Subsea pipelines are widely used for transporting oil and gas, controlling subsea production systems, as well as the utilization of clean energy (e.g., offshore wind power, photovoltaics, and wave energy) with high engineering costs. In the complex marine dynamic environments, subsea pipelines are prone to in situ instability failure, causing significant economic losses and potentially irreparable marine ecological disasters. Currently, the in-situ stability design of subsea pipelines is based solely on the DNV-RP-F109 [

1] standard (established by DET NORSKE VERITAS). The core of the in-situ stability design is how to calculate the forces on the pipelines. The current DNV-RP-F109 [

1] standard primarily assumes a rigid flat seabed and obtains the hydrodynamic load acting on the pipeline by conducting experiments, leading to the completion of the hydrodynamic in situ stability design. However, for the pipeline on the seabed, local scour phenomena may occur due to the fluid force, causing certain sections of the pipeline to be suspended and altering the force acting on the pipeline. Additionally, local scour topography also significantly changes the force on the pipeline, thus affecting its in situ stability. Currently, there is little reporting on the force upon the pipeline considering local scour topography.

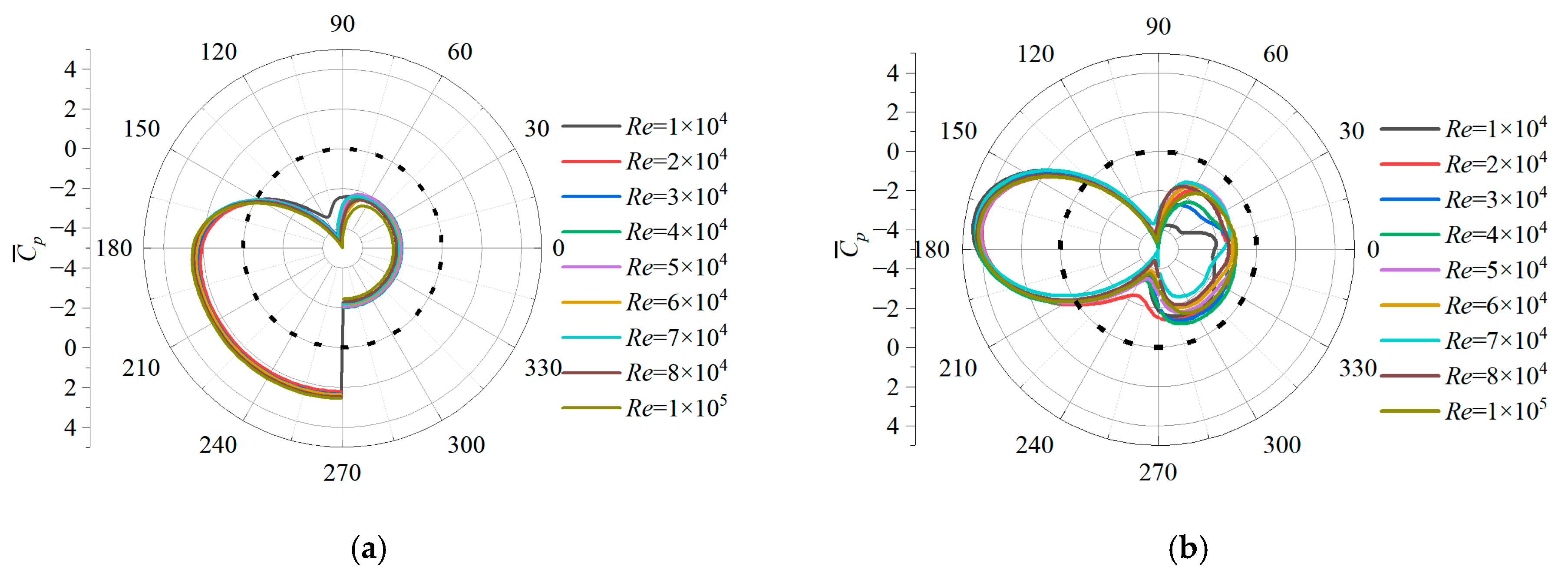

Previous studies on the force acting on the pipeline were primarily based on the assumption of a smooth and flat seabed, focusing on the influence of the suspended height on the force acting on the pipeline. Bearman and Zdravkovich [

2] conducted experiments to study the effect of the gap ratio

G/

D (where

G is the suspended height of the cylinder and the wall, and

D is the cylinder diameter) on the vortex shedding. They found that, when

G/

D is less than 0.3, the vortex shedding is suppressed by the wall, and when

G/

D is larger than 0.3, the non-dimensional vortex shedding frequency, i.e., the Strouhal number

St (

St =

fD/

U0;

f is the vortex shedding frequency,

U0 is the reference flow velocity, and, in the present study, it is the mean flow velocity along the depth) remains around 0.2. Lei et al. [

3] found that the critical gap ratio for suppressing the vortex shedding varies in the range of 0.2–0.3, according to the experimental data, and the specific value is closely related to the boundary layer thickness

δ, i.e., the larger the boundary layer thickness, the lower the critical gap ratio for controlling vortex shedding. For a cylinder completely outside the boundary layer, its drag coefficient is almost independent of the gap ratio. For cylinders that are either fully or partially within the boundary layer, the drag coefficient

CD increases with the increase in the ratio of gap to boundary layer thickness

G/

δ. When the gap ratio

G/

D is larger than 2.0, the influence of the wall on the force acting on the cylinder and vortex shedding can be neglected. Oner et al. [

4] found that, when the gap ratio

G/

D varies from 0 to 0.3, the flow field changes dramatically. When

G/

D is larger than 0.3, the flow field changes slowly, and, when

G/

D is larger than 1.0, the effect of the wall on the flow field is minimal. Buresti and Lanciotti [

5] studied the effect of the wall on the drag coefficient and lift coefficient of a cylinder, finding that, with the gap ratio

G/

D increasing, the average lift coefficient

decreases, and, the thicker the boundary layer, the more severe the decrease, and its value remains larger than zero. The average drag coefficient

does not have a completely monotonic relationship with the gap ratio, and it is significantly influenced by the boundary layer thickness and Reynolds number

Re (in the present study,

Re =

U0D/

υ;

υ is the kinematic viscosity of the fluid). Liu et al. [

6] studied the effect of the pipeline roughness on the force acting on the pipeline and found that, with the pipeline roughness increasing from zero, the drag force decreases, and the lift force decreases first and increases later. Huang et al. [

7] compared the dimensionless hydrodynamic coefficients calculated using the free stream velocity and the velocity at the center of the pipeline, respectively, finding that the latter can approximately eliminate the effect of the boundary layer thickness, and a formula for describing the relationship between the gap ratio

G/

D and the hydrodynamic coefficients was proposed. Akoz [

8] studied the flow characteristics around a partially buried cylinder, and found the separation point of the boundary layer on the pipeline moves upward with an increasing Reynolds number and a decreasing

B/

D (

B is the burial depth).

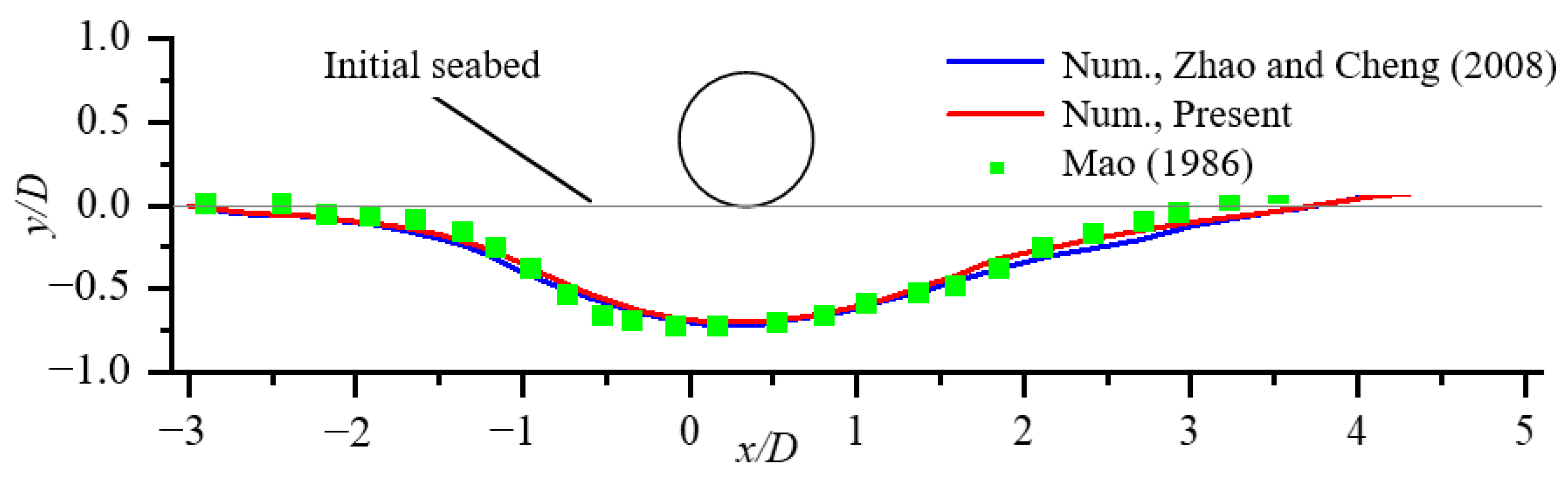

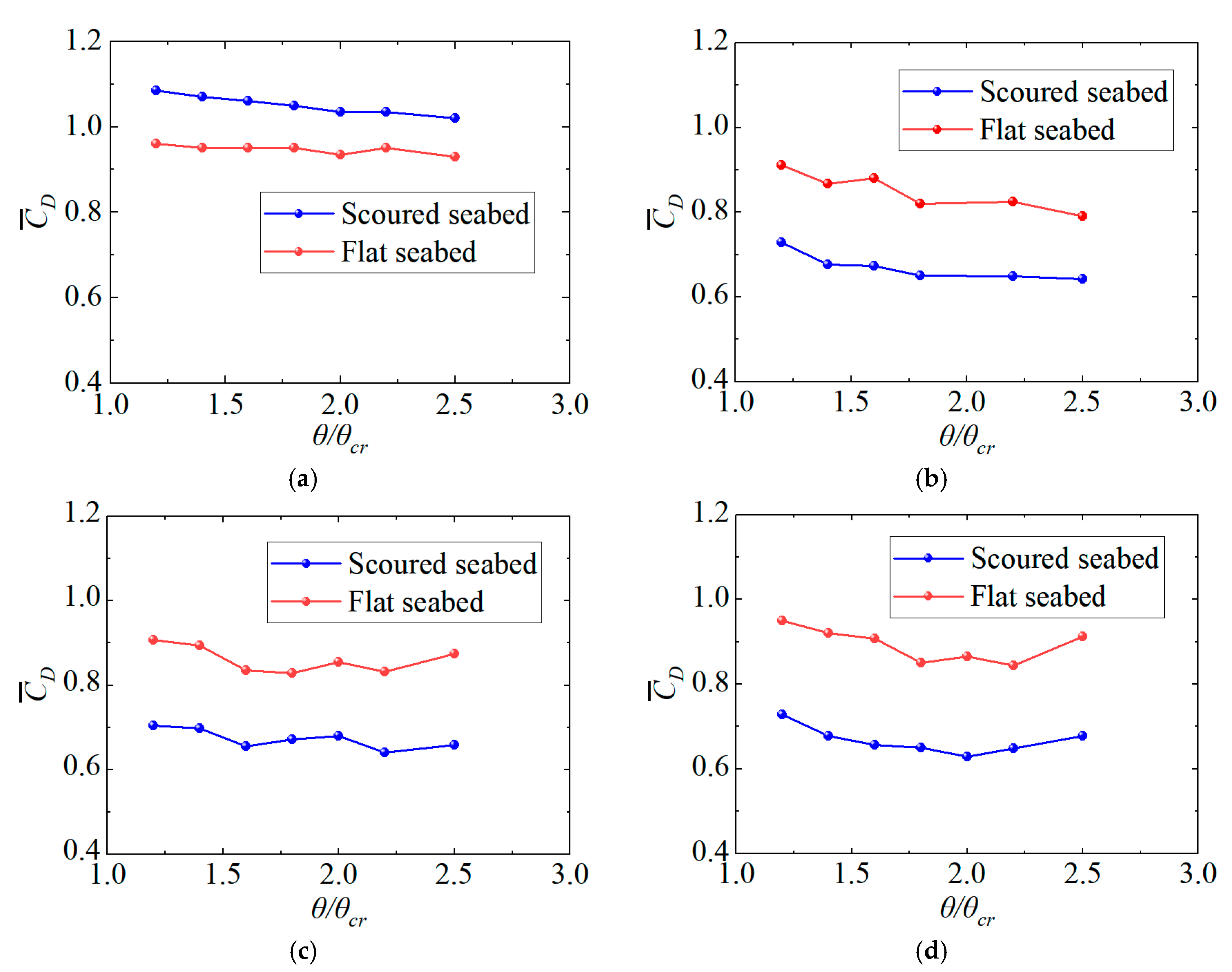

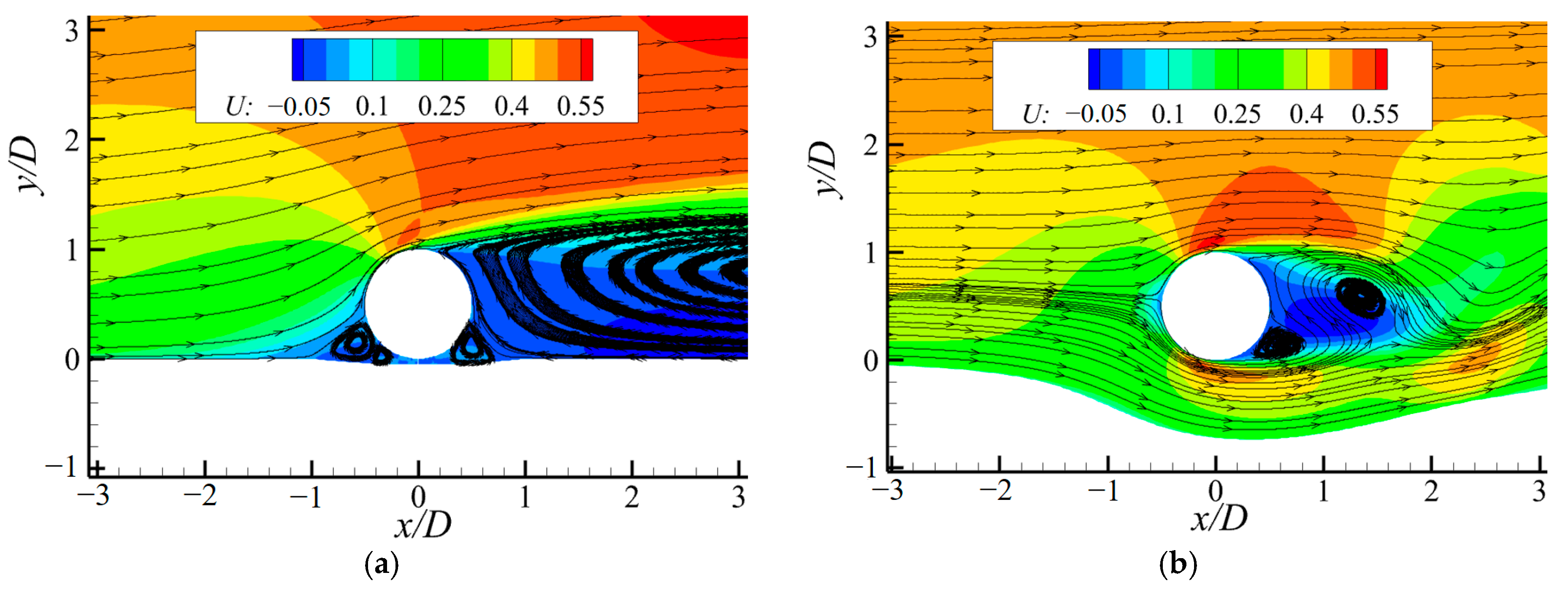

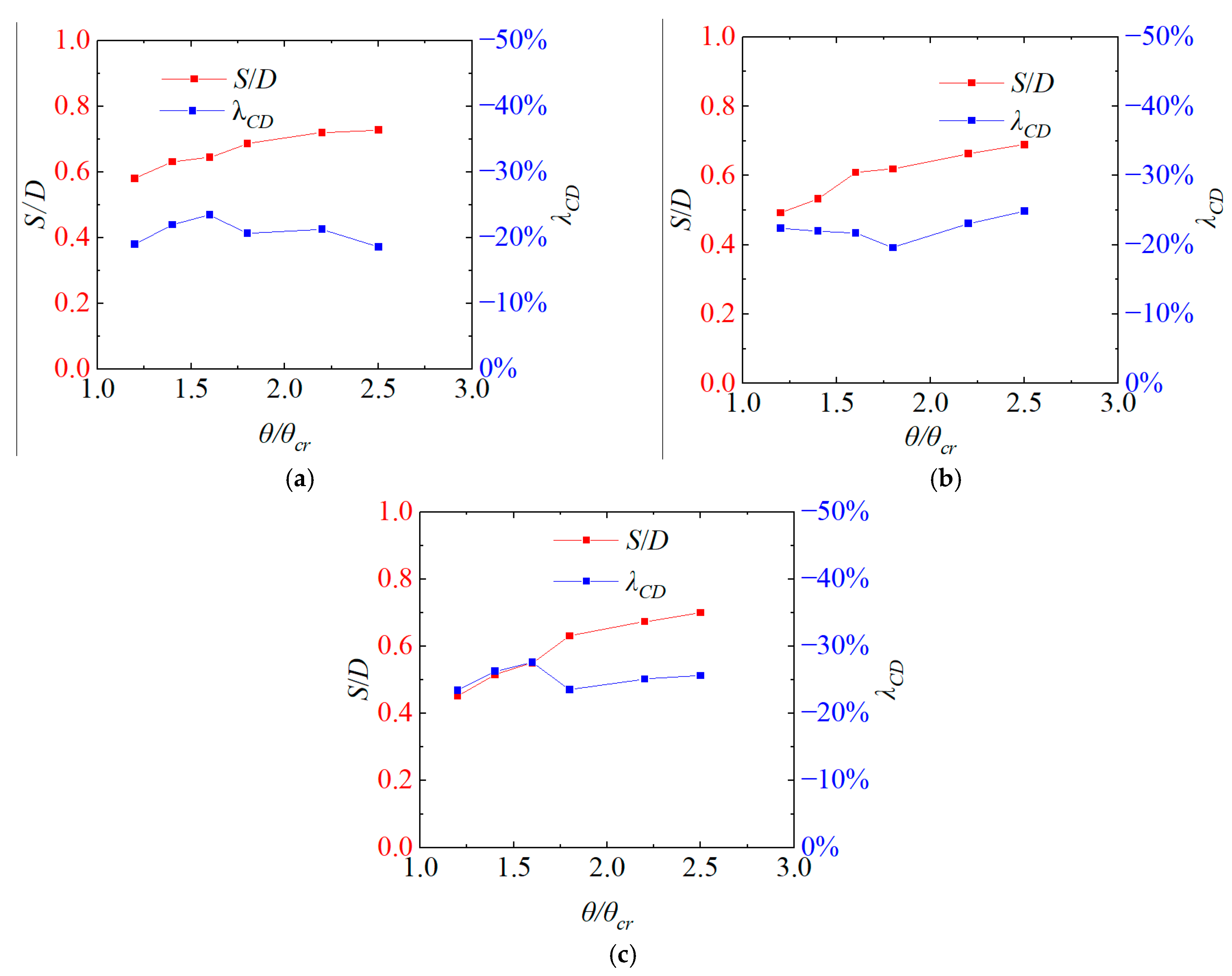

With the continuous research on the force acting on the subsea pipeline, the scour pit below the pipeline is considered to have a larger effect on the force on the pipeline, and some research related to the effects of local scour has been conducted. Jensen et al. [

9] conducted experiments on the change of force acting on the pipeline during the scour process under unidirectional flow conditions. The study selected five instantaneous scour topographies as the boundary conditions for the seabed beneath the pipeline, examining the change in the flow field at different scour times, as well as the variations in various hydrodynamic coefficients (Strouhal number, lift coefficient, and drag coefficient) with scour depth. It was found that the variation in hydrodynamic coefficients with suspended height on a scoured seabed was opposite to that of a pipeline at the same suspended height on a flat seabed, and the average lift coefficient

remains less than zero, which is in contrast to the conclusion obtained from the study on a flat wall by Buresti and Lanciotti [

5]. Chen et al. [

10] built a numerical model using the fully developed scour pit as the seabed boundary below the pipeline, studying the effect of inflow boundary layer thickness on the hydrodynamic coefficients of the pipeline. They found that all hydrodynamic coefficients (drag coefficient, lift coefficient, and Strouhal number) decrease with an increase in boundary layer thickness. Additionally, compared to a flat seabed at the same suspended height, the flow velocity near the pipeline under scour conditions is lower, leading to a smaller drag coefficient and root mean square lift coefficient for the pipeline. Liu et al. [

6] studied the effect of the pipeline roughness on the force acting on the pipeline, considering the seabed scour, finding that, with the pipeline roughness increasing from zero, both the drag force and the lift force increase first and decrease later, which is different from the condition when the pipeline is put on the flat seabed. Jo et al. [

11] conducted research into the hydrodynamic force acting on the pipeline in the trench, finding that the opening length ratio (

W/

H:

W is the opening length of the trench,

H is the depth of the trench) dominates the mean drag force, while the cover depth ratio (

H/

D) affects the mean lift force significantly. In addition, some scholars (Sumer et al. [

12], Zhang et al. [

13]) have studied the impact of pipeline vibration on scour, finding that both the vibration frequency and amplitude of the pipeline can exacerbate the local scour action of the seabed, with the influence of vibration amplitude being more significant. Sumer et al. [

12] conducted an experiment to study the effect of scour pit on pipeline vibration, and the results showed that the scour pit had a significant impact on both the frequency and amplitude of the vibration.

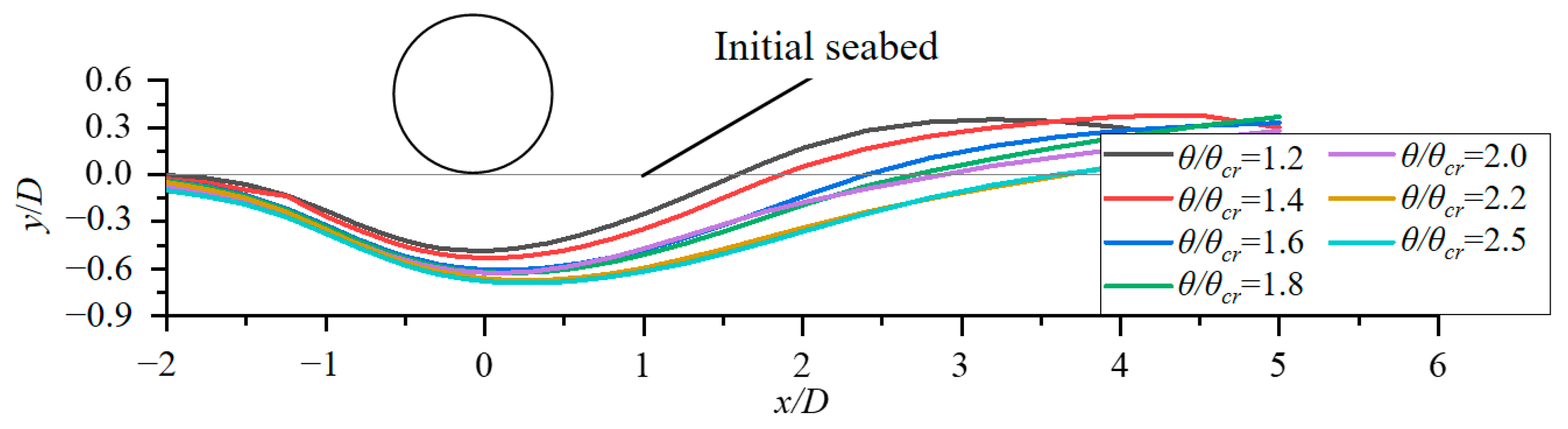

The above research indicates that the presence of a scour pit significantly alters the hydrodynamic characteristics of a subsea pipeline, but the related studies used a fixed smooth wall with a scour pit to simulate the scoured seabed, without considering the impact of flow field change on the local scour. Thus, there is still a lack of discussion on the influence of scour topography variation due to flow field change on the force acting on the pipeline. Therefore, it is necessary to conduct an analysis of the influencing patterns of the Shields number on the force on the pipeline. Additionally, according to the existing research, whether or not the wall was considered, the force upon the pipeline is closely related to the Reynolds number, Re, but the relationship between the force and the Reynolds number is not clear when the scour is considered. Thus, the present study will focus on the effect of Reynolds number and Shields number on the force on the pipeline.