Application of Renewable Energy in Agriculture of the Republic of Uzbekistan

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

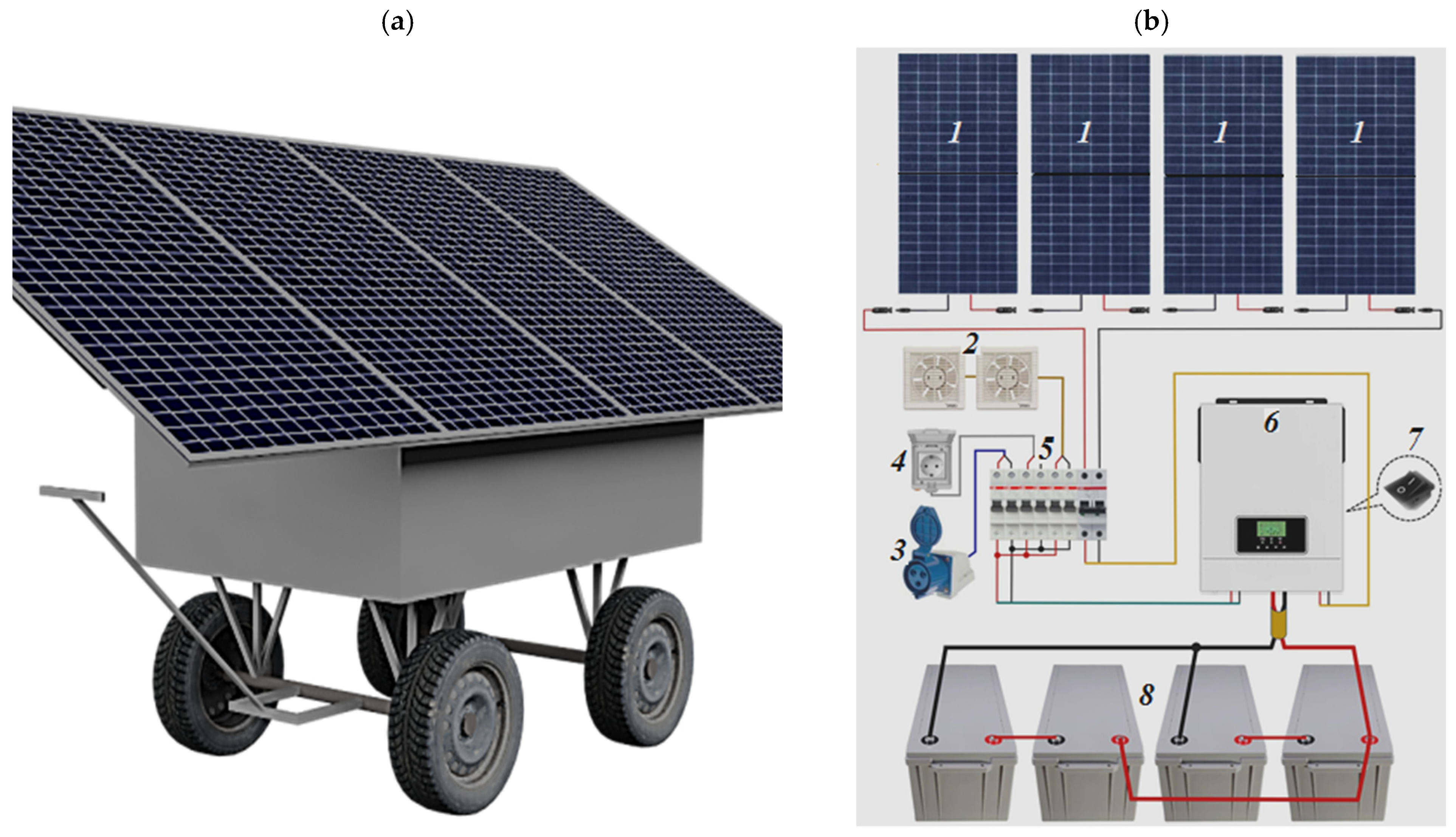

- Mobile Photovoltaic Power Unit (MPPU-8-500-4000) with capacity—N = 4000 W, providing electricity to water lifting plants for water supply for drip irrigation of lands with area—ω = 10 and more hectares.

- Mobile Photovoltaic Power Unit (MPPU-2-550-1100) with capacity—N = 1100 W, providing electricity to water lifting plants for water supply for drip irrigation of lands with area—ω = 0.01–1.0 hectares.

- Mobile Photovoltaic Power Unit (MPPU-4-500-2000) with capacity—N = 2000 W, providing electricity for the own needs of medium and small irrigation pumping stations (for pumping water from drainage systems and lighting).

3.1. Mobile Photovoltaic Power Unit with Capacity—N = 4000 W (MPPU-8-500-4000)

- -

- mechanical impacts-impacts or vibrations, which may damage internal components; and structures, as well as rupture of electrical connections;

- -

- damage to grounding and cable insulation;

- -

- corrosion or oxidation of contacts or connections;

- -

- discharge of batteries (when stored for more than 1 week—loss of capacity by 30–40%, more than 1 month—by 80–100%, which can put it out of operation);

- -

- damage of photovoltaic panels, inverters, connections and other parts under the influence of rain, snow, ice and moisture from them;

- -

- in heavy snowfall or hurricane-force winds, panels and fasteners may snap off;

- -

- and other damage.

- -

- can be used all year round;

- -

- the capability to adjust the orientation of solar panels in accordance with the Sun’s daily trajectory can enhance electricity generation efficiency by up to 45%;

- -

- moving the MPPU-8-500-4000 itself;

- -

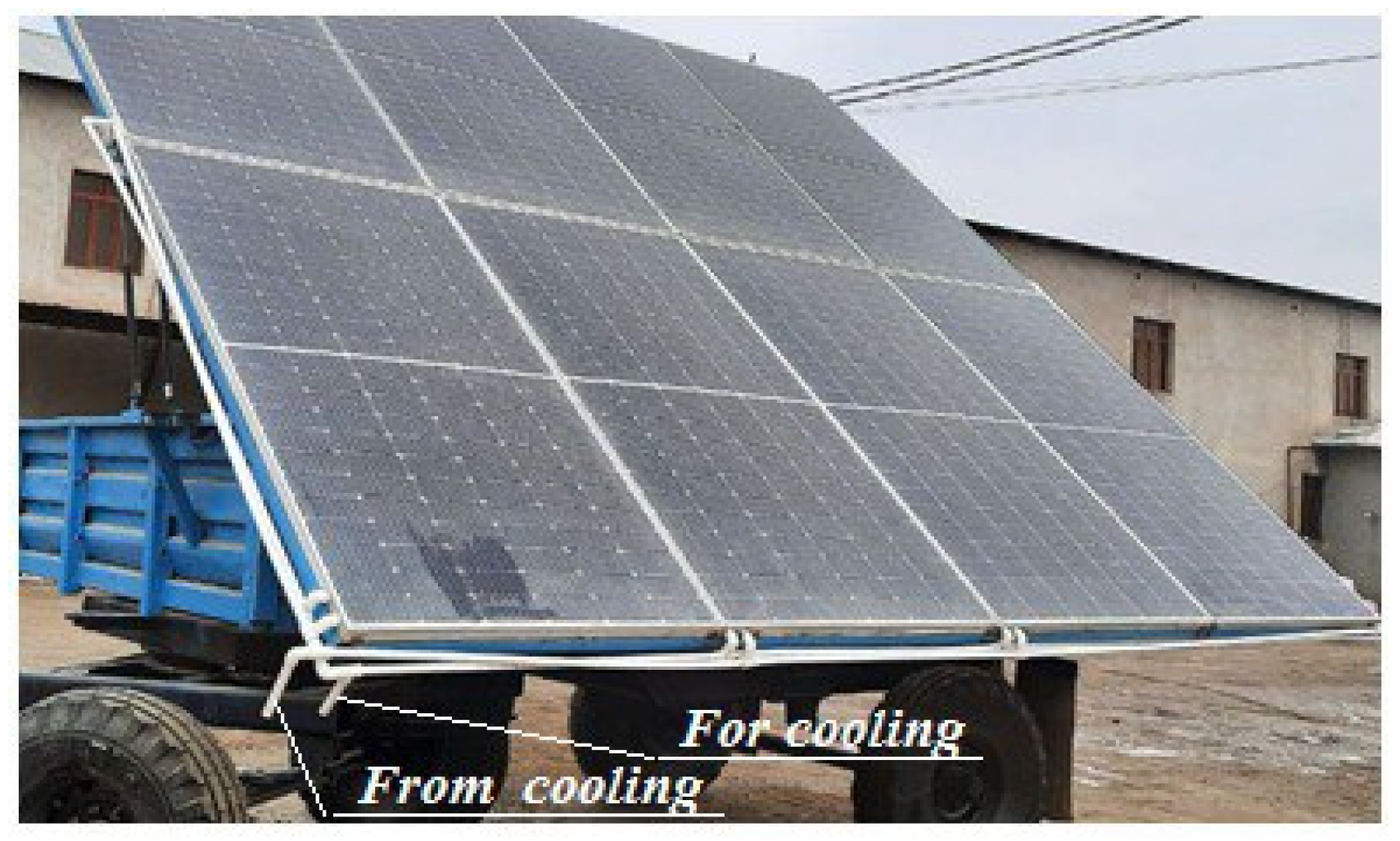

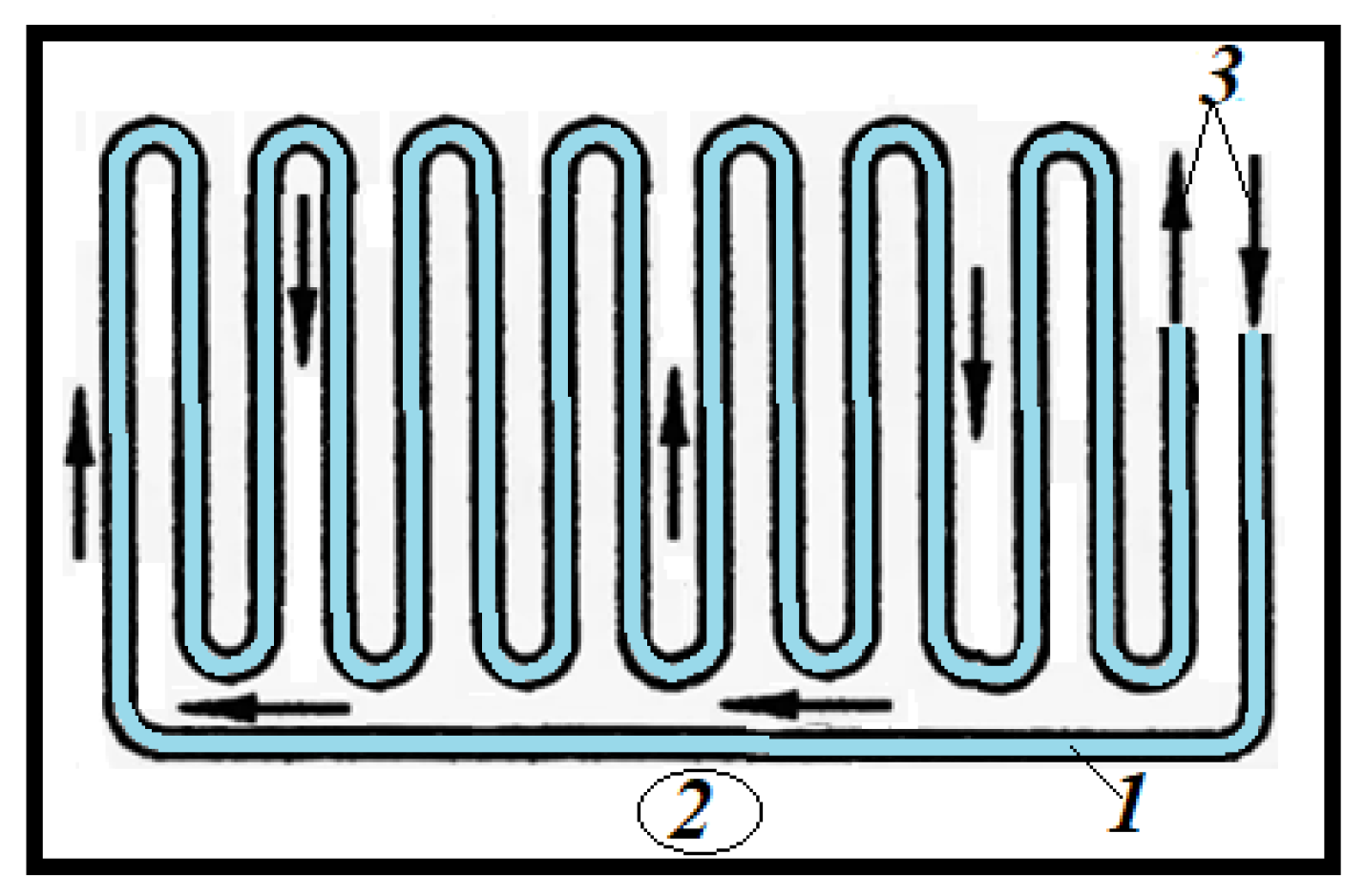

- to prevent efficiency losses in the photovoltaic system during hot summer conditions, the panels were equipped with a water-cooling system designed to maintain their operating temperature within the range of 25–28 °C;

- -

- water supply to furrows and drip irrigation system.

- -

- service of several fields (farms) during the period of (drip) irrigation;

- -

- power supply of electrical appliances at small production facilities of farms in the fall and winter periods;

- -

- lighting, heating and cooling of dwellings and greenhouses;

- -

- lighting, heating and cooling of stores, barber stores, butcher stores, workshops, offices and other public service facilities;

- -

- provision of electric power to equipment for fodder preparation for cattle of livestock farms;

- -

- supply of drinking water for livestock and poultry;

- -

- can be used for other purposes.

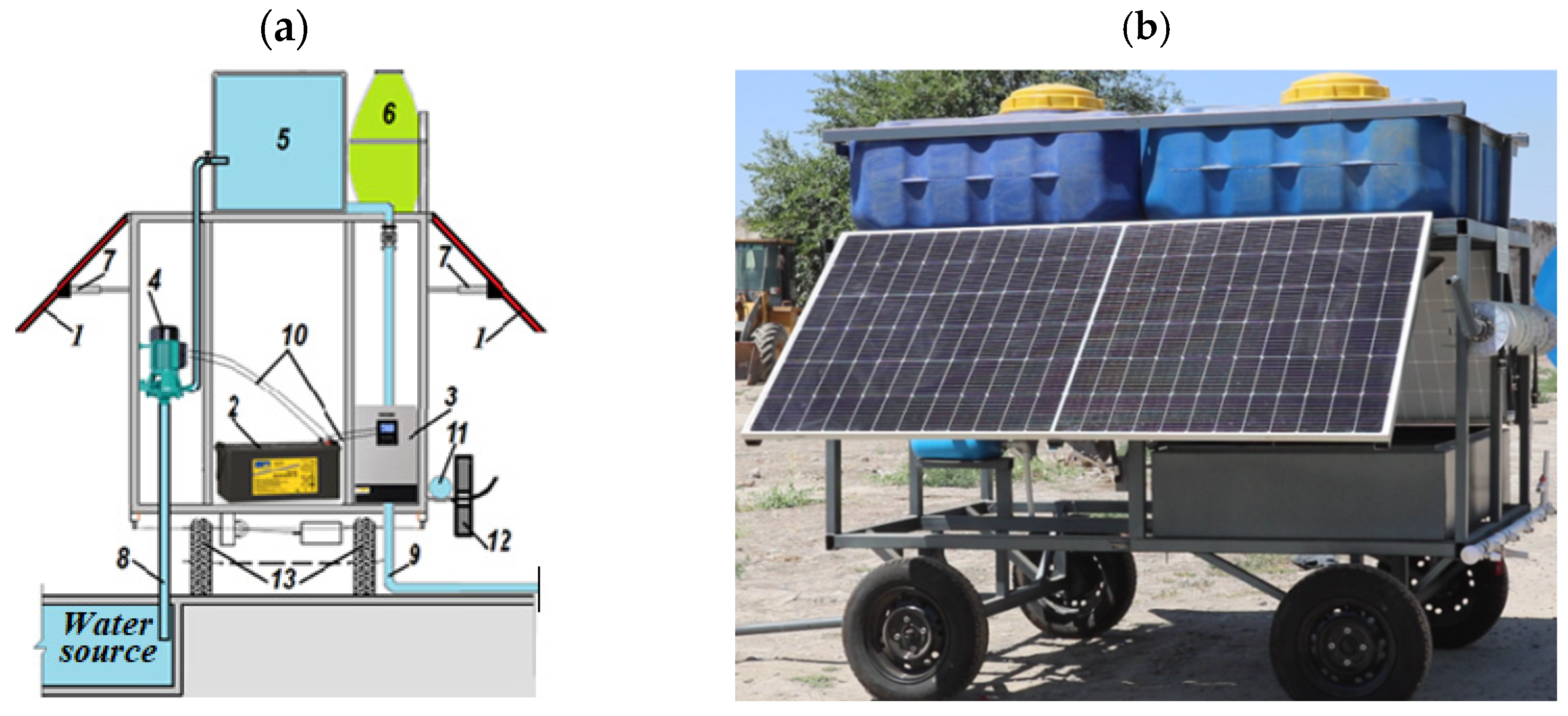

3.2. Mobile Photovoltaic Power Unit with Capacity-N = 1100 W (MPPU-2-550-1100)

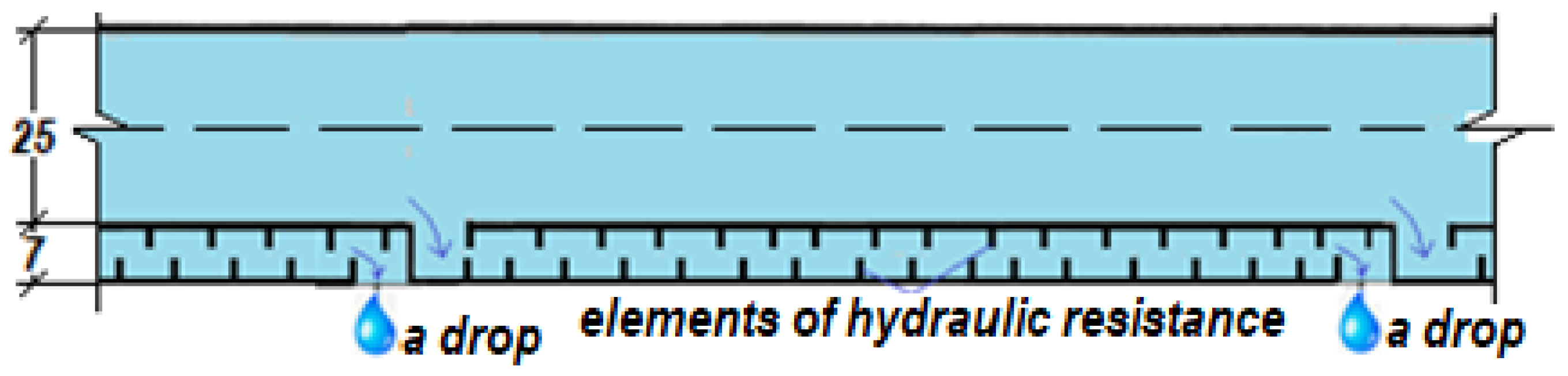

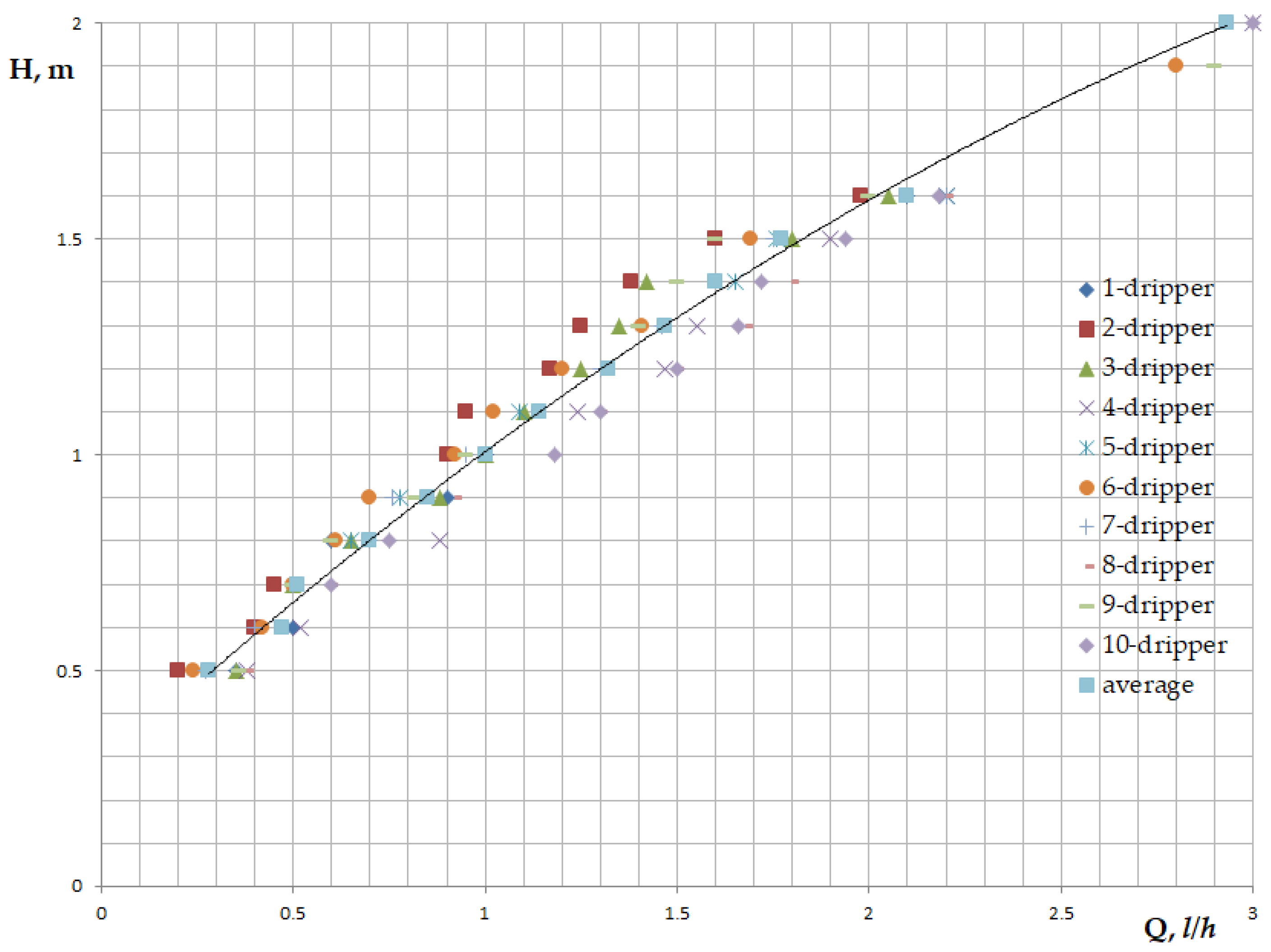

3.2.1. Low Pressure Drip Irrigation System

- Not only colloidal particles and microorganisms contained in irrigation water, but also sand with a diameter of 0.5 mm, as well as suspended sediment moving in the water, can freely pass through the drip lines.

- Operation at a low head of 1.6 ÷ 2.0 m (without installation of a pump creating a head of 20 ÷ 30 m).

- Low cost, simplicity of construction, possibility of installation and operation, repair and dismantling by any water user.

- Production of raw materials and equipment necessary for the system in Uzbekistan.

- When reaching the water column head of 2.5–3.0 m or stuck low-pressure polyethylene pipe in weeds, there were cases of its cracking.

- In low-pressure drip irrigation system, the number of droplets remains constant over time. In this case, the critical stage of crop growth, i.e., the time of full maturation and ripening of grains, is not reached, resulting in yield losses.

- When water supply was stopped (due to a malfunction), the water in the pipe heated up to 75–80 °C, which led to deformation of the polyethylene pipe with drippers (stretching in width and length, expansion of the joints of drippers) and even melting of the polyethylene pipe.

- -

- droplet limit −0.5 m;

- -

- the limit of transition from a drop to a water jet −1.8 m.

3.2.2. Photoelectric Solar Panels

- -

- introduction of drip irrigation on small areas (ω = 0.01–1.0 hectare)—farm, homestead, and dacha plots, as well as in greenhouse farms;

- -

- the possibility of using renewable energy sources (solar);

- -

- cooling of solar panels in hot periods of the year (at t = 40–50 °C);

- -

- low cost of the system, simplicity of construction;

- -

- during the non-vegetation period (autumn–winter), the energy produced by the PV system can be used for other purposes (for supplying electrical equipment of small production enterprises of farms; for lighting, heating, and cooling of residential houses, stores, hairdressing salons, butcher stores, workshops, offices, and other consumer service facilities; for preparing fodder for livestock and poultry farms and supplying drinking water for livestock and poultry farms, etc.);

- -

- manufacturing of all parts from local raw materials;

- -

- utilization of solar energy for the operation of the water pumping device;

- -

- use of compact tanks for water and fertilizer intake instead of a water intake basin;

- -

- no need for qualified specialists for operation;

- -

- ease of installation and operation, repair and dismantling, storage;

- -

- possibility to develop an irrigation regime for rice crops (melon crops) on small areas.

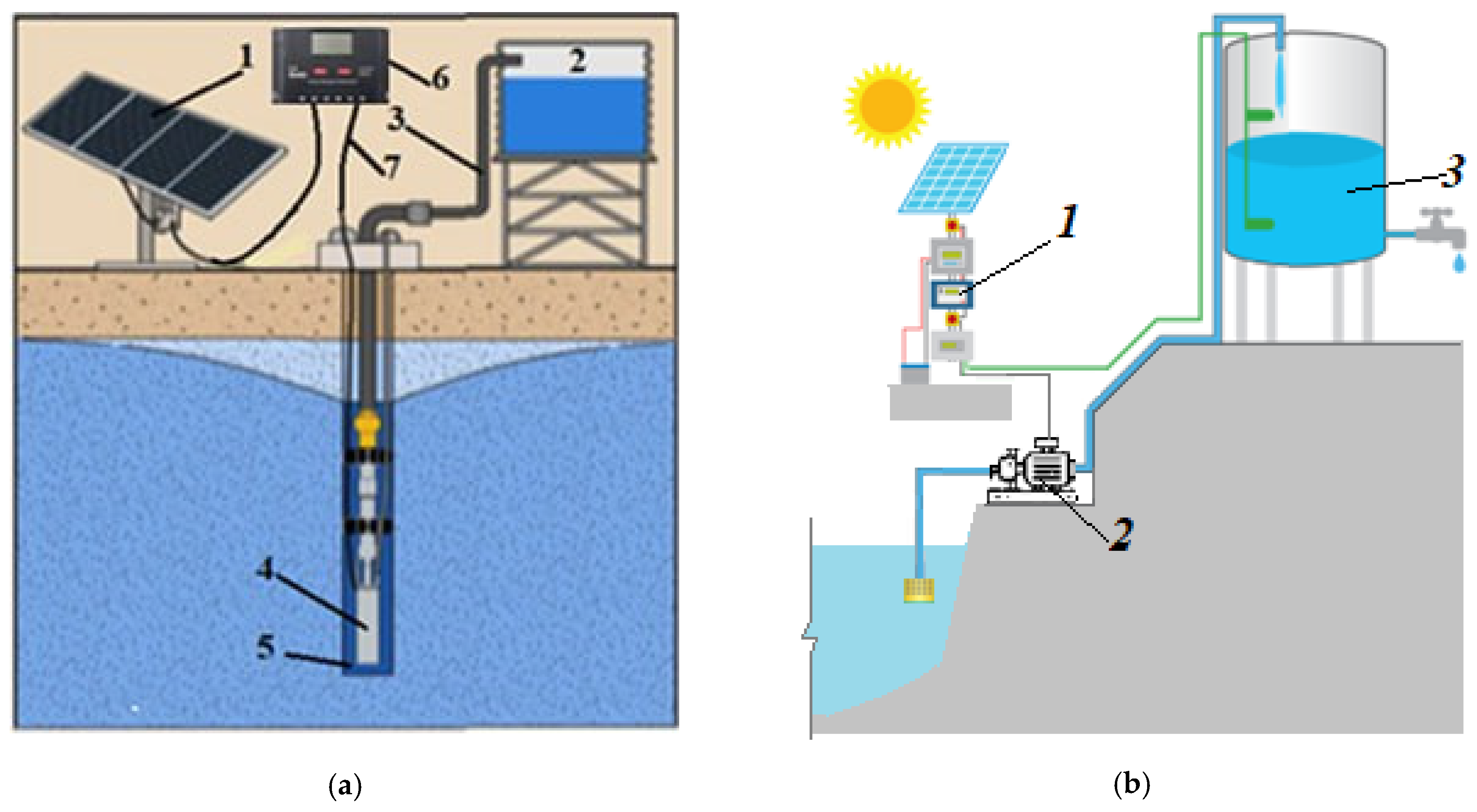

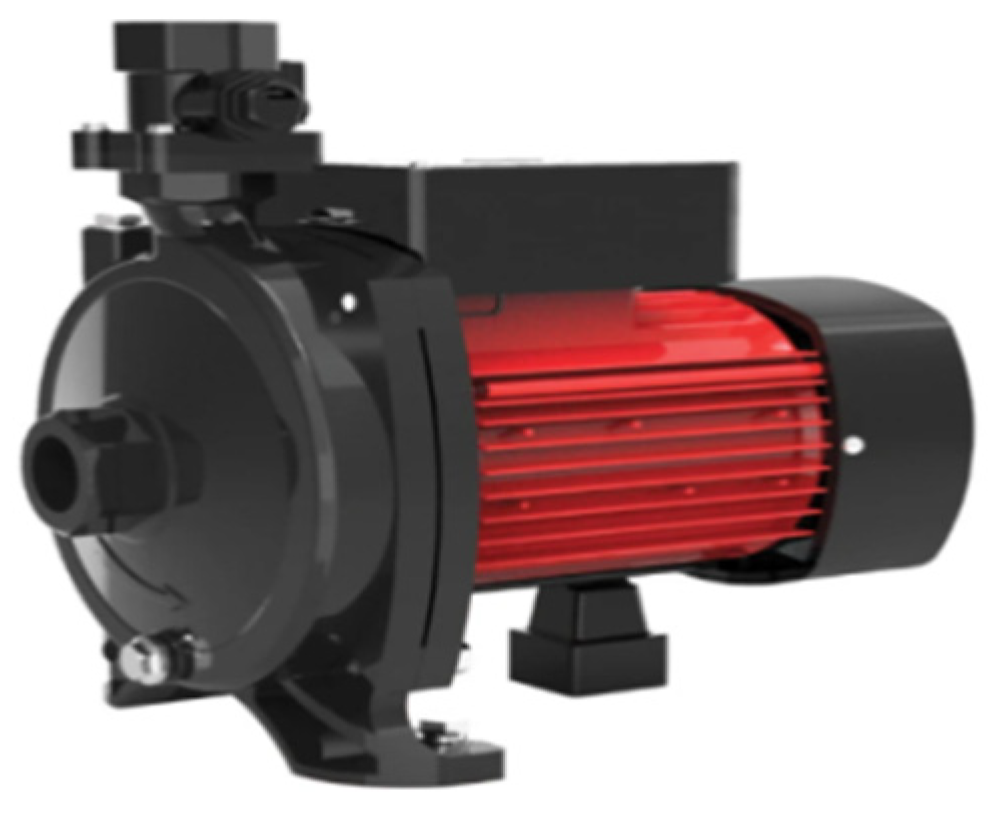

3.2.3. Pumping Installation

3.2.4. Four-Wheeled Cart with Metal Structure

3.2.5. Automated Control System

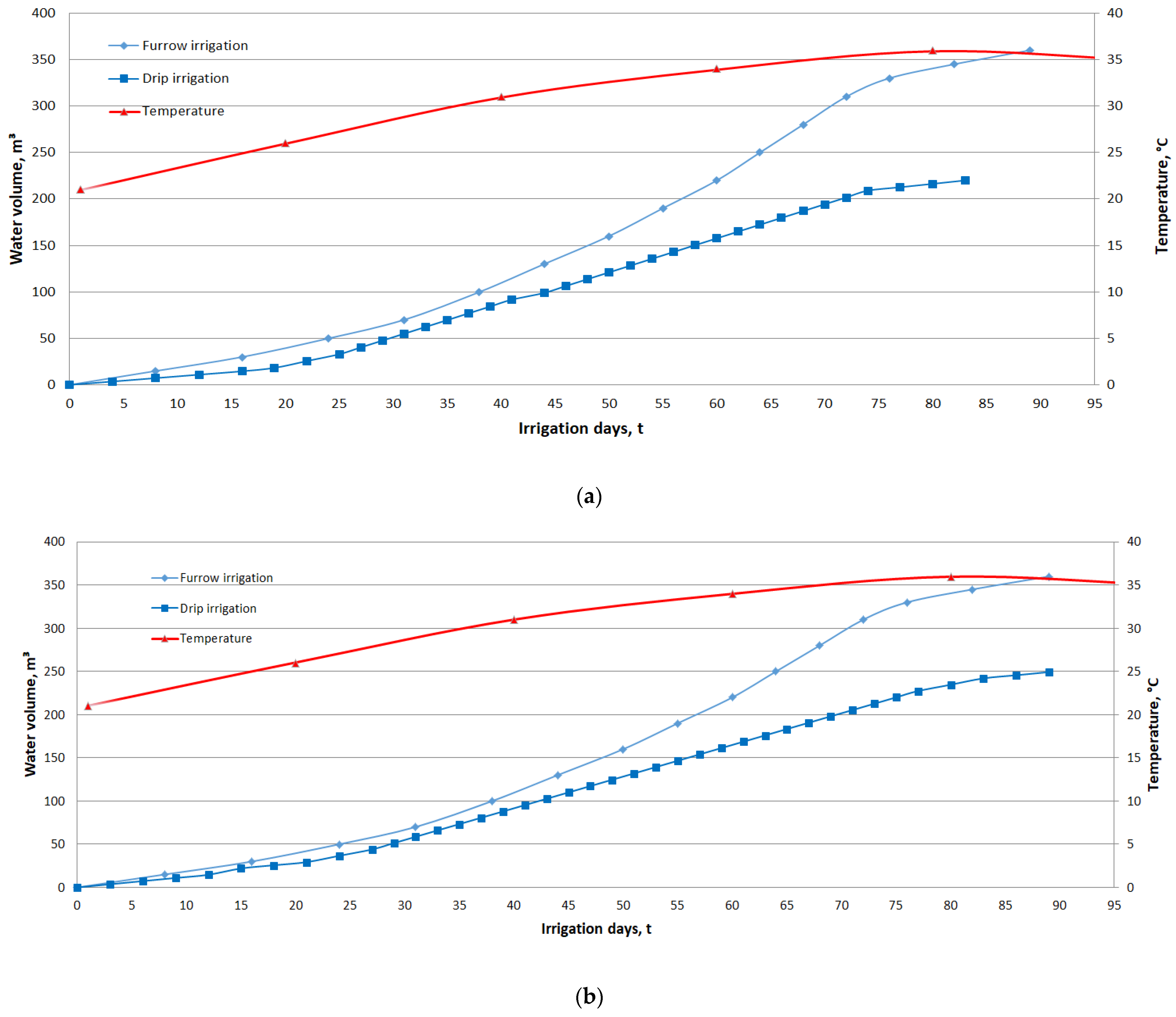

3.2.6. Field Studies to Determine the Drip Irrigation Regime with the Installation of MSUE-2-550-1100

3.3. Mobile Photovoltaic Power Unit with Capacity—N = 2000 W (MPPU-4-500-2000)

3.4. Cooling System for Photovoltaic Solar Panels

3.5. Clean Energy Production

4. Conclusions

- 1.

- Mobile Photovoltaic Power Unit MPPU-8-500-4000 is designed for water supply to agricultural farms and cluster fields with an area of ω = 10.0 ha or more. This unit has the following advantages:

- -

- its mobility enables year-round use for supplying drip irrigation systems of one or several farms during the growing season, as well as for powering electrical equipment at small production facilities of farms in the autumn–winter period;

- -

- the ability to adjust the orientation of solar panels in accordance with the daily trajectory of the sun increases electricity generation efficiency by 1.5–2 times;

- -

- to prevent efficiency losses of the photovoltaic system during hot summer conditions, the panels are equipped with a water-cooling system that maintains their operating temperature in the range of 25–27 °C.

- 2.

- Mobile Photovoltaic Power Unit MPPU-2-550-1100 is designed for water supply to households and garden plots, greenhouses, as well as dehkan farms with an area of ω = 0.01–1.0 ha. This unit offers the following advantages:

- -

- its mobility enables year-round use for drip irrigation of several small plots belonging to one or more farms during the growing season, as well as for lighting and supplying small-capacity electrical appliances in private households in the autumn–winter period;

- -

- the system is equipped with water cooling to maintain the operating temperature of photovoltaic panels within 25–27 °C during summer;

- -

- the capability to adjust the orientation of the solar panels in line with the sun’s daily trajectory increases electricity generation efficiency by 1.5–2 times.

- 3.

- Mobile Photovoltaic Power Unit MPPU-4-500-2000 is designed for supplying energy to auxiliary needs (drainage systems and lighting) of small and medium-sized irrigation pumping stations. This unit provides the following benefits:

- -

- the application of the MPPU-4-500-2000 at pumping stations prevents flooding of the underground part of the station building in the event of an emergency power outage;

- -

- the use of a low-power submersible pumping unit (750 W) for drainage water reduces, and in some stations even eliminates, the need to operate more powerful drainage pumps installed in the station building according to the design.

- 4.

- Mobile photovoltaic power units MPPU-8-500-4000, MPPU-2-550-1100, and MPPU-4-500-2000 can also be applied for water and energy supply in other sectors of the economy.

- 5.

- Observations of mobile photovoltaic systems installed at pumping stations during the growing season revealed that 75–80% of the generated electricity was consumed by submersible pumps, as increased pumping led to higher volumes of gland filtration water. The remaining 20–25% of the electricity was utilized for lighting the pump station building at night. In winter, when the main pump units are shut down and filtration in the engine room is minimized, 72–77% of the generated electricity is allocated to building lighting and the personal needs of operating personnel.

- 6.

- The deployment of mobile, low-pressure drip irrigation systems integrated with photovoltaic panels on household and garden plots, greenhouses, as well as dehkan farms (ω = 0.01–1.0 ha), represents a sustainable adaptation measure to climate change. Such systems can enhance the reliability of water supply for agricultural crops in Uzbekistan, across Central Asia, and in other arid regions, thereby strengthening food security and supporting the resilience of rural communities.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Population of Central Asia 2025. Available online: https://www.worldometers.info/world-population/central-asia-population/ (accessed on 19 September 2025).

- Eurasian Development Bank. Efficient Irrigation and Water Conservation in Central Asia; Reports and Working Papers 23/4; Eurasian Development Bank: Almaty, Kazakhstan, 2023; p. 120. Available online: https://eabr.org/analytics/special-reports/effektivnaya-irrigatsiya-i-vodosberezhenie-v-tsentralnoy-azii/ (accessed on 19 September 2025).

- The Aral Sea Central Asian Countries and Climate Change in the 21st Century. Report; p. 52. Available online: https://www.unescap.org/sites/default/d8files/eventdocuments/The%20Aral%20Sea%20Central%20Asian%20Countries%20and%20Climate%20Change%20in%20the%2021st%20Century_Draft_RUS.pdf (accessed on 19 September 2025). (In Russian).

- Borisova, E.A. Peculiarities of water crisis in Central Asia. J. Hist. Mod. 2012, 1, 138–146. Available online: https://www.socionauki.ru/journal/iis/archive/2012_1/ (accessed on 19 September 2025).

- Ibodzoda, K. Melting Glaciers Are a Problem for All Mankind. Available online: https://kazpravda.kz/n/tayanie-lednikov-problema-vsego-chelovechestva/ (accessed on 19 September 2025).

- Eurasian Development Bank. The Impact of Climate Change on Water Resources in Central Asia; Eurasian Development Bank, Sectoral Review: Almaty, Kazakhstan, 2009; p. 44. Available online: https://www.cawater-info.net/library/rus/eabr_1.pdf (accessed on 19 September 2025).

- World Food Program. Available online: https://ru.wikibrief.org/wiki/World_Food_Programme (accessed on 19 September 2025).

- Decree of the President of the Republic of Uzbekistan dated 16.01.2018 No. DP-5303, On Measures to Further Ensure the Country’s Food Security. 2018. Available online: https://lex.uz/docs/3506753# (accessed on 17 January 2018).

- Rakhimbaev, F.M. Practical Classes on Agricultural Hydraulic Reclamation; Mexnat: Tashkent, Uzbekistan, 1991; p. 392. Available online: https://f.eruditor.link/file/1983604/ (accessed on 15 November 2024).

- Pomortsev, O.A. Temporal patterns of river runoff variability in cryolithozone conditions (using Yakutia as an example). J. Earth Sci. 2007, 223–227. Available online: https://cyberleninka.ru/article/n/vremennye-zakonomernosti-izmenchivosti-rechnogo-stoka-v-usloviyah-kriolitozony-na-primere-yakutii/viewer (accessed on 19 September 2025).

- Koshekov, R.M. The Aral Sea and its problems. Low water in the lower reaches of the Amu Darya and its consequences. Probl. Desert Dev. 2010, 3–4, 50–53. (In Russian) [Google Scholar]

- Karakulov, F.A. Possibilities of reducing water consumption when introducing modern technologies and means of growing agricultural crops in Central Asia. Young Sci. 2022, 6, 104–105. Available online: https://moluch.ru/archive/401/88584/ (accessed on 19 September 2025).

- Mukhamedzhanov, S.S. Summary report “Water conservation in Central Asian countries: Past experience and future guidelines”. In Proceedings of the International Conference of the Network of Water Management Organizations of Eastern Europe, Caucasus and Central Asia (NWO EECCA) “Water for Land Reclamation, Water Supply of Economic Sectors and the Natural Environment in the Context of Climate Change”, Tashkent, Republic of Uzbekistan, 6–7 November 2018; p. 28. Available online: http://www.icwc-aral.uz/pdf/synthesis-report-watersaving.pdf (accessed on 19 September 2025).

- Resolution of the President of the Republic of Uzbekistan. № RP-3823 “On Measures to Improve the Efficiency of Water Resources Use”. 2 July 2018. Available online: https://lex.uz/docs/3804058 (accessed on 19 September 2025).

- Decree of the President of the Republic of Uzbekistan. № DP-602 “On Approval of the Concept of Development of Water Management of the Republic of Uzbekistan for 2020–2030”. 10 July 2020. Available online: https://lex.uz/ru/docs/4892946 (accessed on 19 September 2025).

- Resolution of the President of the Republic of Uzbekistan. № RP-5 “On Measures to Improve the Water Resources Management System and Increase the Efficiency of Their Use at the Grassroots Level”. 5 January 2024. Available online: https://lex.uz/ru/docs/6734975 (accessed on 19 September 2025).

- Majidov, T.; Bekmirzaev, G.; Ikramov, N.; Kan, E.; Berdiev, M.; Buvabekov, B.; Majidov, F. Use of Mobile Photothermic Installation on Application of Drip Irrigation Technology in Orchards of Mountain and Foothill Areas of Uzbekistan. Water 2025, 17, 872. [Google Scholar] [CrossRef]

- Majidov, T.; Tursunov, M.; Ikramov, N.; Buvabekov, B.; Berdiev, M.; Ergashev, S. Comprehensive automated drip irrigation system. E3S Web Conf. 2023, 401, 01025. [Google Scholar] [CrossRef]

- Majidov, T.; Mirzaev, S.; Ikramov, N.; Buvabekov, B.; Berdiev, M.; Turdiev, A. Software for automating the complex system of drip irrigation. AIP Conf. Proc. 2025, 3256, 020045. [Google Scholar] [CrossRef]

- Majidov, T.; Ikramov, N.; Kan, E.; Berdiev, M.; Buvabekov, B. Drip irrigation using renewable energy sources. Irrig. Melior. 2024, 35, 10–19. Available online: https://staff.tiiame.uz/storage/users/547/articles/HIIraiSKcW5fTUAx0O6pFVpyYxdRFlMZ25zbqAb7.pdf (accessed on 19 September 2025). (In Uzbek).

- Majidov, T.; Norkulov, U.; Mamataliev, A. Irrigation of repeated crops using drip irrigation system with low pressure. In Proceedings of the International Conference “World Experience and Advanced Technologies for Efficient Use of Water Resources”, Ashgabat, Turkmenistan, 2–4 April 2010; pp. 253–256. Available online: http://www.eecca-water.net/content/view/517/52/lang,russian/ (accessed on 19 September 2025).

- Shtepa, B.G.; Nosenko, V.F.; Vinnikova, N.V.; Danilchenko, N.V.; Ostapov, I.S.; Fomin, G.E.; Afanasyev, V.A. Mechanization of irrigation. Directory; Agropromizdat: Moscow, Russia, 1990; p. 336. Available online: https://books.totalarch.com/node/7456 (accessed on 19 September 2025).

- Zhuravleva, L.A. Resource-Saving Wide-Capture Circular Irrigation Machines. Ph.D. Thesis, Saratov State Agrarian University named after N.I.Vavilov, Saratov, Russia, 2018; p. 39. Available online: https://www.dissercat.com/content/resursosberegayushchie-shirokozakhvatnye-dozhdevalnye-mashinykrugovogo-deistviya (accessed on 19 September 2025).

- Shodiyev, S.B.; Jorayev, J.T.; Hamroyev, G.F.; Hamroyev, I.F. Introduction of a modern water-saving centralized system of sprinkler (Pivot) irrigation into production. Theory Pract. Mod. Sci. 2023, 92, 14–18. Available online: https://cyberleninka.ru/article/n/zamonaviy-suv-tejamkor-yomg-irlatib-pivot-sug-orishning-markazlashgan-tizimini-ishlab-chiqarishga-joriy-etish (accessed on 19 September 2025).

- Chaudhari, R. Technology Behind Center Pivot Irrigation System. 2024. Available online: https://www.htecfarming.com/center-pivot-irrigation-system/ (accessed on 19 September 2025).

- Qureshi, W.A.; Xiang, Q.; Xu, Z.; Fan, Z. Study on the irrigation uniformity of impact sprinkler under low pressure with and without aeration. Front. Energy Res. 2023, 13, 1135543. [Google Scholar] [CrossRef]

- Arifjanov, A.A.; Kaletova, T.; Jalilova, H. Evaluation of the hydraulic efficiency of the sprinkler irrigation method. Sci. Innov. Dev. 2022, 6, 26–33. [Google Scholar] [CrossRef]

- Jobbagy, J.; Simonik, J.; Klimkiewicz, M.; Varga, R. Quality of operation of bauer rainstar 90/300-reel sprinkling machines in agrifood Imel sa agricultural company. TEKA 2012, 12, 95–99. Available online: https://www.researchgate.net/publication/281774081_quality_of_operation_of_bauer_rainstar_90300_reel_sprinkling_machines_in_agrocoop_imel_sa_agricultural_company (accessed on 19 September 2025).

- Sherov, A.G.; Gadaev, N.N.; Chinniev, C.; Omarova, G. Implementation of pulsar irrigation technology. Gold. Brain 2023, 1, 63–68. Available online: https://researchedu.org/index.php/goldenbrain/article/view/5085 (accessed on 19 September 2025).

- Pinkhasov, M.A. Guidelines for Determining Tariffs for the Provision of Services by Water Management Organizations to Water Users; International Water Management Institute: Tashkent, Uzbekistan, 2009; p. 31. Available online: http://iwrm.icwc-aral.uz/pdf/brochures/guide_tariff_2.pdf (accessed on 19 September 2025).

- Agency of IFAS. Irrigation and Drainage in the Republic of Uzbekistan: History and Current State: To the 70th Anniversary of the International Commission on Irrigation and Drainage; Agency of IFAS: Tashkent, Uzbekistan, 2020; p. 32. Available online: https://aral.uz/doc/NCID_book_web_ru.pdf (accessed on 19 September 2025).

- Majidov, T. Some issues in the use of machine irrigation, the most expensive type of irrigation, and the operation of pumping stations. Irrig. Land Reclam. 2024, 37, 6–15. [Google Scholar]

- García-Chica, A.; Rodriguez-Perez, A.M.; Caparros-Mancera, J.J.; Rodríguez-Gonzalez, C.A.; Chica, R.M. Integrated photovoltaic system for rainwater collection and sustainable irrigation. Irrig. Sci. 2025. [Google Scholar] [CrossRef]

- Scientific and Information Center of the ICWC. Problems of Mechanical Irrigation in Uzbekistan in Modern Usage. CAWATER Info, Knowledge base. Irrigation with Mechanical Drainage. 2012. Available online: http://www.cawater-info.net/bk/4-2-1-4-4.htm (accessed on 19 September 2025). (In Russian).

- Prudnikov, I.A.; Rotar, A.M. Green energy and its role in the state security system. Driv. Enterp. 2022, 15, 84–90. [Google Scholar] [CrossRef]

- Pendzhiev, A.M. Concept of development of renewable energy in the Central Asian region. Altern. Energy Ecol. 2012, 21, 112. Available online: https://cyberleninka.ru/journal/n/mezhdunarodnyy-nauchnyy-zhurnal-alternativnaya-energetika-i-ekologiya?i=957432 (accessed on 19 September 2025).

- Law of the Republic of Uzbekistan. № LRU-539 “On the Use of Renewable Energy Sources”. 21 May 2019. Available online: https://lex.uz/docs/4346835 (accessed on 19 September 2025).

- Butuzov, V.A.; Rashidov, Y.K.; Uzakov, G.N.; Klychev, S.I.; Abdurakhmanov, B.M. Review of the development of renewable energy in Uzbekistan. Plumb. Heat. Air Cond. 2025, 2, 72–79. Available online: https://www.c-o-k.ru/articles/obzor-razvitiya-vozobnovlyaemoy-energetiki-uzbekistana (accessed on 19 September 2025).

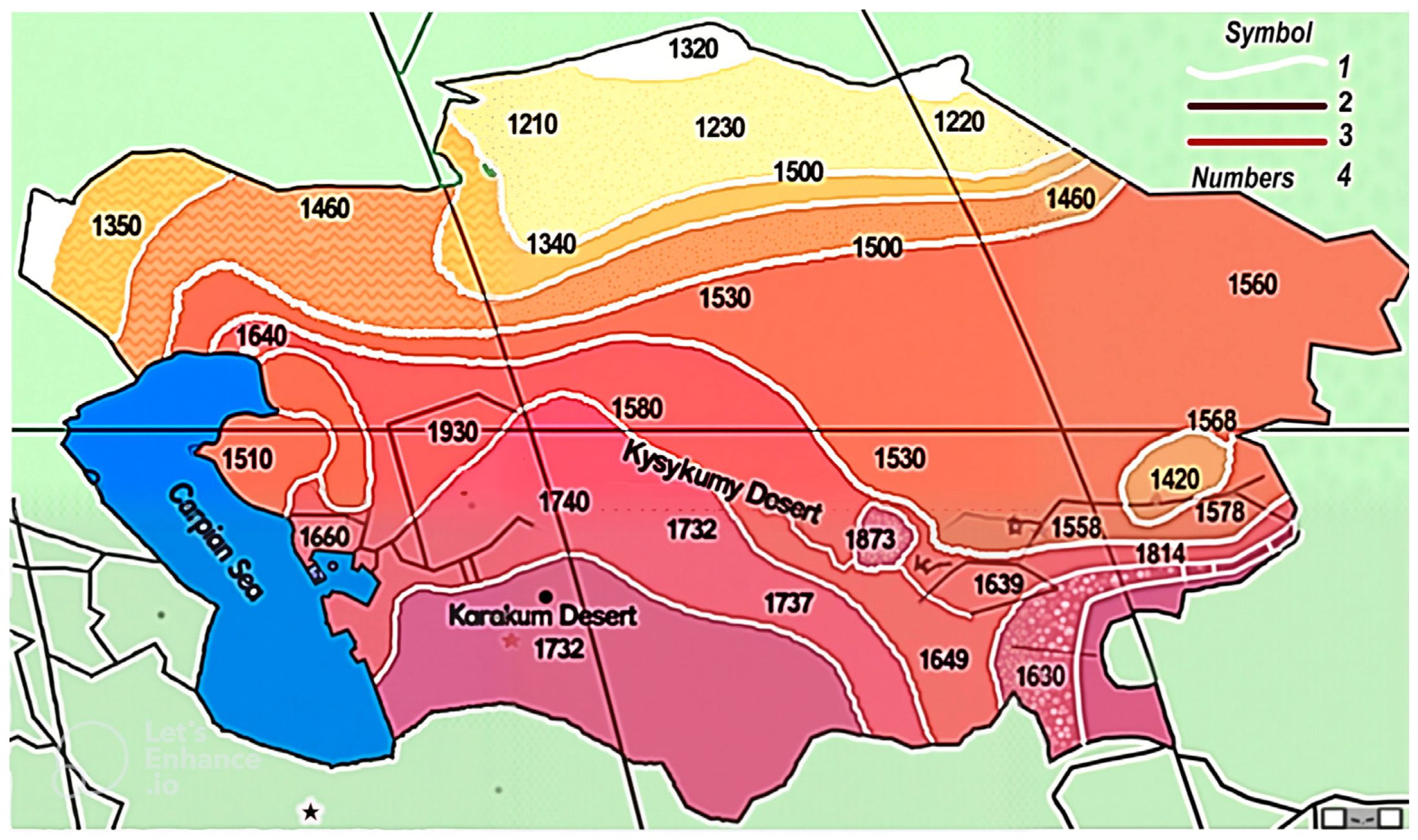

- Kiseleva, S.V.; Kolomiets, Y.G.; Popel, O.S. Assessment of Solar Energy Resources in Central Asia. J. Appl. Energy 2015, 51, 214–218. Available online: https://istina.msu.ru/publications/article/11351454/ (accessed on 19 September 2025). [CrossRef]

- Guillot, E.; Rodriguez, R.; Boullet, N.; Sans, J.-L. Some Details about the Third Rejuvenation of the 1000 kWt Solar Furnace in Odeillo: Extreme Performance Heliostats. In Proceedings of the 23rd International Solar PACES 2017 Conference: International Conference on Concentrated Solar Energy and Chemical Energy Systems, Santiago, Chile, 26–29 September 2017; Volume 2033. Available online: https://pubs.aip.org/aip/acp/issue/2033/1 (accessed on 19 September 2025).

- Svalova, M.V.; Kasatkin, V.V.; Kasatkina, N.Y.; Zakirov, A.Y. Study of solar energy as one of the renewable energy sources that can be used in agriculture. APC Russ. 2019, 26, 620.91–631.171. Available online: https://rusapk.sursau.ru/arhive/738/8562/ (accessed on 19 September 2025).

- Emily Greenfield Solar Farming: Concept and Applications on Sigma Earth’s Renewable Energy Section. 28 June 2022. Available online: https://sigmaearth.com/ru/solar-agriculture-concept-and-scope/ (accessed on 19 September 2025).

- GRUNDFOS SQFlex Catalogue. Renewable Energy Water Supply System. 2020, p. 48. Available online: https://www.grundfos.com/kz/support/documentation/catalogs/ (accessed on 19 September 2025).

- Grundfos Solar Water Pumps. Available online: https://shop.landwater.com.au/collections/grundfos-solar-products (accessed on 19 September 2025).

- Rodriguez, L. Why and How Do Solar Panels Degrade? 29 April 2021. Available online: https://ratedpower.com/blog/solar-panels-degradation/ (accessed on 19 September 2025).

- Law of the Republic of Uzbekistan № LRU-681 “On Homestead Farming”. 1 April 2021. Available online: https://lex.uz/docs/5351489?ONDATE=17.06.2023%2000 (accessed on 19 September 2025).

- Law of the Republic of Uzbekistan. No. ZRU-680 “On Dekhkan Farming”. 1 April 2021. Available online: https://www.lex.uz/en/docs/5351640 (accessed on 4 April 2021).

- Mamarakhimov, E. Homesteaders in Uzbekistan Harvest 2–3 Times a Year. Available online: https://darakchi.uz/uz/129783 (accessed on 19 September 2025).

- Majidov, T.S.; Ikramov, N.M.; Berdiev, M.S.; Fozilov, I.I.; Buvabekov, B.I.; Majidov, F.T. On Inventions, Utility Models and Industrial Designs” A Patent for an Invention. Ministry of Justice of the Republic of Uzbekistan, № IAP 7914. 2025. Available online: https://stumejournals.com/journals/am/2025/1/26 (accessed on 19 September 2025).

- Sanych, S. Drip Tape. Types and Features. 2019. Available online: https://dzen.ru/a/XStWJJmO1gCs-bHG (accessed on 19 September 2025).

- Usmonaliev, B.; Azarov, I.N. Pipe for Drip Irrigation. Patent of the Republic of Uzbekistan. Patent No. IAP 03072, 14 July 2006. [Google Scholar]

- Usmonaliev, B.; Azarov, I.N.; Umurzakov, O.P. Drip Irrigation System for Growing Agricultural Crops. Patent of the Republic of Uzbekistan. Patent No. IAP 03400, 29 June 2007. [Google Scholar]

- Mamatov, S.A. Drip Irrigation System; Central Asian Research Institute of Irrigation: Tashkent, Uzbekistan, 2012; p. 79. Available online: https://staff.tiiame.uz/storage/users/604/books/yvf1NqD2eSo3YDLQqyiRXGgLOuBGXcmr4hV1SBv1.pdf (accessed on 19 September 2025).

- Volskaya, O.N. Improving Technologies for Cleaning and Activating Groundwater for Drip Irrigation Systems and Water Supply of Rural Settlements. Ph.D. Thesis, Volgograd State Agricultural Academy, Saratov, Russia, 2007; p. 12. Available online: https://www.dissercat.com/content/sovershenstvovanie-tekhnologii-ochistki-i-aktivatsii-podzemnykh-vod-dlya-sistem-kapelnogo-or/read (accessed on 19 September 2025).

- Soloviev, M.A.; Maksimov, N.M. Review of methods for combating clogging of drip irrigation systems. Water Treat. 2024, 7, 631.674.6. Available online: https://panor.ru/magazines/vodoochistka/numbers/7519.html# (accessed on 19 September 2025).

- Yunusov, C.A. Innovative technologies for growing cucumbers in open ground. Acad. Res. Educ. Sci. 2022, 3, 340–356. Available online: www.ares.uz (accessed on 19 September 2025).

- Khamidov, M.K.; Mamataliev, A.B. Drip Irrigation of Oilseed Crops; MERIYUS: Tashkent, Uzbekistan, 2015; 120p, Available online: https://akbt.urdu.uz/uz/books/11502 (accessed on 19 September 2025).

- EPA. Centrifugal Pumps. Available online: https://epa.uz/catalog/water-pumps/centrifugal-pumps (accessed on 19 September 2025).

- Ikramov, N.; Kasimov, F.; Rakhimova, M. Energy efficiency monitoring system of operated irrigation pumping stations in Uzbekistan. J. Water Land Dev. 2025, 64, 120–129. [Google Scholar] [CrossRef]

- Ikramov, N.; Majidov, T.; Kan, E.; Mukhammadjonov, A. Monitoring system for electricity consumption at pumping stations. IOP Conf. Ser. Mater. Sci. Eng. 2020, 883, 012101. [Google Scholar] [CrossRef]

- Ikramov, N.; Kan, E.; Mirzoev, M.; Majidov, T. Effect of parallel connection of pumping units on operating costs of pumping station. E3S Web Conf. 2019, 97, 05014. [Google Scholar] [CrossRef]

- Gulich, J.F. Centrifugal Pumps, 4th ed.; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; p. 1264. Available online: https://books.google.co.uz/books/about/Centrifugal_Pumps.html?id=2YnswQEACAAJ&redir_esc=y (accessed on 19 September 2025).

- Jones, G.M.; Sanks, R.L.; Tchobanoglous, G.; Bosserman, B.E. Pumping Station Design, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2008; p. 1104. Available online: https://books.google.co.uz/books/about/Pumping_Station_Design.html?id=biWHfrpd9gsC&redir_esc=y (accessed on 19 September 2025).

- Menon, E.S.; Menon, P.S. Working Guide to Pumps and Pumping Stations: Calculations and Simulations Book; Elsevier: Amsterdam, The Netherlands, 2010; Available online: https://www.spaceelements.in/wpcontent/uploads/2022/01/Working_Guide_to_Pump_and_Pumping_Stations_Calculations_and_Simulations.pdf (accessed on 19 September 2025).

- Stoffel, B. Assessing the Energy Efficiency of Pumps and Pump Units; Elsevier: Amsterdam, The Netherlands, 2015; Available online: https://www.researchgate.net/publication/285429483_Assessing_the_Energy_Efficiency_of_Pumps_and_Pump_Units_Background_and_Methodology (accessed on 19 September 2025).

- Corcoles, J.I.; Tarjuelo, J.M.; Moreno, M.A. Methodology to improve pumping station management of on-demand irrigation networks. Biosys. Eng. 2016, 144, 94–104. Available online: https://www.sciencedirect.com/science/article/abs/pii/S1537511015303718 (accessed on 19 September 2025). [CrossRef]

- Moreno, M.A.; Carrion, P.A.; Planells, P.; Ortega, J.F.; Tarjuelo, J.M. Measurement and improvement of the energy efficiency at pumping stations. Biosys. Eng. 2007, 98, 479–486. Available online: https://www.sciencedirect.com/science/article/abs/pii/S1537511007002310 (accessed on 19 September 2025). [CrossRef]

- Authorities Are Preparing for Abnormal Heat. 2021. Available online: https://www.gazeta.uz/ru/2021/07/04/heat/ (accessed on 19 September 2025).

- Gulkov, V.N.; Kolesnichenko, I.D.; Korotkov, K.E. Study of the Influence of Heating of Solar Modules on the Efficiency of Radiation Conversion; Saint Petersburg Electrotechnical University: St. Petersburg, Russia, 2019; pp. 10–16. Available online: https://izv.etu.ru/assets/files/izvestiya-1_2019_p010-016(3).pdf (accessed on 19 September 2025).

| № | Rolls: | ||

|---|---|---|---|

| Diameter, cm. | Length, m | Whole, kg | |

| 1 | 23 | 243 | 2.4 |

| 2 | 35 | 622 | 6.2 |

| 3 | 48 | 1220 | 12.2 |

| № | Characteristics | Unit of Measurement | Quantity |

|---|---|---|---|

| 1 | Diameter | mm | 25 |

| 2 | Drip type | labyrinthine slot | |

| 3 | Water flow rate per drip (depending on pressure) | L/s | 1–4 |

| 4 | Distance between drips | cm | 20, various |

| 5 | Droplet irregularity: - at 500 m; - at 1000 m. | % % | 10 15 |

| 6 | Water pressure required for system operation | m | 1.6–2.0 |

| 7 | Minimum furrow length | m | 250.0 |

| 8 | Optimum field slope | 0.003–0.006 | |

| 9 | Operating period | year | 1–2 |

| 10 | Operating period of main plastic pipes | year | 12–15 |

| Maximum power of PhEB, Pmax | 550 W | 2 PhEB 1100 W |

| PhEB efficiency, η | 20.88% | 20.88% |

| PhEB no-load voltage, Uoc | 53.90 V | 53.90 V |

| Operating voltage | 45.3 V | 45.3 V |

| PhEB short-circuit current, Isc | 12.6 A | 25.2 A |

| Current at load | 11.04 A | 22.08 A |

| Fill factor, ff | 0.71–0.73 | 0.71–0.73 |

| Cellular polycarbonate thermal collector capacity, V | 17 L | 17 × 2 = 34 L |

| Cellular polycarbonate thermal conductivity, r | 0.2–3.9 W/m·°C | 0.2–3.9 W/m·°C |

| GEL 100 A hour batteries (4 pcs). | 400 Ah, 48 V | |

| Controller with optimum load point tracking | 1100 W, 48 V, 30 A | |

| Inverter with pure sine waveform | 1100 W, 48 V, 30A |

| 1 | Mains voltage, V | 220 |

| 2 | Power consumption, W | 370 |

| 3 | Insulation class | 23 |

| 4 | Warranty, month | 12 |

| 5 | Diameter of outlet opening, mm | 25 |

| 6 | Flow rate, l/min | 90 |

| 7 | Rotation speed, rev/m | 2850 |

| 8 | Frequency, Hz | 50 |

| Field Research Location | Information About the Experimental Field: | Cucumber Information: | Hydromodular Region: IV-b | Water Savings Compared to Furrow Irrigation, % | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Area, ha | Contour Number | Number of Furrows, pcs | Total Length of Furrows, m | Soil Type | Groundwater Depth, m | Variety | Planting Scheme | Planting Day | Germination Day | Water Supply Day | Distance Between Seedlings, m | Number of Seedlings, pcs. | Number of Fruits Per Seedling, pcs. | Total Number of Fruits, pcs. | Average Weight of 1 Fetus, g. | Yield, kg/ton | Irrigation: | |||||||

| Furrow | Drip | |||||||||||||||||||||||

| Irrigation Period | Irrigation Rate, M3/ha | Number of Waterings, times | Irrigation Period | Irrigation Rate, M3/ha | Number of Waterings, times | |||||||||||||||||||

| 2024, growing season from 23 April to 20 July (89 days) | ||||||||||||||||||||||||

| M. Komolov LLC in the Upper Chirchik District of the Tashkent Region of the Republic of Uzbekistan | 0.1 | K-5/3 | 22 | 1100 | Heavy clay | 15.0–18.0 | Asterix F1 | 0.9 × 0.30 | 23.04 | 29.04 | 02.05 | 0.30 × 0.30 | 3367 | 13 | 47,671 | 115 | 5482/54.80 | 26.04–31.06 | 3600 | 12 | 23.04–20.07 | 2200 | 34 | 38.9 |

| 2025, growing season from 11 April to 13 July (95 days) | ||||||||||||||||||||||||

| M. Komolov LLC in the Upper Chirchik District of the Tashkent Region of the Republic of Uzbekistan | 0.1 | K-5/1 | 22 | 1100 | Heavy clay | 13.0–16.0 | AMyp F1 Amur F1 | 0.90 × 0.30 | 11.04 | 16.04 | 18.04 | 0.30 × 0.30 | 3367 | 12 | 44,000 | 126 | 5545/55.50 | 26.04–31.06 | 3600 | 12 | 11.04–13.07 | 2420 | 38 | 32.8 |

| 1 | Mains voltage, V | 220 |

| 2 | Power consumption, W | 750 |

| 3 | Nominal pressure head, m | 6 |

| 4 | Maximum pressure head, m | 10 |

| 5 | Speed of rotation, r/min | 3000 |

| 6 | Nominal flow capacity, m3/h | 30 |

| 7 | Diameter of outlet opening, mm | 75 |

| 8 | Frequency, Hz | 50 |

| Operating Period of Solar Panels-330 Solar Days | Electricity Generated, kWh | Energy Savings: | Economic Benefit, kWh∙Sum (USD) * | |

|---|---|---|---|---|

| Gas, m3 | Conventional Fuel | |||

| Mobile Photovoltaic Power Unit with capacity-N = 1100 W (MPPU-2-550-1100) | ||||

| In 1 h | 1.1 | 0.165 | 0.13512 | 1100 (0.0867) |

| In 1 day | 26.4 | 3.96 | 3243 | 26,400 (2.08) |

| In 1 year | 7920 | 1188 | 973.0 | 7,920,000 (624.10) |

| Mobile Photovoltaic Power Unit with capacity-N = 2000 W (MPPU-4-500-2000) | ||||

| In 1 h | 2.0 | 0.30 | 0.2457 | 2000 (0.1576) |

| In 1 day | 48.0 | 7.20 | 11.80 | 48,000 (3.79) |

| In 1 year | 15,840.0 | 2376 | 1946.0 | 15,840,000 (1220.0) |

| Mobile Photovoltaic Power Unit with capacity-N = 4000 W (MPPU-8-500-4000) | ||||

| In 1 h | 4.0 | 0.60 | 0.49134 | 4000 (0.3152) |

| In 1 day | 96.0 | 14.40 | 47.169 | 96,000 (7.565) |

| In 1 year | 31,680.0 | 4752.0 | 3892.0 | 31,680,000 (2496.40) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Majidov, T.; Ikramov, N.; Bekmirzaev, G.; Berdiev, M.; Buvabekov, B.; Majidov, F.; Hikmatov, F. Application of Renewable Energy in Agriculture of the Republic of Uzbekistan. Water 2025, 17, 3074. https://doi.org/10.3390/w17213074

Majidov T, Ikramov N, Bekmirzaev G, Berdiev M, Buvabekov B, Majidov F, Hikmatov F. Application of Renewable Energy in Agriculture of the Republic of Uzbekistan. Water. 2025; 17(21):3074. https://doi.org/10.3390/w17213074

Chicago/Turabian StyleMajidov, Takhir, Nazir Ikramov, Gulom Bekmirzaev, Mustafo Berdiev, Bakhtiyar Buvabekov, Faxriddin Majidov, and Farruxbek Hikmatov. 2025. "Application of Renewable Energy in Agriculture of the Republic of Uzbekistan" Water 17, no. 21: 3074. https://doi.org/10.3390/w17213074

APA StyleMajidov, T., Ikramov, N., Bekmirzaev, G., Berdiev, M., Buvabekov, B., Majidov, F., & Hikmatov, F. (2025). Application of Renewable Energy in Agriculture of the Republic of Uzbekistan. Water, 17(21), 3074. https://doi.org/10.3390/w17213074