Synthesis of Ce-La-Pr/Mn-O Ternary Oxide Composites via Co-Precipitation and Synergistic Photocatalytic Degradation of Cr(VI)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

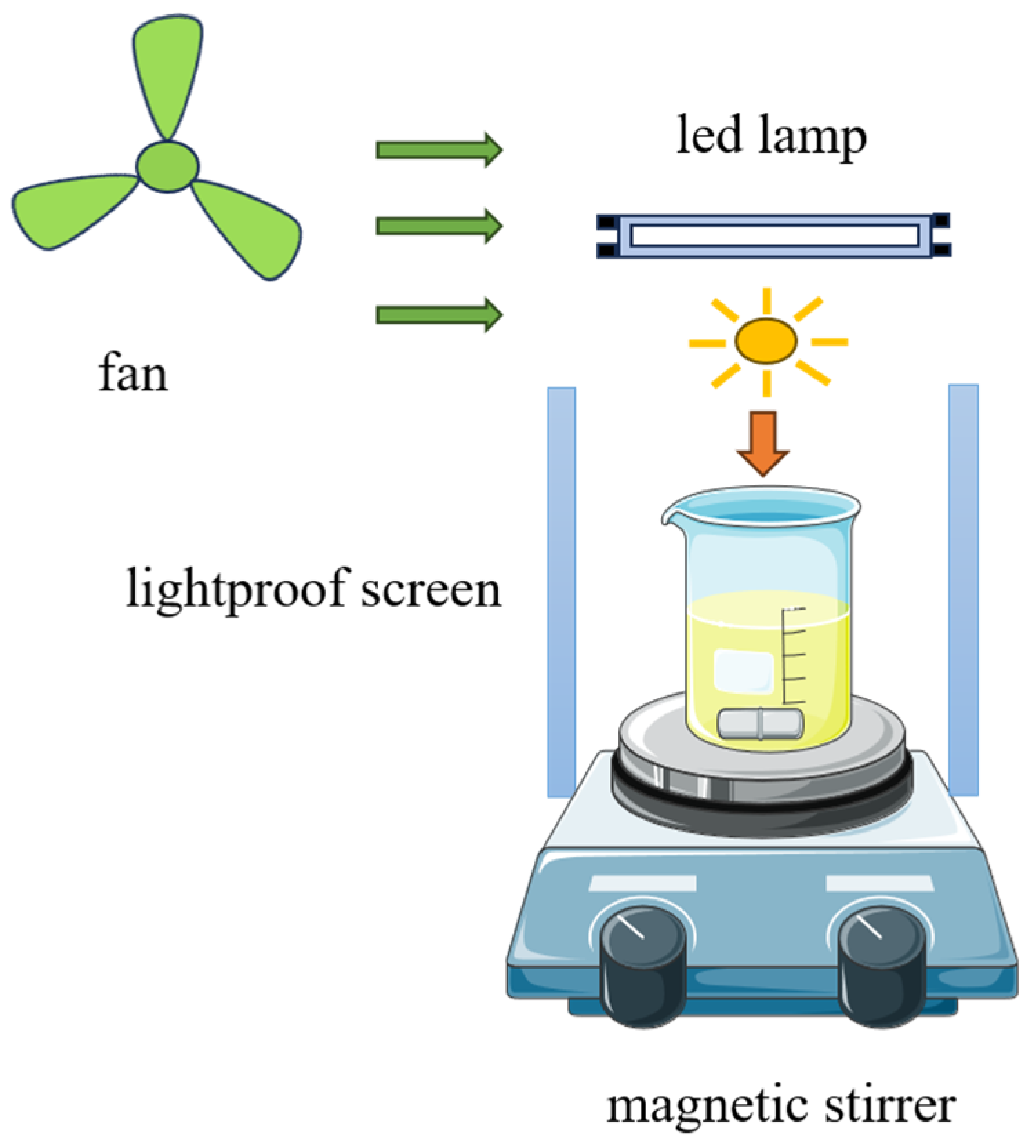

2.2. Synthesis of Ce-La-X(Mn/Pr)-O Ternary Oxide Composites

2.3. Material Characterization

2.4. Cr(VI) Removal Experiment

3. Results and Discussion

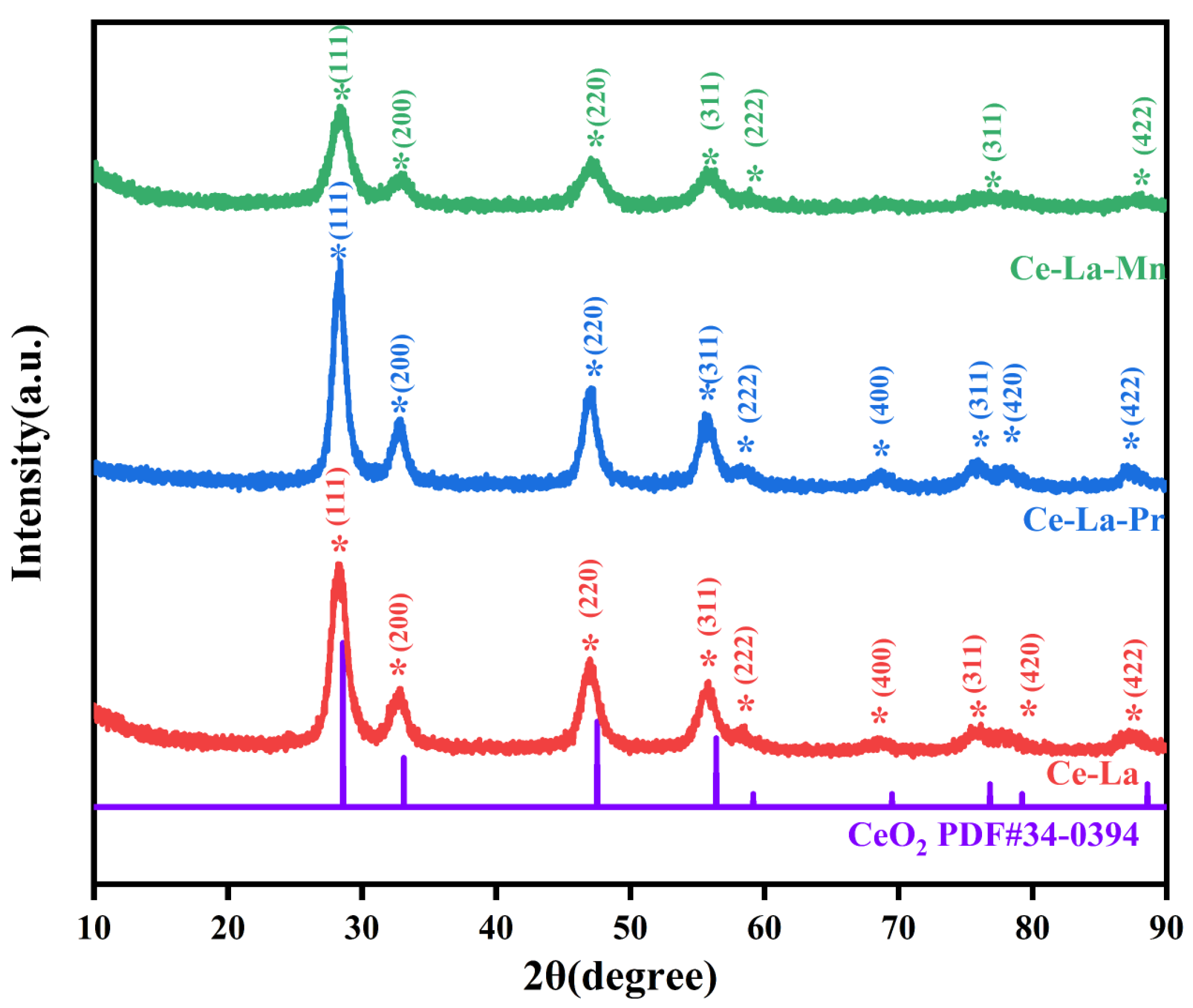

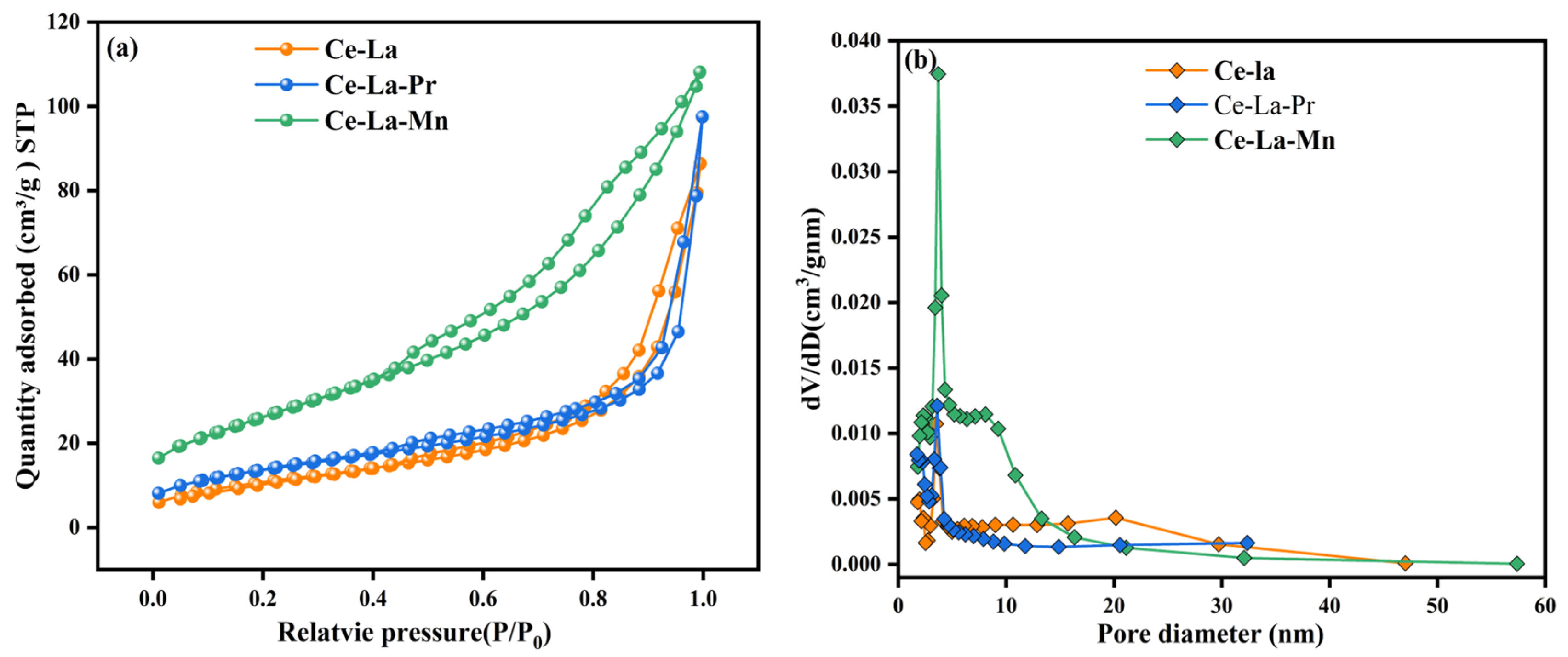

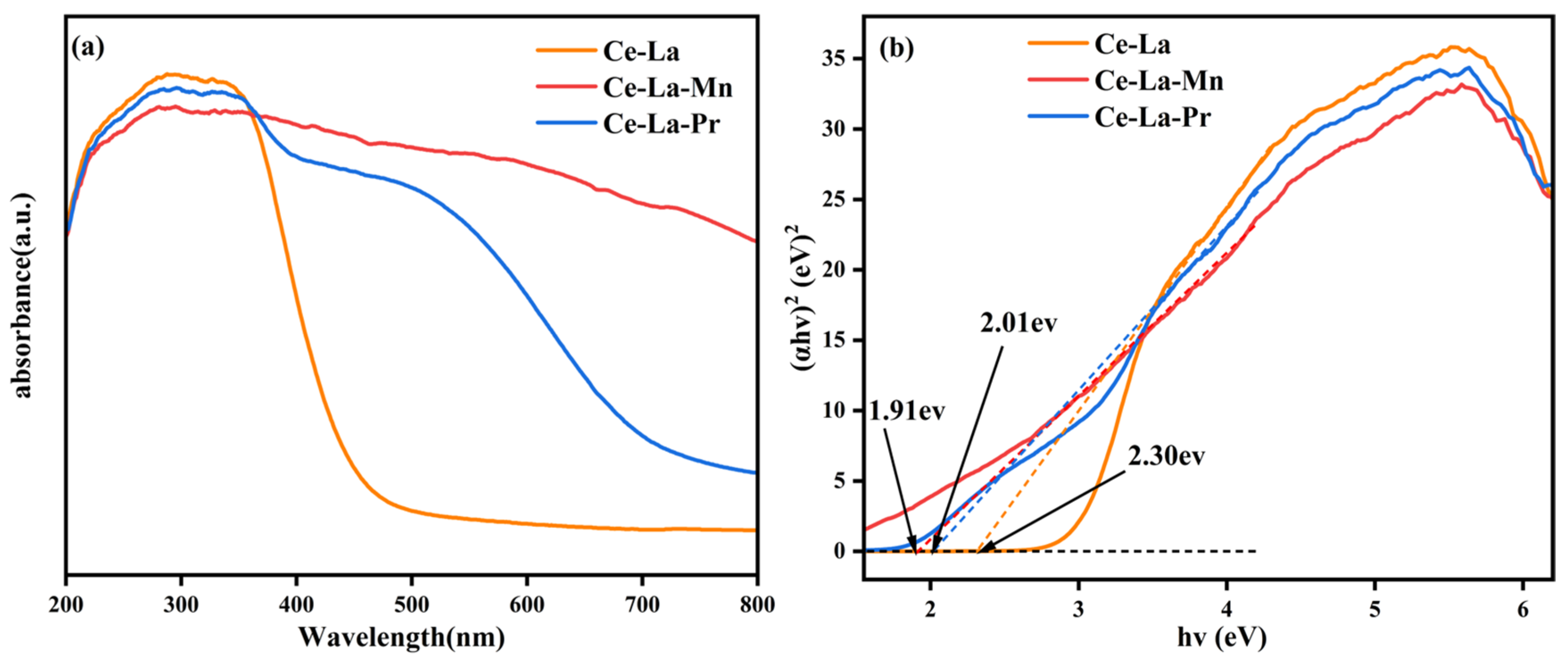

3.1. Crystal Structure, Morphology of Composites

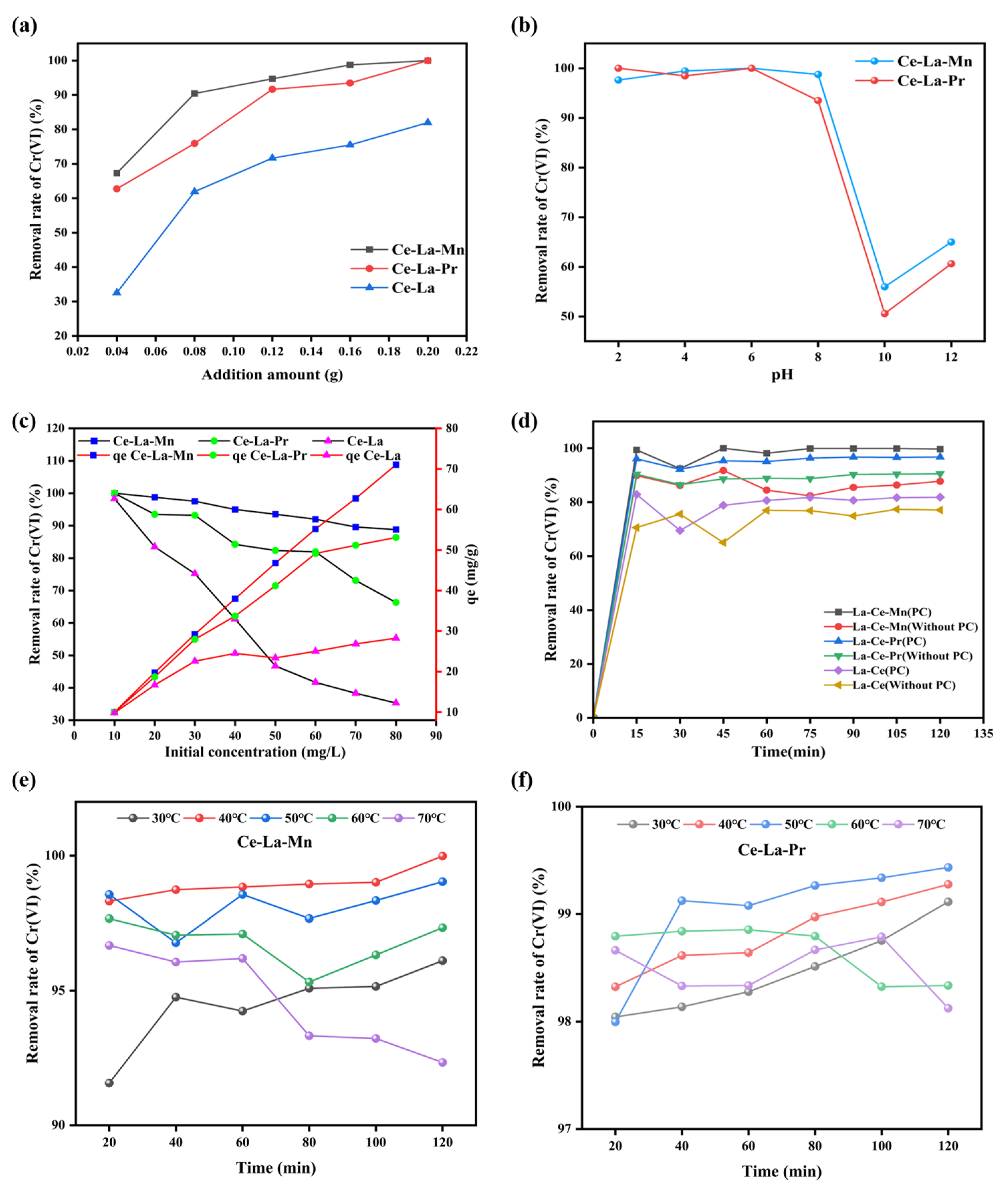

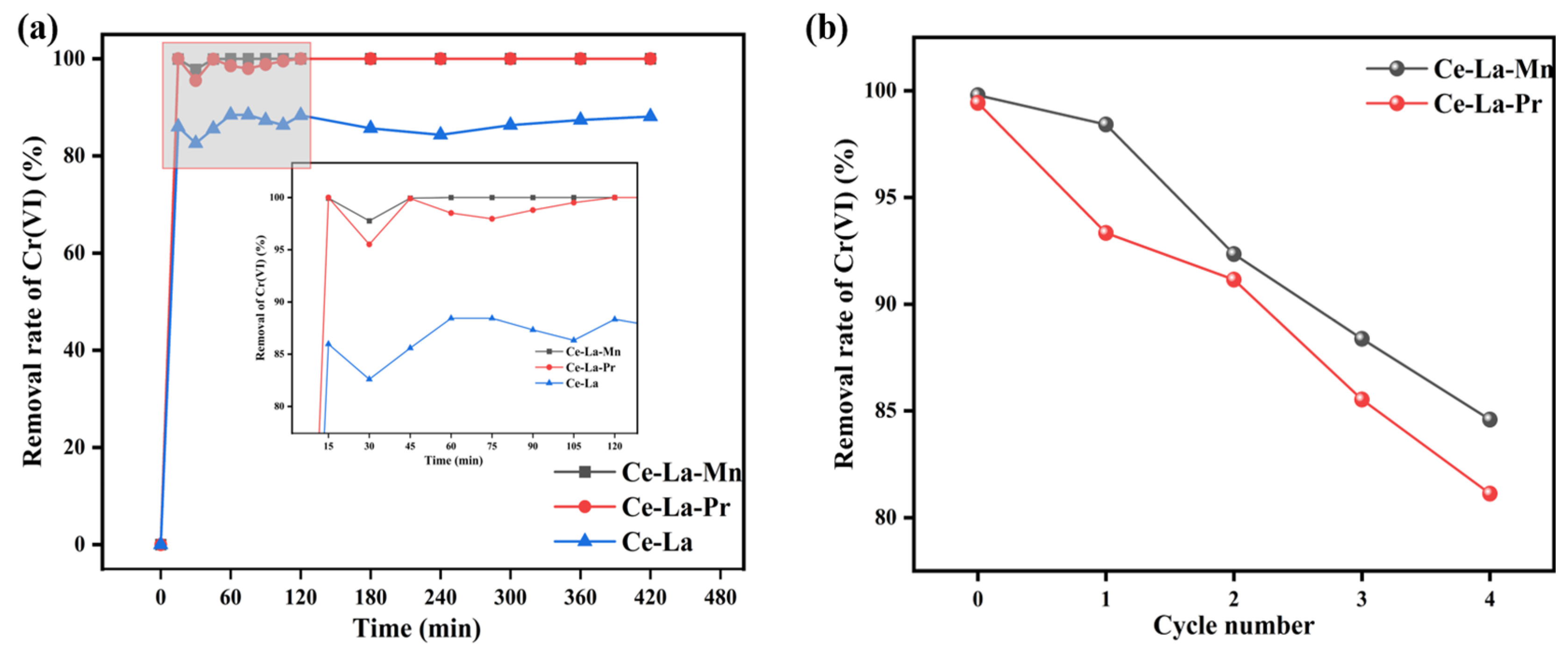

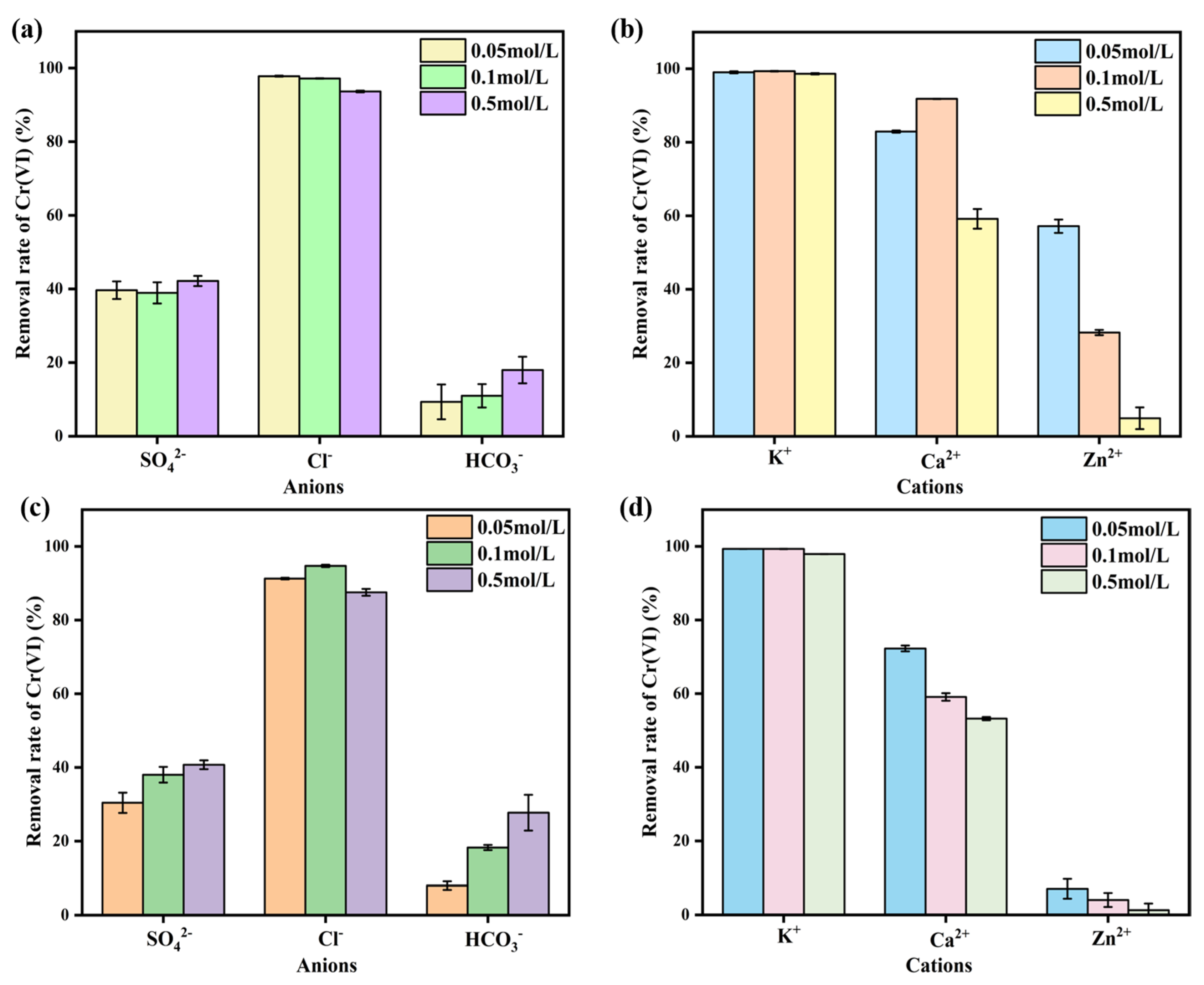

3.2. Cr(VI) Removal Test

3.3. Reaction Kinetics

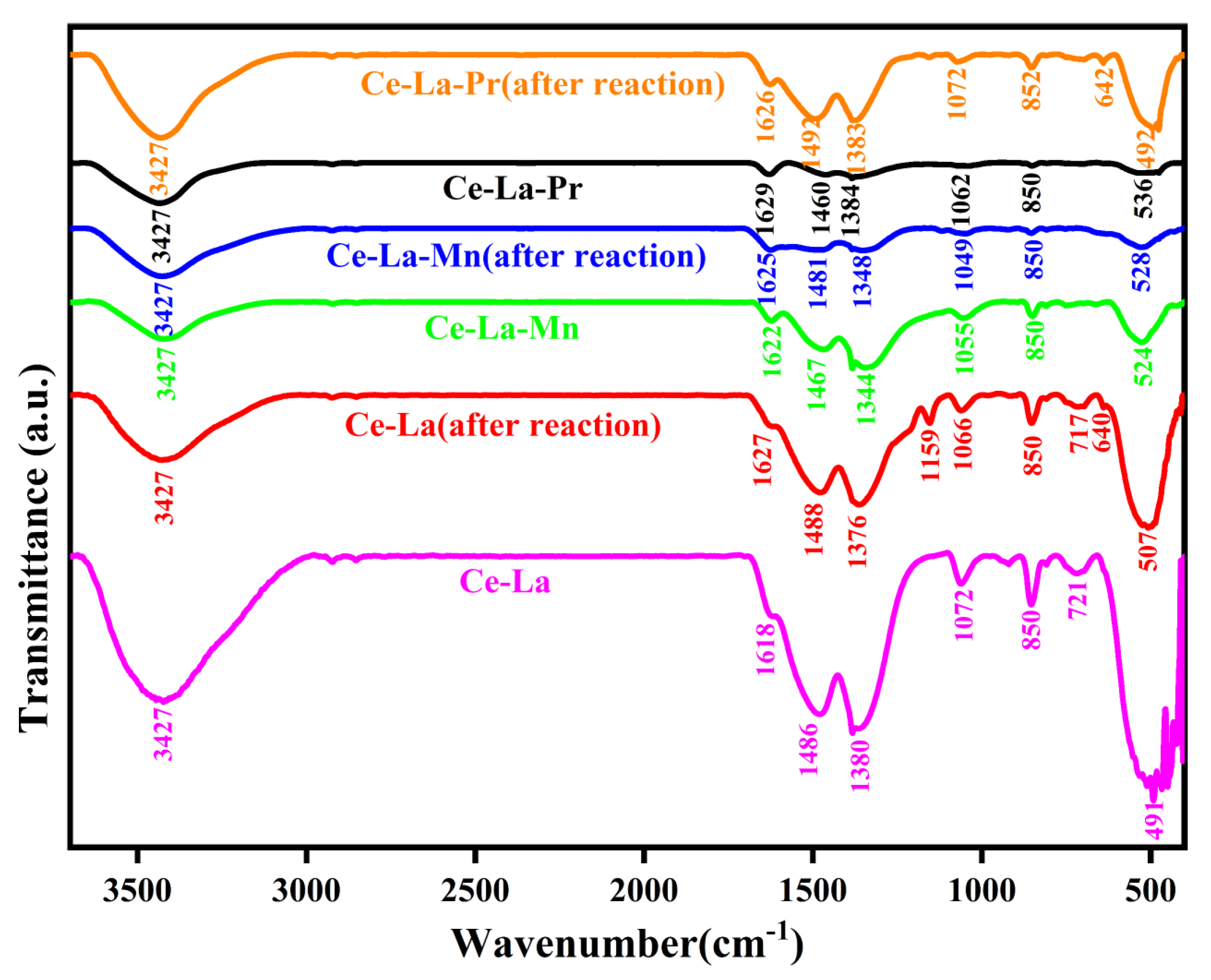

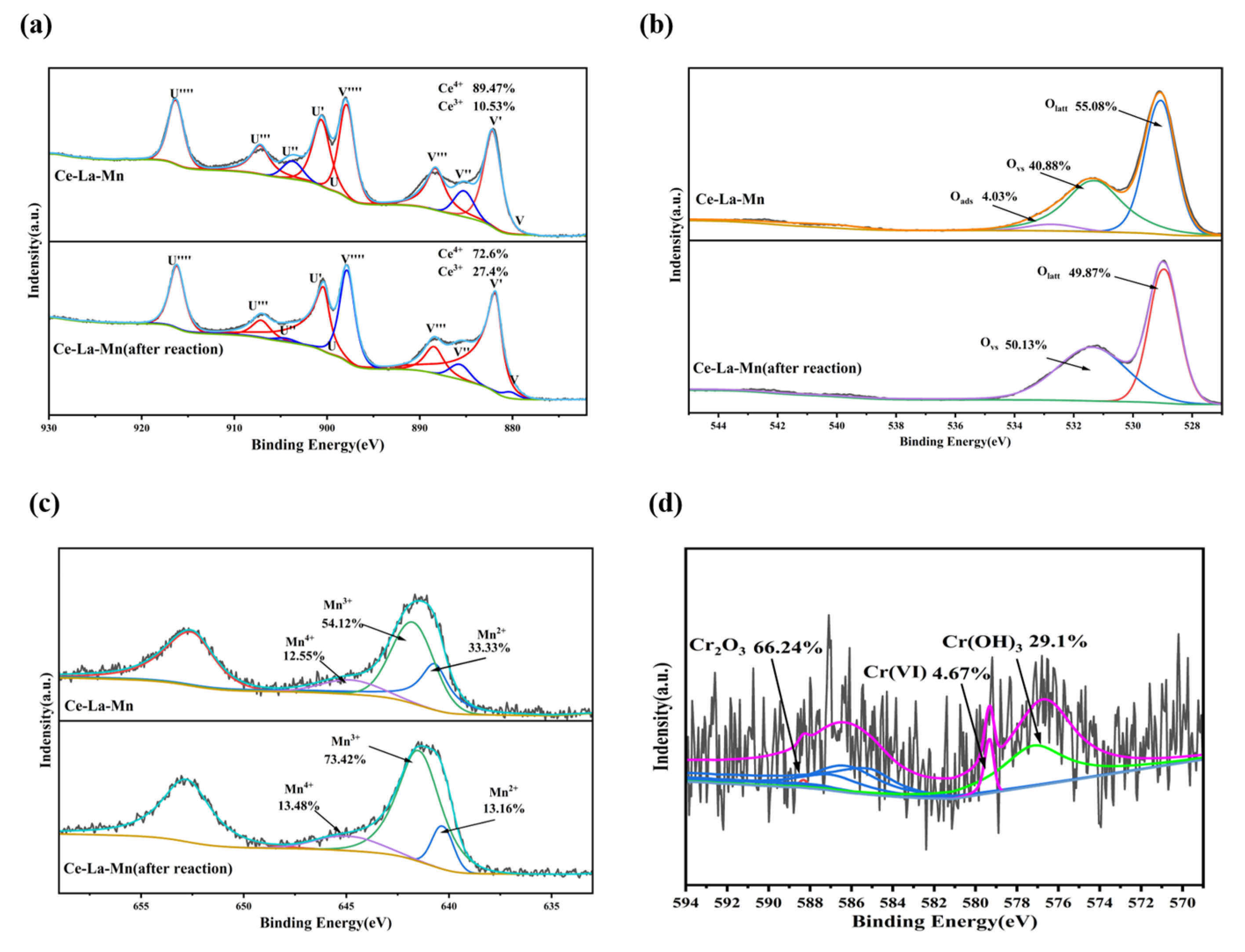

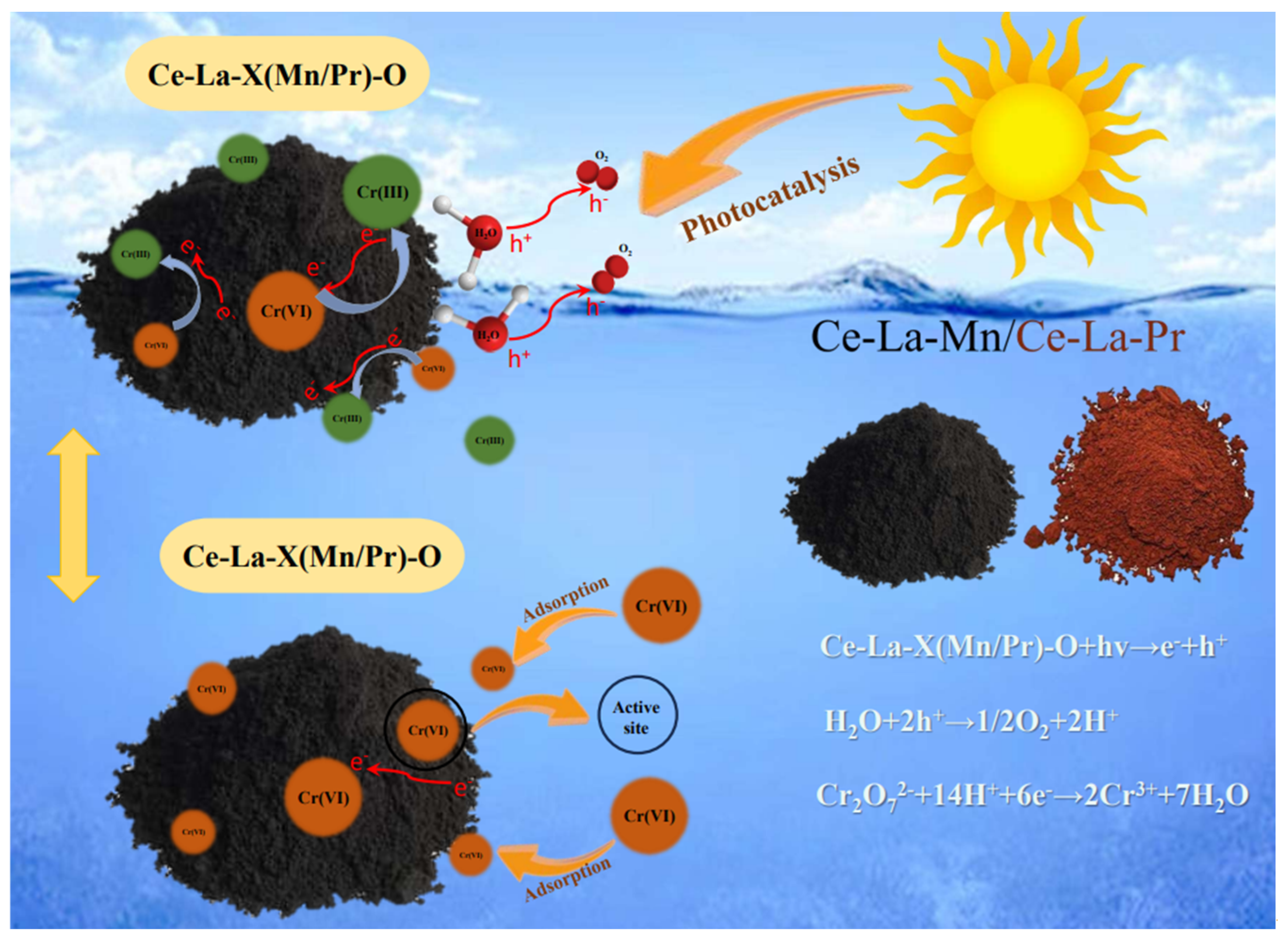

3.4. Reaction Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ramli, N.N.; Kurniawan, S.B.; Ighalo, J.O.; Said, N.S.M.; Marsidi, N.; Buhari, J.; Shah, R.A.R.; Zulkifli, M.; Alias, J.; Daud, N.M.; et al. A review of the treatment technologies for hexavalent chromium contaminated water. BioMetals 2023, 36, 1189–1219. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.; Huang, W.; Zhang, L.; Gao, J.; Zhang, W. Adsorption of Cr(VI) on cerium immobilized cross-linked chitosan composite in single system and coexisted with Orange II in binary system. Int. J. Biol. Macromol. 2017, 103, 605–612. [Google Scholar] [CrossRef] [PubMed]

- Saleem, M.H.; Afzal, J.; Rizwan, M.; Shah, Z.U.H.; Depar, N.; Usman, K. Chromium toxicity in plants: Consequences on growth, chromosomal behavior and mineral nutrient status. Turk. J. Agric. For. 2022, 46, 371–389. [Google Scholar] [CrossRef]

- Naseri, A.; Asghari Sarabi, G.; Samadi, M.; Yousefi, M.; Ebrahimi, M.; Moshfegh, A.Z. Recent advances on dual-functional photocatalytic systems for combined removal of hazardous water pollutants and energy generation. Res. Chem. Intermed. 2022, 48, 911–933. [Google Scholar] [CrossRef]

- Rosales, E.; Ferreira, L.; Angeles Sanroman, M.; Tavares, T.; Pazos, M. Enhanced selective metal adsorption on optimised agroforestry waste mixtures. Bioresour. Technol. 2015, 182, 41–49. [Google Scholar] [CrossRef] [PubMed]

- Irshad, M.A.; Sattar, S.; Nawaz, R.; Al-Hussain, S.A.; Rizwan, M.; Bukhari, A.; Waseem, M.; Irfan, A.; Inam, A.; Zaki, M.E.A. Enhancing chromium removal and recovery from industrial wastewater using sustainable and efficient nanomaterial: A review. Ecotoxicol. Environ. Saf. 2023, 263, 115231. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Lei, X.; Wang, H.; Xiao, J.; Qu, Z. Enhanced Catalytic Performance of La-Doped CoMn2O4 Catalysts by Regulating Oxygen Species Activity for VOCs Oxidation. ACS Catal. 2023, 13, 8293–8306. [Google Scholar] [CrossRef]

- Yang, J.; Yang, S.; Zhang, J.; He, J.; Jiang, W. Photocatalytic treatment of Cr(VI) with ZrO2 and application of by-products as ethane dehydrogenation catalyst. Desalination Water Treat. 2023, 286, 205–216. [Google Scholar] [CrossRef]

- Atran, A.A.; Hamdy, M.S. Improving the Photocatalytic Performance of Porous Ceria under Visible Light Illumination via Mn Incorporation. Catalysts 2023, 13, 523. [Google Scholar] [CrossRef]

- Li, J.; Liu, Q.; Huang, R.; Wang, G. Synthesis of a novel Ce(III)-incorporated cross-linked chitosan and its effective removal of fluoride from aqueous solution. J. Rare Earths 2016, 34, 1053–1061. [Google Scholar] [CrossRef]

- Li, L.; Hu, S.-z.; Huang, T.; Zhang, N.; Wang, Y. Fabricating the ternary CeO2@CNTs/CdSe composite with synchronously enhanced adsorption and photocatalytic activity toward water-soluble pollutants removal. Chem. Eng. J. 2023, 476, 146574. [Google Scholar] [CrossRef]

- Meng, J.; He, M.; Li, F.; Li, T.; Huang, Z.; Cao, W. Combining Ce-metal-organic framework with CdS for efficient photocatalytic removals of heavy metal ion and organic pollutant under visible and solar lights. Inorganica Chim. Acta 2023, 557, 121701. [Google Scholar] [CrossRef]

- Wang, Q.; Cui, M.; Huang, X.; Hou, Y.; Yue, M.; Zhong, Q.; Zhang, Y. The effect of hydrogen peroxide on properties of Ce0.35Zr0.55La0.055Pr0.045O2 oxides and the catalytic performance used on Pd supported three-way catalyst. J. Rare Earths 2017, 35, 1092–1101. [Google Scholar] [CrossRef]

- Jaramillo-Fierro, X.; Cuenca, G.; Ramon, J. Comparative Study of the Effect of Doping ZnTiO3 with Rare Earths (La and Ce) on the Adsorption and Photodegradation of Cyanide in Aqueous Systems. Int. J. Mol. Sci. 2023, 24, 3780. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Zhong, D.; Xu, Y.; Zhang, J.; Jiang, R.; Liao, P. Preparation of La-doped Ti/SnO2-Sb2O4 anode and its electrochemical oxidation performance of rhodamine B. Environ. Sci. Pollut. Res. 2024, 31, 21632–21645. [Google Scholar] [CrossRef] [PubMed]

- Yi, Y.; Fu, Y.; Wang, Y.; Xu, Z.; Diao, Z. Lanthanum/iron co-modified biochar for highly efficient adsorption of low-concentration phosphate from aqueous solution. J. Environ. Chem. Eng. 2024, 12, 111876. [Google Scholar] [CrossRef]

- Zhang, P.; He, M.; Xu, Z.; Li, F.; Fang, D.; Li, C.; Lv, C.; Mo, X.; Li, K.; Wang, H. Incorporation of edge-N into La-doped hierarchical carbon framework enables high-efficiency phosphate electrosorption: Boosting accessible active centers and bridging charge transfer paths. Chem. Eng. J. 2024, 481, 148518. [Google Scholar] [CrossRef]

- Jin, H.-G.; Gu, J.-X.; Lin, W.; Xu, W.-J.; Huang, B.-X.; Yang, F.; Wen, J.-X.; Ren, Y.; Chao, Z.-S. Room temperature aqueous synthesis of Ce(IV)-MOFs with UiO-66 architecture and their photocatalytic decarboxylative oxygenation of arylacetic acids. Microporous Mesoporous Mater. 2022, 346, 112257. [Google Scholar] [CrossRef]

- Kalidasan, K.; Mallapur, S.; Munirathnam, K.; Nagarajaiah, H.; Reddy, M.B.M.; Kakarla, R.R.; Raghu, A.V. Transition metals-doped g-C3N4 nanostructures as advanced photocatalysts for energy and environmental applications. Chemosphere 2024, 352, 141354. [Google Scholar] [CrossRef]

- Arulkumar, E.; Shree, S.S.; Thanikaikarasan, S. Synthesis and characterization of CuO-Mn3O4: Application to chromium (VI) photocatalytic reduction. J. Mater. Sci.-Mater. Electron. 2024, 35, 198. [Google Scholar] [CrossRef]

- Mjahed, M.; Bouda, H.; Salmani, E.; Zahraouy, H.E.; Benyoussef, A. Impact of rare earth (La, Pr, Eu) impurities on the perovskite SrTiO3 for efficient photocatalytic activity. Phys. Scr. 2024, 99, 025916. [Google Scholar] [CrossRef]

- Mikolajczyk, A.; Wyrzykowska, E.; Mazierski, P.; Grzyb, T.; Wei, Z.; Kowalska, E.; Caicedo, P.N.A.; Zaleska-Medynska, A.; Puzyn, T.; Nadolna, J. Visible-light photocatalytic activity of rare-earth-metal-doped TiO2: Experimental analysis and machine learning for virtual design. Appl. Catal. B-Environ. Energy 2024, 346, 123744. [Google Scholar] [CrossRef]

- Li, Q.; He, S.; Wang, L.; Zhao, M.; Guo, T.; Ma, X.; Meng, Z. A novel Z-scheme heterojunction g-C3N4/g-C3N4/Pr6O11 for efficient visible-light photocatalytic degradation of sulfonamide. Appl. Organomet. Chem. 2024, 38, e7344. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, G.; Tang, D. A novel high efficient Mg-Ce-La adsorbent for fluoride removal: Kinetics, thermodynamics and reusability. Desalination Water Treat. 2016, 57, 23844–23855. [Google Scholar] [CrossRef]

- Choi, Y.-B.; Kim, B.-G.; Son, J.-H.; Jung, Y.-G. Synthesis, characteristics, and redox properties of Zr/Sn-doped CeO2 nanoparticles in H2 gas at high temperatures. Ceram. Int. 2019, 45, 12983–12988. [Google Scholar] [CrossRef]

- Zhang, K.; Yu, G.; Zhao, H.; Wang, H.; Zhang, G.; Chen, Y. Preparation, characterisation and catalytic property of ultrafine Ce-La-Mn mixed oxides. J. Exp. Nanosci. 2012, 7, 233–242. [Google Scholar] [CrossRef][Green Version]

- Wang, Y.; Deng, W.; Wang, Y.; Guo, L.; Ishihara, T. A comparative study of the catalytic oxidation of chlorobenzene and toluene over Ce-Mn oxides. Mol. Catal. 2018, 459, 61–70. [Google Scholar] [CrossRef]

- Liu, J.; Wang, T.; Shi, N.; Yang, J.; Serageldin, M.A.; Pan, W.-P. Enhancing the interaction between Mn and Ce oxides supported on fly ash with organic acid ligands interface modification for effective VOC removal: A combined experimental and DFT plus U study. Fuel 2022, 313, 123043. [Google Scholar] [CrossRef]

- Andana, T.; Rappé, K.G.; Nelson, N.C.; Gao, F.; Wang, Y. Selective catalytic reduction of NOx with NH3 over Ce-Mn oxide and Cu-SSZ-13 composite catalysts—Low temperature enhancement. Appl. Catal. B Environ. 2022, 316, 121522. [Google Scholar] [CrossRef]

- Ji, Y.; Ding, B.; Ni, W.; Li, X.; He, X.; Chen, Z.; Ran, S.; Lu, H. Tailoring the crystal structure of CaTiO3 by multielement doping for photo-assisted activation of NO. Chem. Eng. J. 2022, 450, 138255. [Google Scholar] [CrossRef]

- Li, P.; Zhang, W.; Zhang, X.; Wang, Z.; Wang, X.; Ran, S.; Lv, Y. Synthesis, Characterization, and Photocatalytic Properties of Flower-like Mn-doped Ceria. Mater. Res. 2018, 21, e20180167. [Google Scholar] [CrossRef]

- Meena, S.; Anantharaju, K.S.; Vidya, Y.S.; Renuka, L.; Uma, B.; Sharma, S.C.; Prasad, B.D.; More, S.S. Enhanced sunlight driven photocatalytic activity and electrochemical sensing properties of Ce-doped MnFe2O4 nano magnetic ferrites. Ceram. Int. 2021, 47, 14760–14774. [Google Scholar] [CrossRef]

- Lu, M.; Su, Z.; Zhang, Y.; Zhang, H.; Wang, J.; Li, Q.; Jiang, T. Mn-Doped Spinel for Removing Cr(VI) from Aqueous Solutions: Adsorption Characteristics and Mechanisms. Materials 2023, 16, 1553. [Google Scholar] [CrossRef] [PubMed]

- Afroze, S.; Sen, T.K. A Review on Heavy Metal Ions and Dye Adsorption from Water by Agricultural Solid Waste Adsorbents. Water Air Soil Pollut. 2018, 229, 225. [Google Scholar] [CrossRef]

- Cui, Y.W.; Li, J.; Du, Z.F.; Peng, Y.Z. Cr(VI) Adsorption on Red Mud Modified by Lanthanum: Performance, Kinetics and Mechanisms. PLoS ONE 2016, 11, e0161780. [Google Scholar] [CrossRef]

- Luo, Z.; Zhu, Z. Effects of Support Preparation Methods on Structural and Catalytic Properties of Au/MnOx-CeO2. Catal. Lett. 2023, 154, 422–429. [Google Scholar] [CrossRef]

- Al-Bassami, N.S.; Mansour, S.F.; Abdel-Fattah, E.; Abdo, M.A. Ce-Co-Mn-Zn ferrite nano catalyst: A synergetic effect of rare earth Ce3+ on enhanced optical properties and photocatalysis. Ceram. Int. 2023, 49, 20601–20612. [Google Scholar] [CrossRef]

- Wang, S.; Chen, C.; Li, Y.; Zhang, Q.; Li, Y.; Gao, H. Synergistic Effects of Optical and Photoluminescence Properties, Charge Transfer, and Photocatalytic Activity in MgAl2O4Ce and Mn-Codoped MgAl2O4Ce Phosphors. J. Electron. Mater. 2019, 48, 6675–6685. [Google Scholar] [CrossRef]

- Zhao, D.; Cai, C. Cerium-based UiO-66 metal-organic framework for synergistic dye adsorption and photodegradation: A discussion of the mechanism. Dye. Pigment. 2021, 185, 108957. [Google Scholar] [CrossRef]

- Wang, J.; Liang, Y.; Jin, Q.; Hou, J.; Liu, B.; Li, X.; Chen, W.; Hayat, T.; Alsaedi, A.; Wang, X. Simultaneous Removal of Graphene Oxide and Chromium(VI) on the Rare Earth Doped Titanium Dioxide Coated Carbon Sphere Composites. ACS Sustain. Chem. Eng. 2017, 5, 5550–5561. [Google Scholar] [CrossRef]

- Wen, Z.; Zhang, Y.; Cheng, G.; Wang, Y.; Chen, R. Simultaneous removal of As(V)/Cr(VI) and acid orange 7 (AO7) by nanosized ordered magnetic mesoporous Fe-Ce bimetal oxides: Behavior and mechanism. Chemosphere 2019, 218, 1002–1013. [Google Scholar] [CrossRef] [PubMed]

- Zuo, K.; Huang, X.; Liu, X.; Garcia, E.M.G.; Kim, J.; Jain, A.; Chen, L.; Liang, P.; Zepeda, A.; Verduzco, R.; et al. A Hybrid Metal-Organic Framework-Reduced Graphene Oxide Nanomaterial for Selective Removal of Chromate from Water in an Electrochemical Process. Environ. Sci. Technol. 2020, 54, 13322–13332. [Google Scholar] [CrossRef] [PubMed]

- Tao, R.; Li, H.; Liu, Z.; Zhang, X.; Wang, M.; Shen, W.; Qu, M.; Mei, Y. The adsorbent preparation of FeOOH@PU for effective chromium (VI) removal. Environ. Sci. Pollut. Res. 2023, 30, 33160–33169. [Google Scholar] [CrossRef]

- Asuha, S.; Zhou, X.G.; Zhao, S. Adsorption of methyl orange and Cr(VI) on mesoporous TiO2 prepared by hydrothermal method. J. Hazard. Mater. 2010, 181, 204–210. [Google Scholar] [CrossRef] [PubMed]

- Hu, B.; Wu, L.; Ou, M.; Wang, X.; Tang, Y. Sorption Studies of Chromium(VI) onto Cerium/Ferroferric Oxide Composites. J. Inorg. Organomet. Polym. Mater. 2021, 31, 2627–2637. [Google Scholar] [CrossRef]

- Nelson, N.C.; Andana, T.; Rappé, K.G.; Wang, Y. Mechanistic insight into low temperature SCR by ceria-manganese mixed oxides incorporated into zeolites. Catal. Sci. Technol. 2023, 13, 1111–1118. [Google Scholar] [CrossRef]

| Samples | SBET (m2/g) | Vtotal (cm3/g) | P (nm) |

|---|---|---|---|

| Ce-La | 39.3386 | 0.133710 | 13.5958 |

| Ce-La-Pr | 48.8215 | 0.150878 | 12.3616 |

| Ce-La-Mn | 96.2698 | 0.167296 | 6.9511 |

| Temperature | 25 °C | 35 °C | 45 °C | |

|---|---|---|---|---|

| Pseudo-First-Order Kinetics model Ce-La-Mn | K1 | 0.02043 | 0.00725 | 0.01194 |

| R2 | 0.95001 | 0.93181 | 0.94660 | |

| Pseudo-second-order kinetic model Ce-La-Mn | K2 | 0.03555 | 0.04078 | 0.03965 |

| R2 | 0.99987 | 0.99989 | 0.99981 | |

| Pseudo-first-order kinetic model Ce-La-Pr | K1 | 0.01338 | 0.02146 | 0.03111 |

| R2 | 0.91714 | 0.97242 | 0.91314 | |

| Pseudo-second-order kinetic model Ce-La-Pr | K2 | 0.04107 | 0.04037 | 0.04061 |

| R2 | 0.99997 | 0.99999 | 0.99998 | |

| Element | Wt% | At% |

|---|---|---|

| O | 30.46 | 75.39 |

| Ce | 49.95 | 17.55 |

| La | 12.32 | 4.29 |

| Mn | 6.84 | 2.38 |

| Cr | 0.43 | 0.39 |

| pH | 3 | 5 | 6 | 7 | 9 | 11 |

|---|---|---|---|---|---|---|

| Zeta potential (Ce-La-Pr) | 30.3 | 11.96 | 0.38 | 1.28 | 3.97 | 9.14 |

| Zeta potential (Ce-La-Mn) | 2.53 | −6.80 | −7.71 | −8.37 | −12.00 | −18.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, X.; Yu, Z. Synthesis of Ce-La-Pr/Mn-O Ternary Oxide Composites via Co-Precipitation and Synergistic Photocatalytic Degradation of Cr(VI). Water 2024, 16, 1178. https://doi.org/10.3390/w16081178

Feng X, Yu Z. Synthesis of Ce-La-Pr/Mn-O Ternary Oxide Composites via Co-Precipitation and Synergistic Photocatalytic Degradation of Cr(VI). Water. 2024; 16(8):1178. https://doi.org/10.3390/w16081178

Chicago/Turabian StyleFeng, Xiujuan, and Zebang Yu. 2024. "Synthesis of Ce-La-Pr/Mn-O Ternary Oxide Composites via Co-Precipitation and Synergistic Photocatalytic Degradation of Cr(VI)" Water 16, no. 8: 1178. https://doi.org/10.3390/w16081178

APA StyleFeng, X., & Yu, Z. (2024). Synthesis of Ce-La-Pr/Mn-O Ternary Oxide Composites via Co-Precipitation and Synergistic Photocatalytic Degradation of Cr(VI). Water, 16(8), 1178. https://doi.org/10.3390/w16081178