embedded with amino-functionalized SiO2 for high-efficiency oily wastewater treatment. J. Environ. Chem. Eng. 2022, 10, 107121. [Google Scholar] [CrossRef]

- Abuhatab, F.; Hasan, S.W. Green fabrication methods and performance evaluation of eco-friendly membranes for enhanced oil-water separation. J. Environ. Chem. Eng. 2024, 12, 113993. [Google Scholar] [CrossRef]

- Li, B.; Qian, X.; Ran, L.; Han, J.; Yang, C.; Jiao, T. Applications and challenges of superwetted oil-water separation membranes in air under liquids and in specific environments. Prog. Org. Coat. 2024, 195, 108673. [Google Scholar] [CrossRef]

- Al Ansari, Z.; Vega, L.F.; Zou, L. Emulsified oil fouling resistant cellulose acetate-MoS2-nanocomposite membrane for oily wastewater remediation. Desalination 2024, 575, 117335. [Google Scholar] [CrossRef]

- Tian, S.; Zhang, Y.; Sha, Q.; Zhang, X.; Yang, T.; Yan, X.; Han, N. PPS/TA-PEI/β-FeOOH membranes with powerful photo-Fenton self-cleaning capability for efficient oil–water emulsion separation. Chem. Eng. J. 2024, 485, 150069. [Google Scholar] [CrossRef]

- Chen, M.; Wang, Z.; Weng, S.; Yue, J.; Wang, Z.; Zhang, H.; Huang, Z.; You, X.; Li, R.; Fu, Q. Submicron-ultrathin PE/PDVB composite membrane for efficient oil/water separation. J. Memb. Sci. 2024, 701, 122701. [Google Scholar] [CrossRef]

- Samuel, O.; Othman, M.H.D.; Kamaludin, R.; Kurniawan, T.A.; Li, T.; Dzinun, H.; Imtiaz, A. Treatment of oily wastewater using photocatalytic membrane reactors: A critical review. J. Environ. Chem. Eng. 2022, 10, 108539. [Google Scholar] [CrossRef]

- Mohammed, H.J.; Nayyaf, D.R.; Hammoodi, K.A.; Hussein, K.K.A.; Alsayah, A.M.; Kadhim, S.A. Preparation and Evaluation of Nanomembranes for Proton Exchange Membrane Fuel Cells. Jordan J. Mech. Ind. Eng. 2024, 18, 705–709. [Google Scholar] [CrossRef]

- Mabidi, T.J.; Izevbekhai, O.U.; Gitari, W.M.; Mudzielwana, R.; Ayinde, W.B. Preparation and characterization of acid-leached diatomaceous earth for application in the treatment of oily wastewater. Phys. Chem. Earth Parts A/B/C 2023, 132, 103497. [Google Scholar] [CrossRef]

- Wu, Y.; Guo, S.; Huang, H.; Zhang, B. An efficient immersing strategy for enhancing the separation performance of microfiltration carbon membranes for oily wastewater. Surf. Interfaces 2023, 41, 103274. [Google Scholar] [CrossRef]

- Baig, U.; Waheed, A.; Dastageer, M.A. Facile fabrication of silicon carbide decorated ceramic membrane, engineered with selective surface wettability for highly efficient separation of oil-in-water emulsions. J. Environ. Chem. Eng. 2023, 11, 109357. [Google Scholar] [CrossRef]

- Yahaya, N.Z.S.; Azmi, N.F.A.N.; Rahman, M.A.; Abas, K.H.; Othman, M.H.D.; Jaafar, J. 18—Antifouling and self-cleaning photocatalytic membranes in oily wastewater treatment. In Elsevier Series on Advanced Ceramic Materials; Othman, M.H.D., Rahman, M.A., Matsuura, T., Adam, M.R., Makhtar, P.M.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 481–497. [Google Scholar]

- Mubarak, M.F.; Selim, H.; Hawash, H.B.; Hemdan, M. Flexible, durable, and anti-fouling maghemite copper oxide nanocomposite-based membrane with ultra-high flux and efficiency for oil-in-water emulsions separation. Environ. Sci. Pollut. Res. Int. 2024, 31, 2297–2313. [Google Scholar] [CrossRef]

- Ehsan, M.; Razzaq, H.; Razzaque, S.; Kanwal, M.; Hussain, I. Engineering nanocomposite membranes of sodium alginate-graphene oxide for efficient separation of oil-water and antifouling performance. J. Environ. Chem. Eng. 2023, 11, 109185. [Google Scholar] [CrossRef]

- Sun, D.; Wang, Y.; Gao, J.; Liu, S.; Liu, X. Insights into the relation of crude oil components and surfactants to the stability of oily wastewater emulsions: Influence of asphaltenes, colloids, and nonionic surfactants. Sep. Purif. Technol. 2023, 307, 122804. [Google Scholar] [CrossRef]

- Ma, J.; He, J.; Niu, Y.; Cheng, C. One-step fabrication of asymmetric alumina ceramic membranes with tunable pore parameters for oil-water separation. J. Water Process Eng. 2024, 58, 104739. [Google Scholar] [CrossRef]

- Aouadja, F.; Bouzerara, F.; Guvenc, C.M.; Demir, M.M. Fabrication and properties of novel porous ceramic membrane supports from the (Sig) diatomite and alumina mixtures. Bol. Soc. Ceram. Vidr. 2022, 61, 540. [Google Scholar] [CrossRef]

- Abu-Thabit, N.Y.; Azad, A.K.; Mezghani, K.; Akhtar, S.; Hakeem, A.S.; Drmosh, Q.A.; Adesina, A.Y. Rapid, Sustainable, and Versatile Strategy Towards Fabricating Superhydrophobic Cotton Textile Membranes for Separation of Emulsified and Stratified Oil/Water Mixtures. Sep. Purif. Technol. 2024, 330, 125352. [Google Scholar] [CrossRef]

- Wang, T.; Wang, W.; Hu, C.; Zheng, J.; Zhu, Z.; Liu, B. Design of carboxymethyl cellulose/alginate aerogels with anti-fouling and light-driven self-cleaning for enhanced oily wastewater remediation. Carbohydr. Polym. 2024, 342, 122358. [Google Scholar] [CrossRef]

- Ding, Y.; Gao, J.; Chen, Z.; He, Q.; Xia, M.; Xu, P.; Cao, Y.; Chen, Y. Maximizing the benefits of combining fibroin and sericin: Functionalized obsoleted silk cocoon shell for purifying oily wastewater containing Pb2+. J. Clean. Prod. 2023, 422, 138573. [Google Scholar] [CrossRef]

- Yang, H.; Liu, Y.; Xu, B.; Wang, L.; Huang, C.; Chen, C.; He, J.; Luo, L.; Zhang, Y. Rational design of a super anti-fouling PVDF-PC-TBT@X membrane for emulsion/dye wastewater separation. J. Environ. Chem. Eng. 2023, 11, 111256. [Google Scholar] [CrossRef]

- Mohshim, D.F.; Nasir, R.; Mannan, H.A.; Abdulrahman, A.; Mukhtar, H. 3—Challenges of Industries in Dealing with Oily Wastewater Release and Treatments; Basile, A., Cassano, A., Rahimpour, M.R., Makarem, W.T., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 49–70. [Google Scholar]

- Sahu, S.; Purkayastha, D.D. WO3·H2O micro-flowers decorated PVDF/Ti3C2 MXene membrane for oily wastewater treatment. Sep. Purif. Technol. 2024, 330, 125486. [Google Scholar] [CrossRef]

- Shi, P.; Zhang, R.; Pu, W.; Liu, R.; Fang, S. Coalescence and separation of surfactant-stabilized water-in-oil emulsion via membrane coalescer functionalized by demulsifier. J. Clean. Prod. 2022, 330, 129945. [Google Scholar] [CrossRef]

- Bai, Z.; Jia, K.; Lin, G.; Huang, Y.; Liu, C.; Liu, S.; Zhang, S.; Liu, X. Solvent-nonsolvent regulated nano-functionalization of super-wetting membranes for sustainable oil/water separation. Appl. Surf. Sci. 2023, 613, 156085. [Google Scholar] [CrossRef]

- Ning, D.; Lu, Z.; Tian, C.; Yan, N.; Xie, F.; Li, N.; Hua, L. Superwettable cellulose acetate-based nanofiber membrane with spider-web structure for highly efficient oily water purification. Int. J. Biol. Macromol. 2023, 253, 126865. [Google Scholar] [CrossRef] [PubMed]

- Bombom, M.; Zaman, B.T.; Bozyiğit, G.D.; Şaylan, M.; Bayraktar, A.; Arvas, B.; Yolaçan, Ç.; Bakırdere, S. T-cut slotted quartz tube-atom trap strategy for the on-line preconcentration of thallium in well water samples. Meas. J. Int. Meas. Confed. 2023, 220, 113363. [Google Scholar] [CrossRef]

- Basak, S.; Barma, S.; Majumdar, S.; Ghosh, S. Silane-modified bentonite clay-coated membrane development on ceramic support for oil/water emulsion separation using tuning of hydrophobicity. Colloids Surf. A Physicochem. Eng. Asp. 2024, 681, 132812. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, X.; Xu, G.; Chen, J.; Lu, H. Polyvinyl alcohol gel/micro-arc oxidation 3D-printed porous structural aluminium for oil-water separation. Colloids Surf. A Physicochem. Eng. Asp. 2024, 699, 134701. [Google Scholar] [CrossRef]

- Gao, G.; Yu, X.; Hu, X.; Wang, X. Flexible crystalline zinc doped silica nanofibers with superior wettability and remediation for oily wastewater. Sep. Purif. Technol. 2024, 336, 126364. [Google Scholar] [CrossRef]

- Sadek, S.A.; Al-Jubouri, S.M. Highly efficient oil-in-water emulsion separation based on innovative stannic oxide/polyvinylchloride (SnO2/PVC) microfiltration membranes. J. Ind. Eng. Chem. 2024, 140, 577–588. [Google Scholar] [CrossRef]

- Chen, X.; Song, X.; Chen, J.; Chen, Y.; Yu, W.; Liu, Y. A novel polyurethane-polydimethylsiloxane/polylactic acid electrospinning fiber membrane for oil/water separation. Colloids Surf. A Physicochem. Eng. Asp. 2023, 668, 131445. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, L.; Cao, X.; Chan, W.; Jing, Y.; Sun, H.; Zhu, Z.; Liang, W.; Li, J.; Li, A. Removal of PM and oil mist from automobile exhaust by a ‘hamburger’ structured conjugated microporous polymers membrane. Eur. Polym. J. 2023, 195, 112167. [Google Scholar] [CrossRef]

- Yu, Y.; Yue, B.; Wu, J.; Fu, Z.; Cui, Z.; Qu, J.; Hu, J.; Aladejana, J.T.; Lu, Y.; Li, J.; et al. A wood-based MOF membrane with high flux and efficiency for oil-in-water emulsions separation. Colloids Surf. A Physicochem. Eng. Asp. 2023, 674, 131852. [Google Scholar] [CrossRef]

- Xu, Z.Z.; Zhao, M.-W.; Wu, Y.-N.; Liu, J.-W.; Sun, N.; Wang, Z.-Z.; Zhang, Y.-M.; Li, L.; Dai, C.-L. Quantitatively probing interactions between membrane with adaptable wettability and oil phase in oil/water separation. Pet. Sci. 2023, 20, 2564–2574. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, S.; Wu, Y.; Hong, X.; Liang, Y.; Wang, T.; Qiu, J. Enhanced separation performance of microfiltration carbon membranes for oily wastewater treatment by an air oxidation strategy. Chem. Eng. Process. Process Intensif. 2021, 169, 108620. [Google Scholar] [CrossRef]

- Alrasheedi, N.F.; Abdulazeez, I.; Baig, N.; Salhi, B.; Asmaly, H.A.; Haladu, S.A.; Elsharif, A.M. Antifouling macrocyclic-engineered PVDF membrane for the low-pressure separation of surfactant-stabilized oily wastewater. J. Environ. Chem. Eng. 2024, 12, 112850. [Google Scholar] [CrossRef]

- Sutrisna, P.D.; Mustika, P.C.B.W.; Hadi, R.P.; Caren; Gani, Y.E. Improved oily wastewater rejection and flux of hydrophobic PVDF membrane after polydopamine-polyethyleneimine co-deposition and modification. S. Afr. J. Chem. Eng. 2023, 44, 42–50. [Google Scholar] [CrossRef]

- Yu, X.; Ji, J.; Wu, Q.Y.; Gu, L. Direct-coating of cellulose hydrogel on PVDF membranes with superhydrophilic and antifouling properties for high-efficiency oil/water emulsion separation. Int. J. Biol. Macromol. 2024, 256, 128579. [Google Scholar] [CrossRef] [PubMed]

- Usman, J.; Othman, M.H.D.; Ismail, A.F.; Rahman, M.A.; Jaafar, J.; Raji, Y.O.; Gbadamosi, A.O.; El Badawy, T.H.; Said, K.A.M. An overview of superhydrophobic ceramic membrane surface modification for oil-water separation. J. Mater. Res. Technol. 2021, 12, 643–667. [Google Scholar] [CrossRef]

- Gao, Y.; Xu, G.; Zhao, P.; Liu, L.; Zhang, E. One step co-sintering synthesis of gradient ceramic microfiltration membrane with mullite/alumina whisker bi-layer for high permeability oil-in-water emulsion treatment. Sep. Purif. Technol. 2023, 305, 122400. [Google Scholar] [CrossRef]

- Jiang, D.; Gao, C.; Liu, L.; Yu, T.; Li, Y.; Wang, H. Customized copper/cobalt-rich ferrite spinel-based construction ceramic membrane incorporating gold tailings for enhanced treatment of industrial oily emulsion wastewater. Sep. Purif. Technol. 2023, 320, 124131. [Google Scholar] [CrossRef]

| Performance Parameter | Quartz Packed-Bed Filtration Model | Developed Performance Model | Conventional Models (Polymeric, Ceramic, Activated Carbon, Sand Filtration) |

|---|---|---|---|

| Filtration Efficiency (%) | 95–99% (High separation accuracy) | 70–90% (Moderate efficiency) | |

| Oil Rejection Rate (%) | 97–99% (Superior oil separation) | 80–95% (Partial oil rejection, fouling-prone) | |

| Hydrophilicity (Contact Angle, °) | ≤10° (Highly hydrophilic, improved wettability) | 30–90° (Varies by material, lower hydrophilicity) | |

| Fouling Resistance | High (Minimal fouling due to hydrophilic coating) | Packed-bed filtration | Moderate to low (Fouling occurs over time, reducing efficiency) |

| Operational Cost ($/m3) | Low (Quartz is an affordable material) | Cost-effectiveness model: | Medium to high (Polymeric and ceramic membranes have high maintenance costs) |

| Thermal Stability (°C) | Up to 1000 °C (Superior thermal resistance) | 300–800 °C (Limited by polymeric materials) | |

| Chemical Resistance | Excellent (Resistant to acids and alkalis) | Varies (Some degrade in harsh conditions) | |

| Mechanical Durability (Lifespan in Months) | 12–24 (Extended lifespan, robust structure) | 6–18 (Subject to degradation and wear) | |

| Sustainability (Material Reusability) | High (Recyclable, eco-friendly) | Low to moderate (Limited recyclability) | |

| Scalability Potential | High (Easily scalable for industrial applications) | Medium (Higher cost, more complex manufacturing process) | |

| Optimization Approach | Taguchi and Regression Models for Performance Prediction | Empirical Optimization with Limited Predictive Accuracy |

| Quartz Material | Oil Concentration (mg/L ± SD) | Impact of Hydrophilic Nanoparticle Coating |

|---|---|---|

| Oil and water mixture | 183,754.8 ± 1035.6 | Baseline oil concentration before filtration, representing the initial contamination level. |

| Raw | 1859.8 ± 45.6 | Limited oil removal due to inherent surface roughness and lack of hydrophilic functionalization, leading to weak water affinity and increased oil adhesion. |

| Washed | 1583.7 ± 38.9 | Moderate oil rejection due to surface cleaning and removal of organic contaminants, improving wettability and reducing oil deposition on the packed-bed filtration surface. |

| First coating | 29.3 ± 2.5 | Achieved the highest oil removal efficiency, significantly enhanced hydrophilicity, reduced packed-bed filtration fouling, and increased water flux. Hydrophilic nanoparticles optimized surface interactions. |

| Run | Quartz Status | Pressure (bar) | Volume Flow Rate (L/m) | Oil Concentration |

|---|---|---|---|---|

| 1 | 1 (Raw) | 0.5 | 0.76 | 149.25 |

| 2 | 1 (Raw) | 1 | 0.68 | 130.8 |

| 3 | 1 (Raw) | 1.5 | 0.64 | 115.5 |

| 4 | 1 (Raw) | 2 | 0.56 | 98.75 |

| 5 | 1 (Raw) | 2.5 | 0.52 | 82.4 |

| 6 | 1 (Raw) | 3 | 0.44 | 65.9 |

| 7 | 2 (Washed) | 0.5 | 0.76 | 120.1 |

| 8 | 2 (Washed) | 1 | 0.68 | 105.3 |

| 9 | 2 (Washed) | 1.5 | 0.64 | 91.25 |

| 10 | 2 (Washed) | 2 | 0.56 | 78.6 |

| 11 | 2 (Washed) | 2.5 | 0.52 | 65.8 |

| 12 | 2 (Washed) | 3 | 0.44 | 50.2 |

| 13 | 3 (Coated) | 0.5 | 0.85 | 10.5 |

| 14 | 3 (Coated) | 1 | 0.75 | 8.2 |

| 15 | 3 (Coated) | 1.5 | 0.72 | 6.7 |

| 16 | 3 (Coated) | 2 | 0.64 | 5.1 |

| 17 | 3 (Coated) | 2.5 | 0.6 | 2.3 |

| 18 | 3 (Coated) | 3 | 0.5 | 1.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramanamane, N.; Pita, M. Improved Oil/Water Separation by Employing Packed-Bed Filtration of Modified Quartz Particles. Water 2025, 17, 1339. https://doi.org/10.3390/w17091339

Ramanamane N, Pita M. Improved Oil/Water Separation by Employing Packed-Bed Filtration of Modified Quartz Particles. Water. 2025; 17(9):1339. https://doi.org/10.3390/w17091339

Chicago/Turabian StyleRamanamane, Nthabiseng, and Mothibeli Pita. 2025. "Improved Oil/Water Separation by Employing Packed-Bed Filtration of Modified Quartz Particles" Water 17, no. 9: 1339. https://doi.org/10.3390/w17091339

APA StyleRamanamane, N., & Pita, M. (2025). Improved Oil/Water Separation by Employing Packed-Bed Filtration of Modified Quartz Particles. Water, 17(9), 1339. https://doi.org/10.3390/w17091339