Evaluating the Influence of Water Quality on Clogging Behavior in Drip Irrigation Emitters: A CT Imaging Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Water Quality Testing and Experimental Setup

2.1.1. Water Source Conditions

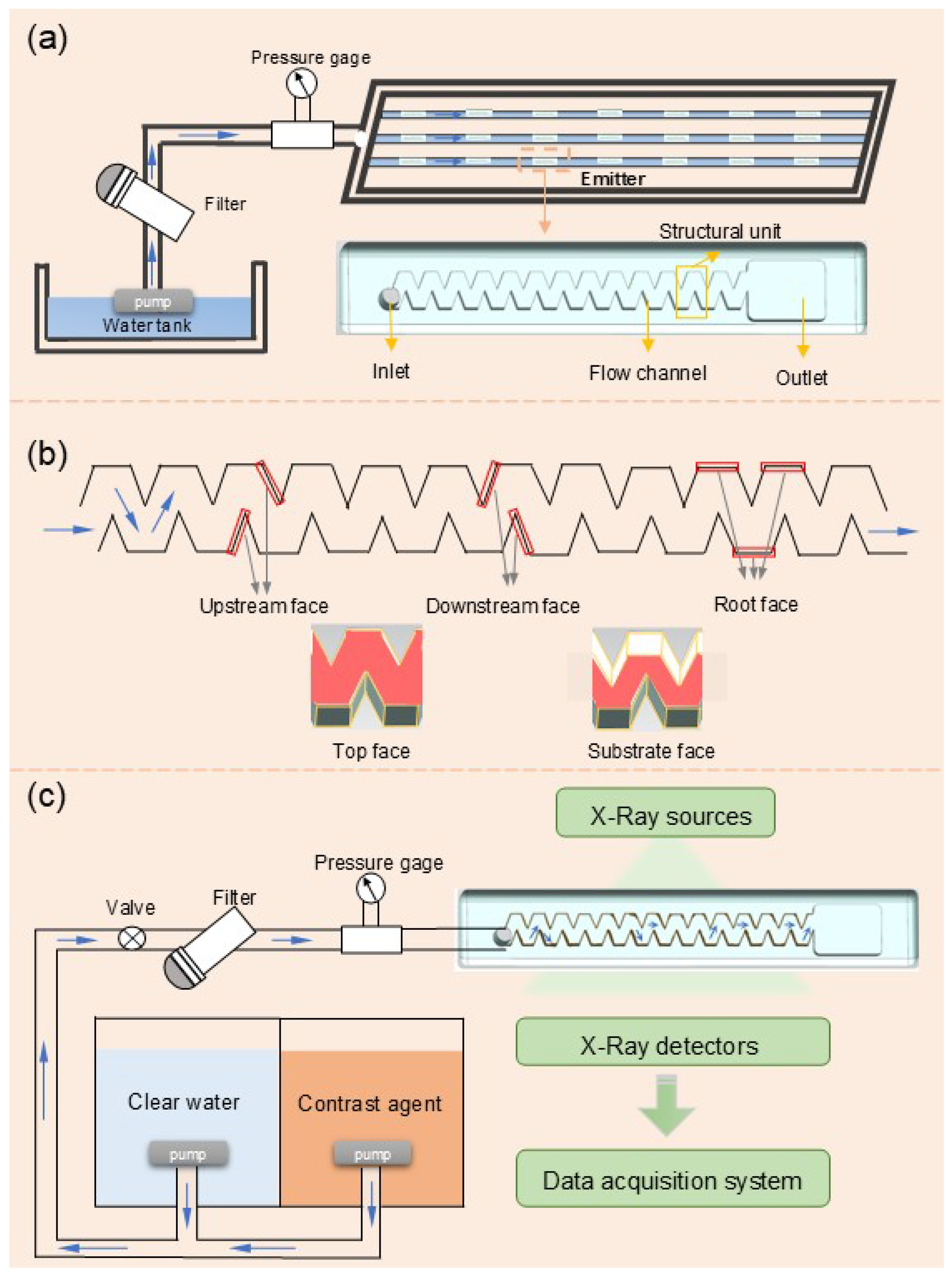

2.1.2. Experimental Setup

2.2. Industrial Computed Tomography (ICT) Technology

2.3. Evaluation Indicators for the Spatial Distributions of Clogging Substances

2.3.1. Mean Thickness of Clogging Substances

2.3.2. Volume Fraction of Clogging Substances

2.3.3. Ratio of Clogging Substances

3. Results and Analysis

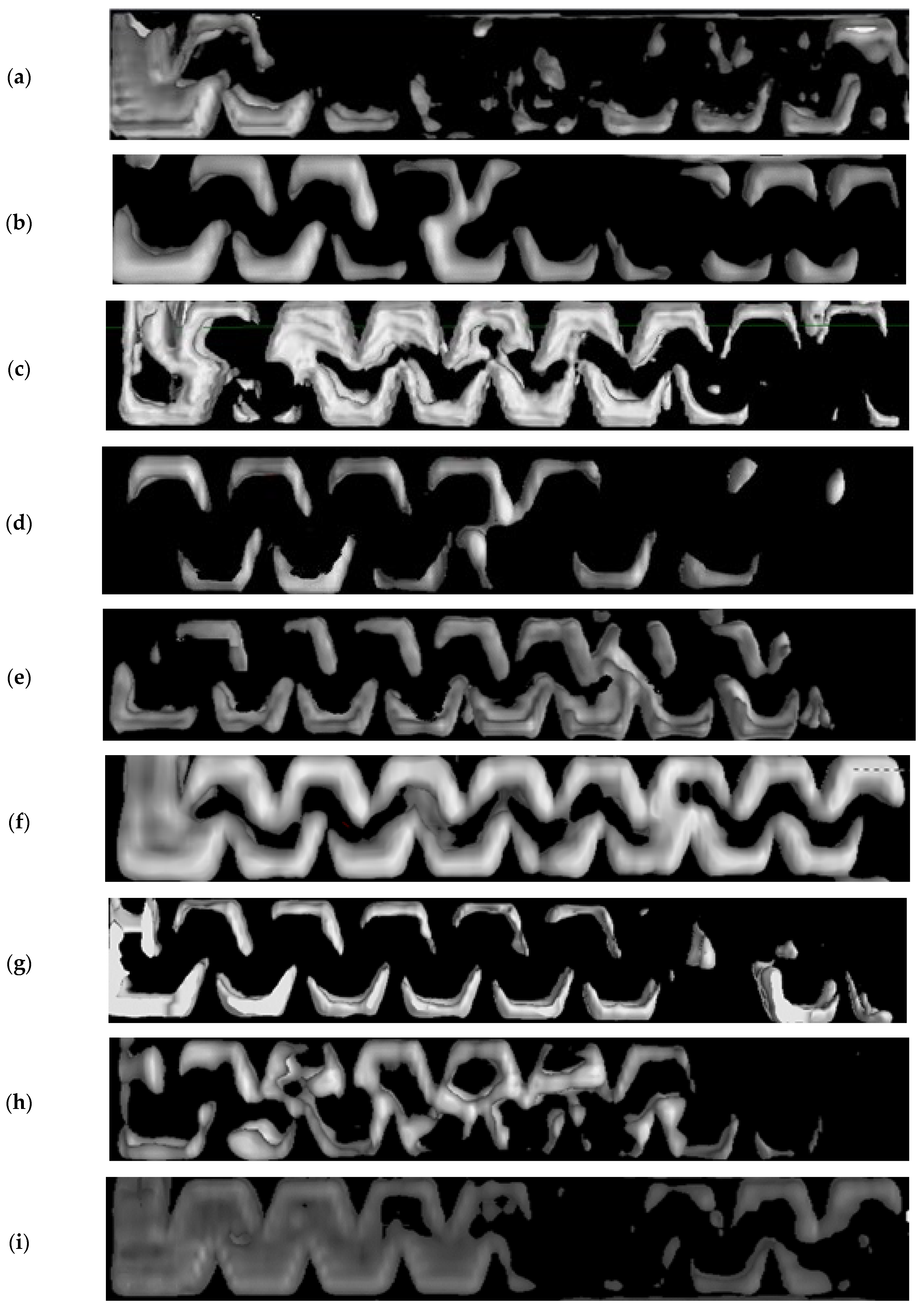

3.1. Apparent Morphology of Clogging Substances in Emitter Flow Channels

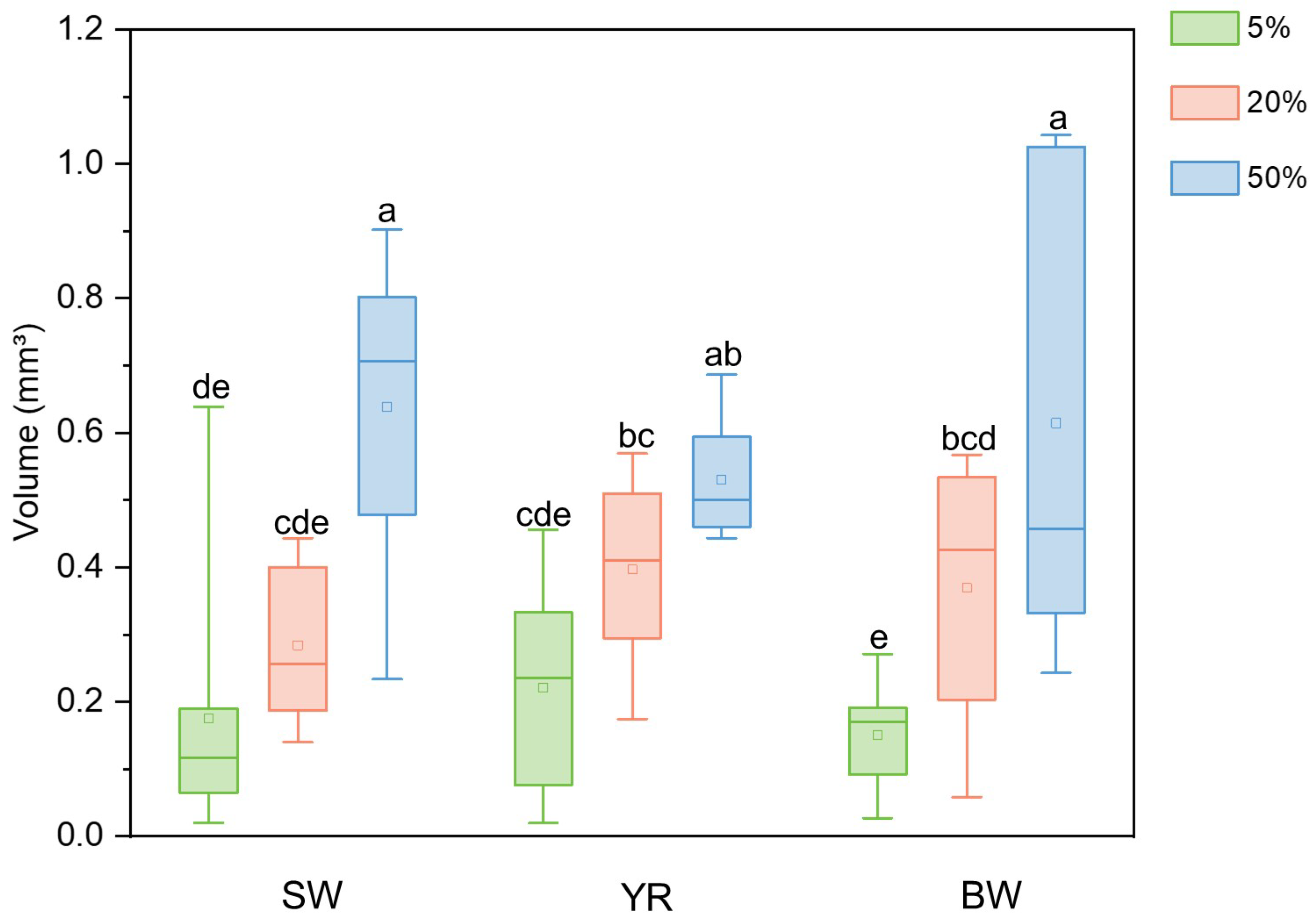

3.2. Distribution of Clogging Substances Under Different Water Sources

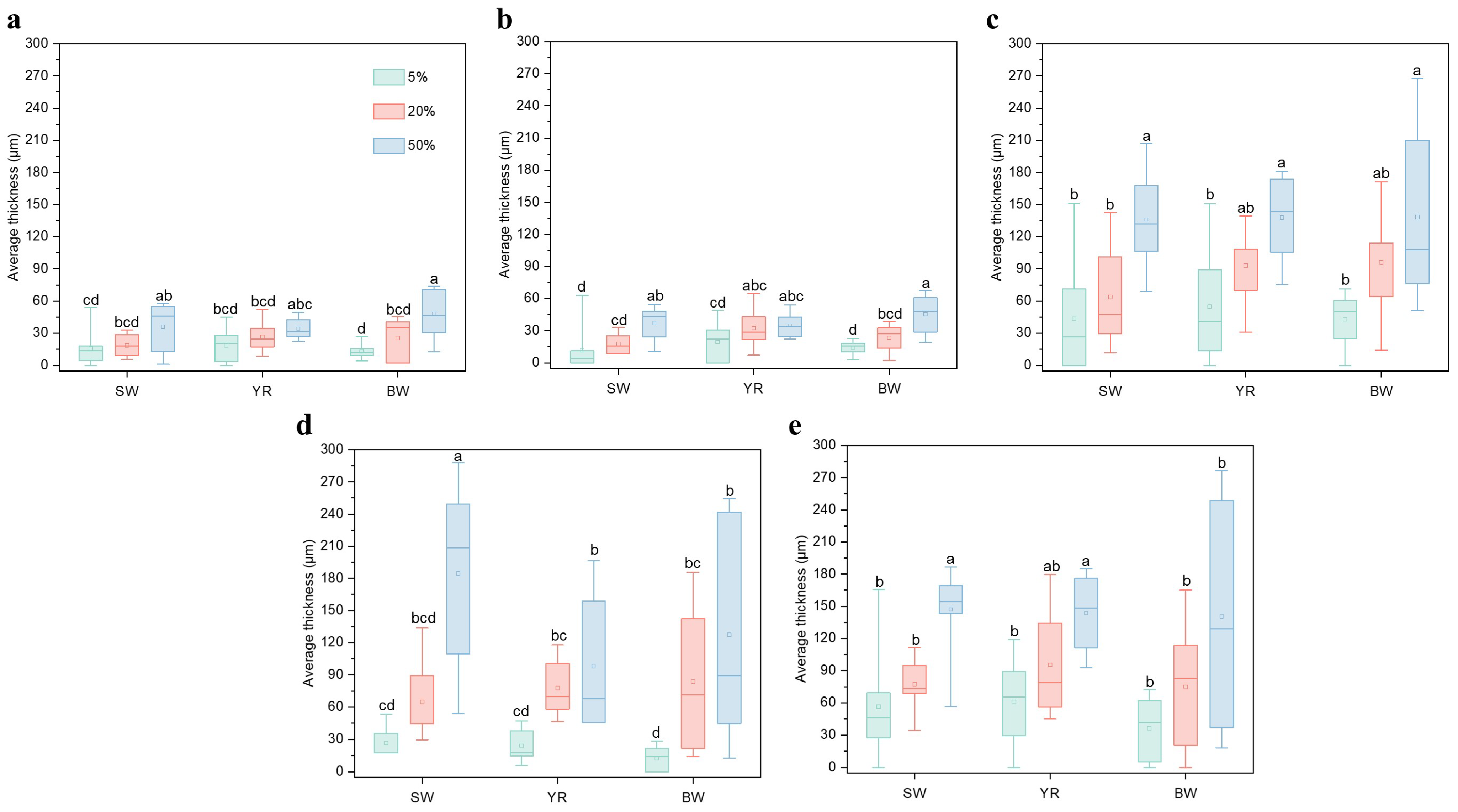

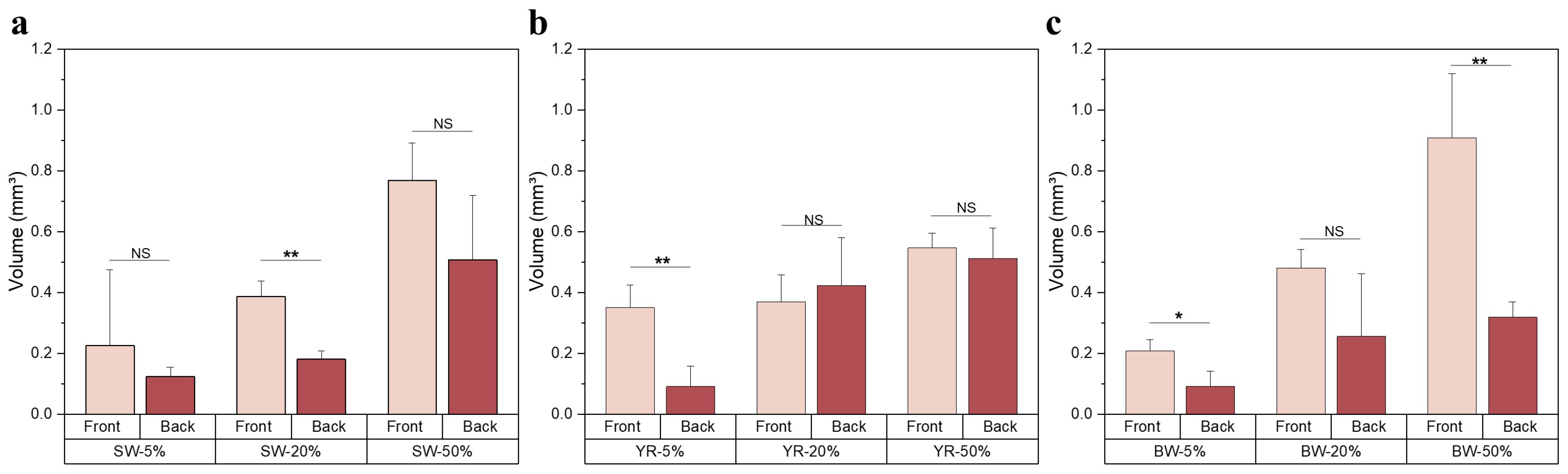

3.2.1. Distribution of Clogging Substances Within Structural Units of Emitter Flow Channels

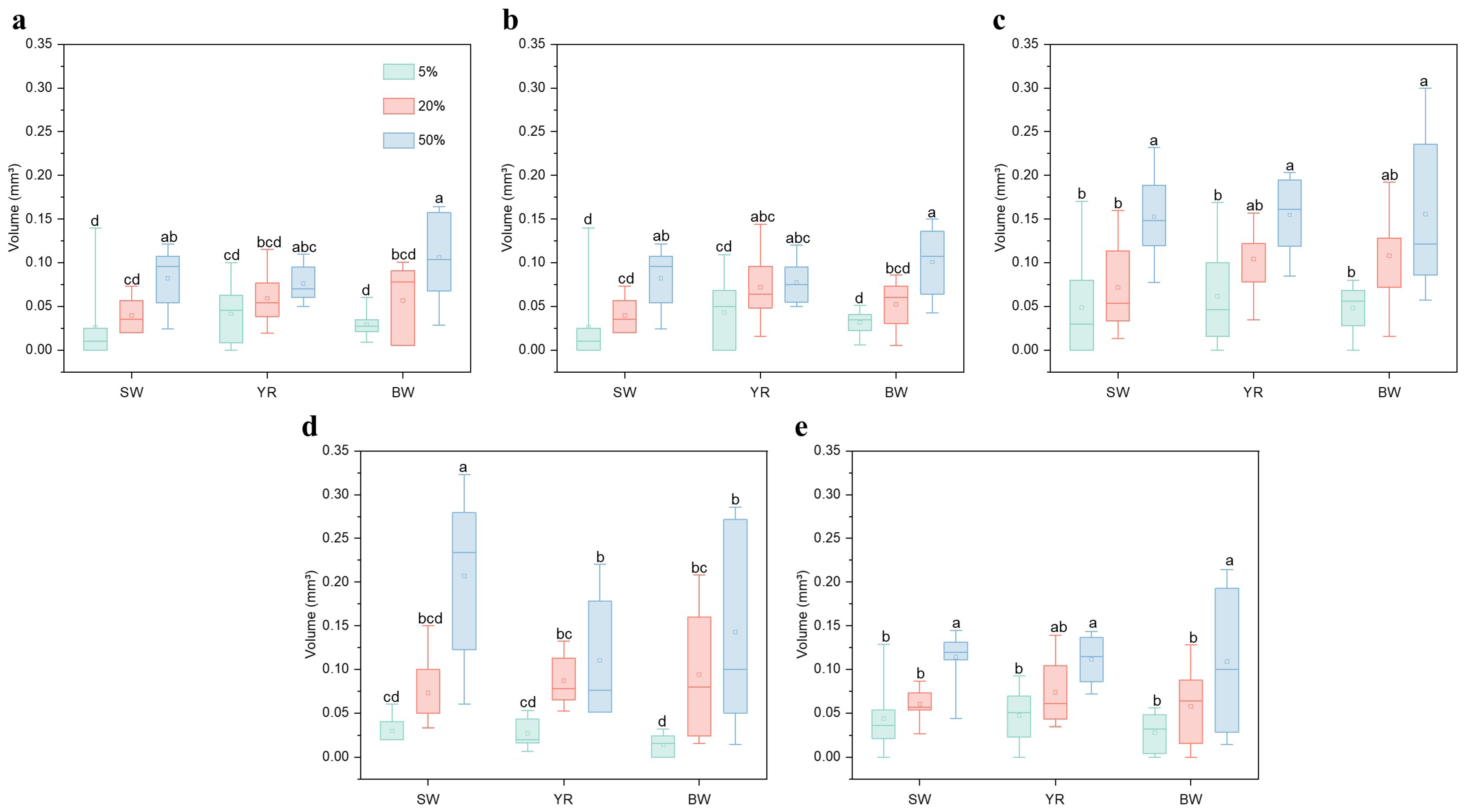

3.2.2. Distribution of Clogging Substances of Emitter Flow Channels on Different Faces

3.3. The Distribution of Clogging Substances in the Direction of Water Flow

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ICT | Industrial Computed Tomography |

| SW | saline water |

| YR | Yellow River water |

| BW | blending water |

| F | front |

| B | back |

References

- Boretti, A.; Rosa, L. Reassessing the projections of the world water development report. NPJ Clean Water 2019, 2, 15. [Google Scholar] [CrossRef]

- Gosling, S.N.; Arnell, N.W. A global assessment of the impact of climate change on water scarcity. Clim. Change 2016, 134, 371–385. [Google Scholar] [CrossRef]

- Yazdandoost, F.; Noruzi, M.M.; Yazdani, S.A. Sustainability assessment approaches based on water-energy Nexus: Fictions and nonfictions about non-conventional water resources. Sci. Total Environ. 2021, 758, 143703. [Google Scholar] [CrossRef]

- Karimidastenaei, Z.; Avellán, T.; Sadegh, M.; Kløve, B.; Haghighi, A.T. Unconventional water resources: Global opportunities and challenges. Sci. Total Environ. 2022, 827, 154429. [Google Scholar] [CrossRef]

- Skaggs, R.K. Drip irrigation in the desert: Adoption, implications, and obstacles. Agric. Water Manag. 2000, 43, 125–142. [Google Scholar] [CrossRef]

- Qiu, X.; Wang, J.; Wang, H.; Wang, C.; Sun, Y.; Li, G. Elimination of clogging of a biogas slurry drip irrigation system using the optimal acid and chlorine addition mode. Agriculture 2022, 12, 777. [Google Scholar] [CrossRef]

- Wan, S.; Kang, Y.; Wang, D.; Liu, S.P.; Feng, L.P. Effect of drip irrigation with saline water on tomato (Lycopersicon esculentum Mill) yield and water use in semi-humid area. Agric. Water Manag. 2007, 90, 63–74. [Google Scholar] [CrossRef]

- Nakayama, F.S.; Bucks, D.A. Water quality in drip/trickle irrigation: A review. Irrig. Sci. 1991, 12, 187–192. [Google Scholar] [CrossRef]

- Liu, L.; Niu, W.; Guan, Y.; Wu, Z.; Ayantobo, O.O. Effects of urea fertigation on emitter clogging in drip irrigation system with muddy water. J. Irrig. Drain. Eng. 2019, 145, 04019020. [Google Scholar] [CrossRef]

- Wang, H.; Ling, G.; Wang, W.; Hu, X.; Gao, X. A Prediction Model of Labyrinth Emitter Service Duration (ESD) under Low-Quality (Sand-Laden Water) Irrigation. Water 2022, 14, 1690. [Google Scholar] [CrossRef]

- Pei, Y.; Li, Y.; Liu, Y.; Zhou, B.; Shi, Z.; Jiang, Y. Eight emitters clogging characteristics and its suitability Under on-site reclaimed water drip irrigation. Irrig. Sci. 2014, 32, 141–157. [Google Scholar] [CrossRef]

- Puig-Bargués, J.; Lamm, F.R. Effect of flushing velocity and flushing duration on sediment transport in microirrigation driplines. Trans. ASABE 2013, 56, 1821–1828. [Google Scholar] [CrossRef][Green Version]

- Zhang, W.; Lv, C.; Zhao, X.; Dong, A.; Niu, W. The influence mechanism of the main suspended particles of Yellow River sand on the emitter clogging—An attempt to improve the irrigation water utilization efficiency in Yellow River basin. Agric. Water Manag. 2021, 258, 107202. [Google Scholar] [CrossRef]

- He, X.; Wu, P.; Zhang, L.; Wei, Y.; Liu, X.; Yang, F.; Zhou, W. Microporous ceramic emitter: A drip irrigation emitter suitable for high-sediment water. J. Water Process Eng. 2024, 67, 106169. [Google Scholar] [CrossRef]

- Li, Y.K.; Zhou, B.; Yang, P. Research advances in drip irrigation emitter clogging mechanism and controlling methods. J. Hydraul. Eng. 2018, 49, 103–114. [Google Scholar] [CrossRef]

- Chen, S.F.; He, X.L.; Wang, Z.F. Development of research on drip irrigation of saline water. Water Sav Irrig. 2010, 2, 6–9, (In Chinese with English Abstract). [Google Scholar]

- Wang, T.; Guo, Z.; Kuo, C.T. Effects of mixing Yellow River water with brackish water on the emitter’s clogging substance and solid particles in drip irrigation. SN Appl. Sci. 2019, 1, 1269. [Google Scholar] [CrossRef]

- Ding, B.; Bai, Y.; Guo, S.; He, Z.; Wang, B.; Liu, H.; Zhai, J.; Cao, H. Effect of irrigation water salinity on soil characteristics and microbial communities in cotton fields in Southern Xinjiang, China. Agronomy 2023, 13, 1679. [Google Scholar] [CrossRef]

- Slama, F.; Zemni, N.; Bouksila, F.; De Mascellis, R.; Bouhlila, R. Modelling the impact on root water uptake and solute return flow of different drip irrigation regimes with brackish water. Water 2019, 11, 425. [Google Scholar] [CrossRef]

- Qadir, M.; Quillérou, E.; Nangia, V.; Murtaza, G.; Singh, M.; Thomas, R.J.; Drechsel, P.; Schmid, E.; Donaj, D.; Noble, A.D. Economics of salt-induced land degradation and restoration. Nat. Resour. Forum. 2014, 38, 282–295. [Google Scholar] [CrossRef]

- Feng, J.; Li, Y.; Wang, W.; Xue, S. Effect of optimization forms of flowpath on emitter hydraulic and anti-clogging performance in drip irrigation system. Irrig. Sci. 2018, 36, 37–47. [Google Scholar] [CrossRef]

- Lv, C.; Zhang, E.; Gan, H.; Niu, W.; Ali, S.; Dong, A.; Zhang, W.; Sun, D. Aerated drip irrigation increased the emitter clogging risk of the Yellow River water drip irrigation. Irrig. Drain. 2023, 72, 3–20. [Google Scholar] [CrossRef]

- Zaiyu, L.; Yan, M.; Hao, G.; Shihong, G.; Yanqun, Z.; Guangyong, L.; Feng, W. The hydraulic performance and clogging characteristics of a subsurface drip irrigation system operating for five years in the North China plain. Agric. Water Manag. 2025, 307, 109217. [Google Scholar] [CrossRef]

- Benlouali, H.; Karmal, I.; Cherif Harrouni, M.; Ghanbaja, J.; Frascari, D.; Hamdani, M.; Choukr-Allah, R. Characterization of clogging deposits in an irrigation pipeline and effect of post-aeration on clogging potential of tertiary-treated wastewater. Water Sci. Technol. 2021, 83, 309–321. [Google Scholar] [CrossRef]

- Shi, K.; Zhangzhong, L.; Han, F.; Zhang, S.; Guo, R.; Yao, X. Reducing emitter clogging in drip fertigation systems by magnetization technology. Sustainability 2023, 15, 3712. [Google Scholar] [CrossRef]

- Petit, J.; Ait-Mouheb, N.; García, S.M.; Metz, M.; Molle, B.; Bendoula, R. Potential of visible/near infrared spectroscopy coupled with chemometric methods for discriminating and estimating the thickness of clogging in drip-irrigation. Biosyst. Eng. 2021, 209, 246–255. [Google Scholar] [CrossRef]

- Li, G.B.; Li, Y.K.; Xu, T.W.; Liu, Y.Z.; Jin, H.; Yang, P.L.; Zhang, F.S.; Tian, Z.F. Effects of average velocity on the growth and surface topography of biofilms attached to the reclaimed wastewater drip irrigation system laterals. Irrig. Sci. 2012, 30, 103–113. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, Y.; Sun, Z.; Shi, N.; Li, B.; Ma, C.; Xiao, Y.; Li, Q.; Li, Y. Increasing iron use efficiency by controlling emitter clogging in drip irrigation systems. Agric. Water Manag. 2023, 290, 108601. [Google Scholar] [CrossRef]

- Ribeiro, M.D.; Azevedo, C.A.D.; Santos, D.B.D.; Szekut, F.D.; Klein, M.R.; Reis, C.F. Optical microscopy and SEM for identifying clogging material in a drip irrigation system. Rev. Caatinga 2018, 31, 997–1007. [Google Scholar] [CrossRef]

- Petit, J.; García, S.M.; Molle, B.; Bendoula, R.; Ait-Mouheb, N. Methods for drip irrigation clogging detection, analysis and understanding: State of the art and perspectives. Agric. Water Manag. 2022, 272, 107873. [Google Scholar] [CrossRef]

- Yao, Y.; Shen, Y.; Ma, C.; Zhang, K.; Li, J.; Xiao, Y.; Li, Y. Spatial distribution of clogging substances in drip irrigation emitters fed with reclaimed water. Irrig. Sci. 2024, 42, 239–251. [Google Scholar] [CrossRef]

- Ma, C.; Li, M.; Hou, P.; Wang, X.; Sun, Z.; Li, Y.; Zhang, K.; Yao, Y.; Li, Y. Biofilm dynamic changes in drip irrigation emitter flow channels using reclaimed water. Agric. Water Manag. 2024, 291, 108624. [Google Scholar] [CrossRef]

- Ramachandrula, V.R.; Kasa, R.R.; Torris, A. Micro-Computed Tomography (µCT) Study of Clogging in Long-Used Strip and Cylindrical Drip Emitters. J. Inst. Eng. India Ser. A 2023, 104, 167–174. [Google Scholar] [CrossRef]

- Chiffre, L.; Carmignato, S.; Kruth, J.; Schmitt, R.; Weckenmann, A. Industrial applications of computed tomography. CIRP Ann. Manuf. Technol. 2014, 63, 655–677. [Google Scholar] [CrossRef]

- Wang, T.; Dai, X.; Zhang, T.; Xin, C.; Guo, Z.; Wang, J. Formation and microbial composition of biofilms in drip irrigation system under three reclaimed water conditions. Water 2022, 14, 1216. [Google Scholar] [CrossRef]

- Davit, Y.; Debenest, G.; Quintard, M. Multiple-scale analysis of transport in porous media with biofilms. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2010; Volume 1254, Issue 1, pp. 175–180. [Google Scholar] [CrossRef]

- Wang, W.; Xu, F.; Zhou, B.; Feng, J.; Li, Y. Structural and fractal characteristics of biofilm attached on surfaces of sediments in Yellow River for drip irrigation. J. Drain Irrig. Mach. Eng. 2014, 32, 914–920, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhou, L.; Wei, C.; Yang, P.; Li, Y.; Zhangzhong, L.; Su, Y.; Ren, S.; He, X. Effects of saline water with different concentrations of calcium and magnesium ions on emitter clogging in drip irrigation integrated water–fertilizer system. Irrig. Drain. 2024, 73, 16–28. [Google Scholar] [CrossRef]

- Zhangzhong, L.; Yang, P.; Ren, S.; Li, Y.; Liu, Y.; Xia, Y. Chemical clogging of emitters and evaluation of their suitability for saline water drip irrigation. Irrig. Drain. 2016, 65, 439–450. [Google Scholar] [CrossRef]

- Lequette, K.; Ait-Mouheb, N.; Wéry, N. Hydrodynamic effect on biofouling of milli-labyrinth channel and bacterial communities in drip irrigation systems fed with reclaimed wastewater. Sci. Total Environ. 2020, 738, 139778. [Google Scholar] [CrossRef]

- Qian, J.; Horn, H.; Tarchitzky, J.; Chen, Y.; Katz, S.; Wagner, M. Water quality and daily temperature cycle affect biofilm formation in drip irrigation devices revealed by optical coherence tomography. Biofouling 2017, 33, 211–221. [Google Scholar] [CrossRef]

- Li, Y.; Liu, H.; Yang, P.; Wu, D. Analysis of tracing ability of different sized particles in drip irrigation emitters with computational fluid dynamics. Irrig. Drain. 2013, 62, 340–351. [Google Scholar] [CrossRef]

- Shen, Y.; Puig-Bargués, J.; Li, M.; Xiao, Y.; Li, Q.; Li, Y. Physical, chemical and biological emitter clogging behaviors in drip irrigation systems using high-sediment loaded water. Agric. Water Manag. 2022, 270, 107738. [Google Scholar] [CrossRef]

- Yang, B.; Wang, F.; Wang, J.; Wang, C.; Qiu, X. Numerical simulation and optimization of the inlet structure of dentiform emitters in drip-irrigation systems. Biosyst. Eng. 2024, 246, 183–190. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Wang, C.; Wang, S.; Qiu, X.; Sun, Y.; Li, G. Characterization of labyrinth emitter-clogging substances in biogas slurry drip irrigation systems. Sci. Total Environ. 2022, 820, 153315. [Google Scholar] [CrossRef]

| Water Source | pH | Suspended Solids mg/L | Specific Conductance μm/cm | Mineralization of Water mg/L | CODCr mg/L | BOD5 mg/L | Total Phosphorus mg/L | Total Nitrogen mg/L | Calcium mg/L | Magnesium mg/L |

|---|---|---|---|---|---|---|---|---|---|---|

| SW | 9.2 | <5 | 9460 | 4760 | 24.8 | 4.2 | 0.16 | 2.04 | 321 | 127 |

| YR | 7.7 | 41 | 796 | 483 | 6.8 | 1.7 | 0.06 | 1.48 | 54.7 | 25.7 |

| The Top Face | The Substrate Face | The Upstream Face | The Downstream Face | The Root Face |

|---|---|---|---|---|

| 2.2248 mm2 | 2.2248 mm2 | 0.561 mm2 | 0.561 mm2 | 0.3876 mm2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, Y.; Xiao, Y.; Hou, P.; Li, S. Evaluating the Influence of Water Quality on Clogging Behavior in Drip Irrigation Emitters: A CT Imaging Study. Water 2025, 17, 1065. https://doi.org/10.3390/w17071065

Yao Y, Xiao Y, Hou P, Li S. Evaluating the Influence of Water Quality on Clogging Behavior in Drip Irrigation Emitters: A CT Imaging Study. Water. 2025; 17(7):1065. https://doi.org/10.3390/w17071065

Chicago/Turabian StyleYao, Yuqian, Yang Xiao, Peng Hou, and Shuqin Li. 2025. "Evaluating the Influence of Water Quality on Clogging Behavior in Drip Irrigation Emitters: A CT Imaging Study" Water 17, no. 7: 1065. https://doi.org/10.3390/w17071065

APA StyleYao, Y., Xiao, Y., Hou, P., & Li, S. (2025). Evaluating the Influence of Water Quality on Clogging Behavior in Drip Irrigation Emitters: A CT Imaging Study. Water, 17(7), 1065. https://doi.org/10.3390/w17071065