Experimental Study on the Sedimentation Performance of an Arc-Plate Linear Sedimentation Tank

Abstract

1. Introduction

2. Materials and Methods

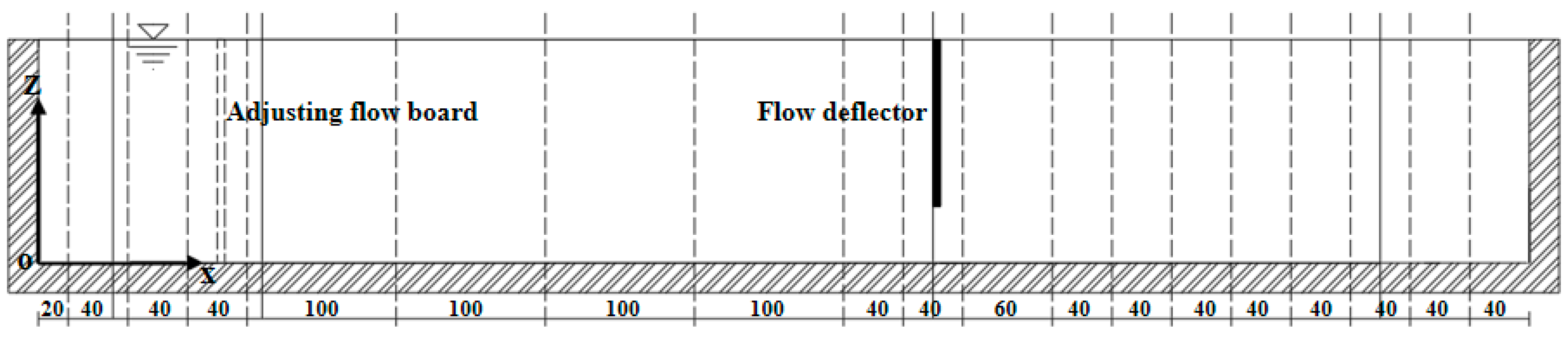

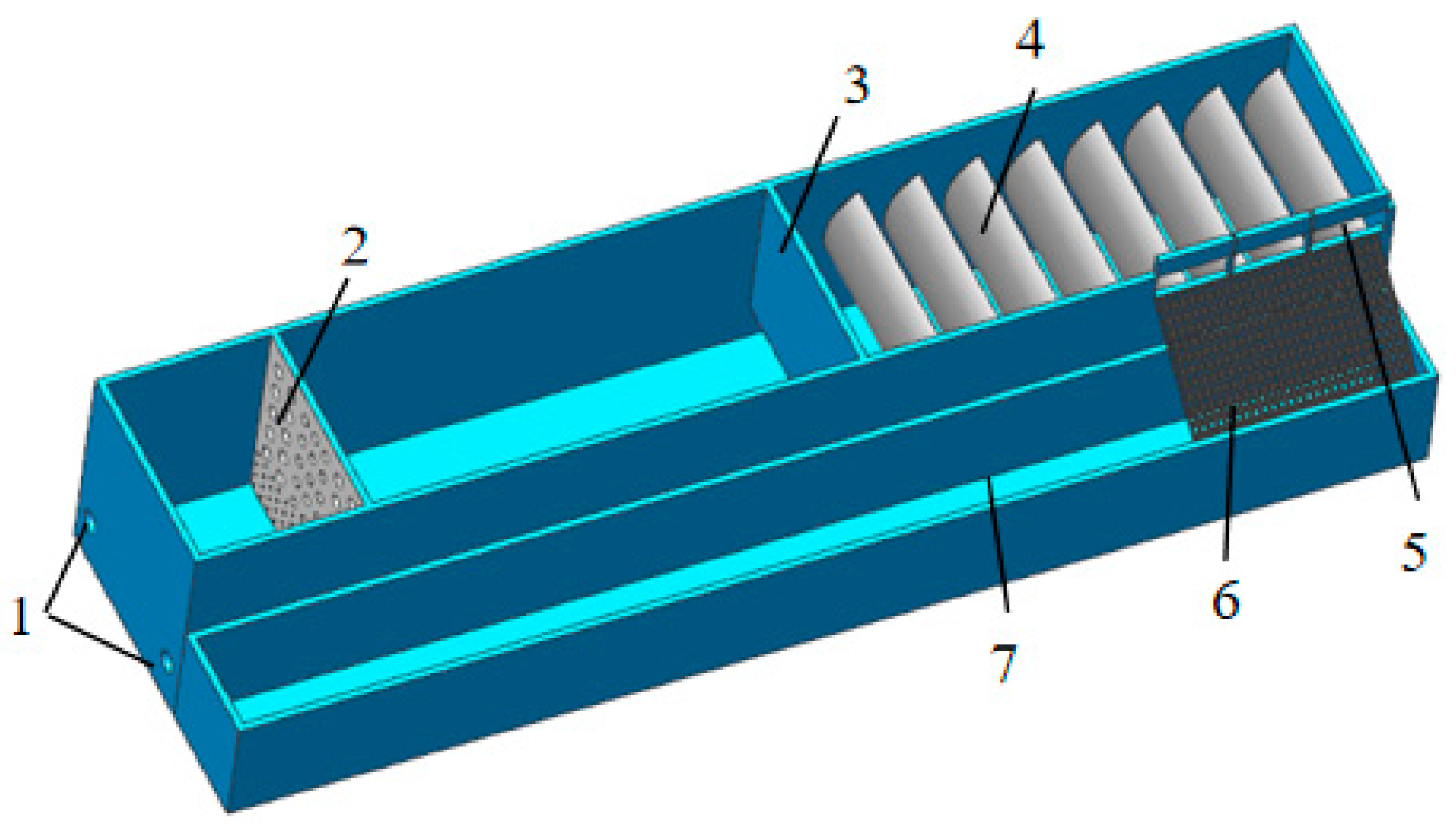

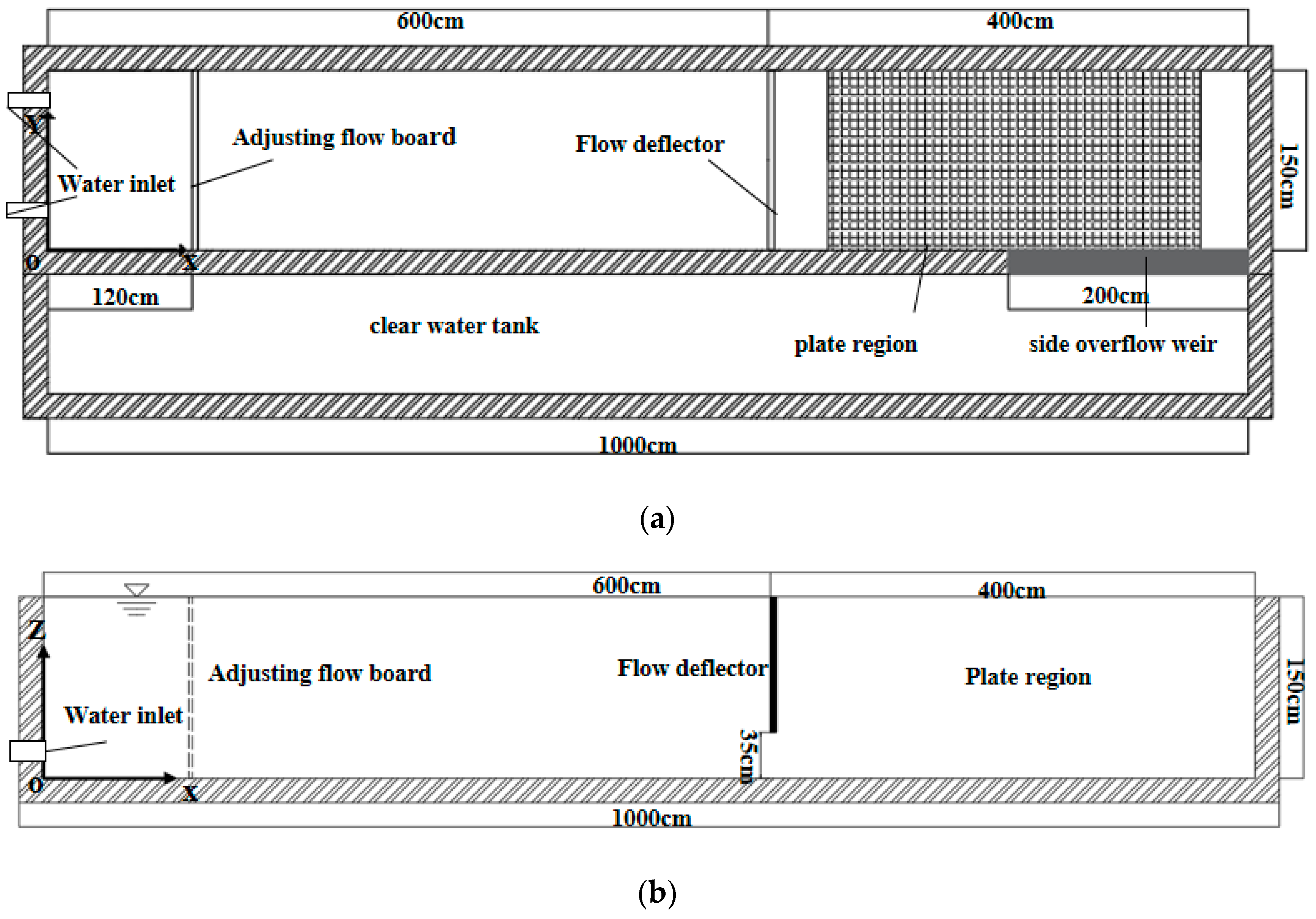

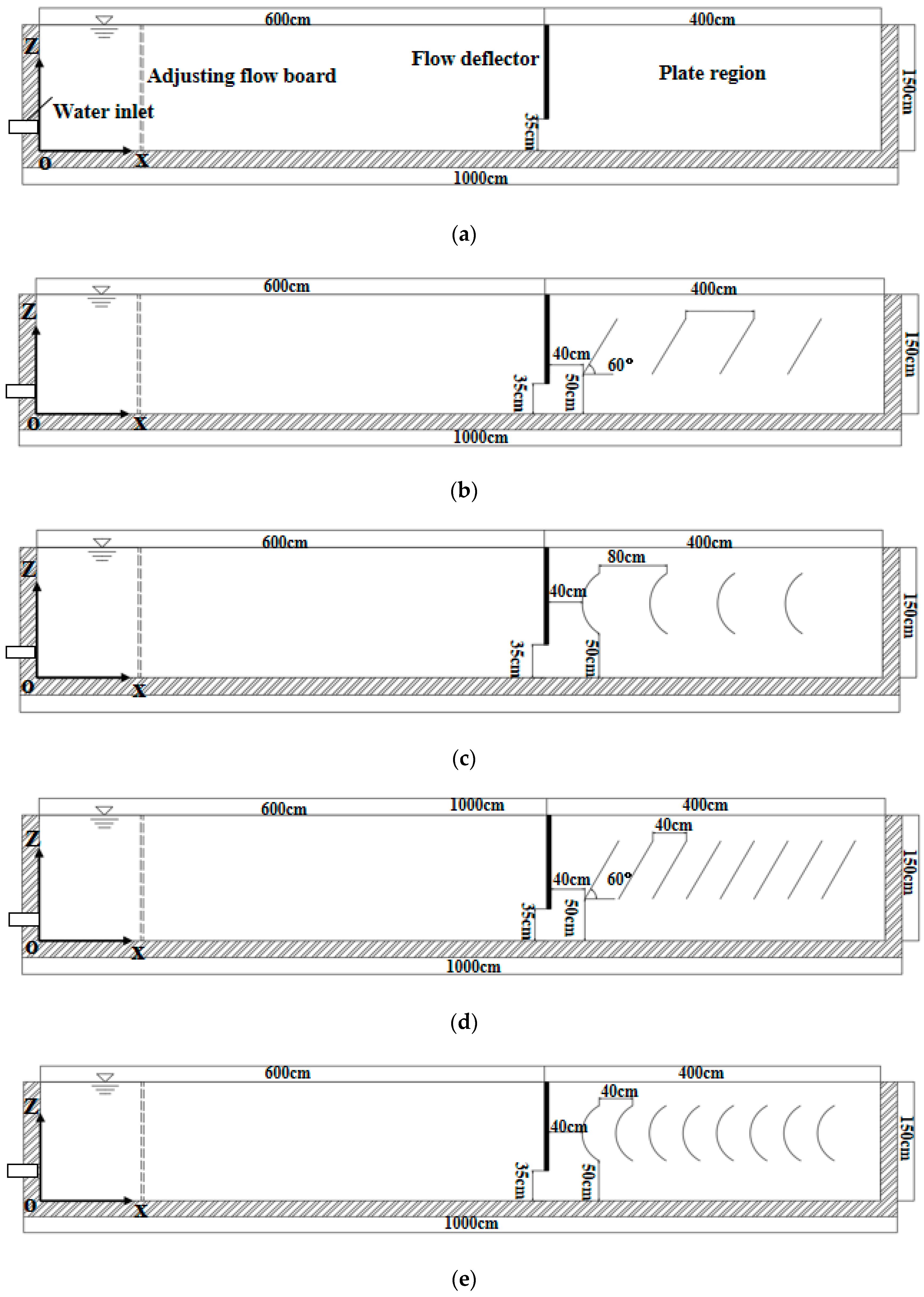

2.1. Structure and Operational Principles of the Linear Sedimentation Tank

2.2. Experimental Setup

2.3. Experimental Conditions

2.4. Experimental Instruments and Measurement Methods

3. Results and Analysis

3.1. Analysis of Flow Characteristics

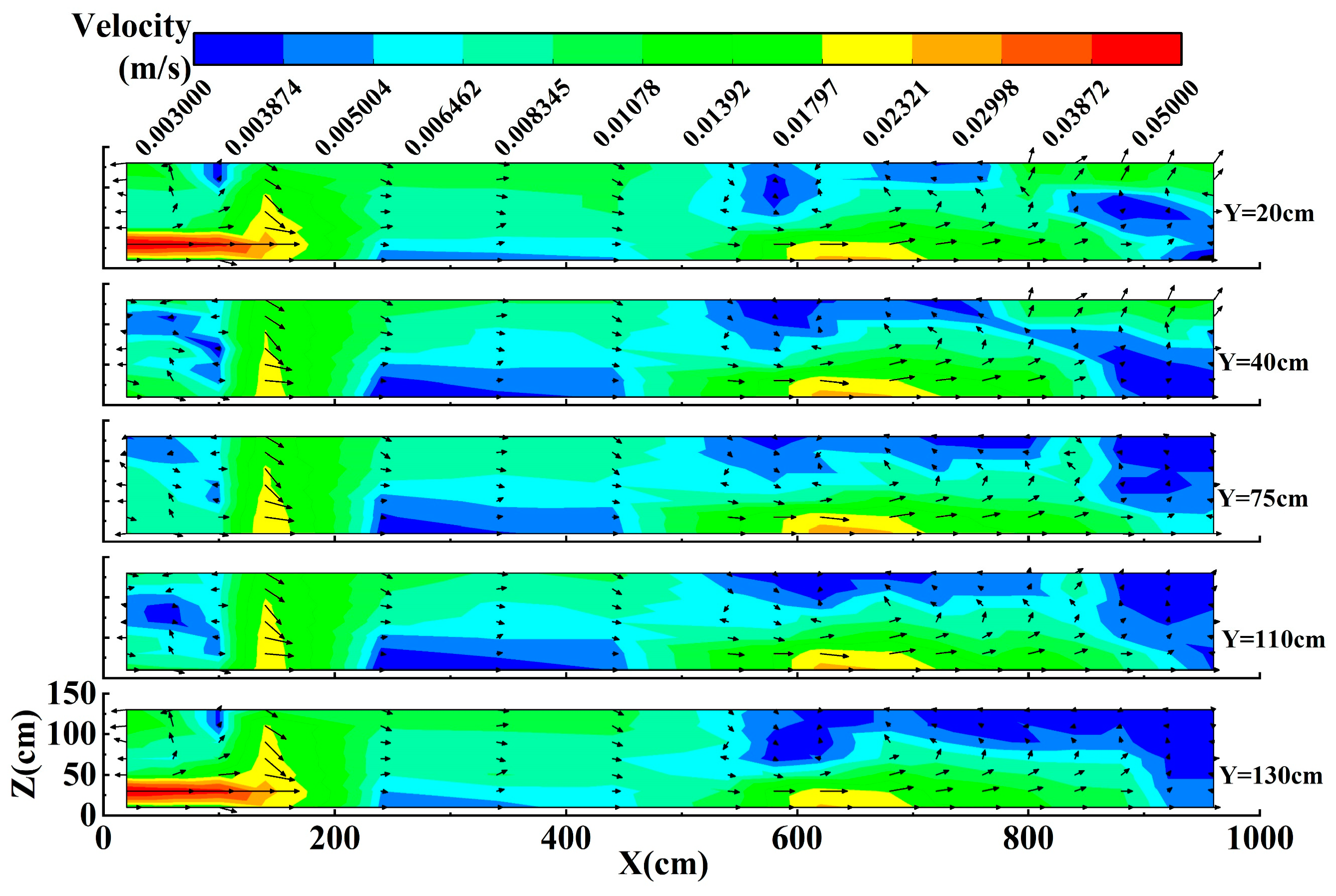

3.1.1. Comparative Analysis of Flow Velocity along Sedimentation Tanks without Plates

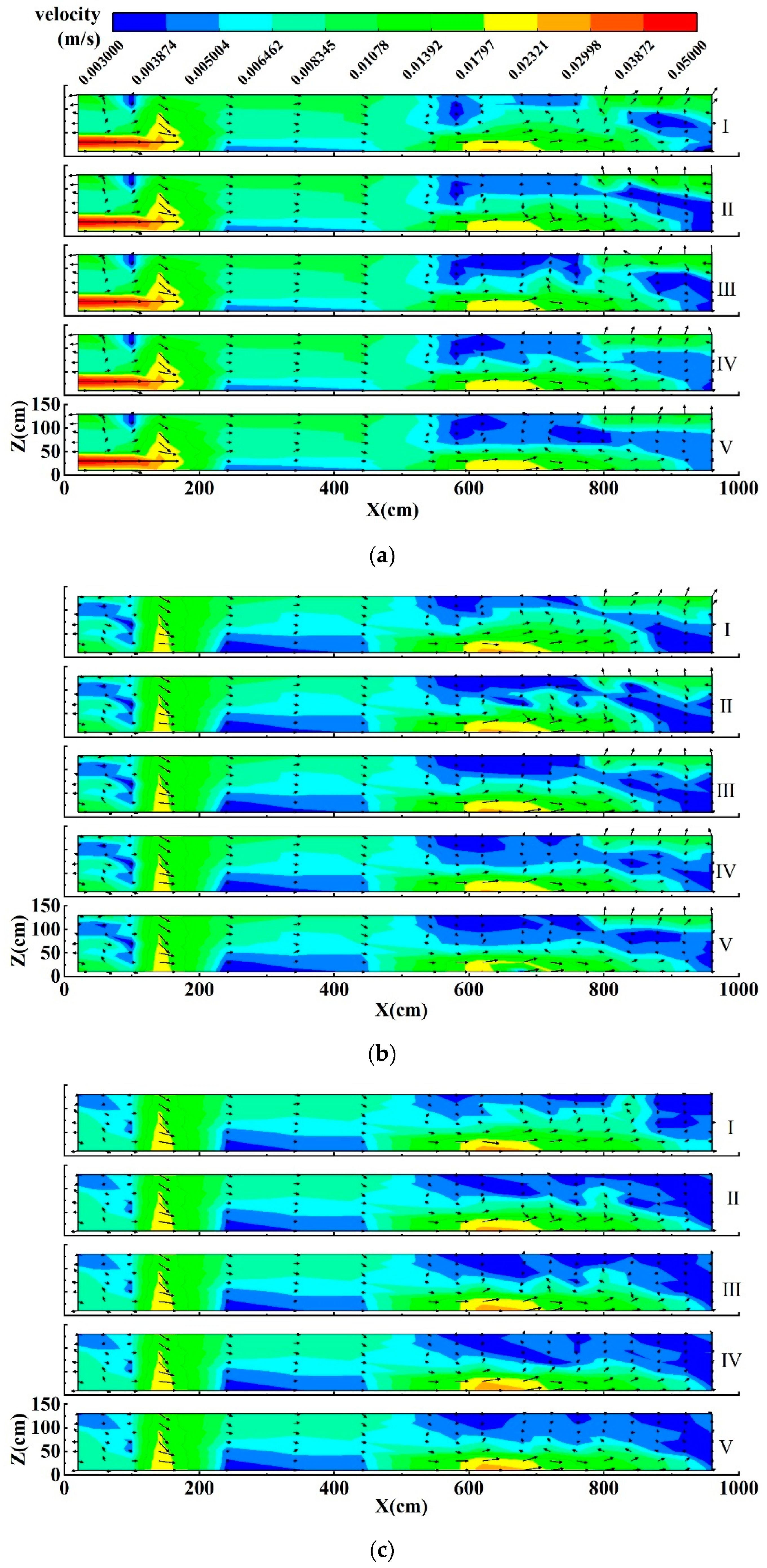

3.1.2. Comparative Analysis of Flow Velocity along Sedimentation Tanks with Different Plate Structures

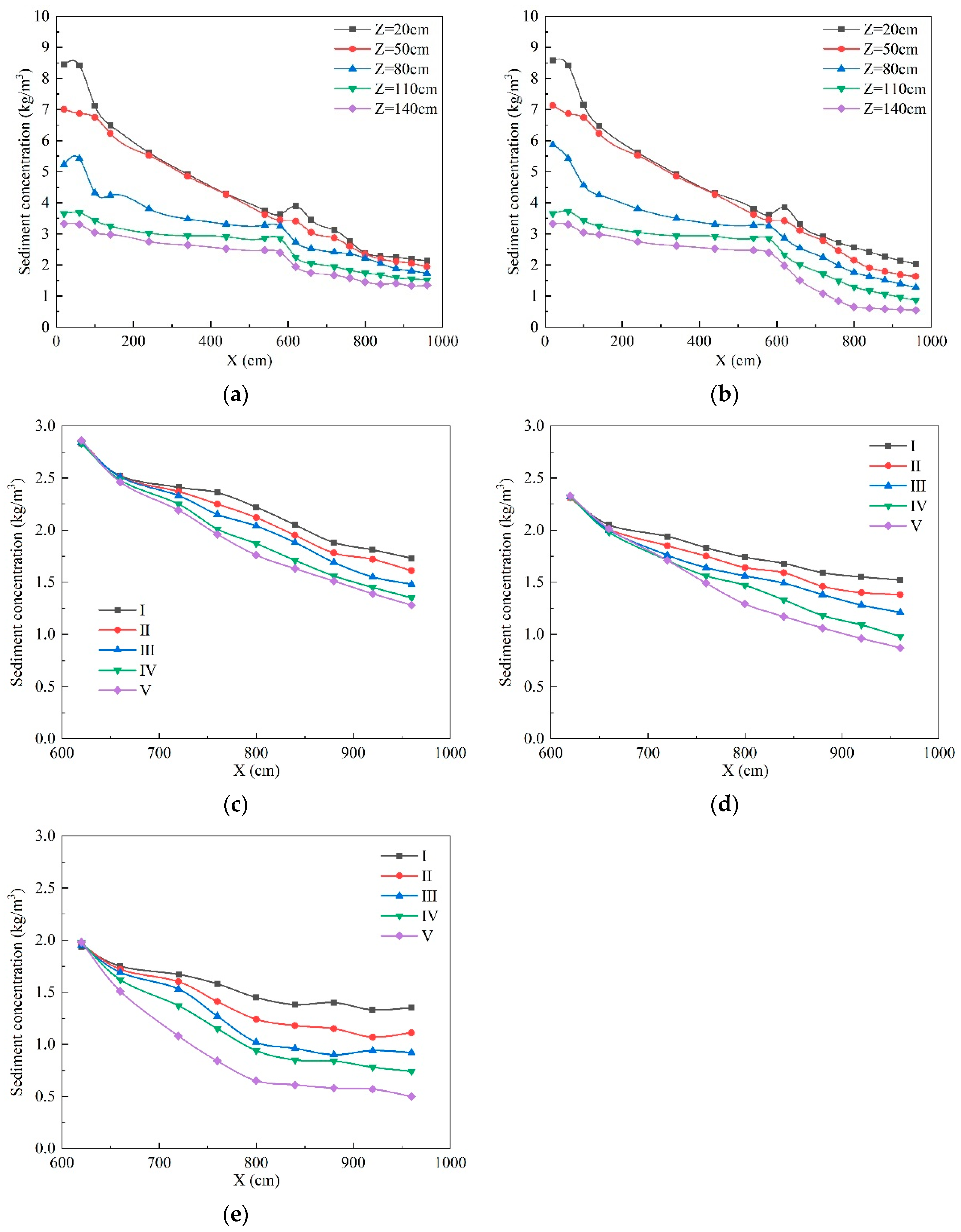

3.2. Analysis of Sediment Concentration Distribution

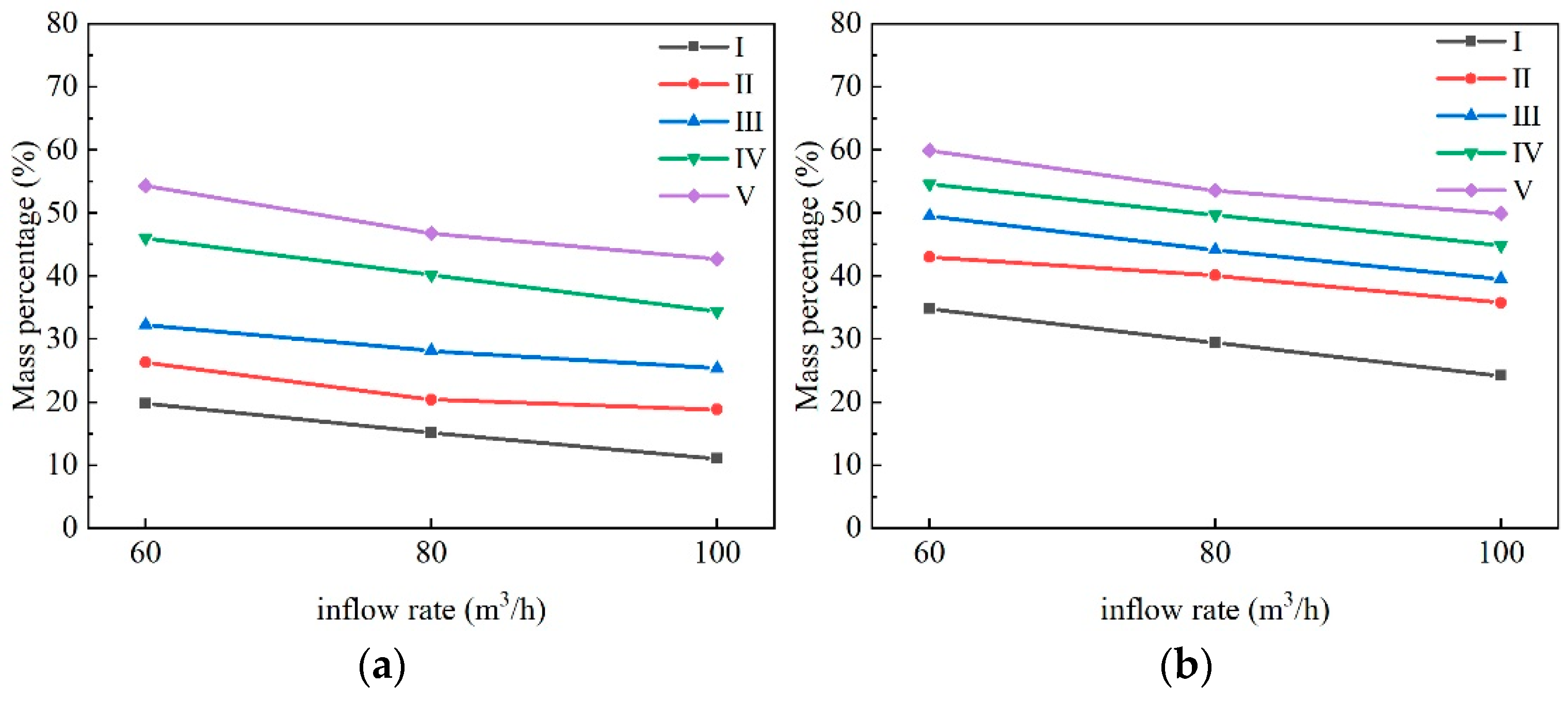

3.3. Analysis of Sediment Removal Efficiency

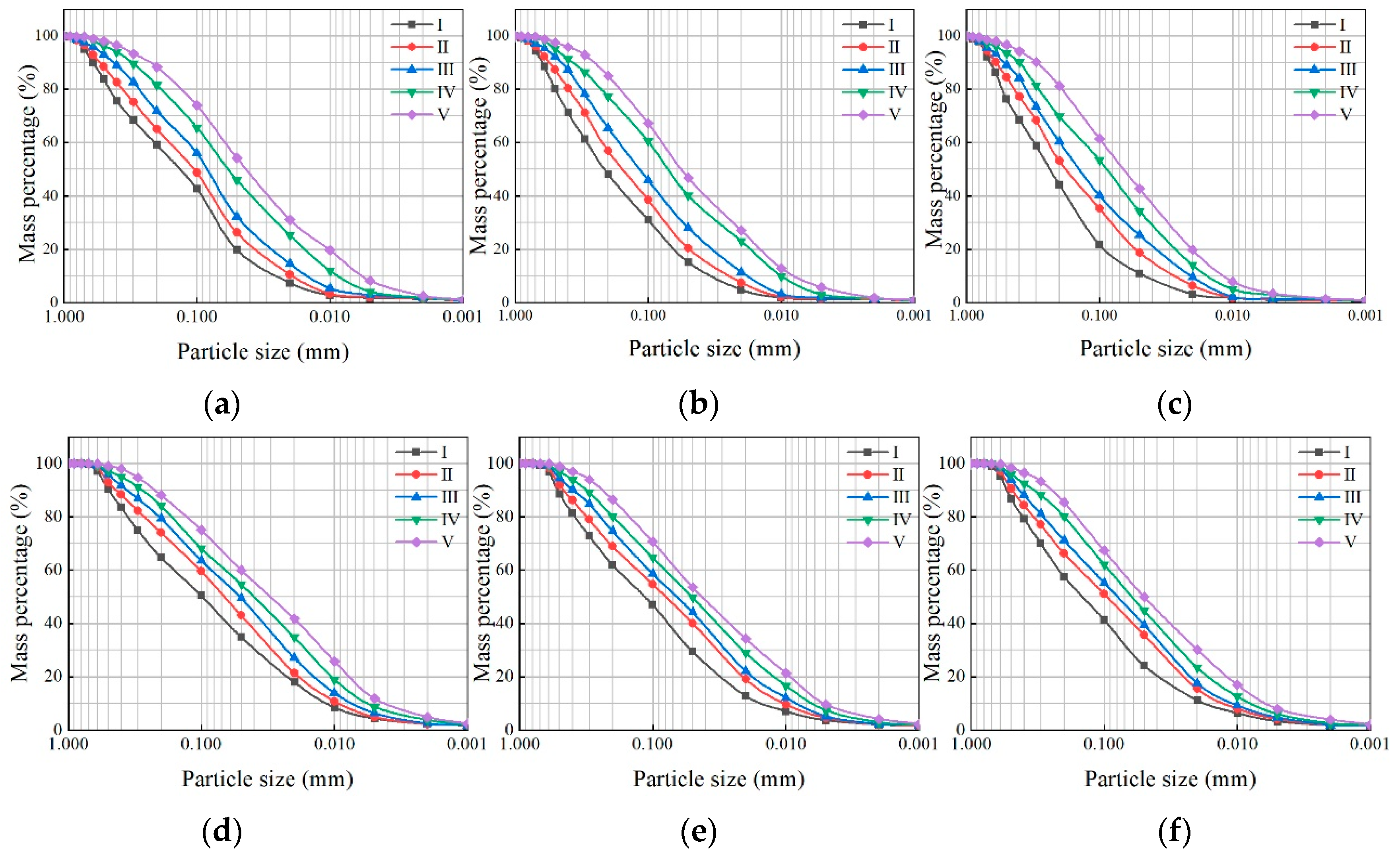

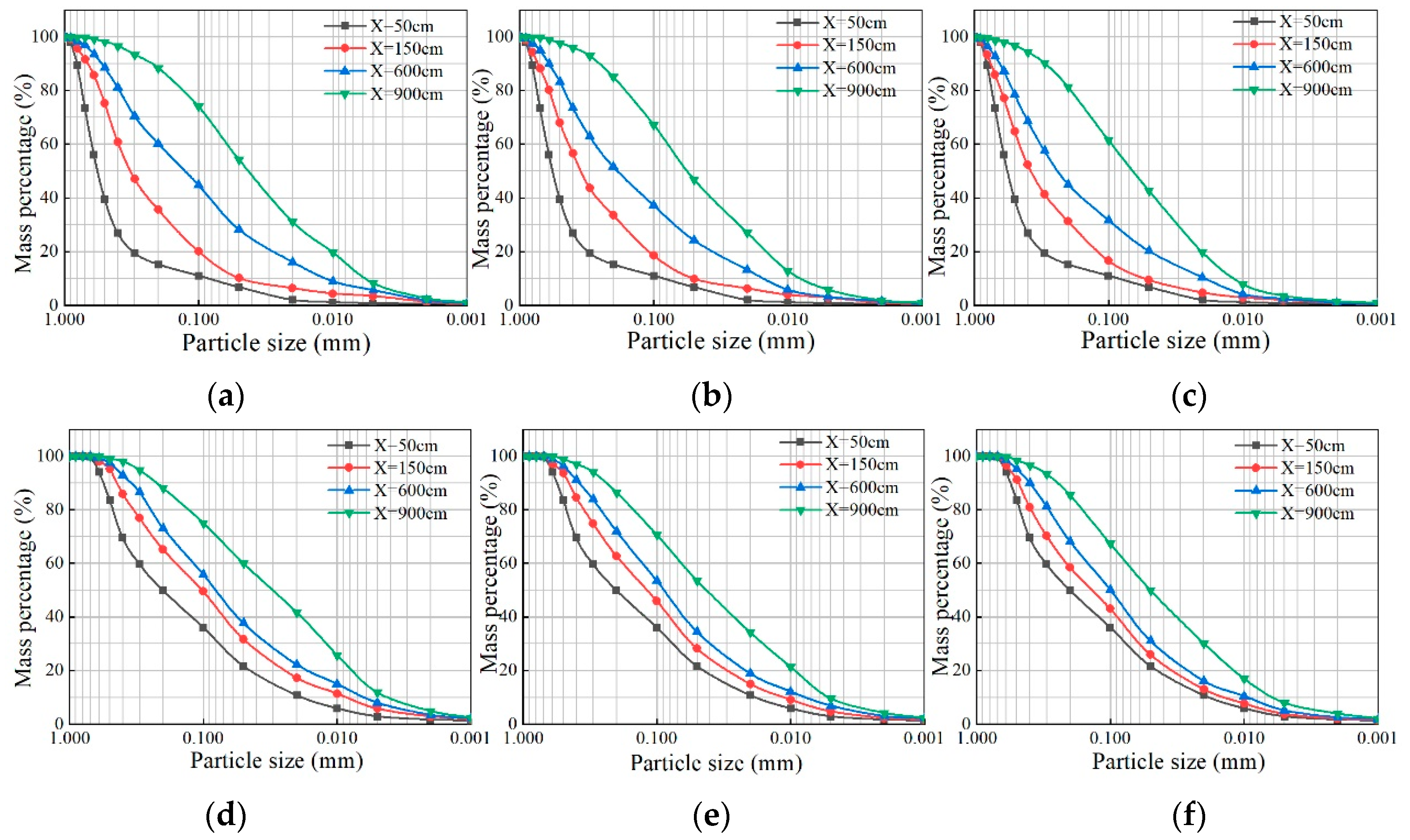

3.4. Analysis of Particle Size Distribution

3.4.1. Distribution of Particle Size in Different Sedimentation Tanks

3.4.2. Distribution of Particle Size in Arc-Plate Sedimentation Tanks

4. Discussion

5. Conclusions

- (1)

- The distribution of the flow field and the velocity characteristics within the arc-plate sedimentation tank create a more favorable environment for the settling of sediment particles. The flow velocity between the arc plates is notably lower when compared to inclined plates, particularly when considering the downward direction of the combined velocity between the plates. This configuration effectively promotes a swifter settling of sediment. An increased number of plates leads to a reduction in the volume of the recirculation zone within the plate region. This alteration proves advantageous in facilitating the settling of sediment.

- (2)

- The arc-plate sedimentation tank proves highly effective in substantially reducing the surface sediment concentration within the plate region. When equipped with eight arc plates, the sediment concentration in the plate area measures between 0.5 and 1.32 kg/m3, indicating a noteworthy reduction ranging from approximately 8 to 34%, when compared to an equivalent number of inclined plates. In contrast to both plate-less tanks and those featuring four arc plates, the reduction in sediment concentration is even more pronounced. Specifically, the decrease ranges from about 33% to 60%, when compared to tanks without plates and from 18% to 44%, when compared to tanks with four arc plates. This highlights the superior sedimentation effect of the arc-plate sedimentation tank compared to its inclined-plate counterpart, with the sedimentation efficiency demonstrating an upward trend with an increasing number of arc plates.

- (3)

- The implementation of the arc-plate sedimentation tank results in a notable enhancement of sediment removal efficiency. Equipped with eight arc plates, the sediment removal efficiency spans from 57.13% to 82.45%, reflecting an improvement of approximately 7–10% when compared with a sedimentation tank featuring eight inclined plates. Furthermore, this efficiency increase becomes even more evident, showing a rise of about 47% to 60%, compared to a tank without plates, and a rise of 15% to 21% in comparison to a tank with four arc plates.

- (4)

- The arc-plate sedimentation tank demonstrates a noteworthy promotion of the settling of fine particle sediments. When equipped with eight arc plates, the mass fraction of sediment particles smaller than 0.05 mm in the tail bottom of the sedimentation tank falls within the range of 42.73% to 59.94%. This signifies an enhancement of approximately 5–7% compared to a sedimentation tank featuring eight inclined plates. Furthermore, this increase becomes more pronounced when compared to a tank without plates, showing a rise of about 25% to 32%, and when compared to a tank with four arc plates, exhibiting an increase of 10% to 20%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, J.; Kang, S. Current situation of water resource utilization in China and water-saving irrigation development strategy. Trans. CSAE 2000, 16, 1–5. [Google Scholar]

- Wang, Y.; Sheng, L.; Li, K.; Sun, H. Analysis of current situation of water resources in China and research on sustainable development countermeasures. J. Water Resour. Water Eng. 2008, 19, 10–14. [Google Scholar]

- Wu, P.; Feng, H. A preliminary study on the development strategy of water-saving agriculture in China. Trans. CSAE 2005, 21, 152–157. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.; Wang, J.; Wang, Z.; Zhao, W. Micro-irrigation in China: History, Present and future. J. Hydraul. Eng. 2016, 47, 372–381. [Google Scholar] [CrossRef]

- Yuan, S.Q.; Li, H.; Wang, X.K. Development status, problems, trends and suggestions of water-saving irrigation equipment in China. J. Drain. Irrig. Mach. Eng. 2015, 33, 78–92. [Google Scholar] [CrossRef]

- Han, S.; Li, Y.; Xu, F.; Sun, D.; Feng, J.; Liu, Z.; Wu, R.; Wang, Z. Effect of Lateral Flushing on Emitter Clogging under Drip Irrigation with Yellow River Water and a Suitable Method. Irrig. Drain. 2018, 67, 199–209. [Google Scholar] [CrossRef]

- He, C.; Scott, E.; Rochfort, Q. Enhancing sedimentation by improving flow conditions using parallel retrofit baffles. J. Environ. Manag. 2015, 160, 1–6. [Google Scholar] [CrossRef]

- Li, Q.; Song, P.; Zhou, B.; Xiao, Y.; Muhammad, T.; Liu, Z.; Zhou, H.; Li, Y. Mechanism of intermittent fluctuated water pressure on emitter clogging substances formation in drip irrigation system utilizing high sediment water. Agric. Water Manag. 2019, 215, 16–24. [Google Scholar] [CrossRef]

- Liu, L.; Niu, W.; Zhou, B. Effect of fine sediment particle size on blockage of labyrinth channel irrigator. Trans. CSAE 2012, 28, 87–93. [Google Scholar] [CrossRef]

- Niu, W.; Liu, L. Effect of particle size and sediment content of muddy water on blockage of labyrinth channel. J. Drain. Irrig. Mach. Eng. 2011, 29, 547–552. [Google Scholar] [CrossRef]

- Yang, X.; Liu, F.; Wu, Y.; Liu, J. Discussion on the selection of the first filter equipment of Xinjiang farmland water-saving irrigation system. China Rural. Water Hydropower 2014, 56, 76–80. [Google Scholar] [CrossRef]

- Jiang, D.S.; Gao, P.; Xu, X.X.; Yang, S.W. Experimental design of structural form of sand settling tank in water cellar. Trans. CSAE 2001, 17, 27–31. [Google Scholar]

- Hu, S.K.; Li, W.X.; Yang, G.; Liu, N.N. The operation effect of linear sand settling pond in agricultural micro-irrigation was improved. J. Drain. Irrig. Mach. Eng. 2020, 38, 626–631. [Google Scholar]

- Hu, S.K.; Li, W.X.; Yang, G.; Liu, N.N.; Jing, J. Optimization of structure of improved linear sand settling pond for drip irrigation. Water Sav. Irrig. 2020, 11, 68–72. [Google Scholar]

- Shahrokhi, M.; Rostami, F.; Said, M.; Sabbagh-Yazdi, S.R.; Syafalni, S.; Abdullah, R. The effect of baffle angle on primary sedimentation tank efficiency. Can. J. Civ. Eng. 2012, 39, 293–303. [Google Scholar] [CrossRef]

- Shahrokhi, M.; Rostami, F.; Said, M.; Yazdi, S.; Syafalni, S. Computational investigations of baffle configuration effects on the performance of primary sedimentation tanks. Water Environ. J. 2013, 27, 484–494. [Google Scholar] [CrossRef]

- Shahrokhi, M.; Rostami, F.; Md Said, M.A.; Syafalni. Numerical modeling of baffle location effects on the flow pattern of primary sedimentation tanks. Appl. Math. Model. 2013, 37, 4486–4496. [Google Scholar] [CrossRef]

- Shahrokhi, M.; Rostami, F.; Said, M.A.M.; Yazdi, S.R.S.; Syafalni. The effect of number of baffles on the improvement efficiency of primary sedimentation tanks. Appl. Math. Model. 2012, 36, 3725–3735. [Google Scholar] [CrossRef]

- Asgharzadeh, H.; Firoozabadi, B.; Afshin, H. Experimental investigation of effects of baffle configurations on the performance of a secondary sedimentation tank. Sci. Iran. 2011, 18, 938–949. [Google Scholar] [CrossRef]

- Gao, H.; Stenstrom, M.K. Generalizing the effects of the baffling structures on the buoyancy-induced turbulence in secondary settling tanks with eleven different geometries using CFD models. Chem. Eng. Res. Des. 2019, 143, 215–225. [Google Scholar] [CrossRef]

- Gao, H.; Stenstrom, M.K. Evaluation of three turbulence models in predicting the steady state hydrodynamics of a secondary sedimentation tank. Water Res. 2018, 143, 445–456. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Stenstrom, M.K. Turbulence and interphase mass diffusion assumptions on the performance of secondary settling tanks. Water Environ. Res. 2019, 91, 101–110. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.; Dao, N.T.; Liu, B.; Terashima, M.; Yasui, H. Computational Fluid Dynamics Study on Attainable Flow Rate in a Lamella Settler by Increasing Inclined Plates. J. Water Environ. Technol. 2019, 17, 76–88. [Google Scholar] [CrossRef]

- Hartloper, C.; Kinzel, M.; Rival, D.E. On the competition between leading-edge and tip-vortex growth for a pitching plate. Exp. Fluids 2013, 54, 1447. [Google Scholar] [CrossRef]

- He, C.; Marsalek, J. Vortex Plate for Enhancing Particle Settling. J. Environ. Eng.-Asce. 2009, 135, 627–635. [Google Scholar] [CrossRef]

- Zhao, F.; Li, L.; Yang, L.; Zheng, Z. Study on the removal rate of the wing type inclined plate sand sink based on orthogonal test. J. China Res. Inst. Water Resour. Hydropower 2020, 18, 417–425. [Google Scholar] [CrossRef]

- Tao, H.; Qiu, X.; Li, Q.; Tan, Y.; Wang, M. Three-dimensional numerical simulation of flow field in separated gill with different gill spacing. Trans. CSAM 2014, 45, 183–189. [Google Scholar] [CrossRef]

- Tao, H.; Qiu, X.; Wang, M. Analysis of water and sediment separation efficiency and mechanism of separation gill based on numerical simulation. Water Sav. Irrig. 2015, 40, 66–71. [Google Scholar] [CrossRef]

- Tao, H.; Qiu, X.; Zhao, L.; Li, L. Numerical simulation of flow field in water-sand separating gills. Trans. CSAE 2013, 29, 38–46. [Google Scholar] [CrossRef]

- Wang, K.; Li, Y.; Ren, S.; Yang, P. Prototype Observation of Flow Characteristics in an Inclined-Tube Settling Tank for Fine Sandy Water Treatment. Appl. Sci. 2020, 10, 3586. [Google Scholar] [CrossRef]

- Wang, K.; Li, Y.; Ren, S.; Yang, P. A Case Study on Settling Process in Inclined-Tube Gravity Sedimentation Tank for Drip Irrigation with the Yellow River Water. Water 2020, 12, 1685. [Google Scholar] [CrossRef]

- Li, L.; Fu, H.; Tan, Y.; Pei, J.; Zhang, J. Test and mechanism analysis of sediment settling characteristics of a new type of heterogeneous flow sediment basin. Trans. CSAE 2021, 37, 90–98. [Google Scholar] [CrossRef]

- Wu, J.; Ma, J.; Tang, Y. Research on the head loss of the regulating plate in sand settling basin. Yellow River 2011, 33, 25–26. [Google Scholar] [CrossRef]

- Demir, A. Determination of settling efficiency and optimum plate angle for plated settling tanks. Water Res. 1995, 29, 611–616. [Google Scholar] [CrossRef]

- Liu, Z.; Xiao, Y.; Li, Y.; Zhou, B.; Feng, J.; Han, S.; Muhammad, T. Influence of operating pressure on emitter anti-clogging performance of drip irrigation system with high-sediment water. Agric. Water Manag. 2019, 213, 174–184. [Google Scholar] [CrossRef]

- Zha, Y.; Hou, P.; Liu, Z.; Wang, K.; Li, Y.; Wang, C. Influence of inclined pipe layout on the sedimentation of Yellow River sediment in sand basin. J. Irrig. Drain. 2023, 42, 1–11. [Google Scholar] [CrossRef]

- Hu, B.; Gui, L. Numerical simulation of water flow pattern in inclined slab settling pond. J. Southwest Univ. Natl. (Nat. Sci. Ed.) 2012, 38, 425–430. [Google Scholar] [CrossRef]

- Doroodchi, E.; Zhou, J.; Fletcher, D.F.; Galvin, K.P. Particle size classification in a fluidized bed containing parallel inclined plates. Miner. Eng. 2005, 19, 162–171. [Google Scholar] [CrossRef]

- Schamber, D.R.; Larock, B.E. Numerical Analysis of Flow in Sedimentation Basins. J. Hydraul. Div. 1981, 107, 575–591. [Google Scholar] [CrossRef]

- Stamou, A.I.; Adams, E.W.; Rodi, W. Numerical modeling of flow and settling in primary rectangular clarifiers. J. Hydraul. Res. 2010, 27, 665–682. [Google Scholar] [CrossRef]

| Sedimentation Tank | I | II | III | IV | V |

|---|---|---|---|---|---|

| Δ | 0 | 0.4 | 0.4 | 0.8 | 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Ye, N.; Han, Y.; He, X. Experimental Study on the Sedimentation Performance of an Arc-Plate Linear Sedimentation Tank. Water 2024, 16, 1075. https://doi.org/10.3390/w16081075

Wang P, Ye N, Han Y, He X. Experimental Study on the Sedimentation Performance of an Arc-Plate Linear Sedimentation Tank. Water. 2024; 16(8):1075. https://doi.org/10.3390/w16081075

Chicago/Turabian StyleWang, Peng, Nansha Ye, Yu Han, and Xiangli He. 2024. "Experimental Study on the Sedimentation Performance of an Arc-Plate Linear Sedimentation Tank" Water 16, no. 8: 1075. https://doi.org/10.3390/w16081075

APA StyleWang, P., Ye, N., Han, Y., & He, X. (2024). Experimental Study on the Sedimentation Performance of an Arc-Plate Linear Sedimentation Tank. Water, 16(8), 1075. https://doi.org/10.3390/w16081075