Abstract

This study addresses the increasing demand for sustainable water production by investigating the integration of solar energy into a multi-effect desalination (MED) plant located in Zuara, Libya. It is acknowledged that regions with high water demand frequently experience elevated levels of solar radiation; thus, this approach seeks to reduce dependence on fossil fuels and mitigate harmful emissions. Three operational modes were analyzed and compared: (1) daytime-only solar operation, (2) hybrid solar–boiler operation, and (3) solar operation with thermal energy storage. A validated mathematical model, informed by real empirical data, was used to assess energy and exergy efficiencies as well as production costs per cubic meter of desalinated water. The results indicate a trade-off between cost-effectiveness and environmental impact. The fossil fuel-based mode demonstrated the highest energy efficiency but also produced the greatest pollution. Conversely, the solar-only daytime mode, while free of emissions, was the costliest (USD 1.4/m3) due to its limited operational hours. The hybrid mode offered a compromise, presenting lower costs (USD 0.79/m3) and moderate land use, yet it still relied on fossil fuels. The thermal storage mode facilitated continuous, clean desalination at a higher cost (USD 0.97/m3) and required the largest solar field area. This study demonstrates the potential of solar-powered MED plants for sustainable water production, particularly in regions characterized by abundant sunlight and water scarcity. Furthermore, this research provides a comprehensive framework for selecting the optimal operational mode based on specific priorities, such as minimizing environmental impact, reducing costs, or maximizing operational flexibility.

1. Introduction

Water desalination is currently experiencing significant advancements and heightened interest, as it represents a crucial method for addressing the persistent shortage and escalating demand for freshwater resources. Desalination can be categorized into two main types: the conversion of saltwater from the liquid phase to the gaseous phase, followed by re-condensation to yield freshwater, and membrane desalination, which separates salt particles from the water without transitioning to the gas phase. A range of desalination processes is under development, aimed at enhancing thermal efficiencies and minimizing carbon emissions [1].

The integration of renewable energy sources with desalination systems presents significant potential for improving potable water supplies in arid regions. This approach effectively addresses water scarcity by utilizing local energy sources that do not contribute to air pollution or exacerbate to the global climate change crisis. Furthermore, as fuel prices continue to rise and fossil fuel reserves diminish, the financial costs associated with desalination and renewable energy systems progressively decrease. This trend can be attributed, in part, to the diverse range of possible configurations between renewable energy technologies and desalination methods [2].

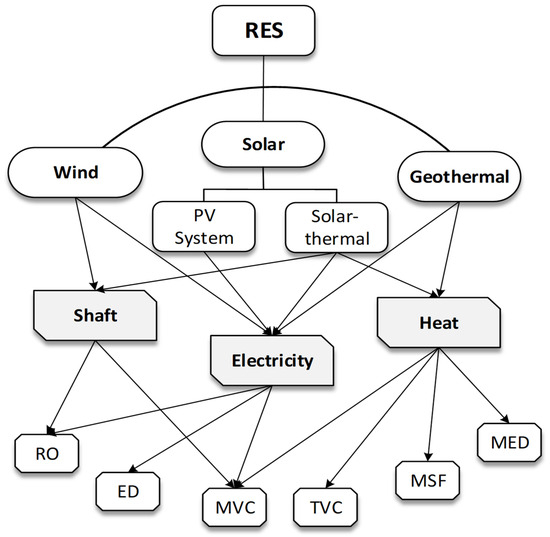

1.1. Renewable Energy-Powered Desalination

Renewable energy sources (RES), such as wind, solar, and geothermal, offer a viable and sustainable alternative for the operation of desalination plants (Figure 1). The utilization of locally available resources has the potential to mitigate the environmental impact and lower the costs associated with desalination, which currently generates over 70 million cubic meters of water daily [3]. Research indicates that the integration of renewable energy not only enhances operational performance but also reduces production costs and improves accessibility, particularly in remote regions [4]. Currently, renewable energy accounts for approximately 1% of the total global desalination capacity. Among renewable energy-powered desalination facilities, reverse osmosis (RO) technology is the most widely utilized, comprising 62% of the capacity, followed by multi-stage flash (MSF) and multi-effect distillation (MED) technologies. Photovoltaic (PV) solar cells represent the predominant renewable energy source, contributing 43% of the total, with solar thermal and wind energy following in prevalence [5]. Abdelkarim et al. [6] investigated the compatibility of solar, geothermal, and wind energy sources with various desalination technologies. Their findings indicate that solar collectors are particularly effective for thermal desalination methods such as MED and MSF. In contrast, wind energy and PV solar energy are deemed more suitable for RO and electrodialysis processes. Notably, RO desalination powered by PV solar energy was identified as the most promising option. Panagopoulos [7] conducted a comprehensive review of desalination technologies and renewable energy sources (RES), emphasizing the advancements in RES that facilitate the desalination of diverse brine solutions. The review also addresses the associated challenges, environmental concerns, and potential future research directions. Additionally, Koroneos et al. [8] developed an integrated model that combines wind and solar energy for the purpose of saltwater desalination, highlighting the factors that influence the selection of renewable energy sources as well as the cost implications of the produced water. Shouman et al. [9] investigated the economics of desalination powered by renewable energy, with a particular emphasis on PV-powered reverse osmosis systems. Their case study revealed that PV/saline water reverse osmosis (SW-RO) systems can produce water at a cost that is competitive with that of fossil fuel-powered plants, thereby underscoring both the economic and environmental advantages of such technologies. Feria et al. [10] conducted a comprehensive review of commercial thermal desalination technologies that are powered by renewable energy sources, specifically focusing on MED, MSF and pressure vapor distillation (PVD). Their analysis encompassed the historical development and prevailing trends within the field, while also summarizing the potential for integrating renewable energy. Furthermore, they highlighted key research priorities, including the enhancement of efficiency, the optimization of energy recovery, and the advancement of hybridization modeling.

Figure 1.

Integration of renewable energy sources with a desalination process [4].

1.2. Solar Desalination Systems

Solar energy can be harnessed either directly, as exemplified by solar stills, or indirectly, through the use of solar collectors for thermal desalination and photovoltaic cells for membrane desalination, to facilitate the desalination of water [11,12,13,14]. A significant body of research has been dedicated to assessing and improving the performance of solar desalination systems, as well as to minimizing associated costs. Younes [11] investigated an innovative active solar desalination system that utilizes a Fresnel focus point, achieving a maximum specific production capacity of 7.3 kg/m2, which is nearly double that of traditional fixed solar basins. The system demonstrates an efficiency of 57%, in contrast to the 35% efficiency observed in solar stills. Additionally, it has a unit production cost of USD 0.0224 per kilogram and an estimated payback period of 11 months. Arunkumar et al. [12] conducted experiments on various designs of solar stills and determined that concentrator-linked compound parabolic concentrator (CPC) tubular stills yield the highest efficiency due to the concentration effect. Additionally, environmental factors such as weather conditions and water temperatures significantly influence solar energy generation, with the concentrator effect being instrumental in elevating water temperature. Mohaisen et al. [13] studied the impact of a condensation cavity on the performance of passive solar desalination systems. The cavity functions as an internal cooling mechanism, thereby enhancing both evaporation rates and freshwater production. The findings indicate that 30% of the freshwater was condensed on the inner surface of the cavity, highlighting a straightforward and economically viable enhancement to the system. Ranjan and Kaushik [14] conducted an investigation into the energy and exergy characteristics of active solar distillation systems that incorporate solar ponds, concluding that such systems are commercially viable. The integration of a solar pond within an active solar system resulted in an increase in daily output to 9.5 L/m2, an enhancement of energy efficiency to 46%, and an improvement in exergy efficiency to 14.81%. The continuous supply of thermal energy, in conjunction with solar radiation, significantly enhances the performance of the system.

Libya relies exclusively on energy production and water desalination through the combustion of conventional fossil fuels. Despite its extensive coastline and abundant solar radiation, the nation faces persistent water shortages, underscoring a significant lack of adoption of renewable energy for water desalination. This study proposes a model to harness solar energy and integrate it with conventional energy sources to enhance water production, offering a sustainable and efficient solution to address Libya’s water scarcity challenges.

1.3. Integration of Solar Energy with Desalination Plants

The integration of solar energy with desalination plants is increasingly recognized as a promising solution to meet growing demands for water and energy. This approach is particularly advantageous due to the compatibility between desalination systems and solar technologies, offering the potential to reduce carbon emissions associated with conventional energy sources.

Numerous studies have highlighted the benefits and challenges of coupling solar power with desalination. For example, Omar et al. [15] reviewed five concentrated solar power and desalination (CSP-D) designs, emphasizing the complexity of identifying the most practical integration methods. Their findings show that waste heat coupling and electrolyte-driven reverse osmosis (RO) systems yielded the best technical and economic outcomes, although significant losses in condenser water and energy posed challenges.

Chandrashekara and Yadav [16] analyzed various solar thermal desalination technologies, concluding that indirect methods are more suitable for medium- to large-scale systems, while simpler solar stills are better for small-scale applications. They noted that using locally available materials can enhance the performance of low-cost solar stills, which are straightforward to construct and meet daily drinking water needs.

Stroud [17] conducted a thermodynamic analysis of solar desalination systems, modeling ten facilities using concentrated solar thermal multi-effect distillation (MED) and photovoltaic-powered reverse osmosis (PV-RO). The study revealed that PV-RO utilizing liquid plant waste was economically favorable in the short term, though long-term efficiency was limited by the inherent thermodynamic constraints of desalination and solar energy conversion.

Other studies explored the potential of advanced solar-driven desalination technologies. Abdul Rahman [18] examined multi-stage humidifiers powered by solar thermal energy, finding that their efficiency improved with more stages. The research highlighted the importance of optimizing surface air velocity and water column height for effective humidification, particularly in remote regions. Hamed et al. [19] compared a fossil-fuel thermal desalination plant with a Fresnel solar system, demonstrating that Fresnel systems significantly reduced fuel costs in areas with high direct normal irradiance (DNI).

Alhaj and Al-Ghamdi [20] applied a life cycle assessment to concentrated solar power and seawater desalination systems, showing a 47% reduction in CO2 emissions compared with conventional thermal desalination. Their study emphasized the critical relationships between solar intensity, seawater properties, and environmental impacts.

Palenzuela et al. [21] investigated various configurations for integrating desalination facilities with parabolic trough (PT) solar power plants. Their analysis indicated that incorporating low-temperature multi-effect distillation (LT-MED) with a CSP plant achieved the highest thermodynamic efficiency. Similarly, Zuo et al. [22] evaluated a solar chimney system designed for freshwater generation, demonstrating its feasibility for combined processes of desalination, humidification, and atmospheric water extraction. Their findings underscore the potential to optimize evaporation and condensation using solar chimney flow dynamics.

While solar desalination systems often entail higher initial costs than traditional methods, their environmental benefits and long-term potential make them a valuable solution for sustainable freshwater production. However, further research is needed to address existing limitations and enhance their efficiency and cost-effectiveness

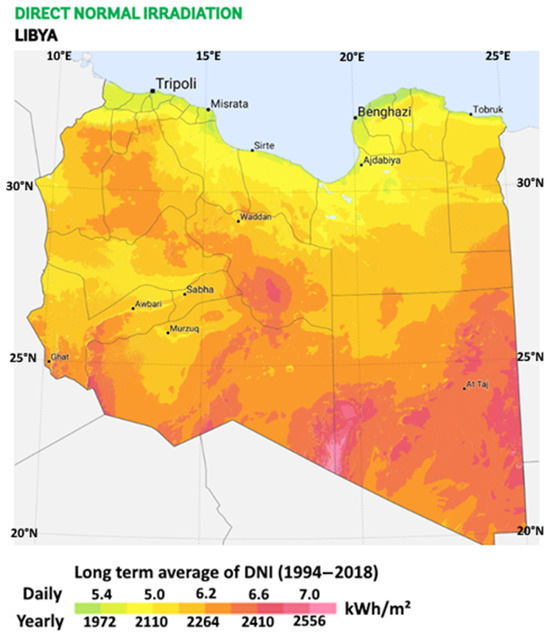

Libya serves as a pertinent example of the dangers associated with drought. It is the second largest country in north Africa, with an area of approximately 1,760,000 km2 with latitudinal coordinates ranging from 19° to 34° N and longitudinal coordinates extending from 9° to 26° E. The country features a Mediterranean coastline that spans approximately 1770 km. As illustrated in Figure 2, the global mean total solar radiation on a horizontal surface varies between 1600 and 2300 kWh/m2 [23].

Figure 2.

Map of Libya showing the yearly and daily average direct normal irradiance (DNI) [24].

The objective of this study is to investigate the integration of solar energy with thermal desalination plants using real industrial data. The Zuara desalination plant, located 100 km west of Tripoli, the capital of Libya, was selected as a model for implementing this integration. This facility operates as a multi-effect distillation (MED) system without thermal vapor compression. A mathematical model was developed to simulate the functioning of the MED installation, and the obtained results were validated against the real data collected from the Zuara desalination plant. This specific type of MED installation is characterized by a low top brine temperature (TBT) of approximately 70 °C, with the operational requirements necessitating saturated steam at low pressure. In this study, it is posited that the saturated steam can be generated from concentrated solar power collectors. This type of collector is deemed suitable for such applications due to its simplicity, ease of manufacture and installation, low cost, high performance, and medium operating temperature, which align well with the requirements of thermal desalination processes.

2. Mathematical Modeling, Results and Authentication with Real Data

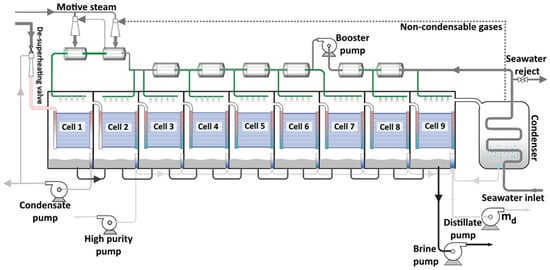

The multi-effect distillation (MED) system operates on the principle of thermal vapor recycling to produce freshwater from seawater. In the first effect, seawater is heated using an external heat source, such as steam from a boiler or solar collectors, causing a portion of the feedwater to evaporate into water vapor while leaving behind concentrated brine. The water vapor produced in each stage is condensed to form freshwater, while its latent heat is transferred to the next stage to evaporate more seawater. This process is repeated across multiple effects, each operating at progressively lower temperatures and pressures, which enhances thermal efficiency.

By recycling latent heat across multiple stages, MED systems achieve high energy efficiency and reduced energy consumption compared with other thermal desalination methods. The brine is discharged as waste, while the condensed vapor is collected as freshwater. MED systems are especially effective for large-scale desalination projects and are well suited for integration with renewable energy sources, such as solar power, to further enhance sustainability.

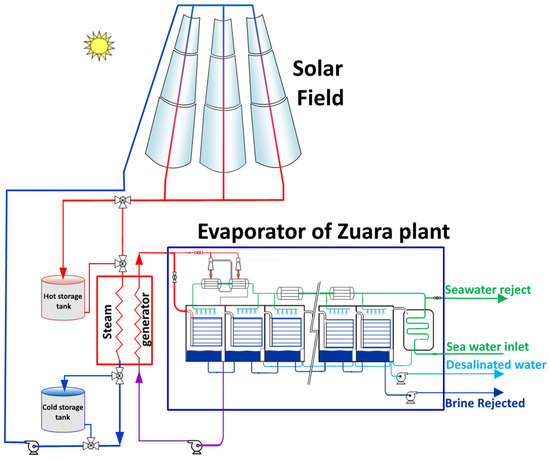

Figure 3 represents a schematic diagram of the evaporator utilized in the Zuara desalination plant.

Figure 3.

Schematic representation of the plant evaporator.

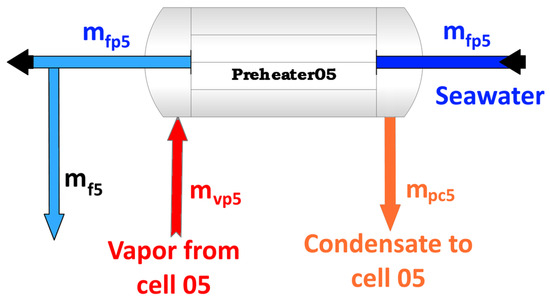

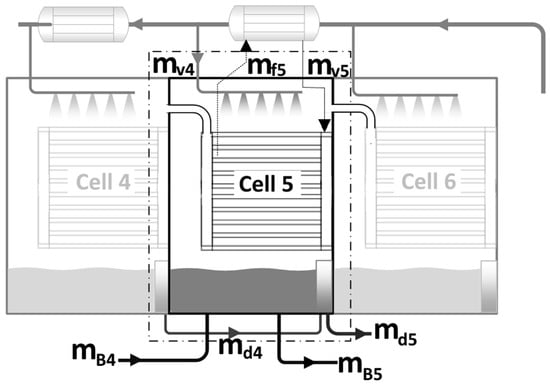

A steady-state mathematical model of a multi effect desalination system without a thermal vapor compressor, along with its solution procedure, was presented in our previous study [25]. Figure 4 and Figure 5 represent examples of the mass and energy balance equations for Preheater 05 and Cell 5, respectively. These equations are expressed as follows:

Figure 4.

Preheater 05 mass flow rates.

Figure 5.

Cell 05 mass balance.

2.1. Preheater 05

Mass balance equation:

Energy balance equation:

where , and represent the mass flow rates of the feed water, inlet vapor and water condensate for Preheater 05, respectively. denote the enthalpies of the feed water, inlet vapor and water condensate for Preheater 05, respectively.

2.2. Cell 5

Mass balance equation:

Energy balance equation:

In this context, , respectively represent the mass flow rates of vapor, brine, and distillate water at the outlet of Cell 04 and at the inlet of Cell 05. Additionally, denotes the feed water for Cell 05, while correspond to the mass flow rates of vapor, brine, and distillate water at the outlet of Cell 05 and the inlet of the subsequent cell, respectively.

Salinity balance equation:

The salinity of vapor, condensate and distillated water is assumed to be equal to zero.

Table 1 presents the specifications of the MED.

Table 1.

Specifications of the MED.

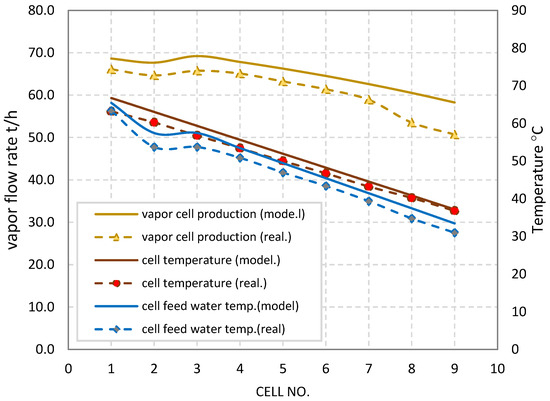

Figure 6 represents both numerical and experimental results, depicting the production of vapor cells, cell temperature, and cell feed water temperature. It is observed that the temperature of the cells decreases from the first to the ninth cell, as the heat source is introduced at the first cell and is subsequently reduced over the course of the process. Consequently, the quantity of vapor produced by the cells diminishes with the decreasing cell temperature, despite the feed water amount remaining constant across all cells. This reduction in steam production can be attributed to the lower temperature of the feed water, as it is well established that the rate of evaporation is directly proportional to the water temperature. Notably, there is a strong correlation between numerical and experimental data.

Figure 6.

Comparison between real and model results.

3. Applications of Solar Integration

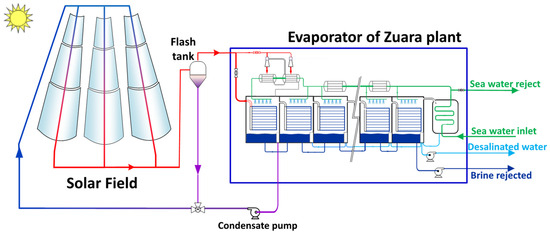

The integration of solar energy into multi-effect water desalination processes can be categorized into three distinct modes:

- Direct steam generated from solar collectors during daytime operation only (Figure 7).

Figure 7. Solar integration of the Zuara desalination plant, Mode 1.

Figure 7. Solar integration of the Zuara desalination plant, Mode 1. - Direct steam generated from solar collectors during daytime, while boilers operate at night (Figure 8).

Figure 8. Solar integration of the Zuara desalination plant (boiler operated with solar collectors), Mode 02.

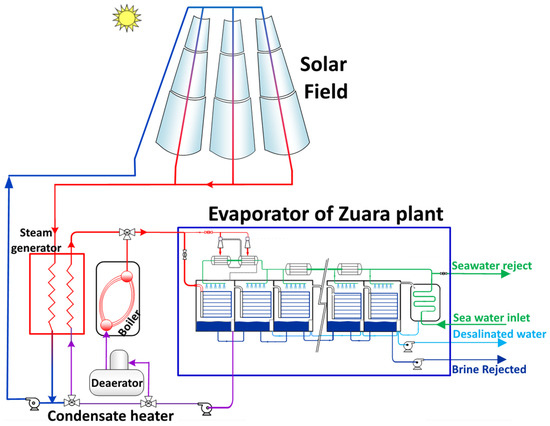

Figure 8. Solar integration of the Zuara desalination plant (boiler operated with solar collectors), Mode 02. - Full direct steam generated from solar collectors to ensure continuous operation throughout the day, supported by a thermal storage system (Figure 9).

Figure 9. Solar integration of the Zuara desalination plant (solar collectors with thermal storage tanks), Mode 03.

Figure 9. Solar integration of the Zuara desalination plant (solar collectors with thermal storage tanks), Mode 03.

3.1. Mode 1: Direct Steam from Solar Collectors

In this mode, shown in Figure 7, all steam required by the system during daytime, is generated by parabolic solar collectors. The use of direct steam generation within the absorber tubes, as opposed to employing a primary oil loop coupled with a secondary water/steam loop, presents several advantages. This approach reduces the necessity for additional equipment and minimizes the auxiliary energy required for pumping, while also eliminating the need for costly heat transfer oil [26].

The concept of direct steam generation in a PTC collector is attractive due to the latent heat transfer process, which limits the operating temperature of the collector to the vapor conduction temperature. This particular system operates at lower temperatures and pressures, potentially utilizing a reduced flow rate and exhibiting lower parasitic energy consumption compared with a vapor flash system, which does not incorporate a flash valve. In comparison with a boiler system, which does not utilize fuel combustion; the on-site system demonstrates superior performance at low temperatures, as water is both cost-effective and commonly employed as a heat transfer fluid.

A flash tank separates steam from hot water by utilizing a pressure drop that causes some of the hot water to flash into steam. Its key components include inlet and outlet nozzles for water entry and exit, a steam outlet at the top for collecting flash steam, and a water drain at the bottom for discharging residual hot water. It also features a pressure relief valve for safety, a level control system to maintain optimal water levels, and insulation to minimize heat loss and enhance efficiency.

3.1.1. Required Thermal Energy

The thermal energy required to complete the desalination process under maximum load conditions can be calculated using the following equation:

where is the steam heat rate inlet desalination unit in (kW), is the saturated steam mass flow rate inlet cell 1 in (kg/s), is the specific enthalpy of saturated steam inlet cell 1 in (kJ/kg), and is the specific enthalpy of condensate water outlet cell 1 in (kJ/kg).

In addition to the heat energy required to operate there are steam extractors to establish a pressure vacuum within the system, as follows:

where is the heat rate inlet steam ejectors in (kW), is the steam mass flow rate inlet ejectors in (kg/s), is the specific enthalpy of saturated steam inlet ejectors in (kJ/kg), and is the specific enthalpy of condensate water outlet ejectors in (kJ/kg).

The total heat energy required for the production of distillate water is equal to the sum of components and , as follows:

Which pertains to an individual distillate unit and can be extrapolated to encompass the entire desalination facility.

The thermal energy required must be supplied by solar energy, while ensuring consistent temperature and pressure of conditions of the steam, using solar parabolic collectors as shown in Figure 7.

3.1.2. Collectors’ Area

The dimensions and surface area of solar collectors are important in estimating the main costs associated with solar energy systems. Several factors affect the calculation of the area required for solar collectors to fulfill energy demands. These factors include solar intensity expressed in (W/m2), as well as absorptivity, emissivity, mean temperature of the absorber tube and the tilt angle of the collector.

The required area of the PTC collector is given by [27]:

where A represents the aperture area in m2, denotes the average daily solar radiation in kWh/m2/day, indicates the collector efficiency, and Δt refers to the average daily operating hours of solar energy collection.

For the overall plant, the total heat generated by collectors should be equivalent to the total heat required to complete the desalination process and produce the distilled water.

The following assumptions have been established to simplify the calculation of the area needed for solar collection:

- The solar collector used in this study is a parabolic trough collector, which represents a specific category of linear focus systems;

- The average daily solar radiation ) in Zuara city is 5.4 kWh/m2/day [28];

- Solar collector efficiency is 65% [29];

- The average daily operating hours for solar energy collection is approximately 8 h [28];

- The estimated lifespan of the collector is 20 years.

The parameters of the desalination plant utilized for the calculation of the solar collectors’ area are summarized in Table 2.

Table 2.

Design parameters of the Zuara desalination plant [30].

3.2. Mode 2: Solar Collectors with Steam Boilers

In this operational mode, steam necessary for the system’s functionality during daylight hours is generated by parabolic solar collectors. Conversely, during nighttime, steam production is facilitated by boilers to maintain the continuous operation of the evaporators and the subsequent production of desalinated water (Figure 8). A notable drawback of this mode is the reliance on fuel, which causes the emission of pollutants into the surrounding environment.

3.3. Mode 3: Solar Collectors Coupled with an Energy Storage System

This proposal examines the feasibility of operating the desalination plant by supplying steam from solar collectors throughout the entire day, using a thermal energy storage system.

Therminol VP-1 is an ultra-high temperature synthetic heat transfer fluid that is suitable for various applications owing to its excellent heat transfer properties. It effectively combines exceptional thermal stability with low viscosity, ensuring consistent and reliable performance across a broad temperature range of 12 °C to 400 °C [31].

The seasonal storage is assumed to be a ground cylindrical tank with a shape ratio of RHD = 0.6 (height divided by diameter). Once the volume is known, the other dimensions can be calculated. The volume of the tank is calculated by knowing the amount of thermal energy to be stored, the temperature difference and the properties of the fluid as follows [32].

where is the volume of the thermal storage tank in m3, D is storage tank diameter in m, H is storage tank height in m, th is the thermal heat rate needed in kW, is the thermal fluid density in kg/m3, is the thermal fluid specific heat in kJ/kg.K, is the thermal fluid maximum temperature in °C, and is the thermal fluid minimum temperature in °C.

This operational mode depends on the deployment of a greater number and larger area of solar collectors compared with previous modes, ensuring the provision of the requisite thermal energy necessary for the operation of the desalination plant during daylight hours, as well as the energy needed for nighttime operation. The additional energy is stored using the thermal storage tank system, which employs thermal fluid for this purpose, as shown in Figure 9. A significant advantage of this mode is the elimination of fuel usage, thereby reducing pollution and enabling continuous operation of the unit. However, it is important to note that the solar field required for this mode will be larger than that of the other operational modes.

3.4. Energy and Exergy Efficiencies for the Proposed Modes

The energy efficiency, as defined by the first law of thermodynamics, of a solar desalination system is expressed as the ratio of the useful energy consumed in the evaporator to the solar radiation received by the collectors. This relationship can be formulated as follows:

Exergy represents the maximum potential of a system to perform useful work as it moves toward thermodynamic equilibrium with a defined environment. It quantifies the maximum useful energy that can be harnessed from a system, considering both the first law of thermodynamics (energy conservation) and the second law of thermodynamics (irreversibilities and entropy generation).

Exergy efficiency, also known as second-law efficiency or rational efficiency, quantifies the effectiveness with which a system transforms available exergy into useful work under real (irreversible) conditions compared with ideal (reversible) conditions. This efficiency is determined by the ratio of useful exergy output to total exergy input.

The total exergy input to the system in Mode 01 is equal to the sum of the exergies derived from solar radiation and seawater entering the system [33]:

In this context, represents the dead state temperature in K, while denotes the equivalent temperature of the sun as a blackbody (5800 K).

In addition, by neglecting the chemical exergy, the physical exergy of the seawater entering the system can be expressed as follows:

here are the specific enthalpies of seawater in at the inlet temperature and at temperature, respectively. represent the specific entropies of seawater in also at inlet temperature and at temperature, respectively.

The total exergy output from the system is equivalent to the sum of the exergy outputs associated with both brine and distillate water, as indicated in [34].

In Mode 2, which involves the integration of solar energy with thermal steam generation to provide the necessary steam for production, both thermal and exergy efficiencies are assessed. The average efficiency for each type is computed over the entire operational period. These calculations are conducted using the following equations:

is the fuel exergy factor, which depends on the fuel type.

The physical exergy of the boiler air inlet, assumed to behave as an ideal gas, is calculated as follows [35]:

The physical exergy of combustion gases outlet, assumed to behave as an ideal gas, is calculated as follows [36]:

Here is the gas specific heat in and is the gas constant in

As for Mode 3 of the study, which employs solar collectors during the whole day in conjunction with thermal storage tanks, the average exergy efficiency is calculated using the following equations:

where and represent the physical exergy at the inlet and the outlet of the system, respectively, as conveyed by the heat transfer fluid stream, in kW.

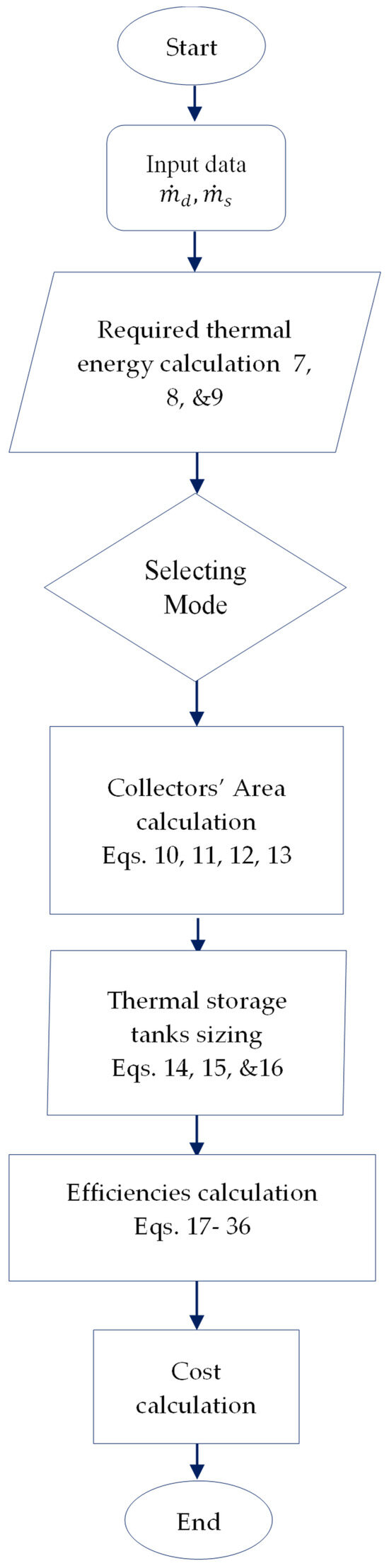

The solving steps are summarized in the flow chart presented in Figure 10.

Figure 10.

Equation solving flow chart.

3.5. Economic Visibility Study

The economic feasibility study of integrating solar energy into desalination plants is essential for analyzing the cost per cubic meter of water both before and after the conversion. The total cost of producing a cubic meter of water includes fixed and variable costs. The variable costs include expenditures on fuel, electricity, chemical consumables, labor wages, and maintenance.

The costs incurred following the conversion process remain consistent with those prior to the modification, with the exception that the expenses associated with the procurement and installation of solar collectors are added to the fixed costs, while the cost of fuel is deducted from the variable costs.

4. Results and Discussion

An experimental investigation of multi-effect desalination plants without a thermal vapor compressor was developed. The equations of the mathematical model were solved using the Python (3.12) programming language. Microsoft Excel was then employed to compare the model’s results with actual readings and to generate the corresponding curves.

The results presented herein were derived from a mathematical model specifically designed for a desalination plant that operates without vapor compressors. This model underwent validation through the utilization of empirical data sourced from the Zuara desalination plant, which also operates without vapor compressors. The Zuara desalination facility comprises three evaporators, each with a capacity of 13,334 m3/day. The real data used represent the average of a single operational day for each unit, as reported by Muftah et al. [37]. The costs associated with the supply and installation of solar collectors, as presented in the subsequent results, are obtained from Gaia Solar [38], a Chinese company specializing in this sector. The design parameters of the parabolic trough collector used in the following analysis are shown in Table 3.

Table 3.

Basic parameters of the solar collector manufactured by Gaia Solar [38].

One of the most important parameters for the success of this study is the identification of the necessary collector area. This area is determined through the application of Equations (3)–(10), utilizing the design parameters presented in Table 1. The heat rates for the evaporator, ejector and total inlet, in addition to the required area for collectors, are detailed in Table 4.

Table 4.

Required heat for desalination and area of solar collectors.

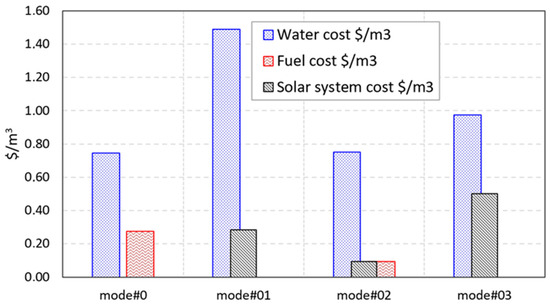

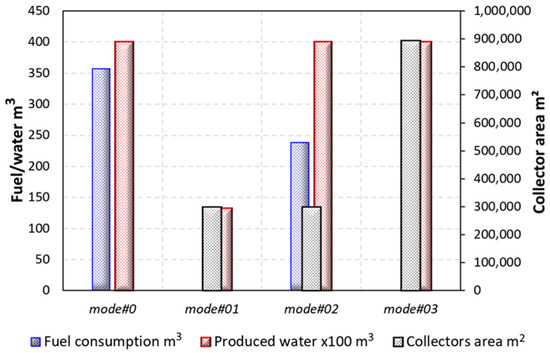

Table 5 shows a comparative analysis of the three operational modes in addition to mode 0, which represents the thermal desalination plant without the integration of solar energy. This comparison is based on several criteria, including the cost per cubic meter of produced desalinated water, the level of environmental pollution generated, and the area required for the solar field. Environmental pollution is quantified by the amount of fuel consumed.

Table 5.

Comparison between different modes.

Figure 11 shows the relationship among the cost associated with produced water, fuel, and solar system across the three modes under investigation. The cost of water is highest in the first mode, while fuel costs are elevated in Mode 0 and Mode 2. Notably, fuel costs are absent in the first and third modes, as these rely exclusively on solar energy. The primary advantage of these two modes lies in their beneficial effects on the environment, categorizing them as environmentally clean processes. In contrast, Mode 0 exerts the most significant negative impact on the surrounding environment, as it operates solely as a pure thermal process.

Figure 11.

Comparison of the specific costs of produced water, fuel consumption and solar system installation.

The cost of water production is elevated in the first mode due to the operation of the plant exclusively during daytime hours. The price for a cubic meter of desalinated water produced under this mode is found to be USD 1.4/m3. An additional advantage of this process is its minimal solar collection area. Conversely, the second mode is distinguished by its lower cost per cubic meter of produced water and a reasonable area requirement for the solar field; however, it faces criticism due to the emission of combustion gases that contribute to environmental pollution.

Figure 12 presents a comparative analysis of the operational and design parameters of this study. Mode 0 exhibits the highest fuel consumption, as both the first and second modes do not utilize any fuel. The second mode is characterized as having moderate fuel consumption, and an increased area allocated for the solar field. A significant limitation of the third mode is the substantial area required for the installation of solar collectors. Additionally, the third mode incorporates storage tanks to overcome the deficiency of solar energy during nighttime. The first and third modes yield the most favorable impact on the surrounding environment; however, the first mode is associated with low desalination productivity, while the third mode incurs high capital costs and necessitates a larger solar field area.

Figure 12.

Comparison of solar field area, fuel consumption and produced water.

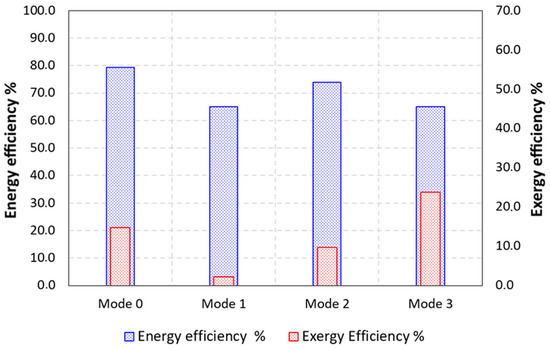

The flow rates and temperatures for the examined modes were established by applying principles of the first law of thermodynamics (energy balances). The energy and exergy efficiencies for the proposed modes were computed using Equations (14)–(29). These calculations were based on the following assumptions: (1) the chemical exergy of all system streams was neglected except for the fuel, and (2) the combustion air and exhaust gases were treated as ideal gases. The outcomes of these calculations are summarized in Table 6.

Table 6.

Energy and exergy efficiencies for the different modes.

The energy and exergy efficiency of the system decreased when using solar energy for steam generation, in comparison with the use of a conventional boiler, as illustrated in Figure 13. This reduction in efficiency can be attributed to the elevated temperature of the energy source (the sun) and the diminished availability of energy in the outputs of thermal desalination processes.

Figure 13.

Energy and exergy efficiencies for the proposed integration modes.

While it is accurate to assert that Mode 0, which represents the current operational state of the plant, exhibits the highest energy efficient, it concurrently generates the most significant environmental impact due to elevated pollutant emissions resulting from fuel consumption. Conversely, Mode 3 offers the greatest exergy efficiency without any detrimental environmental emissions and facilitates high and stable productivity throughout the day by using thermal energy storage tanks; however, it necessitates a solar field area that is approximately three times larger than that required for Mode 1.

Mode 2 presents a viable alternative as it combines solar energy with boiler operation, thereby reducing pollution and minimizing the solar collection area while still achieving an acceptable level of thermal and energy efficiency.

In comparison with the first and second modes, the implementation of a thermal energy storage system in Mode 3 has the potential to decrease the amount of exergy destroyed by the system. Consequently, this enhancement contributes to an overall improvement in exergy efficiency.

The availability of energy is assessed through the evaluation of exergy efficiency. Data on solar radiation in the region of Zuara desalination plant were sourced from NASA website [39]. Hourly solar radiation data are accessible on this website for the entire year.

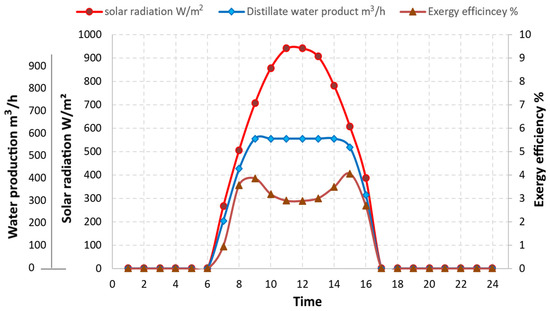

Figure 14 presents the solar radiation, desalinated water production and exergy efficiencies for Mode 1 on 30 May 2022. The productivity begins with the acquisition of solar radiation at approximately 7:00 AM, peaking between 9:00 AM and 2:00 PM. This peak productivity is maintained at the maximum capacity of the desalination unit, as determined by the TBT value. Following this period, productivity begins to decline until sunset.

Figure 14.

Produced water, solar radiation and exergy efficiency for Mode 1 on 30 May 2022.

The efficiencies of solar radiation and exergy commence their increase at sunrise, specifically at 7:00 AM, coinciding with the initiation of operations of the desalination unit. These efficiencies attain their peak values of about 941 W/m2 at 12:00 PM and 3.8% at 9:00 AM, respectively.

During both the morning and afternoon periods, when solar radiation levels are adequate to maximize the production of desalinated water, a decline in exergy efficiency decreases is observed. This decrease is attributed to the rise in the generated thermal energy.

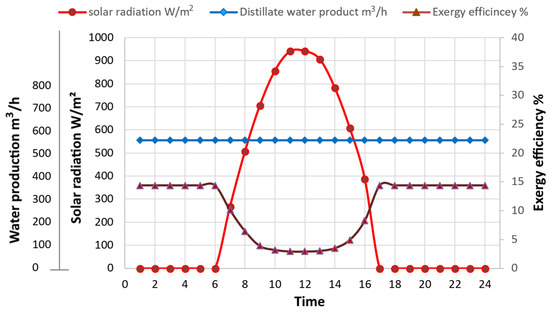

Figure 15 presents the volume of desalinated water produced, solar radiation levels and exergy efficiency for Mode 02 on 30 May 2022. In this mode, the water productivity remained constant throughout the day, as the boiler was operated during periods of low or absent solar radiation.

Figure 15.

Produced water, solar radiation and exergy efficiency for Mode 2 on 30 May 2022.

The exergy efficiency remained constant at 14.5% while the boiler was operated as an energy source, attributable to the stability of all operational parameters. However, this efficiency exhibited a gradual decline upon transitioning to solar energy. At the peak solar radiation level of approximately 940 W/m2 the exergy efficiency had diminished to 2.9% by around midday.

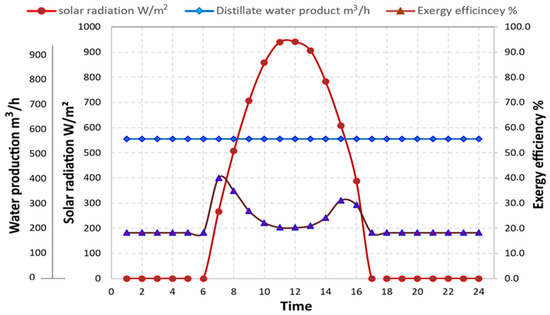

Figure 16 shows the relationship between solar radiation, distilled water and unit exergy efficiency for Mode 3, which uses storage tanks. The solar radiation values range from 0 W/m2 at 6:00 AM to 950 W/m2 at 11:00 PM, indicating a constant production rate throughout the day. The unit exergy efficiency varies from about 18% at 6:00 AM to 40% at 7:00 AM, subsequently declining to 20% at midday, coinciding with the peak solar radiation. Thereafter, the efficiency increases again, reaching a local maximum of 32% at 3:00 PM.

Figure 16.

Produced water, solar radiation and exergy efficiency of Mode 3 on 30 May 2022.

The unit’s exergy efficiency reached a stable minimum of 18% during nighttime operations, when it utilized thermal energy sourced from the thermal storage tanks. This operational mode allows for a consistent throughput of distilled water, maintaining the maximum capacity of a desalination unit throughout the day. However, a significant limitation of this approach is the substantial area required for the solar field. Conversely, the advantages of this mode include its environmentally sustainable nature and its ability to supply the total energy requirements.

5. Conclusions

This study explores how to balance costs, sustainability, and operational continuity in solar-powered MED systems by evaluating three operational modes with different energy sources and storage setups. The findings clarify renewable energy’s role in desalination and offer strategic insights for optimizing system performance across diverse regions.

Mode 1, relying solely on solar energy during daylight, achieves zero emissions but operates for limited hours, resulting in the highest production cost of USD 1.4/m3 and requiring minimal land area. Mode 2, a hybrid approach combining solar energy during the day with boilers at night, balances cost and sustainability with a competitive production cost of USD 0.79/m3 and moderate land use, though it still involves some reliance on fossil fuels. Mode 3, incorporating thermal energy storage for continuous 24-h operation, offers zero emissions and stable productivity but comes at a higher cost of USD 0.97/m3 and necessitates a significantly larger solar field area.

Among these, Mode 2 emerges as the most balanced option, offering economic viability and reduced environmental impact without excessive land requirements. Mode 3 is ideal for regions prioritizing uninterrupted, environmentally sustainable water production, provided land and budgetary constraints are manageable. Mode 1, while costlier, is suitable for areas with limited land availability and simpler operational demands. These insights underline the importance of tailoring operational modes to regional needs and constraints to optimize outcomes.

In summary, solar-powered MED plants present a promising pathway to sustainable water production, enabling reduced environmental impact and enhanced access to clean water. Future research should focus on advancing thermal energy storage technologies, exploring hybrid configurations with multiple renewable sources, and optimizing system designs to improve efficiency and reduce costs. By leveraging solar energy effectively, this study lays the foundation for addressing water scarcity challenges sustainably and equitably.

The analysis focused on cost, land use and emissions without addressing maintenance costs or broader environmental impacts. The results are based on current thermal storage technologies that may evolve in the future, which may enable the exploration of advanced storage technologies in the future, as well as the investigation of hybrid energy systems, and the development of more comprehensive economic models that enable broader studies and provide a deeper assessment of environmental impacts.

Author Contributions

Conceptualization, A.K.M., L.Z.-G., M.M.A. and W.H.; Methodology, A.K.M., L.Z.-G., M.M.A., N.B., B.M.A. and L.K.; Software, A.K.M.; Validation, A.K.M.; Formal analysis, A.K.M., L.Z.-G., M.M.A., W.H., N.B., B.M.A. and L.K.; Investigation, A.K.M., L.Z.-G., M.M.A., W.H., N.B., B.M.A. and L.K.; Writing—original draft, A.K.M., L.Z.-G., M.M.A., W.H., N.B., B.M.A. and L.K.; Writing—review & editing, A.K.M., L.Z.-G., M.M.A., W.H., N.B., B.M.A. and L.K. All authors have read and agreed to the published version of the manuscript.

Funding

The authors extend their appreciation to the Deanship of Scientific Research at Northern Border University, Arar, KSA for funding this research work through the project number “NBU-FFR-2025-2933-05”.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Nomenclature | Subscripts | |||

| A | Heat transfer area | m2 | A | Air |

| Cp | Fluid heat capacity | kJ/kg/K | b | Brine water |

| Fuel exergy factor | --- | B | Boiler | |

| h | Stream specific enthalpy | kJ/kg | D | Distillate water |

| I | Average daily solar radiation | kWh/m2/day | coll. | Solar collector |

| LHV | Fuel specific low heating value | kJ/kg | ej | Steam ejector |

| Stream mass flow rate | kg/s | Fuel | ||

| Q | Heat rate | kW | g | Combustion gas |

| Δt | Time | h | i | Stream inlet |

| T | Temperature | °C | min | Minimum |

| S | Stream specific entropy | kJ/kg/K | mix | Maximum |

| V | Volume | m3 | o | Stream outlet |

| ρ | Thermal fluid density | Kg/m3 | th | Thermal energy |

| η | Energy efficiency | % | tot | Total heat rate |

| Exergy rate | kW | St | Steam | |

| ε | Exergy efficiency | % | Sw | Seawater |

References

- Somashekar, V.; Anand, A.V.; Hariprasad, V.; Elsehly, E.M.; Kapulu, M. Advancements in saline water treatment: A review. Water Reuse 2023, 13, 475–491. [Google Scholar] [CrossRef]

- Goosen, M.; Mahmoudi, H.; Ghaffour, N.; Sablani, S.S. Application of renewable energies for water desalination. In Desalination, Trends and Technologies; Schorr, M., Ed.; IntechOpen: London, UK, 2011; pp. 89–118. [Google Scholar] [CrossRef]

- Muftah, A.K.; Zili-Ghedira, L.; Dhahri, H.; Abugderah, M.M. Solar Integration in Water Desalination Systems A Literature Review. In Proceedings of the 2022 IEEE 2nd International Maghreb Meeting of the Conference on Sciences and Techniques of Automatic Control and Computer Engineering (MI-STA), Sabratha, Libya, 23–25 May 2022; pp. 620–627. [Google Scholar]

- International Renewable Energy Agency (IRENA). Water Desalination Using Renewable Energy; IEA-ETSAP and IRENA: Abu Dhabi, United Arab Emirates, 2013. [Google Scholar]

- Gude, V.G. Energy storage for desalination processes powered by renewable energy and waste heat sources. Appl. Energy 2015, 137, 877–898. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Assad ME, H.; Sayed, E.T.; Soudan, B. Recent progress in the use of renewable energy sources to power water desalination plants. Desalination 2018, 435, 97–113. [Google Scholar] [CrossRef]

- Panagopoulos, A. Water-energy nexus: Desalination technologies and renewable energy sources. Environ. Sci. Pollut. Res. 2021, 28, 21009–21022. [Google Scholar] [CrossRef] [PubMed]

- Koroneos, C.; Dompros, A.; Roumbas, G. Renewable energy driven desalination systems modelling. J. Clean. Prod. 2007, 15, 449–464. [Google Scholar] [CrossRef]

- Shouman, E.R.; Sorour, M.H.; Abulnour, A.G. Economics of renewable energy for water desalination in developing countries. J. Eng. Sci. Technol. Rev. 2015, 8, 227–231. [Google Scholar] [CrossRef]

- Feria-Díaz, J.J.; López-Méndez, M.C.; Rodríguez-Miranda, J.P.; Sandoval-Herazo, L.C.; Correa-Mahecha, F. Commercial thermal technologies for desalination of water from renewable energies: A state of the art review. Processes 2021, 9, 262. [Google Scholar] [CrossRef]

- Younas, O. Desalination of Seawater/Brackish by Multi-Effect Solar Still Coupled with a Point Focus Fresnel Lens. Doctoral Dissertation, The Petroleum Institute, Abu Dhabi, United Arab Emirates, 2013. [Google Scholar]

- Arunkumar, T.; Vinothkumar, K.; Ahsan, A.; Jayaprakash, R.; Kumar, S. Experimental study on various solar still designs. ISRN Renew. Energy 2012, 2012, 569381. [Google Scholar] [CrossRef]

- Mohaisen, H.S.; Esfahani, J.A.; Ayani, M.B. Effect of condensing cavity on the performance of a passive solar desalination system: An experimental study. Environ. Sci. Pollut. Res. 2021, 28, 5080–5091. [Google Scholar] [CrossRef]

- Ranjan, K.R.; Kaushik, S.C. Exergy analysis of the active solar distillation systems integrated with solar ponds. Clean Technol. Environ. Policy 2014, 16, 791–805. [Google Scholar] [CrossRef]

- Omar, A.; Nashed, A.; Li, Q.; Leslie, G.; Taylor, R.A. Pathways for integrated concentrated solar power-Desalination: A critical review. Renew. Sustain. Energy Rev. 2020, 119, 109609. [Google Scholar] [CrossRef]

- Chandrashekara, M.; Yadav, A. Water desalination system using solar heat: A review. Renew. Sustain. Energy Rev. 2017, 67, 1308–1330. [Google Scholar]

- Stroud, M. Solar Desalination in the Southwest United States: A Thermoeconomic Analysis Utilizing the Sun to Desalt Water in High Irradiance Regions. Master Thesis, The University of Arizona, Tucson, AZ, USA, 2012. [Google Scholar]

- Abd-ur-Rehman, H.M. Experimental Investigation of Solar Driven Multi-Stage Stepped Bubbler Humidifier. Doctoral Dissertation, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia, 2015. [Google Scholar]

- Hamed, O.A.; Kosaka, H.; Bamardouf, K.H.; Al-Shail, K.; Al-Ghamdi, A.S. Concentrating solar power for seawater thermal desalination. Desalination 2016, 396, 70–78. [Google Scholar] [CrossRef]

- Alhaj, M.; Al-Ghamdi, S.G. Integrating concentrated solar power with seawater desalination technologies: A multi-regional environmental assessment. Environ. Res. Lett. 2019, 14, 074014. [Google Scholar] [CrossRef]

- Palenzuela, P.; Alarcón-Padilla, D.C.; Zaragoza, G. Large-scale solar desalination by combination with CSP: Techno-economic analysis of different options for the Mediterranean Sea and the Arabian Gulf. Desalination 2015, 366, 130–138. [Google Scholar] [CrossRef]

- Zuo, L.; Ding, L.; Chen, J.; Zhou, X.; Xu, B.; Liu, Z. Comprehensive study of wind supercharged solar chimney power plant combined with seawater desalination. Sol. Energy 2018, 166, 59–70. [Google Scholar] [CrossRef]

- Brika, B. The water crisis in Libya: Causes, consequences and potential solutions. Desalination Water Treat. 2019, 167, 351–358. [Google Scholar] [CrossRef]

- Global Solar Atlas, Photovoltaic Power Potential. Available online: https://globalsolaratlas.info/download/libya (accessed on 20 November 2021).

- Muftah, A.K.; Zili-Ghedira, L.; Dhahri, H.; Abugderah, M.M. Experimental and numerical studies of multi-effect desalination plants without thermal vapor compression. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 1–9. [Google Scholar] [CrossRef]

- Giglio, A.; Lanzini, A.; Leone, P.; García, M.M.R.; Moya, E.Z. Direct steam generation in parabolic-trough collectors: A review about the technology and a thermo-economic analysis of a hybrid system. Renew. Sustain. Energy Rev. 2017, 74, 453–473. [Google Scholar] [CrossRef]

- Marefati, M.; Mehrpooya, M.; Shafii, M.B. Optical and thermal analysis of a parabolic trough solar collector for production of thermal energy in different climates in Iran with comparison between the conventional nanofluids. J. Clean. Prod. 2018, 175, 294–313. [Google Scholar] [CrossRef]

- Alsharif, A.; Tan, C.W.; Ayop, R.; Lau, K.Y.; Moh’d Dobi, A. A rule-based power management strategy for Vehicle-to-Grid system using antlion sizing optimization. J. Energy Storage 2021, 41, 102913. [Google Scholar] [CrossRef]

- Babar, O.A.; Tarafdar, A.; Malakar, S.; Arora, V.K.; Nema, P.K. Design and performance evaluation of a passive flat plate collector solar dryer for agricultural products. J. Food Process Eng. 2020, 43, e13484. [Google Scholar] [CrossRef]

- Manuals and Performance Test Sheets for Boilers of Zuara Desalination Plant; SIDEM Company: Fujairah, United Arab Emirates, 2005.

- Zhang, Y. Investigation of Heat Transfer and Entropy Production of High Temperature Molten Chloride Salts Circulation in Concentrating Solar Power Systems. Doctoral Dissertation, The University of Arizona, Tucson, AZ, USA, 2022. [Google Scholar]

- Campos-Celador, Á.; Diarce, G.; Larrinaga, P.; García-Romero, A.M. A simple method for the design of thermal energy storage systems. Energy Storage 2020, 2, e140. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Thermodynamic aspects of renewables and sustainable development. Renew. Sustain. Energy Rev. 2005, 9, 169–189. [Google Scholar] [CrossRef]

- Padilla, R.V.; Fontalvo, A.; Demirkaya, G.; Martinez, A.; Quiroga, A.G. Exergy analysis of parabolic trough solar receiver. Appl. Therm. Eng. 2014, 67, 579–586. [Google Scholar] [CrossRef]

- Muftah, A.; Fellah, G. Exergy Analysis for Unit Two of Zuara Desalination Plant. In Proceedings of the First International Chemical and Process Engineering Conference and Exhibition, Rome, Italy, 10–13 May 2009; pp. 5–7. [Google Scholar]

- Behbahaninia, A.; Ramezani, S.; Hejrandoost, M.L. A loss method for exergy auditing of steam boilers. Energy 2017, 140, 253–260. [Google Scholar] [CrossRef]

- Ibrahim, T.K.; Basrawi, F.; Awad, O.I.; Abdullah, A.N.; Najafi, G.; Mamat, R.; Hagos, F.Y. Thermal performance of gas turbine power plant based on exergy analysis. Appl. Therm. Eng. 2017, 115, 977–985. [Google Scholar] [CrossRef]

- Dezhou Gaia Solar Energy Co. Ltd. 2018. Available online: https://gaiasolar.en.made-in-china.com (accessed on 18 December 2022).

- NASA Prediction of Worldwide Energy Resources [Internet] Hampton: Power Data Access Viewer. Available online: https://power.larc.nasa.gov/data-access-viewer/ (accessed on 25 December 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).