Sustainable Wastewater Treatment Through Anaerobic Digestion in the Instant Coffee Industry: A Techno-Economic and Environmental Assessment

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Study of the AD Process: Preparation of the Substrate and Inoculum

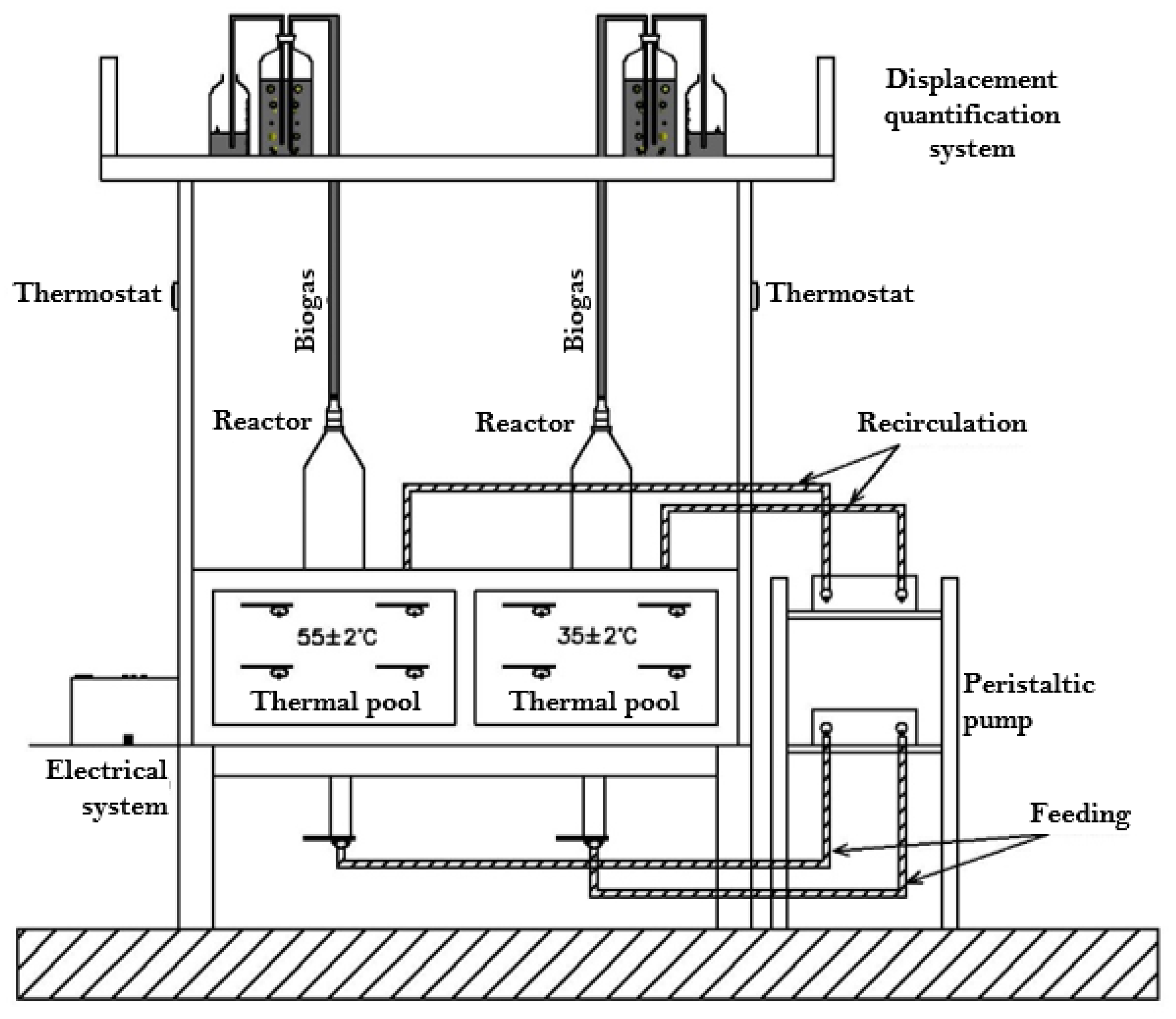

2.2. Assembly and Operation of Continuous Reactors

2.3. Analytical Tests for Process Control

2.4. Kinetic Study Models

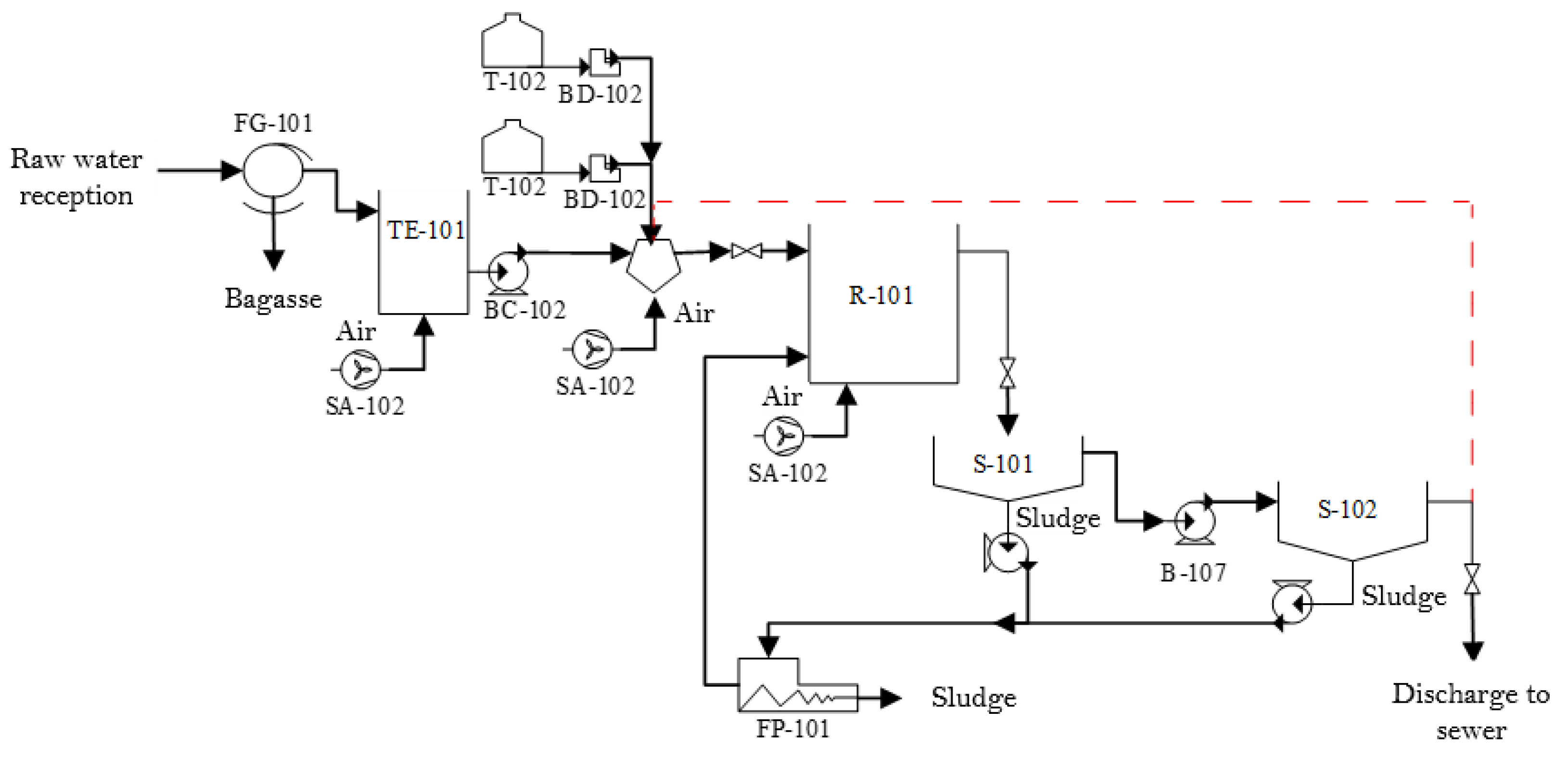

2.5. Case Study

2.6. Technical and Economic Evaluation and Sustainability of the Proposal

3. Results and Discussion

3.1. Characteristics of Wastewater

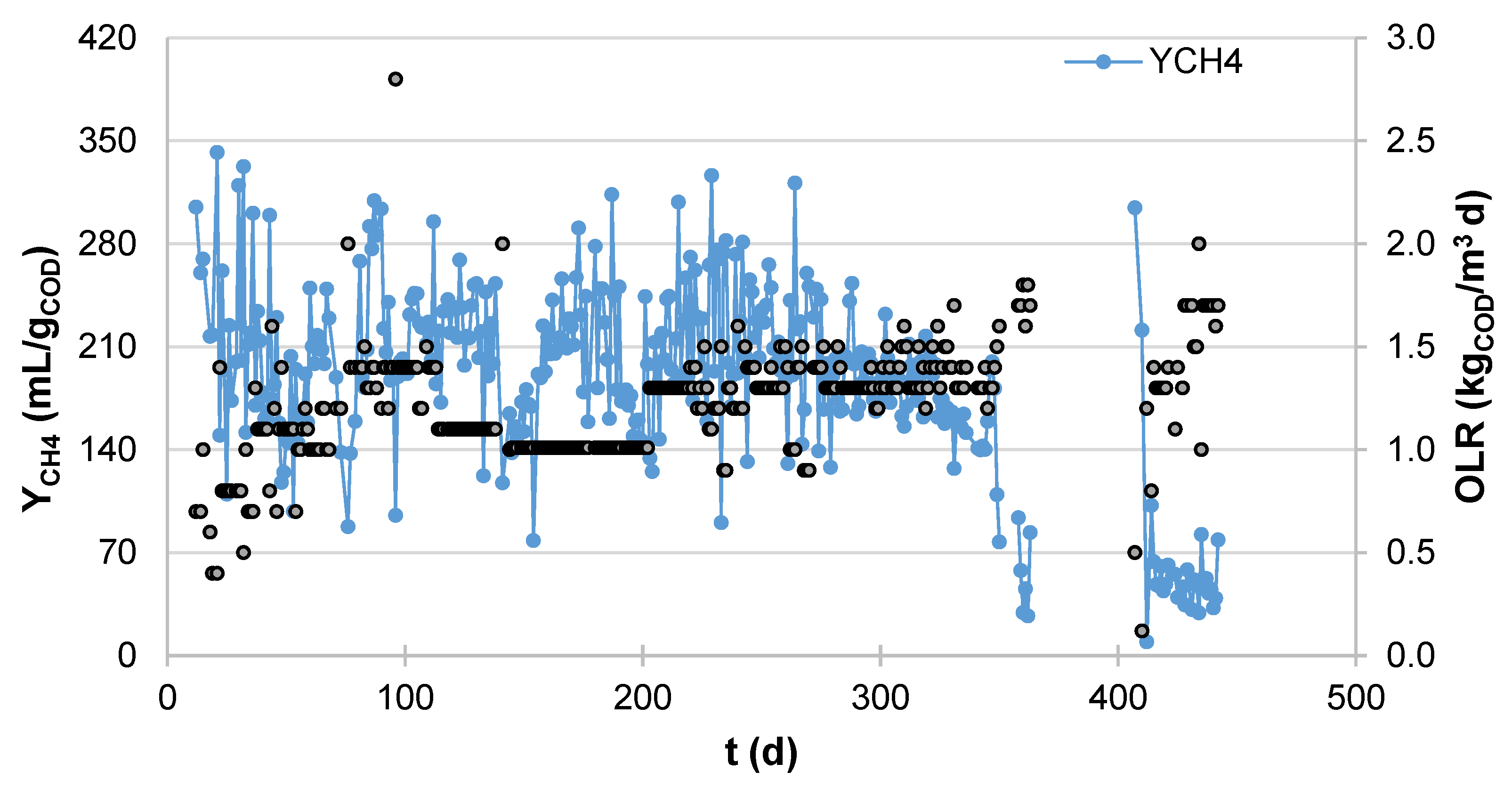

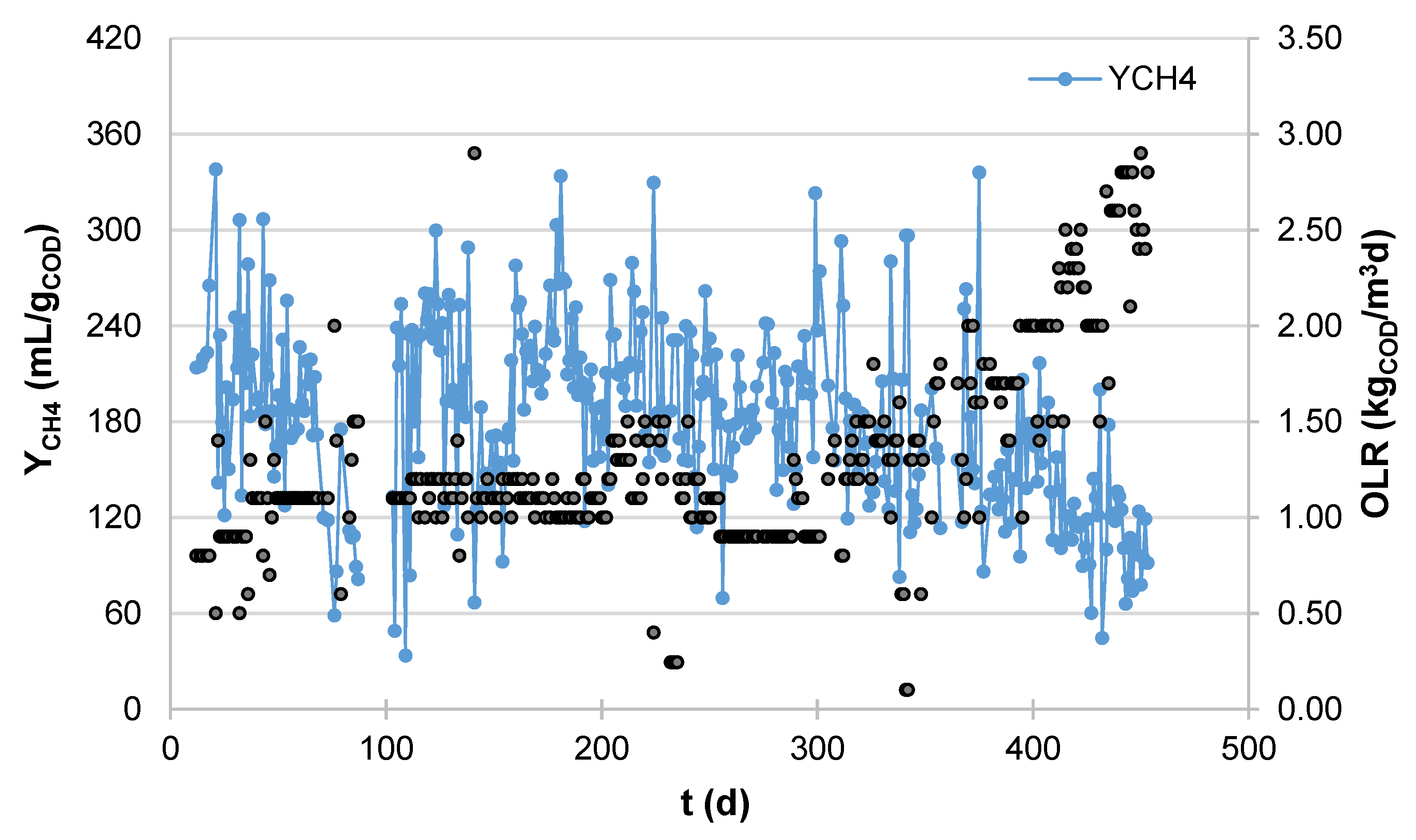

3.2. AD Process Yields

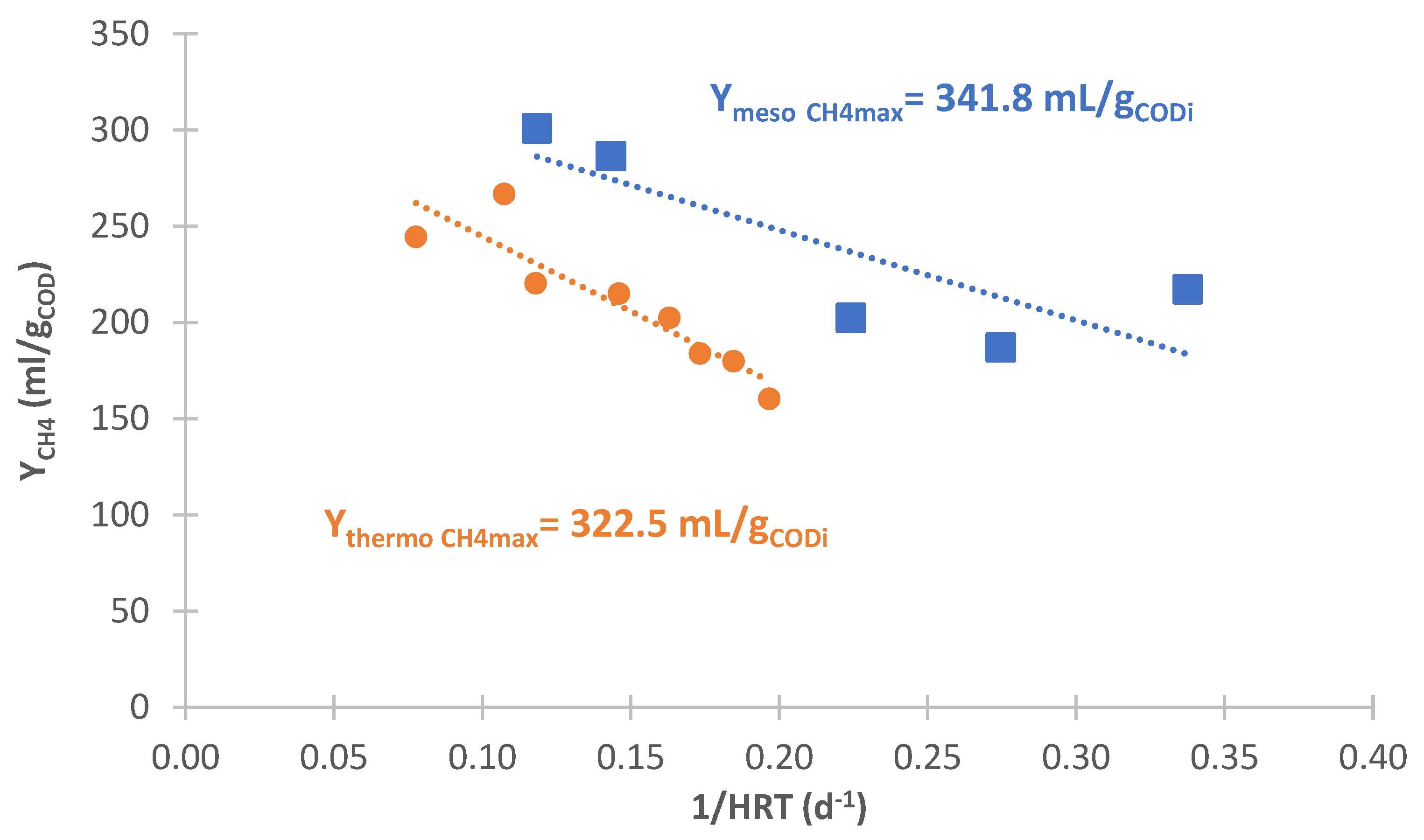

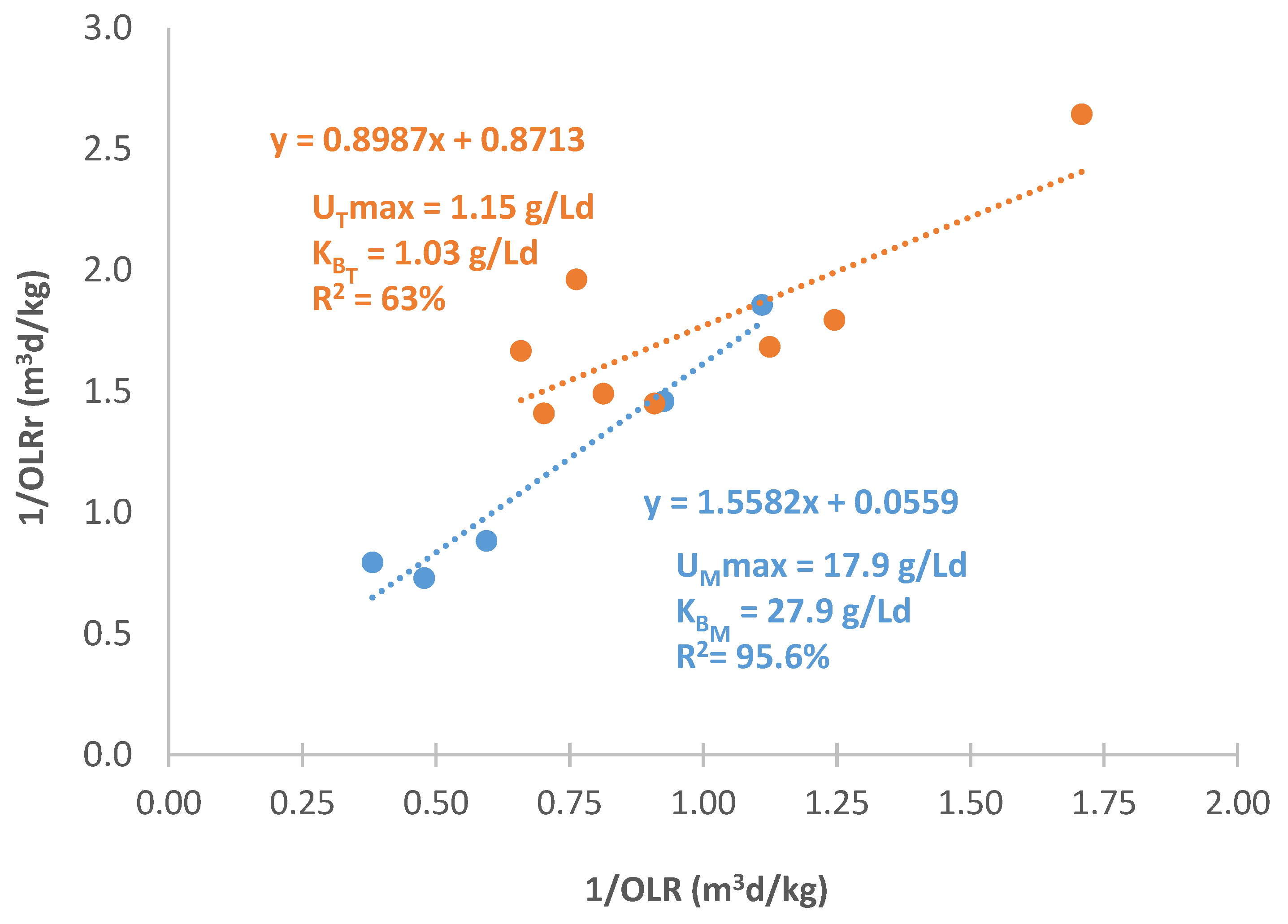

3.3. Results of the Kinetic Study Modellation

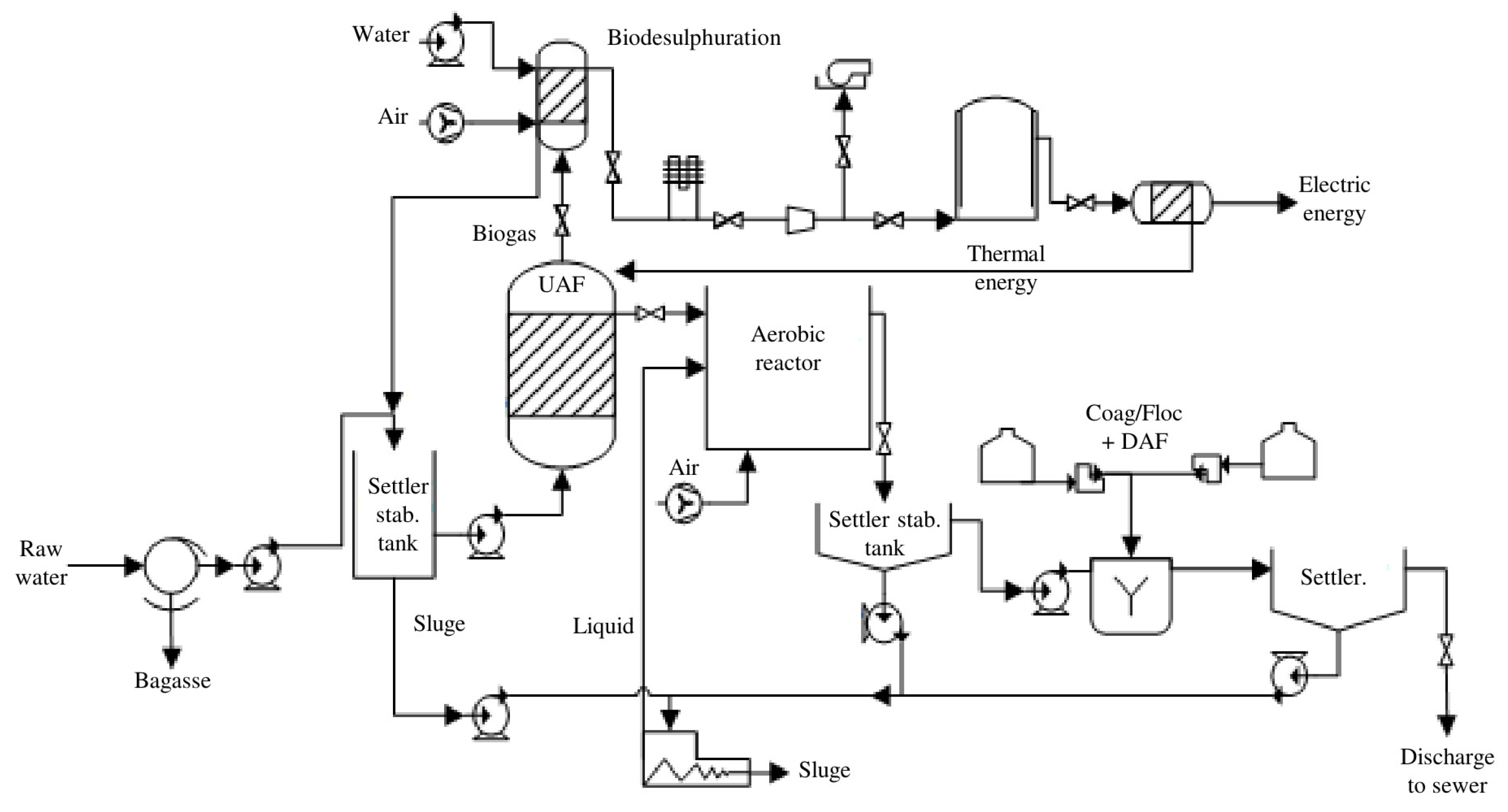

3.4. Technological Proposal with the Redesign of the Treatment Plant

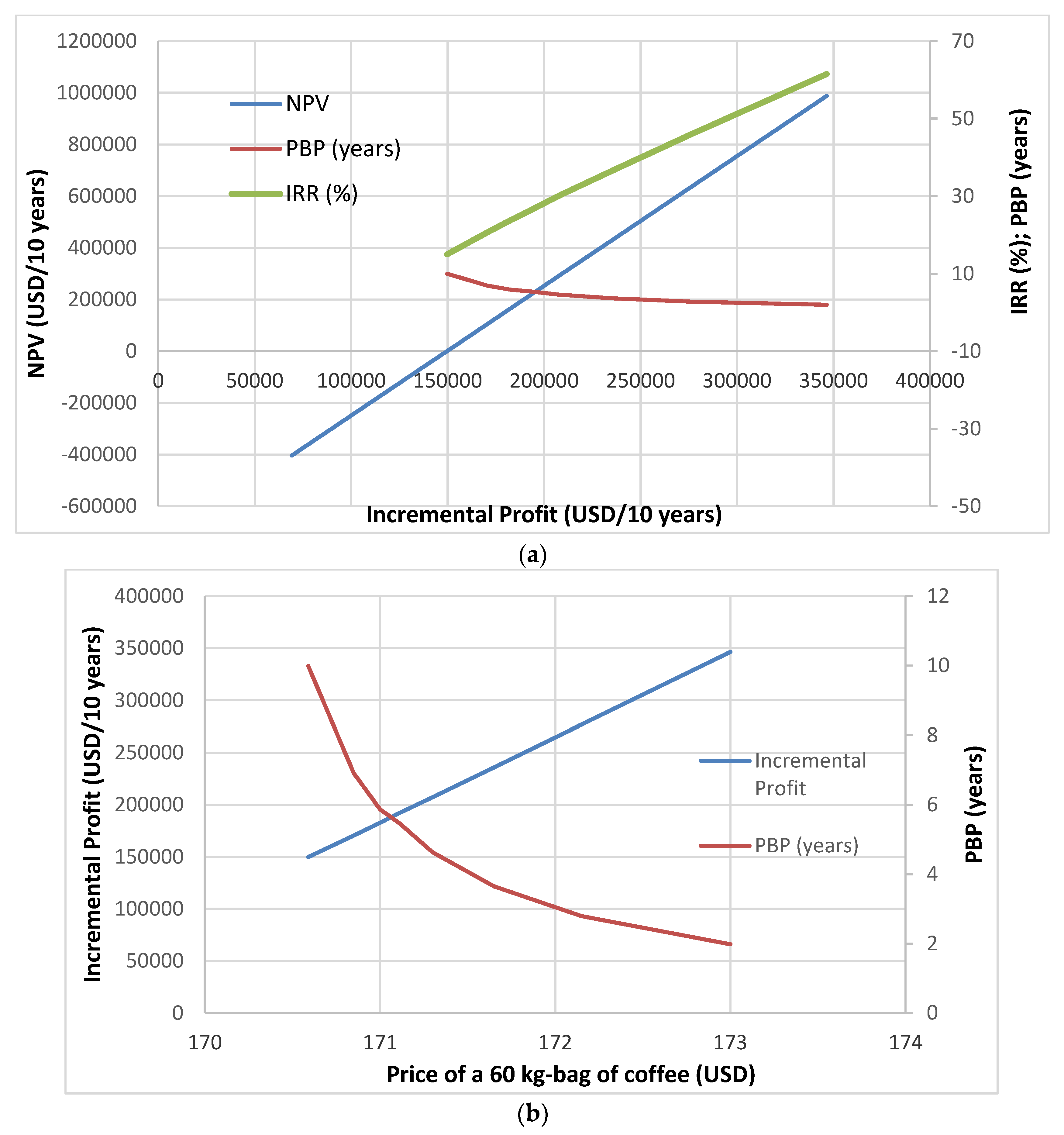

3.5. Economic Evaluation of the Technological Proposal

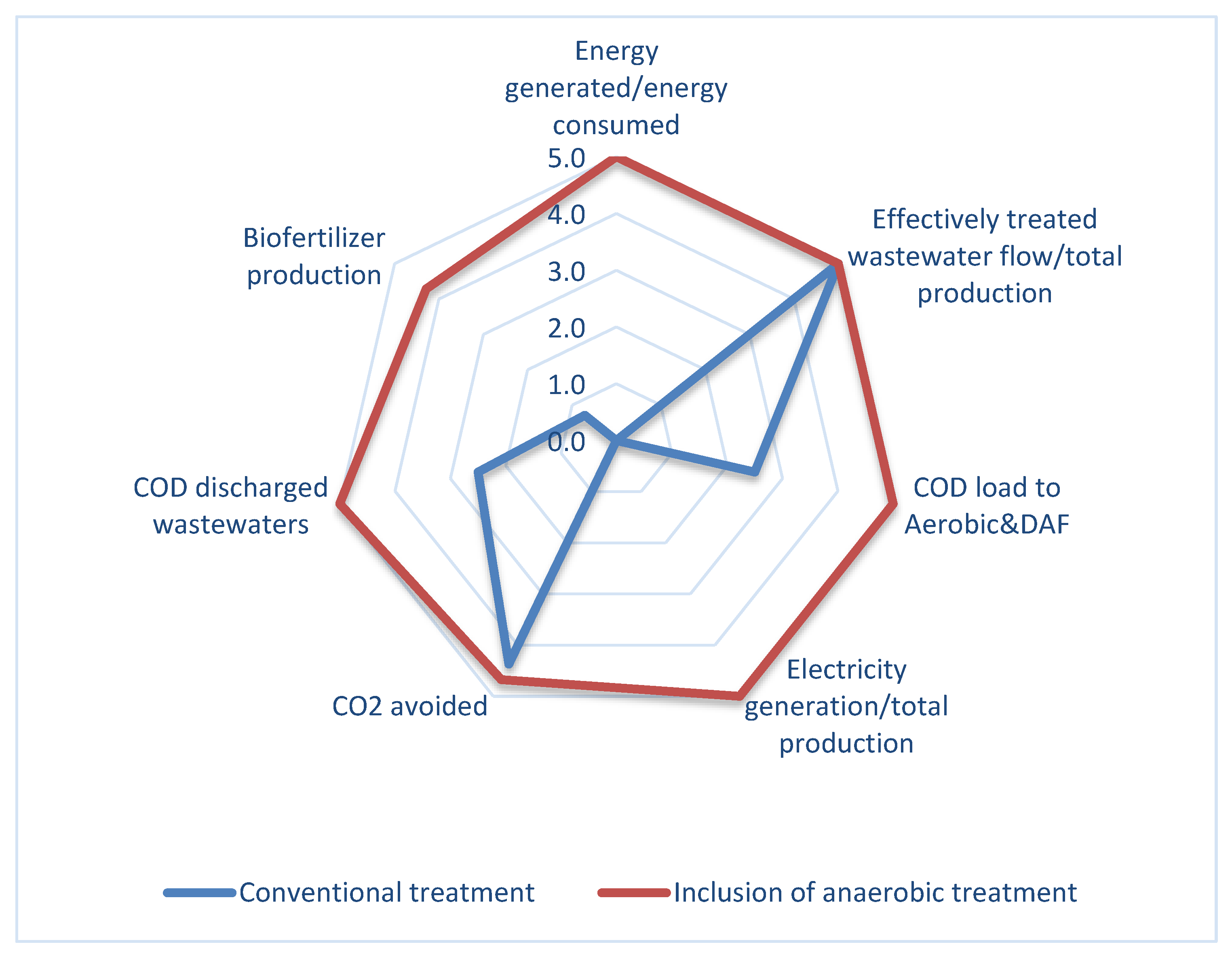

3.6. Biophysical Indicators of Sustainability for the Proposal

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- da Cruz Correia, P.F.; Mendes dos Reis, J.G.; Amorim, P.S.; Costa, J.S.d.; da Silva, M.T. Impacts of Brazilian Green Coffee Production and Its Logistical Corridors on the International Coffee Market. Logistics 2024, 8, 39. [Google Scholar] [CrossRef]

- de Melo Pereira, G.V.; de Carvalho Neto, D.P.; Magalhães Júnior, A.I.; do Prado, F.G.; Pagnoncelli, M.G.B.; Karp, S.G.; Soccol, C.R. Chapter Three—Chemical composition and health properties of coffee and coffee by-products. In Advances in Food and Nutrition Research; Toldrá, F., Ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 65–96. [Google Scholar]

- Kittichotsatsawat, Y.; Tippayawong, N.; Tippayawong, K.Y. Prediction of arabica coffee production using artificial neural network and multiple linear regression techniques. Sci. Rep. 2022, 12, 14488. [Google Scholar] [CrossRef] [PubMed]

- International Coffee Organization. Coffee Report and Outlook; International Coffee Organization: Boston, MA, USA, 2023. [Google Scholar]

- Bondam, A.F.; Diolinda da Silveira, D.; Pozzada dos Santos, J.; Hoffmann, J.F. Phenolic compounds from coffee by-products: Extraction and application in the food and pharmaceutical industries. Trends Food Sci. Technol. 2022, 123, 172–186. [Google Scholar] [CrossRef]

- Said, N.S.M.; Abdullah, S.R.S.; Ismail, N.I.; Hasan, H.A.; Othman, A.R. Phytoremediation of real coffee industry effluent through a continuous two-stage constructed wetland system. Environ. Technol. Innov. 2020, 17, 100502. [Google Scholar] [CrossRef]

- Erazo, S.; Agudelo-Escobar, L.M. Determination of Electrogenic Potential and Removal of Organic Matter from Industrial Coffee Wastewater Using a Native Community in a Non-Conventional Microbial Fuel Cell. Processes 2023, 11, 373. [Google Scholar] [CrossRef]

- Agudelo-Escobar, L.M.; Cabrera, S.E.; Avignone Rossa, C. A Bioelectrochemical System for Waste Degradation and Energy Recovery From Industrial Coffee Wastewater. Front. Chem. Eng. 2022, 4, 814987. [Google Scholar] [CrossRef]

- Campos, R.C.; Pinto, V.R.A.; Melo, L.F.; Rocha, S.J.S.S.D.; Coimbra, J.S. New sustainable perspectives for “Coffee Wastewater” and other by-products: A critical review. Future Foods 2021, 4, 100058. [Google Scholar] [CrossRef]

- Selvamurugan, M.; Doraisamy, P.; Maheswari, M. An integrated treatment system for coffee processing wastewater using anaerobic and aerobic process. Ecol. Eng. 2010, 36, 1686–1690. [Google Scholar] [CrossRef]

- Córdova Mosquera, A.; Gómez-Salcedo, Y.; Riera, M.A.; Rodríguez-Díaz, J.M.; Pereda-Reyes, I. Influencia de los procesos oxidativos avanzados en la digestión anaerobia de aguas residuales de la industria del café. Cent. Azúcar 2019, 46, 89–100. [Google Scholar]

- Bułkowska, K.; Zielińska, M. Enhanced Anaerobic Digestion of Spent Coffee Grounds: A Review of Pretreatment Strategies for Sustainable Valorization. Energies 2025, 18, 4810. [Google Scholar] [CrossRef]

- Deng, Z.; Sun, C.; Ma, G.; Zhang, X.; Guo, H.; Zhang, T.; Zhang, Y.; Hu, Y.; Li, D.; Li, Y.-Y.; et al. Anaerobic treatment of nitrogenous industrial organic wastewater by carbon–neutral processes integrated with anaerobic digestion and partial nitritation/anammox: Critical review of current advances and future directions. Bioresour. Technol. 2025, 415, 131648. [Google Scholar] [CrossRef]

- Dai, C.; Yang, L.; Wang, J.; Li, D.; Zhang, Y.; Zhou, X. Enhancing anaerobic digestion of pharmaceutical industries wastewater with the composite addition of zero valent iron (ZVI) and granular activated carbon (GAC). Bioresour. Technol. 2022, 346, 126566. [Google Scholar] [CrossRef]

- Huang, X. The Promotion of Anaerobic Digestion Technology Upgrades in Waste Stream Treatment Plants for Circular Economy in the Context of “Dual Carbon”: Global Status, Development Trend, and Future Challenges. Water 2024, 16, 3718. [Google Scholar] [CrossRef]

- Pérez-Pérez, T.; Pereda-Reyes, I.; Correia, G.T.; Pozzi, E.; Kwong, W.H.; Oliva-Merencio, D.; Zaiat, M.; Montalvo, S.; Huiliñir, C. Performance of EGSB reactor using natural zeolite as support for treatment of synthetic swine wastewater. J. Environ. Chem. Eng. 2021, 9, 104922. [Google Scholar] [CrossRef]

- Jung, K.-W.; Kim, D.-H.; Lee, M.-Y.; Shin, H.-S. Two-stage UASB reactor converting coffee drink manufacturing wastewater to hydrogen and methane. Int. J. Hydrogen Energy 2012, 37, 7473–7481. [Google Scholar] [CrossRef]

- Rodrigues, C.V.; Camargo, F.P.; Lourenço, V.A.; Sakamoto, I.K.; Maintinguer, S.I.; Silva, E.L.; Varesche, M.B.A. Optimized conditions for methane production and energy valorization through co-digestion of solid and liquid wastes from coffee and beer industries using granular sludge and cattle manure. J. Environ. Chem. Eng. 2023, 11, 111250. [Google Scholar] [CrossRef]

- Manthos, G.; Zagklis, D.; Zafiri, C.; Kornaros, M. Techno-Economic Assessment of Anaerobic Digestion for Olive Oil Industry Effluents in Greece. Sustainability 2024, 16, 1886. [Google Scholar] [CrossRef]

- Fernandez, N.; Forster, C.F. A study of the operation of mesophilic and thermophilic anaerobic filters treating a synthetic coffee waste. Bioresour. Technol. 1993, 45, 223–227. [Google Scholar] [CrossRef]

- Charles, W.; Carnaje, N.P.; Cord-Ruwisch, R. Methane conversion efficiency as a simple control parameter for an anaerobic digester at high loading rates. Water Sci. Technol. 2011, 64, 534–540. [Google Scholar] [CrossRef]

- Michaud, S.; Bernet, N.; Buffière, P.; Roustan, M.; Moletta, R. Methane yield as a monitoring parameter for the start-up of anaerobic fixed film reactors. Water Res. 2002, 36, 1385–1391. [Google Scholar] [CrossRef] [PubMed]

- Standard Methods for the Examination of Water and Wastewater, 24th ed.; American Public Health Association: Washington, DC, USA, 2022; p. 1536.

- Kapdan, I.K. Kinetic analysis of dyestuff and COD removal from synthetic wastewater in an anaerobic packed column reactor. Process Biochem. 2005, 40, 2545–2550. [Google Scholar] [CrossRef]

- Grau, P.; Dohányos, M.; Chudoba, J. Kinetics of multicomponent substrate removal by activated sludge. Water Res. 1975, 9, 637–642. [Google Scholar] [CrossRef]

- Green, D.W.; Southard, M.Z. Perry’s Chemical Engineers’ Handbook, 9th ed.; McGraw-Hill Education: New York, NY, USA, 2019; p. 1. [Google Scholar]

- Van Der Berg, D.J.; Teke, G.M.; Görgens, J.F.; Van Rensburg, E. Predicting commercial-scale anaerobic digestion using biomethane potential. Renew. Energy 2024, 235, 121304. [Google Scholar] [CrossRef]

- Ashenafi Hailemariam, F.; Velmurugan, P.; Selvaraj, S.K. Treatment of wastewater from coffee (coffea arebica) industries using mixed culture Pseudomonas florescence and Escherichia coli bacteria. Mater. Today Proc. 2021, 46, 7396–7401. [Google Scholar] [CrossRef]

- Novita, E. Biodegradability Simulation of Coffee Wastewater Using Instant Coffee. Agric. Agric. Sci. Procedia 2016, 9, 217–229. [Google Scholar] [CrossRef]

- Amani, T.; Nosrati, M.; Sreekrishnan, T.R. Anaerobic digestion from the viewpoint of microbiological, chemical, and operational aspects—A review. Environ. Rev. 2010, 18, 255–278. [Google Scholar] [CrossRef]

- Dinsdale, R.M.; Hawkes, F.R.; Hawkes, D.L. The mesophilic and thermophilic anaerobic digestion of coffee waste containing coffee grounds. Water Res. 1996, 30, 371–377. [Google Scholar] [CrossRef]

- Aslanzadeh, S.; Rajendran, K.; Taherzadeh, M.J. A comparative study between single-and two-stage anaerobic digestion processes: Effects of organic loading rate and hydraulic retention time. Int. Biodeterior. Biodegrad. 2014, 95, 181–188. [Google Scholar] [CrossRef]

- Cruz-Salomón, A.; Ríos-Valdovinos, E.; Pola-Albores, F.; Lagunas-Rivera, S.; Meza-Gordillo, R.; Ruíz-Valdiviezo, V.M. Evaluation of hydraulic retention time on treatment of coffee processing wastewater (CPWW) in EGSB bioreactor. Sustainability 2017, 10, 83. [Google Scholar] [CrossRef]

- Cárdenas-Cleves, L.M.; Marmolejo-Rebellón, L.F.; Torres-Lozada, P. Anaerobic Codigestion of Sugarcane Press Mud with Food Waste: Effects on Hydrolysis Stage, Methane Yield, and Synergistic Effects. Int. J. Chem. Eng. 2018, 2018, 9351848. [Google Scholar] [CrossRef]

- Raposo, F.; De la Rubia, M.A.; Fernández-Cegrí, V.; Borja, R. Anaerobic digestion of solid organic substrates in batch mode: An overview relating to methane yields and experimental procedures. Renew. Sustain. Energy Rev. 2012, 16, 861–877. [Google Scholar] [CrossRef]

- Manchala, K.R.; Sun, Y.; Zhang, D.; Wang, Z.-W. Anaerobic Digestion Modelling. In Advances in Bioenergy; Elsevier: Amsterdam, Netherlands, 2017; Volume 2, pp. 69–141. [Google Scholar]

- Padilla-Gasca, E.; López-López, A. Kinetics of Organic Matter Degradation in an Upflow Anaerobic Filter Using Slaughterhouse Wastewater. J. Bioremed. Biodegrad. 2010, 1, 106. [Google Scholar] [CrossRef]

- Okoli, C.S.; Okonkwo, P.C. Substrate Reduction Kinetics and Performance Evaluation of Fluidized-Bed Reactor for Treatment of Brewery Wastewater. Niger. J. Technol. 2015, 35, 91–96. [Google Scholar] [CrossRef]

- Sumantri, I.; Budiyono, B.; Purwanto, P. Kinetic Study of Anaerobic Digestion of Ketchup Industry Wastewater in a Three-stages Anaerobic Baffled Reactor (ABR). Bull. Chem. React. Eng. Catal. 2019, 14, 326–335. [Google Scholar] [CrossRef]

- Li, Y.; Lu, J.; Xu, F.; Li, Y.; Li, D.; Wang, G.; Li, S.; Zhang, H.; Wu, Y.; Shah, A.; et al. Reactor performance and economic evaluation of anaerobic co-digestion of dairy manure with corn stover and tomato residues under liquid, hemi-solid, and solid state conditions. Bioresour. Technol. 2018, 270, 103–112. [Google Scholar] [CrossRef]

- Li, Y.; Han, Y.; Zhang, Y.; Luo, W.; Li, G. Anaerobic digestion of different agricultural wastes: A techno-economic assessment. Bioresour. Technol. 2020, 315, 123836. [Google Scholar] [CrossRef]

- Mainardis, M.; Flaibani, S.; Mazzolini, F.; Peressotti, A.; Goi, D. Techno-economic analysis of anaerobic digestion implementation in small Italian breweries and evaluation of biochar and granular activated carbon addition effect on methane yield. J. Environ. Chem. Eng. 2019, 7, 103184. [Google Scholar] [CrossRef]

- Salsabil, M.R.; Laurent, J.; Casellas, M.; Dagot, C. Techno-economic evaluation of thermal treatment, ozonation and sonication for the reduction of wastewater biomass volume before aerobic or anaerobic digestion. J. Hazard. Mater. 2010, 174, 323–333. [Google Scholar] [CrossRef]

- Carlini, M.; Mosconi, E.; Castellucci, S.; Villarini, M.; Colantoni, A. An Economical Evaluation of Anaerobic Digestion Plants Fed with Organic Agro-Industrial Waste. Energies 2017, 10, 1165. [Google Scholar] [CrossRef]

- Unver, O.; Bhaduri, A.; Hoogeveen, J. Water-use efficiency and productivity improvements towards a sustainable pathway for meeting future water demand. Water Secur. 2017, 1, 21–27. [Google Scholar] [CrossRef]

- Vanham, D.; Mekonnen, M.M. The scarcity-weighted water footprint provides unreliable water sustainability scoring. Sci. Total Environ. 2021, 756, 143992. [Google Scholar] [CrossRef] [PubMed]

- Safieddin Ardebili, S.M. Green electricity generation potential from biogas produced by anaerobic digestion of farm animal waste and agriculture residues in Iran. Renew. Energy 2020, 154, 29–37. [Google Scholar] [CrossRef]

- Qian, S.; Chen, L.; Xu, S.; Zeng, C.; Lian, X.; Xia, Z.; Zou, J. Research on Methane-Rich Biogas Production Technology by Anaerobic Digestion Under Carbon Neutrality: A Review. Sustainability 2025, 17, 1425. [Google Scholar] [CrossRef]

- Simeonov, I.; Chorukova, E.; Kabaivanova, L. Two-Stage Anaerobic Digestion for Green Energy Production: A Review. Processes 2025, 13, 294. [Google Scholar] [CrossRef]

| Parameter | Method | Equipment |

|---|---|---|

| pH | Potentiometric | Fisher Scientific Accumet AB150 (Thermo Fisher Scientific, Singapore) |

| Salinity, conductivity, dissolved oxygen | Multiparametric measurement | HANNA HI98194 (Hanna Instruments, Woonsocket, RI, USA) |

| COD | UV-Vis spectrophotometer | Thermo Scientific-Evolution 60S (Thermo Fisher Scientific, Waltham, MA, USA) |

| BOD5 | Respirometric | BOD Hach-BOD Trak II (Hach, Düsseldorf, Germany) |

| TS, VS, and VSS | Gravimetric | Memmert D-91126 (Memmert GmbH + Co. KG, Schwabach, Germany) |

| VFA/Alc ratio | Potentiometric/titration | Fisher Scientific Accumet AB150 |

| Tannin concentration | UV-Vis spectrophotometer | Thermo Scientific-Evolution 60S |

| Code | Denomination |

|---|---|

| FG | Rotary filter |

| BC | Centrifugal pump |

| TE | Equalization tank |

| R | Reactor |

| SA | Air blower |

| S | Sedimentation tank |

| T | Storage tank |

| BD | Dosing pump |

| FP | Filter press |

| Ƴ | Coagulation–flocculation mixer |

| CO | Compressor |

| Q | Gas burner |

| AG | Gas storage tank |

| RC | Combustion unit |

| Parameter | Equation |

|---|---|

| Energy generated/energy consumed | kWhe generated/kWhe consumed |

| Effectively treated wastewater flow/total production | m3/tons of coffee |

| COD load to Aerobic & DAF | Value (kgCOD d−1) |

| Electricity generation/total production | kWhe generated/tons of coffee |

| CO2 avoided | Value (tons CO2) |

| COD discharged wastewater/COD initial | COD discharged wastewater/COD initial |

| Biofertilizer production/total production | Biofertilizer production/tons of coffee |

| Parameter | Units | Wastewater from the Instant Coffee Industry | Simulated Wastewater |

|---|---|---|---|

| pH | 5.25 ± 1.25 | 5.5 ± 0.5 | |

| Salinity | % | 1.17 ± 0.54 | 0.35 ± 0.11 |

| Dissolved oxygen | mg L−1 | 3.3 ± 2.9 | 7.46 ± 1.6 |

| BOD5 | mg L−1 | 3397.8 ± 1090.3 | 3387.8 ± 139.7 |

| COD | mg L−1 | 6124.8 ± 2608.2 | 7537.96 ± 84.64 |

| Biodegradability index | 0.5 ± 0.09 | 0.44 ± 0.017 | |

| Tannins | mg L−1 | 333.1 ± 45.4 | 416.01 ± 46.9 |

| Process | Principal Parameters | Other Remarks |

|---|---|---|

| Anaerobic digestion (UAF) | Effective volume: 1530 m3, HRT: 7.5 d, COD: 7.5 kgCOD m−3 Biogas generation: 623 m3 | It is placed before the existing aerobic reactor |

| Biogas biodesulphurization | Capacity: 80 m3 Biogas upgraded: 540 m3 | Upgrade biogas from 52% to 60% of methane content |

| CHP unit | Electric energy: 1117.9 kWh Thermal energy: 1441.9 kWh | Revenues for energy sale |

| Separation processes | Semisolid sludge as biofertilizer: 50.6 t d−1 | Revenues for biofertilizer sale |

| Parameter | Value | Unit |

|---|---|---|

| Instant coffee production | 11.5 | t d−1 |

| Volume of wastewater generated | 209 | m3 d−1 |

| Volume of biogas produced | 623.13 | m3 d−1 |

| Volume of methane produced | 236.79 | m3 d−1 |

| Amount of CO2 not emitted due to the application of anaerobic treatment | 17.93 | t d−1 |

| Amount of CO2 not emitted in the conventional treatment | 7.17 | t d−1 |

| Amount of electrical energy consumed in the technological proposal | 669.96 | kWhe d−1 |

| Amount of electrical energy generated from the biogas produced | 1117.92 | kWhe d−1 |

| COD in affluent | 7500 | mg L−1 |

| COD load to the conventional treatment/DAF | 197.5 | kg d−1 |

| COD discharged wastewater in the conventional treatment | 946 | mg L−1 |

| COD load to the AD + conventional treatment/DAF | 101.4 | kg d−1 |

| COD discharged wastewater in the AD + conventional treatment/DAF | 485 | mg L−1 |

| Amount of biofertilizer produced in the conventional treatment | 2.1 | m3 d−1 |

| Amount of biofertilizer produced in the AD + conventional treatment/DAF | 12.6 | m3 d−1 |

| Indicators | Conventional Treatment Plant | Treatment Plant with AD |

|---|---|---|

| Energy generated/energy consumed | 0.0 | 5.0 |

| Effectively treated wastewater flow/total production | 5.0 | 5.0 |

| COD load to Aerobic & DAF | 2.5 | 5.0 |

| Electricity generation/total production | 0.0 | 5.0 |

| CO2 avoided | 4.4 | 4.7 |

| COD discharged wastewaters | 2.5 | 5.0 |

| Biofertilizer production | 0.7 | 4.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Córdova-Mosquera, R.A.; Morales-Paredes, C.A.; Pérez-Almeida, I.B.; Saquete, M.D.; Boluda-Botella, N.; Oliva-Merencio, D.; Pais-Chanfrau, J.-M.; Rodríguez-Díaz, J.M.; Pereda-Reyes, I. Sustainable Wastewater Treatment Through Anaerobic Digestion in the Instant Coffee Industry: A Techno-Economic and Environmental Assessment. Water 2025, 17, 3207. https://doi.org/10.3390/w17223207

Córdova-Mosquera RA, Morales-Paredes CA, Pérez-Almeida IB, Saquete MD, Boluda-Botella N, Oliva-Merencio D, Pais-Chanfrau J-M, Rodríguez-Díaz JM, Pereda-Reyes I. Sustainable Wastewater Treatment Through Anaerobic Digestion in the Instant Coffee Industry: A Techno-Economic and Environmental Assessment. Water. 2025; 17(22):3207. https://doi.org/10.3390/w17223207

Chicago/Turabian StyleCórdova-Mosquera, Rosa Alexandra, Carlos Augusto Morales-Paredes, Iris B. Pérez-Almeida, María Dolores Saquete, Nuria Boluda-Botella, Deny Oliva-Merencio, José-Manuel Pais-Chanfrau, Joan Manuel Rodríguez-Díaz, and Ileana Pereda-Reyes. 2025. "Sustainable Wastewater Treatment Through Anaerobic Digestion in the Instant Coffee Industry: A Techno-Economic and Environmental Assessment" Water 17, no. 22: 3207. https://doi.org/10.3390/w17223207

APA StyleCórdova-Mosquera, R. A., Morales-Paredes, C. A., Pérez-Almeida, I. B., Saquete, M. D., Boluda-Botella, N., Oliva-Merencio, D., Pais-Chanfrau, J.-M., Rodríguez-Díaz, J. M., & Pereda-Reyes, I. (2025). Sustainable Wastewater Treatment Through Anaerobic Digestion in the Instant Coffee Industry: A Techno-Economic and Environmental Assessment. Water, 17(22), 3207. https://doi.org/10.3390/w17223207