Abstract

The heat exchanger in a hydropower unit plays a critical role in ensuring the stability of the unit and improving operational efficiency. This paper conducted a global flow-field/heat-transfer numerical analysis of multi-tube heat exchangers in hydropower units (with 98 tubes) and applied it to optimization research under actual operating conditions. Using a three-dimensional two-phase flow model, this work systematically analyzes the effects of different sand content and particle size on heat-transfer performance, revealing the impact of particle-flow and fluid-flow nonuniformity on heat-exchange efficiency. This research fills the gap in existing studies regarding the analysis of the impact of complex operating conditions on hydropower unit radiators. To address the issues of nonuniform flow fields and poor flow mixing in existing heat exchangers, an improved inlet/outlet structural-optimization plan is proposed. The original cylindrical inlet/outlet is replaced with a square structure, and its area is increased. The optimized structure improves flow uniformity, reduces flow losses, enhances heat-transfer performance by 7.7%, and achieves a significant reduction of 0.53 K in oil temperature. The findings of this study provide theoretical and engineering guidance for the design and optimization of heat exchangers in hydropower units and are of high value for practical applications.

1. Introduction

Heat exchangers are critical components of hydrogenerator sets [1,2], serving a fundamental role in controlling operating temperatures and ensuring the safe, stable, and efficient performance of the entire power-generation system. Effective heat dissipation is essential for sustaining generator reliability, particularly under conditions of high load or extended operation. In practical power plant operations, the cooling medium—most commonly water—often contains varying amounts of sand and suspended particulate matter, which can significantly impact both the thermal performance and the operational lifespan of the exchanger [3]. As the demand for greater energy efficiency and longer equipment service life continues to grow, the advanced design and optimization of heat exchangers in hydrogenerator applications have become pressing priorities for both researchers and industry practitioners [4].

The structural design of heat exchangers has a profound impact on their thermal performance and operational reliability. Conventional configurations, such as shell-and-tube [5], plate [6], and multipipe [7] heat exchangers, exhibit distinct advantages depending on the specific application requirements. Key design features, including tube-bundle arrangement [8], flow-channel geometry [9], and the configuration of inlet and outlet domains [10], play crucial roles in determining flow distribution and heat-transfer efficiency. In recent years, considerable research efforts have been directed toward structural optimization to further enhance exchanger performance. Strategies such as optimizing tube layouts, modifying baffle or partition arrangements, and improving inlet/outlet geometry have been widely explored [11,12,13,14]. Additionally, the introduction of advanced designs such as helical coils [15], finned surfaces [16], and turbulence promoters [17] has demonstrated significant potential for improving heat transfer rates and mitigating flow maldistribution in various engineering contexts.

A variety of methods, including experiments, theoretical analysis, and numerical simulation, have been employed to study flow and heat transfer in the heat exchangers. Among these, computational fluid dynamics (CFD) has become especially valuable, as it enables detailed analysis of complex flow and temperature fields and supports the optimization of exchanger designs under diverse operating conditions [18]. Wang et al. [19] conducted numerical simulations on the semi-annular cooler of a hydrogenerator guide bearing and proposed an optimization scheme that resulted in a maximum increase of 73.8% in heat-transfer capacity for the optimized cooler. Shi et al. [20] numerically investigated the thermo-hydrodynamic characteristics of the upper guide bearing in a 1000 MW large-scale hydrogenerator and indicated that installation deviations may result in abnormal heat transfer. Georgescu et al. [21] developed a cooling water system model for a 115 MW hydrogenerator. They also carried out simulation studies on the performance of oil–water heat exchangers used for the heavy thrust bearing, the turbine, and the generator guide bearing. Muhsen et al. [22] numerically analyzed a fractal-fin counterflow heat exchanger for hydropower generators and found that the fractal geometry significantly reduced pressure drop, improved temperature uniformity, and enhanced overall cooling performance compared to conventional designs. Kahraman et al. [23] conducted a numerical study on an exchanger system with additional plates to enhance the performance of the thrust bearing oil cooling system in a hydropower plant. Doost et al. [24] numerically investigated the effects of cooling water temperature and flow rate on heat-exchanger performance. They found that when the temperature of the cooling water is below 20 °C, the radiator maintains sufficient performance.

Despite the increasing application of numerical simulation techniques to the study of coolers in hydroelectric power plants, the unique operational environment of these systems presents additional challenges not typically encountered in conventional industrial exchangers. Heat exchangers in hydropower plants, especially bearing coolers, differ significantly from those used in other industries. They operate with cooling water drawn directly from reservoirs or rivers, which often contains sand, gravel, and suspended solids, causing fouling, erosion, and blockages [25,26]. Drawer-type designs are typically adopted to improve cooling efficiency and mitigate sediment effects, but they must ensure reliability and maintain heat-transfer performance over long maintenance cycles. These unique operational challenges distinguish hydropower heat exchangers from other heat exchangers and form the basis for the novelty of the present study. As a result of these operational challenges, there is a growing need for research that not only employs advanced simulation methods, but also accounts for the coupled effects of sand content, particle size, and dynamic operational scenarios. Such studies are essential for improving the reliability and efficiency of cooling systems in hydropower applications.

Multiturn piping heat exchangers are widely used in industrial cooling systems due to their compact structure and high heat-transfer efficiency. However, the complex flow characteristics within these systems, especially when they are used with the sediment-laden cooling water typical of hydropower applications, significantly affect heat-transfer performance. Sediment contamination and suboptimal pipe-inlet structures can create flow disturbances and maldistribution, leading to increased hydraulic losses and reduced heat-exchanger efficiency.

Although many studies have investigated pipe-geometry optimization and turbulence effects, the specific impact of sediment and inlet structure on heat-transfer performance in large-scale multipipe heat exchangers remains underexplored. This study addresses this gap by systematically analyzing the heat-transfer characteristics of a drawer-type heat exchanger comprising 98 individual piping channels under varying operating conditions.

This work focuses on revealing how sediment presence and inlet design influence heat-transfer efficiency and proposes a targeted optimization strategy for pipe inlet structures. Unlike conventional approaches that predominantly emphasize modifications to pipe shape, this targeted approach aims to effectively enhance heat-transfer performance in the sediment-affected environments typical of hydropower cooling systems.

The remainder of this article is organized as follows: Section 1 introduces the numerical models and assumptions used in this study, with fluid models, boundary conditions, and methods for obtaining numerical solutions described in detail. In Section 2, the numerical simulation results are presented, focusing on the variations in flow distribution, velocity nonuniformity coefficient, and heat-transfer coefficients across the multipipe system. Section 3 proposes an optimization scheme, compares the performance of the original and optimized designs, and demonstrates the significant improvements in heat-transfer efficiency, oil-temperature reduction, and flow uniformity achieved through the optimization. Finally, Section 4 summarizes the main contributions of this study and discusses potential directions for future research.

2. Heat-Exchanger Modeling and Condition Confirmation

2.1. Heat-Transfer Equation

The heat exchanger is placed in the oil tank of the water-guide bearing in the hydrogenerator, and the water flows through the multiturn piping of the heat exchanger, thus carrying away the heat that is transferred from the lubricating oil to the pipe wall [27]. The water flow in the pipeline still follows the continuity equation, the Navier–Stokes equation, and the energy equation [28,29,30], which are respectively expressed as follows:

where represents the specific heat capacity of water, T and k are the temperature and heat-transfer coefficient of the water stream, respectively, and represents the internal heat source. For the simulations in this work, water is considered an incompressible fluid. Therefore, the continuity equation shown in Equation (1) neglects the time derivative of density, as is appropriate for incompressible flow conditions.

In developing the present numerical model, several physical assumptions and simplifications were adopted to reflect the typical operating conditions of the heat exchanger while ensuring computational efficiency and clarity. Specifically, the fluid is modeled as incompressible and Newtonian, with all relevant physical properties (including density, viscosity, thermal conductivity, and specific heat) treated as constants evaluated at the mean operating temperature. The influences of radiation and phase change are not considered in this analysis. For cases in which the Reynolds number exceeds the laminar–turbulent transition threshold, the standard k- turbulence model is utilized to account for turbulent effects. The turbulence characteristics of the coolant flow are modeled using the standard turbulence model, which solves transport equations for the turbulent kinetic energy k and its dissipation rate . The k- model is widely used in similar studies and has been proven to provide reliable results under various flow conditions, including those in the heat exchangers. The advantage of the k- model lies in its high computational efficiency, which makes it suitable for most industrial flow scenarios, particularly in cases with high turbulence intensity, where it can effectively simulate flow characteristics. The governing equations are as follows:

where is the turbulent viscosity, is the generation of turbulence kinetic energy due to mean velocity gradients, and , , , and are empirical constants. The model effectively captures the turbulence effects under the studied operating conditions. It is worth noting that, compared to other turbulence models (such as the k- model or the Reynolds Stress Model), the main advantage of the k- model lies in its good stability and computational efficiency. Particularly in complex flow scenarios, the k- model has a lower computational cost for most engineering applications and is capable of accurately predicting the overall characteristics of most industrial fluid flows.

The boundary conditions are set in accordance with the practical application scenario, where the pipe inlet is defined as a velocity (or pressure) inlet with a uniform temperature profile. The outlet is assigned a constant pressure (hydrostatic) boundary, and no-slip conditions are applied at all solid walls. Either constant temperature or adiabatic (insulated) boundaries are imposed as appropriate.

The flow within heat-exchanger piping is a two-phase flow doped with solid particles, and this flow is considered as particle transport, where the particles are tracked in a Lagrangian fashion [31]. Particle tracking is performed by formulating a set of ordinary differential equations in time for each particle, including equations for the particle’s position, velocity, temperature, and mass. The motion equation utilizes the forward Eulerian integration of particle velocity over each time step to calculate the particle’s displacement and is written as follows:

Therefore, the particle displacement can be calculated as follows:

where , , and are the drag, buoyancy, and centripetal forces on the particles, while , and are the virtual mass force, pressure gradient force, and Bassett force, respectively. In Equation (6), the gravitational force acting on the particles was neglected. Under the present operating conditions, the characteristic flow velocity and pipe dimensions yield a particle settling time much longer than the fluid residence time in the heat exchanger. Consequently, the influence of gravity on particle transport and the overall flow field is negligible. For cases involving larger or heavier particles, or under low-velocity conditions, it would be appropriate to include the gravitational term.

Moreover, the temperature change is controlled by convective heat transfer, latent heat transfer, and radiative heat transfer. The form of heat transfer is mainly interphase heat transfer during particle transport, so only convective heat transfer [32] is considered, and the heat transfer can be given by the following equation:

where is the thermal conductivity of the fluid, and are the temperatures of the fluid and the particles, and represents the Nusselt number.

Based on the heat-transfer equation shown in Equation (7), the heat exchange between the fluid and the solid walls is modeled using the standard convective heat-transfer equation, expressed as follows:

where h is the local heat-transfer coefficient, is the heat transfer surface area, is the temperature of the solid wall, and is the temperature of the fluid. This equation captures the convective heat transfer at the solid-liquid interface, which is essential for simulating the overall heat transfer process in the heat exchanger.

The velocity nonuniform coefficient for a given cross-section is defined as follows:

where is the local velocity in the pipe (or location), is the mean velocity over all N pipes (or sampling points), and N is the total number of sampling locations at the cross-section. A smaller indicates a more uniform velocity distribution.

Furthermore, the local heat-transfer coefficient [33] for each pipe is calculated based on the classical definition, as follows:

where q is the rate of heat transfer between the oil and the water within a pipe section, A is the heat-transfer surface area, and is the temperature difference between the pipe wall and the bulk fluid (typically taken as the average of inlet and outlet temperatures for the corresponding section). In the numerical simulations, q is determined from the local energy balance, and is computed based on simulated temperature fields. The heat-transfer coefficient for each pipe is then obtained by applying Equation (10) to the relevant segment.

The local heat flux q at the fluid–wall interface is obtained by integrating the convective heat transfer over the wall surface

where h is the local heat-transfer coefficient, and are the wall and fluid temperatures, respectively, and A is the interface area. These values are extracted directly from the CFD solution field.

Moreover, the local heat-transfer coefficient h can be further calculated based on the local Nusselt number, as follows:

where is the local Nusselt number obtained from the CFD results, is the thermal conductivity of the cooling water, and D is the inner diameter of the heat-exchanger tube. The Nusselt number is determined using the simulated local convective heat flux, and the temperature difference is given by the following equation:

2.2. Heat Exchanger Modeling and Meshing

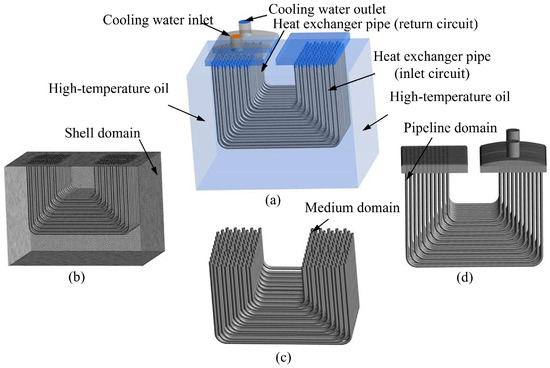

A large amount of heat is generated during the operation of hydrogenerator sets due to the friction between the rotating shaft and supporting bearings; heat exchangers are able to effectively reduce the rising temperatures triggered by this heat. The studied drawer-type heat exchanger is installed at the guide bearing of hydroelectric generator set. It mainly consists of 49 inlet pipes and 49 return pipes made of copper, with all of the heat-exchanger tubes immersed in the high-temperature oil. The low-temperature water flows into the 49 inlet pipes and continuously absorbs the heat from the high-temperature oil, then reaches the return chamber. The water is forced to flow into the 49 return pipes and finally exits from the outlet of the return pipes. In order to facilitate the numerical calculation, the calculation model is set up as a three-dimensional structure, as shown in Figure 1a; this structure consists of shell, pipeline, and medium domains, of which the shell domain is the high-temperature oil, the pipeline domain is the 98 heat-exchanger tubes, and the medium domain is the low-temperature water.

Figure 1.

(a) Heat-exchanger geometry model, (b) shell domain, (c) medium domain, and (d) pipeline domain.

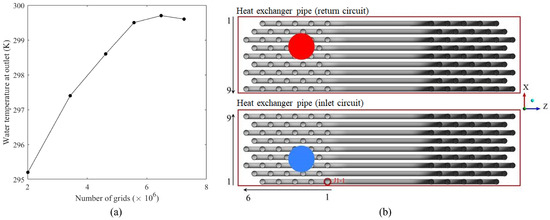

Next, the meshing is carried out for the shell, medium, and pipeline domains, as shown in Figure 1b–d, respectively. The mesh-independence verification of the numerical calculations is carried out for the case of 0.16 MPa inlet pressure, and the results are shown in Figure 2a. With the increase in grid numbers, the water temperature of the heat exchanger at the outlet the outlet water temperature of the heat exchanger gradually rises and stabilizes when the grid number reaches 5.57 × . Therefore, a grid number of 5.57 × is selected for the subsequent calculations to balance the accuracy and efficiency of calculations. In this setup, a hexahedral structured mesh is used for the shell and medium domains to obtain higher computational accuracy. A mesh refinement method is applied near the pipeline domain with 14 refined mesh layers, with minimum and maximum mesh sizes of 0.1 mm and 0.5 mm, respectively. The shell region has a complex structure, so a tetrahedral unstructured mesh is used with a fixed mesh size of 0.4 mm. The meshing and grid number of each region are shown in Table 1. The mesh number of the whole computational domain is about 5.57 × , and the mesh quality is larger than 0.67, which ensures the accuracy of computation.

Figure 2.

(a) Mesh-independent validation results. (b) Numbering of 98 pipes for the heat exchanger.

Table 1.

Three computational-domain grid schemes.

All numerical simulations in this study were performed using ANSYS FLUENT, 15.0 a commercial finite-volume-based computational fluid dynamics solver. The governing equations were discretized using a second-order upwind scheme for the convection terms and a central difference scheme for diffusion terms. The pressure–velocity coupling was resolved using the SIMPLE algorithm. For all transient simulations, a fixed time step of s was employed to ensure numerical stability and accuracy. The calculations were continued until the results reached a statistically steady state, and the residuals for all primary variables were set to be less than as the convergence criterion.

Moreover, to simulate 8 h of physical time for the erosion validation case, the computation required approximately 96 h of wall-clock time using 24 CPU cores in parallel. The actual computational cost depended on the solution convergence at each step and the output frequency. Simulations were performed on a workstation equipped with an Intel Xeon Gold 6330 CPU (2.5 GHz) and 128 GB RAM (Intel, Santa Clara, CA, USA).

Numerical simulation of the internal flow in each computational domain of the heat exchanger is carried out. The shell domain is a single-phase fluid domain with an oil temperature of 313.15 K. The pipeline inlet is specified as a full-pressure boundary with a fixed water temperature of 293.15 K, and the outlet is set as a hydrostatic boundary. Flow velocity in the pipe is controlled by varying the inlet full pressure . Changing the operating conditions allows the effects of flow speed , sand content and sand particle size on the performance of 98 pipes in the heat exchanger to be investigated. The enthalpy model is utilized in calculations to consider heat transfer, which is carried out by interfaces between different domains. Table 2 shows the boundary conditions for eight conditions. The selection of case conditions, including sand content, particle size, and inlet pressure, was based on typical operational data and field measurements collected from hydrogenerator stations in service, as well as relevant engineering standards. The values chosen are representative of the range encountered during routine maintenance and operation of heat exchangers in hydropower plants. For example, the sand content and particle size intervals correspond to those observed in water samples taken from multiple generator cooling systems under different working environments. Inlet pressures were selected to match both standard design specifications and the actual operating range observed in practice.

Table 2.

Numerical calculation conditions.

In this study, the characteristic inner diameter of each heat-exchanger pipe is 20 mm, as used in the numerical model. According to the boundary conditions listed in Table 2, the typical inlet velocities of the cooling water range from 2 m/s to 8 m/s depending on the inlet pressure. For example, under the standard experimental condition (inlet pressure 0.16 MPa), the calculated average velocity in the pipe is about 3.5 m/s. Moreover, For a typical velocity of 3.5 m/s and D = 20 mm, the Reynolds number is approximately 70,000, indicating that the flow regime is turbulent under all practical conditions. Therefore, in all simulations, the standard k- turbulence model is adopted to accurately capture the main flow and heat-transfer characteristics in the exchanger pipes.

Additionally, each pipe is named to facilitate comparison of the characteristics such as heat-transfer performance, pressure drop, and pipe-wall failure. As shown in Figure 2b, J and H are used to differentiate between the inlet and return circuits. Pipes are given labels 1 to 6 from inside to outside, and for the water inlet loop, numbers 1 to 9 are given along the X-positive direction, while the return piping is numbered 1 to 9 along the negative X-direction. E.g., J1-1 denotes the inlet loop piping labeled, with the first digit denoting X-axis number, and the last digit indicating Z-axis number.

In order to verify the accuracy of numerical calculations, an experimental study was carried out at water flow rate of 8 m/s, sand content of 1% and sand particle size of 0.85 mm, the results are presented in reference [34]. Further, numerical simulations of such experimental conditions were carried out to collect the erosion rate (i.e., mass lost per unit area) of the heat exchanger due to sediment erosion at different moments, and it is worth noting that, for consistency with the experiments performed in study [34], only the inlet right-angled “L” section of a pipe with the shortest measured length in the heat exchanger is considered when the mass lost is counted. During the simulations, the particles in the water flow cause erosion on the surface of the pipes is assumed. The erosion rate is calculated using a particle tracking model, where each particle’s movement is tracked in a Lagrangian manner, and the equation for particle motion is as follows:

where is the particle velocity. The erosion rate is calculated by integrating the impact of each particle with the pipe surface over time. The mass loss is then computed using the following equation:

where is mass loss, is erosion rate and A represents pipe surface area. The erosion rate is influenced by factors such as follows: sand content, particle size, and flow velocity. In our simulations, we account for the effects of different sand contents and particle sizes on the erosion of heat-exchanger surfaces. Specifically, is computed using an empirical impact-based model within the ANSYS Fluent discrete phase model (DPM), supported by user-defined functions (UDFs), The erosion rate is calculated as follows:

where C is an empirical constant, is the particle mass, is the impact velocity, and is the impact angle. The exponents and are determined based on referenced experimental studies (see Ref. [34]). This approach allows quantifying the local wall material loss due to particle-laden flows. In this study, the parameter values used are , , (impact angle) obtained from CFD particle tracking for each collision event, and (SI units). Parameters , , and C were calibrated using the experimental data set in [34], which investigated the erosion of the elbow pipe under similar sediment-laden flow conditions. While this calibration is not an independent validation, it is still valuable, as it demonstrates the self-consistency of the erosion model and indicates that the calibrated parameters enable the simulation to accurately reproduce the physical erosion trends observed in controlled experiments, thereby increasing confidence in the model’s predictive capability under similar operating conditions.

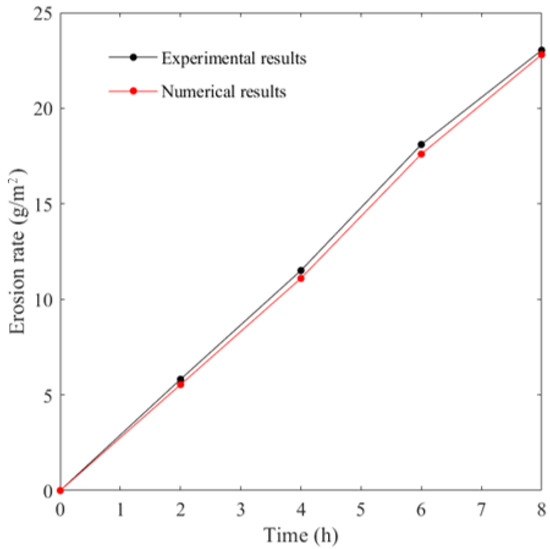

A comparison of the experimental results with numerical simulation results is shown in Figure 3, where the erosion rate obtained from the experimental and numerical simulations gradually increases with increasing time, and the growth curves of the two are almost consistent, which proves the accuracy of numerical simulation. Notably, although the results obtained by numerical simulation tend to be approaching the experimental values, but has been slightly lower than the experimental results, which may be attributed to that the experimental heat exchanger medium contains other chemical ions, whose corrosion caused to a certain extent exacerbates the scouring behavior of the heat exchanger. It should be noted that, in addition to erosion rate, other validation indicators such as pressure drop and heat-transfer performance are also important for comprehensively assessing the reliability of the numerical model. However, due to the lack of corresponding experimental measurements under the current operating conditions, these aspects could not be validated in this study. Further experimental work will be carried out in the future to obtain relevant data, so as to provide a more complete and rigorous validation of the model.

Figure 3.

Comparison of erosion rates obtained from experiments and numerical simulations when water flow rate is 8 m/s, sand content is 1% and sand particle size is 0.85 mm.

Furthermore, the calculated temperature drops for both oil and water are subject to modeling inaccuracies stemming from factors such as mesh resolution, boundary condition assumptions, uncertainties in physical property values, and turbulence model selection. A preliminary uncertainty analysis was conducted by comparing simulation results across different mesh densities in Figure 2a and by varying selected input parameters. The maximum deviation in predicted temperature drops due to mesh refinement was found to be less than 2%, which indicates that the modeling error associated with grid resolution is relatively minor. Although boundary conditions and physical properties were specified according to standard reference values, minor discrepancies under actual operating conditions may further influence the results.

3. Heat-Exchanger Performance and Flow Analysis

3.1. Flow Speed in Shell Process

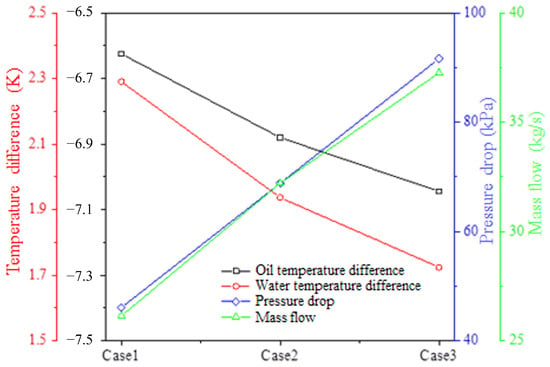

The variable for Cases 1, 2 and 3 is the total pressure and increased water pressure enhances flow speed. Figure 4 shows the temperature difference of oil, water and pressure drop of shell process. As the differential pressure increases, the shell flow rate and pressure drop increase. Furthermore, the growth ratio of flow rate decreases with higher differential pressure. Moreover, the increase of flow rate makes oil temperature difference grow gradually, while water temperature difference decreases progressively. This is because a higher flow rate increases the instantaneous temperature difference between the oil and water, which enhances the convective heat-transfer capacity.

Figure 4.

The effect of flow speed on heat-transfer performance and shell pressure drop.

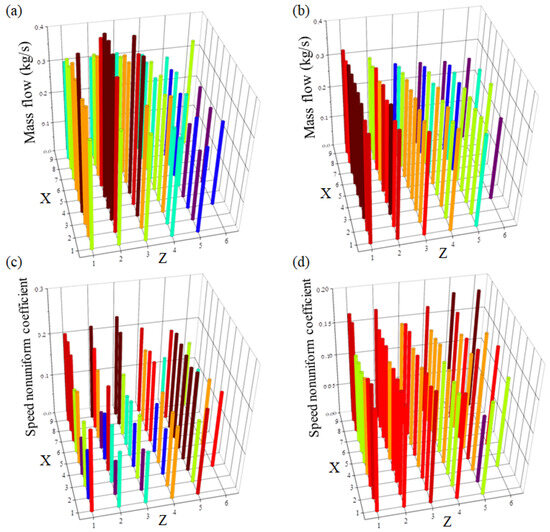

Further, Case 1 is used as an example to explore the flow distribution in 98 pipelines, as shown in Figure 5a,b. For inlet circuit, the pipes for larger inlet flows are J3-2 and J3-3, which are closer to the cooling water inlet. The flow rates for other pipes essentially decrease with increasing distance from the inlet. For inlet circuit, the pipes for larger inlet flows are J3-2 and J3-3, which are closer to cooling water inlet. The flow rates for other pipes essentially decrease with increasing distance from the inlet. Compared to inlet circuit, the inlet flow distribution of outlet circuit is a little more average. However, they are still characterized by uneven flow distribution at each location of each pipeline and medium section. Therefore, the velocity nonhomogeneity coefficient is introduced to determine the flow doping in the pipeline, as shown in Figure 5c,d. For inlet circuit, the speed nonuniform coefficients are smaller for pipes close to coolant inlet location. Whereas, in the region away from coolant inlet, the water flow needs to undergo a series of unsteady flow such as impacting the wall, doping, etc. before entering the pipeline, which leads to a larger speed nonuniform coefficient. At the same flow conditions, the increase in speed nonuniform coefficient leads to more flow losses. For return circuit, the speed nonuniform coefficient is significantly reduced compared to the inlet circuit, which is resulted from the relatively even flow distribution and secondary mixing.

Figure 5.

Distribution of flow in each (a) inlet and (b) return circuit, and distribution of nonhomogeneity coefficients in the inlet section of each (c) inlet and (d) return circuit under Case 1.

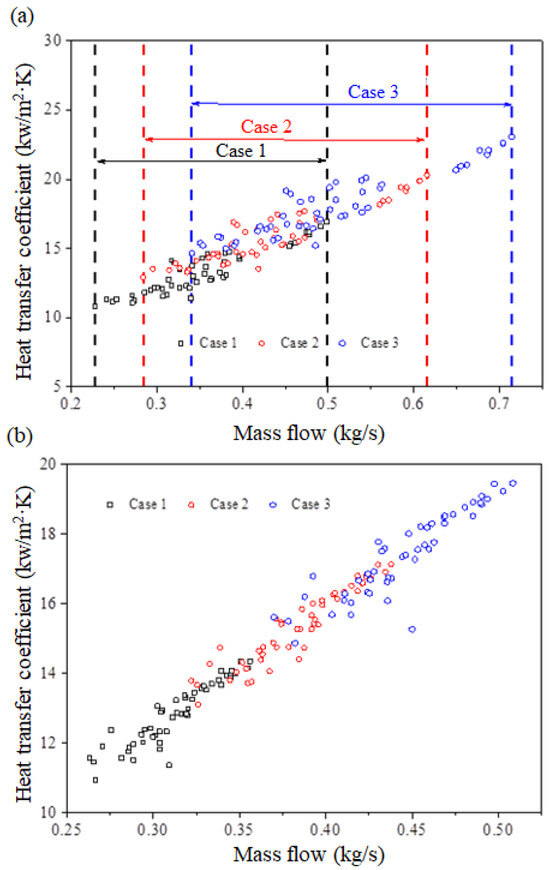

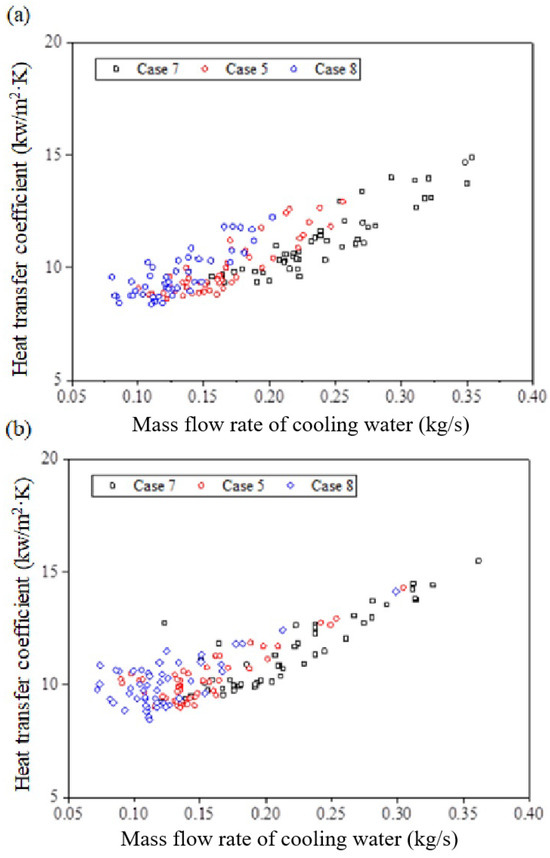

The flow rate distribution affects the heat-transfer coefficient, so Figure 6 establishes the correlation between flow rate and heat-transfer coefficient for 98 pipes. The heat-transfer coefficient tends to have a increase proportionally with mass flow rate because the flow rate in the pipeline increases when flow rate increases, and it is usually considered that the increasing Reynolds number will enhance convective heat transfer. Moreover, the heat-transfer coefficient of inlet circuit is slightly larger than that of return circuit, which might be attributed to the unsteady flow in inlet circuit and the increase in turbulent kinetic energy, which increases the convective heat transfer; the heat-transfer coefficient increases accordingly.

Figure 6.

Correspondence between the flow rate and heat-transfer coefficient of each pipe in the (a) inlet circuit and (b) return circuit.

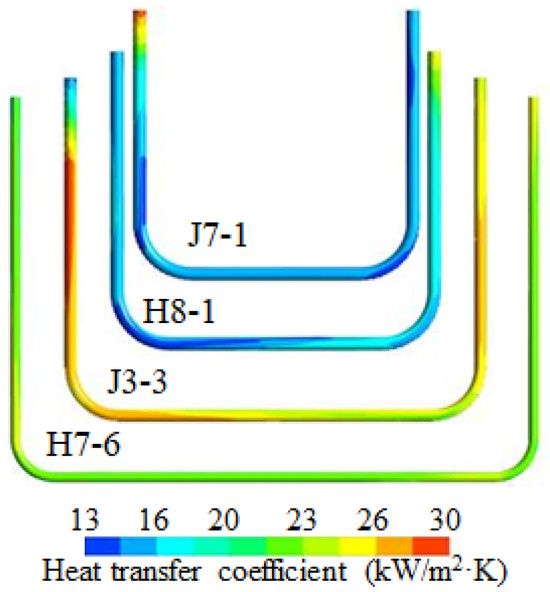

The distributions of the heat-transfer coefficients of four pipes J7-1, H8-1, J3-3 and H7-6 are plotted by selecting Case 2, as shown in Figure 6. The heat-transfer coefficients are calculated based on the equation in Equation (10). However, the heat-transfer coefficient presented in Figure 6 is for the entire length of the pipe, and it is calculated using the average temperature difference () over the length of the pipe segment, rather than the local temperature difference at each point. This simplification is used because integrating local temperature differences along the pipe length would introduce significant computational complexity and may not offer substantial improvement in the overall analysis of heat-transfer performance. Using the average temperature difference provides a more practical and efficient way to assess the heat-transfer performance of the entire segment, especially in scenarios where detailed local temperature profiles are challenging to obtain or are not the focus of the analysis. The heat-transfer coefficients of H7-6 are uniformly distributed overall, but the heat-transfer coefficients are the smallest. The larger heat-transfer areas of J7-1 and H8-1 are obtained from the pipe inlet, which is attributed to the instability of inlet flow; these areas enhance convective heat transfer. J3-3 is near the coolant inlet and has a higher flow rate. The inlet heat-transfer coefficient of this heat-exchanger pipe is the smallest, reaches its maximum in the downstream region, and then becomes more uniform along the downstream flow. It is worth noting that according to Figure 6, pipes with higher mass flow rates generally exhibit higher heat-transfer coefficients. For J3-3, the heat-transfer coefficient at the inlet is slightly lower than the downstream value, likely due to local flow development effects or temperature gradients near the entrance. However, its overall heat-transfer coefficient is among the highest in the system because of its higher flow rate. Moreover, the high temperature observed at the end of pipe J7-1, as shown in Figure 7, is mainly attributed to nonuniform flow and local stagnation effects, which limit the cooling capacity at this position.

Figure 7.

Contour of heat-transfer coefficient distribution for four pipes of J7-1, H8-1, J3-3, and H7-6 under Case 2.

It should be noted that although increasing the flow rate significantly improves the heat-exchange efficiency, it also leads to a greater energy demand because of the enhanced flow resistance in the system, which must then be overcome. While heat-transfer performance improves, the pressure drop across the heat exchanger and, consequently, the required pumping power also increase. This trade-off between heat-transfer enhancement and energy consumption should be considered in the actual engineering application.

3.2. Sand Content in Shell Process

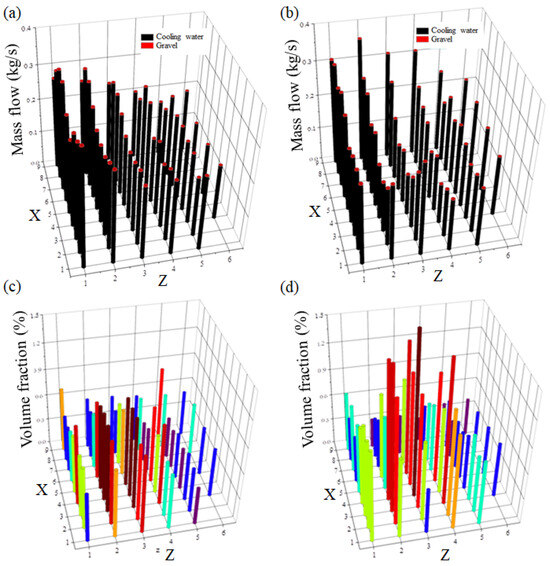

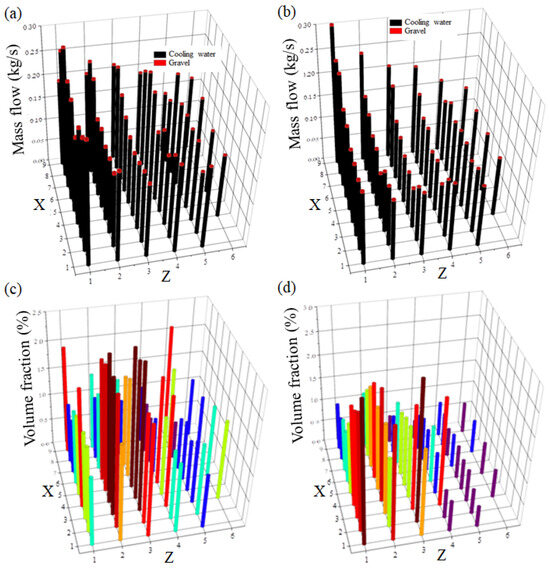

Similarly, Cases 5, 7, and 8 are selected to study heat-exchanger performance and flow field for three levels of sand content for comparative analysis. Distributions of mass flow rate of gravel and water within each pipe are plotted for Case 7, as shown in Figure 8a,b. The presence of gravel leads to a decrease in the mass flow rate of cooling water in the pipe process and an overall decrease in cooling water at the pipe inlet. The gravel mass flow rate at the pipe inlet increases as the volume fraction of gravel increases. Additionally, the presence of gravel causes a significant increase in mass flow rate of pipe 9 in X-direction, and the cooling water is drained to surrounding pipes. From the distribution of gravel volume fraction, as shown in Figure 8c,d, it can be seen that the gravel is mainly concentrated along the X-direction of pipes 2∼5 and the Z-direction of pipes 2∼4. As the gravel volume fraction at the pipe entrance increases, this centralization tendency becomes more pronounced.

Figure 8.

Distribution of flow in each (a) inlet and (b) return circuit and distribution of gravel volume fraction in the inlet section of each (c) inlet and (d) return circuit under Case 7.

Figure 9 shows the distribution of the relationship between cooling-water flow rate and the average heat-transfer coefficient of the heat exchanger for a sand particle size of 0.5%, 1%, and 1.5%. As can be seen from the figure, whether in the inlet or outlet loop, the higher the sand content (1.5%), the lower the overall heat-transfer coefficient. This indicates that the presence of sand particles in the water has a more significant negative impact on the heat-transfer performance. The analysis suggests that while increasing the flow rate of the cooling water generally improves heat-transfer efficiency, the effect is less pronounced for flows with higher sand content. Therefore, for water sources with higher sand content, additional measures, such as filtration, can be required to optimize heat-transfer efficiency.

Figure 9.

Distribution of the relationship between the flow rate of the cooling water and heat-transfer coefficient for the radiator, (a) inlet circuit, and (b) return circuit.

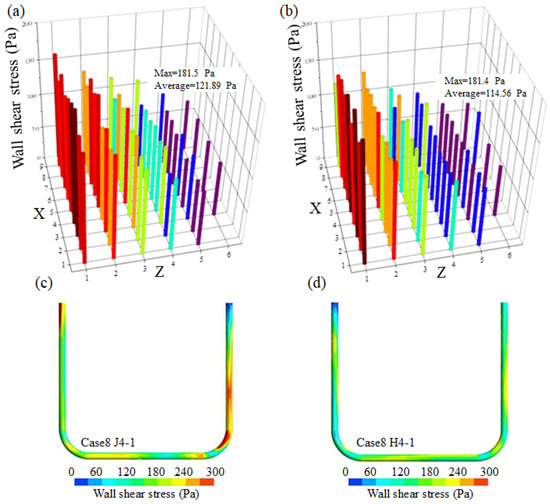

The overall density of two-phase flow increases because of the gravel mixing with the cooling water; under those conditions, the shear stress on each pipe of the heat exchanger will increase. Figure 10a,b plot the distribution of shear stress in inlet and outlet circuits under Case 8. The average wall shear stress of No. 1 pipe in Z-direction for both circuits is significantly higher than that of other heat-exchanger tubes and decreases gradually with the increase in Z-direction labeling. This occurs because the length of heat-exchanger pipe grows gradually; the local high shear at the elbow accounts for a smaller percentage of the heat-exchanger pipe. At Case 8, the average shear stresses in pipes of the inlet and return circuits are 121.89 Pa and 114.56 Pa, respectively, while the maximum shear stresses are 181.5 Pa and 181.4 Pa, respectively.

Figure 10.

Distribution of average wall shear stress in each (a) inlet and (b) return circuit; wall shear-stress distribution of heat-exchanger pipes of (c) J4-1 and (d) H4-1 under Case 8.

The wall shear-stress distributions of H4-1 and J4-1 under Case 8 are further compared in Figure 10c,d. The tangential velocity component at the entrance of the inlet circuit caused by incoming flow distortion leads to the increasing wall shear stress, and the gravel siltation at the elbow generates local high shear, while the wall shear stress at the outlet of the heat-exchanger pipe is small. Therefore, as the volume fraction of gravel in coolant increases, wall-abrasion failure is most likely to occur near the heat-exchanger pipe entrance and elbow.

3.3. Sand Particle Size

The effects of sand particle size on each pipe of the heat exchanger can be explored by comparing Cases 4, 5, and 6. Case 6 is selected to study the mass flow distribution of cooling water and gravel within 98 pipes, as shown in Figure 11a,b. The main fluid in the heat exchanger is cooling water, and the mass flow rate of gravel is quite small. Meanwhile, the increase in particle size of gravel causes the mass flow rate of the cooling water to rise at a given sand content. As for the inlet and return circuits, in a response similar to that seen in Figure 7, the presence of gravel leads to a significant increase in the mass flow rate of pipe 9 in the X-direction, and the cooling water is displaced to surrounding pipes. Figure 11 shows the volume fraction distribution of each heat-exchanger pipe inlet. The uniformity of the volume fraction of gravel in the return circuit is worse than that in inlet circuit, and the gravel is mainly concentrated in pipe No. 1∼5 in the X-direction.

Figure 11.

Distribution of flow in each (a) inlet and (b) return circuit and distribution of the gravel volume fraction in the inlet section of each (c) inlet and (d) return circuit under Case 6.

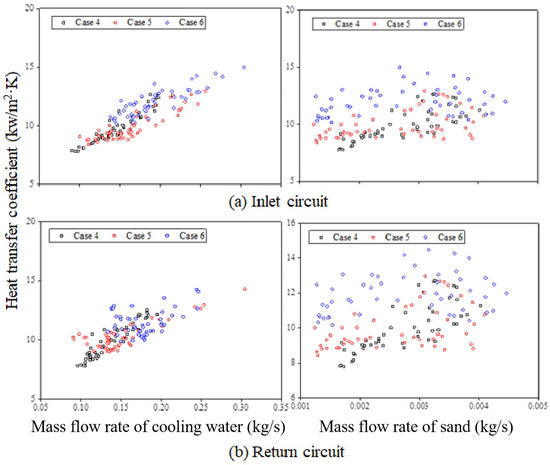

Figure 12 shows the distribution of the relationship between the two media at the heat-exchanger inlet and the heat-transfer coefficient, comparing the impact on heat-transfer performance at a sand content of 1% with sand particle sizes of 0.1 mm, 0.3 mm, and 0.5 mm. In the inlet loop, the mass flow rate of the cooling water shows a significant positive correlation with the heat-transfer coefficient, tending to follow a linear relationship. As the flow rate of the cooling water increases, the flow velocity in the pipe increases, and the increase in Reynolds number enhances the convective heat transfer between the cooling water and the wall. In the return loop, this positive correlation remains for smaller sand particle sizes (0.1 mm). However, as the sand particle size increases (0.3 mm and 0.5 mm), this positive correlation becomes less significant, and the heat-transfer coefficient in the heat exchanger for Case 5 and Case 6 initially decreases and then increases as the flow rate of the cooling water increases. In Case 4, the increase in mass flow rate with increasing sand particle size causes the heat-transfer coefficients in both the inlet and return loop heat exchangers to show a linear increase. However, this trend disappears with larger particle sizes, but the increase in particle size leads to an overall increase in the heat-transfer coefficient of the heat exchanger due to the increase in the flow rate of the cooling water.

Figure 12.

The relationship between the mass flow rate of the cooling water, sand mass flow rate, and heat-transfer coefficient: (a) inlet circuit and (b) return circuit.

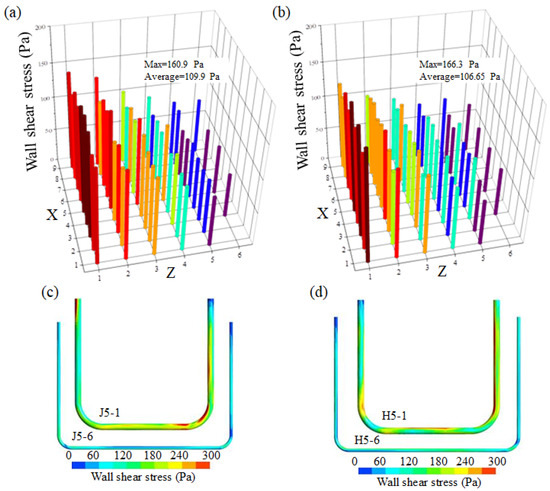

When impurities are present in the coolant, it not only affects the heat-transfer performance, but also significantly reduces the life of the heat exchanger. The wall shear caused by particulate impurities, and therefore the wall shear stress caused by gravel, is used to analyze the abrasion strength of sand-containing cooling water on heat-exchanger pipes. As shown in Figure 13a,b, average wall shear stress differs for all pipes under Case 5. Overall, along the increasing pipe number in the Z-direction, the average wall shear stress of pipeline decreases gradually. The average shear stresses in the inlet and return circuits are 109.9 Pa and 106.65 Pa, and the maximum shear stresses are 160.9 Pa and 166.3 Pa, respectively.

Figure 13.

Distribution of average wall shear stress in each (a) inlet and (b) return circuit; distribution of wall shear stress in heat-exchanger pipes of (c) J5-1, J5-6 and (d) H5-1, H5-6 under Case 5.

The distributions of wall shear stress across J5-1 vs. J5-6 and H5-1 vs. H5-6 are further compared in Case 5, as shown in Figure 13c,d, respectively. All heat-exchanger pipes produce localized high shear at the entrance, while the shear is small at the exit, a difference that might be caused by the presence of incoming flow distortion in the inlet gravel and might produce tangential velocity component leading to partial erosion damage at the inlet wall. Moreover, the gravel will silt up near the elbow, and the increase in localized volume fraction of gravel leads to a significant high shear near all tube elbows. Therefore, it can be assumed that the higher percentage of shorter heat-exchanger pipe elbows leads to an overall higher wall shear in Z-direction of heat-exchanger pipe No. 1; similarly, the longer heat-exchanger pipe has a lower average wall shear stress.

4. Heat-Exchanger Optimization

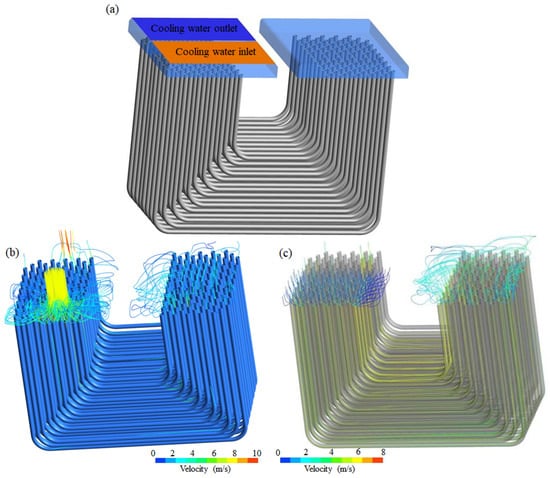

From the above analysis, it can be seen that the gravel doping and irrational inlet structure of the pipes lead to uneven distribution of flow in the 98 pipes and to deformed inflow at the pipe inlets, which causes flow loss and affects heat-transfer performance. The inlet and outlet domains of the traditional drawer-type heat exchanger form an arched column, as shown in Figure 1a,d; in this structure, the flow mixing and the irrational pipe inlet structure lead to an uneven flow among the 49 inlet pipes and distorted inflow at each pipe entrance, increasing flow losses and reducing the heat-transfer performance of the heat exchanger. To improve this situation, the inlet and outlet domains are optimized to a flat square design, and their areas are increased, as shown in Figure 14. Next, Case 2 is adopted to validate the optimization scheme.

Figure 14.

(a) Structure of the heat-exchanger optimization scheme, (b) flow line distribution of the original heat-exchanger pipe, (c) flow line distribution of the optimized heat-exchanger pipe under Case 2.

As shown in Figure 14b,c, the cooling water mixes before it enters the pipe and return circuit, which leads to flow turbulence in both regions. The optimized structure makes this turbulence become uniform, which can reduce resistance loss along the original scheme, and help to improve the heat-transfer performance of some pipes.

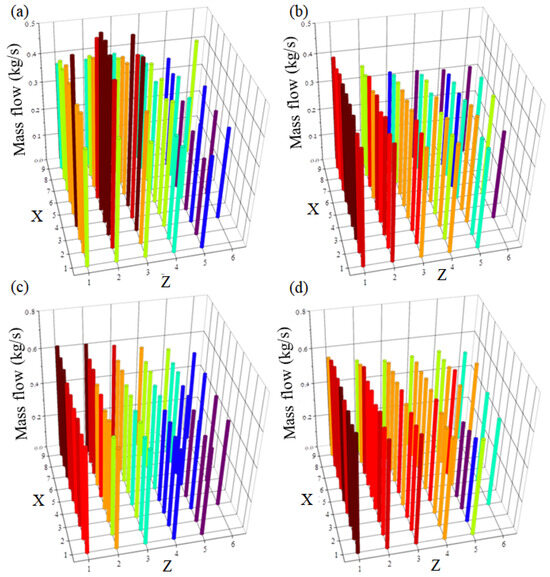

To demonstrate the advanced features of optimized structure more intuitively, the flow distribution of each pipe for inlet and return circuits are plotted, as shown in Figure 15. Compared to the prototype, the flow distribution of each pipeline for optimized structure is relatively uniform, which is conducive to reducing the along-track resistance at higher flow rates in some original pipes. At the same time, a clear flow pattern emerges: the larger the numbering in the X-direction, the higher the flow rate.

Figure 15.

Distribution of flow in (a) the inlet and (b) the return circuit for the original structure and distribution of flow in (c) the inlet and (d) the return circuit for the optimized structure under Case 7.

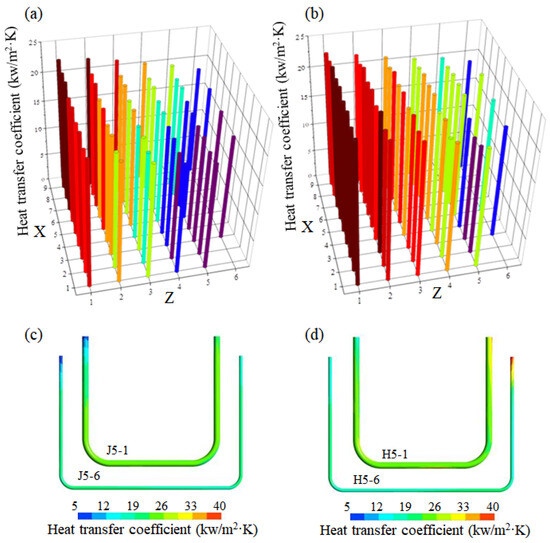

The average heat-transfer coefficients of each pipe in the inlet and return circuits after optimization of the structure are further plotted as shown in Figure 16a,b. The average distribution of cooling water flow makes the heat-transfer coefficient distribution of each pipe more uniform, while the increase in flow rate induces an overall increase in the heat-transfer coefficient compared to the prototype, and the heat-transfer performance has been optimized. Compared to Figure 7, the reduction in inlet nonhomogeneity for the optimized structure shown in Figure 16c,d results in a more uniform distribution of heat-transfer coefficients. The heat-transfer coefficient at the entrance of inlet circuit is smaller, and the downstream heat-transfer coefficient distribution is more uniform.

Figure 16.

Distribution of average heat-transfer coefficients in (a) the inlet and (b) the return circuit pipes; distribution of wall shear stress in the heat-exchanger pipes of (c) J5-1 and J5-6 and of (d) H5-1 and H5-6 under Case 2.

Finally, Table 3 presents the numerical results of the optimized scheme compared with the original scheme under Case 2, where and represent the drop in oil temperature and rise in water temperature, respectively. The results show that the modified scheme significantly increases the cooling water flow rate under the same pressure boundary conditions due to smoother pipe flow, which in turn leads to an increase in oil temperature by 0.53 K compared to the original scheme. The increase in cooling water flow also reduces the unit water temperature rise from 1.94 K to 1.28 K. Moreover, as shown in Table 3, the optimized design achieves improvements in several key performance metrics: a 7.7% increase in both oil-temperature drop and total heat-transfer rate, a 53.1% increase in water flow rate, and a 34.0% reduction in the velocity nonuniform coefficient compared to the prototype. Although the pressure drop increases by 19.0%, it remains within acceptable engineering limits. These results confirm that the proposed optimization scheme is effective in enhancing both the thermal and hydraulic performance of the heat exchanger.

Table 3.

Comparison of key performance metrics between the prototype and improved design.

A systematic analysis of the robustness of the proposed optimization scheme under a broader range of operating conditions, such as varying flow rates, levels of sand content, and particle sizes, was not performed in this study, primarily due to computational and scope limitations. However, considering the underlying physical mechanisms and the consistent trends observed in the tested cases, it is anticipated that the optimization would continue to deliver improvements in heat transfer and flow distribution across a variety of practical conditions. For greater engineering assurance, future investigations should extend the robustness assessment to a wider range of operating conditions, thereby further validating the general applicability and reliability of the optimized design in real-world scenarios.

In this study, the factors affecting heat-exchanger performance (e.g., increasing flow velocity and heat-transfer area, etc.) are analyzed first using heat-transfer theory, and the weaknesses of the prototype drawer-type heat-exchanger structure are investigated via detailed and accurate numerical calculations. By optimizing the inlet and outlet domain to a flat square structure and increasing its area, the design effectively improves inlet flow into the pipe is effectively improved, which further improves the performance of the heat exchanger.

5. Conclusions

This study focuses on the heat-transfer performance of a complex drawer-type heat exchanger featuring 98 individual piping channels—a configuration rarely comprehensively analyzed in the existing literature. Unlike conventional works that mainly emphasize general optimization of pipe shape, our research addresses a unique challenge faced in hydropower applications: the presence of sediment-laden cooling water. Therefore, an equivalent three-dimensional model of heat exchangers is developed and accurate numerical simulations are carried out in this paper. The flow distribution, velocity nonhomogeneity coefficient, and heat-transfer coefficient of the inlet and return circuits under different cooling-medium parameters are discussed separately. The results show that, under cooling-medium flows with varying flow rates, sand contents, and sand particle sizes, the flow distribution in the heat-exchanger pipes becomes uneven, and the entrance of each pipe experiences aberrant inflow, which increases flow losses and adversely affects heat-transfer performance. Based on the above research, an optimization scheme for the prototype is proposed, where the original columnar inlet and outlet are reshaped into a square shape and the area is enlarged. The optimized structure reduces the drop in oil temperature by 0.53 K, and the working efficiency of the heat exchanger is improved by 7.7%.

Although the study was conducted based on heat exchangers of hydrogenerator sets, the effects of sand content and particle size of the cooling medium on cooling efficiency are still generalizable to other heat exchangers used in industrial applications. Moreover, in addition to optimizing the inlet and outlet domain structures, the performance of the heat exchanger in hydrogenerator sets can be further improved by converting the circular piping into a spiral shape to increase the heat-transfer area or by reducing the sand content in the water entering the pipes. Additionally, the primary focus was placed on improving heat-transfer performance and flow-distribution uniformity, with pressure drop and other factors accounted for only indirectly. However, maximization of heat transfer often comes at the expense of increased pressure loss and potentially higher operating costs. Initial construction costs, maintenance requirements, and long-term operational efficiency are also important aspects in practical engineering applications. Although a quantitative multi-objective optimization was beyond the scope of this work, the need to balance thermal performance, hydraulic losses, and economic factors should be carefully evaluated in future studies to ensure that the optimized design is truly effective and viable for real-world implementation.

Author Contributions

Conceptualization: Z.J. and L.W.; Data curation: S.H.; Formal analysis: S.H. and Z.J.; Funding acquisition: Z.J.; Investigation: W.Z.; Software: L.W. and W.Z.; Writing—original draft: Z.J.; Writing—review & editing: S.H. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the Postdoctoral Fellowship Program Project (Research on Dooperative Optimization Scheduling Model and Algorithm of Basin Ladder Multi-energy Complementary System, Grant No. 327606).

Data Availability Statement

Data will be available upon request.

Conflicts of Interest

All authors were employed by the company Huadian Electric Power Research Institute Co., Ltd. They declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- El-Zohri, E.H.; Shafey, H.M.; Kahoul, A. Performance evaluation of generator air coolers for the hydro-power plant of Aswan High Dam at Egypt. Energy 2019, 179, 960–974. [Google Scholar] [CrossRef]

- Najar, F.A.; Harmain, G.A. Thermal effects for conventional and water-cooled thrust bearing using finite difference method: Comparative analysis. Int. J. Precis. Technol. 2015, 5, 14–26. [Google Scholar] [CrossRef]

- Frota, M.N.; Ticona, E.M.; Neves, A.V.; Marques, R.P.; Braga, S.L.; Valente, G. On-line cleaning technique for mitigation of biofouling in the heat exchangers: A case study of a hydroelectric power plant in Brazil. Exp. Therm. Fluid Sci. 2014, 53, 197–206. [Google Scholar] [CrossRef]

- Çay, M.S.; Gezer, D. Assessment of an External Cooling System Using Experimental Methods for Thrust Bearing in a Large Hydraulic Unit. Water 2025, 17, 795. [Google Scholar] [CrossRef]

- Wang, J.; Bian, H.; Cao, X.; Ding, M. Numerical performance analysis of a novel shell-and-tube oil cooler with wire-wound and crescent baffles. Appl. Therm. Eng. 2021, 184, 116298. [Google Scholar] [CrossRef]

- Wang, S.; Qu, J.G.; Kong, L.J.; Zhang, J.F.; Qu, Z.G. Numerical and experimental study of heat-transfer characteristics of needle-to-ring-type ionic wind generator for heated-plate cooling. Int. J. Therm. Sci. 2019, 139, 176–185. [Google Scholar] [CrossRef]

- Amanowicz, Ł.; Wojtkowiak, J. Thermal performance of multipipe earth-to-air heat exchangers considering the nonuniform distribution of air between parallel pipes. Geothermics 2020, 88, 101896. [Google Scholar] [CrossRef]

- Tian, X.X.; Asaadi, S.; Moria, H.; Kaood, A.; Pourhedayat, S.; Jermsittiparsert, K. Proposing tube-bundle arrangement of tubular thermoelectric module as a novel air cooler. Energy 2020, 208, 118428. [Google Scholar] [CrossRef]

- Bruschewski, M.; Scherhag, C.; Schiffer, H.P.; Grundmann, S. Influence of channel geometry and flow variables on cyclone cooling of turbine blades. J. Turbomach. 2016, 138, 061005. [Google Scholar] [CrossRef]

- Ghorab, M.G. Cooling performance and flow-field analysis of a hybrid scheme with different outlet configurations. Appl. Therm. Eng. 2013, 61, 799–816. [Google Scholar] [CrossRef]

- Lad, A.A.; James, K.A.; King, W.P.; Miljkovic, N. Reduced order design optimization of liquid cooled heat sinks. J. Electron. Packag. 2021, 143, 041105. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Abdelgaied, M. Numerical and experimental investigation of a novel configuration of indirect evaporative cooler with internal baffles. Energy Convers. Manag. 2016, 126, 526–536. [Google Scholar] [CrossRef]

- Yuan, J.; Gu, Z.; Bao, J.; Yang, T.; Li, H.; Wang, Y.; Pei, L.; Jiang, H.; Chen, L.; Yuan, C. Structure optimization design and performance analysis of liquid cooling plate for power battery. J. Energy Storage 2024, 87, 111517. [Google Scholar] [CrossRef]

- Ye, L.; Lv, G.; Ding, Y. Structure optimization of radiant cooling panel: A literature review and assessment. Energy Build. 2024, 310, 114097. [Google Scholar] [CrossRef]

- Nada, S.A.; Eid, E.I.; Abd El Aziz, G.B.; Hassan, H.A. Performance enhancement of shell and helical coil water coolers using different geometric and fins conditions. Heat-Transf.—Asian Res. 2016, 45, 631–647. [Google Scholar] [CrossRef]

- Ghazi, T.; Attar, M.R.; Ghorbani, A.; Alshihmani, H.; Davoodi, A.; Passandideh-Fard, M.; Sardarabadi, M. Synergistic effect of active-passive methods using fins surface roughness and fluid flow for improving cooling performance of heat sink heat the pipes. Exp. Heat Transf. 2024, 37, 649–664. [Google Scholar] [CrossRef]

- Ismail, K.A.R.; Lino, F.A.M. Fins and turbulence promoters for heat transfer enhancement in latent heat storage systems. Exp. Therm. Fluid Sci. 2011, 35, 1010–1018. [Google Scholar] [CrossRef]

- Muratçobanoğlu, B.; Mandev, E.; Ceviz, M.A.; Manay, E.; Afshari, F. CFD simulation and experimental analysis of cooling performance for thermoelectric cooler with liquid cooling heat sink. J. Therm. Anal. Calorim. 2024, 149, 359–377. [Google Scholar] [CrossRef]

- Wang, Y.; Cai, Y.; Zhang, J.; Chen, Z.; Li, C.; Sun, W. Investigation on heat transfer mechanism simulation and structure optimization design of hydraulic turbine bearing semi-ring cooler. Heliyon 2025, 11, e42328. [Google Scholar] [CrossRef]

- Shi, Y.; Cao, J.; Zhai, L.; Wang, Z.W. The influence of installation deviation on the upper guide bearing thermo-hydrodynamic characteristics of a 1000 MW giant hydropower unit. Phys. Fluids 2024, 36, 5. [Google Scholar] [CrossRef]

- Georgescu, S.C.; Georgescu, A.M.; Jumara, A.; Piraianu, V.F.; Dunca, G. Numerical simulation of the cooling water system of a 115 MW Hydro-Power Plant. Energy Procedia 2016, 85, 228–234. [Google Scholar] [CrossRef][Green Version]

- Muhsen, A.A.; Kizilova, N. The Advanced Cooling System of Generator for Hydropower Plant. Changes 2022, 8, 10. [Google Scholar][Green Version]

- Kahraman, G. Increasing the Power Generation by Raising the Capacity of the Thrust Bearing Oil Cooling System in Hydroelectric Power Plants. J. Fail. Anal. Prev. 2020, 20, 1445–1449. [Google Scholar] [CrossRef]

- Doost, A.K.; Majlessi, R. Heat transfer analysis in cooling system of hydropower’s generator. Open J. Appl. Sci. 2015, 5, 98. [Google Scholar] [CrossRef]

- Bambang Teguh, P.; Hidayat, D.; Adnyana, D.N. Failure Analysis and Optimisation of Tube Water Cooler of Hydropower Plant. Int. J. Eng. Technol. 2013, 13. [Google Scholar]

- Reis, M.P.; de Paula, R.S.; Reis, A.L.M.; e Souza, C.C.; Júnior, R.B.d.O.; Ferreira, J.A.; Mota, H.R.; de Carvalho, M.F.; Jorge, E.C.; Cardoso, A.V.; et al. Microbial composition of a hydropower cooling water system reveals thermophilic bacteria with a possible role in primary biofilm formation. Biofouling 2021, 37, 246–256. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, Y.; Liu, B.; Ge, X.; Zheng, Y.; Fernandez-Rodriguez, E. Research on oil mist leakage of bearing in Hydropower Station: A review. Energies 2022, 15, 2632. [Google Scholar] [CrossRef]

- Sotiropoulos, F.; Abdallah, S. The discrete continuity equation in primitive variable solutions of incompressible flow. J. Comput. Phys. 1991, 95, 212–227. [Google Scholar] [CrossRef]

- Girault, V.; Raviart, P.A. Finite Element Methods for Navier-Stokes Equations: Theory and Algorithms; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Bradshaw, P.; Ferriss, D.H.; Atwell, N.P. Calculation of boundary-layer development using the turbulent energy equation. J. Fluid Mech. 1967, 28, 593–616. [Google Scholar] [CrossRef]

- Chu, K.W.; Yu, A.B. Numerical simulation of complex particle–fluid flows. Powder Technol. 2008, 179, 104–114. [Google Scholar] [CrossRef]

- Kakac, S.; Yener, Y.; Pramuanjaroenkij, A. Convective Heat Transfer; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Salimpour, M.R. heat-transfer coefficients of shell and coiled tube heat exchangers. Exp. Therm. Fluid Sci. 2009, 33, 203–207. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Wang, T.; Zhang, J.; Li, L.; Zhang, Y. Experimental analysis and model prediction of elbow pipe’s erosion in water-cooled radiator. Sci. Rep. 2024, 14, 6880. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).