1. Introduction

With urban development and increasing awareness of environmental protection, the limitations of traditional wastewater treatment systems in precise water management, resource utilization, and intelligent operation have become increasingly evident. In recent years, the concentration of nitrogen and phosphorus in wastewater has increased significantly. Membrane bioreactors (MBRs), due to their superior solid–liquid separation performance and efficient nitrogen and phosphorus removal capacity compared to traditional activated sludge systems, have been become one of the technologies for high-performance wastewater treatment solutions [

1,

2]. However, in engineering practice, MBRs still face several unresolved problems, which have drawn increasing attention to intelligent solutions. Fundamentally, an MBR integrates a biological reactor with a membrane filtration unit, where microbial processes degrade organic matter and nutrients while the membrane ensures high-quality effluent. Nonetheless, several operational challenges remain unresolved: (i) membrane fouling leads to a progressive increase in transmembrane pressure (TMP) and cleaning frequency; (ii) fluctuations in influent characteristics and operational parameters (e.g., dissolved oxygen, C/N ratio, pH, hydraulic retention time) often result in unstable effluent concentrations of total nitrogen (TN) and total phosphorus (TP); and (iii) the high aeration demand substantially elevates energy consumption. Collectively, these problems not only increase operation and maintenance costs but also constrain the resilience and scalability of MBR systems in full-scale engineering practice. For example, AI methods have been begun to be introduced by some researchers; artificial neural networks (ANN), support vector machines (SVM), random forests (RF), and gradient boosting decision trees (Python software version 3.9XGBoost) have been used, and models for nitrogen and phosphorus removal efficiency in MBRs have been successfully constructed [

1,

2,

3]. In recent years, the transformation of MBR systems has been accelerated under the drive of AI, and interpretable models and edge intelligence deployment have been become international research hotspots [

2,

4]. In practical engineering, high-precision prediction of anaerobic MBR (An MBR) membrane fouling has been supported by intelligent control frameworks [

5], which marks the transition of the technology from theory to application. Obvious advantages of AI technology in improving the automation and stability of MBR systems have been demonstrated, and it is regarded as the future trend of intelligent wastewater treatment [

6,

7]. For

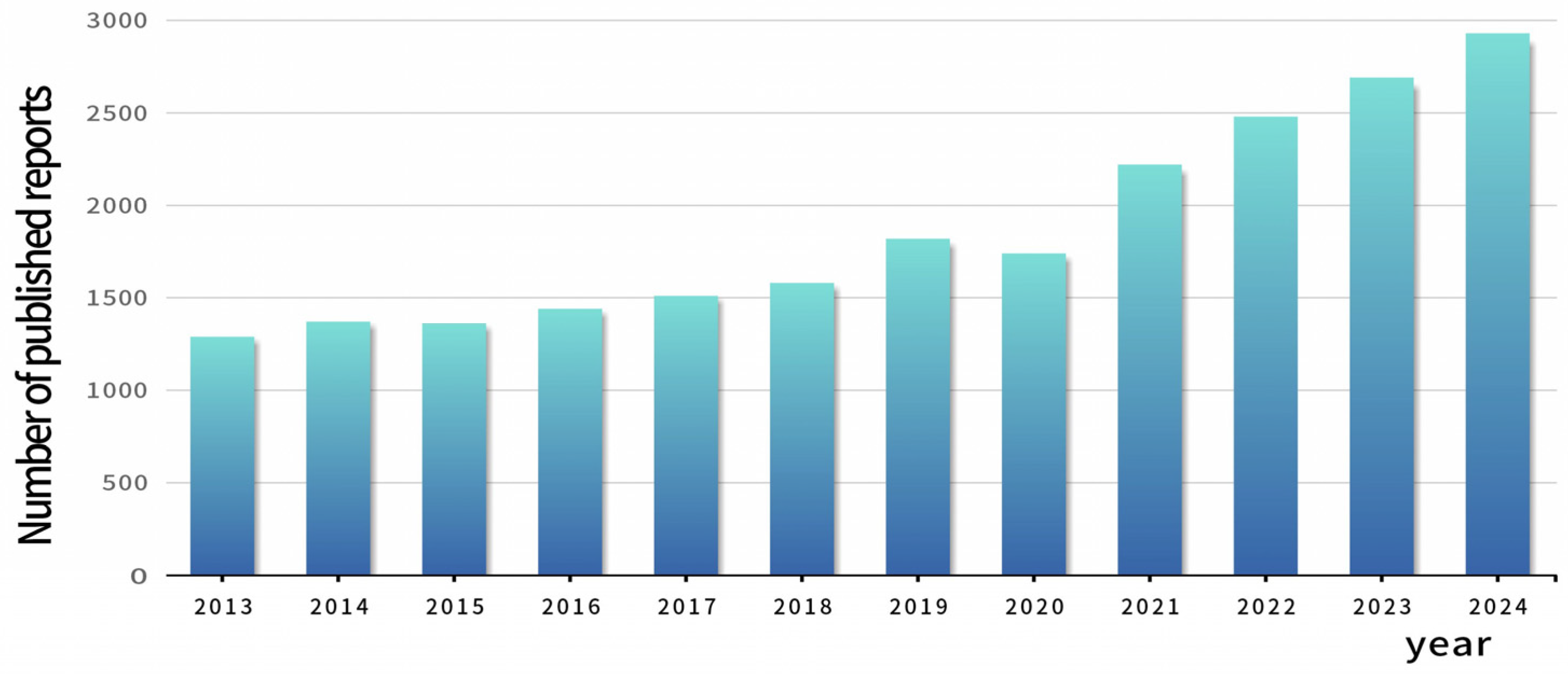

Figure 1, the literature search was conducted in Google Scholar using the combined keywords “AI,” “Membrane Bioreactor,” “Nitrogen,” and “Phosphorus.” This keyword strategy was designed to capture a comprehensive range of studies focusing on the integration of intelligent technologies into MBR systems for nutrient removal, while ensuring sufficient breadth to reflect the overall research landscape. Based on the retrieved results from 2013 to 2024, a clear upward trend was observed, underscoring the growing significance of AI-driven MBR research in wastewater treatment.

Excellent performance of MBR technology in nitrogen and phosphorus removal is demonstrated, but multiple bottlenecks are still faced by it in actual operation. Membrane flux is limited by membrane fouling, which leads to an increase in transmembrane pressure (TMP); an increase in energy consumption and an increase in cleaning frequency are caused by this, and thus operation and maintenance costs are increased [

8,

9]. On the other hand, the efficiency of nitrogen and phosphorus removal is highly dependent on the nonlinear coupling of parameters such as dissolved oxygen (DO) concentration, carbon-to-nitrogen (C/N) ratio, hydraulic retention time, and pH; fluctuations in effluent total nitrogen (TN) and total phosphorus (TP) are easily caused by this, and the risk of exceeding standards is increased [

10,

11]. To address these issues, an optimization path centered on AI has been introduced by researchers [

12]. Driven by the goal of synergistic governance of carbon, nitrogen, and phosphorus, an integrated intelligent control architecture needs to be constructed for MBR systems. A foundation for real-time monitoring and feature extraction is provided by the integration of multi-source sensors and data acquisition systems, while the response speed to membrane fouling and resource management efficiency can be notably improved by AI models through decision optimization [

13,

14]. However, problems such as prediction errors, incomplete data, and difficulties in membrane fouling control still exist [

4].

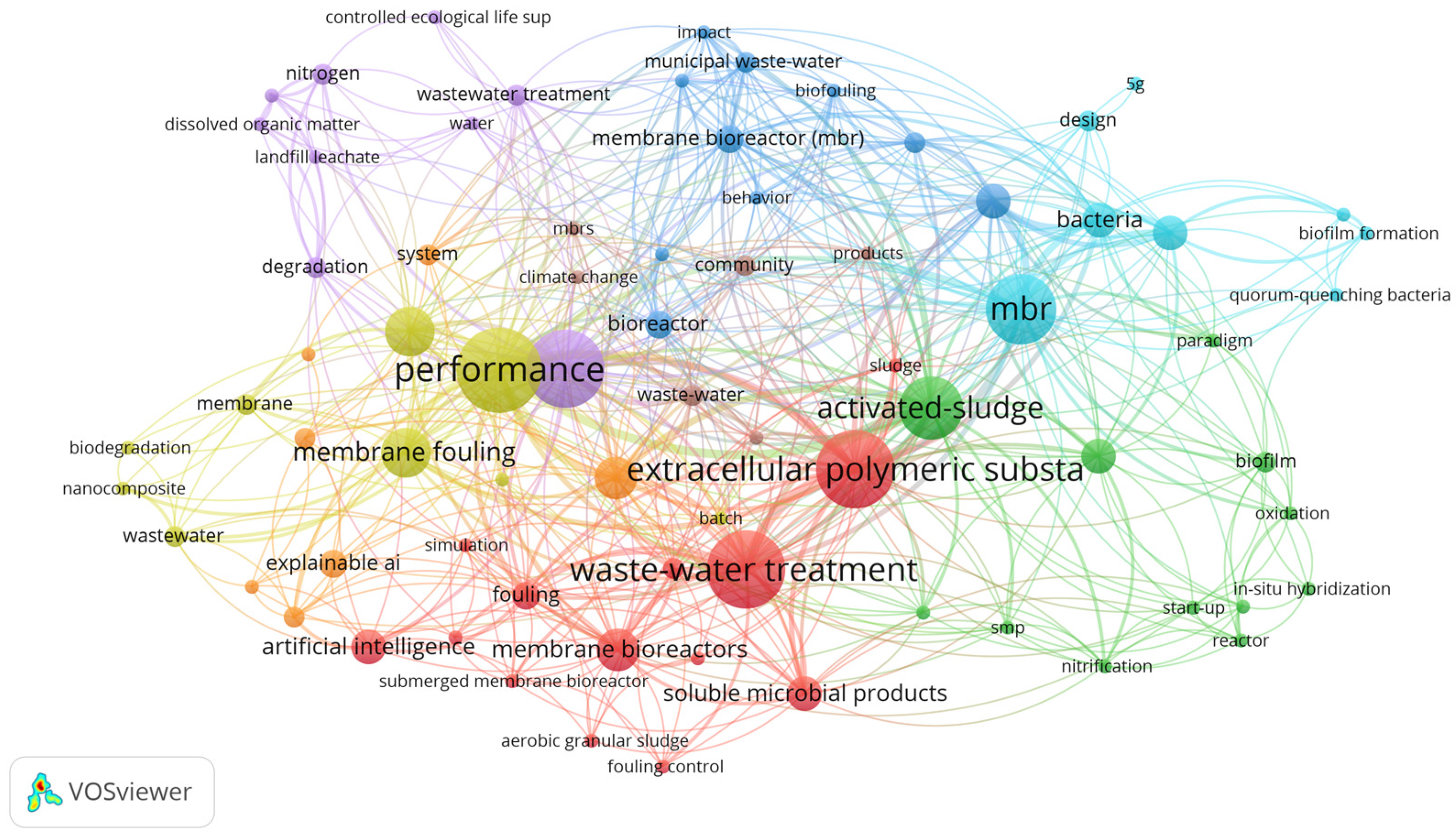

Figure 2 presents a keyword co-occurrence map generated using VOSviewer, in which “Performance,” “extracellular polymeric,” and “waste-treatment” emerge as the main hotspots. This suggests that current research primarily emphasizes intelligent regulation and synergistic pollutant treatment.

With the continued advancement of AI in wastewater treatment, its integration with MBR systems has evolved from conventional operational status prediction to system-level optimization and full-process intelligent control. Nevertheless, current research still faces major challenges, including limited model generalization, difficulties in constructing closed-loop control systems, and inadequate adaptation to multi-source heterogeneous data. At this stage, the latest international research is focused on the following three directions: Closed-loop integrated control: Cross-plant collaborative optimization is enabled by federated learning frameworks [

15]; Multi-source adaptive modeling: Prediction accuracy in low-data scenarios is improved by transfer learning [

16]; Dynamic parameter optimization: Energy consumption is reduced by reinforcement learning while water quality is ensured [

17].

The innovative framework of this review systematically traces the evolution of AI-MBR intelligent control architectures, with sections organized as progressive layers of analysis. First, AI-driven control architectures and integration models in MBR systems are reviewed to establish the foundation by identifying key challenges and opportunities. Second, the adaptability and robustness of intelligent technologies under multi-source wastewater conditions are examined, reflecting the complexity of practical influent scenarios. Third, the intelligent regulation of membrane operating parameters is highlighted, directly addressing issues such as fouling, transmembrane pressure, and energy consumption. In addition, engineering applications related to enhanced nitrogen and phosphorus removal and circular economy practices are summarized, extending AI-MBR control toward sustainability goals. Finally, current challenges and future research directions are outlined to bridge practical needs with long-term innovation.

2. AI-Based Intelligent Control Framework for Membrane Bioreactors

Before elaborating on the AI-based intelligent control framework, it is essential to briefly review the research status and challenges of conventional control operation for membrane bioreactors (MBRs). Rule-based and PID strategies are effective for basic regulation but remain inadequate for coping with the nonlinear, time-varying nature of MBRs and the coupled impacts of fouling and influent variability. In practice, persistent membrane fouling drives transmembrane pressure (TMP) rise and cleans frequency, jeopardizing effluent stability, while aeration-dominated energy demand constrains scalability [

8]. Recent reviews and case studies show that data-driven/AI approaches (e.g., ANN/SVM/RF, deep learning, and reinforcement learning) can improve fouling prediction, parameter optimization, and closed-loop decision support under fluctuating conditions [

2,

3]. Nevertheless, MBR control operation still faces key challenges, including energy consumption increase induced by fouling, difficulties in accurately predicting membrane lifespan, and the stringent requirements of real-time models for data quality and algorithm interpretability [

12,

13]. These gaps motivate the AI-based control framework presented in the following sections.

2.1. Development of Intelligent Control System Framework

The evolution of the MBR intelligent control system architecture signifies that a shift from empirical adjustment to data-driven and autonomous optimization is being undergone by wastewater treatment. In recent years, AI technology has gradually been embedded into the system structure, which promotes the development of control modes toward multi-level, modular, and closed-loop directions [

18]. As shown in

Table 1, a notable transition of the system architecture has been undergone: from relying on manual experience, to introducing a single AI model for auxiliary prediction, and then constructing an intelligent closed-loop system integrating perception, prediction, decision-making, and feedback.

As shown in

Table 1, the MBR intelligent control system has rapidly evolved from a single-point prediction model to a modern closed-loop architecture characterized by multi-source perception, deep decision-making, and distributed collaboration. The essence of this evolution lies in the integration of AI, which enhances the system’s ability to interpret complex conditions, its autonomy in operational regulation, and its responsiveness to load fluctuations, thereby establishing a solid foundation for future intelligent and adaptive wastewater treatment.

2.2. Examination of Key Functional Components

The AI-driven MBR control system has established a data-driven, closed-loop optimized intelligent operation architecture. Its core functions are achieved through three closely integrated modules: a model prediction module for perception and forecasting, a control decision module for intelligent decision-making, and an execution feedback module for reliable implementation and feedback. For the model prediction module, based on real-time and historical data (water quality, membrane parameters, etc.), time-series models such as LSTM and convolutional neural network (CNN) are used to predict key targets (e.g., membrane fouling, effluent concentration), and a basis for decision-making is provided by this. For the control decision module, prediction results are converted into specific control instructions (such as adjusting DO, reflux ratio, and dosage), and multi-objective optimization algorithms like reinforcement learning are applied to achieve complex regulations. For the execution feedback module, the reliable execution of instructions (driving equipment) is ensured, and the new state of the system is fed back in real-time, forming a closed-loop cycle; the stable and efficient operation of the system is jointly guaranteed by these [

22,

23,

24,

25].

Focus on accurate pre-judgment is placed by the model prediction module. Its core innovation lies in the use of deep time-series models (such as CNN-LSTM) to effectively capture the nonlinear and time-series characteristics of data, so that prediction accuracy is improved (e.g., the R

2 for membrane fouling prediction can reach 0.90) [

5]. Another key focus is the enhancement of generalization ability; for example, data from neighboring points are integrated (based on the idea of transfer learning), which leads to a notable reduction in the prediction error of target points (with Mean Squared Error (MSE) decreased by more than 70%) [

26].

Responsibility for intelligent optimization is taken by the control decision module. Its innovation is reflected in the application of advanced algorithms to solve complex decision-making problems. Multi-agent deep deterministic policy gradient (MADDPG) has been successfully introduced; the balance of multiple objectives such as water quality, energy consumption, and cost is realized through the collaborative optimization of dissolved oxygen and chemical dosage by distributed agents [

22], and the advantage of AI in handling coupled control challenges is demonstrated by this.

The reliability of the closed loop is ensured by the execution feedback module. Its innovation lies in the integration of new technologies to improve efficiency and robustness. For the cloud-edge collaboration framework, data are preprocessed on the edge side to reduce the load, while high-precision anomaly detection is achieved by the cloud-based model, and the safety of the control environment is ensured by this [

24]. The ability to verify execution results and pre-judge risks is enhanced by digital twin technology through virtual-real synchronous mapping [

25].

While different AI models focus on specific aspects of control system applications, their common goals include enhancing generalization and interpretability, minimizing complexity and data reliance, strengthening robustness to dynamic conditions, and improving module collaboration efficiency.

2.3. Integration Strategies of Control Systems

Profound changes have occurred in the integration mode of AI-MBR control platforms, evolving from centralized to distributed and collaborative architectures. The “cloud–edge–end” structure has become the mainstream paradigm, characterized by rational allocation of computing tasks. The cloud undertakes global model training, big data storage and analysis, and long-term strategy optimization. The edge layer, located close to data sources, is responsible for real-time data processing, lightweight model inference, rapid local decision-making, and abnormal condition responses. The end layer, comprising sensors and actuators, focuses on data collection and instruction execution. Notable improvements in system performance are brought by this hierarchical architecture: in terms of response speed, millisecond-level local decision-making is enabled by edge computing, avoiding cloud transmission delays (e.g., independent operation of edge controllers can be achieved when the network is disconnected [

27]), while non-real-time optimization is focused on by the cloud; in terms of data security, original sensitive data (such as process parameters and water quality information) can be retained in local or edge nodes, with only necessary features or model updates shared (e.g., federated learning [

21]), and the risk of privacy leakage is effectively reduced by this; in terms of cost, the demand for expensive bandwidth and the consumption of cloud computing resources are reduced by edge processing, and resource utilization and deployment flexibility are improved by containerized microservices (such as Docker deployment [

28]). However, the deployment of edge nodes and the complexity of distributed management may increase initial costs. Representative AI-MBR control platforms and integration architectures, together with their core characteristics and impacts, are summarized in

Table 2.

In summary, ANN and RFR offer accuracy and robustness, while LSTM captures time-series dynamics. RL, SDAE, FWNN, and GNN enhance adaptability, feature extraction, and data integration but face challenges in computation, scalability, and interpretability, indicating trade-offs between performance and applicability

2.4. Current Research Focuses and Future Directions

In recent years, the integration of MBR systems with AI technology has deepened, with research increasingly focusing on model generalization, collaborative control, and platform intelligence. The construction logic and control capabilities of these systems continue to evolve, and future development is expected to concentrate on the following directions:

Generalization ability to adapt to complex operating conditions is a core requirement for the large-scale application of AI-MBR systems. A framework integrating federated learning and MPC was proposed by Xu et al. [

39]; privacy protection and cross-plant control optimization are realized by this framework through collaborative training of a global model (without sharing raw data); an instance transfer modeling framework was constructed by Huang et al. [

16], in which sample weights are dynamically adjusted, and the R

2 value of COD prediction is improved to 0.80 in low-data scenarios; transfer support for wastewater treatment plants with data scarcity is provided by this.

Multi-agent systems (MAS) have become a key approach to cope with dynamic loads. A multi-agent reinforcement learning architecture was developed by Chen et al. [

22]; aeration and dosing tasks are assigned to independent agents in this architecture, and dual optimization of nitrogen and phosphorus removal efficiency and energy consumption is achieved through distributed collaboration; the strong robustness of this method under fluctuating operating conditions was further verified by Nam et al. [

17], and it is proved by this that its adaptability is superior to traditional single-point control.

Improvement of model interpretability to enhance user trust has become a new trend. Fuzzy logic rules were embedded into reinforcement learning strategies by Huang et al. [

40], enabling control decisions to have semantic interpretation; the Causal is system was developed by Guo et al. [

41]; variable relationships and heterogeneous effects are visualized by this system through interactive causal graphs, notable improvements in the transparency of causal models are achieved, and an intuitive basis for process adjustment is provided by this.

Nevertheless, despite notable progress, three major bottlenecks remain in practical implementation: limited model generalization, delayed engineering response, and barriers to cross-system integration.

3. Smart Remediation Technology for Multi-Source Wastewater

3.1. Compositional Analysis of Multi-Source Wastewater

The diversity of wastewater sources arises from domestic sewage, industrial effluents, agricultural pollution, and initial rainwater runoff, each contributing complex pollution structures and distinct treatment requirements.

3.1.1. Compositional Analysis of Domestic Sewage

Domestic sewage mainly comes from residents’ washing, bathing, kitchen water use, and excretion behaviors, with characteristics such as regionality, periodicity, and composite pollution presented. It was pointed out by Raboni et al. [

42] in their research that in community sewage, the concentrations of chemical oxygen demand (COD) and biochemical oxygen demand over 5 days (BOD

5) reach peaks at noon, which are 64.5% and 66.6% higher than the daily average values, respectively, while they drop by more than 60% in the early morning; the difficulty of regulating the treatment system is increased by this. High concentrations of COD, BOD

5, nitrogen and phosphorus nutrients, pathogenic microorganisms, and drug residues are often contained in rural domestic sewage [

43]. Characteristics of its water quality include strong seasonality, spatial dispersion, and large fluctuations in water volume. The concentrations of COD and ammonium ion (NH

4+) often reach more than 500 mg/L and 40 mg/L, respectively. Due to the lack of centralized drainage systems in most rural areas, drastic changes in water volume occur, high costs are associated with the centralized treatment mode, and difficulties are encountered in actual operation. Therefore, treatment technologies adapted to decentralized discharge and variable loads need to be adopted [

44,

45].

The difficulties of AI-modeling in rural domestic sewage treatment mainly include the following aspects: Great fluctuations in the water quality and quantity of rural sewage occur, resulting in unstable model input [

42]; The forms of pollutants such as nitrogen and phosphorus are complex and the load is high, so the model needs to adapt to multiple reaction processes at the same time [

44]; And notable impacts on the removal efficiency are exerted by changes in hydraulic load, packing characteristics, etc., in the project operation, increasing the difficulty of model generalization [

45].

3.1.2. Compositional Analysis of Industrial Wastewater

Industrial wastewater comes from various industries such as textiles, chemical, papermaking, electroplating, and pharmaceuticals, with a high-pollution load, a high-toxicity level, and significantly different components. A large number of hard-to-degrade dyes and heavy-metal ions are often contained in textile wastewater, and the COD concentration can reach 1854 mg/L [

46]. High-concentration antibiotics and trace organic pollutants are rich in pharmaceutical wastewater, which exert strong inhibition on the microbial system [

47]. Because a substantial fraction of these constituents is non-biodegradable, the conventional activated sludge process is inherently limited—biomass activity can be inhibited and the BOD/COD ratio remains low [

47]. Therefore, enhanced pretreatment (e.g., equalization, coagulation–flotation, adsorption, or advanced oxidation) and/or advanced post-treatments (e.g., ozonation–biological activated carbon, activated carbon adsorption, or membrane separation) are required to remove inhibitory/refractory species, improve biodegradability, and ensure that effluent quality consistently meets discharge standards [

8,

9,

47,

48]. In the wastewater of some chemical and pharmaceutical enterprises, high salinity (total dissolved solids (TDS) > 10,000 mg/L) and high ammonia-nitrogen concentration (TN > 500 mg/L) are common, which are the main causes of membrane fouling and system toxicity failure [

48].

Multiple challenges are faced by AI modeling in wastewater treatment: the high idle rate of treatment facilities and the difficulty of supervision and implementation [

46]; the activity of key microorganisms will be inhibited by high-salt or high-toxicity environments [

48].

3.1.3. Compositional Analysis of Agricultural Wastewater

Agricultural wastewater mainly consists of livestock and poultry breeding effluents, irrigation return flows, and pesticide–fertilizer runoff, characterized by strong seasonality, high intermittency, and non-point source diffusion. This type of pollution is dominated by phosphorus and often contains high concentrations of total phosphorus and composite pollutants existing in dissolved or particulate forms [

49]. Most agricultural wastewater is discharged through non-point sources, with hidden paths and wide distribution; thus, its governance is made much more difficult than that of point-source wastewater. A high pollution load is contained in livestock and poultry breeding wastewater, with COD often ranging from 4000 to 20,000 mg/L, accompanied by antibiotics and pathogenic bacteria. If proper treatment is not conducted, the safety of aquatic ecosystems will be seriously threatened by it [

50]. Farmland return water comes from surface runoff after irrigation; although the concentrations of nitrogen and phosphorus are relatively low, the discharge area is wide, which easily causes eutrophication of lake water bodies and abnormal algae reproduction [

51].

Multiple difficulties are faced by AI modeling in agricultural pollution treatment: spatial heterogeneity, time lag, complex coupling of hydrological and biochemical processes [

49]; multiple interactions of emerging pollutants, difficulty in determining resource utilization safety thresholds, complex multi-process collaborative optimization [

50]; complex coupling of policy behaviors, difficulty in integrating multi-scale processes, cumulative effects of historical pollution [

51].

3.1.4. Compositional Analysis of Initial Rainwater Runoff and Combined Sewerage

Initial rainwater runoff refers to the water flow with high pollution load formed by the scouring of hardened ground, roofs, and roads during the early stage of rainstorms. Such runoff often contains large amounts of suspended solids (SS), COD, heavy metals, and trace organic pollutants, with a pollution intensity much higher than that of later-stage runoff [

52]. Combined sewage refers to the part of mixed rainwater and sewage in combined sewer systems that is directly discharged into water bodies due to insufficient treatment capacity, usually containing feces, pathogens, and nutrients; extremely high ecological risks are posed by it [

53]. Due to significant differences in site conditions and pollutant compositions, wide fluctuations are shown in the proportion of initial erosion load (FF

n). For example, FF

30 is significant in residential areas, where the event concentration peaks of COD and TP can reach 2000 mg/L and 20 mg/L, respectively [

54]. Combined sewer overflows (CSO) mostly occur rapidly in a short time during peak rainfall periods. Untreated mixed sewage is directly discharged into water bodies, often accompanied by high concentrations of pollutants such as ammonia nitrogen, pathogens, and antibiotic resistance genes; severe impacts on aquatic ecosystems are caused by this [

53].

Problems are also faced by AI modeling in initial rainwater runoff and combined sewerage: the mechanism of pollutant phase distribution is complex, with high spatial and temporal variability, making modeling difficult [

52]; sudden discharge has strong intermittency, data on emerging pollutants is sparse, and the chiral transformation mechanism is complex [

53]; strong data heterogeneity and high site specificity limit the generalization ability of models [

54].

3.2. Intelligent Treatment Mechanism for Multi-Source Wastewater

Significant differences in water volume, quality, and pollutant composition exist among various types of wastewaters. These differences pose adaptability challenges for traditional treatment processes but also create opportunities for optimization through intelligent control technologies. As shown in

Table 3, effective treatment requires AI technologies to be adapted to specific conditions, with models selected according to pollution characteristics to achieve optimal operation and control.

3.2.1. Intelligent Strategies for Domestic Sewage Treatment

Domestic sewage has large load fluctuations and complex compositions, and obvious advantages of intelligent control technologies have been shown in such treatment systems. The brain-inspired image-and-temporal fusion model with CNN–LSTM (BITF-CL) model was proposed by Li et al. [

65]; image and water quality time-series data are combined by this model, and an R

2 of 0.91 for COD prediction within 1 h is achieved, outperforming LSTM and CNN-LSTM models. An AAO process control framework based on DQN was constructed by Hu et al. [

66]; DO setpoints are dynamically adjusted by this framework to effectively reduce energy consumption while stable effluent quality is ensured. Neuron agglomerative clustering (NAC) compression technology was developed by Wang et al. [

67]; notable effects in reducing model computing and storage loads have been shown by this technology, making it suitable for deployment in edge computing environments. In rural areas, a real-time monitoring system based on soft sensors was designed by Li et al. [

68] to realize continuous detection of COD and NH

4+, and regulation accuracy is enhanced by this. An Auto machine learning (ML) model was deployed in Inner Mongolia by Cao et al. [

69] to predict water quality changes and sewage production, and the practicality and feasibility of intelligent decentralized governance technologies are verified by this.

However, these systems still encounter difficulties in engineering applications, including severe hourly fluctuations in water volume and limited data from decentralized treatment. Future optimization should focus on developing lightweight edge models and exploring integrated architectures that combine federated learning with transfer learning.

3.2.2. Intelligent Strategies for Industrial Wastewater

Industrial wastewater is characterized by diverse sources, high pollutant concentrations, and strong toxicity, rendering its treatment much more difficult than that of domestic sewage. To enhance the operational stability and treatment efficiency of systems, AI models are widely utilized for pollutant concentration prediction and operational parameter optimization. A prediction model based on RF was constructed by Peerzade et al. [

70], with R

2 values of 0.74 and 0.70 for COD and TN prediction accuracy, respectively, while better performance was demonstrated by the gradient boosting (GB) model. The Cat Boost model was proposed by Wei et al. [

71], which outperforms other machine learning methods in the treatment of high-salt wastewater. MADDPG was introduced into the control layer by Chen et al. [

22], realizing dynamic adjustment of DO and chemical dosage, and effectively reducing energy consumption and greenhouse gas emissions. In addition, in terms of intelligent monitoring, multi-source sensor information needs to be integrated by industrial wastewater systems to enhance the ability of abnormal state identification and fault response [

72].

Due to strong water quality heterogeneity and toxicity inhibiting microbial activity, significant constraints are faced by such systems in engineering applications. To address these issues, future optimization can be achieved by constructing industry-specific pre-trained models and developing robust control algorithms against toxic shocks.

3.2.3. Intelligent Strategies for Agricultural Wastewater

Agricultural wastewater has non-point source characteristics, intermittent discharge, and wide distribution, making its governance often face prominent problems such as “difficult positioning, difficult monitoring, difficult prediction, and difficult regulation”. To improve treatment efficiency and response capabilities, AI technologies have been introduced into agricultural wastewater governance by researchers, and intelligent, low-consumption solutions suitable for rural areas have been developed. An intelligent operation and maintenance system was constructed by Feng Wenqian et al. [

73] to conduct real-time monitoring and management of the livestock and poultry breeding wastewater treatment process, realizing stable regulation of key parameters, ensuring that effluent water quality meets standards, and reducing operating costs at the same time. The pig house wastewater treatment process was optimized by Dan et al. [

74] using the intermittent cycle extended aeration system (ICEAS) technology, and the removal efficiency of NH

4+, TN, and TP was notably improved by adjusting aeration and mixing cycles. In terms of farmland irrigation monitoring, a multi-sensor Internet of Things system was developed by the research team from SNS College of Engineering and Technology in India, which can collect real-time water quality parameters of agricultural water, effectively improving the level of irrigation water management and ensuring agricultural ecological security [

75].

Engineering applications show that such systems are still difficult to completely overcome the challenges of hidden diffusion paths of non-point source pollution and difficult prediction of storm runoff peaks. Future research should focus on the application of developing coupled prediction models of rainfall–runoff–pollution by combining satellite remote sensing and ground sensing data.

3.2.4. Intelligent Strategies of Initial Rainwater Runoff and Combined Sewerage

Initial rainwater runoff and combined sewage are characterized by strong suddenness, concentrated pollution load, and high treatment requirements, making them key and difficult points in urban non-point source pollution control and emergency treatment. In recent years, data-driven control strategies combining AI with real-time monitoring have become a research hotspot. A CNN–LSTM model was constructed by Baek et al. [

76] in the Nakdong River basin in South Korea, integrating radar images and water quality monitoring data to simulate the temporal changes of pollutants. The results show that the NSE values of the model for TN, TP, and total organic carbon (TOC) parameters are all higher than 0.75, notably outperforming traditional algorithms, which demonstrates the application potential of deep learning in nonlinear pollution prediction. In terms of CSO management, it has been pointed out by Saddiqi et al. [

77] that sensor-based real-time monitoring systems, MPC, and reinforcement learning algorithms have been widely adopted to dynamically adjust the operating status of pumping stations and gates, which has notably improved response speed and effectively alleviated the risk of overflow pollution.

Although these systems demonstrate advantages in treatment performance, they still encounter challenges in engineering applications, including sudden spatiotemporal fluctuations in pollution load (e.g., COD peaks up to 2000 mg/L) and insufficient timeliness in emergency response. Therefore, it is imperative to establish a real-time decision-making system integrating meteorology, hydrology, and AI, and to enhance model robustness under extreme weather conditions.

4. Intelligent Control Technologies for Membrane Operating Parameters

4.1. Control of Critical Membrane Operating Parameters

The stable operation of MBR systems depends on the condition of membrane modules, with key operating parameters including transmembrane pressure (TMP), membrane flux, air scouring intensity, and cycle cleaning. In recent years, researchers have increasingly applied data-driven methods for membrane parameter prediction and adaptive regulation to optimize system performance.

4.1.1. Intelligent Prediction and Control of Transmembrane Pressure (TMP)

TMP is a core indicator of membrane fouling, and its increase results in higher energy consumption and more frequent cleaning. Lag issues are presented in traditional monitoring, while the timeliness of intervention is improved by AI models through real-time prediction. A GRU–LSTM hybrid model was constructed by Yasmin et al. [

78], and the TMP prediction accuracy was notably improved by fusing time–series features. An adaptive model based on forgetting factor recursive least squares autoregressive with exogenous input (FFRLS–ARX) model was developed by Prado-Rubio et al. [

79] to predict the fouling rate in real time, with an error of <10% within 20 min, and gain analysis was combined to guide operations. However, the insufficient generalization ability of models under complex working conditions and prediction deviations easily caused by dynamic load fluctuations have become major bottlenecks of current technologies. As shown in

Table 4, a range of AI techniques have demonstrated high accuracy in TMP prediction and strong generalization capability, thereby enhancing both the timeliness and reliability of membrane-fouling early warning.

4.1.2. Intelligent Control of Membrane Flux

Fluctuations in membrane flux affect effluent quality and energy consumption. The stability is improved by AI through flux tracking and adaptive control. A control strategy based on ANN and internal model control (IMC) was proposed by Abdul et al. [

82] to achieve high-precision tracking of target flux and enhance system response capability. Adaptive neuro–fuzzy inference system (ANFIS) and ANN were used by Hosseinzadeh et al. [

83] to model osmotic membrane bioreactor (OMBR) flux changes, and flux trends under different parameters were predicted, with an accuracy of R

2 > 0.98 under complex working conditions. However, under high-load operation conditions, the nonlinear characteristics of biochemical reactions become more prominent. To improve the robustness of the model, it is necessary to introduce multi-source sensor data for coupled modeling.

Table 5 presents a comparison of AI models applied to membrane-flux optimization. Among them, ANFIS and ANN exhibit superior predictive performance under complex operating conditions, offering a solid foundation for intelligent flux regulation.

4.1.3. Control of Air Scouring Intensity

Air scouring is utilized to control membrane fouling, and its intensity regulation needs to strike a balance between fouling control and energy consumption. Model-free DRL can reduce energy consumption by approximately 3–5% under the same water quality conditions and notably shorten training time [

86]. When parameters such as COD, NH

4+ concentration, and flow rate are optimized by the ANFIS model, the energy-saving rate reaches 33%, the operating cost is notably reduced, and the prediction error is significantly smaller than that of ANN [

87]. However, the coupling mechanism between aeration intensity and membrane fouling is complex, and it is still necessary to implement dynamic adjustment strategies based on real-time fouling status to further improve the control effect.

4.1.4. Intelligent Optimization of Membrane Cleaning Cycle

Membrane cleaning (including physical and chemical cleaning) is an important means to maintain the long-term stable operation of the system. Frequent cleaning will increase costs and damage membrane materials, while delayed cleaning is likely to cause irreversible fouling. An intelligent cleaning and maintenance system was developed by Woo et al. [

88] that can accurately identify the end of membrane life, avoid ineffective high-frequency cleaning, and reduce operating costs. In another study, the frequency of chemical cleaning was reduced by matching the cleaning cycle and intensity, resulting in a 26% reduction in membrane fouling [

89]. At present, the damage mechanism of chemical cleaning to membrane materials still lacks quantitative evaluation, and it is urgent to optimize the cleaning strategy and decision-making process with the help of digital twin technology. As indicated in

Table 6, AI-based strategies for optimizing membrane-cleaning cycles have proven effective in extending membrane lifespan, reducing cleaning frequency and chemical demand, and thereby achieving a marked reduction in overall operating costs.

4.2. Enhancement of Nitrogen and Phosphorus Removal Efficiency

MBR systems are widely used for removing nutrient pollutants such as nitrogen (N) and phosphorus (P) owing to their efficient solid–liquid separation and flexible, controllable operation. In recent years, AI has played a critical role in enhancing nitrogen and phosphorus removal efficiency through real-time sensing and joint regulation technologies. As shown in

Table 7, AI models have demonstrated significant advantages in nutrient removal.

4.2.1. Improvement of Nitrogen Removal Efficiency

Complex operating states in wastewater treatment systems can be accurately identified by artificial intelligence models, and excellent adaptive regulation capabilities are possessed by them, especially notable effects in dynamically optimizing nitrogen removal process. A Fuzzy Neural Network (FNN) control system was proposed by Huang et al. [

99] to adjust nitrate reflux in the A/O process, thereby enhancing denitrification efficiency. The results showed that the TN removal rate was increased by 10.5%, the COD removal rate was increased by 14%, and the operating cost was decreased by 17%. An online DO regulation framework based on DRL was constructed by Hu et al. [

66]; by reducing the DO setpoint from 3.96 mg/L to 3.88 mg/L, the effluent TN was stabilized within the standard range of 6–8 mg/L, while the synergistic optimization of energy consumption reduction and denitrification efficiency improvement was achieved.

4.2.2. Improvement of Phosphorus Removal Efficiency

Biological phosphorus removal is highly dependent on the phosphorus release-uptake mechanism and is sensitive to operating parameters such as DO concentration, carbon source type, and reaction time. A control framework integrating DRL and simulators was constructed by Mohammadi et al. [

100] to realize dynamic optimal control of phosphorus discharge under complex influent conditions. Compared with traditional strategies, phosphorus emissions were reduced by 36% by this method, effectively improving phosphorus removal efficiency and system response speed. A phosphorus removal efficiency prediction model based on Support Vector Machine with Radial Basis Function kernel (SVM_rbf) was built by Kumar et al. [

94] and applied to the hybrid constructed wetland system. The results showed that the TP prediction accuracy of this model reached R

2 = 0.74, outperforming methods such as ANN, RF, and multiple linear regression; the ability to identify TP variation trends was notably enhanced by this, and data support for subsequent optimization of operating parameters was provided.

4.2.3. Improvement of Removal Efficiency Under Synergistic Nitrogen and Phosphorus Removal

Interactive relationships between nitrogen and phosphorus as well as their nonlinear coupling with operating parameters can be identified by AI-driven synergistic optimization mechanisms, thereby improving the overall pollutant removal performance of the system. An A

2O real-time control system combining LSTM with Attention Mechanism (LSTM-ATT) and DRL was developed by Hu et al. [

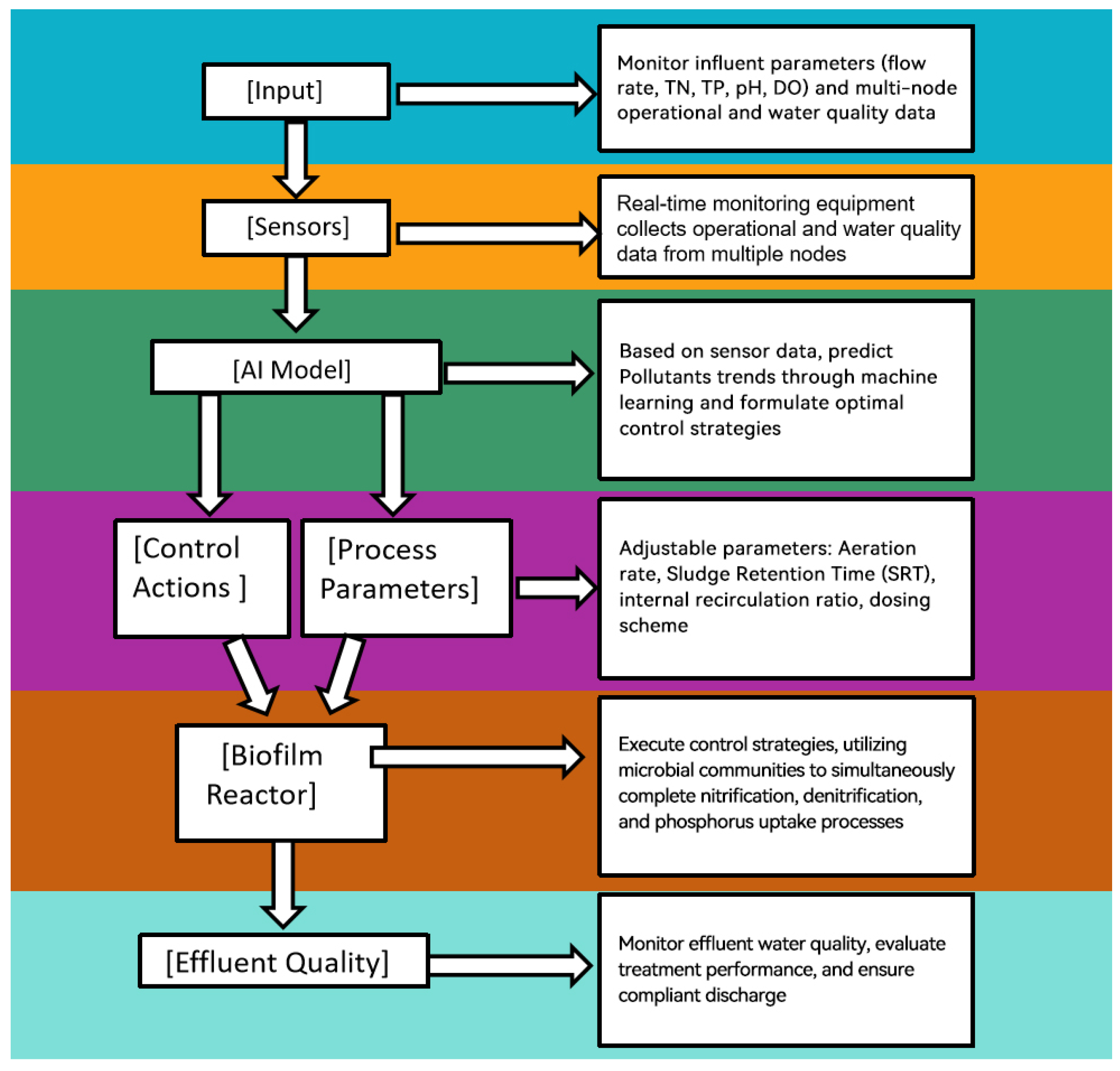

66], which notably improved the system’s control accuracy and treatment efficiency. Experiments have proven that the effluent TN and TP concentrations are reduced to 6.88 mg/L and 0.05 mg/L, respectively, by the system, with removal rates reaching 87.3% and 99.4%, respectively. Meanwhile, aeration energy consumption is effectively reduced by the system through optimizing DO setpoints. The optimization mechanism of AI on nitrogen and phosphorus removal pathways in the biofilm wastewater treatment process is shown in

Figure 3. The removal effects of effluent TN and TP are further improved by the system through feedback control of key parameters such as aeration intensity, SRT, and reflux ratio.

4.2.4. Common Difficulties and Challenges

Despite the notable achievements of AI in improving nitrogen and phosphorus removal efficiency, some common challenges are still faced by it. Firstly, nitrogen and phosphorus removal efficiency is highly dependent on the complex nonlinear coupling relationships among multiple parameters such as DO, C/N ratio, pH, SRT, HRT, and reflux ratio [

10,

11]. Strong learning capabilities are required by AI models to capture these complex relationships and make globally optimal decisions. Secondly, the performance of AI models is highly dependent on high-quality and comprehensive operational data. Due to large differences in water quality, processes, and scales among different wastewater treatment plants, the construction of AI models with strong generalization ability and transferability remains challenging [

2]. The problem of data silos also limits the collaborative training and optimization of models. Finally, the pursuit of the highest nitrogen and phosphorus removal rates is often accompanied by higher energy consumption (such as aeration and mixing) or chemical agent consumption. When multiple objectives such as removal efficiency, energy consumption, chemical consumption, and membrane life are synergistically optimized by AI, it is necessary to establish a reasonable evaluation system and optimization strategy [

22].

5. Applications of Circular Economy and Sustainability

With the advancement of the “dual carbon” strategy and the concept of circular economy, wastewater treatment systems are transitioning from end-of-pipe treatment to resource regeneration platforms. Intelligent technologies not only improve nitrogen and phosphorus removal efficiency but also provide crucial support for resource recovery and energy optimization.

5.1. Nitrogen and Phosphorus Recovery in the Context of Circular Economy

Within the framework of the circular economy, sewage treatment systems are rapidly transforming into resource-recovery facilities, with nitrogen and phosphorus recovery emerging as the core pathway of resource-oriented treatment.

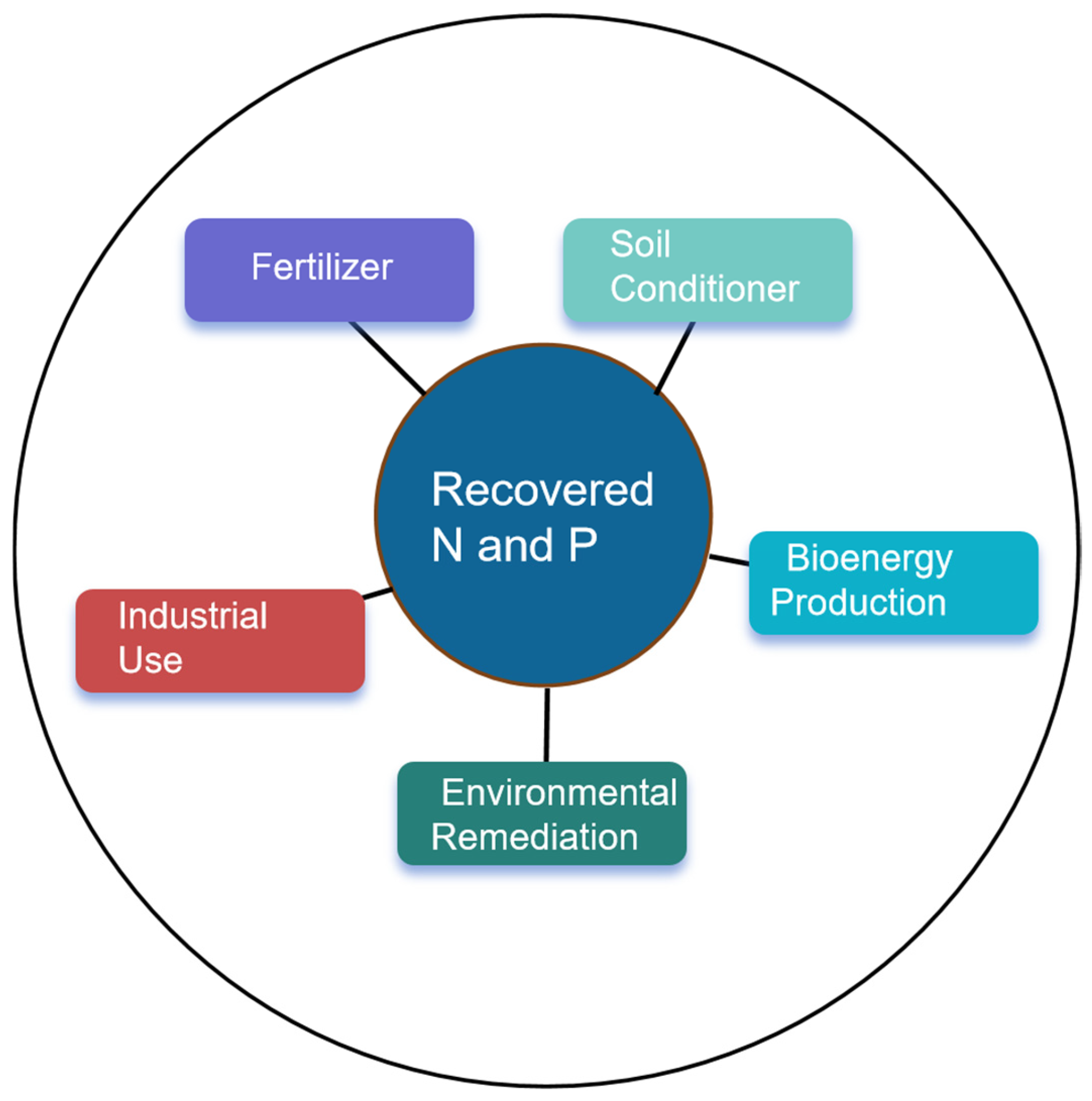

Table 8 illustrates the application of AI in this recovery process, while

Figure 4 highlights its support for resource utilization.

A full-process optimization path based on a surrogate model was proposed by Durkin et al. [

105]; by embedding an AI module in the closed-loop of simulation, prediction and control, the nitrogen recovery efficiency is effectively improved.

In terms of phosphorus recovery, a phosphorus recovery prediction model based on rough set machine learning was constructed by Balasubramanian et al. [

106]. This model comprehensively considers variables such as pH, initial phosphorus concentration, and Mg/P ratio, achieving a prediction accuracy of 91.4% and identifying the key parameter combinations required for efficient recovery. In another study, machine learning was adopted to optimize the electrochemically induced phosphorus recovery process. The model achieved a prediction R

2 of 0.98 on the test set and an experimental verification R

2 of 0.78, providing a reliable tool for large-scale recovery of phosphorus resources [

107].

In terms of synergistic nitrogen and phosphorus recovery, nitrogen recovery pathways for dairy and municipal wastewater were optimized by researchers. The results showed that the nitrogen recovery rate reached 85% and the phosphorus recovery rate reached 97% [

108].

5.2. Energy Optimization in the Context of the “Dual Carbon” Goals

Driven by the “dual carbon” policy, wastewater treatment has become a significant contributor to energy use and carbon emissions, making energy efficiency improvement and low-carbon transformation core tasks for industry development. In recent years, the application of AI and data-driven control strategies in wastewater treatment has offered new approaches for precise energy regulation. As shown in

Table 9, AI models demonstrate substantial potential for energy conservation and emission reduction, with AI-assisted aeration optimization identified as a key pathway for current energy optimization.

Studies have shown that dynamic adjustment of aeration intensity based on AI can typically achieve a 10–30% reduction in energy consumption and a 15% reduction in carbon emissions. Data mining methods were adopted by Asadi et al. [

112] to establish a relationship model between the aeration system and DO concentration, and an energy consumption optimization strategy based on operational data was proposed by them. Their research results showed that constructing a multivariate regression model can notably reduce aeration intensity and frequency based on ensuring effluent quality, thereby achieving a 31.5% reduction in aeration energy consumption. In addition to energy-saving optimization, AI regulation systems are also used to reduce carbon emissions during wastewater treatment. An aeration optimization control system based on CNN and reinforcement learning was constructed by Yu et al. [

110]; By adjusting operating parameters in real time, system intelligence is enhanced while energy consumption and emissions are effectively reduced. Specifically, the system achieved a 7.02% reduction in energy use and an 18% reduction in greenhouse gas emissions, providing stable and reliable technical support for the low-carbon operation of wastewater treatment plants. This synergistic optimization of energy and emissions aligns with the global trend of sustainable development. For example, the European Green Deal mandates substantial reductions in energy consumption and carbon emissions across industries and promotes a circular economy, while the U.S. Environmental Protection Agency’s ENERGY STAR

® program establishes efficiency benchmarks and certification systems for wastewater treatment plants. The core ideas and quantitative results of the AI-driven MBR energy-saving and carbon-reduction technology in this study not only contribute to China’s “dual carbon” goals but also offer a reference solution for meeting international standards and addressing global climate challenges, with broad potential for international promotion.

5.3. Intelligent Applications for Energy Conservation and Emission Reduction

Against the backdrop of the continuous advancement of the “dual carbon” strategy, the wastewater treatment industry faces an urgent demand for synergy between resource recovery and emission reduction. In recent years, artificial intelligence and intelligent control systems have demonstrated favorable effects on energy conservation and emission reduction in multiple engineering practices. These systems not only enhance operational efficiency but also reduce carbon emission intensity and resource consumption. As shown in

Table 10, representative examples illustrate the deployment pathways and achievements of intelligent technologies across different regions and systems.

Nevertheless, the large-scale promotion of intelligent technologies still encounters multiple obstacles, including data silos and heterogeneity, inconsistent standards and interfaces, and high initial investment as well as operation and maintenance costs.

Notable differences in data formats and collection frequencies exist among different wastewater treatment plants, making cross-plant model migration difficult. For example, targeted adaptation of input and output layers is required by the transfer learning model of the Antwerp plant in Belgium [

116], and additional sensor investment is required by the MADDPG system of the Jiangsu plant in China due to data heterogeneity [

22].

A lack of universal protocols exists between edge devices, cloud platforms, and AI models. Although the SVM-ANFIS system of the Kavoor plant in India has been successfully deployed locally, integration with systems of other plants is difficult for it [

113]; customized feature engineering is relied on by the RF model of the Milwaukee plant in the United States [

117], increasing the cost of cross-system adaptation.

Upgrading of sensors, edge computing devices, and model maintenance resources is required for the deployment of intelligent systems. Although the GA-MLP-BP model at the Cheonan plant in South Korea has been applied, hardware update costs are difficult to be afforded by rural/small and medium-sized plants [

114]; despite the high potential benefits of Light GBM optimization at the Oxley plant in Australia, its promotion is hindered by upfront investment [

115].

In summary, AI technology has demonstrated an effective pathway for energy conservation and emission reduction in wastewater treatment, as evidenced by 15% energy savings at the Singapore plant and an 8% reduction at the Jiangsu plant in China. However, overcoming promotion bottlenecks requires strategies such as formulating data-sharing standards, developing lightweight models, and exploring public–private partnership frameworks to achieve broader technological inclusiveness.

6. Conclusions and Perspectives for Future Research

The intelligent transformation and technological innovation of wastewater treatment have been significantly advanced by the integration of artificial intelligence (AI) with membrane bioreactor (MBR) systems. By incorporating state-of-the-art algorithms such as machine learning, deep learning, and reinforcement learning into MBR operation and management, it becomes possible to achieve real-time monitoring of pollutant removal, dynamic optimization of operating parameters, and intelligent early warning of abnormal conditions. These advances have markedly improved the accuracy of wastewater treatment and the stability of system performance.

The empowerment of MBR systems by AI is mainly reflected in three aspects. First, the removal efficiency of nitrogen, phosphorus, and other conventional pollutants has been substantially enhanced, and the long-term stability of effluent quality has been secured, thereby supporting stricter discharge standards and water reuse. Second, under the challenge of multi-source heterogeneous wastewater and fluctuating loads, adaptive parameter adjustment and integrated analysis of multi-source big data have improved system adaptability and robustness to complex conditions. Third, synergistic optimization of operating parameters, energy consumption, and resource recovery pathways has facilitated the integration of nutrient utilization with energy efficiency, accelerating the engineering transformation toward green and low-carbon technologies.

Nevertheless, several bottlenecks remain, including insufficient interpretability, limited generalization, data silos, and issues of security and privacy protection. Moreover, practical engineering applications of AI-empowered systems are constrained by inconsistent standards, high initial investment, and difficulties in cross-sector collaboration. Addressing these challenges requires methodological innovation, standardization, and multi-stakeholder cooperation to ensure the sustainable development and widespread adoption of intelligent wastewater treatment technologies.

Looking forward, three key directions should be prioritized for large-scale deployment of AI-driven MBR systems. First, model interpretability and generalization must be enhanced through approaches such as explainable AI, transfer learning, and federated learning, in order to strengthen system reliability across complex scenarios. Second, efforts should focus on standardization and interdisciplinary collaboration, promoting data sharing, refining technical specifications, and deepening integration among industry, academia, and research institutions. Third, the field should establish and widely adopt a standardized, quantitative framework for the comprehensive assessment of energy consumption, carbon emissions, and economic benefits (e.g., via Life Cycle Assessment, LCA, and Life Cycle Costing, LCC). Future work should develop integrated evaluation models that dynamically quantify trade-offs and synergies among these three pillars. For example: Energy—beyond direct electricity use (aeration, pumping), account for indirect energy embedded in chemicals and membrane materials; Carbon—include direct emissions (e.g., N2O from biological processes) and indirect emissions from energy and materials to compute a full carbon footprint (e.g., kg CO2-eq·m−3); Economics—evaluate not only OPEX reductions but also CAPEX for AI deployment, the value of recovered nutrients (e.g., struvite), and potential carbon-credit revenues. Such a holistic Energy–Carbon–Economic (ECE) framework will provide clear, quantitative justification for adopting AI-MBR technologies and will guide stakeholders and policymakers in the transition to truly green, low-carbon, and sustainable development.