Integrated Environmental–Economic Assessment of CO2 Storage in Chinese Saline Formations

Abstract

1. Introduction

2. Materials and Methods

2.1. Background Information

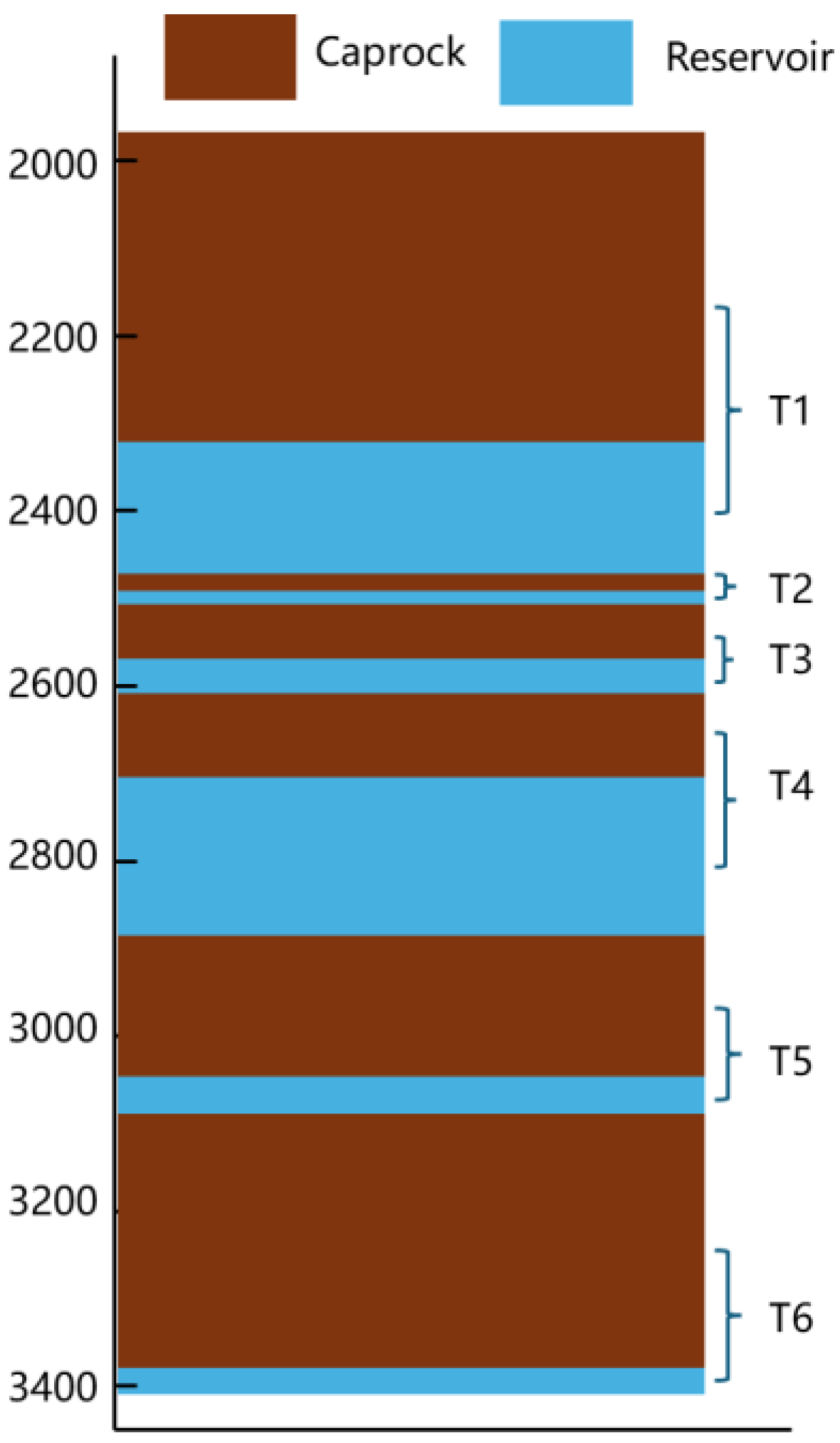

- (1)

- From ~1964 m down to 2323 m, the T1 caprock (dark mudstone) overlies the T1 reservoir (~2323–2470 m).

- (2)

- T2 follows immediately below, showing a thin seal (2470–2483 m) over its reservoir (2483–2501 m).

- (3)

- T3 extends from 2501 m, with a caprock to 2572 m and a reservoir to 2608 m.

- (4)

- The thicker T4 unit spans 2608–2874 m, with ~95 m of seal and ~171 m of reservoir.

- (5)

- Similarly, T5 is marked by a long caprock (2874–3035 m) above its reservoir (3035–3082 m).

- (6)

- Finally, T6 occupies 3082–3406 m, with ~285 m of mudstone seal and a 39 m sandy reservoir at its base.

2.2. Goal and Scope Definition

2.3. Environmental Analysis

2.3.1. Carbon Capture, Compression, and Transportation

2.3.2. Carbon Storage

2.3.3. Brine Management

2.3.4. Scenario Analyses

2.4. Economic Analysis

2.5. MCDM Analyses

3. Results

3.1. Environmental Results

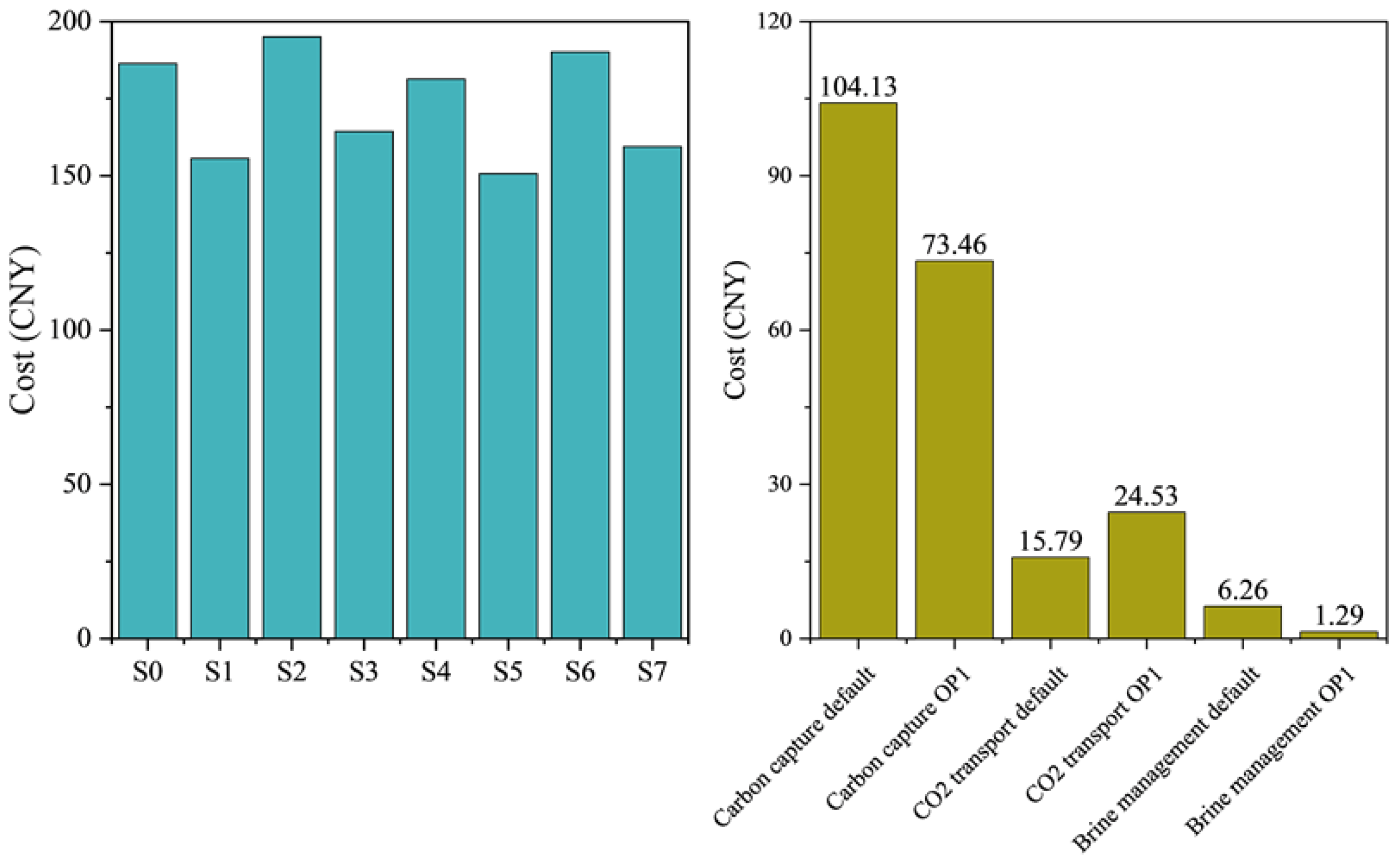

3.2. Economic Analysis

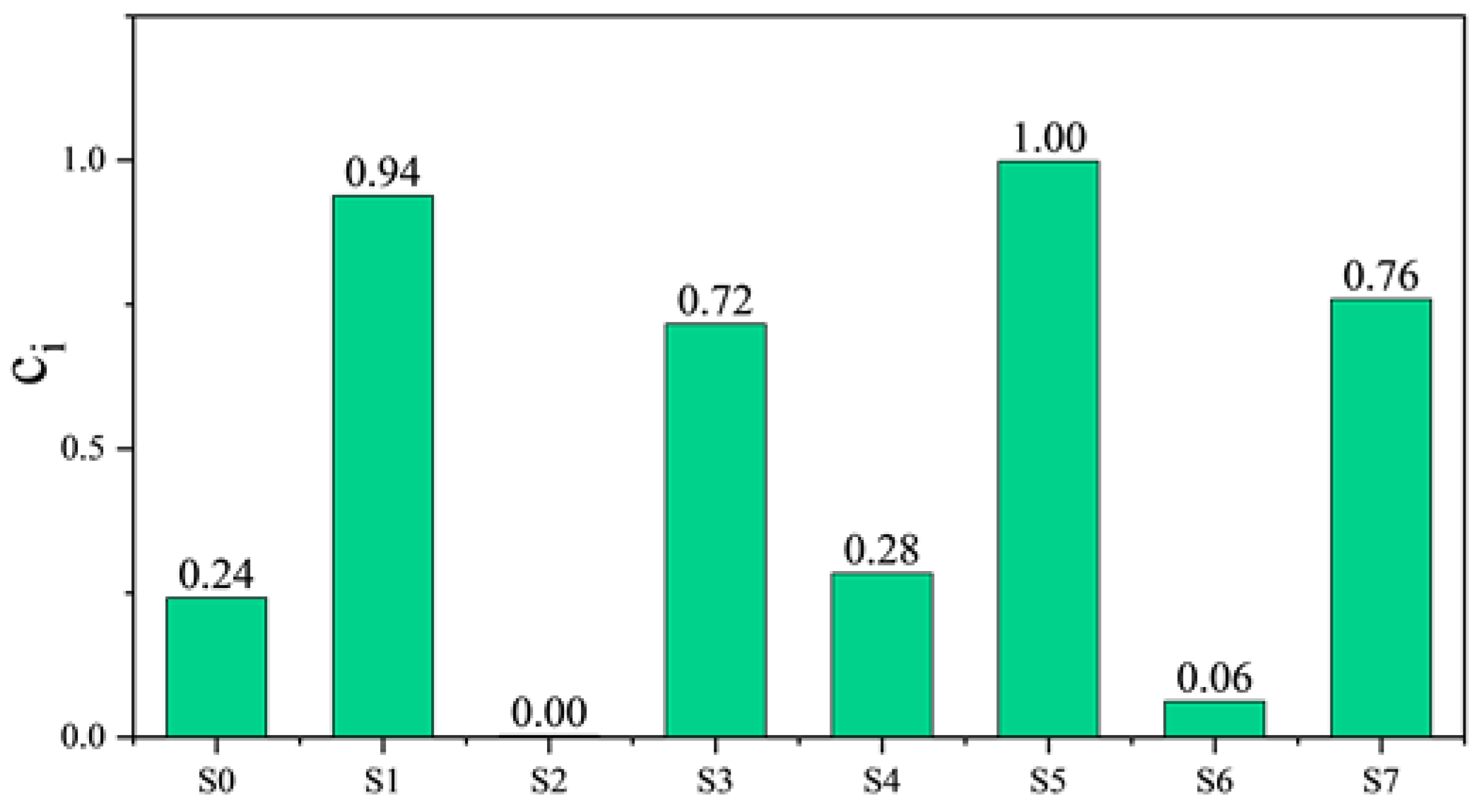

3.3. MCDM Framework

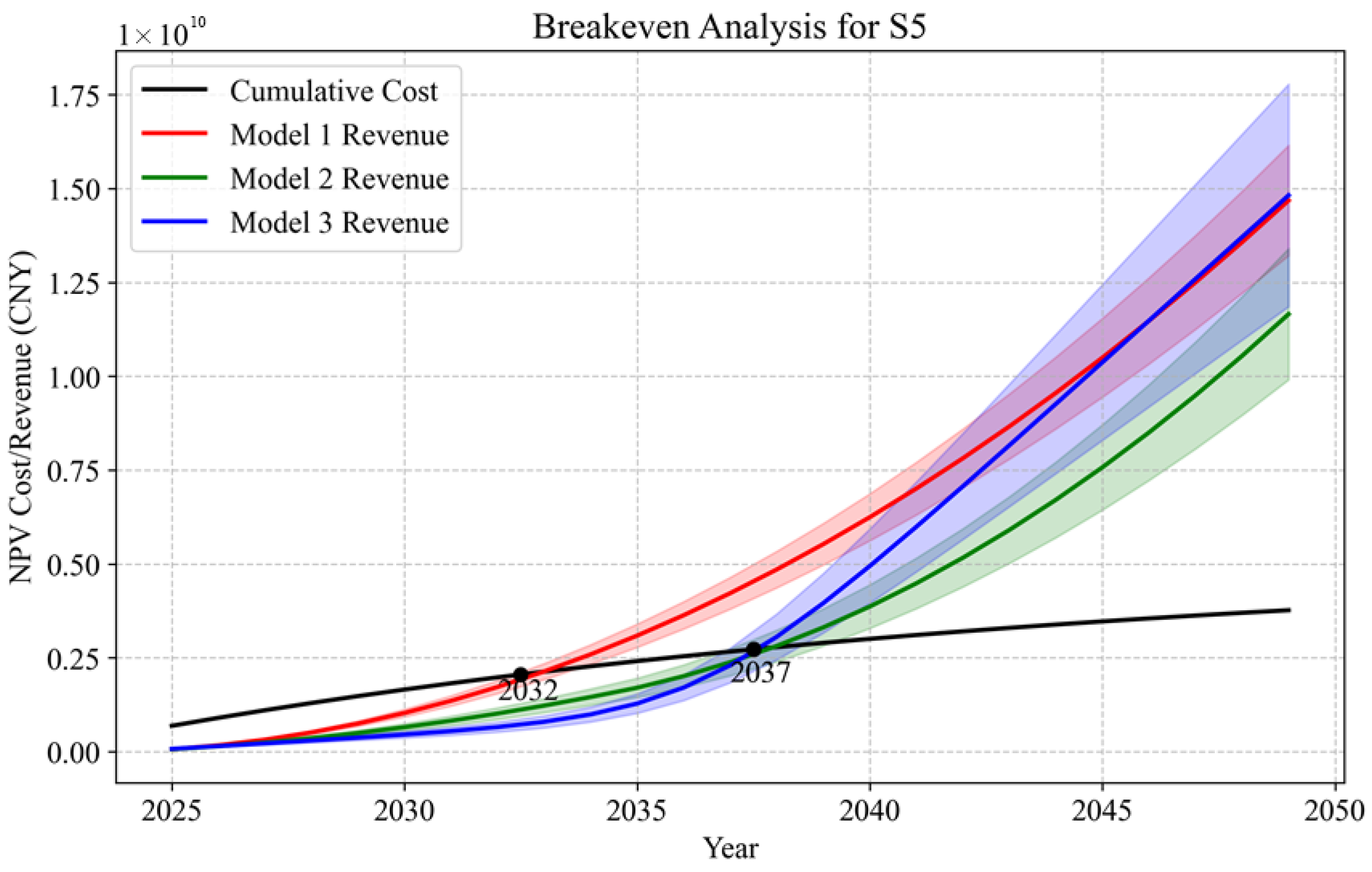

3.4. Breakeven Analysis of the Best Scenario

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- IPCC. Global Warming of 1.5 °C: IPCC Special Report on Impacts of Global Warming of 1.5 °C Above Pre-Industrial Levels in Context of Strengthening Response to Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; Cambridge University Press: Cambridge, UK, 2022. [Google Scholar] [CrossRef]

- Skea, J.; Shukla, P.R.; Reisinger, A.; Slade, R.; Fradera, R.; Pathak, M.; Al Khourdajie, A.; van Diemen, R.; Abdulla, A.; Akimoto, K.; et al. Climate Change 2022—Mitigation of Climate Change: Working Group III Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2023. [Google Scholar] [CrossRef]

- Global CCS Institute. Available online: https://status23.globalccsinstitute.com/ (accessed on 1 January 2025).

- Bongaarts, J. IPCC, 2023: Climate Change 2023: Synthesis Report. IPCC, 184 p., doi: https://doi.org/10.59327/IPCC/AR6-9789291691647. Popul. Dev. Rev. 2024, 50, 577–580. [Google Scholar] [CrossRef]

- Section 45Q Credit for Carbon Oxide Sequestration—Policies. Available online: https://www.iea.org/policies/4986-section-45q-credit-for-carbon-oxide-sequestration (accessed on 1 January 2025).

- Wang, P.; Shi, B.; Li, N.; Kang, R.; Li, Y.; Wang, G.; Yang, L. CCUS development in China and forecast its contribution to emission reduction. Sci. Rep. 2023, 13, 17811. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Z.; Chen, Y.; Fu, M.; Li, M.; Yang, K.; Zeng, L.; Liang, J.; Ma, R.; Xie, Q. Role of CO2 geological storage in China’s pledge to carbon peak by 2030 and carbon neutrality by 2060. Energy 2023, 272, 127165. [Google Scholar] [CrossRef]

- Kelemen, P.; Benson, S.M.; Pilorgé, H.; Psarras, P.; Wilcox, J. An overview of the status and challenges of CO2 storage in minerals and geological formations. Front. Clim. 2019, 1, 9. [Google Scholar] [CrossRef]

- Yujia, W.; Zhaofeng, X.; Zheng, L. Lifecycle analysis of coal-fired power plants with CCS in China. Energy Procedia 2014, 63, 7444–7451. [Google Scholar] [CrossRef]

- Gupta, A.; Paul, A.R.; Haque, N. Life cycle assessment of carbon capture and storage in saline aquifers for coal-fired power generation: An Indian scenario. Greenh. Gases Sci. Technol. 2023, 13, 81–98. [Google Scholar] [CrossRef]

- Dong, C.; Jiang, J.; Ye, B.; Xia, C.; Zhang, Y. LCA-based cost-benefit assessment and carbon footprint accounting of CCUS technologies in China. J. Clean. Prod. 2025, 486, 144557. [Google Scholar] [CrossRef]

- Wang, P.; Robinson, A.J.; Papadokonstantakis, S. Prospective techno-economic and life cycle assessment: A review across established and emerging carbon capture, storage and utilization (CCS/CCU) technologies. Front. Energy Res. 2024, 12, 1412770. [Google Scholar] [CrossRef]

- Hu, M. Building impact assessment—A combined life cycle assessment and multi-criteria decision analysis framework. Resour. Conserv. Recycl. 2019, 150, 104410. [Google Scholar] [CrossRef]

- Zanghelini, G.M.; Cherubini, E.; Soares, S.R. How multi-criteria decision analysis (MCDA) is aiding life cycle assessment (LCA) in results interpretation. J. Clean. Prod. 2018, 172, 609–622. [Google Scholar] [CrossRef]

- Dias, L.C.; Freire, F.; Geldermann, J. Perspectives on multi-criteria decision analysis and life-cycle assessment. In New Perspectives in Multiple Criteria Decision Making: Innovative Applications and Case Studies; Doumpos, M., Figueira, J.R., Greco, S., Zopounidis, C., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 315–329. [Google Scholar] [CrossRef]

- Wang, J.-J.; Jing, Y.-Y.; Zhang, C.-F.; Zhao, J.-H. Review on multi-criteria decision analysis aid in sustainable energy decision-making. Renew. Sustain. Energy Rev. 2009, 13, 2263–2278. [Google Scholar] [CrossRef]

- Le Roux, D.; Olivès, R.; Neveu, P. Combining entropy weight and TOPSIS method for selection of tank geometry and filler material of a packed-bed thermal energy storage system. J. Clean. Prod. 2023, 414, 137588. [Google Scholar] [CrossRef]

- Zhou, Z.; Chi, Y.; Dong, J.; Tang, Y.; Ni, M. Model development of sustainability assessment from a life cycle perspective: A case study on waste management systems in China. J. Clean. Prod. 2019, 210, 1005–1014. [Google Scholar] [CrossRef]

- Davarpanah, A. Comparative Evaluation of Carbon Capture, Utilization, and Storage (CCUS) Technologies Using Multi-Criteria Decision-Making Approaches. ACS Sustain. Chem. Eng. 2024, 12, 9498–9510. [Google Scholar] [CrossRef]

- Yuan, X.; Zhao, X. Evaluation of CO2 sequestration suitability in bohai bay basin based on entropy weighted TOPSIS approach. Acad. J. Sci. Technol. 2025, 14, 24–27. [Google Scholar] [CrossRef]

- A Scientific Approach to Evaluating Carbon Storage Sites. Available online: https://www.slb.com/resource-library/insights-articles/a-scientific-approach-to-evaluating-carbon-storage-sites (accessed on 1 January 2025).

- Singh, B.; Strømman, A.H.; Hertwich, E. Life cycle assessment of natural gas combined cycle power plant with post-combustion carbon capture, transport and storage. Int. J. Greenh. Gas Control 2011, 5, 457–466. [Google Scholar] [CrossRef]

- Steubing, B.; De Koning, D.; Haas, A.; Mutel, C.L. The activity browser—An open source LCA software building on top of the brightway framework. Softw. Impacts 2020, 3, 100012. [Google Scholar] [CrossRef]

- GB/T 51316-2018; Standard for Design of Carbon Dioxide Capture and Purification Engineering for Flue Gas. The Standardization Administration of China: Beijing, China, 2018.

- Koornneef, J.; Van Keulen, T.; Faaij, A.; Turkenburg, W. Life cycle assessment of a pulverized coal power plant with post-combustion capture, transport and storage of CO2. Int. J. Greenh. Gas Control 2008, 2, 448–467. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.; Zhang, J.; Zheng, C. Life Cycle Carbon Emission Assessment for a Coal-fired Power Plant Using MEA CO2 Capture and Storage Technology. Jounal Power Eng. 2011, 5, 362–368. [Google Scholar]

- Grant, T.; Anderson, C.; Hooper, B. Comparative life cycle assessment of potassium carbonate and monoethanolamine solvents for CO 2 capture from post combustion flue gases. Int. J. Greenh. Gas Control 2014, 28, 35–44. [Google Scholar] [CrossRef]

- Skone, T.J.; James, R.B., III; Marriott, J.; Cooney, G.; Littlefield, J.; Jamieson, M. Gate-to-Grave Life Cycle Analysis Model of Saline Aquifer Sequestration of Carbon Dioxide. 2013. Available online: https://www.osti.gov/biblio/1515271 (accessed on 1 January 2025).

- Chen, P. Effects of the entropy weight on TOPSIS. Expert Syst. Appl. 2021, 168, 114186. [Google Scholar] [CrossRef]

- Zhu, Y.; Tian, D.; Yan, F. Effectiveness of entropy weight method in decision-making. Math. Probl. Eng. 2020, 2020, 1–5. [Google Scholar] [CrossRef]

- Behzadian, M.; Khanmohammadi Otaghsara, S.; Yazdani, M.; Ignatius, J. A state-of the-art survey of TOPSIS applications. Expert Syst. Appl. 2012, 39, 13051–13069. [Google Scholar] [CrossRef]

- Liang, S.; Lin, X.; Liu, X.; Pan, H. The pathway to China’s carbon neutrality based on an endogenous technology CGE model. Int. J. Environ. Res. Public Health 2022, 19, 6251. [Google Scholar] [CrossRef]

- Cassisa, C.; Chen, X.; Zhang, D. The Role of China’s ETS in Power Sector Decarbonisation; The International Energy Agency (IEA): Paris, France, 2021. [Google Scholar]

- Guinan, A.; Sheriff, A.; Morgan, D.; Shih, C.Y. FECM/NETL CO2 Saline Storage Cost Model (2024): User’s Manual. 2024. Available online: https://www.osti.gov/biblio/2496286 (accessed on 1 January 2025).

- Bisinella, V.; Hulgaard, T.; Riber, C.; Damgaard, A.; Christensen, T.H. Environmental assessment of carbon capture and storage (CCS) as a post-treatment technology in waste incineration. Waste Manag. 2021, 128, 99–113. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Liu, Z.; Pan, Z.; González-Arias, J.; Shang, L.; Wang, Y.; Zhang, Z. Advances in life cycle assessment of chemical absorption-based carbon capture technologies. Sep. Purif. Technol. 2024, 346, 127252. [Google Scholar] [CrossRef]

- Li, Z.; Luo, Z.; Wang, Y.; Fan, G.; Zhang, J. Suitability evaluation system for the shallow geothermal energy implementation in region by entropy weight method and TOPSIS method. Renew. Energy 2022, 184, 564–576. [Google Scholar] [CrossRef]

| Layers | Caprock Lithology | Reservoir Lithology | Seal–Reservoir Thickness Ratio |

|---|---|---|---|

| T1 | Predominantly dark grey–black mudstone, with thin sandstone beds | Light grey coarse to medium sandstone, interbedded with fine sandstones (grey–green and brown–yellow) | 2.44 |

| T2 | Red–brown and grey–green mudstone | Upper: brown mudstone and grey–green silty fine sandstone. Lower: light grey medium sandstone and brown–yellow fine sandstone | 0.72 |

| T3 | Light brown mudstone and sandy mudstone | Light grey coarse to medium sandstone; basal grey–green sandy mudstone | 1.97 |

| T4 | Brown mudstone and sandy mudstone, with a ~10 m interval of light grey medium sandstone and green–grey fine sandstone | Grey medium to fine sandstone, with ~7 m of brown mudstone at the midsection; basal light grey fine sandstone | 0.57 |

| T5 | Predominantly light reddish–brown fine sandstone, interbedded with reddish–brown muddy sandstone and grey–green fine to medium sandstone | Light red fine sandstone and siltstone | 3.43 |

| T6 | Dominantly mudstone (light grey, grey–green, brown–yellow interbeds), with thin layers of light red sandstone | Pink sandstone and light grey fine sandstone, interbedded with brown–grey mudstone | 7.31 |

| Process | Materials/Energy | Amount | Units | Source | |

|---|---|---|---|---|---|

| Default | Option1 | ||||

| Capture | MEA | 2.34 | -- | kg/ton CO2 | [25] |

| NaOH | 0.13 | -- | |||

| K2CO3 | -- | 0.12 | [27] | ||

| KOH | -- | 4.5 | |||

| Electricity | 23.6 | 17 | kWh/ton CO2 | [26,27] | |

| Steam | 4 | 2.3 | GJ/ton CO2 | ||

| Steel | 317 | 317 | ton/unit | [26] | |

| Concrete | 1 | 1 | m3/unit | ||

| Compression | Electricity | 103 | -- | kWh/t CO2 | Authors’ own data |

| Steel | 65 | -- | ton/unit | [26] | |

| Concrete | 65 | -- | m3/unit | ||

| Copper | 7 | -- | ton/unit | ||

| PVC | 20 | -- | ton/unit | ||

| Diesel | 1978 | -- | GJ/unit | ||

| Land use | 400 | -- | m2/unit | Authors’ own data | |

| Transportation | Electricity | 1.9 | -- | kWh/ton CO2 | Authors’ own data |

| Steel | 48,000 | -- | ton/unit | [26] | |

| PVC | 232 | -- | |||

| Diesel | 165,500 | -- | GJ/unit | ||

| Diesel | -- | 0.133 | GJ/ton CO2 | Authors’ own data | |

| Tank truck | -- | 360 | item/unit | ||

| Land use | 150,000 | -- | m2/unit | ||

| Site preparation | Diesel | 585 | -- | GJ/unit | [22] |

| Steel | 6820 | -- | ton/unit | ||

| Barite | 8770 | -- | |||

| Bentonite | 650 | -- | |||

| Concrete | 6500 | -- | m3/unit | ||

| Land use | 14,000 | -- | m2/unit | [28] | |

| Well construction | Diesel | 126 | -- | GJ/unit | [22] |

| Steel | 1462 | -- | ton/unit | ||

| Barite | 1880 | -- | |||

| Bentonite | 140 | -- | |||

| Concrete | 1400 | -- | m3/unit | ||

| Land use | 3000 | -- | m2/unit | [28] | |

| CO2 injection | Electricity | 46 | -- | kWh/ton CO2 | Authors’ own data |

| Land use | 400 | -- | m2/unit | [28] | |

| Well closure | Steel | 24.8 | -- | ton/well | [28] |

| Concrete | 51.3 | -- | m3/well | ||

| Monitoring | -- | -- | -- | -- | Authors’ own data |

| Brine Management | Diesel | 0.0133 | -- | GJ/ton CO2 | |

| Tank truck | 104 | -- | item/unit | ||

| Electricity | -- | 1.73 | kWh/ton CO2 | [28] | |

| RO facilities | -- | 1 | unit | Authors’ own data | |

| Land use | -- | 6400 | m2/unit | [28] | |

| Scenarios | Capture | Transport | Brine Management | Others | |||

|---|---|---|---|---|---|---|---|

| Default | Option1 | Default | Option1 | Default | Option1 | Default | |

| Default (S0) | √ | √ | √ | √ | |||

| Alternative 1 (S1) | √ | √ | √ | √ | |||

| Alternative 2 (S2) | √ | √ | √ | √ | |||

| Alternative 3 (S3) | √ | √ | √ | √ | |||

| Alternative 4 (S4) | √ | √ | √ | √ | |||

| Alternative 5 (S5) | √ | √ | √ | √ | |||

| Alternative 6 (S6) | √ | √ | √ | √ | |||

| Alternative 7 (S7) | √ | √ | √ | √ | |||

| Material/Energy | Price (CNY) |

|---|---|

| MEA (kg) | 8.5~9.7 |

| NaOH (kg) | 3.5~4.2 |

| K2CO3 (kg) | 5.5~6.5 |

| KOH (kg) | 4.0~5.0 |

| Electricity (kWh) | 0.60~0.70 |

| Steam (GJ) | 30~50 |

| Steel (ton) | 3310~3750 |

| Concrete (m3) | 500~700 |

| Copper (ton) | 67,710~77,280 |

| PVC (ton) | 5400~10,800 |

| Diesel (GJ) | 50~61 |

| Barite (ton) | 700~1000 |

| Bentonite (ton) | 2200~3500 |

| RO facility (4200 ton/d) | 7,300,000 |

| Tank truck for brine (30 m3) | 187,086 |

| Tank truck for CO2 (30 m3) | 2,175,420 |

| Indicators | Weights |

|---|---|

| GWP | 0.16 |

| FFP | 0.15 |

| Land_use | 0.17 |

| Water_use | 0.17 |

| Material_resources | 0.12 |

| Human_toxicity | 0.12 |

| Cost | 0.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, W.; Jiang, Z.; Jing, T.; Zhang, J.; Yang, Z.; Li, X.; Zhou, J.; Zhao, J.; Zhang, S. Integrated Environmental–Economic Assessment of CO2 Storage in Chinese Saline Formations. Water 2025, 17, 2320. https://doi.org/10.3390/w17152320

Zhao W, Jiang Z, Jing T, Zhang J, Yang Z, Li X, Zhou J, Zhao J, Zhang S. Integrated Environmental–Economic Assessment of CO2 Storage in Chinese Saline Formations. Water. 2025; 17(15):2320. https://doi.org/10.3390/w17152320

Chicago/Turabian StyleZhao, Wentao, Zhe Jiang, Tieya Jing, Jian Zhang, Zhan Yang, Xiang Li, Juan Zhou, Jingchao Zhao, and Shuhui Zhang. 2025. "Integrated Environmental–Economic Assessment of CO2 Storage in Chinese Saline Formations" Water 17, no. 15: 2320. https://doi.org/10.3390/w17152320

APA StyleZhao, W., Jiang, Z., Jing, T., Zhang, J., Yang, Z., Li, X., Zhou, J., Zhao, J., & Zhang, S. (2025). Integrated Environmental–Economic Assessment of CO2 Storage in Chinese Saline Formations. Water, 17(15), 2320. https://doi.org/10.3390/w17152320