1. Introduction

A single-thread meandering river has significantly different flow patterns from a straight trapezoidal channel. In a straight, uniform channel, the primary flow is downstream (streamwise direction). With no significant cross-stream, flow patterns present the motion is mostly parallel to the banks velocity is highest near the surface and center, slower near the bed and banks due to shear. When the river bends the centrifugal force on the moving water pushes it outward towards the outer bank, creating a cross-stream pressure gradient [

1]. This means that the flow depth is slightly higher in the outer bank. Near the surface, the outward push of centrifugal force is stronger than the inward pull from the pressure gradient. On the other hand, close to the bed, the flow is slower, but the inward pressure gradient still acts, pushing the water toward the inner bank. The combination of these two motions near the surface and near the bed generates a rotational circulation in the cross-section, known as secondary current [

2].

Figure 1a shows the secondary flow flowing transversely to the primary flow from the outer to the inner river bends.

Figure 1b illustrates the secondary rotational flow forming due to the differential pressure across the river’s cross-section, resulting in the creation of a centripetal force. The secondary flow exerts shear stress on the riverbanks and bed, resulting in scouring on the outer bend, which is the removal of sediments from the meander outer bank by means of the flow. This is a natural and dynamic process that varies according to hydrodynamic, geotechnical, and geometrical conditions [

2]. Outer bank scouring results from secondary downward, vertical flows close to the outer bend wall. Hence, local scouring reduces the slope stability of nearby river banks [

3].

Because of the secondary rotational flow, the streamlines on the water surface are perpendicular to the flow from the inner to outer bend, but go from the outer to inner bend on the river bed. Knowing the flow pattern and scouring mechanisms are crucial when deciding how best to protect the river bed and banks [

4], such as spur dikes, vanes, and ripraps, among others [

5,

6,

7]. However, implementing structural measures in large, deep rivers can be costly, time-consuming, and may have undesired environmental consequences. In addition, methods like spur dikes can hinder safe navigation. Therefore, relatively low-cost measures that can be implemented quickly and safely are preferred [

8].

The air bubble screen technique for scouring control generates a rising air bubble screen caused by a pressurized porous (perforated) tube on the bed. The bubble-impacted flow can counteract the downward vertical velocities associated with secondary flows. Moreover, secondary flow cells, such as those induced by air bubbles, efficiently redistribute the patterns of velocity and boundary shear stress [

9]. Several studies [

10,

11] have shown the bubble technique to minimize local scour along a 193° bend.

Blanckaert and De Vriend [

12] experimentally investigated the turbulence structure in one cross-section of a sharp open-channel bend. Their results showed that the downstream mean velocity increases towards the outer bend, and that maximum velocities occur in the lower part of the water column. In addition, the secondary flow power, i.e., the rate of work performed by the streamwise flow to maintain the secondary circulation is, in most outer bends, strongly reduced compared with the straight uniform flow. Blanckaert and Graf [

13] investigated mean flow and turbulence in an open-channel bend. They showed that the outer bank cell and the reduced turbulent activity protect the outer bank and the adjacent bed, which limits an important driver behind the morphologic evolution of bends. Blanckaert [

14] studied the varying bed topography and flow field in a channel with a 193° bend in an experimental study, which revealed the presence of a secondary flow towards the outer bend near the water surface but to the inner bend near the bed. Blanckaert and De Vriend [

15] used nonlinear modeling for the mean flow redistribution in curved open channels to account for the feedback between the secondary circulation, the vertical distribution of the downstream velocity, and its width distribution. In addition, they showed that it can reproduce the velocity flattening and reduce downstream velocity with increasing curvature, typical of curved-channel flow. Vaghefi et al. [

16] reported that the maximum secondary flow power occurs at the 45° cross-section in a 90° flume. Hence, they simulated the flow around a T-shaped spur dike with the SSIIM (Sediment Simulation In Intakes with Multiblock option) model with sediment simulation in the intakes with multiblock options. They concluded that this phenomenon occurs due to the cross of the streamlines and the outer bend wall. The method put forward by Shukry [

17] is used here to determine the secondary flow power with the following equations:

where

Syz is the dimensionless power of secondary flow,

K is the kinetic energy,

Vyz is the average velocity vector projected on the lateral and vertical planes;

V is the mean cross-sectional velocity and

u,

v,

w are the time average velocities in a plane.

Due to the displacement of the maximum velocity zone and the reduction in the lateral pressure gradient in the experiment with the air jet (bubble screen) system, the secondary flow power has decreased compared to the control experiment (without an air jet system). Decreasing bend scour with in-phase and out-of-same-phase hydraulic jets method in a 180° bend has been investigated by Tamoradi et al. [

18]. They reported that the maximum scour depth shifts from the outer bend to the channel centerline. In another study, Tamoradi and Ahadiyan [

8] showed that the maximum scour depth decreased by reducing the distance between the perforated tube and the outer wall.

Conceptually, the air bubble system along the outer bend creates a flow opposite to the direction of the secondary flow caused by the curvature that neutralizes it and reduces scouring in the outer wall of the bend. Tamoradi and Ahadiyan [

19] did experiments with different injection discharges. Their results showed a reduction in scour depth in the main experiments compared to the reference tests. Dugué et al. [

11] investigated the interplay between the air bubble screen, the bubble-induced secondary flow, the patterns of longitudinal flow, and the morphology in shallow flow depth. Also, the results showed the potential of the bubble screen technique to modify morphology in various applications in shallow rivers and open channels.

Using experimental and theoretical modeling, Abduo et al. [

20] studied the counteracting of secondary flow in open channel bends. They simulated and predicted the velocity distribution in the channel bend using FLUENT with the

k-ε turbulent model. Their results showed that the bubble screen system helps reducing the secondary flow’s downward movement and shift the core of maximum downstream velocities away from the outer bank. Champagne et al. [

21] investigated the effect of air injection on reducing the scour of stilling basins. They reported that using that to reduce scouring was efficient and effective. Seyedashraf et al. [

22] investigated the application of computational intelligence methods for complex two-phase flow pattern recognition. They found that the employed models were efficient to simulate the helical flow pattern in the strongly curved 60° bend. According to Rodi and Leschziner [

23], a strongly curved bend is defined if R/b > 3 where R is the radius of the curvature, and b is the channel width. Tipireddy and Barkdoll [

24] evaluated the optimal configuration of air injection to scour control around a cylindrical bridge pier. They experimented with clear water conditions with noncohesive sediment and air injected through a horizontal, semicircular air diffuser. These were placed on the upstream pier half at the level of the original sediment bed before scouring initiation. They determined the diffuser location, number, and size of ports previously to be optimal. Their findings showed that the scour had been reduced by 35% compared to the absence of an air jet injection system.

Tamoradi et al. [

18] investigated the effect of spacings among the tube ports on the amount of the outer bank scour. The maximum scour depth decreased by increasing the spacings between tube ports. Tamoradi and Ahadiyan [

8] investigated the effect of both the ports’ spacings and the bend’s outer wall distance on the outer bank scour in the 180° bend. Their findings showed that the maximum scour depth was reduced by decreasing the port’s spacing and distance between the outer wall and tube.

The air bubble screen can be considered as a recent technique to reduce scouring with the following advantages: (i) there is no need for an extra structure within the river [

19]; (ii), the non-rigidity of the created barriers and tubes against the flow and their flexibility makes it less intrusive to the navigation system [

18]. As disadvantages the following can be considered: (i) the need to have access to an air compressor, which requires a constant supply of energy; (ii) the placement of the perforated pipe in the bed, that will require some fixation points to keep it in place; (iii) the influence of sediment deposition and flora development in the structure that may affect the air bubbles flows; and (iv) the dependency of the flow conditions, as higher flow rates will lead to a inertia dominant role over bubble induced forces.

The bubble screen technique is a function of several variables, namely: the bubble screen cross angle, the air injection flow rate, the injection tube discharge, ports distance and diameter on the perforated tube, the distance of the perforated tube from the outer wall of the river bend, etc., may affect the capability of this technique for river bed and bank protection.

One of the open questions in this study is the definition of efficiency and the function of the air bubble screen’s angle—that is, how efficiency is defined. This study aims to clarify the role of the bubble screen’s incidence angle relative to the mainstream flow and the effect of the air injection flow rate in controlling scouring. The research was conducted through carefully designed and planned laboratory experiments.

The air bubble screen method has been applied to other hydraulic cases namely, to reduce the noise levels in aquatic environments [

25] prevent the sea water intrusion into rivers [

26], to remove plastics from rivers [

27] and prototype case as described in the great bubble barrier [

28]. Commercial solutions for air bubble screens are available [

29,

30,

31].

A crucial issue of the air bubble screens is the need for energy to make the system work. A cost–benefit analysis should be carried out prior to the installation to assess the use of renewable energy sources, such as solar panels and batteries, to make the system work.

2. Materials and Methods

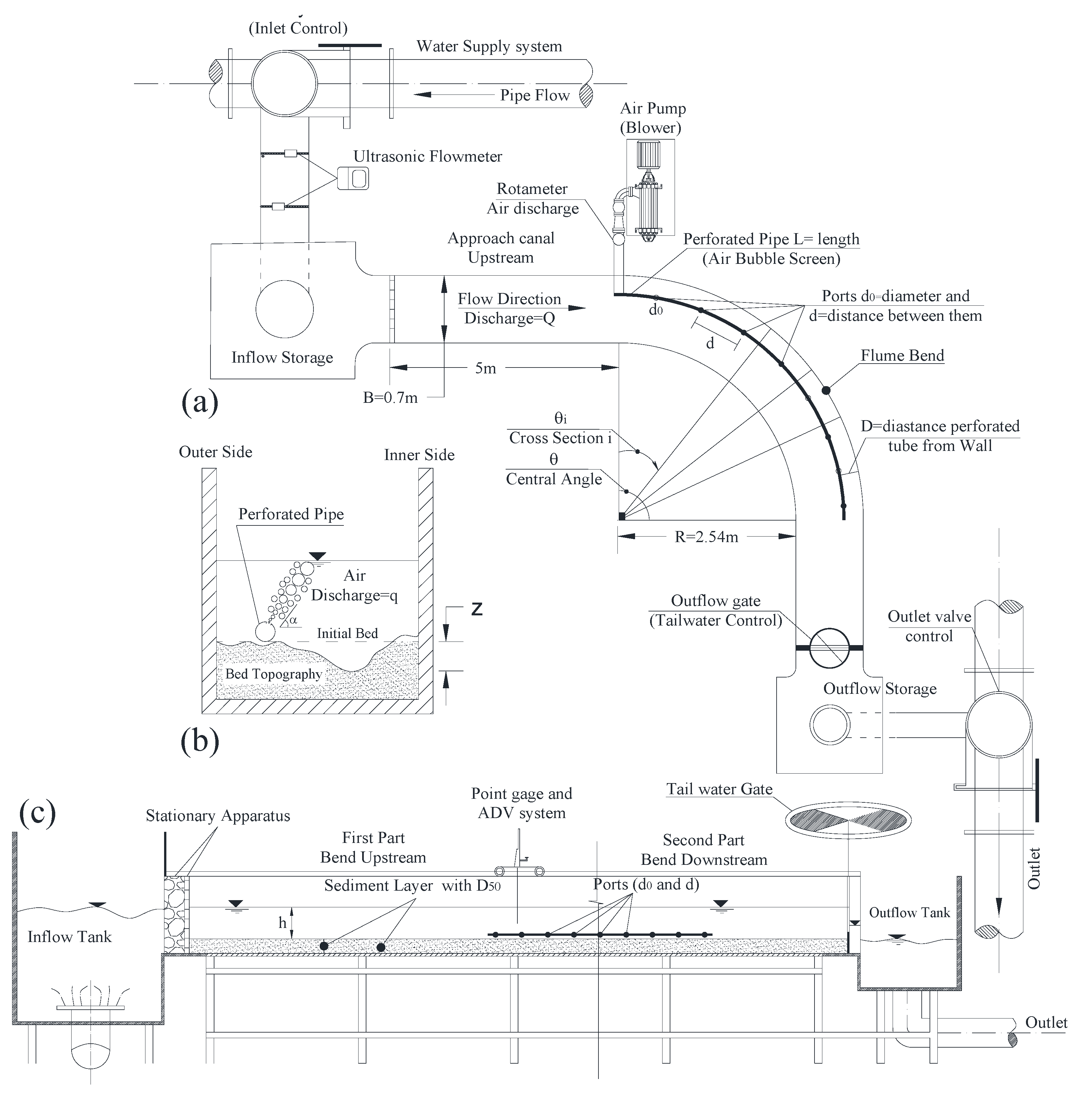

As shown in

Figure 2a–c, the effective parameters on the scouring in a 90° bend with the presence of the bubble screen system are the following: scour depth (

z); the variable water depth from the bed (Z); flume width (

B); flume bed slope (

S); bend or arc radius (

R); air injection discharge (

q); main flow rate (

Q); fluid density (

ρ); dynamic viscosity (

μ); gravity acceleration (

g); average particles diameter (

D50); particles diameter standard deviation (

σg); sediment density (

ρs); static friction angle (

φ); angle between air-bubbles and mainstream (

α); pipe length (

L); port diameter (

d0); port distance on the perforated tube (

d); perforated tube distance from the outer wall (

D); perforated tube diameter (

D0), and water depth (

h) and

θi is the angle of the

i-th cross-section measured from the origin of the bend as shown in

Figure 2a. According to the Buckingham theorem, Equation (2) holds:

Equation (2) contains

n = 22 variables and with

r = 3 fundamental dimensions one has

n −

r = 19 non-dimensional groups. The flow depth

h can be used to scale the different length related variables. It is possible to combine the flow rate, Q, with the flow section, (

Bh), the flow depth, and the viscosity to obtain the Reynolds number. Similar reasoning can be made using the flow rate, the flow section, and the gravity acceleration, g, to obtain the Froude number. Combining the variables in dimensionless groups, it is possible to write:

where in Equation (3) two parameters Fr = Q/(

Bh(gh)

0.5) and Re =

Q/μB are the Froude and Reynolds numbers, respectively;

V,

h, and μ are the flow mean velocity, flow depth, and absolute viscosity, respectively. The dimensionless parameter

q/Q represents the flow rate ratio of the air injection to the mainstream flow discharge. However, according to Shukry [

17] the viscosity effect can be ignored in the fully turbulent regime, that is, when the Re > 10

4. In this research, the minimum and maximum Reynolds numbers were equal to 4.3 × 10

4 and 5.6 × 10

4, respectively. Moreover, in this study, the values of σ

g,

D0/h,

B/h,

D50/

h,

d/h,

d0/

h,

D/h,

L/h,

ρs/

ρ, and S were considered constant. However, investigating the maximum scouring depth at each

θi is essential for controlling bend erosion. Thus, the investigating variables for the effect of the air bubble screen on scouring control in this study are the following:

It is also important to consider the air bubbles dynamics and the two parameters, the Bond,

Bo, and Weber,

We, number given, respectively, by:

where Δρ =

ρw −

ρair is the density difference between water (

w) and air (

air), σ is the surface tension,

db is the bubble diameter and V is the scale of bubble’s velocity. Since both the Bond and Weber numbers depend on bubble size, and surface tension σ is fixed (as both cases involve an air-water interface), it is not possible to simultaneously preserve the physics of the water flow (given by the Froude number) and the physics associated with the bubble scale (given by the Bond or Weber numbers). Inevitably, one of these phenomena will be distorted in physical modeling.

2.1. Laboratory Setup

Experiments were conducted in a 90° arched rectangular flume at the hydraulics laboratory of the Shahid Chamran University of Ahvaz, Iran (

Figure 2). The flume dimensions were 0.7 m wide, and the upstream and downstream of the 90° bend straight reaches lengths were 5 m and 3 m, respectively.

The flume bend was a mild system with outer and inner bend radiuses of 3.15 m and 2.54 m, respectively. The water supply system toward the flume was provided by a pump connected to a reservoir. The flow rate and flow height were controlled by means of an upstream butterfly inlet valve and an outlet gate. To avoid scouring induced by initial filling of the channel, the following procedure was followed: (i) the outlet gate of the flume was closed before turning on the pump, (ii) then the butterfly inlet valve was slightly opened to impose a small flow to gently fill the channel. Then, the flow rate was gradually increased until it reached the desired flow rate, and the end gate was steadily raised to provide the desired depth in the channel. The flow rate was controlled using a valve and measured with an Ultrasonic flow meter model NG3100-TFM. In addition, the outlet gate was controlled to regulate the water surface level. The flume bed was covered with a 0.20 m thickness uniform sediment layer with characterized by

D50 = 1.5 mm and a standard deviation

. The sediment surface was leveled with the help of a designed leveling device to prepare the sediment bed for each test. This device consisted of a vertical metal blade that could be moved along the width and length of the flume. The sediment surface was flattened by moving the device along the channel and shifting its plate. All experiments were carried out in clear water conditions (

V/VC ≤ 0.90), where

Vc is the flow velocity at particles’ incipient motion in a straight channel.

Figure 2 shows a view of the experimental flume’s characteristics in this research. This Figure shows the channel’s plan, cross-section, and longitudinal profile. Moreover, the view of the actual condition of the canal is represented in

Figure 3. An ultrasonic flowmeter Digi Sonic E+ model measured the main channel flow rate with an accuracy of ±0.01 L/s. The bubble screen system was formed from a perforated pipe with an outer diameter of 1.5 cm mounted on a metal base. The highest velocity occurs at the discharge of the port outlet position because of the jet and main channel flow intersection. In addition, the distance between the ports on the perforated pipe and the distance pipe from the bend outer wall was 2.5 cm and 5 cm, respectively. These distances were determined by trial and error to obtain the best effect in controlling the scour. The diameter of the holes in the pipe was 1 mm, and the spacing between holes in the air supply pipe was 2.5 cm. Three attack angles of the bubble screen cross with the mainstream, α, were considered using the perforated pipe port configurations. The injected air flow rate was measured through an RMC model Rotameter with a range of 5 to 50 Lmin

−1 and an accuracy of ±0.02 Lmin

−1. The air injection was provided using 2800 W air blowers. The air blowers were connected at the pipe’s start and end to allow air to flow uniformly throughout the perforated pipe. The flow velocity and flow pattern were measured using a 3D computer-operated ACM3-RS Electro-Magnetic Current Meter (Takahata-cho, Nishinomiya, Hyogo 663-8202, Japan) velocity meter (JEFALEC ACM3-RS model with an accuracy of ±2%) with an acquisition frequency of 20 Hz. This system consisted of a signal conditioning module, a probe with an acoustic transmitter, three acoustic receivers, and an electromagnetic current processor.

2.2. Methodology

Preliminary tests were carried out to determine the range of flow rates leading to bedload transport only. Hence, four flow rates were determined Q = {30, 33, 36, 39} Ls−1 with a constant water depth of 0.11 m. The corresponding Froude numbers were Fr = {0.37, 0.41, 0.45, 0.47}, respectively. The flow rate ranges were selected based on the clear water condition.

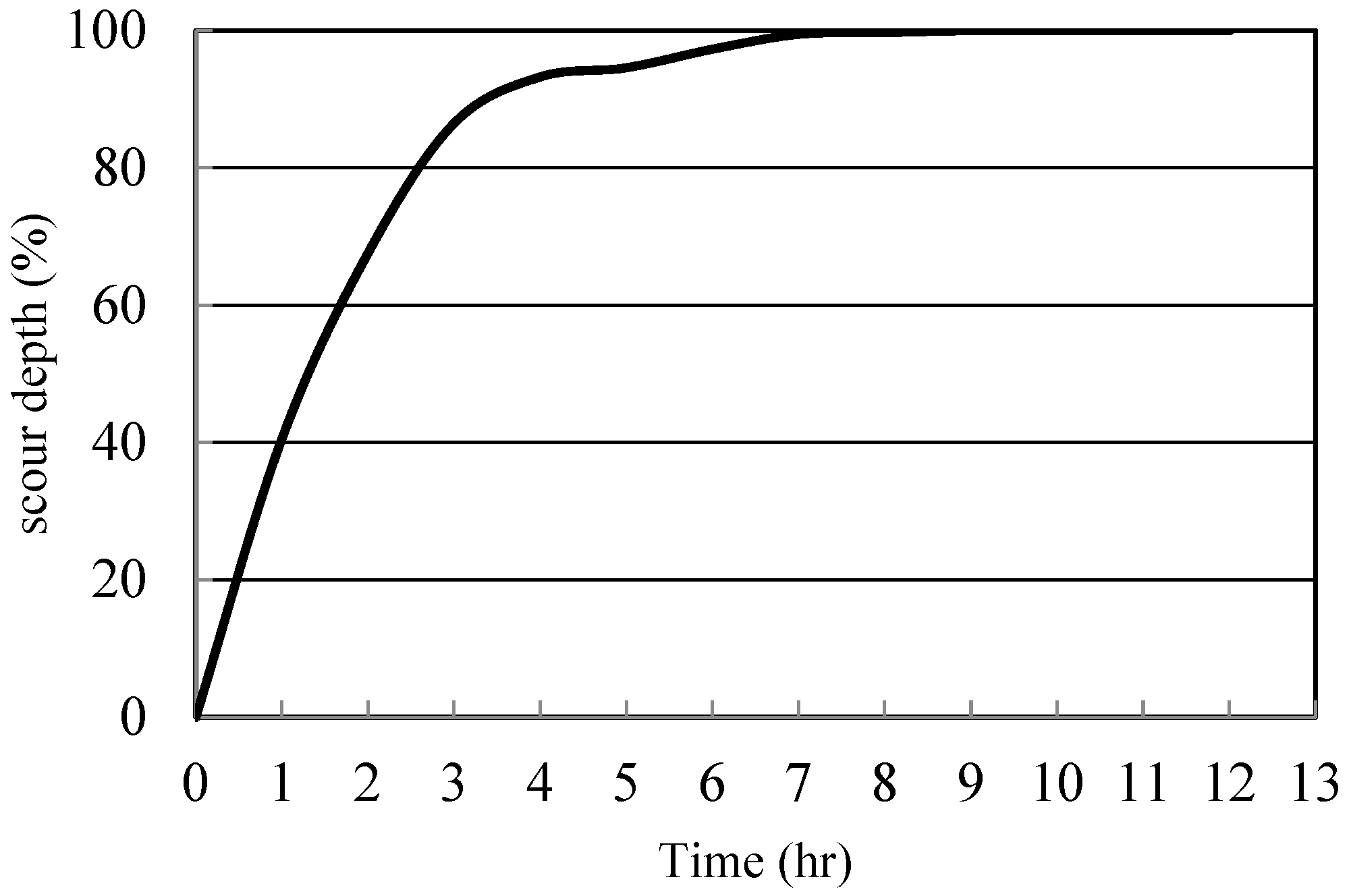

For the experiments is critical to define the equilibrium time, that is, time required for the scouring rate to be zero along the bend. This time was determined in an empirical way. A long-time experiment was performed for 12 h at a flow rate of 33 Ls

−1.

Figure 4 shows the results of the maximum scouring percentage versus time at the bend. According to

Figure 4, 90% of the scouring occurs after 4 h. That was verified in 13 cross-sections along the channel bend. Hence, this time was assumed to be the equilibrium time for all the experiments.

Three angles, α = 0°, 45 °, and 90° were considered to investigate the effect of the angle between the air bubble system and the main flow direction on the scour reduction. Experiments were carried out at different air flow rates. Those were determined by trial and error based on the most significant effect of outer bend scouring control. As a result, all experiments were performed with three air injection flow rates of 46 Lmin

−1, 48 Lmin

−1, and 50 Lmin

−1.

Figure 5a shows the mild bend with a 3D velocity meter;

Figure 5b shows the perforated tube installed along the outer bend (according to

Figure 2) to investigate the effect of the air bubble screen system on the bend scouring;

Figure 5c shows the action air bubble system. In addition,

Table 1 presents the air velocity and the momentum values of the air and main flow. So, the air outlet velocity at the ports for discharges of 30 Lmin

−1, 46 Lmin

−1, 48 Lmin

−1, and 50 Lmin

−1 is 3.98 ms

−1 were 6.10 ms

−1, 6.37 ms

−1, and 6.63 ms

−1, respectively. On the other hand, the momentum of the air bubble screen is higher than the flow momentum, as indicated in

Table 1.

In

Table 1, the last column, MAJ/MMF is the ratio of the momentum air jet (MAJ) to the momentum main flow (MMF). Each experiment was stopped after four hours from the start of the experiment for the bed’s morphological equilibrium, and then the flume was dried and drained. After the end of the scouring process, the bed was drained and fixed with cement slurry to prevent further bed scouring and erosion. Then, the sedimented bed topography was surveyed using a laser meter model X310 with an accuracy of 1.5 mm. The measured topographic points had a width distance of 3.5 cm for each cross-section with β

I = 5° (See

Figure 2, where β

i is the angle between each consecutive cross-section) along the bend. However, twenty points were measured at each cross-section, and 24 cross-sections along the canal bend were selected to measure the bed topography.

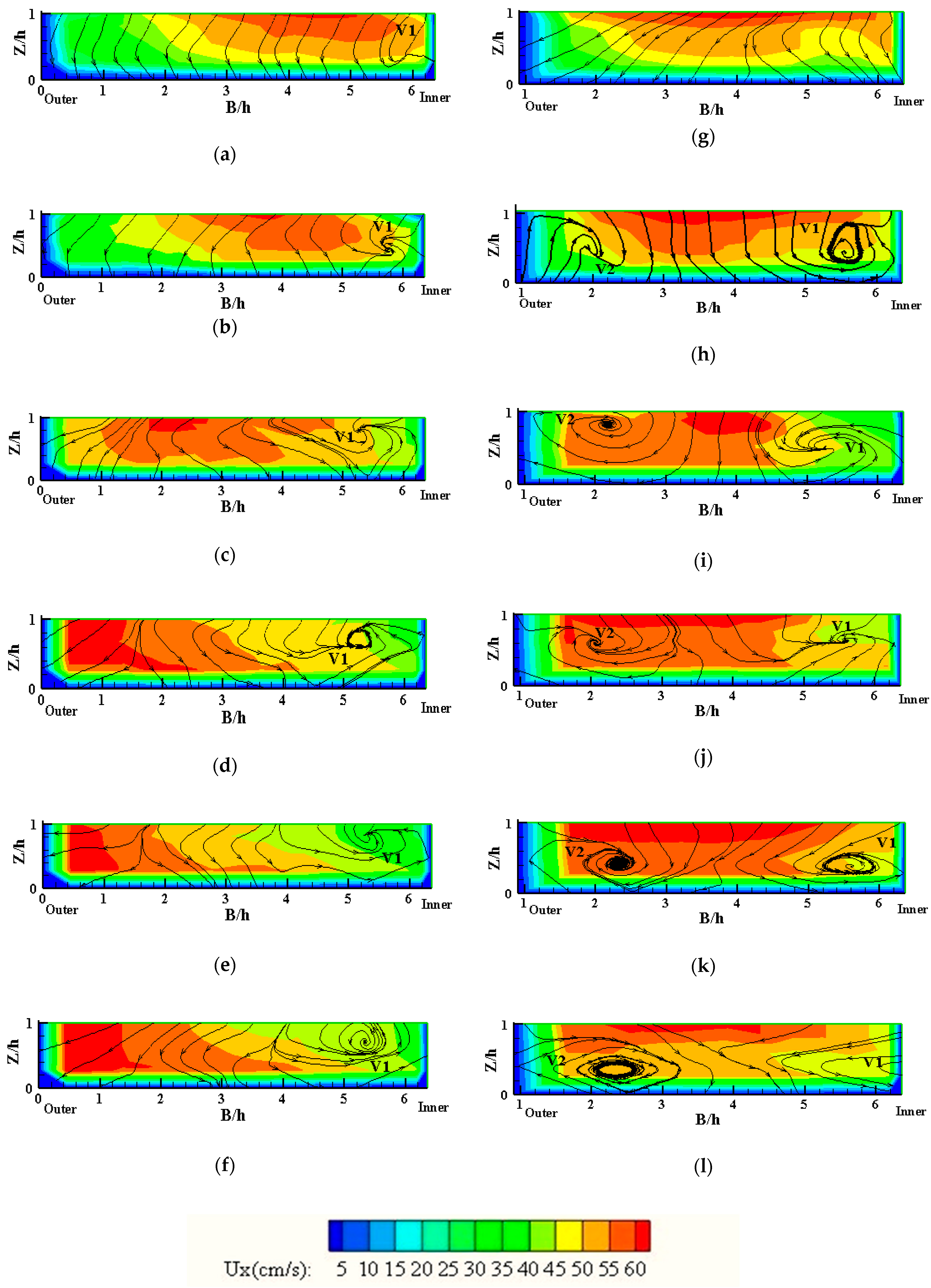

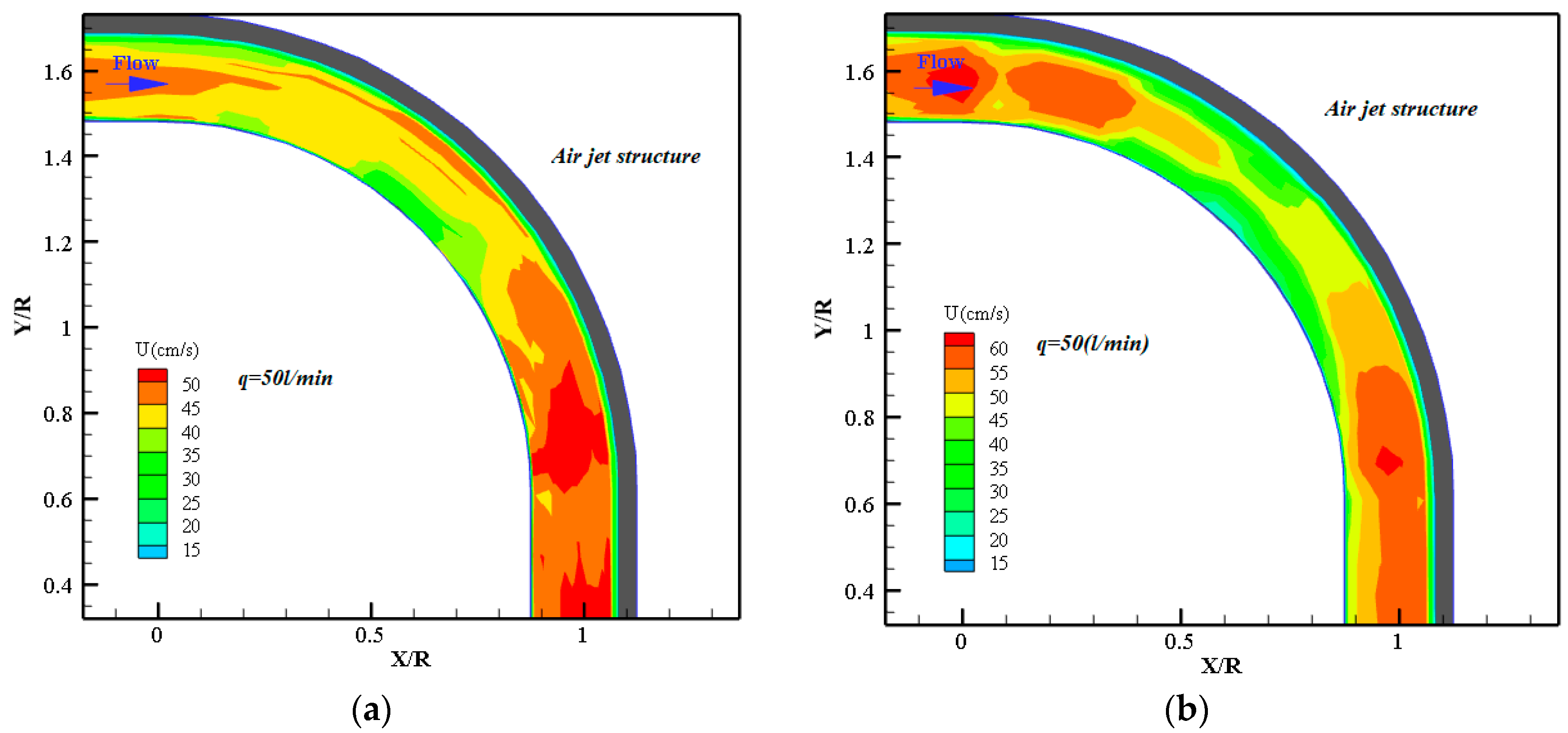

The velocity distribution along the bend with and without the air bubble screen system was measured using an electromagnetic velocity meter (

Figure 5a). The velocity patterns are essential to investigate flow patterns and the air bubble effect on secondary flow in the river bend. Therefore, measurements of the three velocity components (longitudinal, transverse, and vertical) were performed for the main flow rate of 36 L/s and air injection flow rate of 50 Lmin

−1, at 20 Hz frequency, for 60 s at each point. The bed sediment was also fixed using slurry-diluted cement after reaching the morphological equilibrium to minimize the effect of the electromagnetic velocity probe on bed changing and variations in measuring the velocity field.

The bed-fixing procedure took at least 24 h for the diluted cement to dry and fix the bed. Velocity measurements were performed in 12 cross-sections at θ

i angles (See

Figure 2) of 0°, 15°, 30°, 45°, 55°, 60°, 65°, 70°, 75°, 80°, 85°, and 90° within the bend length. The velocity measurement points in each cross-section in the transverse direction of the flume were {5, 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60, 65, and 68} cm from the outer bank. At each point, at least four vertical points in a vertical direction were measured.

Table 2 shows the performed tests indicated by the nomenclature R xx Y Z.

4. Conclusions

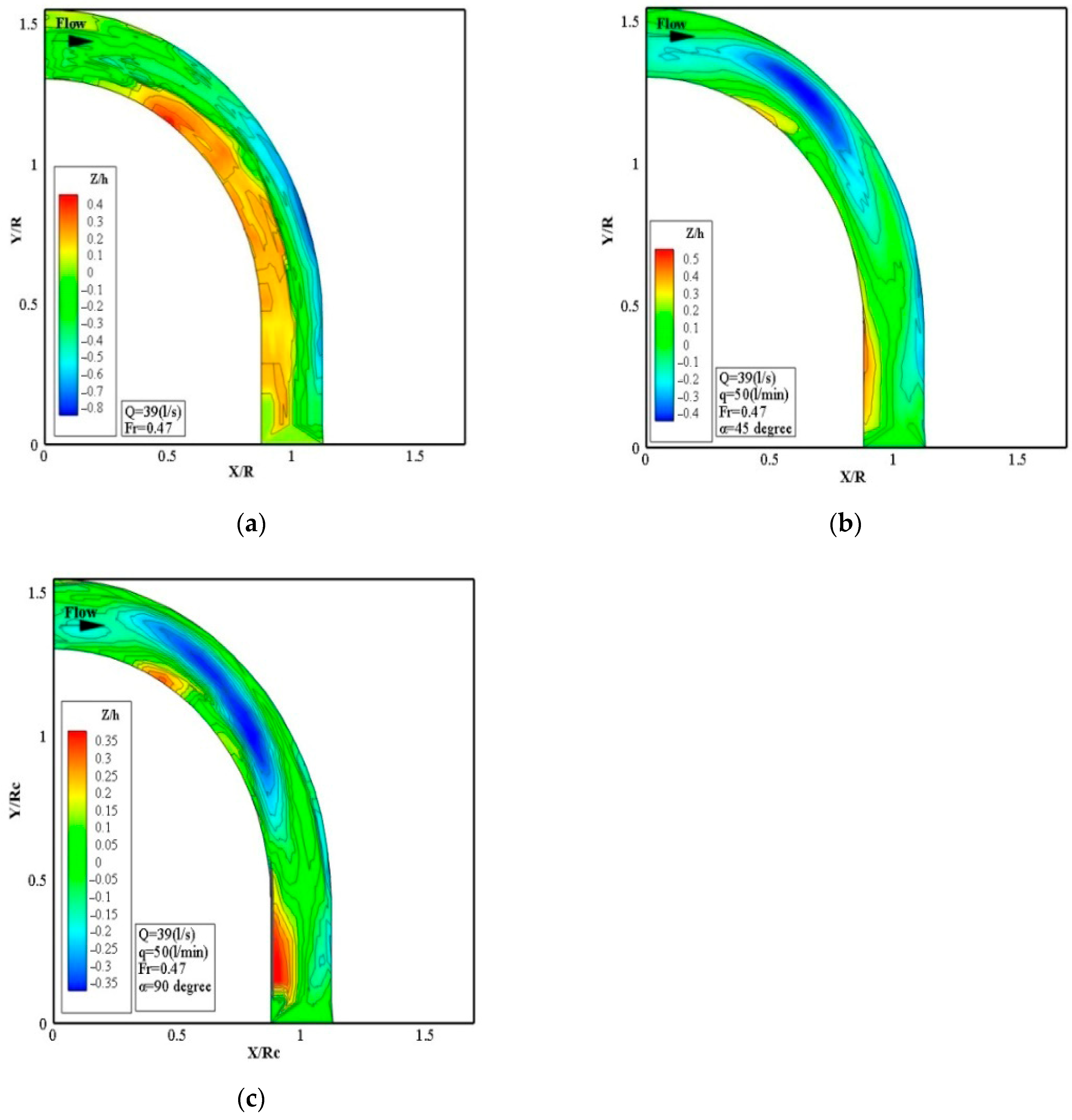

Experiments were performed under clear water conditions to investigate the effect of the air bubble jet system on bed topography and velocity field in a 90° channel bend. The measurements presented have shown that maximum scour depth depends on non-dimensional parameters such as Froude number, air bubble cross-attack angle with the mainstream, and the ratio of injecting air flow rate to main flow rate.

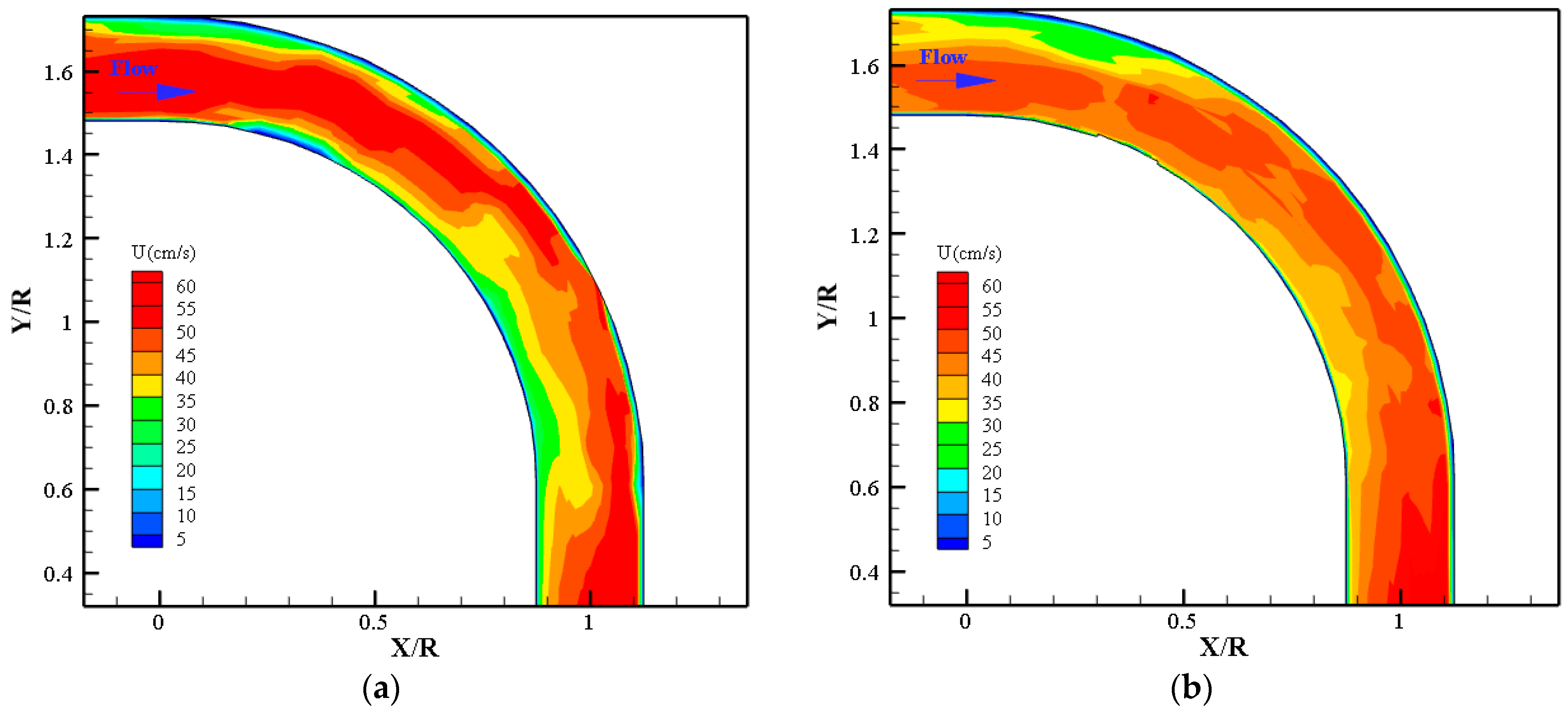

Regarding the effect of the bubble jet screen on the distribution of flow velocities, in bends without aeration, secondary flows induced by centrifugal forces shift the maximum velocity zone toward the outer wall, resulting in pronounced scouring and bed instability. The introduction of an air bubble screen system generates counter-rotating vortices that effectively redirect the high-velocity core from the outer wall to the channel centerline. This redistribution reduces near-bed velocities and outer bend erosion, while also displacing the thalweg from the outer bank toward the centerline. Overall, the aeration system demonstrates strong potential as a flow control measure to mitigate bend scour and enhance channel stability.

This study also demonstrated the significant impact of an air bubble screen system on secondary flow dynamics, bed morphology, and scour depth in channel bends. In the reference experiments without aeration, centrifugal forces and pressure gradients generated strong secondary flows that displaced the maximum velocity zone toward the outer bank, resulting in intensified scouring. With aeration, the formation of counter-rotating vortices redistributed secondary flow power, displaced the velocity core toward the channel centerline, and reduced the transverse pressure gradient.

The presence of air bubbles also induced notable changes in bed morphology. While the reference test showed progressive scouring from the inner wall to the outer bank with maximum erosion near 70°, aerated cases redirected the maximum scour zone to the channel centerline, where opposing circulation cells intersected. This redistribution reduced outer-bank erosion and corrected sedimentation along the inner wall, with the strongest effect observed at an injection angle of 90°, where bubble jets interacted most effectively with the main flow.

The scour depth measurements further confirmed the efficiency of the aeration system. Compared with the reference case, maximum scour was reduced by 57–79.8% depending on the attack angle, with the greatest reduction achieved under perpendicular injection (α = 90°, Fr = 0.47). These findings are consistent with previous studies but highlight improved performance due to optimized flow and aeration conditions.

Overall, the air bubble screen system proved highly effective in mitigating bend scour, reducing outer-bank erosion, and promoting channel stability. Its performance was strongly dependent on the bubble injection angle, with α = 90° providing the most favorable hydraulic and morphological outcomes.

The results obtained are promising in validating an environmentally friendly solution to reduce scour. However, further studies to validate this technique must be performed to address issues like more complex fluvial geometries and different hydrodynamic conditions.