Wise Choice of Showerhead Patterns: How to Save Energy during Showering While Maintaining Thermal Comfort

Highlights

- Heat transfer affected comfort and energy use during showers;

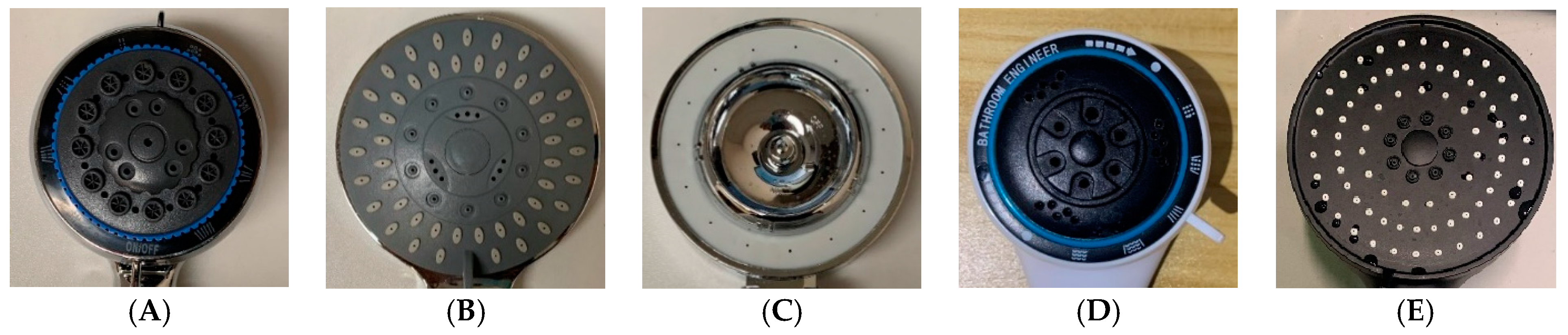

- Five showerheads with 18 spray patterns were tested to analyze heat transfer performance;

- Critical factors influencing heat transfer were nozzle area, pressure, and resistance;

- Better heat transfer could reduce energy usage by up to 20% while maintaining the same comfort level.

Abstract

1. Introduction

2. Methodology

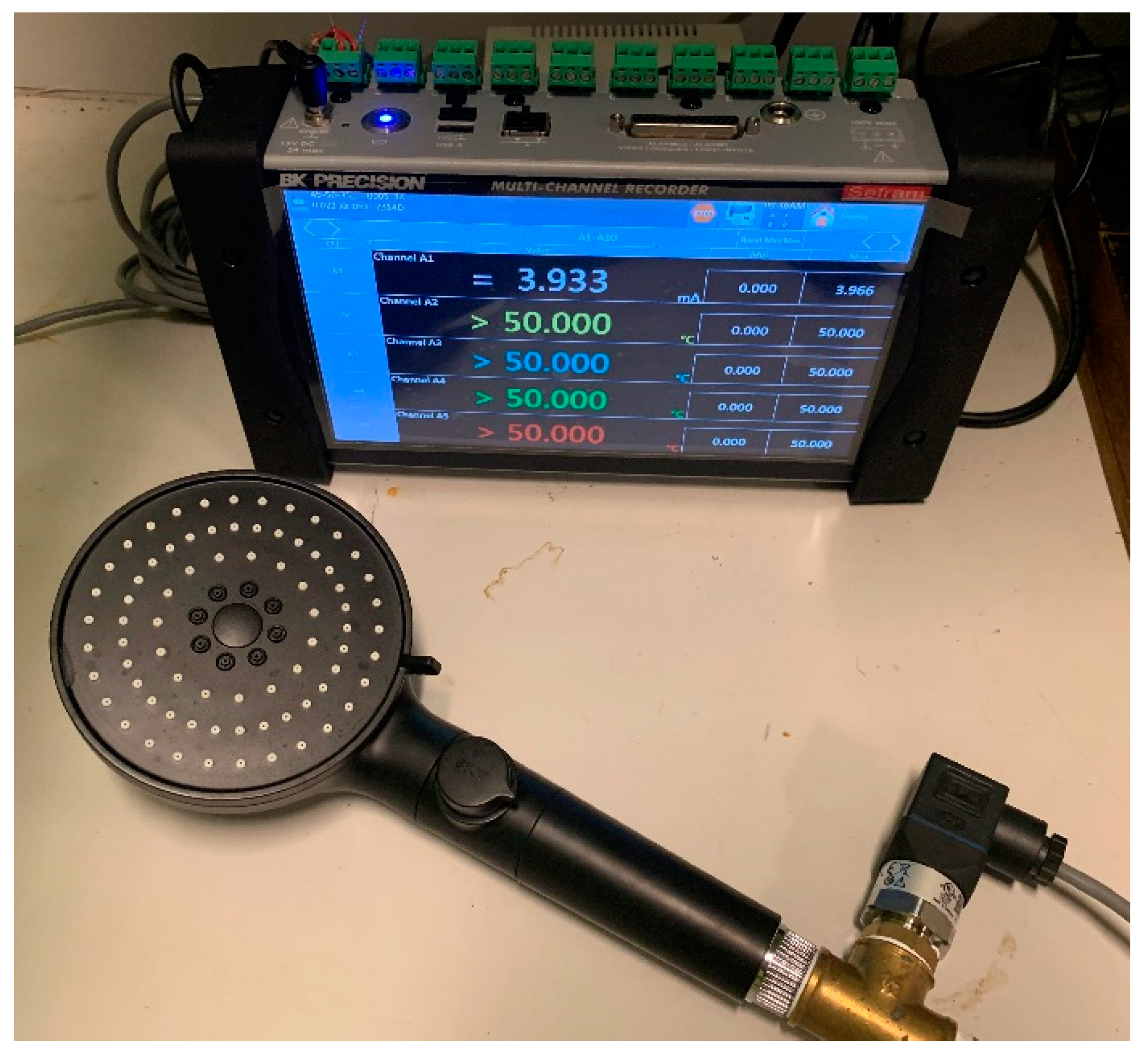

2.1. Experiment Setup

2.2. Data Analysis

3. Results and Discussions

3.1. General Results

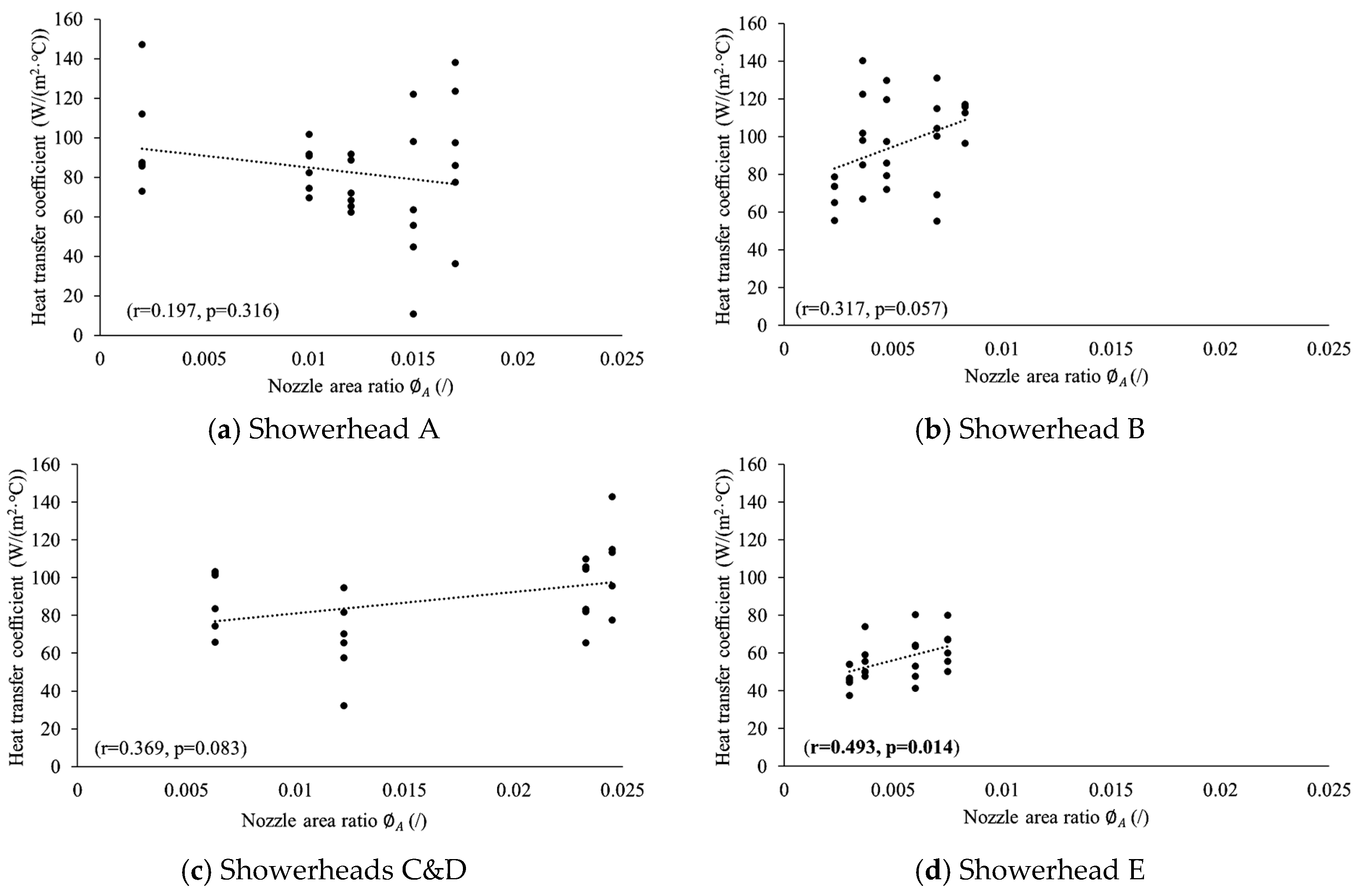

3.2. Impacts of Spray Patterns on the Heat Transfer Coefficient for the Same Showerhead

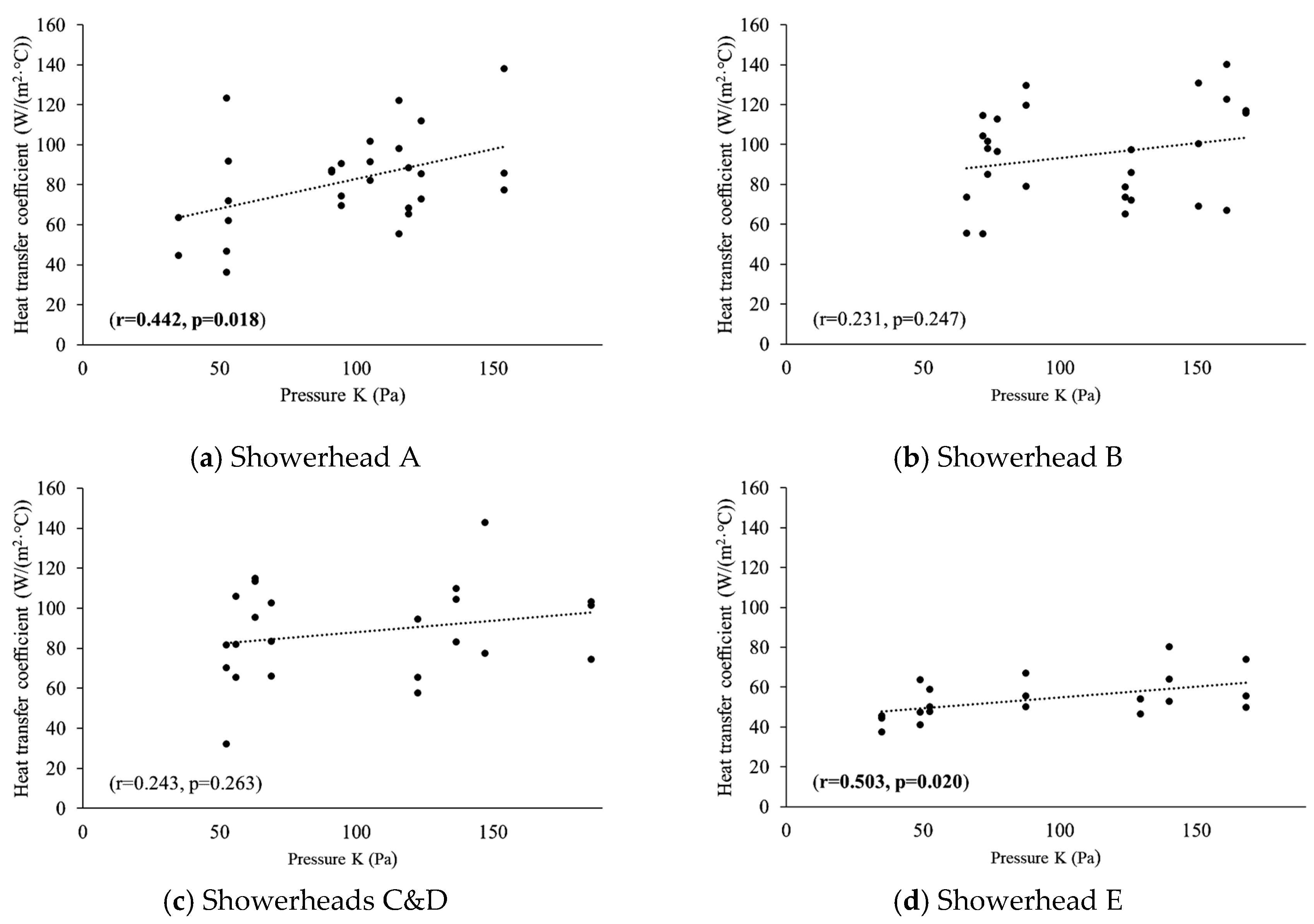

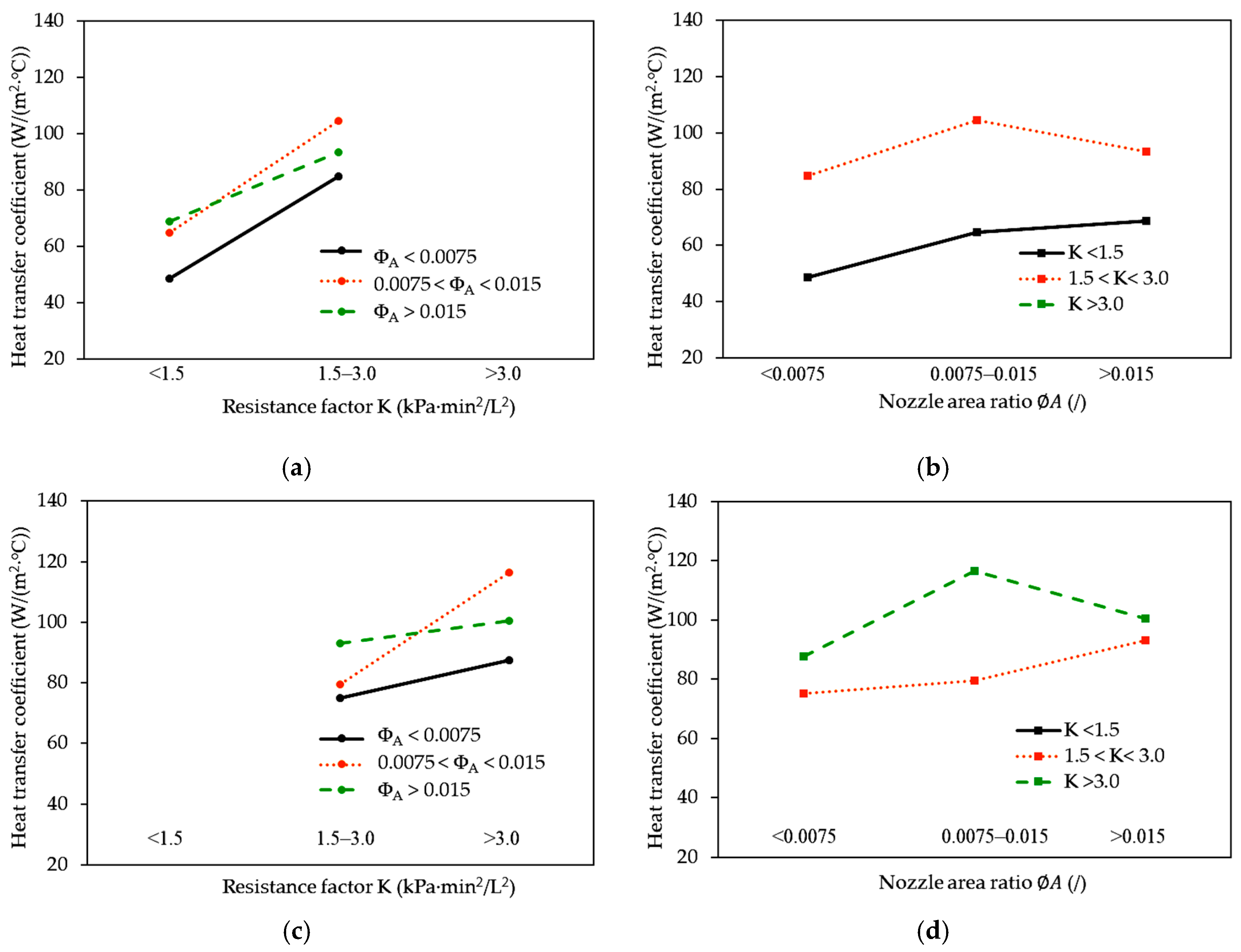

3.3. Interactive Impacts of the Parameters of Showerhead Pattern on the Heat Transfer Coefficient

3.4. Integrated Impacts of the Parameters of Showerhead Pattern on the Heat Transfer Coefficient

4. Discussions

4.1. Impacts of Showerhead Patterns on the Heat Transfer Coefficient

4.2. Selection of the Optimal Showerhead

4.3. Suggestions for Manufacturers and Users

4.4. Limitations and Future Studies

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- McDonald, C. Four Surprising Benefits of Your Daily Shower. Available online: https://www.wellnessworkdays.com/post/four-surprising-benefits-of-your-daily-shower#:~:text=Did%20you%20know%20taking%20a,and%20serotonin%2C%20on%20the%20inside (accessed on 28 September 2023).

- International Energy Agency (IEA). Worldwide Trends in Energy Use and Efficiency; IEA: Paris, France, 2008. [Google Scholar]

- Eurostat, Energy Use in Households in 2020. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/-/ddn-20220617-1 (accessed on 28 September 2023).

- U.S. Department of Energy, “Water heating”. Available online: https://www.energy.gov/energysaver/water-heating#:~:text=Water%20heating%20accounts%20for%20about,energy%20expense%20in%20any%20home (accessed on 28 September 2023).

- Wanjiru, E.M.; Sichilalu, S.M.; Xia, X. Optimal control of heat pump water heater-instantaneous shower using integrated renewable-grid energy systems. Appl. Energy 2017, 201, 332–342. [Google Scholar] [CrossRef]

- Kordana, S.; Słyś, D.; Dziopak, J. Rationalization of water and energy consumption in shower systems of single-family dwelling houses. J. Clean. Prod. 2014, 82, 58–69. [Google Scholar] [CrossRef]

- Piotrowska, B.; Słyś, D. Comprehensive Analysis of the State of Technology in the Field of Waste Heat Recovery from Grey Water. Energies 2022, 16, 137. [Google Scholar] [CrossRef]

- Veeraboina, P.; Ratnam, G. Analysis of the opportunities and challenges of solar water heating system (SWHS) in India: Estimates from the energy audit surveys & review. Renew. Sustain. Energy Rev. 2012, 16, 668–676. [Google Scholar] [CrossRef]

- Grecksch, K. Achieving Water Efficiency in the Public Sector Through Social Norms. Front. Environ. Sci. 2021, 9, 575583. [Google Scholar] [CrossRef]

- Rossi, G. Achieving ethical responsibilities in water management: A challenge. Agric. Water Manag. 2015, 147, 96–102. [Google Scholar] [CrossRef]

- Manouseli, D.; Kayaga, S.M.; Kalawsky, R. Evaluating the Effectiveness of Residential Water Efficiency Initiatives in England: Influencing Factors and Policy Implications. Water Resour. Manag. 2019, 33, 2219–2238. [Google Scholar] [CrossRef]

- Shi, L.; Wang, L.; Li, H.; Zhao, Y.; Wang, J.; Zhu, Y.; He, G. Impact of residential water saving devices on urban water security: The case of Beijing, China. Environ. Sci. Water Res. Technol. 2022, 8, 326–342. [Google Scholar] [CrossRef]

- Chu, J.; Wang, C.; Chen, J.; Wang, H. Agent-based residential water use behavior simulation and policy implications: A case-study in Beijing city. Water Resour. Manag. 2009, 23, 3267–3295. [Google Scholar] [CrossRef]

- Dieu-Hang, T.; Grafton, R.Q.; Martínez-Espiñeira, R.; Garcia-Valiñas, M. Household adoption of energy and water-efficient appliances: An analysis of attitudes, labelling and complementary green behaviours in selected OECD countries. J. Environ. Manag. 2017, 197, 140–150. [Google Scholar] [CrossRef]

- Adeyeye, K.; She, K.; Meireles, I. Beyond the flow rate: The importance of thermal range, flow intensity, and distribution for water-efficient showers. Environ. Sci. Pollut. Res. 2020, 27, 4640–4660. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Mui, K.W.; Wong, L.T.; Tsui, P.H.; Chan, W.K. Aerosol generation rates for showerheads. Build. Serv. Eng. Res. Technol. 2019, 40, 595–610. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, Y.; Lu, H.; Lin, Z. Prediction of outflow parameters for a shower head. Water Res. 2021, 202, 117436. [Google Scholar] [CrossRef]

- Zhou, Y. Impact Evaluation of low Flow Showerheads for Bathing of Hong Kong. Ph.D. Thesis, The Hong Kong Polytechnic University, Hong Kong, China, 2018. [Google Scholar]

- Wong, L.-T.; Mui, K.-W.; Zhou, Y. Impact evaluation of low flow showerheads for Hong Kong residents. Water 2016, 8, 305. [Google Scholar] [CrossRef]

- Wong, L.T.; Poon, C.; Mui, K.W.; Zhang, D. Experimental study of the heat transfer coefficient between human skin and the flowing water during showering. In Proceedings of the 48th CIB W062 Symposium Conference, Leuven, Belgium, 29–31 August 2023. [Google Scholar]

- Cebo-Rudnicka, A.; Malinowski, Z.; Buczek, A. The influence of selected parameters of spray cooling and thermal conductivity on heat transfer coefficient. Int. J. Therm. Sci. 2016, 110, 52–64. [Google Scholar] [CrossRef]

- Hnizdil, M.; Chabicovsky, M.; Raudensky, M.; Lee, T.-W. Heat Transfer during Spray Cooling of Flat Surfaces with Water at Large Reynolds Numbers. J. Flow Control Meas. Vis. 2016, 04, 104–113. [Google Scholar] [CrossRef]

- Somasundaram, S.; Tay, A. Comparative study of intermittent spray cooling in single and two phase regimes. Int. J. Therm. Sci. 2013, 74, 174–182. [Google Scholar] [CrossRef]

- Puschmann, F.; Specht, E. Transient measurement of heat transfer in metal quenching with atomized sprays. Exp. Therm. Fluid Sci. 2004, 28, 607–615. [Google Scholar] [CrossRef]

- Hou, Y.; Liu, X.; Liu, J.; Li, M.; Pu, L. Experimental study on phase change spray cooling. Exp. Therm. Fluid Sci. 2013, 46, 84–88. [Google Scholar] [CrossRef]

- Hong Kong Water Supplies Department. Voluntary Water Efficiency Labelling Scheme on Showers for Bathing. Hong Kong Water Supplies Department. Available online: https://www.wsd.gov.hk/en/plumbing-engineering/water-efficiency-labelling-scheme/wels-on-showers-for-bathing/voluntary-water-efficiency-labelling-scheme-on-sho/index.html (accessed on 12 October 2022).

- Hou, Y.; Tao, Y.; Huai, X.; Zou, Y.; Sun, D. Numerical simulation of multi-nozzle spray cooling heat transfer. Int. J. Therm. Sci. 2018, 125, 81–88. [Google Scholar] [CrossRef]

- United Nations (UN) General Assembly, Sustainable Development Goals. United Nations Development Programme, New York, USA, 2015. 2015. Available online: https://sdgs.un.org/goals (accessed on 12 October 2022).

- Woolf, D.; Pau, I.; Shouler, M. Shower head design: Increasing performance at lower flow rates. In Proceedings of the CIB W062 Symposium, Taipei, Taiwan, 18–20 September 2006. [Google Scholar]

- Zhang, D.; Mui, K.-W.; Wong, L.-T. Establishing the Relationship between Occupants’ Thermal Behavior and Energy Consumption during Showering. Buildings 2023, 13, 1300. [Google Scholar] [CrossRef]

- Orr, P.; Papadopoulou, L.; Twigger-Ross, C. Water Efficiency and Behaviour Change Rapid Evidence Assessment (REA) FINAL REPORT; Twenty 65: London, UK, 2018. [Google Scholar]

| Showerhead | Pattern | Water Flow Rate (L/min) | Heat Transfer Coefficient (W/(m2·°C)) | (/) | Pressure P (kPa) | Resistance Factor K (kPa·min2/L2) | ||

|---|---|---|---|---|---|---|---|---|

| Tw = 35 | Tw = 38 | Tw = 41 | ||||||

| A | 1 | 6 | 62.2 | 91.8 | 71.9 | 0.012 | 53.2 | 1.5 |

| 7.2 | 65.4 | 88.6 | 68.3 | 0.012 | 119.0 | 2.3 | ||

| 2 | 6 | 86.4 | 87.4 | 147.2 | 0.022 | 91.0 | 2.5 | |

| 7.2 | 111.9 | 72.9 | 85.7 | 0.022 | 123.6 | 2.4 | ||

| 3 | 6 | 46.9 | 36.2 | 123.4 | 0.014 | 52.5 | 1.5 | |

| 7.2 | 138 | 77.3 | 85.9 | 0.014 | 154.0 | 3.0 | ||

| 4 | 6 | 82.3 | 101.7 | 91.6 | 0.017 | 105.0 | 2.9 | |

| 7.2 | 69.6 | 74.3 | 90.8 | 0.017 | 94.5 | 1.8 | ||

| 5 | 6 | 63.6 | 44.6 | 10.7 | 0.010 | 35.0 | 1.0 | |

| 7.2 | 122.1 | 98.1 | 55.5 | 0.010 | 115.5 | 2.2 | ||

| Mean (S.D.) | 81.9 (23.5) | 0.015 (0.004) | 94.3 (35.4) | 2.1 (0.6) | ||||

| B | 1 | 6 | 101.8 | 85.1 | 98.1 | 0.004 | 73.5 | 2.0 |

| 7.2 | 122.6 | 140.1 | 67 | 0.004 | 161.0 | 3.1 | ||

| 2 | 6 | 147.3 | 96.4 | 112.7 | 0.008 | 77.0 | 2.1 | |

| 7.2 | 117.1 | 115.8 | 147.1 | 0.008 | 168.0 | 3.2 | ||

| 3 | 6 | 119.6 | 129.6 | 79.2 | 0.005 | 87.5 | 2.4 | |

| 7.2 | 72 | 86 | 97.4 | 0.005 | 126.0 | 2.4 | ||

| 4 | 6 | 104.5 | 114.7 | 55.3 | 0.007 | 71.8 | 2.0 | |

| 7.2 | 69.2 | 130.9 | 100.3 | 0.007 | 150.5 | 2.9 | ||

| 5 | 6 | 164.1 | 73.6 | 55.5 | 0.002 | 65.8 | 1.8 | |

| 7.2 | 78.7 | 73.7 | 65.2 | 0.002 | 123.9 | 2.4 | ||

| Mean (S.D.) | 94.9 (23.8) | 0.005 (0.002) | 110.5 (37.9) | 2.5 (0.5) | ||||

| C | 1 | 6 | 66 | 102.7 | 83.5 | 0.006 | 68.8 | 1.9 |

| 7.2 | 74.4 | 103.2 | 101.4 | 0.006 | 186.0 | 3.6 | ||

| Mean (S.D.) | 88.5 (14.8) | 0.006 (0.000) | 127.4 (66.7) | 2.80 (1.1) | ||||

| D | 1 | 6 | 70.3 | 81.7 | 32.3 | 0.012 | 52.5 | 1.5 |

| 7.2 | 94.7 | 57.6 | 65.4 | 0.012 | 122.5 | 2.4 | ||

| 2 | 6 | 95.6 | 113.5 | 115 | 0.025 | 63.0 | 1.8 | |

| 7.2 | 148.4 | 77.6 | 142.8 | 0.025 | 147.0 | 2.8 | ||

| 3 | 6 | 105.9 | 65.4 | 81.9 | 0.023 | 56.0 | 1.6 | |

| 7.2 | 109.9 | 104.5 | 83.3 | 0.023 | 136.5 | 2.6 | ||

| Mean (S.D.) | 88.1 (25.6) | 0.020 (0.006) | 96.3 (39.8) | 2.1 (0.5) | ||||

| E | 1 | 6 | 59.0 | 50.2 | 47.7 | 0.004 | 52.5 | 1.5 |

| 7.2 | 50.0 | 74.1 | 55.5 | 0.004 | 168.0 | 3.2 | ||

| 2 | 6 | 50.3 | 55.5 | 67.0 | 0.008 | 87.5 | 2.4 | |

| 7.2 | 60.2 | 67.5 | 80.2 | 0.008 | 212.8 | 4.1 | ||

| 3 | 6 | 41.2 | 47.6 | 63.6 | 0.006 | 49.0 | 1.4 | |

| 7.2 | 53.0 | 64.1 | 80.3 | 0.006 | 140.0 | 2.7 | ||

| 4 | 6 | 44.5 | 45.7 | 37.4 | 0.003 | 35.0 | 1.0 | |

| 7.2 | 46.6 | 54.0 | 54.0 | 0.003 | 129.5 | 2.5 | ||

| Mean (S.D.) | 56.2 (11.3) | 0.005 (0.002) | 109.3 (59.5) | 2.3 (1.0) | ||||

| Water Pressure P | Resistance Factor K | ||

|---|---|---|---|

| Heat transfer coefficient | 0.283 (0.004) | 0.321 (0.001) | 0.395 (<0.001) |

| Nozzle area ratio | −0.024 (0.811) | −0.013 (0.893) | |

| Water pressure | 0.941 (<0.001) |

| Water Flow Rate | Parameters | df | Mean Square | F | p |

|---|---|---|---|---|---|

| 6 L/min | Nozzle area ratio | 2 | 1213.759 | 2.685 | 0.079 |

| Resistance factor | 1 | 8289.777 | 18.340 | <0.001 | |

| Nozzle area ratio × Resistance factor | 2 | 148.029 | 0.327 | 0.722 | |

| 7.2 L/min | Nozzle area ratio | 2 | 1188.027 | 1.991 | 0.149 |

| Resistance factor | 1 | 2665.309 | 4.467 | 0.040 | |

| Nozzle area ratio × Resistance factor | 2 | 477.769 | 0.801 | 0.456 |

| Water Flow Rate | Parameters | Unstandardized β | Standardized β (CI95%) | p |

|---|---|---|---|---|

| 6 L/min | Constant | 3.959 | / | |

| ) | 0.039 | 0.06 (−0.11–0.19) | 0.598 | |

| Ln(K) | 0.926 | 0.59 (0.57–1.28) | <0.001 | |

| 7.2 L/min | Constant | 4.672 | / | |

| ) | 0.191 | 0.46 (0.08–0.30) | <0.001 | |

| Ln(K) | 0.691 | 0.37 (0.21–1.17) | 0.005 |

| Parameters | Case 1 | Case 2 |

|---|---|---|

| Showerhead patter | B2 | E4 |

| Nozzle area ratio (/) | 0.008 | 0.003 |

| Resistance factor (kPa·min2/L2) | 3.24 | 2.50 |

| Water flow rate (L/min) | 7.2 | 7.2 |

| Water temperature (°C) | 38 | 41 |

| Heat transfer coefficient (W/(m2·°C)) | 115.8 | 54.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Mui, K.-W.; Wong, L.-T. Wise Choice of Showerhead Patterns: How to Save Energy during Showering While Maintaining Thermal Comfort. Water 2024, 16, 928. https://doi.org/10.3390/w16070928

Zhang D, Mui K-W, Wong L-T. Wise Choice of Showerhead Patterns: How to Save Energy during Showering While Maintaining Thermal Comfort. Water. 2024; 16(7):928. https://doi.org/10.3390/w16070928

Chicago/Turabian StyleZhang, Dadi, Kowk-Wai Mui, and Ling-Tim Wong. 2024. "Wise Choice of Showerhead Patterns: How to Save Energy during Showering While Maintaining Thermal Comfort" Water 16, no. 7: 928. https://doi.org/10.3390/w16070928

APA StyleZhang, D., Mui, K.-W., & Wong, L.-T. (2024). Wise Choice of Showerhead Patterns: How to Save Energy during Showering While Maintaining Thermal Comfort. Water, 16(7), 928. https://doi.org/10.3390/w16070928