Stochastic–Dynamic Modeling of Chute Slabs Under Spillway Flows

Abstract

1. Introduction

- First, it is evident that in turbulent flows, the velocity, and consequently the pressure, fluctuates unpredictably. For this reason, the approach of adopting hard upper and lower limits for these fluctuations is questionable, especially if these limits are obtained from experiments of a limited observation period. It is evident that these limits depend on the duration of the observations, as record-breaking values may continue to arrive as long as the observations continue.

- Second, in digital sensors, such as Acoustic Doppler Velocimeters, measurement error increases when small sampling rates are employed [12]. On the other hand, large sampling rates introduce aggregation, smoothing the signal and trimming peak values [13]. Ideally, reliable measurements should be obtained at high rates. However, this is compromised either by the introduced error at high frequencies or by the smoothing effect at low frequencies. As a result, the frequency of modern Doppler-based velocimeters is practically limited to a range of a few hundred Hz, which compromises the ability to capture very high but short-lasting velocities.

- Finally, assessing the stability of slabs includes checking the maximum stress on the anchoring bars against their capacity. This must be carried out taking into account the dynamic nature of the slab–bar system. It is well known from stress analysis that in shock loading (see Section 2.13.4 in [14]) the dynamic amplification factor (response maximum amplitude relative to the displacement due to a static force of equal magnitude) is 2. Evidently, the temporal profile of the uplift force influences the maximum stress on the system.

2. Materials and Methods

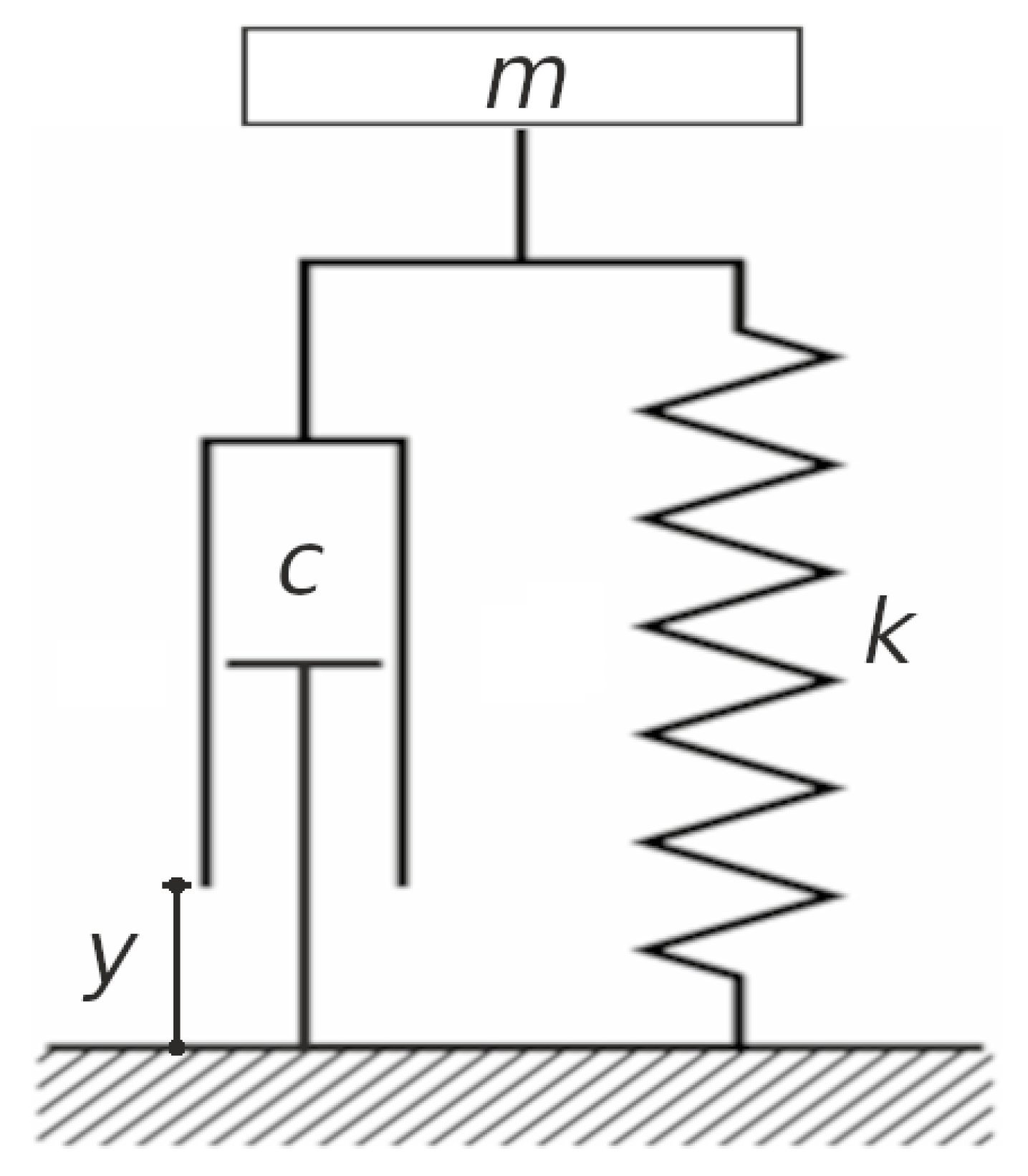

2.1. Dynamic Simulation

2.2. Stochastic Simulation

2.3. Case Study

3. Results

4. Discussion

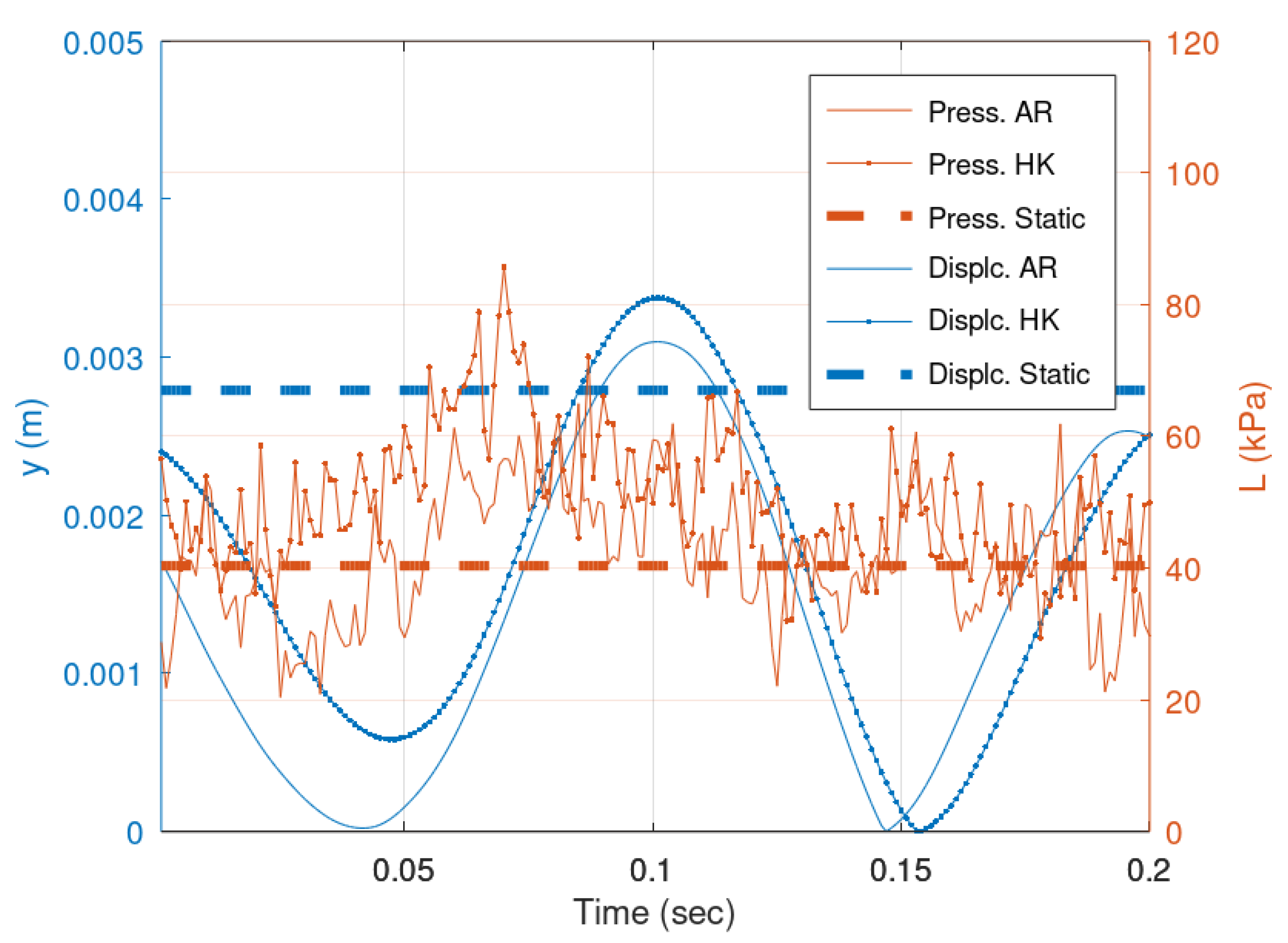

- The deterministic–static method may underestimate the maximum stress on an anchoring bar. In our case study, the stochastic–dynamic approach resulted in 9% to 19% higher maximum displacement, depending on the stochastic persistence of the velocity. For the case study’s mean velocity of 30.05 m/s, the summation of positive and negative pressure coefficients obtained from the synthetic velocity time series is , similar to the value suggested in [9]. Consequently, the maximum expected uplift pressure is 80 kPa, closely matching the maximum value observed in the stochastic–dynamic approach shown in Figure 5. However, the maximum displacement according to the deterministic–static approach is 2.83 mm, whereas the stochastic–dynamic approach yielded maximum displacements of 3.10 mm and 3.38 mm for synthetic velocity time series generated using AR1 and HK, respectively. This underscores the significance of considering the dynamic behavior of the slab–anchoring bar system.

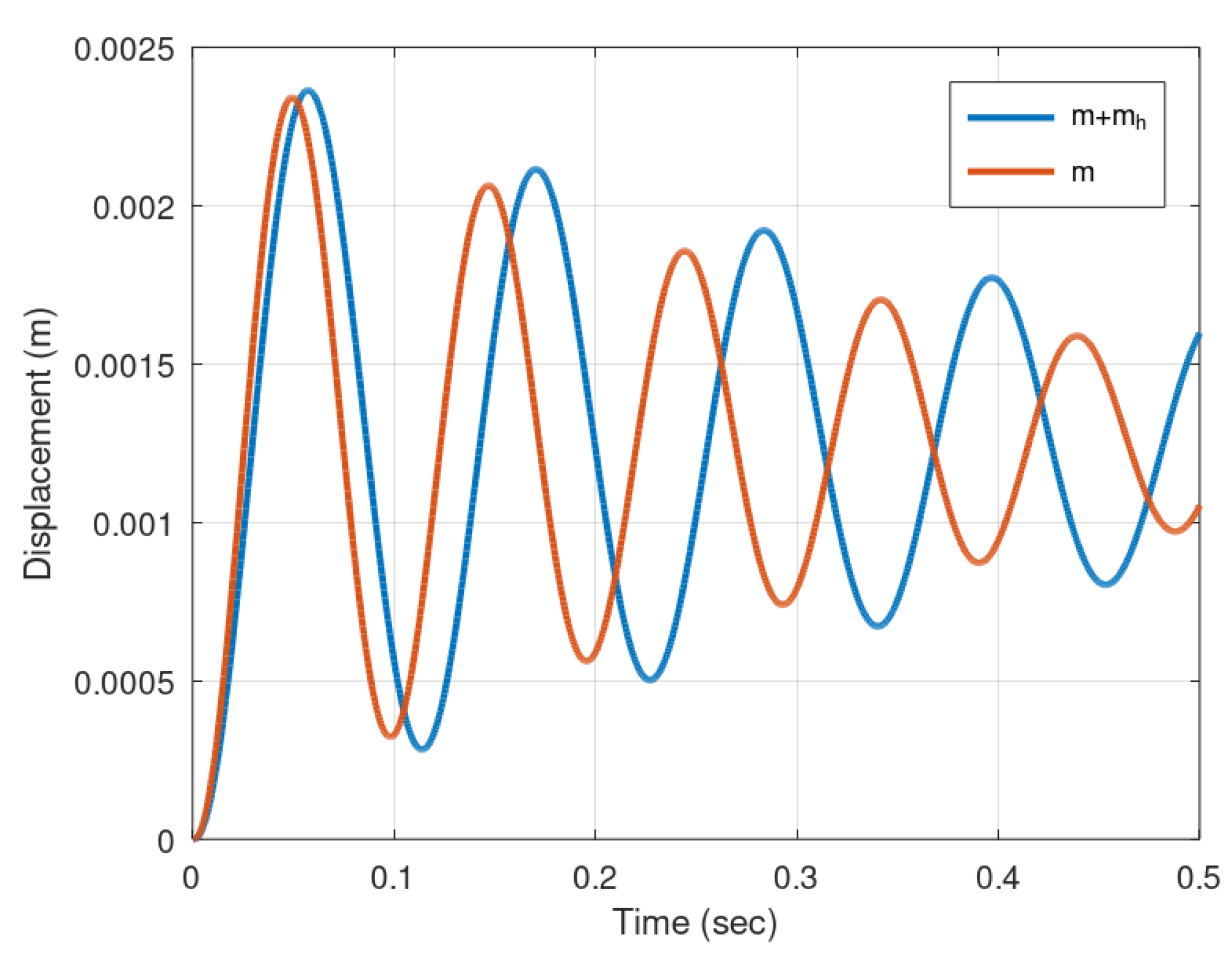

- Under typical conditions, the stochastic persistence plays a significant role in determining the maximum stress on chute slabs. Specifically, the maximum displacement calculated in the case study using synthetic time series of velocities with a Hurst–Kolmogorov (HK) model was 9% higher than that calculated using an autoregressive model of order 1 (AR1). This result is consistent with the findings of Fiorotto and Salandin [16], who highlighted the importance of persistence times, defined as the number of consecutive exceedances of uplift pressure. However, our study adopts a more generalized approach, treating persistence as an inherent property of the stochastic structure of flow velocity, which is the primary driving force behind the stresses on the chute slab.

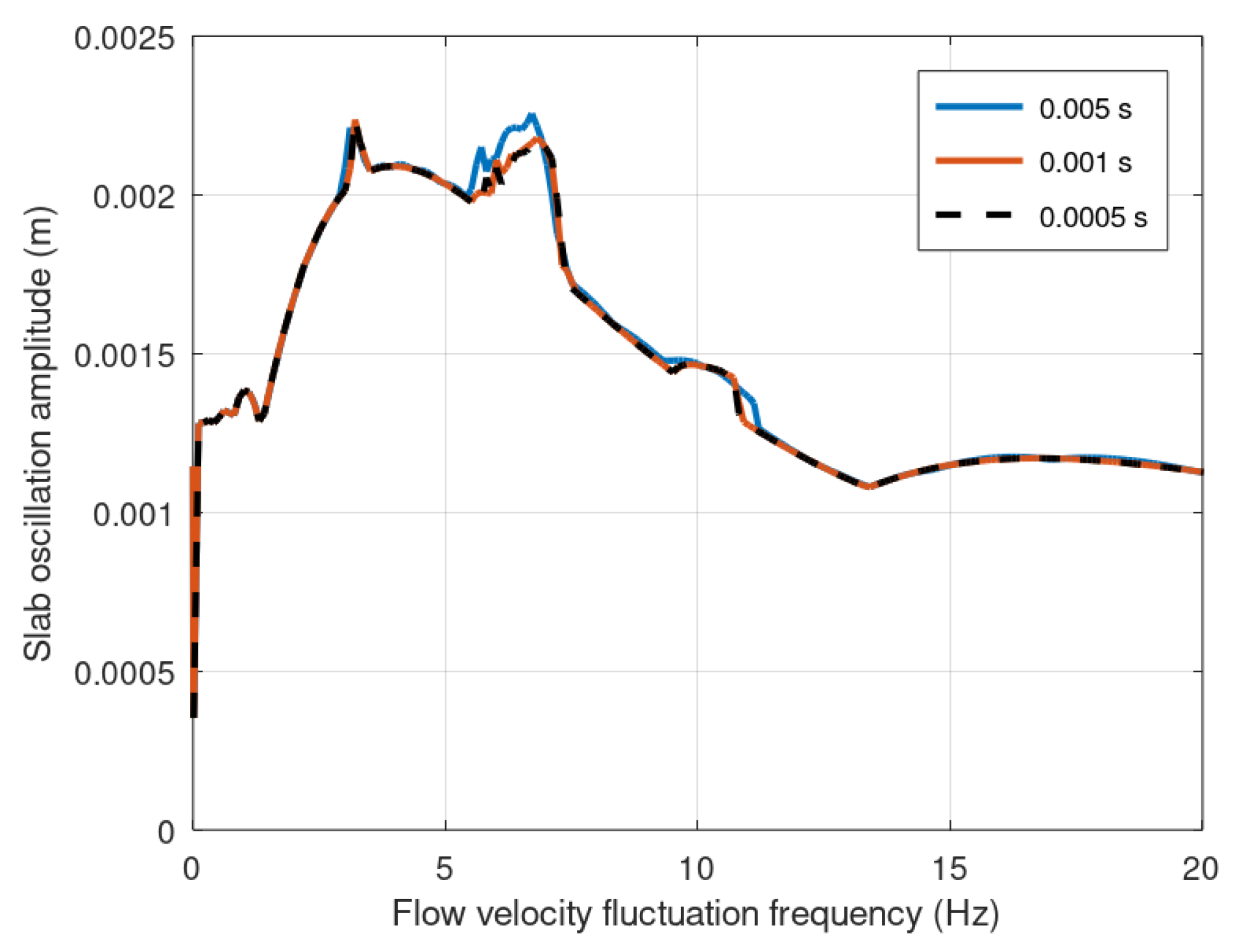

- The simulation time step must be carefully chosen to ensure that numerical errors remain within acceptable tolerance limits. In our case study, which, although hypothetical, is based on typical characteristics, the time step needed to be finer than . Consequently, simulations were performed with time steps of and . At these time scales, the variance of the flow velocity was assumed to be constant. As a result, the stress indices (i.e., the displacements) for the time step were lower compared to those for the time step due to the proportionally shorter interval duration for smaller time steps. This effect is more evident in the case of AR1. This discrepancy is attributed to the fact that AR1, suitable for Markovian processes, produces a much steeper climacogram compared to Hurst–Kolmogorov processes. In contrast, Hurst–Kolmogorov processes, with their less steep climacogram, exhibit smaller deviations under the same assumption [20]. This further highlights the importance of selecting the most appropriate stochastic scheme for analysing stochastic process that drive dynamic systems.

5. Conclusions

- While deterministic models can offer rough estimates, they may overlook critical stress factors introduced by random fluctuations in flow velocity. The persistence of the magnitude of flow velocity significantly impacts the maximum stress developed on the anchoring bar. The duration of extreme conditions is also influenced by this persistence, which in turn controls creep and likely the rate of overall structural degradation.

- Various researchers have conducted experiments to obtain velocity and pressure measurements in turbulent flows. However, this study, which focuses on the maximum stress of anchoring bars, highlights that such datasets provide minimal support for studying maximum stress. This is because, as found in this study, maximum stress is not directly related to maximum pressure, and the persistence of velocity in physical models does not necessarily match that of real-world systems, as suggested by previous studies.

- In the stochastic–dynamic approach, accurately representing the system’s response requires selecting an appropriate simulation time step. However, finer time steps demand higher-frequency observations, which may not always be feasible. In such cases, disaggregation of available measurements using suitable stochastic models (e.g., filtered Hurst–Kolmogorov) may be necessary to generate input time series for the dynamic system at the required temporal scale.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AR1 | Autoregressive lag 1 |

| HK | Hurst–Kolmogorov |

| IFT | Independent Forensic Team |

| Probability density function |

References

- Boelens, R.; Shah, E.; Bruins, B. Contested Knowledges: Large Dams and Mega-Hydraulic Development. Water 2019, 11, 416. [Google Scholar] [CrossRef]

- Song, J.; Sciubba, M.; Kam, J. Risk and Impact Assessment of Dams in the Contiguous United States Using the 2018 National Inventory of Dams Database. Water 2021, 13, 1066. [Google Scholar] [CrossRef]

- Ageing Dams Pose Growing Threat. 2024. Available online: https://unu.edu/press-release/ageing-dams-pose-growing-threat (accessed on 23 September 2024).

- France, J.W.; Alvi, I.A.; Dickson, P.A.; Falvey, H.T.; Rigbey, S.; Trojanowski, J. Independent Forensic Team Report: Oroville Dam Spillway Incident. 2018. Available online: https://damsafety.org/sites/default/files/files/Independent%20Forensic%20Team%20Report%20Final%2001-05-18.pdf (accessed on 6 June 2024).

- Koskinas, A.; Tegos, A.; Tsira, P.; Dimitriadis, P.; Iliopoulou, T.; Papanicolaou, P.; Koutsoyiannis, D.; Williamson, T. Insights into the Oroville Dam 2017 Spillway Incident. Geosciences 2019, 9, 37. [Google Scholar] [CrossRef]

- Frizell, K. Uplift and Crack Flow Resulting from High Velocity Discharges over Open Offset Joints; U.S. Department of the Interior Bureau of Reclamation, Technical Service Center: Denver, CO, USA, 2007. [Google Scholar]

- Wahl, T.L.; Heiner, B.J. Laboratory Measurements of Hydraulic Jacking Uplift Pressure at Offset Joints and Cracks. J. Hydraul. Eng. 2024, 150, 04024016. [Google Scholar] [CrossRef]

- Te Chow, V. Open Channel Hydraulics; McGraw-Hill: New York, NY, USA, 1959; pp. 28–29. [Google Scholar]

- Bellin, A.; Fiorotto, V. Direct dynamic force measurement on slabs in spillway stilling basins. J. Hydraul. Eng. 1995, 121, 686–693. [Google Scholar] [CrossRef]

- Toso, J.W.; Bowers, C.E. Extreme Pressures in Hydraulic-Jump Stilling Basins. J. Hydraul. Eng. 1988, 114, 829–843. [Google Scholar] [CrossRef]

- Fiorotto, V.; Rinaldo, A. Fluctuating uplift and lining design in spillway stilling basins. J. Hydraul. Eng. 1992, 118, 578–596. [Google Scholar] [CrossRef]

- The Comprehensive Manual for Velocimeters Vector | Vectrino | Vectrino Profiler; NORTEK AS: Rud, Norway, 2018.

- Shumway, R.H.; Stoffer, D.S. Time Series Analysis and Its Applications; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Liew, J.R.; Shanmugam, N.; Yu, C. Structural Analysis. In Structural Engineering Handbook; Wai-Fah, C., Ed.; CRC Press LLC: New York, NY, USA, 1999. [Google Scholar]

- Gardner, M.; Sitar, N. Modeling of Dynamic Rock–Fluid Interaction Using Coupled 3-D Discrete Element and Lattice Boltzmann Methods. Rock Mech. Rock Eng. 2019, 52, 5161–5180. [Google Scholar] [CrossRef]

- Fiorotto, V.; Salandin, P. Design of Anchored Slabs in Spillway Stilling Basins. J. Hydraul. Eng. 2000, 126, 502–512. [Google Scholar] [CrossRef]

- Barjastehmaleki, S.; Fiorotto, V.; Caroni, E. Design of Stilling Basin Linings with Sealed and Unsealed Joints. J. Hydraul. Eng. 2016, 142, 04016064. [Google Scholar] [CrossRef]

- Pierce, R. The Method of Variation of Parameters. 2024. Available online: https://www.mathsisfun.com/calculus/differential-equations-variation-parameters.html (accessed on 22 July 2024).

- Harihara, P.; Childs, D.W. Solving Problems in Dynamics and Vibrations Using MATLAB; Department of Mechanical Engineering Texas A & M University: College Station, TX, USA, 2014; pp. 11–21. [Google Scholar]

- Koutsoyiannis, D. Stochastics of Hydroclimatic Extremes—A Cool Look at Risk, 3rd ed.; KALLIPOS: Athens, Greece, 2023. [Google Scholar]

- Matalas, N.; Wallis, J. Generation of synthetic flow sequences. In Systems Approach to Water Management; Biswas, A., Ed.; McGraw-Hill: New York, NY, USA, 1976. [Google Scholar]

- Salas, J.D. Chap. 19: Analysis and modelling of hydrological time series. In Handbook of Hydrology; Maidment, D., Ed.; McGraw-Hill: New York, NY, USA, 1993; Volume 19. [Google Scholar]

- Cook, R.A.; Kunz, J.; Fuchs, W.; Konz, R.C. Behavior and design of single adhesive anchors under tensile load in uncracked concrete. ACI Struct. J. 1998, 95, 9–26. [Google Scholar]

- Clough, R.W. Effects of Earthquakes on Under-Water Structures. In Proceedings of the 2nd World Conference on Earthquake Engineering, Tokyo, Japan, 11–18 July I960.

- Sinha, J.K.; Singh, S.; Rama Rao, A. Added mass and damping of submerged perforated plates. J. Sound Vib. 2003, 260, 549–564. [Google Scholar] [CrossRef]

- Dong, R. Effective Mass and Damping of Submerged Structures; Technical Report; Lawrence Livermore National Lab. (LLNL): Livermore, CA, USA, 1978. [Google Scholar]

- Jafari, R.; Sui, J. Velocity Field and Turbulence Structure around Spur Dikes with Different Angles of Orientation under Ice Covered Flow Conditions. Water 2021, 13, 1844. [Google Scholar] [CrossRef]

- Chanson, H.; Carosi, G. Turbulent time and length scale measurements in high-velocity open channel flows. Exp. Fluids 2007, 42, 385–401. [Google Scholar] [CrossRef]

- Kim, H.S.; Choi, S.; Park, M.; Ryu, Y. Flow Turbulence and Pressure Fluctuations in a Hydraulic Jump. Sustainability 2023, 15, 14246. [Google Scholar] [CrossRef]

- Chowdhury, S.; Sen, D.; Dey, S. Submerged wall jet on a macro-rough boundary: Turbulent flow characteristics and their scaling laws. Environ. Fluid Mech. 2024, 24, 587–610. [Google Scholar] [CrossRef]

- Dimitriadis, P.; Papanicolaou, P. Statistical analysis of positively buoyant turbulent jets. In Proceedings of the European Geosciences Union General Assembly 2012, EGU General Assembly, Vienna, Austria, 22–27 April 2012. [Google Scholar]

- Rozos, E.; Leandro, J.; Koutsoyiannis, D. Stochastic Analysis and Modeling of Velocity Observations in Turbulent Flows. J. Environ. Earth Sci. 2024, 6, 4–56. [Google Scholar] [CrossRef]

- Rozos, E.; Wieland, J.; Leandro, J. Measuring Turbulent Flows: Analyzing a Stochastic Process with Stochastic Tools. Fluids 2024, 9, 128. [Google Scholar] [CrossRef]

- Dimitriadis, P.; Koutsoyiannis, D.; Papanicolaou, P. Stochastic similarities between the microscale of turbulence and hydro-meteorological processes. Hydrol. Sci. J. 2016, 61, 1623–1640. [Google Scholar] [CrossRef]

- Kränkel, T.; Lowke, D.; Gehlen, C. Prediction of the creep behaviour of bonded anchors until failure—A rheological approach. Constr. Build. Mater. 2015, 75, 458–464. [Google Scholar] [CrossRef]

- Nordin, C.F.; McQuivey, R.S.; Mejia, J.M. Hurst phenomenon in turbulence. Water Resour. Res. 1972, 8, 1480–1486. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rozos, E.; Koutsoyiannis, D.; Leandro, J. Stochastic–Dynamic Modeling of Chute Slabs Under Spillway Flows. Water 2025, 17, 621. https://doi.org/10.3390/w17050621

Rozos E, Koutsoyiannis D, Leandro J. Stochastic–Dynamic Modeling of Chute Slabs Under Spillway Flows. Water. 2025; 17(5):621. https://doi.org/10.3390/w17050621

Chicago/Turabian StyleRozos, Evangelos, Demetris Koutsoyiannis, and Jorge Leandro. 2025. "Stochastic–Dynamic Modeling of Chute Slabs Under Spillway Flows" Water 17, no. 5: 621. https://doi.org/10.3390/w17050621

APA StyleRozos, E., Koutsoyiannis, D., & Leandro, J. (2025). Stochastic–Dynamic Modeling of Chute Slabs Under Spillway Flows. Water, 17(5), 621. https://doi.org/10.3390/w17050621