Abstract

Approximately 10 million megagrams of sewage sludge is produced each year in the European Union alone. To date, options to utilize sewage sludge are limited. Local regulations and sludge characteristics strictly determine waste management options. Thermal disposal methods are recommended for highly contaminated sludge. Pyrolyzed sewage sludge generates biochar that can be used as a value-added agricultural product or as an alternative fuel. The biochar production itself carries the risk of emitting harmful compounds. Unfortunately, these important safety considerations are rarely addressed in the literature. This research investigates the mechanistic effects of the storage headspace-to-biochar volume ratio and stored biochar headspace ventilation on hazardous gas emissions. Five hazardous organic compounds were emitted by biochar. However, based on this initial proof-of-the-concept research, we could not derive conclusive trends for the effects of the headspace-to-biochar volume ratio or air exchanges in the biochar headspace. Further research, which is broader in scope (feedstock type, pyrolysis conditions), should be carried out. Nevertheless, caution should be exercised when designing biochar storage, aiming to lower the risk of occupational exposure to hazardous gas emissions. Monitoring air pollutants, tracking the highest permissible concentrations and workers’ exposure, and using personal protective equipment are recommended.

1. Introduction

1.1. Properties of Sewage Sludge

Approximately 10 million megagrams of sewage sludge is produced in the European Union alone. Sludge is a by-product of municipal wastewater treatment [1]. Sewage sludge may still contain wastewater pollutants that are difficult to remove with conventional treatments. The physicochemical properties of sewage sludge (e.g., concentrations of persistent organic compounds, heavy metals, organic acids, solids content, pH, and calorific value) and environmental regulations determine the potential for alternative uses beyond conventional landfills. Sewage sludge is a potential feedstock for phosphorus recovery, soil amendment, and fertilizer products [2].

1.2. Sewage Sludge Treatment Options

To date, the options to utilize sewage sludge as a resource are limited. Sewage sludge has a relatively high water content, directly affecting the techno-economic and processing options [3]. Dewatering, thickening, conditioning, drying, and incineration reduce its volume at a relatively high energy input. However, thermal disposal methods are recommended for highly contaminated sludge.

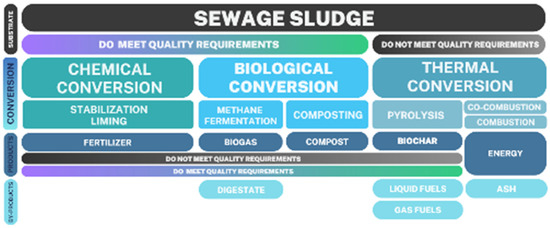

Interest in the thermal processing of sewage sludge for resource recovery is growing. Pyrolysis is a thermal process in which a feedstock undergoes decomposition at high temperatures without oxygen. Pyrolyzed sewage sludge generates tar oils, syngas components, and biochar that can potentially be used as a value-added by-product in agriculture or as an alternative fuel [4,5,6]. A summary of the sludge treatment options is presented in Figure 1 [7].

Figure 1.

Sewage sludge management options [8,9,10].

The properties of sludge-derived biochar depend mainly on the pyrolysis process conditions and feedstock [11,12]. Biochar derived from sewage sludge has a sufficiently high carbon content and can, therefore, be used as a soil amendment as well as a source of energy. Conversion of sewage sludge into biochar can reduce the bioavailability of heavy metals and other pollutants and reduce the waste volume [4]. However, sewage sludge-derived biochar tends to be of lower quality compared to plant biomass-derived biochar, such as lower specific surface area and higher ash content.

1.3. Volatile Organic Compound Emissions from Biochar

Biochar production from sewage sludge carries the risk of emitting harmful volatile organic compounds (VOCs) [13]. These important occupational safety considerations are rarely addressed in the literature. Large-scale biochar production involves sewage sludge handling, storage, transportation, and application involving workers who are at risk of inhaling both gaseous VOCs and VOCs sorbed to biochar, which, in turn, can be hazardous as airborne particulate matter [14,15]. Ventilation of the biochar storage area can affect the quantity and composition of emitted gases [13].

A VOC is defined as any organic compound and creosote fraction that has a vapor pressure of 0.01 kPa or more at 293.15 K or has a corresponding volatility under its specific conditions of use [14]. The common VOCs are aromatic hydrocarbons, halogenated hydrocarbons, alkanes and cycloalkanes, alcohols, aldehydes, and ketones or terpenes [15]. Short-term exposure to VOCs can irritate the mucous membranes of the eyes and upper and lower respiratory tracts and cause headaches and dizziness [16]. Long-term exposure increases the risk of respiratory and cardiovascular diseases, congenital fetal defects, and neurotoxic disorders. Long-term exposure significantly increases the risk of cancer (mainly lung and leukemia) and damage to the nervous system, kidneys, and liver.

To date, the safety of biochar production from sewage sludge is poorly understood. However, some common-sense approaches should be tested, leading to safer practices in biochar handling and storage and improving end-user conditions. This research investigates the mechanistic effects of two such approaches: (1) headspace-to-biochar volume ratio in storage and (2) ventilation of stored biochar headspace on hazardous gas emissions.

2. Materials and Methods

2.1. Sewage Sludge

The raw sewage sludge was collected at the BEST-EKO Ltd. WWTP in Rybnik, Poland, and stored in a laboratory freezer until testing. The moisture content was 80% (according to PN-EN 14346:2011) [17], the organic dry matter content was 72% (according to PN-EN 15169:2011) [18], and the ash content was 28% (according to PN-Z−15008-04:1993) [19]. Before testing, the sewage sludge was dried for 24 h at 105 °C (WAMED, KBC-65W, Warsaw, Poland) and ground. The ground raw sewage sludge was sieved separately through a 1 mm mesh sieve to homogenize the material.

2.2. Biochar Production

The low-temperature pyrolysis process was carried out in a muffle furnace (SNOL, 8.1/1100, Utena, Lithuania) at 240 °C with a processing time of 1 h, following the experimentation procedure described elsewhere [11]. The moisture content of the biochar was 1.25% (according to PN-EN 14346:2011 [17]), the organic dry matter content was 71% (according to PN-EN 15169:2011 [18]), and the ash content was 29% (according to PN-Z−15008-04:1993 [19]). The biochar had a bulk density of 604 kg m−3.

2.3. Experimental Setup

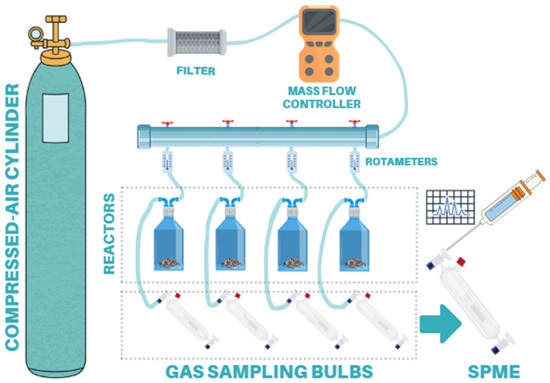

A conceptual drawing of the experimental setup is shown in Figure 2. Air from the compressed cylinder was routed to a filter to remove moisture and VOCs. The mass flow controller directed air to the distribution vessel, which evenly delivered airflow monitored by rotameters to reactors simulating the storage of biochar.

Figure 2.

Laboratory-scale experimental stand for testing the effects of storage headspace-to-biochar volume ratio and stored biochar headspace ventilation on hazardous gas emissions from sewage sludge-derived biochar.

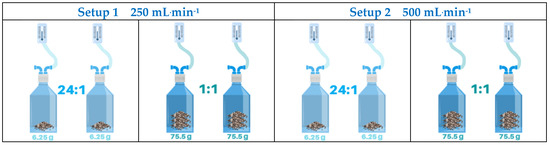

Four 250 mL glass reactors were filled with biochar to create two headspace-to-biochar volume ratios. Biochar amounts of 6.25 g or 75.5 g resulted in a headspace-to-biochar volume ratio of 24:1 or 1:1, respectively. Experiments were conducted at two airflow rates set to either 250 (setup 1) or 500 mL·min−1 (setup 2), resulting in four air exchanges (AE) per min of biochar headspace, i.e., 1.04, 2.00, 2.08, and 4.00 (air exchanges per min) (Figure 3).

Figure 3.

Headspace ventilation biochar samples produced from sewage sludge in reactors during two setups for headspace ventilation resulted in four air exchanges of biochar headspace per minute.

2.4. Chemical Analysis of Gases Emitted from Biochar

Gaseous emissions from each reactor were routed to glass bulbs, from where air samples were collected for chemical analyses. Solid-phase microextraction (SPME) holders, equipped with DVB/Carboxen/PDMS fibers, were inserted into each gas sampling bulb through a septum [5,6]. The fiber was then ejected from the housing needle and exposed to the gaseous emissions for 25 min. Gas samples were then delivered for analysis on a gas chromatograph—mass spectrometer (GC–MS), Agilent 5975C GC coupled to a 5983 MS equipped with a quadrupole mass detector (Agilent Technologies Inc., Palo Alto, CA, USA). Separation was carried out in an HP-5 Agilent (Phenomenex, Torrance, CA, USA) (30 m × 0.25 mm × 0.25 µm) column [12]. Scanning (1 scan/s) was carried out in the range of 35–400 m/z using electron-impact ionization at 70 eV.

Helium was used as the carrier gas with a flow rate of 1.0 mL·min−1 in a splitless mode for SPME. The oven temperature program was as follows: the initial temperature was set at 50 °C increasing by 4 °C·min−1 until reaching 130 °C, then by 10 °C·min−1 until 180 °C, and finally by 20 °C·min−1 until 240 °C, with a hold at 240 °C for 4 min. The injector was maintained at 200 °C. Chromatographic conditions were carried out according to Łyczko et al. [15]. A blank GC–MS run with the same temperature program was performed to establish a baseline bleed profile of the HP-5 column. The results of this blank run confirmed that the detected peaks were not artifacts of the column.

Qualitative analysis was used. Resulting chromatograms were searched for the presence of hazardous organic compounds using Annex 1 of the European Union regulation EC No. 1272/2008 [20]. The European Parliament Regulation (EC) No. 1272/2008 was the foundation for determining these substances [20]. The document defines the hazard class of individual substances to ensure high levels of protection for human health and the environment. Next, the peak area of each hazardous organic compound was compared to the total peak area of the analyzed sample. The hazard class of individual organic compounds was determined based on CAS numbers and publicly available data.

3. Results and Discussion

A simplified quantitative assessment of the occurrence of hazardous volatile organic compounds emitted from the stored biochar is presented in Table 1. All data are summarized and available as Supplementary Materials.

Table 1.

Simplified quantitative assessment of the occurrence of hazardous volatile organic compounds emitted from stored biochar.

It should be reported that numerous additional compounds (from 24 to 81, Supplementary Materials) were present in the biochar headspace, but did not make it onto the list due to the lack of significant hazard context within the scope of this research. In the case of reactors with a headspace-to-biochar ratio of 24:1, the airflow increase reduced the number of hazardous substances detected from 4 to 2. In contrast, in reactors with a 1:1 headspace-to-biochar ratio, there was no change, and the number of hazardous substances present was two (Table 1).

Table 2 summarizes the hazardous compounds emitted from our biochar. The identified compounds largely overlap with the compounds emitted from carbonized RDF fuel reported by Białowiec et al. [14] and research on sewage sludge by Łyczko et al. [15].

Table 2.

Identified hazardous organic compounds emitted from stored biochar derived from sewage sludge.

Octamethyl-cyclotetrasiloxane was consistently the most abundant compound emitted from biochar. More than a twofold increase in emissions was observed due to the increase in headspace air exchange rate (from 28 to 62, Table 1). Other hazardous compounds were identified, such as bis(2-ethylhexyl) phthalate, pentanoic acid, ethylbenzene, and styrene (Table 1).

Octamethyl-cyclotetrasiloxane has a hazard class 2 for reproductive toxicity and an aquatic chronic class 4, both being the highest in their respective categories. Siloxanes may be found in the biochars derived from sewage sludge, as they are present in the wastewater. Due to adsorption on the activated sludge flocks’ surfaces, siloxanes are transferred from wastewater to sewage sludge [21]. Bis(2-ethylhexyl) phthalate has a reproductive toxicity hazard class of 1B. Pentanoic acid has a hazard class for skin corrosion/irritation in category 1B. Ethylbenzene is a flammable liquid with a hazard class of category 2. Styrene has a category 3 hazard class for a flammable liquid, acute toxicity with a category 4, serious eye damage/eye irritation with a category 2, and skin corrosion/irritation with a category 2.

No conclusive trends could be found in the effects of the headspace-to-biochar volume ratio or air exchanges in biochar headspace. Caution should be exercised when designing biochar storage, aiming to lower the risk of occupational exposure to hazardous gas emissions.

Monitoring air pollutants, tracking the highest permissible concentrations and workers’ exposure, and using personal protective equipment are recommended. People working with biochar can, therefore, be exposed to the effects of hazardous organic compounds. It is recommended that exposure both via inhalation and dermal contact is reduced.

4. Conclusions

This research confirms that sewage sludge biochar emits hazardous organic compounds, including harmful and toxic substances. Research to date has mainly focused on the adsorption of VOCs by biochar rather than emissions from the biochar itself. Five hazardous organic compounds were identified in gaseous emissions from stored biochar produced from sewage sludge. These compounds are classified as toxic to reproductive and aquatic systems and hazardous to inhale and/or in skin contact. Due to the limited amount of data and relatively narrow range of the biochars, no conclusive trends could be found in the effects of the headspace-to-biochar volume ratio or air exchanges in biochar headspace. Further research covering broader types of biochar feedstocks and pyrolysis conditions should be carried out to monitor and mitigate the problem of VOC emissions from biochar. Caution should be exercised when designing biochar storage, aiming to lower the risk of occupational exposure to hazardous gas emissions. Monitoring air pollutants, tracking the highest permissible concentrations and workers’ exposure, and using personal protective equipment are recommended. People working with biochar can, therefore, be exposed to the effects of hazardous organic compounds. It is recommended that exposure both via inhalation and dermal contact is reduced.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/w17010058/s1.

Author Contributions

Conceptualization, E.S. and A.B.; methodology, E.S., Ł.B. and A.B.; software, Ł.B.; validation, E.S., Ł.B., J.A.K. and A.B.; formal analysis, E.S.; investigation, E.S. and M.L.; resources, E.S.; data curation, E.S. and Ł.B.; writing—original draft preparation, E.S.; writing—review and editing, E.S. and A.B.; visualization, E.S.; supervision, A.B. and J.A.K.; project administration, A.B.; funding acquisition, M.L. and A.B. All authors have read and agreed to the published version of the manuscript.

Funding

“The research is financed under the individual student research project “Młode umysły—Young Minds Project” from the subsidy increased for the period 2020–2025 in the amount of 2% of the subsidy referred to Art. 387 (3) of the Law of 20 July 2018 on Higher Education and Science, obtained in 2019”. Project number N010/0009/21 titled “Investigation of volatile organic compound emissions from biochar under varying conditions of storage”. The APC is financed by Wrocław University of Environmental and Life Sciences.

Data Availability Statement

All data derived during the experiments are given in the paper.

Conflicts of Interest

The authors declare no conflicts of interest and declare that the funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Kosek, K.; Luczkiewicz, A.; Fudala-Książek, S.; Jankowska, K.; Szopińska, M.; Svahn, O.; Tränckner, J.; Kaiser, A.; Langas, V.; Björklund, E. Implementation of advanced micropollutants removal technologies in wastewater treatment plants (WWTPs)—Examples and challenges based on selected EU countries. Environ. Sci. Policy 2020, 112, 213–226. [Google Scholar] [CrossRef]

- Jama-Rodzeńska, A.; Sowiński, J.; Koziel, J.A.; Białowiec, A. Phosphorus recovery from sewage sludge ash based on cradle-to-cradle approach—Mini-review. Minerals 2021, 11, 985. [Google Scholar] [CrossRef]

- Anjum, M.; Al-Makishah, N.H.; Barakat, M.A. Wastewater sludge stabilization using pre-treatment methods. Process Saf. Environ. Prot. 2016, 102, 615–632. [Google Scholar] [CrossRef]

- Wang, X.; Chang, V.W.C.; Li, Z.; Chen, Z.; Wang, Y. Co-pyrolysis of sewage sludge and organic fractions of municipal solid waste: Synergistic effects on biochar properties and the environmental risk of heavy metals. J. Hazard. Mater. 2021, 412, 125200. [Google Scholar] [CrossRef] [PubMed]

- Białowiec, A.; Micuda, M.; Szumny, A.; Łyczko, J.; Koziel, J.A. Quantification of VOC emissions from carbonized refuse-derived fuel using solid-phase microextraction and gas chromatography-mass spectrometry. Molecules 2018, 23, 3208. [Google Scholar] [CrossRef] [PubMed]

- Białowiec, A.; Micuda, M.; Szumny, A.; Łyczko, J.; Koziel, J.A. Waste to carbon: Influence of structural modification on VOC emission kinetics from stored carbonized refuse-derived fuel. Sustainbility 2019, 11, 935. [Google Scholar] [CrossRef]

- Mrozik, A.; Michalska, J. Zastosowanie bioaugmentacji w procesach biologicznego oczyszczania ścieków i utylizacji osadów. Ochr. Sr. 2018, 40, 35–44. [Google Scholar]

- Stasta, P.; Boran, J.; Bebar, L.; Stehlik, P.; Oral, J. Thermal processing of sewage sludge. Appl. Therm. Eng. 2006, 26, 1420–1426. [Google Scholar] [CrossRef]

- Cieślik, B.M.; Namieśnik, J.; Konieczka, P. Review of sewage sludge management: Standards, regulations and analytical methods. J. Clean. Prod. 2015, 90, 1–15. [Google Scholar] [CrossRef]

- Al-Malack, M.H.; Abuzaid, N.S.; Bukhari, A.A. Physico-chemical Characteristics of Municipal Sludge Produced at Three Major Cities of the Eastern Province of Saudi Arabia. J. King Saud Univ. Eng. Sci. 2008, 20, 15–26. [Google Scholar] [CrossRef]

- Pulka, J.; Manczarski, P.; Stepien, P.; Styczyńska, M.; Koziel, J.A.; Białowiec, A. Waste-to-carbon: Is the torrefied sewage sludge with high ash content a better fuel or fertilizer? Materials 2020, 13, 954. [Google Scholar] [CrossRef]

- Rosik, J.; Łyczko, J.; Marzec, Ł.; Stegenta-Dąbrowska, S. Application of Composts’ Biochar as Potential Sorbent to Reduce VOCs Emission during Kitchen Waste Storage. Materials 2023, 16, 6413. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kumar, P.S.; Varjani, S.; Saravanan, A. A critical review on the biochar production techniques, characterization, stability and applications for circular bioeconomy. Biotechnol. Rep. 2020, 28, e00570. [Google Scholar] [CrossRef]

- Białowiec, A.; Micuda, M.; Szumny, A.; Łyczko, J.; Koziel, J.A. The proof-of-the-concept of application of pelletization for mitigation of volatile organic compounds emissions from carbonized refuse-derived fuel. Materials 2019, 12, 1692. [Google Scholar] [CrossRef] [PubMed]

- Łyczko, J.; Koziel, J.A.; Banik, C.; Białowiec, A. The proof-of-concept: The transformation of naphthalene and its derivatives into decalin and its derivatives during thermochemical processing of sewage sludge. Energies 2021, 14, 6479. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, B.; Zheng, Y.; Hu, X.; Creamer, A.E.; Annable, M.D.; Li, Y. Biochar for volatile organic compound (VOC) removal: Sorption performance and governing mechanisms. Bioresour. Technol. 2017, 245, 606–614. [Google Scholar] [CrossRef]

- PN-EN 14346:2011; Characterization of Waste—Calculation of Dry Matter by Determination of Dry Residue or Water Content. Polish Committee for Standardization: Warsaw, Poland, 2011.

- PN-EN 15169:2011; Characterization of Waste—Determination of Loss on Ignition in Waste, Sludge, and Sediments. Polish Committee for Standardization: Warsaw, Poland, 2013.

- PN-Z−15008-04:1993; Municipal solid waste—Tests for fuel properties—Determination of combustible and non-combustible content. Polish Committee for Standardization: Warsaw, Poland, 2013.

- Jagadeeswaran, I.; Sriram, H. EU 1272/2008—Classification, Labelling and Packaging of Substances and Mixtures. In Medical Device Guidelines and Regulations Handbook; Springer: Cham, Switzerland, 2022; pp. 261–295. [Google Scholar] [CrossRef]

- Bernardo, F.; Ratola, N.; Sánchez-Soberón, F.; Alves, A.; Homem, V. Presence, behaviour, and risk assessment of volatile methylsiloxanes in wastewater: A year-long comprehensive study within a wastewater treatment plant. Sci. Total Environ. 2024, 951, 175486. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).