Characterization of Non-Constant Flow in the Recession Process of Pressurized Pipelines with Air Valves

Abstract

1. Introduction

2. Mathematical Model

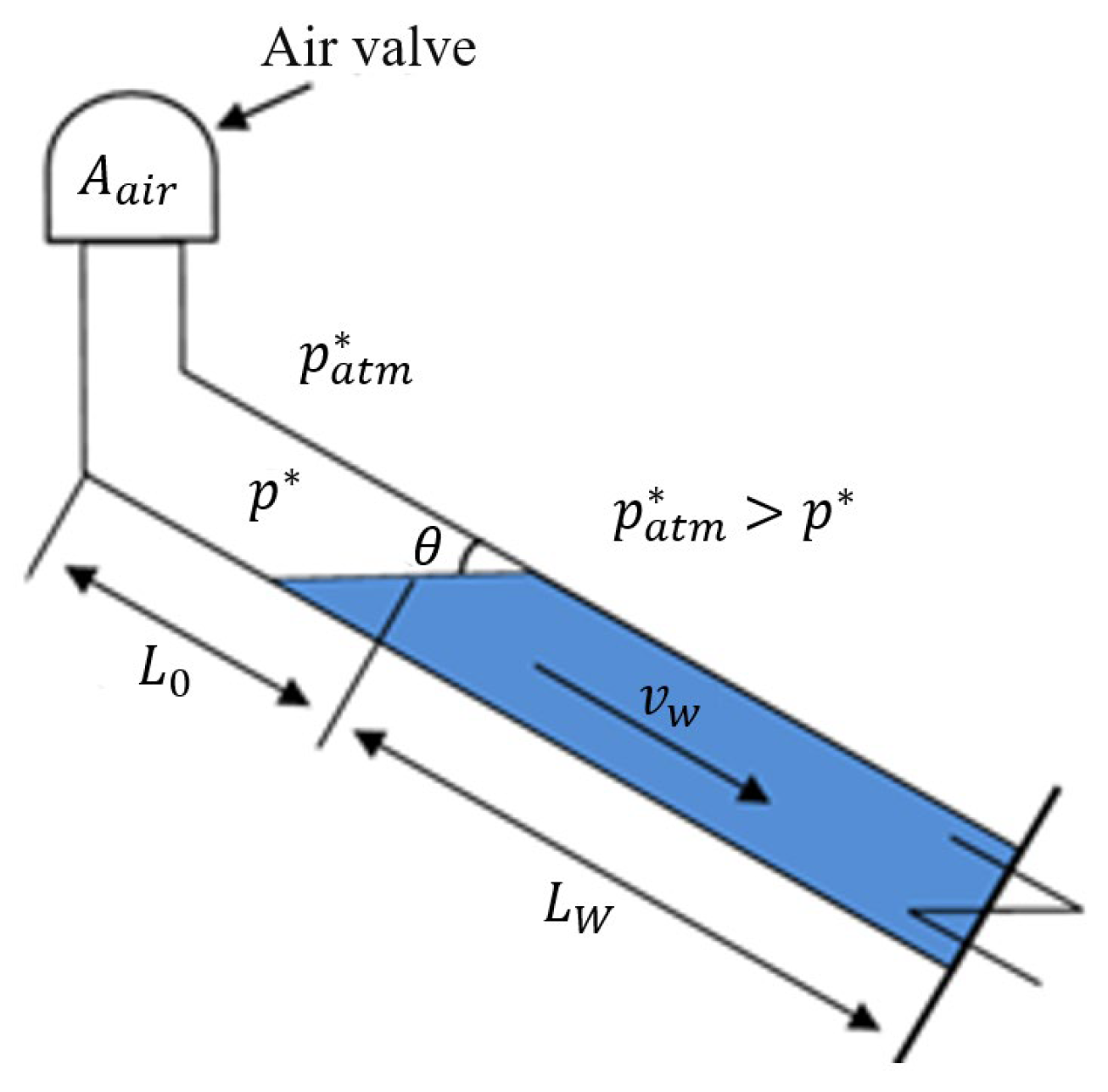

2.1. Schematic Diagram of Emptying in Pressurized Pipelines

2.2. Mathematical Model of the Emptying Process

- (1)

- The wall shear stress acting on the water column is assumed constant and is evaluated using the Darcy–Weisbach equation;

- (2)

- The air–water interface is well-defined and remains parallel to the horizontal plane;

- (3)

- The characteristic time of the thermodynamic process within the air pocket during emptying is much shorter than the heat-exchange time scale, so the process is treated as adiabatic;

- (4)

- The pipeline possesses sufficient structural strength to withstand the sub-atmospheric pressures developed during emptying without significant deformation or collapse.

2.2.1. Liquid Phase Model

2.2.2. Gas Phase Model

2.2.3. Air Valve Model

- (1)

- The air inflow is isentropic;

- (2)

- The air temperature inside the pipeline is assumed equal to the water temperature;

- (3)

- Variations in the air volume within the pipeline depend solely on the water outflow.

2.2.4. Drain Valve Operation Model

2.3. Initial and Boundary Conditions

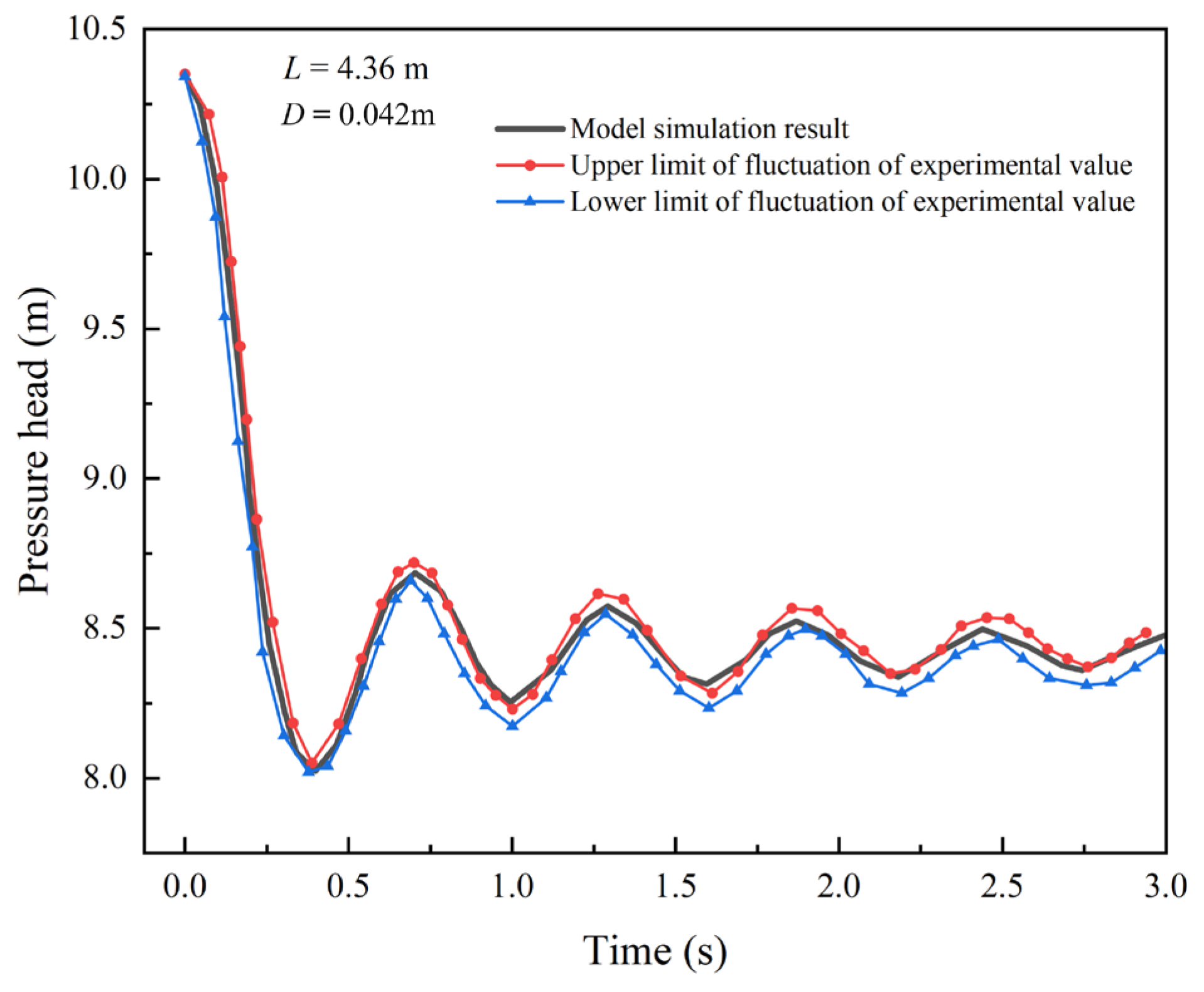

2.4. Model Verification

3. Analysis of Transient Flow in Pressurized Pipelines During Water Drainage

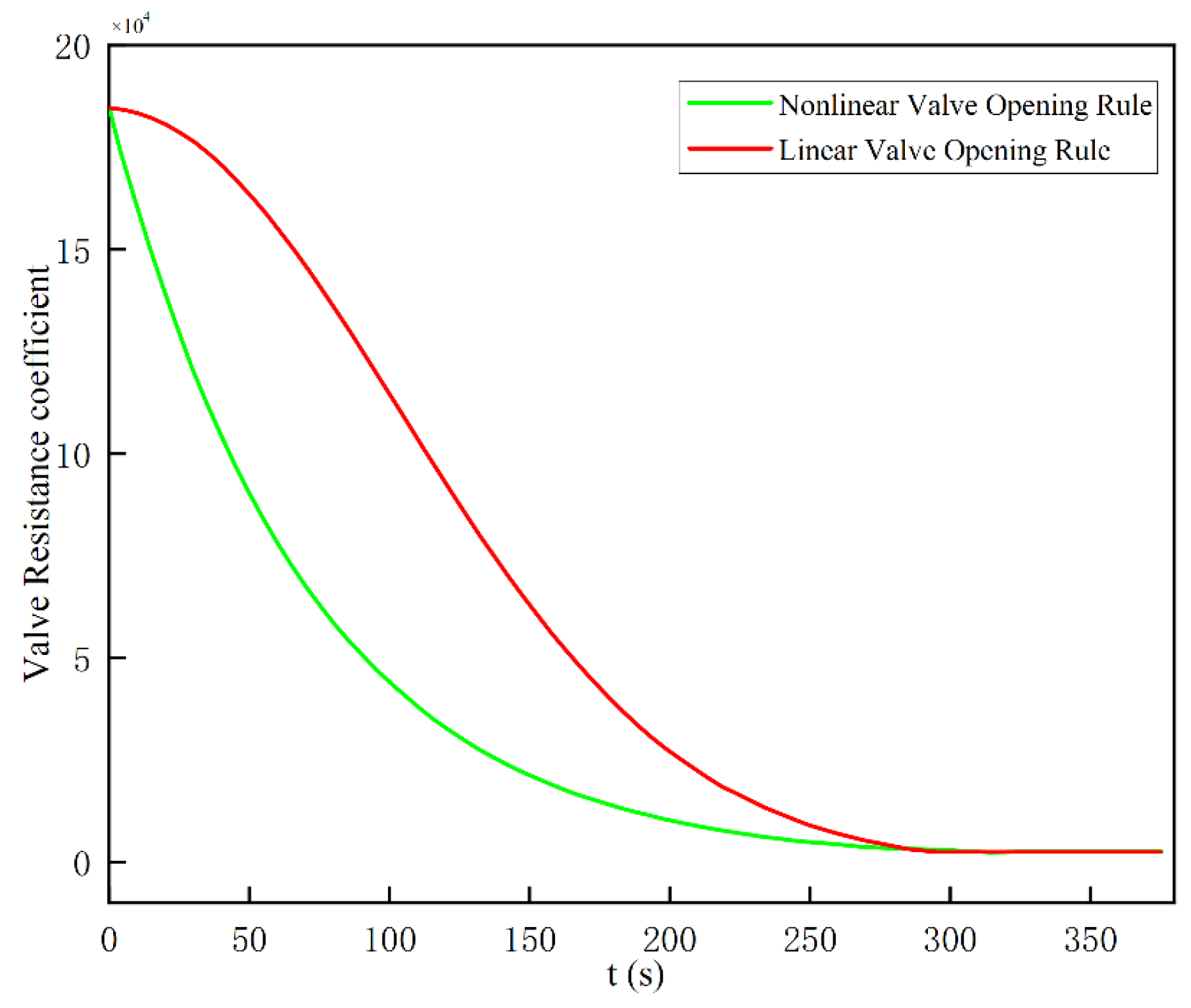

3.1. Impact of the Water Drainage Valve Opening Strategy on the Drainage Process

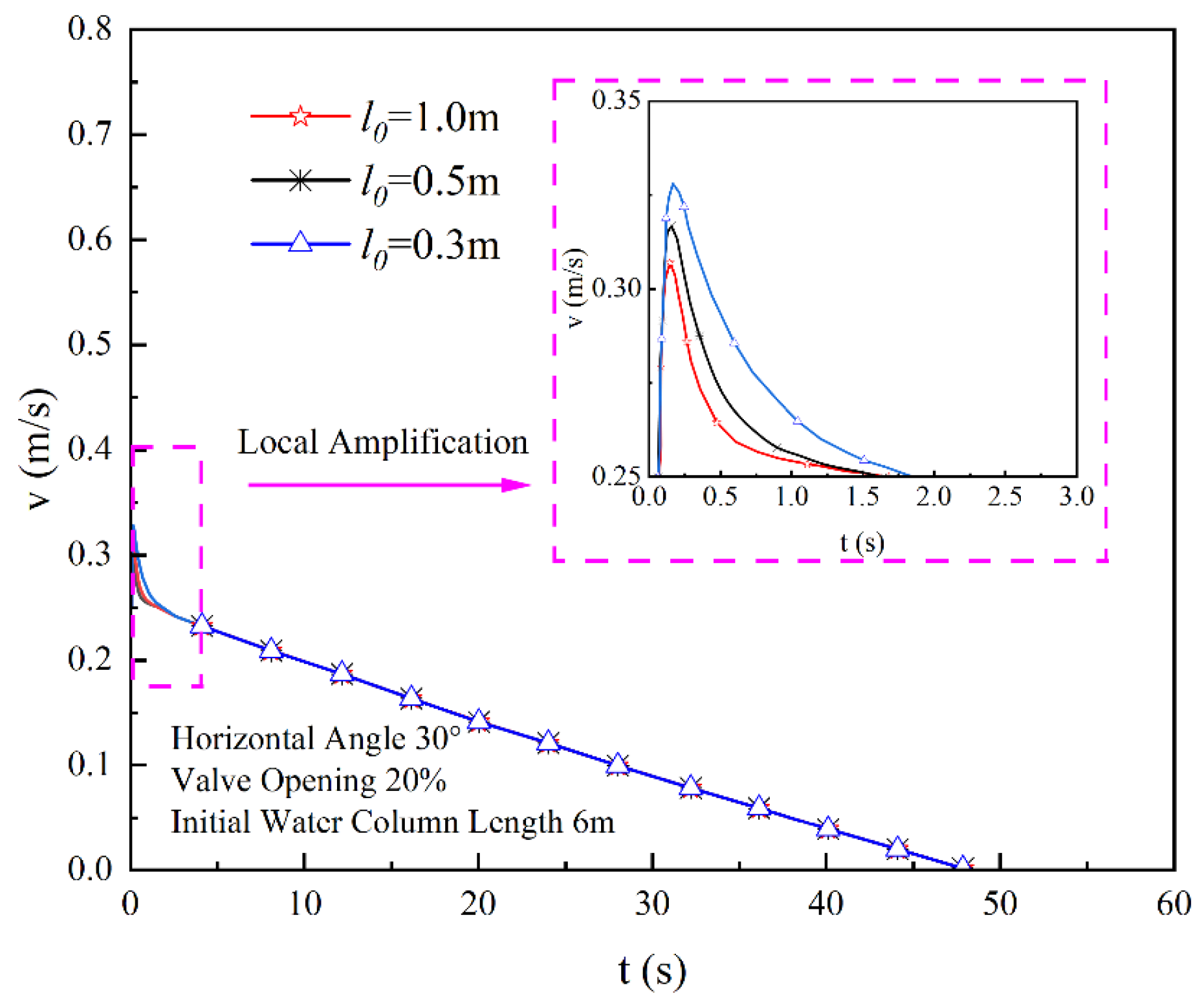

3.2. Impact of Different Boundary Conditions on Water Drainage Velocity

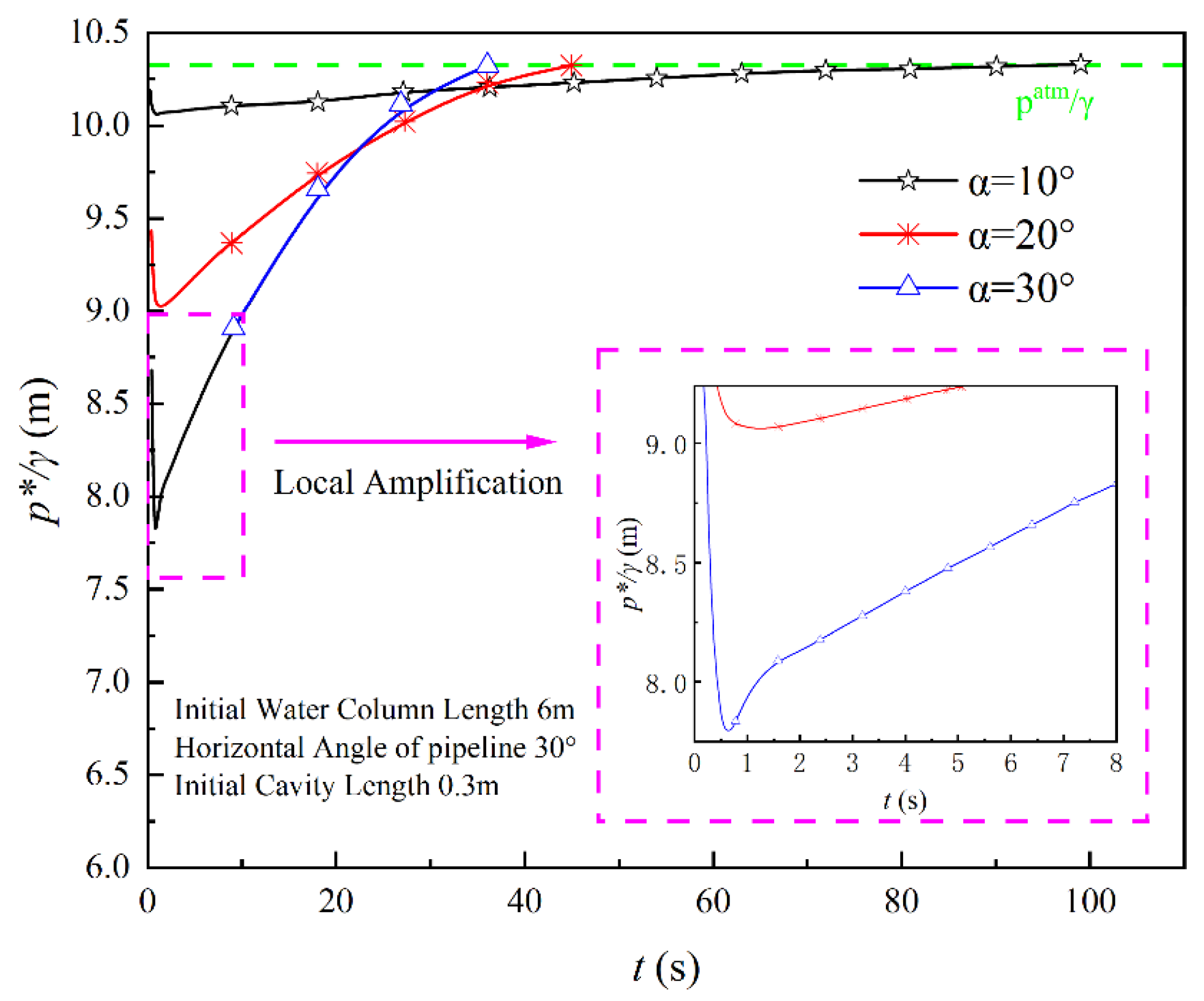

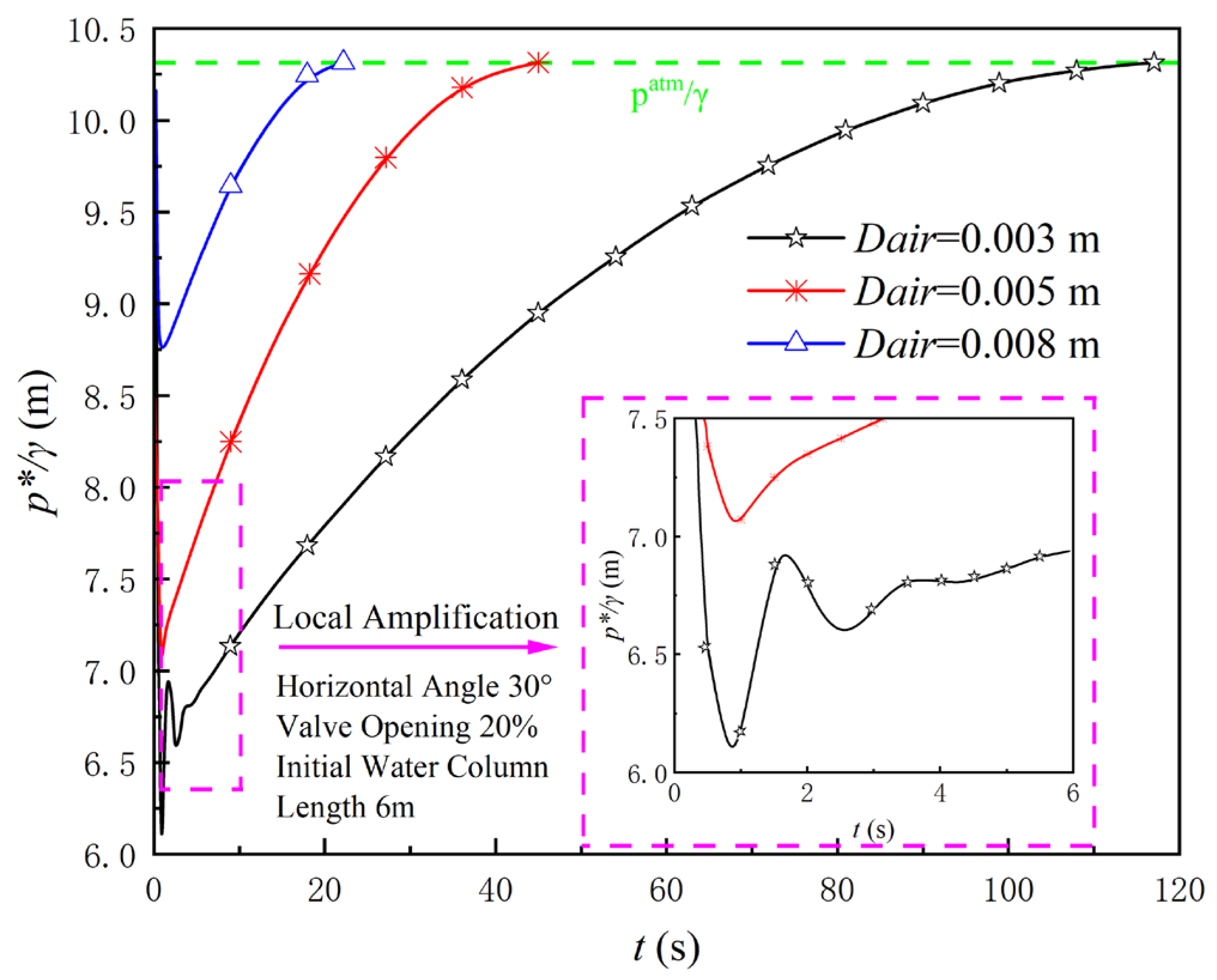

3.3. The Influence of Different Boundary Conditions on Cavity Pressure

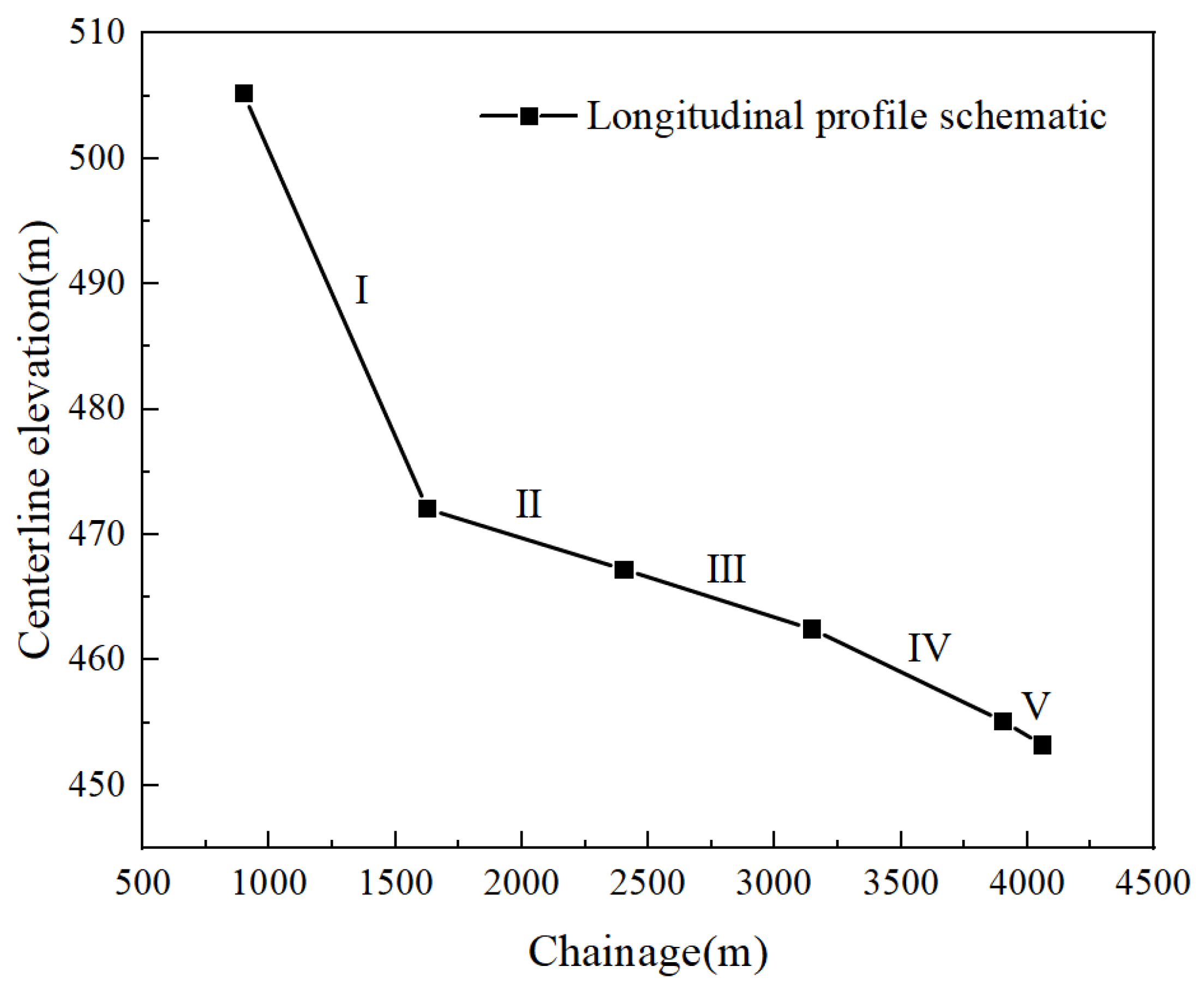

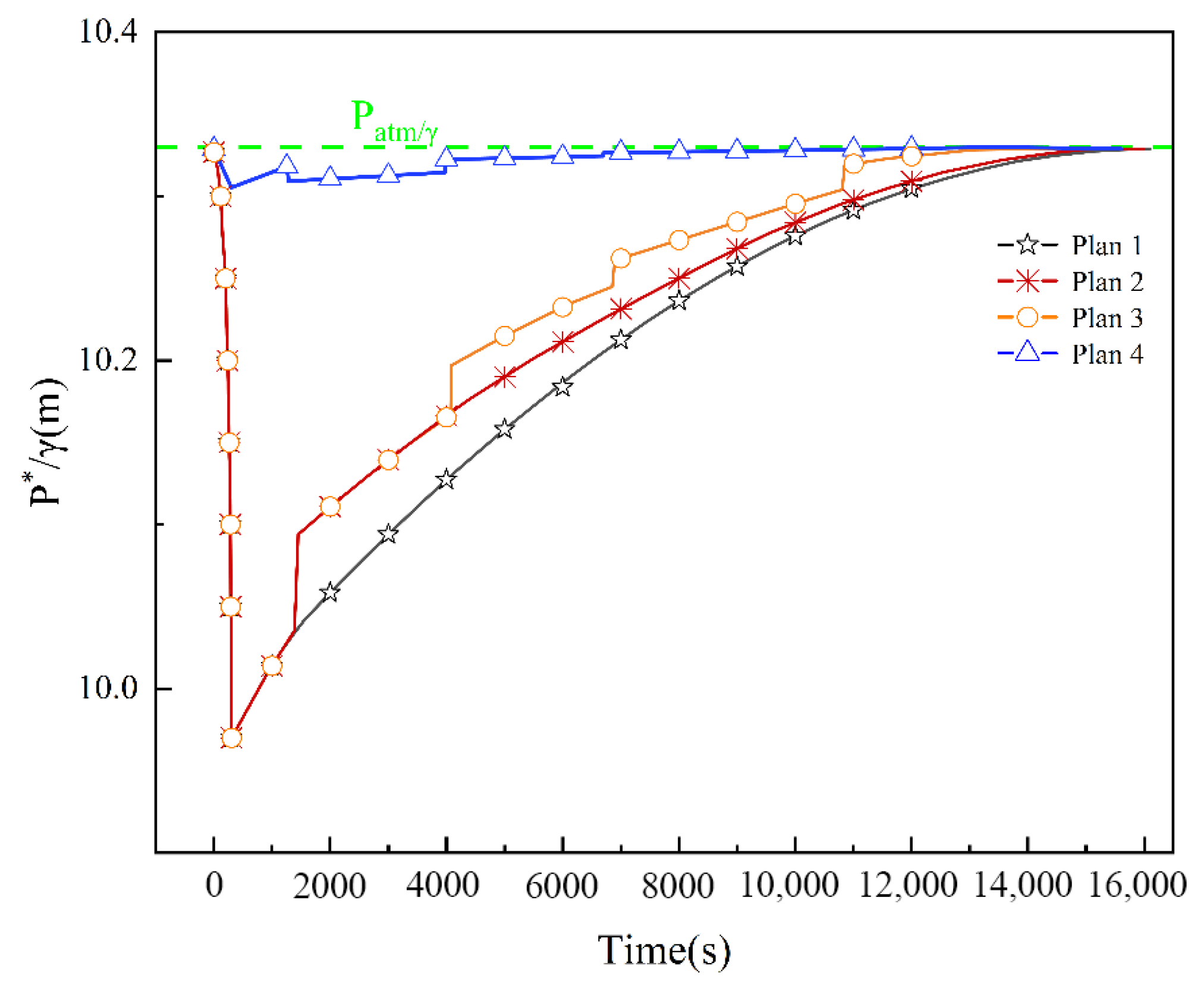

4. Case Study: Heihe River Drainage Section of the Hanjiang-to-Weihe River Diversion Project

5. Conclusions

- (1)

- A mathematical model for the drainage process was developed using the rigid water column assumption and validated by experiments. The results show that the model matches experimental data well, with a maximum error of 3.59%.

- (2)

- During drainage in pressurized pipelines with air valves, both linear and nonlinear power-function valve opening strategies improve the process. The nonlinear opening strategy increased the minimum cavity pressure head by 0.1014 m and delayed its occurrence by 0.655 s compared to the linear strategy. It also effectively reduced the rapid increase in drainage water velocity at the start of drainage.

- (3)

- As the valve opening degree increases, drainage water velocity rises significantly and drainage time shortens. At 20% opening, velocity increased by 0.2 m/s and drainage time dropped by 55.7%. At a larger opening, velocity increased by 0.48 m/s and drainage time fell by 65.4%. However, the minimum cavity pressure head fell by 1.05 m and 2.286 m, reducing drainage stability. Increasing the valve opening degree speeds up drainage but may reduce process stability.

- (4)

- Increasing the air valve diameter improves drainage stability in pressurized pipelines. Small air valves (0.003 m) caused pressure fluctuations due to low air intake, but these weakened when the diameter increased to 0.005 m or more. At 0.005 m and 0.008 m, the drainage time was reduced by 54% and 63.3%, respectively, compared to the small valves.

- (5)

- Well arrangement of multiple air valves can reduce negative pressure head duration without changing the minimum pressure value. All schemes showed drainage flow rates that first rose then fell, reaching a maximum of 3.61 m3/s. Compared to Scheme 1, drainage times for Schemes 2, 3, and 4 were reduced by 105.71 s, 273.5 s, and 498.62 s.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, H.K.; Tian, R.; Wang, Q.G. Calculation of Hydraulic Transient Process in Long-Distance Water Conveyance Pipelines. Water Resour. Dev. Manag. 2022, 42, 32–38. [Google Scholar]

- Wang, Q. Study on Filling Test of Long-Distance, Large-Section, Pressurized Water Conveyance Tunnel. Water Resour. Dev. Manag. 2021, 41, 41–45. [Google Scholar]

- Tang, X.L.; Liu, Z.K.; Zhang, L.; Li, X.Q. Experimental investigations on characteristics of water-air two-phase flows during water-fillings in undulation pipelines. J. Hydrodyn. 2024, 12, 706–724. [Google Scholar] [CrossRef]

- RolandoYezid, P.; Arman, R.; Musandji, F. Experimental Investigation of the Emptying Process and Air Cavity Dynamic in Pipelines. J. Irrig. Drain. Eng. 2022, 148, 04022040. [Google Scholar] [CrossRef]

- Zhang, H.Z.; Li, Y.H.; Jiang, J.; Wang, Y.C.; Luo, S. Influence of filling velocity on the hydraulic characteristics of the air valve hump section. China Rural Water Hydropower 2019, 11, 172–187. [Google Scholar]

- Zhou, L.; Cai, B.H.; Hu, C.Z.; Lu, Y. Simulation of Hydraulic Transients during Pipeline Filling with Multiple Air Pockets. J. Huazhong Univ. Sci. Technol. 2025, 53, 158–165. [Google Scholar]

- Liang, X.; Wang, Y.L.; Cui, S.J.; Zhou, B.; Wang, L.; Cao, W. Analysis of Pipeline Filling Characteristics under Different Inclination Angles. Water Resour. Power 2024, 42, 60–62. [Google Scholar]

- Ling, W.F.; Bryan, K.; Ahmad, M. Numerical investigation of filling transients in small-scale pipelines with submerged outlet. J. Hydraul. Res. 2016, 55, 647–656. [Google Scholar]

- Yan, J.S.; Liao, G.L. Three-dimensional numerical simulation of hydraulic characteristics during the filling process of pressurized pipelines. Water Resour. Hydropower Eng. 2015, 46, 110–114. [Google Scholar]

- Lin, L.; David, Z.; Biao, H. Analysis of pressure transient following rapid filling of a vented horizontal pipe. Water 2018, 10, 1698. [Google Scholar] [CrossRef]

- Coronado-Hernández, E.O.; Fuertes-Miquel, V.S.; Iglesias-Rey, L.P.; Martínez-Solano, F.J. Rigid water column model for simulating the emptying process in a pipeline using pressurized air. J. Hydraul. Eng. 2018, 144, 06018004. [Google Scholar] [CrossRef]

- Paternina-Verona, A.D.; Coronado-Hernández, E.O.; Aguirre-Mendoza, M.A.; Espinoza-Román, H.G.; Fuertes-Miquel, V.S. Three-Dimensional Simulation of Transient Flows during the Emptying of Pipes with Entrapped Air. J. Hydraul. Eng. 2023, 149, 13302. [Google Scholar] [CrossRef]

- Laanearu, J.; Annus, I.; Koppel, T.; Bergant, A.; Vučković, S.; Hou, Q.; Tijsseling, A.S.; Anderson, A.; van’t Westende, J.M. Emptying of large-scale pipeline by pressurized air. J. Hydraul. Eng. 2012, 138, 1090–1100. [Google Scholar] [CrossRef]

- Besharat, M.; Coronado-Hernández, O.E.; Fuertes-Miquel, V.S.; Viseu, M.T.; Ramos, H.M. Backflow air and pressure analysis in emptying a pipeline containing an entrapped air pocket. Urban Water J. 2018, 15, 769–779. [Google Scholar] [CrossRef]

- Coronado-Hernández, O.E.; Fuertes-Miquel, V.S.; Angulo-Hernández, F.N. Emptying operation of water supply networks. Water 2018, 10, 22. [Google Scholar] [CrossRef]

- Tijsseling, A.S.; Hou, Q.; Bozkuş, Z.; Laanearu, J. Improved one-dimensional models for rapid emptying and filling of pipelines. J. Press. Vessel Technol. Trans. ASME 2016, 138, 031301. [Google Scholar] [CrossRef]

- Fuertes-Miquel, V.S.; Coronado-Hernández, E.O.; Iglesias-Rey, L.P.; Mora-Meliá, D. Transient phenomena during the emptying process of a single pipe with water–air interaction. J. Hydraul. Res. 2019, 57, 318–326. [Google Scholar] [CrossRef]

- Tasca, E.S.A.; Karney, B. Improved Air Valve Selection through Better Device Characterization and Modeling. J. Hydraul. Eng. 2023, 149, 142–156. [Google Scholar] [CrossRef]

- Bian, S.K.; Zhang, X.Y.; Li, G.; Li, L. Study on valve-closure law and air-valve optimization in gravity flow pipelines. Adv. Sci. Technol. Water Resour. 2025, 45, 55–61. [Google Scholar]

- Wu, F.; Liu, W.Y.; Zai, S.M.; He, R.; Gao, X.J.; Huang, J.; Nie, M.M. Airflow characteristics and water hammer elimination effect of the staged exhaust air valve. J. Drain. Irrig. Mach. Eng. 2025, 1–9. Available online: https://link.cnki.net/urlid/32.1814.th.20250620.1730.004 (accessed on 17 June 2025).

- Li, N.; Zhang, J.; Shi, L.; Chen, X.Y.; Zhang, X. Water Hammer Protection Characteristics of a Combined Air Vessel and Overpressure Relief Valve. J. Drain. Irrig. Mach. Eng. 2020, 38, 254–260. [Google Scholar]

- Bashiri-Atrabi, H.; Hosoda, T. The motion of entrapped air cavities in inclined ducts. J. Hydraul. Res. 2015, 53, 814–819. [Google Scholar] [CrossRef]

- Izquierdo, J.; Fuertes, V.S.; Cabrera, E.; Iglesias, P.L.; Garcia-Serra, J. Pipeline start-up with entrapped air. J. Hydraul. Res. 1999, 37, 579–590. [Google Scholar] [CrossRef]

- Brunone, B.; Karney, B.W.; Mecarelli, M.; Ferrante, M. Velocity profiles and unsteady pipe friction in transient flow. J. Water Resour. Plan. Manag. 2000, 126, 236–244. [Google Scholar] [CrossRef]

- Huang, H.; Guo, P.C.; Yan, J.G.; Li, B. Progress in the study of friction models for unsteady flow in pressurized pipelines. J. Hydrodyn. 2025, 40, 274–296. [Google Scholar]

- Fuertes-Miquel, V.S. Hydraulic Transients with Entrapped Air Pockets. Ph.D. Thesis, Polytechnic University of Valencia, Valencia, Spain, 2001. [Google Scholar]

- Lee, N. Effect of Pressurization and Expulsion of Entrapped Air in Pipelines. Ph.D. Thesis, School of Civil and Environmental Engineering, Georgia Institute of Technology, Atlanta, GA, USA, 2005. [Google Scholar]

- Leon, A.S.; Ghidaoui, M.S.; Schmidt, A.R. A robust two-equation model for transient-mixed flows. J. Hydraul. Res. 2010, 48, 44–56. [Google Scholar] [CrossRef]

- Martin, C. Entrapped air in pipelines. In Proceedings of the Second International Conference on Pressure Surges, London, UK, 22–24 September 1976. [Google Scholar]

- Iglesias-Rey, L.P.; Fuertes-Miquel, V.S.; García-Mares, F.J. Comparative study of intake and exhaust air flows of different commercial air valves. In Proceedings of the 16th Conference on Water Distribution System Analysis, Bari, Italy, 13–16 July 2014. [Google Scholar]

- Wylie, E.; Streeter, V. Fluid Transients in Systems; Prentice Hall: Hoboken, NJ, USA, 1993. [Google Scholar]

- Liu, X.M.; Xie, Y.B. Study on calculation methods for the friction resistance coefficient in long-distance district heating networks. Fluid. Mach. 2022, 50, 100–104. [Google Scholar]

| Research Source | Mathematical Model | Key Control Parameters | Valve Opening Law | Air Valve Arrangement |

|---|---|---|---|---|

| Coronado-Hernández and Fuertes-Miquel et al. [11,15,17] | Rigid water column model for single-pipe systems | Valve opening time, air valve orifice size, pipe slope | Linear opening | Single air valve |

| Tasca and Bian et al. [18,19] | One-dimensional transient flow model | Break-point opening, air valve orifice size | Two-stage linear closing | Ordinary, three-action or improved dual-orifice air valve |

| Wu et al. [20] | Coupled 3D CFD & MOC transient flow model | Buffer plate orifice size | Staged exhaust triggered by pressure difference | Staged exhaust air valve |

| Li et al. [21] | Combined air vessel–relief valve transient model (MOC) | Valve opening/closing law | Two-stage linear closing | Integrated air vessel & over-pressure relief valve |

| Working Condition Number | Initial Length of the Emptying Column | Maximum Valve Opening | Diameter of the Air Inlet Hole of the Air Valve |

|---|---|---|---|

| Test 1 | 0.3 m | 20% | 0.005 m |

| Test 2 | 0.5 m | 20% | 0.005 m |

| Test 3 | 1.0 m | 20% | 0.005 m |

| Test 4 | 0.5 m | 10% | 0.005 m |

| Test 5 | 0.5 m | 20% | 0.005 m |

| Test 6 | 0.5 m | 30% | 0.005 m |

| Test 7 | 0.5 m | 20% | 0.003 m |

| Test 8 | 0.5 m | 20% | 0.005 m |

| Test 9 | 0.5 m | 20% | 0.008 m |

| Pipe Section Number | I | II | III | IV | V |

|---|---|---|---|---|---|

| Pipe length (m) | 732.12 | 777.07 | 749.98 | 750.00 | 159.26 |

| Elevation difference (m) | 33.11 | 4.83 | 4.75 | 7.34 | 1.91 |

| 0.0452 | 0.0062 | 0.0063 | 0.0098 | 0.0120 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, S.; Ma, J.; Zhang, B.; Jia, J.; Li, J. Characterization of Non-Constant Flow in the Recession Process of Pressurized Pipelines with Air Valves. Water 2025, 17, 3022. https://doi.org/10.3390/w17203022

Sun S, Ma J, Zhang B, Jia J, Li J. Characterization of Non-Constant Flow in the Recession Process of Pressurized Pipelines with Air Valves. Water. 2025; 17(20):3022. https://doi.org/10.3390/w17203022

Chicago/Turabian StyleSun, Shuaihui, Jinyang Ma, Bo Zhang, Jingwen Jia, and Jiuwang Li. 2025. "Characterization of Non-Constant Flow in the Recession Process of Pressurized Pipelines with Air Valves" Water 17, no. 20: 3022. https://doi.org/10.3390/w17203022

APA StyleSun, S., Ma, J., Zhang, B., Jia, J., & Li, J. (2025). Characterization of Non-Constant Flow in the Recession Process of Pressurized Pipelines with Air Valves. Water, 17(20), 3022. https://doi.org/10.3390/w17203022