Unveiling the Secrets of Particle Size in Aerobic Granules: Impacts on Emerging Contaminants Removal, Stability, and Sustainability: A Review

Abstract

1. Introduction

2. Formation Mechanism of AGS

2.1. Microbial Auto-Aggregation Hypothesis

2.2. Extracellular Polymeric Substances Hypothesis

2.3. Filamentous Bacteria Framework Hypothesis

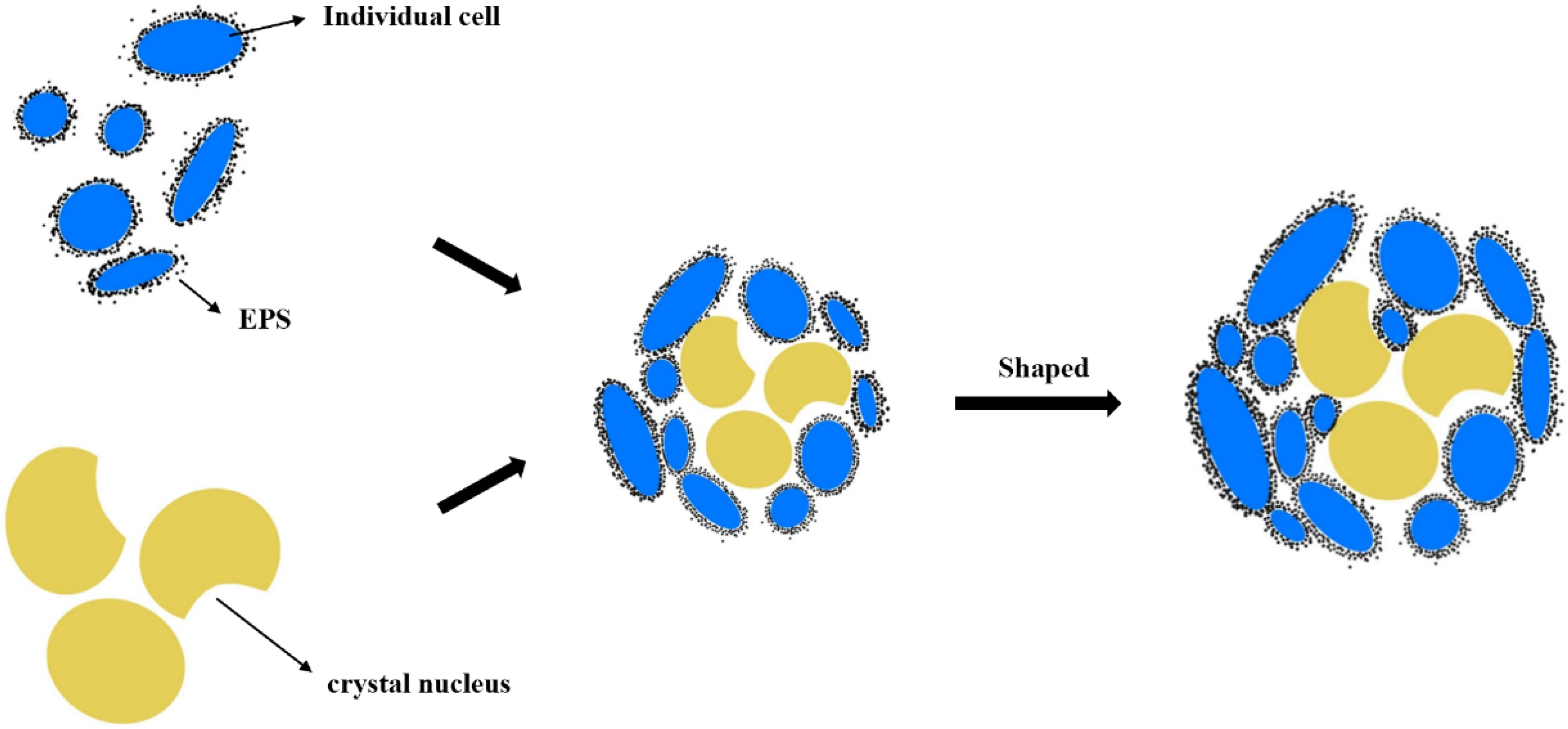

2.4. Nucleation Hypothesis

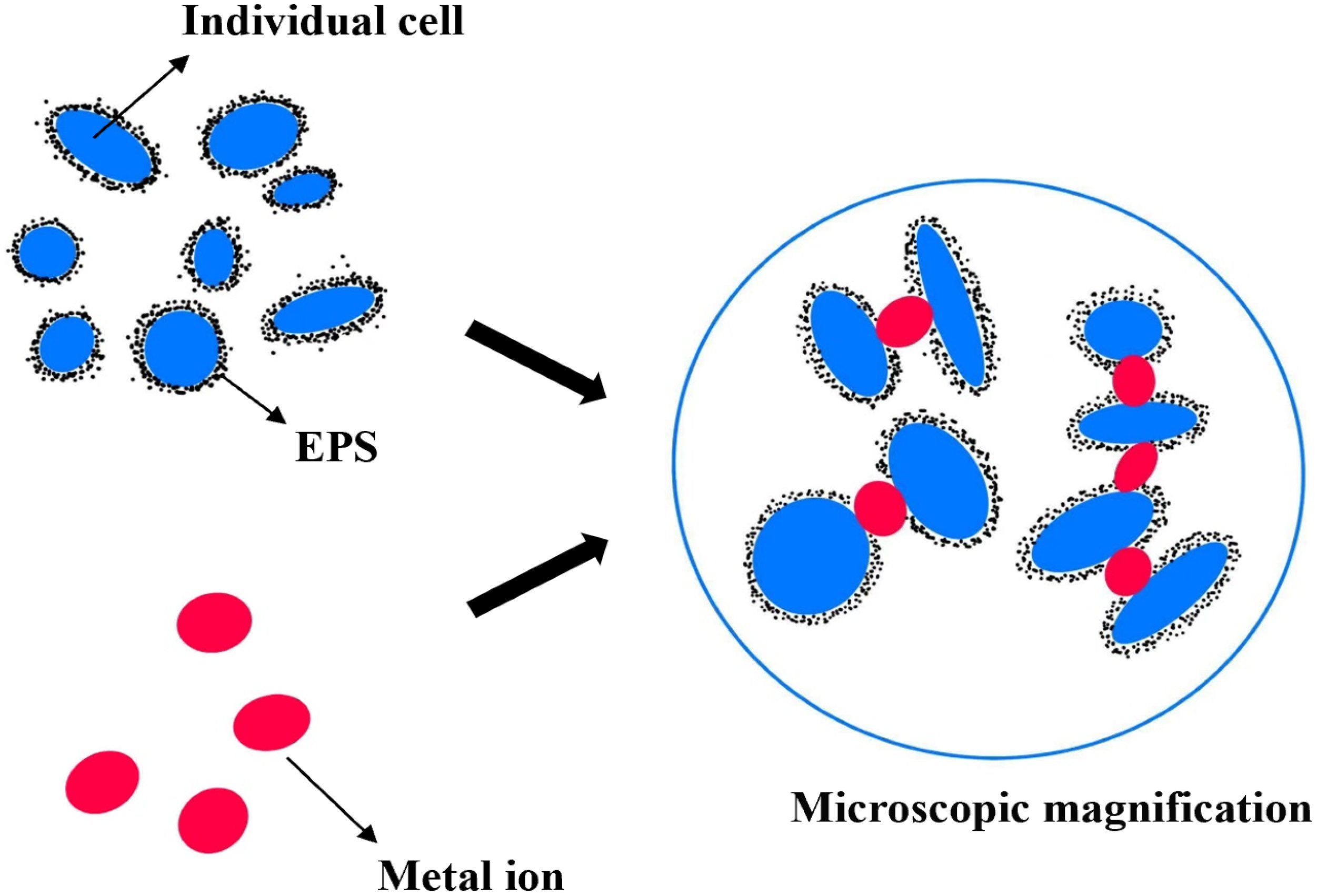

2.5. Metal Cation Hypothesis

2.6. Selective Pressure-Driven Hypothesis

3. Investigation of Factors Influencing Particle Size of AGS

3.1. DO Concentration

3.2. Temperature

3.3. pH

3.4. Seed Sludge Type

3.5. Sludge Loading Rate (SLR)

3.6. Wastewater Concentration

3.7. Shear Force

3.8. MLSS and SRT

3.9. EPS

3.10. Microbial Community

3.11. External Additive

3.12. Reactor Configuration

4. Impact of AGS Size on Removal of Emerging Contaminants

4.1. Microplastics

4.2. Antibiotics

4.3. Endocrine-Disrupting Chemicals

4.4. Persistent Organic Pollutants

5. Influence of AGS Size on Bulking Prevention and Long-Term Stability

5.1. Expansion Causes

5.2. Measures to Prevent Expansion

5.3. Instability Causes

5.4. Granule Size Optimization for Stability

6. Impact of AGS Particle Size on Environmental Sustainability

6.1. Energy Consumption of AGS

6.2. GHG Emissions

| Reactor Type | Working Volume | Granular Size | Influent COD and TN | DO and OLR | pH and Temperature | N2O Emission | Relationship | Reference |

|---|---|---|---|---|---|---|---|---|

| SBR | D = 0.32 mm | COD = 500 mg/L TN = 300 mg/L | DO = 0.35 mg/L | T = 20–32 °C pH = 6.5–8.0 OLR = 1.6 kg/(m3·day) | The removal rate of TN was 53%, and the N2O emission of AGS was the lowest at 22.3°C, pH 7.1, and aeration rate 0.20 m3/h. | When the particle size of AGS is small, the emission of N2O is higher, and with the gradual increase of particle size, the emission of N2O is gradually reduced. | [11] | |

| SBR | 3 L | D = 0.212–2 mm | COD = 258 mg/L TN = 73.7 mg/L | DO = 1–4 mg/L | pH = 7.5 | The N2O emission rate was significantly higher in the 0.212–1 mm range, being 1.5–17 times greater than in particles larger than 1 mm. | [147] | |

| DFBBRS | 608 mL | D(average) = 0.6–0.85 mm | COD = 144–182 mg/L TN = 29.5–53.5 mg/L | OLR = 5.4–7.13 kg/(m3·day) | pH = 7.3–7.72 T = 17–23 °C | TN effluent concentration of 6.2 ± 1 mg/L, N2O conversion rate of 78.53%. | [148] | |

| SBR | 1250 m3 | D = 0.212–2 mm | COD = 531 mg/L TN = 54 mg/L | OLR = 5-10 kg/(m3·day) | T = 9.7–20.6 °C | Daily averaged N2O emission factor ranged from 0.02% to 1.58%. | [150] | |

| SBR | 98 L | D = 0.256-0.427 mm | COD = 224 ± 38 mg/L TN = 60 ± 2 mg/L | T = 21–26 °C pH = 7.0 ± 0.5 | The removal efficiency of TN is 36–44%. The conversion rate of nitrogen into N2O in influent water is 0.47–5.28%. | [161] | ||

| SBAR | 6 L | D = 0.8–1 mm | COD = 300 ± 50 mg/L TN = 45 ± 5 mg/L | T = 28 ± 1 °C pH = 7.5 ± 0.2 | In SBARs during stable operation, total N2O emissions from fully aerobic SND were three times higher than from anoxic-aerobic SND. | [162] | ||

| SBR | 98 L | D = 0.2–0.4 mm | COD = 174 mg/L TN = 54 mg/L | DO = 7.2–8.5 mg/L | T = 23 ± 2 °C pH = 7.0 ± 0.5 OLR = 1.28 kg/(m3·day) | When COD/N = 1.55 mg/L, the yield of N2O is 1.08. In the anoxic phase, the yield of N2O was 2.06 mg/L. | [163] | |

| SBR | 3.2 L | D = 0.212–2 mm | COD = 160 mg/L TN = 40 mg/L | DO = 1–4 mg/L | T = 31 ± 1 °C pH = 7.3–7.8 OLR = 0.08–0.32 kg/(m3·day) | When DO concentration is 2 mg/L, the maximum N2O yield was 127.6 mg/m3, and the removal efficiency of TN was 61.68%. | [164] |

7. Conclusions and Prospect

- (1)

- Investigate the ideal particle size range: Research suggests that AGS particles between 0.3 and 1.0 mm enhance wastewater treatment, but understanding is limited and findings often conflict with practical results. Future studies should explore optimal AGS sizes under varying conditions to optimize particle size and maintain granule stability.

- (2)

- Enhancing the removal efficiency of emerging contaminants: Future research will concentrate on examining the influence of various AGS particle sizes on the removal efficiency of emerging contaminants. By accurately identifying the optimal particle size range, it is anticipated that the removal efficiency of these contaminants can be substantially enhanced.

- (3)

- Evaluate the impact on environmental sustainability: The integration of sustainability indicators into the analysis of AGS systems offers a framework for investigating strategies to decrease energy consumption, reduce greenhouse gas emissions, including N2O and CO2, and mitigate the environmental impact on surrounding ecosystems by optimizing granule size and operational parameters.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

Abbreviations

| Serial Number | English Abbreviation | Full English Name |

| 1 | AGS | aerobic granular sludge |

| 2 | SBR | sequencing batch reactor |

| 3 | CFR | continuous flow reactor |

| 4 | MBR | membrane bioreactor |

| 5 | DO | dissolved oxygen |

| 6 | EPS | extracellular polymeric substances |

| 7 | OLR | organic loading rate |

| 8 | MLSS | mixed liquor suspended solids |

| 9 | SRT | sludge retention time |

| 10 | COD | chemical oxygen demand |

| 11 | SGV | superficial gas velocity |

| 12 | SND | simultaneous nitrification and denitrification |

| 13 | TN | total nitrogen |

| 14 | TP | total phosphorus |

| 15 | SOUR | specific oxygen uptake rate |

| 16 | AHL | n-acyl homoserine lactone |

| 17 | AGMBR | aerobic granular sludge membrane bioreactor |

| 18 | TB-EPS | tightly bound extracellular polymeric substances |

| 19 | LB-EPS | loosely bound EPS |

| 20 | ALR | airlift reactor |

| 21 | CFAB | continuous-flow airlift fluidized bed |

| 22 | PAC | polyaluminum chloride |

| 23 | MBF | microbial flocculant |

| 24 | CFR-TST | continuous-flow reactor with a two-zone sedimentation tank |

| 25 | POPs | persistent organic pollutants |

| 26 | PPCPs | pharmaceutical and personal care products |

| 27 | EDCs | endocrine disrupting compounds |

| 28 | BAC | benzalkonium chloride |

| 29 | SMX | sulfamethoxazole |

| 30 | OFL | ofloxacin |

| 31 | ROX | roxithromycin |

| 32 | LB-PN | loosely bound protein |

| 33 | PE-MPs | polyethylene microplastics |

| 34 | DMP-PLA | degradable microplastic–polylactic acid |

| 35 | ROS | reactive oxygen species |

| 36 | CIP | ciprofloxacin |

| 37 | AOB | ammonium-oxidizing bacteria |

| 38 | NOB | nitrite-oxidizing bacteria |

| 39 | MBGS | microalgal-bacterial granular sludge |

| 40 | CAS | conventional activated sludge |

| 41 | EBPR | enhanced biological phosphorus removal |

| 42 | PAOs | polyphosphate-accumulating organisms |

| 43 | GAOs | glycogen-accumulating organisms |

| 44 | GHG | greenhouse gas |

References

- Lin, L.; Chen, S.; Hou, Y.; Lei, L. Study on the formation process and mechanism of aerobic granular sludge in the sequencing batch biofilter granular reactor. Environ. Sci. Pollut. Res. Int. 2023, 30, 107661–107672. [Google Scholar] [CrossRef]

- Kreuk, M.K.; Kishida, N.; Van Loosdrecht, M.C. Aerobic granular sludge--state of the art. Water Sci. Technol. 2007, 55, 75–81. [Google Scholar] [CrossRef]

- Wan, C.; Yang, X.; Lee, D.J.; Zhang, Q.; Li, J.; Liu, X. Formation of filamentous aerobic granules: Role of pH and mechanism. Appl. Microbiol. Biotechnol. 2014, 98, 8389–8397. [Google Scholar] [CrossRef]

- Gao, M.; Yang, S.; Wang, M.; Wang, X.H. Nitrous oxide emissions from an aerobic granular sludge system treating low-strength ammonium wastewater. J. Biosci. Bioeng. 2016, 122, 601–605. [Google Scholar] [CrossRef]

- Tumendelger, A.; Alshboul, Z.; Lorke, A. Methane and nitrous oxide emission from different treatment units of municipal wastewater treatment plants in Southwest Germany. PLoS ONE 2019, 14. [Google Scholar] [CrossRef]

- Cao, R.J.; Ji, Y.T.; Han, T.X.; Deng, J.S.; Zhu, L.; Xu, X.Y. The stability of aerobic granular sludge under low energy consumption: Optimization of the granular size distribution by a novel internal component. Environ. Sci. Water Res. Technol. 2021, 7, 1125–1136. [Google Scholar] [CrossRef]

- Wang, S.; Huang, X.; Liu, L.; Shen, Y.; Yan, P.; Chen, Y.; Guo, J.; Fang, F. Understanding the mechanism in aggregation ability between aerobic and anammox granular sludge from the perspective of exopolysaccharides. J. Water Process Eng. 2020, 38, 101629. [Google Scholar] [CrossRef]

- Adav, S.S.; Lee, D.J. Single-culture aerobic granules with Acinetobacter calcoaceticus. Appl. Microbiol. Biotechnol. 2008, 78, 551–557. [Google Scholar] [CrossRef]

- Ivanov, V.; Wang, X.H.; Tay, S.T.L.; Tay, J.H. Bioaugmentation and enhanced formation of microbial granules used in aerobic wastewater treatment. Appl. Microbiol. Biotechnol. 2006, 70, 374–381. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Lv, M.L.; Dai, X.; Zhou, J.H.; Xu, X.Y. The stability of aerobic granular sludge under 4-chloroaniline shock in a sequential air-lift bioreactor (SABR). Bioresour. Technol. 2013, 140, 126–130. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Liu, Y.; Kuschk, P.; Wang, J.; Chen, Y.; Wang, X. Poly aluminum chloride (PAC) enhanced formation of aerobic granules: Coupling process between physicochemical--biochemical effects. Chem. Eng. J. 2016, 284, 1127–1135. [Google Scholar] [CrossRef]

- Deng, S.; Wang, L.; Su, H. Role and influence of extracellular polymeric substances on the preparation of aerobic granular sludge. J. Environ. Manage. 2016, 173, 49–54. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Guo, L.; Ren, X.; Zhao, Y.; Jin, C.; Gao, M.; Ji, J.; She, Z. Effect of magnetic field intensity on aerobic granulation and partial nitrification-denitrification performance. Proc. Saf. Environ.Prot. 2022, 160, 859–867. [Google Scholar] [CrossRef]

- Liu, X.M.; Sheng, G.P.; Luo, H.W.; Zhang, F.; Yuan, S.J.; Xu, J.; Zeng, R.J.; Wu, J.G.; Yu, H.Q. Contribution of extracellular polymeric substances (EPS) to the sludge aggregation. Environ. Sci. Technol. 2010, 44, 4355–4360. [Google Scholar] [CrossRef]

- Beun, J.J.; Hendriks, A.; van Loosdrecht, M.C.M.; Morgenroth, E.; Wilderer, P.A.; Heijnen, J.J. Aerobic granulation in a sequencing batch reactor. Water Res. 1999, 33, 83–90. [Google Scholar] [CrossRef]

- Du, S.; Zhang, Z.H.; Zhang, Y.F.; Jian, P.C. Characteristics of Aerobic Granular Sludge Cultivated by Promoting and Inhibiting Filamentous Bacteria. Adv. Mater. Res. 2011, 183–185, 1075–1079. [Google Scholar] [CrossRef]

- Han, X.; Jin, Y.; Yu, J. Rapid formation of aerobic granular sludge by bioaugmentation technology: A review. Chem. Eng. J. 2022, 437, 134971. [Google Scholar] [CrossRef]

- Song, T.; Zhang, X.; Li, J. The formation and distinct characteristics of aerobic granular sludge with filamentous bacteria in low strength wastewater. Bioresour. Technol. 2022, 360, 127409. [Google Scholar] [CrossRef]

- Tao, J.; Qin, L.; Liu, X.; Li, B.; Chen, J.; You, J.; Shen, Y.; Chen, X. Effect of granular activated carbon on the aerobic granulation of sludge and its mechanism. Bioresour. Technol. 2017, 236, 60–67. [Google Scholar] [CrossRef]

- Xu, J.; Pang, H.; He, J.; Wang, M.; Nan, J.; Li, L. Enhanced aerobic sludge granulation by applying carbon fibers as nucleating skeletons. Chem. Eng. J. 2019, 373, 946–954. [Google Scholar] [CrossRef]

- Verawaty, M.; Pijuan, M.; Yuan, Z.; Bond, P.L. Determining the mechanisms for aerobic granulation from mixed seed of floccular and crushed granules in activated sludge wastewater treatment. Water Res. 2012, 46, 761–771. [Google Scholar] [CrossRef] [PubMed]

- Kong, Q.; Ngo, H.H.; Shu, L.; Fu, R.S.; Jiang, C.H.; Miao, M.S. Enhancement of aerobic granulation by zero-valent iron in sequencing batch airlift reactor. J. Hazard. Mater. 2014, 279, 511–517. [Google Scholar] [CrossRef]

- Heijnen, J.J.; Van Loosdrecht, M.C.M.; Mulder, R.; Weltevrede, R.; Mulder, A. Development and Scale-Up of an Aerobic Biofilm Air-Lift Suspension Reactor. Water Sci. Technol. 1993, 27, 253–261. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Liu, Z.; Huang, X.; Fang, F.; Guo, J.; Yan, P. Effect of EPS and its forms of aerobic granular sludge on sludge aggregation performance during granulation process based on XDLVO theory. Sci. Total Environ. 2021, 795, 148682. [Google Scholar] [CrossRef]

- Li, X.M.; Liu, Q.Q.; Yang, Q.; Guo, L.; Zeng, G.M.; Hu, J.M.; Zheng, W. Enhanced aerobic sludge granulation in sequencing batch reactor by Mg2+ augmentation. Bioresour. Technol. 2009, 100, 64–67. [Google Scholar] [CrossRef]

- Jiang, H.L.; Tay, J.H.; Liu, Y.; Tiong-Lee Tay, S. Ca2+ augmentation for enhancement of aerobically grown microbial granules in sludge blanket reactors. Biotechnol. Lett. 2003, 25, 95–99. [Google Scholar] [CrossRef] [PubMed]

- Agridiotis, V.; Forster, C.F.; Carliell-Marquet, C. Addition of Al and Fe salts during treatment of paper mill effluents to improve activated sludge settlement characteristics. Bioresour. Technol. 2007, 98, 2926–2934. [Google Scholar] [CrossRef]

- Cai, W.; Jin, M.; Zhao, Z.; Lei, Z.; Zhang, Z.; Adachi, Y.; Lee, D.J. Influence of ferrous iron dosing strategy on aerobic granulation of activated sludge and bioavailability of phosphorus accumulated in granules. Bioresour. Technol. Rep. 2018, 2, 7–14. [Google Scholar] [CrossRef]

- Sun, F.; Lu, Y.; Wu, J. Comparison of operational strategies for nitrogen removal in aerobic granule sludge sequential batch reactor (AGS-SBR): A model-based evaluation. J. Environ. Chem. Eng. 2019, 7, 103314. [Google Scholar] [CrossRef]

- Awang, N.A.; Shaaban, M.G. Effect of reactor height/diameter ratio and organic loading rate on formation of aerobic granular sludge in sewage treatment. Int. Biodeterior. Biodegrad. 2016, 112, 1–11. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Tay, J.H. Fast formation of aerobic granules by combining strong hydraulic selection pressure with overstressed organic loading rate. Water Res. 2015, 80, 256–266. [Google Scholar] [CrossRef]

- Xu, D.; Liu, J.; Ma, T.; Gao, Y.; Zhang, S.; Li, J. Rapid granulation of aerobic sludge in a continuous-flow reactor with a two-zone sedimentation tank by the addition of dewatered sludge. J. Water Process Eng. 2021, 41, 101941. [Google Scholar] [CrossRef]

- Xu, D.; Liu, J.; Ma, T.; Zhao, X.; Ma, H.; Li, J. Coupling of sponge fillers and two-zone clarifiers for granular sludge in an integrated oxidation ditch. Environ. Technol. Innov. 2022, 26, 102264. [Google Scholar] [CrossRef]

- Liu, H.; Xiao, H.; Huang, S.; Ma, H.; Liu, H. Aerobic granules cultivated and operated in continuous-flow bioreactor under particle-size selective pressure. J. Environ. Sci. 2014, 26, 2215–2221. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Sun, Y.; Liu, Y.; Yuan, W.; Dai, L.; Xu, W.; Wang, H. In-situ sludge settleability improvement and carbon reuse in SBR process coupled with hydrocyclone. Sci. Total Environ. 2019, 695, 133825. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, H.; Xu, Y.; Tu, Q.; Chen, X. Achieving enhanced denitrification via hydrocyclone treatment on mixed liquor recirculation in the anoxic/aerobic process. Chemosphere 2017, 189, 206–212. [Google Scholar] [CrossRef]

- Kent, T.R.; Bott, C.B.; Wang, Z.W. State of the art of aerobic granulation in continuous flow bioreactors. Biotechnol. Adv. 2018, 36, 1139–1166. [Google Scholar] [CrossRef]

- Arumugham, T.; Yuniarto, A.; Abdullah, N.; Yuzir, A.; Aminabhavi, T.M.; Kamyab, H.; Vasseghian, Y. Effective removal of organic substances and nutrients using microgranular sludge in a sequential batch reactor. J. Water Process Eng. 2024, 59, 105080. [Google Scholar] [CrossRef]

- Yu, C.; Wang, K.; Zhang, K.; Liu, R.; Zheng, P. Full-scale upgrade activated sludge to continuous-flow aerobic granular sludge: Implementing microaerobic-aerobic configuration with internal separators. Water Res. 2024, 248, 120870. [Google Scholar] [CrossRef]

- Di Bella, G.; Torregrossa, M. Simultaneous nitrogen and organic carbon removal in aerobic granular sludge reactors operated with high dissolved oxygen concentration. Bioresour. Technol. 2013, 142, 706–713. [Google Scholar] [CrossRef]

- Mady, E.; Oleszkiewicz, J.; Yuan, Q. Simultaneous biological nutrients removal from wastewater with high ammonium and phosphorus loading using aerobic granular sludge. J. Water Process Eng. 2024, 64, 105650. [Google Scholar] [CrossRef]

- Ab Halim, M.H.; Anuar, A.N.; Azmi, S.I.; Jamal, N.S.A.; Wahab, N.A.; Ujang, Z.; Shraim, A.; Bob, M.M. Aerobic sludge granulation at high temperatures for domestic wastewater treatment. Bioresour. Technol. 2015, 185, 445–449. [Google Scholar] [CrossRef]

- Sun, Y.; Angelotti, B.; Wang, Z.W. Continuous-flow aerobic granulation in plug-flow bioreactors fed with real domestic wastewater. Sci. Total Environ. 2019, 688, 762–770. [Google Scholar] [CrossRef]

- Song, Z.; Ren, N.; Zhang, K.; Tong, L. Influence of temperature on the characteristics of aerobic granulation in sequencing batch airlift reactors. J. Environ. Sci. 2009, 21, 273–278. [Google Scholar] [CrossRef]

- Araujo, J.M.; Berzio, S.; Gehring, T.; Nettmann, E.; Florencio, L.; Wichern, M. Influence of temperature on aerobic granular sludge formation and stability treating municipal wastewater with high nitrogen loadings. Environ. Res. 2022, 212, 113578. [Google Scholar] [CrossRef]

- Yang, S.F.; Li, X.Y.; Yu, H.Q. Formation and characterisation of fungal and bacterial granules under different feeding alkalinity and pH conditions. Process Biochem. 2008, 43, 8–14. [Google Scholar] [CrossRef]

- Lashkarizadeh, M.; Munz, G.; Oleszkiewicz, J.A. Impacts of variable pH on stability and nutrient removal efficiency of aerobic granular sludge. Water Sci. Technol. 2016, 73, 60–68. [Google Scholar] [CrossRef] [PubMed]

- Niu, X.; Han, X.; Jin, Y.; Yue, J.; Zhu, J.; Xie, W.; Yu, J. Aerobic granular sludge treating hypersaline wastewater: Impact of pH on granulation and long-term operation at different organic loading rates. J. Environ. Manage. 2023, 330, 117164. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Yu, H.J.; Ma, C.C. Study on the impact of do and organic matter on aerobic granular sludge treating municipal sewage. Adv. Mater. Res. 2014, 989, 603–606. [Google Scholar] [CrossRef]

- Wang, X.C.; Chen, Z.L.; Kang, J.; Zhao, X.; Shen, J.M.; Yang, L. The key role of inoculated sludge in fast start-up of sequencing batch reactor for the domestication of aerobic granular sludge. J. Environ. Sci. 2019, 78, 127–136. [Google Scholar] [CrossRef]

- Lei, L.; Yao, J.C.; Liu, Y.D.; Li, W. Performance, sludge characteristics and microbial community in a salt-tolerant aerobic granular SBR by seeding anaerobic granular sludge. Int. Biodeterior. Biodegrad. 2021, 163, 105258. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, C.; Xie, Y.; Chen, R.; Huang, M.; Hu, X.; Wang, B.; Guo, W.; Huang, H.; Wang, R.; et al. Self-Aggregation and Denitrifying Strains Accelerate Granulation and Enhance Denitrification. Water 2022, 14, 1482. [Google Scholar] [CrossRef]

- Deng, J.; Wang, H.; Huang, J.; Hu, J.; Pan, Z.; Gao, R.; Wang, L.; Xu, D. Synergistic TA/(NH4)2SO4 conditioning for sludge dewatering: Mechanisms of EPS redistribution and hydrophobic enhancement. J. Environ. Manag. 2025, 389, 126266. [Google Scholar] [CrossRef] [PubMed]

- Abirami, B.; Kevin, V.; Padmaja, A.; Sanjay, S.; Devik, D.; Balakrishnan, P. Studies on Enhancing Granule Formation in Aerobic Granular Sludge Treatment Method. Water Environ. 2025, 2, 85–95. [Google Scholar]

- Jafari, K.A.; Yuan, Q. Long-term stability and nutrient removal efficiency of aerobic granules at low organic loads. Bioresour. Technol. 2017, 234, 336–342. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Tay, J.H. Influence of starvation time on formation and stability of aerobic granules in sequencing batch reactors. Bioresour. Technol. 2008, 99, 980–985. [Google Scholar] [CrossRef]

- Yue, J.; Han, X.; Jin, Y.; Yu, J. Potential of direct granulation and organic loading rate tolerance of aerobic granular sludge in ultra-hypersaline environment. Environ. Res. 2023, 228, 115831. [Google Scholar] [CrossRef]

- Rosa-Masegosa, A.; Muñoz-Palazon, B.; Gonzalez-Lopez, J.; Gonzalez-Martinez, A. Elucidating the role of organic loading rate on the performance and microbial dynamics of a novel continuous-flow aerobic granular sludge reactor. J. Water Process Eng. 2024, 65, 105820. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, F.; Jiang, T.; Wei, Y.; Wang, T.; Yang, F. Aerobic granulation with low strength wastewater at low aeration rate in A/O/A SBR reactor. Enzym. Microb. Technol. 2011, 49, 215–222. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Lv, Y.; Zeng, H.; Zhang, J. Long term operation of continuous-flow system with enhanced biological phosphorus removal granules at different COD loading. Bioresour. Technol. 2016, 216, 761–767. [Google Scholar] [CrossRef]

- Sajjad, M.; Kim, I.S.; Kim, K.S. Development of a novel process to mitigate membrane fouling in a continuous sludge system by seeding aerobic granules at pilot plant. J. Membr. Sci. 2016, 497, 90–98. [Google Scholar] [CrossRef]

- Pan, Z.; Wei, H.; Qiu, C.; Yang, Q.; Liang, Y.; Huang, Z.; Li, J. Two-stage sequencing batch reactors with added iron shavings for nutrient removal and aerobic sludge granulation treating real wastewater with low carbon to nitrogen ratios. Bioresour. Technol. 2024, 396, 130380. [Google Scholar] [CrossRef]

- Geng, M.; You, S.; Guo, H.; Ma, F.; Xiao, X.; Zhang, J.; Ma, X. Response of aerobic granular sludge to loading shock: Performance and proteomic study. Chem. Eng. J. 2022, 444, 136458. [Google Scholar] [CrossRef]

- Chen, R.; Guo, W.; Li, L.; Wang, H.; Wang, B.; Hu, X.; Ji, B.; Zhou, D.; Lyu, W. Aerobic granulation in a continuous-flow simultaneous nitrification, endogenous denitrification, and phosphorus removal system fed with low-strength wastewater: Granulation mechanism and microbial succession. Chem. Eng. J. 2024, 487, 150598. [Google Scholar] [CrossRef]

- Tay, J.H.; Liu, Q.S.; Liu, Y. The effect of upflow air velocity on the structure of aerobic granules cultivated in a sequencing batch reactor. Water Sci. Technol. 2004, 49, 35–40. [Google Scholar] [CrossRef]

- Xu, J.; Ju, H.; He, J.; Pang, H. The Performance of Aerobic Granular Sludge Under Different Aeration Strategies at Low Temperature. Water Air Soil. Pollut. 2022, 233, 43. [Google Scholar] [CrossRef]

- Wan, C.; Fu, L.; Li, Z.; Liu, X.; Lin, L.; Wu, C. Formation, application, and storage-reactivation of aerobic granular sludge: A review. J. Env. Environ. Manag. 2022, 323, 116302. [Google Scholar] [CrossRef] [PubMed]

- Ji, G.; Zhai, F.; Wang, R.; Wang, R.; Ni, J. Sludge granulation and performance of a low superficial gas velocity sequencing batch reactor (SBR) in the treatment of prepared sanitary wastewater. Bioresour. Technol. 2010, 101, 9058–9064. [Google Scholar] [CrossRef]

- Winkler, M.K.; Kleerebezem, R.; van Loosdrecht, M.C. Integration of anammox into the aerobic granular sludge process for main stream wastewater treatment at ambient temperatures. Water Res. 2012, 46, 136–144. [Google Scholar] [CrossRef]

- Nancharaiah, Y.V.; Reddy, G.K.K. Aerobic granular sludge technology: Mechanisms of granulation and biotechnological applications. Bioresour. Technol. 2018, 247, 1128–1143. [Google Scholar] [CrossRef] [PubMed]

- De Sousa, R.S.L.; Mendes, B.a.R.; Milen, F.P.I.; Bezerra, D.S.A. Aerobic granular sludge: Cultivation parameters and removal mechanisms. Bioresour. Technol. 2018, 270, 678–688. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.; Wang, K. Continuous flow aerobic granular sludge: Recent developments and applications. Water Sci. Technol. 2024, 89, 1155–1178. [Google Scholar] [CrossRef]

- Lin, Q.; Sun, S.; Yang, J.; Hu, P.; Liu, Z.; Liu, Z.; Song, C.; Yang, S.; Wu, F.; Gao, Y.; et al. Enhanced aerobic granular sludge by thermally-treated dredged sediment in wastewater treatment under low superficial gas velocity. J. Environ. Manag. 2024, 368, 122210. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Zhang, J.; Wang, J.; Zhu, H.; Xiong, J.; Nong, G.; Luo, M.; Wang, J. Direct start-up of aerobic granular sludge system with dewatered sludge granular particles as inoculant. J. Environ. Manag. 2023, 326, 116540. [Google Scholar] [CrossRef]

- Chen, X.; Gong, Y.; Li, Z.; Guo, Y.; Zhang, H.; Hu, B.; Yang, W.; Cao, Y.; Mu, R. Key function of Kouleothrix in stable formation of filamentous aerobic granular sludge at low superficial gas velocity with polymeric substrates. Bioresour. Technol. 2024, 397, 130466. [Google Scholar] [CrossRef] [PubMed]

- Gao, D.; Liu, L.; Liang, H.; Wu, W.M. Aerobic granular sludge: Characterization, mechanism of granulation and application to wastewater treatment. Crit. Rev. Biotechnol. 2011, 31, 137–152. [Google Scholar] [CrossRef]

- Luo, Y.; Yi, K.; Zhang, X.; Li, B.; Cao, R.; Pang, Y.; Li, M.; Hou, C.; Lv, J.; Li, X.; et al. Simultaneous partial nitrification, denitrification, and phosphorus removal in sequencing batch reactors via controlled reduced aeration and short-term sludge retention time decrease. J. Environ. Manag. 2023, 344, 118598. [Google Scholar] [CrossRef]

- Chen, D.; Li, H.; Xue, X.; Zhang, L.; Hou, Y.; Chen, H.; Zhang, Y.; Song, Y.; Zhao, S.; Guo, J. Enhanced simultaneous partial nitrification and denitrification performance of aerobic granular sludge via tapered aeration in sequencing batch reactor for treating low strength and low COD/TN ratio municipal wastewater. Environ. Res. 2022, 209, 112743. [Google Scholar] [CrossRef]

- Yu, N.; Lv, Y.; Li, B.; Wang, J.; Mou, H.; Zhao, Y. Simultaneous phosphorus removal and sludge reduction in continuous-flow reactor with granules under long sludge retention time. J. Environ. Chem. Eng. 2023, 11, 110140. [Google Scholar] [CrossRef]

- Adav, S.S.; Lee, D.J.; Tay, J.H. Extracellular polymeric substances and structural stability of aerobic granule. Water Res. 2008, 42, 1644–1650. [Google Scholar] [CrossRef]

- Liu, X.; Pei, Q.; Han, H.; Yin, H.; Chen, M.; Guo, C.; Li, J.; Qiu, H. Functional analysis of extracellular polymeric substances (EPS) during the granulation of aerobic sludge: Relationship among EPS, granulation and nutrients removal. Environ. Res. 2022, 208, 112692. [Google Scholar] [CrossRef] [PubMed]

- Song, Q.; Hua, Y.; Yu, Y.; Chen, C.; Wu, B.; Dai, X. Impediments to bioaccessibility in the anaerobic digestion of waste activated Sludge: An in-depth review of challenges and influencing factors. Energ. Environ. Sustain. 2025, 1, 100026. [Google Scholar] [CrossRef]

- Corsino, S.F.; Campo, R.; Di Bella, G.; Torregrossa, M.; Viviani, G. Study of aerobic granular sludge stability in a continuous-flow membrane bioreactor. Bioresour. Technol. 2016, 200, 1055–1059. [Google Scholar] [CrossRef]

- Yu, G.H.; He, P.J.; Shao, L.M. Characteristics of extracellular polymeric substances (EPS) fractions from excess sludges and their effects on bioflocculability. Bioresour. Technol. 2009, 100, 3193–3198. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, X.; Zhang, S.; Qi, H.; Hou, Y.; Gao, M.; Wang, J.; Zhang, A.; Chen, Y.; Liu, Y. A comparison between exogenous carriers enhanced aerobic granulation under low organic loading in the aspect of sludge characteristics, extracellular polymeric substances and microbial communities. Bioresour. Technol. 2022, 346, 126567. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.H.; Ren, Q.; Xu, X.L.; Fang, J.Y.; Wang, T.; Wang, K.M.; Wang, H.Y. Enhancing stability of aerobic granules by microbial selection pressure using height-adjustable influent strategy. Water Res. 2021, 201, 117356. [Google Scholar] [CrossRef]

- Li, A.J.; Yang, S.F.; Li, X.Y.; Gu, J.D. Microbial population dynamics during aerobic sludge granulation at different organic loading rates. Water Res. 2008, 42, 3552–3560. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; He, J.T.; Chen, X.; Li, Z.H. Turning alkalinity deficiency-induced metabolic disorder into an opportunity for promoting granulation and enhancing heat generation. J. Water Process Eng. 2024, 62, 105373. [Google Scholar] [CrossRef]

- Zhang, Z.; Qiu, J.; Xiang, R.; Yu, H.; Xu, X.; Zhu, L. Organic loading rate (OLR) regulation for enhancement of aerobic sludge granulation: Role of key microorganism and their function. Sci. Total Environ. 2019, 653, 630–637. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, H.; Lu, Y.Y.; Ren, Z.Q.; Gao, N.; Wang, J.J.; Huang, B.C.; Jin, R.C. In-situ synthesis of lanthanum-coated sludge biochar for advanced phosphorus adsorption. J. Environ. Manag. 2025, 373, 123607. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Zhu, F.; Wang, Z.; Wu, J.; Gao, Y.; Li, K.; Zhao, C.; Wang, X. Harnessing corn straw biochar: A breakthrough in eco-friendly Cu (II) wastewater treatment. Waste Manag. 2025, 197, 25–34. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Mao, X.; Tang, X.; Tang, H.; Shen, Y.; Shi, W. Pre-coagulation for membrane fouling mitigation in an aerobic granular sludge membrane bioreactor: A comparative study of modified microbial and organic flocculants. J. Membr. Sci. 2022, 644, 120129. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Y.; Gao, X.; Chen, H.; Xu, X.; Zhu, L. Role of biochar in the granulation of anaerobic sludge and improvement of electron transfer characteristics. Bioresour. Technol. 2018, 268, 28–35. [Google Scholar] [CrossRef]

- Wang, X.; Ming, J.; Chen, C.M.; Yoza, B.A.; Li, Q.-W.; Liang, J.H.; Gadd, G.M.; Wang, Q.H. Rapid aerobic granulation using biochar for the treatment of petroleum refinery wastewater. Pet. Sci. 2020, 17, 1411–1421. [Google Scholar] [CrossRef]

- Hou, Y.; Gan, C.; Chen, R.; Chen, Y.; Yuan, S.; Chen, Y. Structural characteristics of aerobic granular sludge and factors that influence its stability: A mini review. Water 2021, 13, 2726. [Google Scholar] [CrossRef]

- Li, D.; Yang, J.; Li, Y.; Zhang, J. Research on rapid cultivation of aerobic granular sludge (AGS) with different feast-famine strategies in continuous flow reactor and achieving high-level denitrification via utilization of soluble microbial product (SMP). Sci. Total Environ. 2021, 786, 147237. [Google Scholar] [CrossRef]

- Ramos, C.; Su a Rez-Ojeda, M.I.a.E.; Carrera, J.a.N. Biodegradation of a high-strength wastewater containing a mixture of ammonium, aromatic compounds and salts with simultaneous nitritation in an aerobic granular reactor. Process Biochem. 2016, 51, 399–407. [Google Scholar] [CrossRef]

- Xu, D.; Li, J.; Liu, J.; Ma, T. Rapid aerobic sludge granulation in an integrated oxidation ditch with two-zone clarifiers. Water Res. 2020, 175, 115704. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, P.; Xing, Y.; Li, W.; Yang, J.; Abbas, G.; Liu, S.; He, Z.; Zhang, J.; Zhang, H.; et al. Effect of particle size on the performance of autotrophic nitrogen removal in the granular sludge bed reactor and microbiological mechanisms. Bioresour. Technol. 2014, 157, 240–246. [Google Scholar] [CrossRef]

- De Kreuk, M.K.; Heijnen, J.J.; Van Loosdrecht, M.C.M. Simultaneous COD, nitrogen, and phosphate removal by aerobic granular sludge. Biotechnol. Bioeng. 2005, 90, 761–769. [Google Scholar] [CrossRef] [PubMed]

- Ni, Y.; Yang, J.; Pan, J.; Wu, S.; Zou, J.; Li, J. Effects of enhanced biological phosphorus removal on rapid control of sludge bulking and fast formation of aerobic granular sludge. Bioresour. Technol. 2024, 402, 130820. [Google Scholar] [CrossRef] [PubMed]

- Guo, T.; Pan, K.; Chen, Y.; Tian, Y.; Deng, J.; Li, J. When aerobic granular sludge faces emerging contaminants: A review. Sci. Total. Environ. 2024, 907, 167792. [Google Scholar] [CrossRef]

- Zhang, B.; Huang, S.; Wu, L.; Guo, Y.; Shi, W.; Lens, P.N.L. Micro(nano)plastic size and concentration co-differentiate the treatment performance and toxicity mechanism in aerobic granular sludge systems. Chem. Eng. J. 2023, 457, 141212. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, B.; Liu, Y.; Feng, X.; Shi, W. Revealing the influencing mechanisms of polystyrene microplastics (MPs) on the performance and stability of the algal-bacterial granular sludge. Bioresour. Technol. 2022, 354, 127202. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, N.; Yang, G.; Xie, Z.; Yu, N.; Wang, D.; Liu, X.; Xia, J.; Tang, L. Revealing the behavior of perfluorooctane sulfonic acid in an aerobic granular sludge system: Fate and impact. Chem. Eng. J. 2023, 454, 140478. [Google Scholar] [CrossRef]

- Castellanos, R.M.; Bassin, J.P.; Bila, D.M.; Dezotti, M. Biodegradation of natural and synthetic endocrine-disrupting chemicals by aerobic granular sludge reactor: Evaluating estrogenic activity and estrogens fate. Environ. Pollut. 2021, 274, 116551. [Google Scholar] [CrossRef]

- Ely, C.; Moreira, I.S.; Bassin, J.P.; Dezotti, M.W.C.; Mesquita, D.P.; Costa, J.; Ferreira, E.C.; Castro, P.M.L. Treatment of saline wastewater amended with endocrine disruptors by aerobic granular sludge: Assessing performance and microbial community dynamics. J. Environ. Chem. Eng. 2022, 10, 107272. [Google Scholar] [CrossRef]

- Li, D.; Gao, J.; Dai, H.; Wang, Z.; Zhao, Y.; Cui, Y. Higher spreading risk of antibacterial biocide and heavy metal resistance genes than antibiotic resistance genes in aerobic granular sludge. Environ. Res. 2022, 212, 113356. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Meng, S.; Yan, L.; Zhang, X.; Wei, Q.; Wei, D. Coupling of submersible microbial fuel cell into aerobic granular sludge bioreactor for ciprofloxacin stress alleviation: Performance and mechanism. J. Clean. Prod. 2022, 373, 133902. [Google Scholar] [CrossRef]

- Lin, J.; Cheng, Q.; Kumar, A.; Zhang, W.; Yu, Z.; Hui, D.; Zhang, C.; Shan, S. Effect of degradable microplastics, biochar and their coexistence on soil organic matter decomposition: A critical review. TrAC Trends Anal. Chem. 2025, 183, 118082. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, B.; Zhao, Z.; Yang, C.; Zhang, B.; Cui, F.; Lens, P.N.L.; Shi, W. Metagenomic analysis reveals the responses of microbial communities and nitrogen metabolic pathways to polystyrene micro(nano)plastics in activated sludge systems. Water Res. 2023, 241, 120161. [Google Scholar] [CrossRef]

- Jachimowicz, P.; Jo, Y.J.; Cydzik-Kwiatkowska, A. Polyethylene microplastics increase extracellular polymeric substances production in aerobic granular sludge. Sci. Total Environ. 2022, 851, 158208. [Google Scholar] [CrossRef]

- Zheng, X.; Han, Z.; Shao, X.; Zhao, Z.; Zhang, H.; Lin, T.; Yang, S.; Zhou, C. Response of aerobic granular sludge under polyethylene microplastics stress: Physicochemical properties, decontamination performance, and microbial community. J. Environ. Manag. 2022, 323, 116215. [Google Scholar] [CrossRef] [PubMed]

- Hou, H.; Wang, S.; Ji, B.; Zhang, Y.; Pi, K.; Shi, Y. Adaptation responses of microalgal-bacterial granular sludge to polystyrene microplastic particles in municipal wastewater. Environ. Sci. Pollut. Res. Int. 2022, 29, 59965–59973. [Google Scholar] [CrossRef] [PubMed]

- Otieno, J.O.; Jachimowicz, P.; Zielińska, M.; Mądzielewska, W.I.; Cydzik-Kwiatkowska, A. The effect of tire microplastics on aerobic granular sludge performance. Emerg. Contam. 2025, 11, 100513. [Google Scholar] [CrossRef]

- Li, Y.; Guo, M.; Kong, X.; Jia, X.; Zhao, X. Coupling micro-electric field into aerobic granular sludge system for sulfadiazine abatement: Performance, mechanism, toxicity, and microbial characteristics. Chem. Eng. J. 2024, 483, 149258. [Google Scholar] [CrossRef]

- Song, X.; Sun, S.; Gao, Y.; Zhang, W.; Zhou, L.; B, J.C.; Wan, J.; Chen, J.; Zhou, L.; Yu, G. Laboratory-scale study of a biodegradable microplastic polylactic acid stabilizing aerobic granular sludge system. Environ. Pollut. 2022, 306, 119329. [Google Scholar] [CrossRef]

- Wang, S.; Ma, X.; Wang, Y.; Du, G.; Tay, J.H.; Li, J. Piggery wastewater treatment by aerobic granular sludge: Granulation process and antibiotics and antibiotic-resistant bacteria removal and transport. Bioresour. Technol. 2019, 273, 350–357. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, Y.; Zhang, Z.; Dong, J.; Fu, J.; Xu, X.; Zhu, L. Enhancement of PPCPs removal by shaped microbial community of aerobic granular sludge under condition of low C/N ratio influent. J. Hazard. Mater. 2020, 394, 122583. [Google Scholar] [CrossRef]

- Cheng, L.; Wei, M.; Hu, Q.; Li, B.; Li, B.; Wang, W.; Abudi, Z.N.; Hu, Z. Aerobic granular sludge formation and stability in enhanced biological phosphorus removal system under antibiotics pressure: Performance, granulation mechanism, and microbial successions. J. Hazard. Mater. 2023, 454, 131472. [Google Scholar] [CrossRef]

- Li, X.; Zhao, X.; Li, Y.; Li, X.; Kong, X.; Wei, Q.; Guo, M. Microelectricity enhances aerobic granular sludge granulation and sulfamethazine degradation: Performance, mechanism, antibiotic resistance genes and microbial community. J. Environ. Manage. 2025, 373, 123889. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, W.; Ni, J.; Hu, B. Cultivation of granules containing anaerobic decolorization and aerobic degradation cultures for the complete mineralization of azo dyes in wastewater. Chemosphere 2020, 246, 125753. [Google Scholar] [CrossRef] [PubMed]

- Mario, R.V.; Durán-Lvarez, J.C.; Blanca, J.C.; Olivia, Z.; Blanca, P. Occurrence of perfluorinated carboxylic acids in Mexico City’s wastewater: A monitoring study in the sewerage and a mega wastewater treatment plant. Sci. Total Environ. 2021, 774, 145060. [Google Scholar]

- Qiu, B.; Liao, G.; Wu, C.; Dai, C.; Bin, L.; Gao, X.; Zhao, Y.; Li, P.; Huang, S.; Fu, F. Rapid granulation of aerobic granular sludge and maintaining its stability by combining the effects of multi-ionic matrix and bio-carrier in a continuous-flow membrane bioreactor. Sci. Total Environ. 2022, 813, 152644. [Google Scholar] [CrossRef]

- De Vleeschauwer, F.; Dries, J. Full dynamic control of dairy wastewater treatment by aerobic granular sludge using electric conductivity and oxygen uptake rate. Water Sci. Technol. 2023, 88, 2707–2718. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.H.; Zhang, Z.M.; Zhao, H.; Yu, H.T.; Alvarez, P.J.; Xu, X.Y.; Zhu, L. Optimizing granules size distribution for aerobic granular sludge stability: Effect of a novel funnel-shaped internals on hydraulic shear stress. Bioresour. Technol. 2016, 216, 562–570. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, S.F.; Liu, Q.S.; Tay, J.H. The role of cell hydrophobicity in the formation of aerobic granules. Curr. Microbiol. 2003, 46, 270–274. [Google Scholar] [CrossRef]

- Lee, D.J.; Chen, Y.Y.; Show, K.Y.; Whiteley, C.G.; Tay, J.H. Advances in aerobic granule formation and granule stability in the course of storage and reactor operation. Biotechnol. Adv. 2010, 28, 919–934. [Google Scholar] [CrossRef]

- Liu, L.; Li, W.W.; Sheng, G.P.; Liu, Z.F.; Zeng, R.J.; Liu, J.X.; Yu, H.Q.; Lee, D.J. Microscale hydrodynamic analysis of aerobic granules in the mass transfer process. Environ. Sci. Technol. 2010, 44, 7555–7560. [Google Scholar] [CrossRef]

- Long, B.; Yang, C.Z.; Pu, W.H.; Yang, J.K.; Liu, F.B.; Zhang, L.; Zhang, J.; Cheng, K. Tolerance to organic loading rate by aerobic granular sludge in a cyclic aerobic granular reactor. Bioresour. Technol. 2015, 182, 314–322. [Google Scholar] [CrossRef]

- Long, B.; Xuan, X.; Yang, C.; Zhang, L.; Cheng, Y.; Wang, J. Stability of aerobic granular sludge in a pilot scale sequencing batch reactor enhanced by granular particle size control. Chemosphere 2019, 225, 460–469. [Google Scholar] [CrossRef]

- Verawaty, M.; Tait, S.; Pijuan, M.; Yuan, Z.; Bond, P.L. Breakage and growth towards a stable aerobic granule size during the treatment of wastewater. Water Res. 2013, 47, 5338–5349. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, R.; Du, Y.; Huang, S.; Zhao, F.; Kim, D.H.; Ng, H.Y.; Shi, X.; Xu, B. From waste to Wealth: Exploring the Effect of particle size on biopolymer Harvesting from aerobic granular sludge. Bioresour. Technol. 2024, 418, 131977. [Google Scholar] [CrossRef]

- De Vleeschauwer, F.; Caluwe, M.; Dobbeleers, T.; Stes, H.; Dockx, L.; Kierens, F.; D’aes, J.; Copot, C.; Dries, J. Performance and stability of a dynamically controlled EBPR anaerobic/aerobic granular sludge reactor. Bioresour. Technol. 2019, 280, 151–157. [Google Scholar] [CrossRef]

- Huang, J.S.; Tsao, C.W.; Lu, Y.C.; Chou, H.H. Role of mass transfer in overall substrate removal rate in a sequential aerobic sludge blanket reactor treating a non-inhibitory substrate. Water Res. 2011, 45, 4562–4570. [Google Scholar] [CrossRef]

- Shanmeem, K.S.; Sabumon, P.C. A Review on the Stability, Sustainability, Storage and Rejuvenation of Aerobic Granular Sludge for Wastewater Treatment. Water 2023, 15, 950. [Google Scholar] [CrossRef]

- Li, W.W.; Zhang, H.L.; Sheng, G.P.; Yu, H.Q. Roles of extracellular polymeric substances in enhanced biological phosphorus removal process. Water Res. 2015, 86, 85–95. [Google Scholar] [CrossRef] [PubMed]

- Pronk, M.; De Kreuk, M.K.; De Bruin, B.; Kamminga, P.; Kleerebezem, R.; Van Loosdrecht, M.C. Full scale performance of the aerobic granular sludge process for sewage treatment. Water Res. 2015, 84, 207–217. [Google Scholar] [CrossRef] [PubMed]

- Strubbe, L.; Van Dijk, E.J.H.; Deenekamp, P.J.M.; Van Loosdrecht, M.C.M.; Volcke, E.I.P. Oxygen transfer efficiency in an aerobic granular sludge reactor: Dynamics and influencing factors of alpha. Chem. Eng. J. 2023, 452, 139548. [Google Scholar] [CrossRef]

- Strubbe, L.; Van Dijk, E.J.H.; Carrera, P.; Van Loosdrecht, M.C.M.; Volcke, E.I.P. Impact of oxygen transfer dynamics on the performance of an aerobic granular sludge reactor. Chem. Eng. J. 2024, 482, 148843. [Google Scholar] [CrossRef]

- Thompson, R.L.; Lassaletta, L.; Patra, P.K.; Wilson, C.; Wells, K.C.; Gressent, A.; Koffi, E.N.; Chipperfield, M.P.; Winiwarter, W.; Davidson, E.A. Acceleration of global N2O emissions seen from two decades of atmospheric inversion. Nat. Clim. Chang. 2019, 9, 993–998. [Google Scholar] [CrossRef]

- Thomson, A.J.; Giannopoulos, G.; Pretty, J.; Baggs, E.M.; Richardson, D.J. Biological sources and sinks of nitrous oxide and strategies to mitigate emissions. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2012, 367, 1157–1168. [Google Scholar] [CrossRef]

- Kim, D.J.; Kim, Y. Effect of ammonium concentration on the emission of N(2)O under oxygen-limited autotrophic wastewater nitrification. J. Microbiol. Biotechnol. 2011, 21, 988–994. [Google Scholar] [CrossRef]

- Pan, K.; Guo, T.; Liao, H.; Huang, Z.; Li, J. Nitrous oxide emissions from aerobic granular sludge: A review. J. Clean. Prod. 2024, 434, 139990. [Google Scholar] [CrossRef]

- Tallec, G.; Garnier, J.; Billen, G.; Gousailles, M. Nitrous oxide emissions from denitrifying activated sludge of urban wastewater treatment plants, under anoxia and low oxygenation. Bioresour. Technol. 2008, 99, 2200–2209. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Bao, Z.; Sun, D. Study on emission characteristics and reduction strategy of nitrous oxide during wastewater treatment by different processes. Environ. Sci. Pollut. Res. 2015, 22, 4222–4229. [Google Scholar] [CrossRef] [PubMed]

- Quoc, B.N.; Cavanaugh, S.K.; Hunt, K.A.; Bryson, S.J.; Winkler, M.K.H. Impact of aerobic granular sludge sizes and dissolved oxygen concentration on greenhouse gas N2O emission. Water Res. 2024, 255, 121479. [Google Scholar] [CrossRef]

- Eldyasti, A.; Nakhla, G.; Zhu, J. Influence of biofilm thickness on nitrous oxide (N2O) emissions from denitrifying fluidized bed bioreactors (DFBBRs). J. Biotechnol. 2014, 192, 281–290. [Google Scholar] [CrossRef]

- Tang, P.; Wang, Y.; Li, J.; Chen, G. Multiple-perspective research on the spatial distribution of full-size aerobic granular sludge in wastewater treatment. J. Environ. Chem. Eng. 2022, 10, 107135. [Google Scholar] [CrossRef]

- Van Dijk, E.J.H.; Van Loosdrecht, M.C.M.; Pronk, M. Nitrous oxide emission from full-scale municipal aerobic granular sludge. Water Res. 2021, 198, 117159. [Google Scholar] [CrossRef] [PubMed]

- Kazimierowicz, J.; Debowski, M.; Zielinski, M. Technological, Ecological, and Energy-Economic Aspects of Using Solidified Carbon Dioxide for Aerobic Granular Sludge Pre-Treatment Prior to Anaerobic Digestion. Int. J. Environ. Res. Public Health 2023, 20, 4234. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Debowski, M.; Zielinski, M. Biohythane Production in Hydrogen-Oriented Dark Fermentation of Aerobic Granular Sludge (AGS) Pretreated with Solidified Carbon Dioxide (SCO(2)). Int. J. Mol. Sci. 2023, 24, 4442. [Google Scholar] [CrossRef]

- Chu, Y.; Zhang, X.; Tang, X.; Jiang, L.; He, R. Uncovering anaerobic oxidation of methane and active microorganisms in landfills by using stable isotope probing. Environ. Res. 2025, 271, 121139. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Wang, Q.; Wang, J.; Lei, Z.; Yuan, T.; Zhang, Z.; Lee, D.J. Energy and resource recovery from a future aerobic granular sludge wastewater treatment plant and benefit analysis. Chem. Eng. J. 2024, 487, 150558. [Google Scholar] [CrossRef]

- Dababat, S.; Berzio, S.; Wichern, M.; Lubken, M. Anaerobic digestibility of aerobic granular sludge from continuous flow reactors: The role of granule size distribution. Water Sci. Technol. 2023, 87, 3047–3058. [Google Scholar] [CrossRef]

- Guo, H.; Van Lier, J.B.; De Kreuk, M. Digestibility of waste aerobic granular sludge from a full-scale municipal wastewater treatment system. Water Res. 2020, 173, 115617. [Google Scholar] [CrossRef] [PubMed]

- Ji, B.; Liu, Y. Assessment of microalgal-bacterial granular sludge process for environmentally sustainable municipal wastewater treatment. ACS EST Water 2021, 1, 2459–2469. [Google Scholar] [CrossRef]

- Ji, B.; Zhang, M.; Wang, L.; Wang, S.; Liu, Y. Removal mechanisms of phosphorus in non-aerated microalgal-bacterial granular sludge process. Bioresour. Technol. 2020, 312, 123531. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, Q.; Yang, L.; Wei, W.; Ni, B.J.; Chen, X. Impacts of granular sludge properties on the bioreactor performing nitrate/nitrite-dependent anaerobic methane oxidation/anammox processes. Bioresour. Technol. 2023, 386, 129510. [Google Scholar] [CrossRef]

- Ji, B.; Zhang, M.; Gu, J.; Ma, Y.; Liu, Y. A self-sustaining synergetic microalgal-bacterial granular sludge process towards energy-efficient and environmentally sustainable municipal wastewater treatment. Water Res. 2020, 179, 115884. [Google Scholar] [CrossRef] [PubMed]

- Daudt, G.C.; Xavier, J.A.; Meotti, B.; Guimarães, L.B.; Costa, R.H.D. Researching new ways to reduce N2O emission from a granular sludge sequencing batch reactor treating domestic wastewater under subtropical climate conditions. Braz. J. Chem. Eng. 2019, 36, 209–220. [Google Scholar] [CrossRef]

- Zhang, F.; Li, P.; Chen, M.; Wu, J.; Zhu, N.; Wu, P.; Chiang, P.; Hu, Z. Effect of operational modes on nitrogen removal and nitrous oxide emission in the process of simultaneous nitrification and denitrification. Chem. Eng. J. 2015, 280, 549–557. [Google Scholar] [CrossRef]

- Velho, V.F.; Magnus, B.S.; Daudt, G.C.; Xavier, J.A.; Guimar A Es, L.B.; Costa, R. Effect of COD/N ratio on N2O production during nitrogen removal by aerobic granular sludge. Water Sci. Technol. 2017, 76, 3452–3460. [Google Scholar] [CrossRef]

- Peng, B.; Liang, H.; Wang, S.; Gao, D. Effects of DO on N2O emission during biological nitrogen removal using aerobic granular sludge via shortcut simultaneous nitrification and denitrification. Environ. Technol. 2020, 41, 251–259. [Google Scholar] [CrossRef] [PubMed]

| Factors | Effect on AGS Particle Size |

|---|---|

| DO | DO concentration of 2–6 mg/L helps form larger sludge particles and maintain stability. |

| Temperature | A temperature range of 20 °C to 30 °C effectively promotes larger AGS formation. |

| pH | Keeping the pH in the range of 6.5 to 7.5 helps maintain particle uniformity and moderation. |

| Seed sludge type | Inoculating mature AGS and specific microbial strains accelerates the granulation process. |

| SLR | SBRs readily form large, uniform AGS granules at elevated SLR, while CFRs under identical SLR yield significantly smaller granules. |

| EPS | Increased EPS content promotes sludge particle agglomeration and the formation of larger AGS particles. |

| MLSS and SRT | Higher sludge concentration and a sludge age of 10 to 20 days promote stable AGS formation with larger particle size. |

| Shear force | The lower shear force (0.8–1.2 N/m2) contributes to the formation of AGS and the increase of particle size. |

| Wastewater concentration | At high organic, nitrogen and phosphorus concentrations, SBR-cultivated AGS attains larger particle sizes, whereas under low concentrations, CFR maintains AGS at a moderate, stable size. |

| External additive | The addition of PAC, MMF, and biochar can affect the particle size of AGS. |

| Reactor type | The particle size of AGS cultivated in CFRs is often smaller than that cultured in SBRs. |

| Emerging Contaminants | Granulation Strategy | Removal Efficiency | Relationship Between Particle Size and Pollutant Removal | Removal Method | Reference |

|---|---|---|---|---|---|

| Microplastics | Inoculate aerobic granular sludge and introduce TMPs | SLR = 0.24 kg COD/(kg MLSS·d), TMPs > 52.6%, COD > 80%, NH4+-N > 96%, TP = 60–75%, TMPs > 52.6% | With increasing TMPs, the proportion of small particles (<40 μm) decreased, while the proportion of larger particles (90–355 μm) increased. However, larger granules (>710 μm) nearly disappeared. | Biodegradation, adsorption, and chemical transformation. | [100] |

| Inoculate active sludge and introduce MPs or NPs | SLR = 0.36 kg COD/(kg MLSS·d), MPs = 95%, NPs = 98.9%, COD > 91.3%, PO43−-P = 68.4–73.6% | Exposure to MPs and NPs reduced the AGS particle size to 3.25 mm and 3.02 mm, respectively, impairing TN removal efficiency. | Resisting the stress of microplastics by enhancing EPS secretion and leveraging sludge adsorption. | [103] | |

| Inoculate mature ABGS | SLR = 0.13 kg COD/(kg MLSS·d), MPs > 96%, COD = 90.6–92.1%, TP = 92.8–95.7%, TN = 98.8–99.6% | AGS (0.67 mm) may experience structural disruption due to microplastic attachment and excessive filamentous bacterial growth, impairing pollutant removal efficiency. | Resisting the stress of microplastics by enhancing EPS secretion and leveraging sludge adsorption. | [104] | |

| Persistent Organic Pollutants (POPs) | Internal settling tank | Under an SLR of 0.13 kg COD/(kg MLSS·d), the PFOS removal efficiencies reached 89.23 ± 0.92%, 71.92 ± 1.45%, and 48.15 ± 1.90% at concentrations of 0.1, 0.5, and 5.0 mg/L, respectively. | The average particle size of AGS was 1.3 mm. Smaller particles, due to their larger specific surface area, could provide more adsorption sites, and thus exhibit greater pollutant removal capacity. | AGS are mainly removed by adsorption methods such as electrostatic, hydrophobic and ion bridging. | [105] |

| Endocrine Disruptors Chemicals | Alternating anaerobic and aerobic conditions with SRT of 15 days | SLR = 0.2 kg COD/(kg MLSS·d), COD = 94%, NH4+-N = 96%, PO43 – P = 90%, E2 = 99%, EE2 = 93% | Smaller granules enhance rapid adsorption and degradation due to higher mass transfer efficiency, while larger ones provide stronger adsorption but slower degradation. | Biodegradation, adsorption, and the role of microbial communities. | [106] |

| Endocrine Disruptors Chemicals | Inoculate high-salt-adapted sludge | SLR = 0.22 kg COD/(kg MLSS·d), E2 = 100%, EE2 = 47%, BPA = 95% | Intermediate-sized granules (0.32–0.52 mm) achieve higher adsorption and degradation efficiencies, leading to more effective pollutant removal. | Biodegradation, adsorption, and the role of microbial communities. | [107] |

| Antibiotics | Internal settling tank | Under an SLR of 0.114 kg COD/(kg MLSS·d), the removal rate of COD decreased to 82.42% and the removal rate of SMX decreased. The coexistence of PS and SMX reduces the wastewater treatment performance of SBR. | The coexistence of PS and SMX gradually reduces the particle size (from 1.86 to 1.43 mm), reduces the sedimentation, and reduces the removal efficiency of pollutants. | The AGS system responds to adverse environments by increasing the secretion of EPS. | [108] |

| Submersible MFCS are coupled to AGS. | SLR = 0.24 kg COD/(kg MLSS·d), COD = 92.1%, CIP (average removal efficiency) = 83.2% | AGS of 1.5–2 mm was conducive to the enrichment of antibiotic resistance genes and the removal rate of CIP was effectively improved. | The continuous electrical stimulation promotes microbial activity and secretes more EPS to resist CIP stress. | [109] |

| Reactor Type | Working Volume | Granular Size | Granulation Strategy | Treatment Performances | Relationship Between Particle Size and Stability | Reference |

|---|---|---|---|---|---|---|

| SBR | 3 L | D(average) = 0.404–0.52 mm (90 days) | The activated sludge with EBPR activity is added and the precipitation selective pressure is applied | Under a sludge loading rate of 0.3 kg COD/(kg MLSS·d), PO43−-P stabilized below 0.5 mg/L while TN removal efficiency reached 71.7 ± 0.4%. | The small size (0.404-0.52 mm) and compact structure of AGS is conducive to improving particle stability and simultaneous nitrification and denitrification efficiency. | [101] |

| SBR | 5 L | D = 0.7–2.8 mm | Internal settling tank | Under an SLR of 0.413-0.484 kg COD/(kg MLSS·d), the TN removal efficiency (83.57 ± 4.38%) and SND removal efficiency (87.17 ± 3.04%) were the highest in 87.51% of the particles. | The AGS particle size range of 1.8–3 mm is the best particle size, which is conducive to structural stability and synchronous nitrification and denitrification rate. | [112] |

| MBR | D(average) = 0.8 mm (125 days) | Addition of biological carrier and multi-ion matrices | COD removal efficiency is high and stable, and the TN removal efficiency fluctuates greatly. | When the particle size of AGS was about 0.8 mm, the granular sludge remained stable without excessive expansion. | [124] | |

| SBR | 10 L | D = 0.7–1.9 mm | Novel funnel-shaped internals | Under an SRT of 0.38 kg COD/(kg MLSS·d), the removal efficiency of COD is 95.8 ± 3.7%, the removal efficiencies of NH4+-N and TN are 98.1 ± 0.9% and 81.6 ± 2.1%, respectively. | The optimal stability of AGS is found within the particle size range of 0.7 mm to 1.9 mm, with the highest nitrogen removal efficiency observed at a diameter of 1.3 mm. | [126] |

| CAGR | 24.2 L | D(average) = 1.8 mm (65 days) | Different selection pressures are generated by adjusting the depth of the movable baffle | At 67 days, under an SRT of 0.8 kg COD/(kg MLSS·d), the removal efficiencies of COD, TIN and TP are 93.3%, 86.7% and 90%, respectively. | The size range of 1-1.43 mm is conducive to the stability of the AGS, and the large particles (d > 1.43 mm) are easy to destabilize. | [130] |

| SBR | 125 L | D = 2–3 mm | Size selection pressure and the control of SRT | Under an SRT of 0.36 kg COD/(kg MLSS·d), effluent COD and TP concentrations are below 70 mg/L and 0.7 mg/L, respectively. Effluent TN concentration is between 30–40 mg/L. | The stability of the particle size range of 2–3 mm AGS is the best. | [131] |

| SBR | 5 L | D = 0.164–1.55 mm | Inoculate mature aerobic granular sludge | Under an SLR of 0.114 kg COD/(kg MLSS·d), the removal efficiencies of TN and TP were 86% and 30%, respectively. | When the particle size is in balance with the critical size, it is beneficial to the stability of AGS structure. | [132] |

| SBR | 3.3 L | D(average) = 0.725 mm | Internal settling tank | Under a sludge loading rate of 0.625 kg COD/(kg MLSS·d), the system demonstrated removal efficiencies of 86% for COD and 30% for TN, with the effluent COD concentration stabilized at 18.9 ± 6.6 mg/L. | When the size of AGS ranges from 0.4–0.8 mm, the density and hydrophobicity of AGS particles are high and stable. | [133] |

| EBPR anaerobic/aerobic granular sludge reactor | First phase = 11.1 L Second phase = 6 L | D = 0.3 mm (100 days) | Dynamic control of anaerobic and aerobic | Under an SLR of 0.4 kg COD/(kg MLSS·d), the effluent COD and PO4-P concentrations averaged 58 ± 27 mg/L and 0.53 ± 0.77 mg/L, respectively, while TN remained between 30–40 mg/L. | Medium aerobic granular sludge is beneficial to inhibit filamentous bacteria and accumulate slow-growing microorganisms, and increase structural stability. | [134] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Xu, D.; Li, J.; Guo, T.; Li, Z.; Yan, A.; Wu, S.; Gu, C. Unveiling the Secrets of Particle Size in Aerobic Granules: Impacts on Emerging Contaminants Removal, Stability, and Sustainability: A Review. Water 2025, 17, 2503. https://doi.org/10.3390/w17172503

Wu S, Xu D, Li J, Guo T, Li Z, Yan A, Wu S, Gu C. Unveiling the Secrets of Particle Size in Aerobic Granules: Impacts on Emerging Contaminants Removal, Stability, and Sustainability: A Review. Water. 2025; 17(17):2503. https://doi.org/10.3390/w17172503

Chicago/Turabian StyleWu, Shuangxia, Dong Xu, Jun Li, Tao Guo, Zhaoxian Li, Ailan Yan, Shuyun Wu, and Chaoguang Gu. 2025. "Unveiling the Secrets of Particle Size in Aerobic Granules: Impacts on Emerging Contaminants Removal, Stability, and Sustainability: A Review" Water 17, no. 17: 2503. https://doi.org/10.3390/w17172503

APA StyleWu, S., Xu, D., Li, J., Guo, T., Li, Z., Yan, A., Wu, S., & Gu, C. (2025). Unveiling the Secrets of Particle Size in Aerobic Granules: Impacts on Emerging Contaminants Removal, Stability, and Sustainability: A Review. Water, 17(17), 2503. https://doi.org/10.3390/w17172503