Life Cycle Assessment of a Vegetable Tannin-Based Agent Production for Waters Treatment

Abstract

1. Introduction

2. Materials and Methods

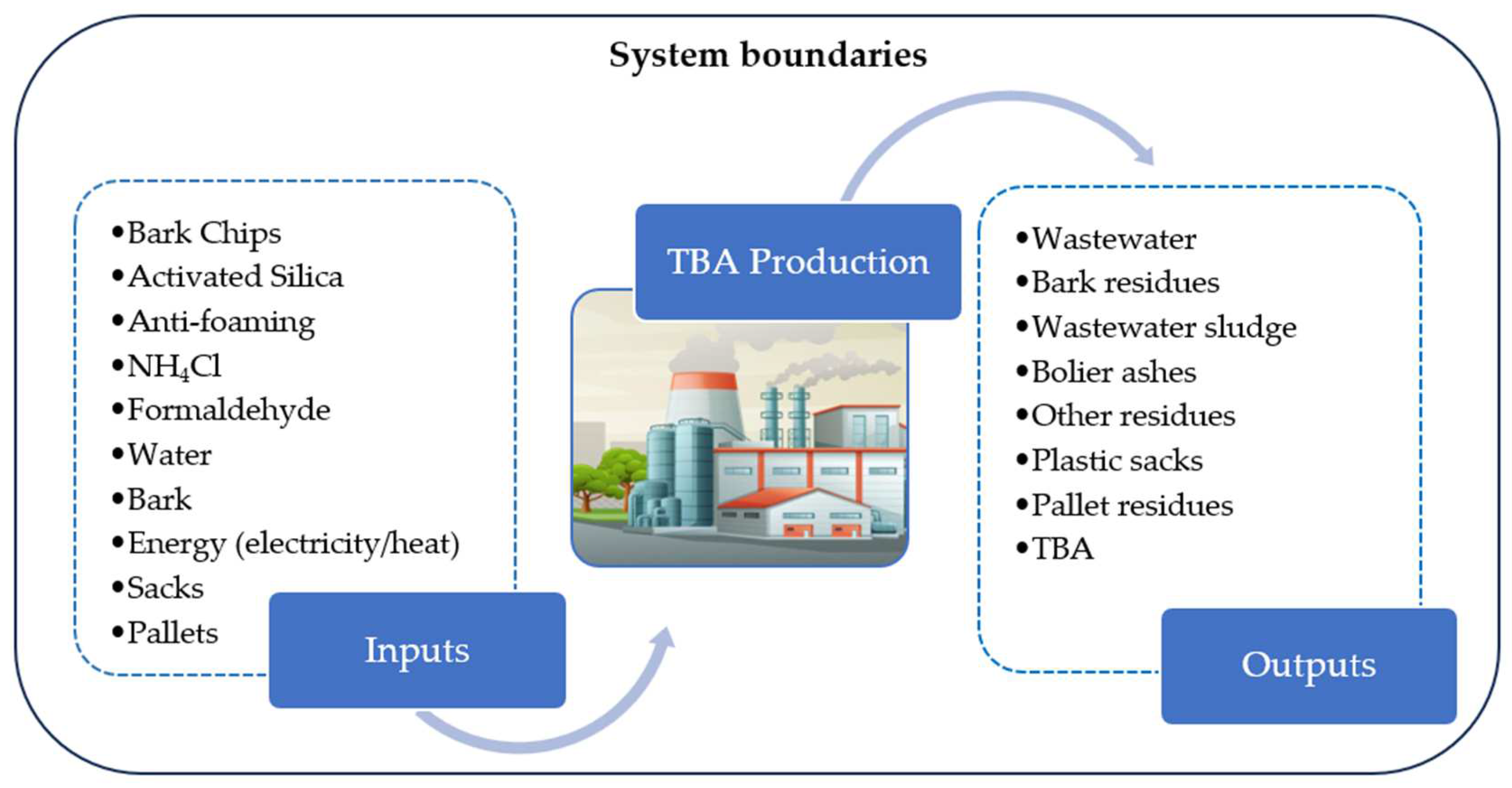

2.1. Definition of the Goal and Scope of the Life Cycle Assessment

2.2. Allocation, Limitations, and Life Cycle Inventory

2.3. Performing the Life Cycle Impact Assessment

2.4. Comparison between TBA and Traditional Coagulant

3. Results and Discussion

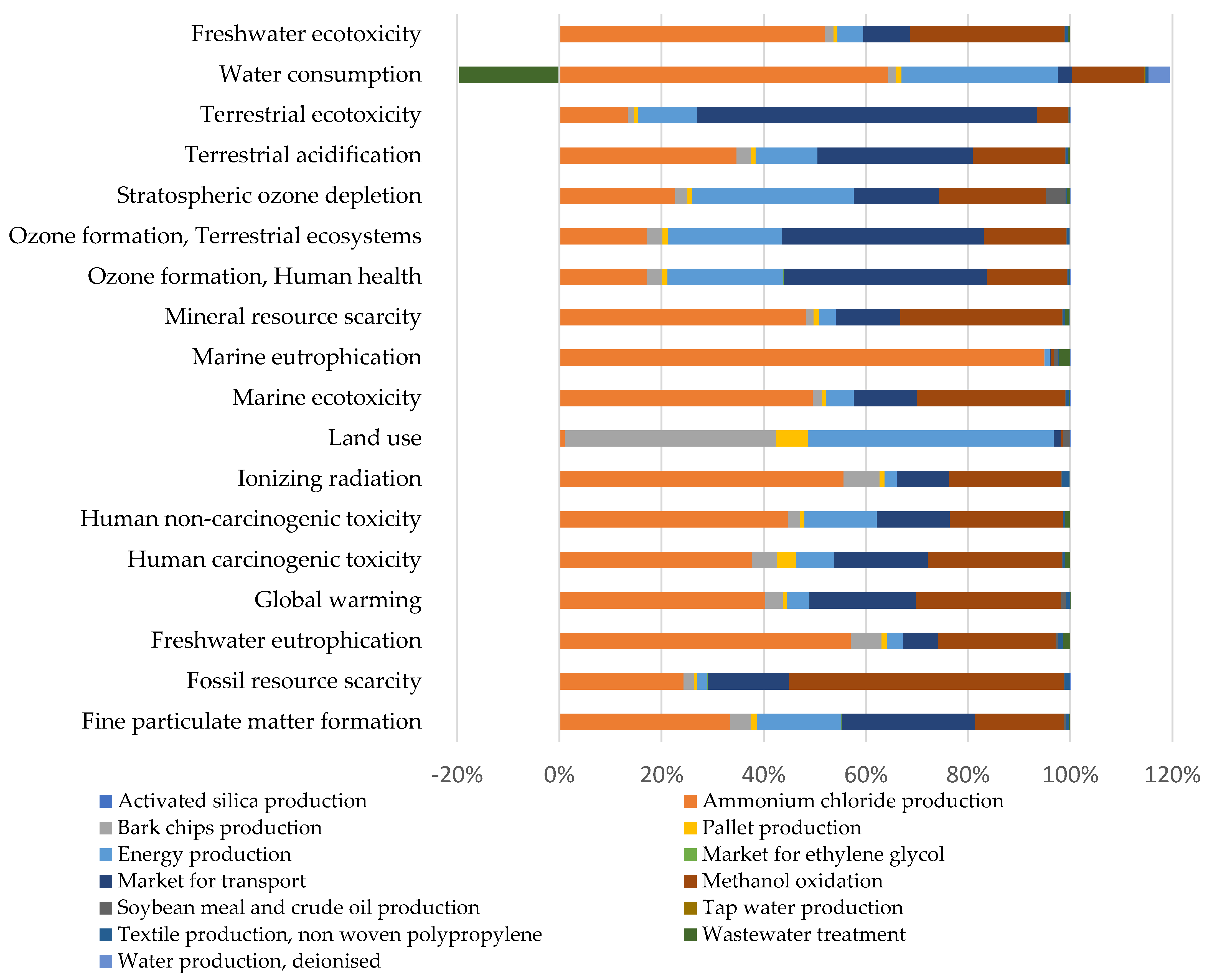

3.1. Life Cycle Impact Assessment of TBA Production

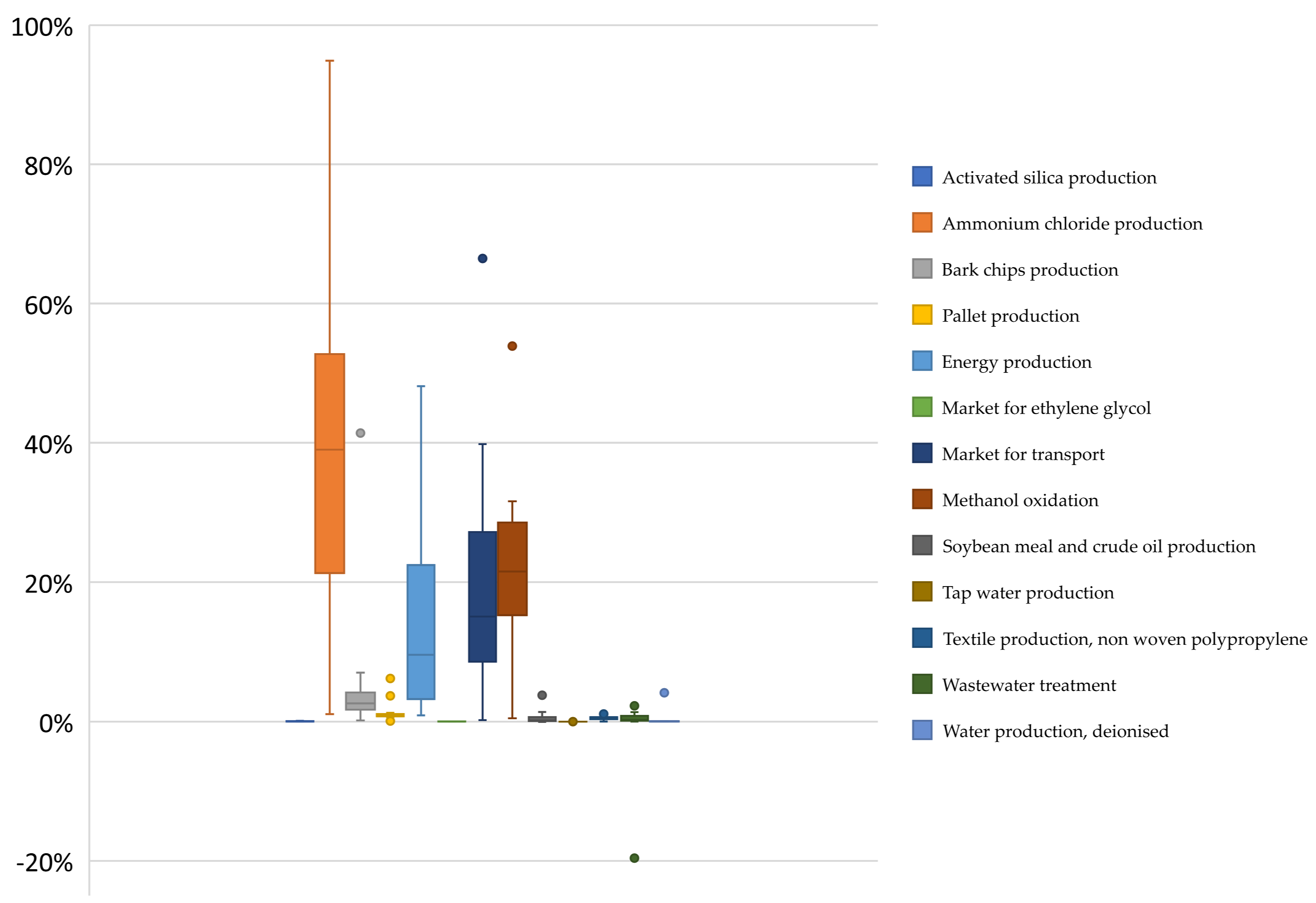

3.2. Sensitivity Analysis for Soy Lecithin and Anti-Foaming Agent

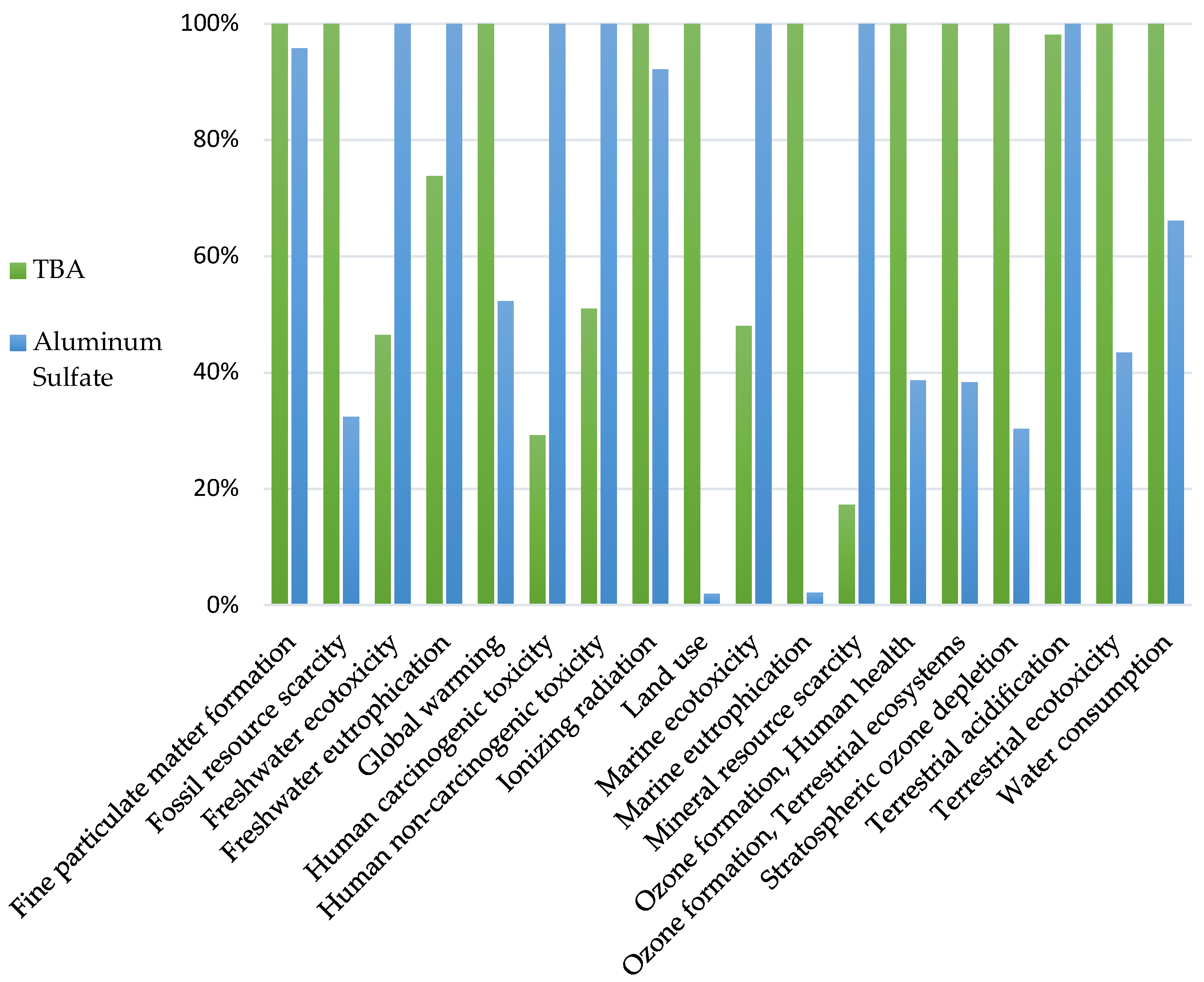

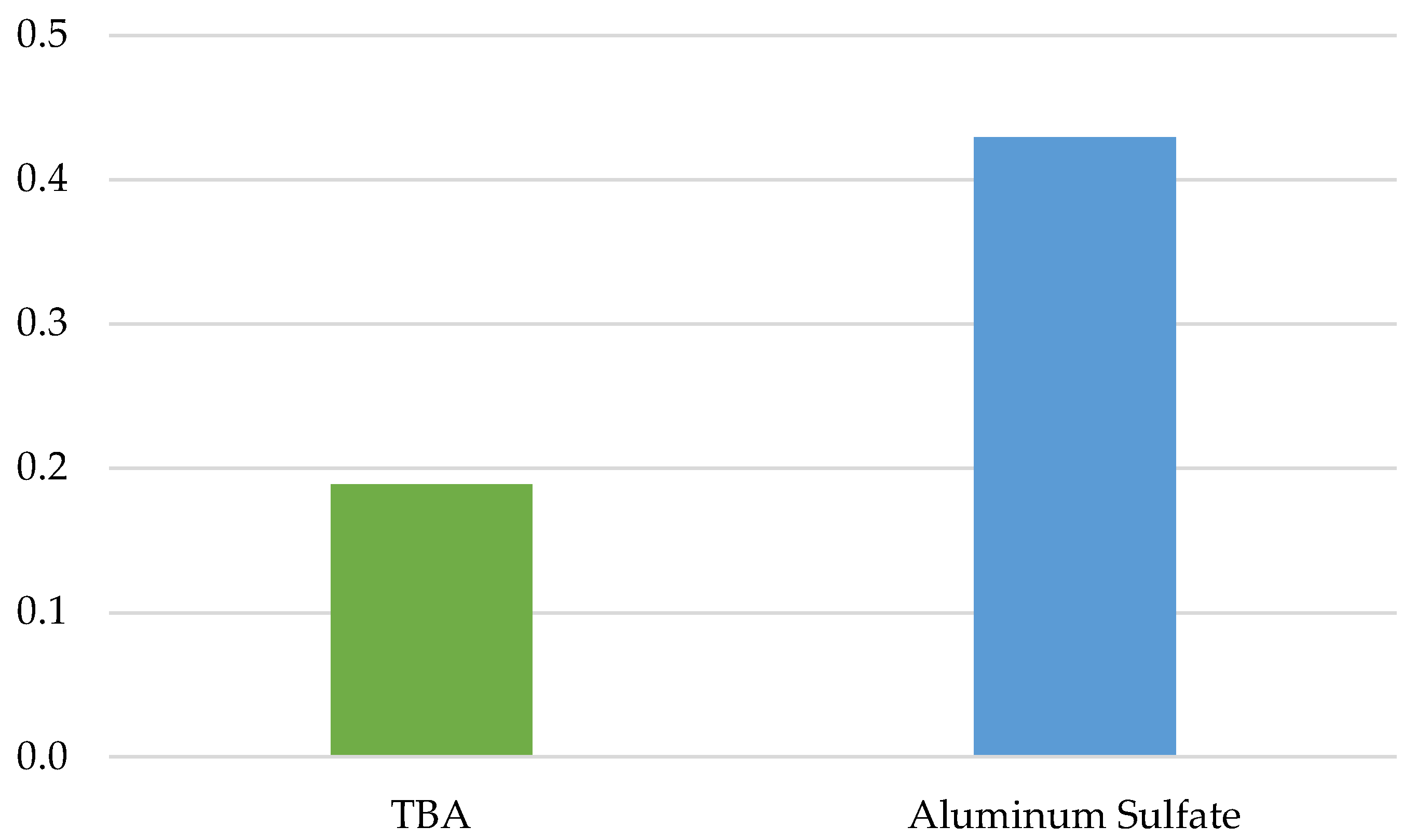

3.3. Comparative Life Cycle Assessment: Organic versus Inorganic Products

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bratby, J. Coagulation and Flocculation in Water and Wastewater Treatment, 3rd ed.; IWA Publishing: London, UK, 2016. [Google Scholar]

- Ritcher, C.A. Água: Métodos e Tecnologia de Tratamento; Blücher: São Paulo, Brazil, 2009. [Google Scholar]

- Bondy, S.C. Low levels of aluminum can lead to behavioral and morphological changes associated with Alzheimer’s disease and age-related neurodegeneration. Neurotoxicology 2016, 52, 222–229. [Google Scholar] [CrossRef] [PubMed]

- Kurniawan, S.B.; Abdullah, S.R.S.; Imron, M.F.; Said, N.S.M.; Ismail, N.; Hasan, H.A.; Othman, A.R.; Purwanti, I.F. Challenges and opportunities of biocoagulant/bioflocculant application for drinking water and wastewater treatment and its potential for sludge recovery. Int. J. Environ. Res. Public Health 2020, 17, 9312. [Google Scholar] [CrossRef] [PubMed]

- Hadj Mansour, Y.; Othmani, B.; Ben Rebah, F.; Mnif, W.; Saoudi, M.; Khadhraoui, M. Could plant-based flocculants substitute the conventional synthetic chemicals in the sludge dewatering process? Water 2023, 15, 2602. [Google Scholar] [CrossRef]

- Hesse, M.C.S.; Santos, B.; Selesu, N.F.H.; Corrêa, D.O.; Mariano, A.B.; Vargas, J.V.C.; Vieira, R.B. Optimization of flocculation with tannin-based flocculant in the water reuse and lipidic production for the cultivation of Acutodesmus obliquus. Sep. Sci. Technol. 2017, 52, 936–942. [Google Scholar] [CrossRef]

- Klumb, A.K.; Faria, O.L.V. Produção de coagulante vegetal catiônico a partir de cascas de eucalipto (Eucalyptus tereticornis). VETOR-Rev. Ciências Exatas E Eng. 2012, 22, 71–80. [Google Scholar]

- Tomasi, I.T.; Machado, C.A.; Boaventura, R.A.R.; Botelho, C.M.S.; Santos, S.C.R. Tannin-based coagulants: Current development and prospects on synthesis and uses. Sci. Total Environ. 2022, 822, 153454. [Google Scholar] [CrossRef] [PubMed]

- Ding, T.; Bianchi, S.; Ganne-Chédeville, C.; Kilpeläinen, P.; Haapala, A.; Räty, T. Life cycle assessment of tannin extraction from spruce bark. IForest-Biogeosci. For. 2017, 10, 807. [Google Scholar] [CrossRef]

- Carlqvist, K.; Arshadi, M.; Mossing, T.; Östman, U.B.; Brännström, H.; Halmemies, E.; Nurmi, J.; Lidén, G.; Börjesson, P. Life-cycle assessment of the production of cationized tannins from Norway spruce bark as flocculants in wastewater treatment. Biofuels Bioprod. Biorefin. 2020, 14, 1270–1285. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management. Life Cycle Assessment: Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management. Life Cycle Assessment. Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. (Eds.) Life Cycle Assessment: Theory and Practice; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Arias, A.; González-García, S.; González-Rodríguez, S.; Feijoo, G.; Moreira, M.T. Cradle-to-gate life cycle assessment of bio-adhesives for the wood panel industry. A comparison with petrochemical alternatives. Sci. Total Environ. 2020, 738, 140357. [Google Scholar] [CrossRef] [PubMed]

- Carlqvist, K.; Wallberg, O.; Lidén, G.; Börjesson, P. Life cycle assessment for identification of critical aspects in emerging technologies for the extraction of phenolic compounds from spruce bark. J. Clean. Prod. 2022, 333, 130093. [Google Scholar] [CrossRef]

- Sánchez-Martín, J.; González-Velasco, M.; Beltrán-Heredia, J. Surface water treatment with tannin-based coagulants from Quebracho (Schinopsis balansae). Chem. Eng. J. 2010, 165, 851–858. [Google Scholar] [CrossRef]

- Sánchez-Martín, J.; Beltrán-Heredia, J.; Solera-Hernández, C. Surface water and wastewater treatment using a new tannin-based coagulant. Pilot plant trials. J. Environ. Manag. 2010, 91, 2051–2058. [Google Scholar] [CrossRef] [PubMed]

- Lugo, L.; Martin, A.; Diaz, J.; Perez-Florez, A.; Celis, C. Implementation of modified acacia tannin by mannich reaction for removal of heavy metals (Cu, Cr and Hg). Water 2020, 12, 352. [Google Scholar] [CrossRef]

- Banch, T.J.; Hanafiah, M.M.; Alkarkhi, A.F.; Abu Amr, S.S. Factorial design and optimization of landfill leachate treatment using tannin-based natural coagulant. Polymers 2019, 11, 1349. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.; Kumar, S.; Garg, M. Domestic wastewater treatment using Tanfloc: A tannin based coagulant. In Geostatistical and Geospatial Approaches for the Characterization of Natural Resources in the Environment; Raju, N., Ed.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Justina, M.D.; Muniz, B.R.B.; Bröring, M.M.; Costa, V.J.; Skoronski, E. Using vegetable tannin and polyaluminium chloride as coagulants for dairy wastewater treatment: A comparative study. J. Water Process Eng. 2018, 25, 173–181. [Google Scholar] [CrossRef]

- Radovic, S.; Sekulic, M.T.; Agarski, B.; Pap, S.; Vukelic, D.; Budak, I.; Prodanovic, J. Life cycle assessment of new bio-based coagulant production for sustainable wastewater treatment. Int. J. Environ. Sci. Technol. 2023, 20, 7433–7462. [Google Scholar] [CrossRef]

- Simões, R.; Simões, C.; Ferreira, R.; Rodrigues, A.C. Life cycle assessment of the extraction of condensed tannins from acacia bark residues. In Proceedings of the Multi Conference on Computer Science and Information Systems, Porto, Portugal, 15 July 2023. [Google Scholar]

- Bolton, A.; Bouchard, C.; Barbeau, B.; Jedrzejak, S. Comparative life cycle assessment of water treatment plants. Desalination 2012, 284, 42–54. [Google Scholar] [CrossRef]

- Niquette, P.; Monette, F.; Azzouz, A.; Hausler, R. Impacts of substituting aluminium-based coagulants in drinking water treatment. Water Qual. Res. J. Can. 2004, 39, 303–310. [Google Scholar] [CrossRef]

| Flow | Unit | Quantity | Transportation * | Transport Type |

|---|---|---|---|---|

| Inputs | ||||

| Bark chips | kg | 1,578,206 | 246,064 | Freight, lorry |

| Activated silica | kg | 183 | 3 | Freight, lorry |

| Anti-foaming | kg | 137 | 201 | |

| Ammonium chloride | kg | 147,555 | 3,014,468 | Freight, sea |

| 168,877 | Freight, lorry | |||

| Formaldehyde ** | kg | 246,732 | 687,885 | Freight, lorry |

| Deionized water ** | kg | 420,113 | ||

| Water | kg | 22,764 | ||

| Soy lecithin | kg | 1131 | 159 | Freight, lorry |

| Electricity | MWh | 140 | ||

| Heat | GJ | 5860 | ||

| Sacks | kg | 2261 | 1826 | Freight, lorry |

| Pallets | unit | 943 | 2096 | Freight, lorry |

| Output | ||||

| Wastewater | m3 | 2322 | ||

| Wastewater sludge *** | ton | 117 | ||

| Boiler ashes *** | ton | 22 | ||

| Other residues *** | ton | 19 | ||

| Plastic sacks *** | kg | 700 | ||

| TBA coagulant/flocculant | kg | 565,250 |

| Flow | Ecoinvent Process Providers Used |

|---|---|

| Inputs | |

| Bark chips | Bark chips production, hardwood, at sawmill|Cutoff, U—RoW |

| Activated silica | Activated silica production|Cutoff, U—GLO |

| Anti-foaming | Market for ethylene glycol|Cutoff, U—GLO |

| Ammonium chloride | Ammonium chloride production|Cutoff, U—GLO |

| Formaldehyde | Oxidation of methanol|Cutoff, U—RoW |

| Deionized water | Water production, deionized|Cutoff, U—RoW |

| Water | Tap water production, underground water with disinfection|Cutoff, U—BR |

| Soy lecithin | Soybean meal and crude oil production, mechanical extraction|Cutoff, U—RoW |

| Electricity | Market for electricity, medium voltage|Cutoff, U—BR-Southern grid |

| Heat | Heat and power co-generation, wood chips, 6667 kW |Cutoff, U—RoW |

| Sacks | Textile production, non-woven polypropylene, spun bond|Cutoff, U—RoW |

| Pallets | EUR flat pallet production|Cutoff, U—RoW |

| Transport by ground | Market for transport, freight, lorry, unspecified|Cutoff, U—RoW |

| Transport by sea | Market for transport, freight, sea, container ship|Cutoff, U—GLO |

| Output | |

| Wastewater treatment | Treatment of wastewater, average, capacity 1E9l/year|Wastewater, average|Cutoff, U—RoW |

| Water | TBA Dosage (mg/L) | Turbidity Removal (%) | Source |

|---|---|---|---|

| Surface water (river) | 20 | 90.0 | Sanchez-Martin et al. [16] |

| Surface water (river) | 2 | 50.0~60.0 | Sanchez-Martin et al. [17] |

| Industrial wastewater | 375 | 95.0 | Lugo et al. [18] |

| Landfill leachate | 1460 | 53.5 * | Banch et al. [19] |

| Domestic wastewater | 15 | 80.0 | Singh et al. [20] |

| Dairy wastewater | 200 | 86.6 | Justina et al. [21] |

| Impact Category | ||

|---|---|---|

| Fine particulate matter formation | 2.7 × 10−3 | kgPM2.5-eq |

| Fossil resource scarcity | 673.1 × 10−3 | kgoil-eq |

| Global warming | 1518.6 × 10−3 | kgCO2-eq |

| Ozone formation, Human health | 6.2 × 10−3 | kgNOx-eq |

| Mineral resource scarcity | 4.5 × 10−3 | kgCu-eq |

| Land use | 1.0 | m2acrop-eq |

| Water consumption | 18.9 × 10−3 | m3 |

| Human carcinogenic toxicity | 104.8 × 10−3 | kg1,4-DCB-eq |

| Terrestrial ecotoxicity | 7673.8 × 10−3 | kg1,4-DCB-eq |

| Terrestrial acidification | 6.3 × 10−3 | kgSO2-eq |

| Ozone formation, Terrestrial ecosystems | 6.3 × 10−3 | kgNox-eq |

| Freshwater eutrophication | 0.3 × 10−3 | kgP-eq |

| Marine ecotoxicity | 83.6 × 10−3 | kg1,4-DCB-eq |

| Marine eutrophication | 1.10 × 10−3 | kgN-eq |

| Ionizing radiation | 50.4 × 10−3 | kBqCo-60-eq |

| Human non-carcinogenic toxicity | 1364.3 × 10−3 | kg1,4-DCB-eq |

| Stratospheric ozone depletion | 92.9 × 10−6 | kgCFC11-eq |

| Freshwater ecotoxicity | 61.8 × 10−3 | kg1,4-DCB-eq |

| Absolute Results | Relative Results | ||||

|---|---|---|---|---|---|

| Name | Unit | TBA | Al2(SO4)3 | TBA | Al2(SO4)3 |

| Fine particulate matter formation | kgPM2.5-eq | 2.7 × 10−3 | 2.6 × 10−3 | 100% | 96% |

| Fossil resource scarcity | kgoil-eq | 673.1 × 10−3 | 218.1 × 10−3 | 100% | 32% |

| Freshwater ecotoxicity | kg1,4-DCB-eq | 61.8 × 10−3 | 133.1 × 10−3 | 46% | 100% |

| Freshwater eutrophication | kgP-eq | 335.1.3 × 10−6 | 453.9 × 10−6 | 74% | 100% |

| Global warming | kgCO2-eq | 1518.6 × 10−3 | 793.9 × 10−3 | 100% | 52% |

| Human carcinogenic toxicity | kg1,4-DCB-eq | 104.8 × 10−3 | 358.7 × 10−3 | 29% | 100% |

| Human non-carcinogenic toxicity | kg1,4-DCB-eq | 1364.3 × 10−3 | 2673.9 × 10−3 | 51% | 100% |

| Ionizing radiation | kBqCo-60-eq | 50.4 × 10−3 | 46.4 × 10−3 | 100% | 92% |

| Land use | m2acrop-eq | 1.0 | 20.8 × 10−3 | 100% | 2% |

| Marine ecotoxicity | kg1,4-DCB-eq | 83.6 × 10−3 | 173.9 × 10−3 | 48% | 100% |

| Marine eutrophication | kgN-eq | 1109.7 × 10−6 | 23.4 × 10−6 | 100% | 2% |

| Mineral resource scarcity | kgCu-eq | 4.5 × 10−3 | 26.3 × 10−3 | 17% | 100% |

| Ozone formation, Human health | kgNOx-eq | 6.2 × 10−3 | 2.4 × 10−3 | 100% | 39% |

| Ozone formation, Terrestrial ecosystems | kgNOx-eq | 6.3 × 10−3 | 2.4 × 10−3 | 100% | 38% |

| Stratospheric ozone depletion | kgCFC11-eq | 92.9 × 10−6 | 28.2 × 10−6 | 100% | 30% |

| Terrestrial acidification | kgSO2-eq | 6.3 × 10−3 | 6.4 × 10−3 | 98% | 100% |

| Terrestrial ecotoxicity | kg1,4-DCB-eq | 7673.8 × 10−3 | 3333.9 × 10−3 | 100% | 43% |

| Water consumption | m3 | 18.9 × 10−3 | 12.4 × 10−3 | 100% | 66% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, L.d.L.C.d.; Silva, J.B.M.; Neves, L.S.; Renato, N.d.S.; Moltó, J.; Conesa, J.A.; Borges, A.C. Life Cycle Assessment of a Vegetable Tannin-Based Agent Production for Waters Treatment. Water 2024, 16, 1007. https://doi.org/10.3390/w16071007

Santos LdLCd, Silva JBM, Neves LS, Renato NdS, Moltó J, Conesa JA, Borges AC. Life Cycle Assessment of a Vegetable Tannin-Based Agent Production for Waters Treatment. Water. 2024; 16(7):1007. https://doi.org/10.3390/w16071007

Chicago/Turabian StyleSantos, Lucas de Lima Casseres dos, Jean Bruno Melo Silva, Luisa Soares Neves, Natalia dos Santos Renato, Julia Moltó, Juan Antonio Conesa, and Alisson Carraro Borges. 2024. "Life Cycle Assessment of a Vegetable Tannin-Based Agent Production for Waters Treatment" Water 16, no. 7: 1007. https://doi.org/10.3390/w16071007

APA StyleSantos, L. d. L. C. d., Silva, J. B. M., Neves, L. S., Renato, N. d. S., Moltó, J., Conesa, J. A., & Borges, A. C. (2024). Life Cycle Assessment of a Vegetable Tannin-Based Agent Production for Waters Treatment. Water, 16(7), 1007. https://doi.org/10.3390/w16071007