The Mechanism of Dust Transportation Based on Wind Tunnel Experiments and Numerical Simulations

Abstract

1. Introduction

2. Methodology

2.1. Wind Tunnel Experiment

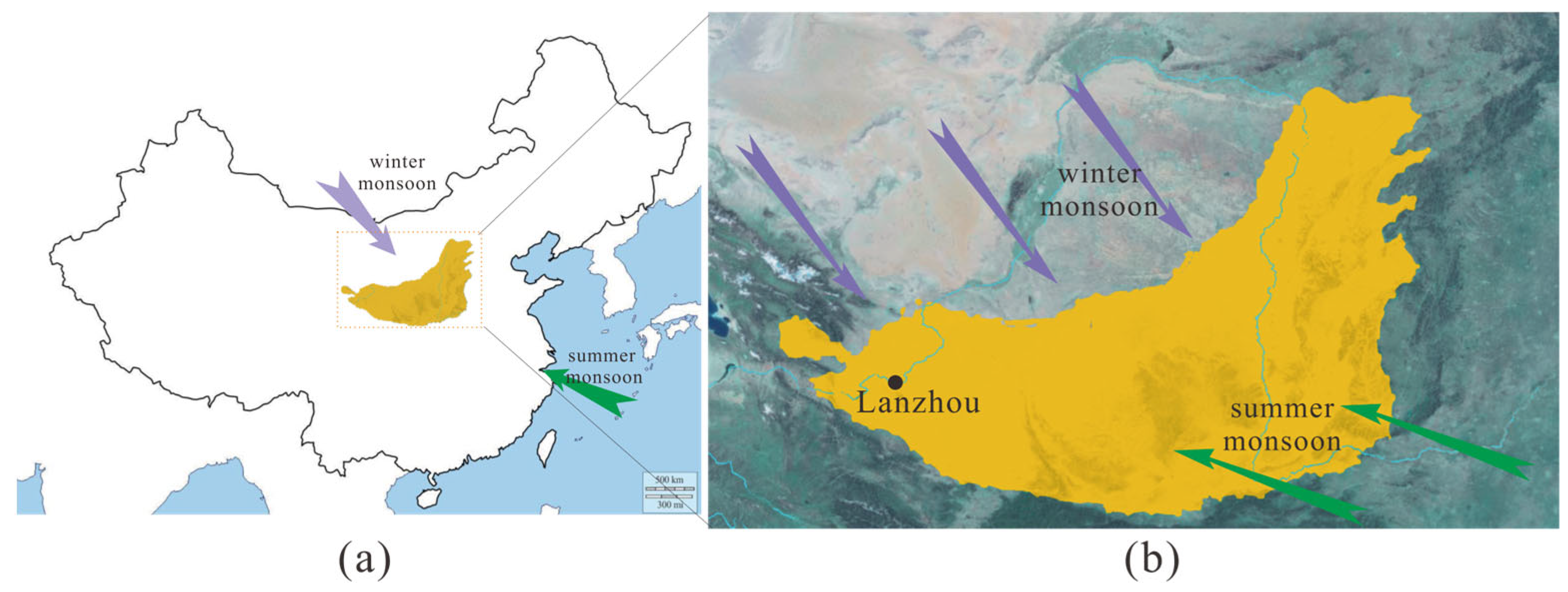

2.1.1. Sampling Location and Sample Pretreatment

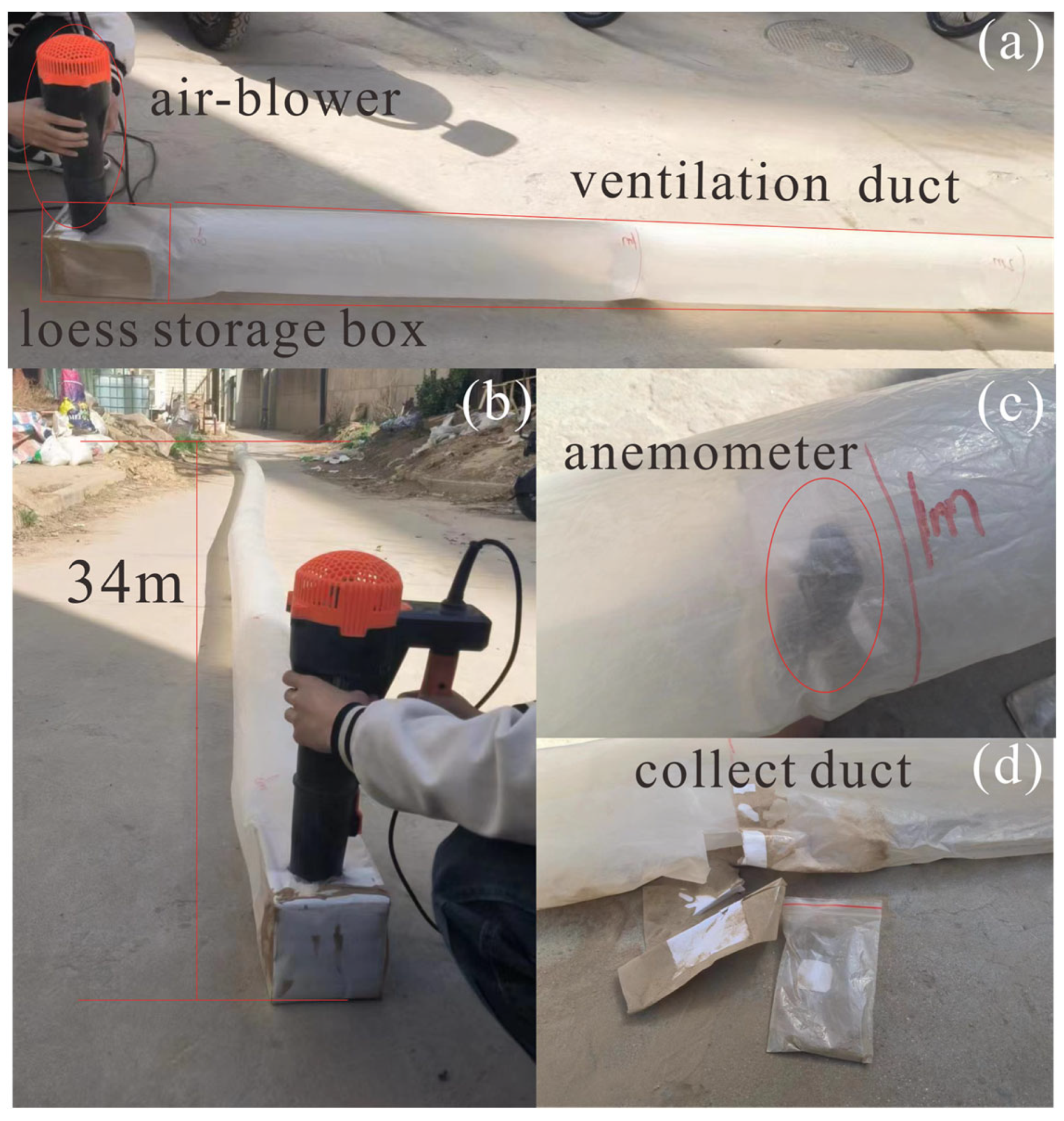

2.1.2. Wind Tunnel Experimental Device and Experimental Procedure

2.2. Derivation of the Particle Motion Equations

2.2.1. Horizontal Direction

2.2.2. Vertical Direction Ascending Segment

2.2.3. Vertical Direction Settling Segment

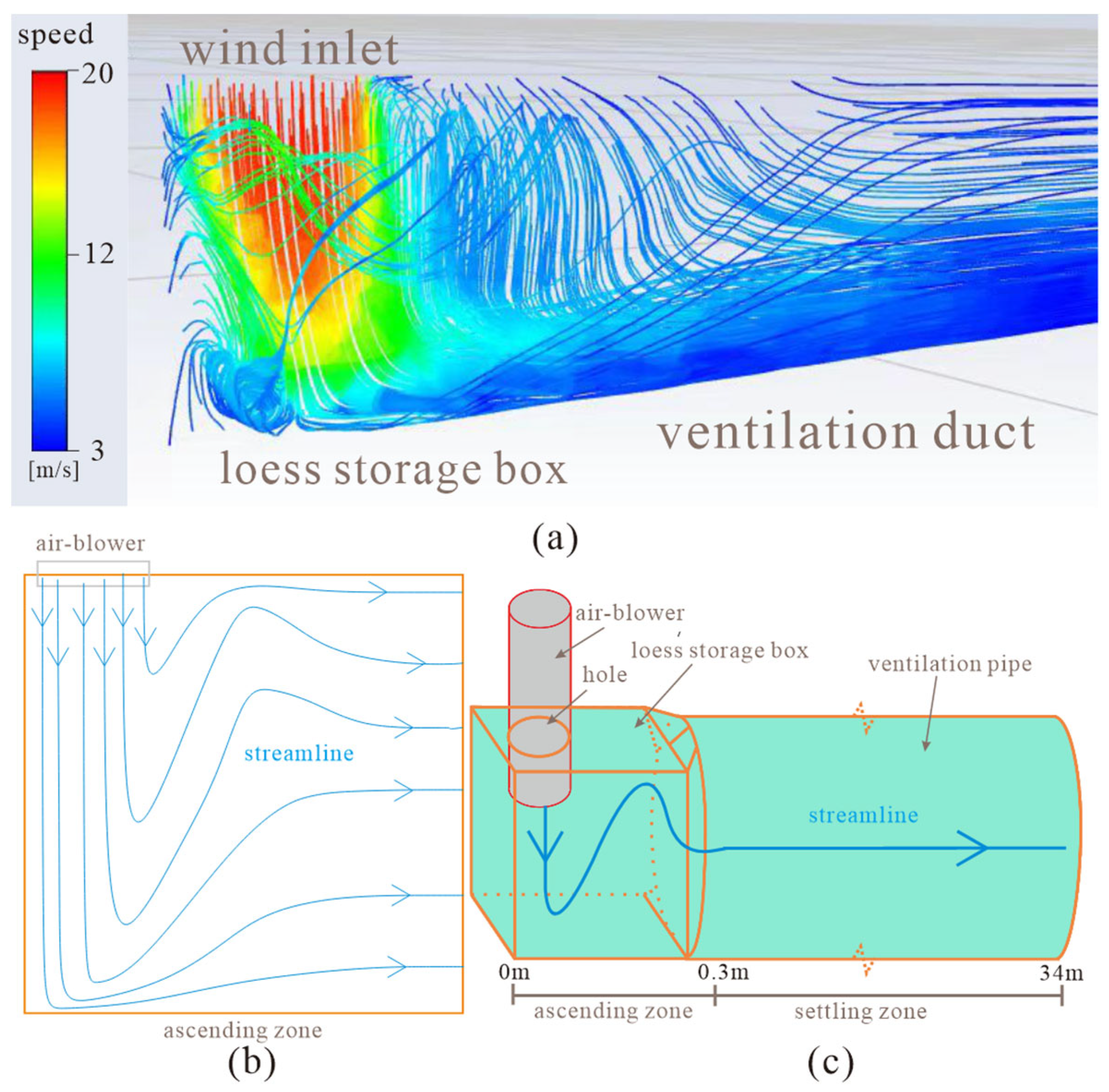

2.3. Numerical Simulation

2.4. Software Introduction

3. Results and Analysis

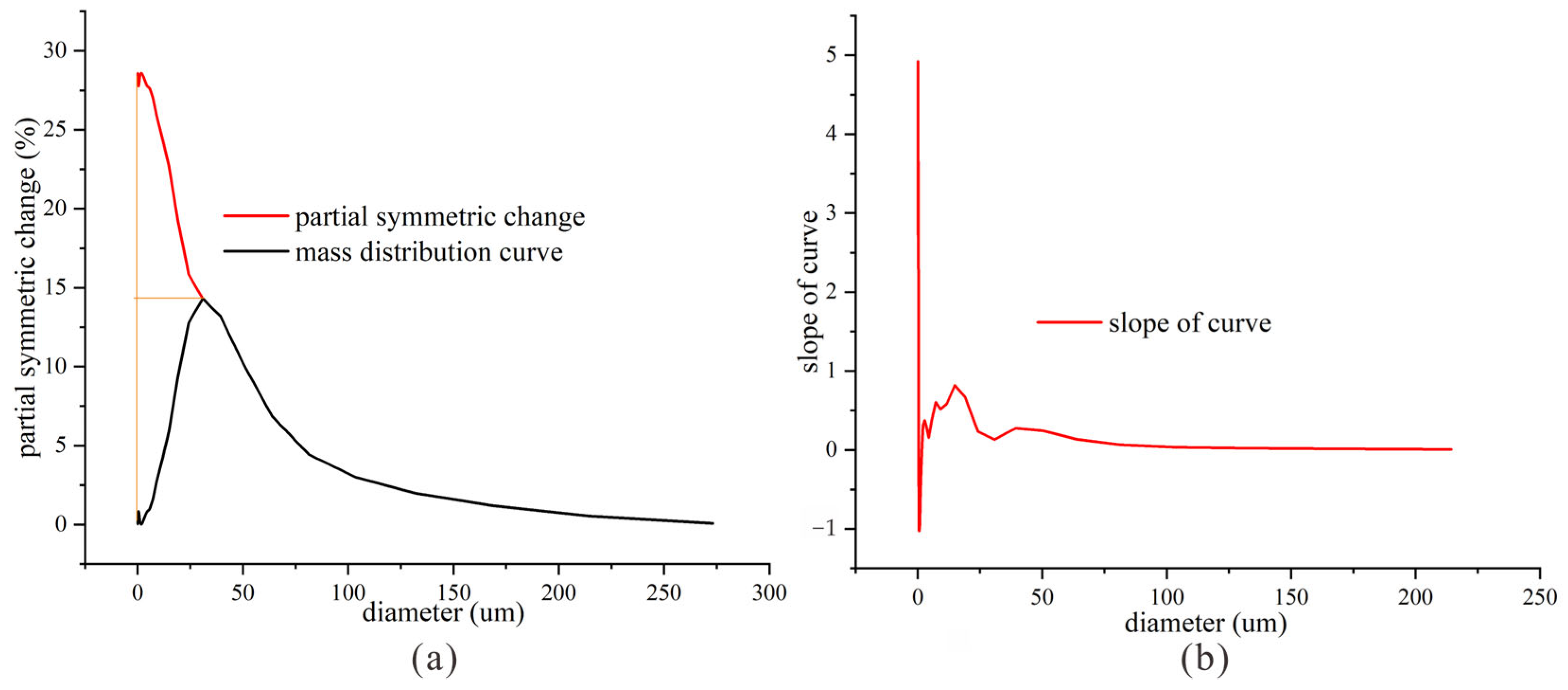

3.1. Particle Size Analysis in the Experimental Results

3.2. Particle Motion Process

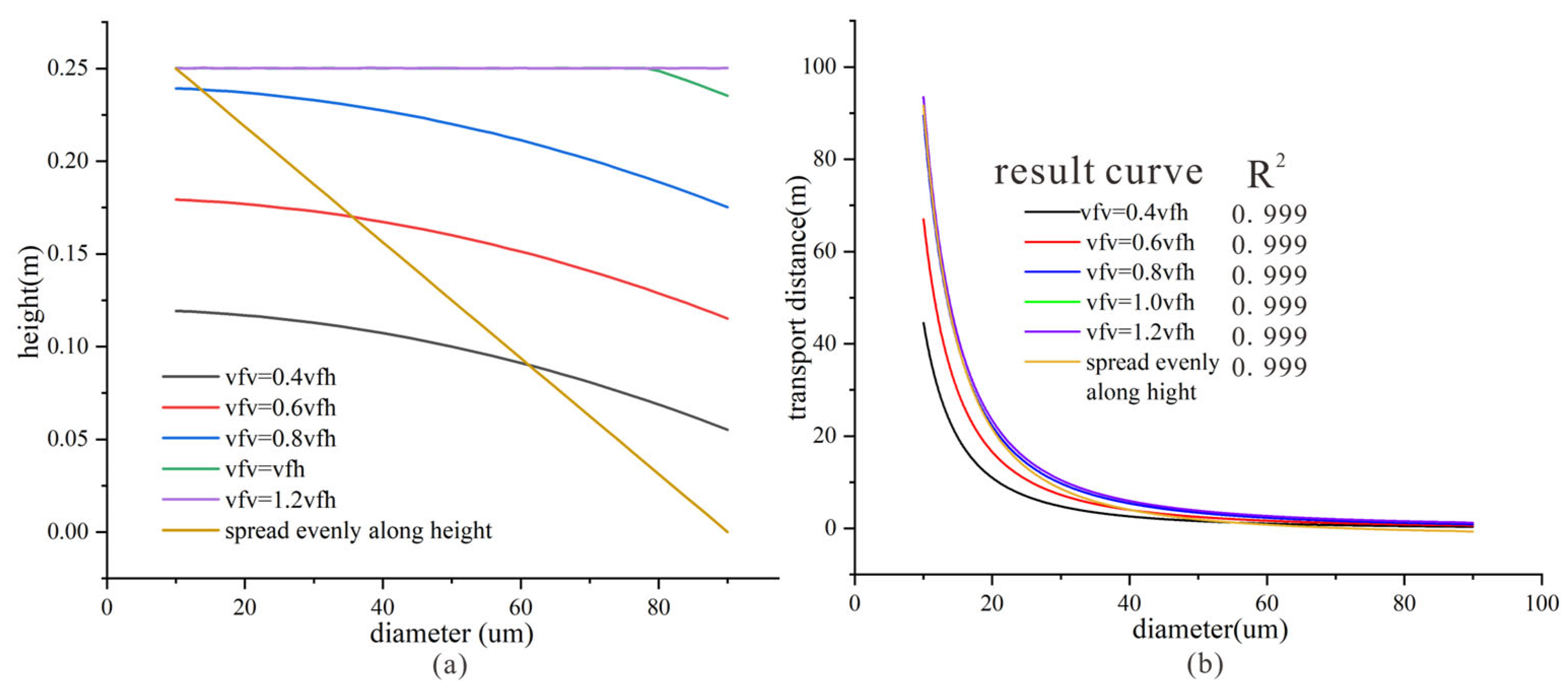

3.2.1. Influence of the Ascending Wind Speed Values

- (1)

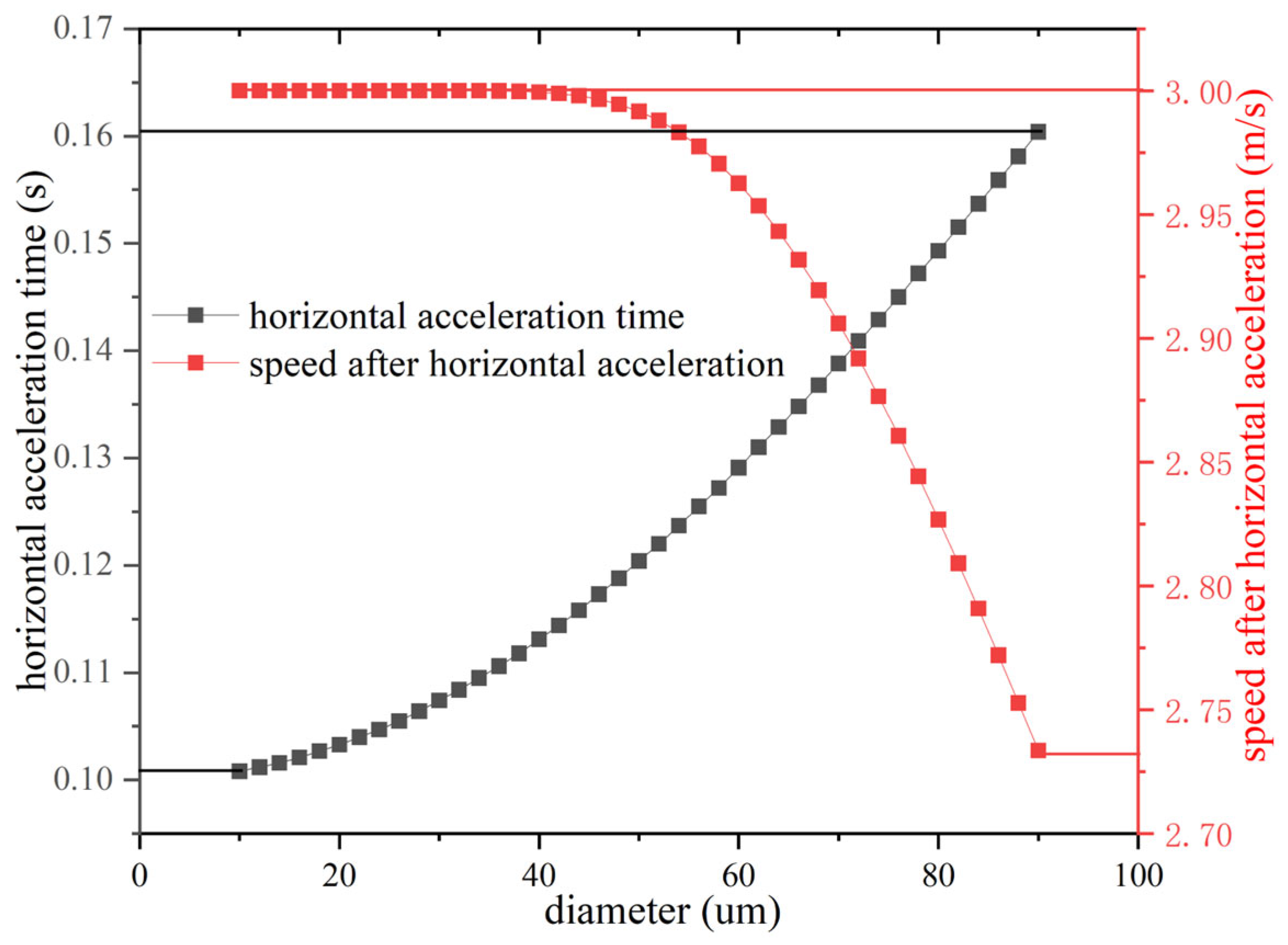

- Horizontal wind speed

- (2)

- Vertical wind speed

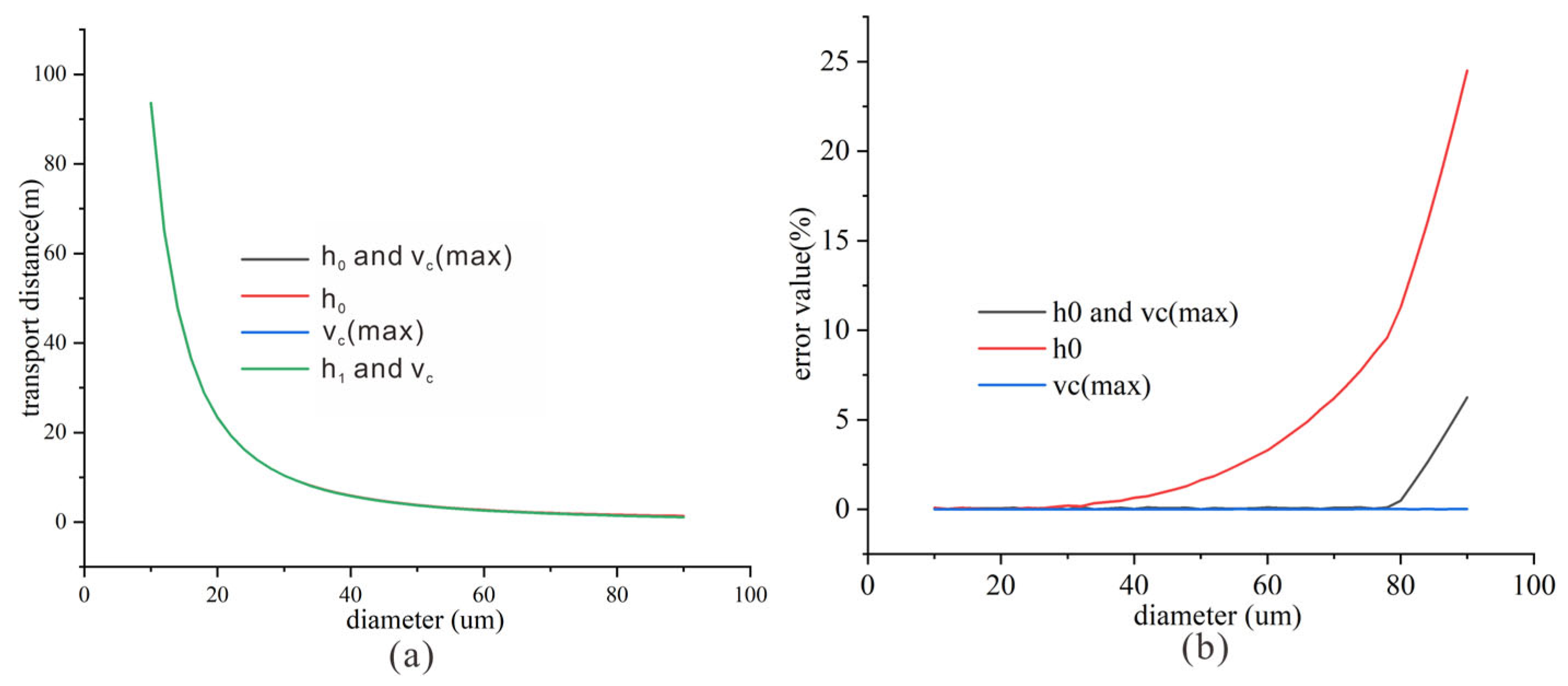

3.2.2. Analysis of the Influence of Approximate Values for Settling Velocity and Height in the Descending Segment

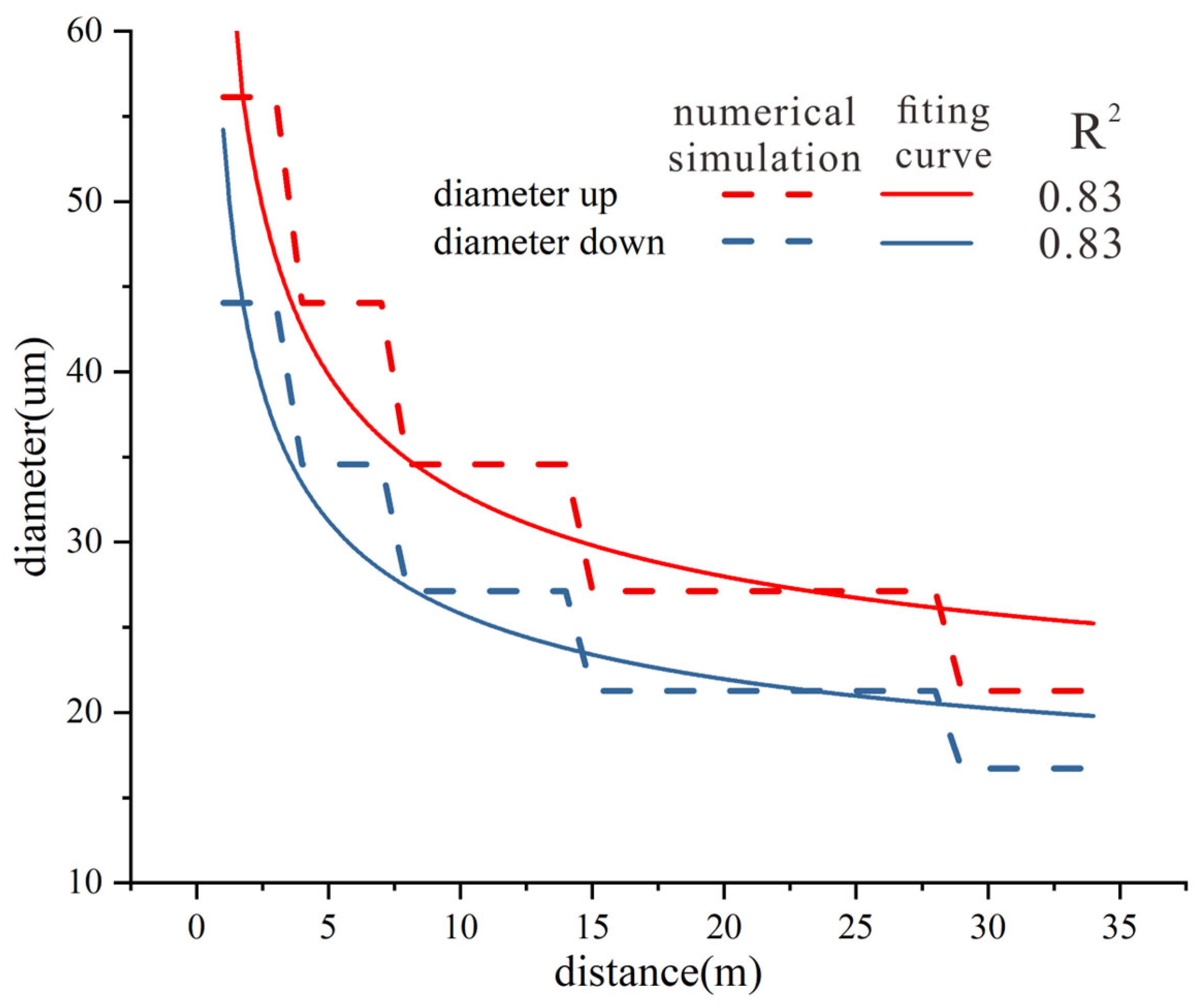

3.2.3. Fitting of Theoretical Formulas with Experimental Results

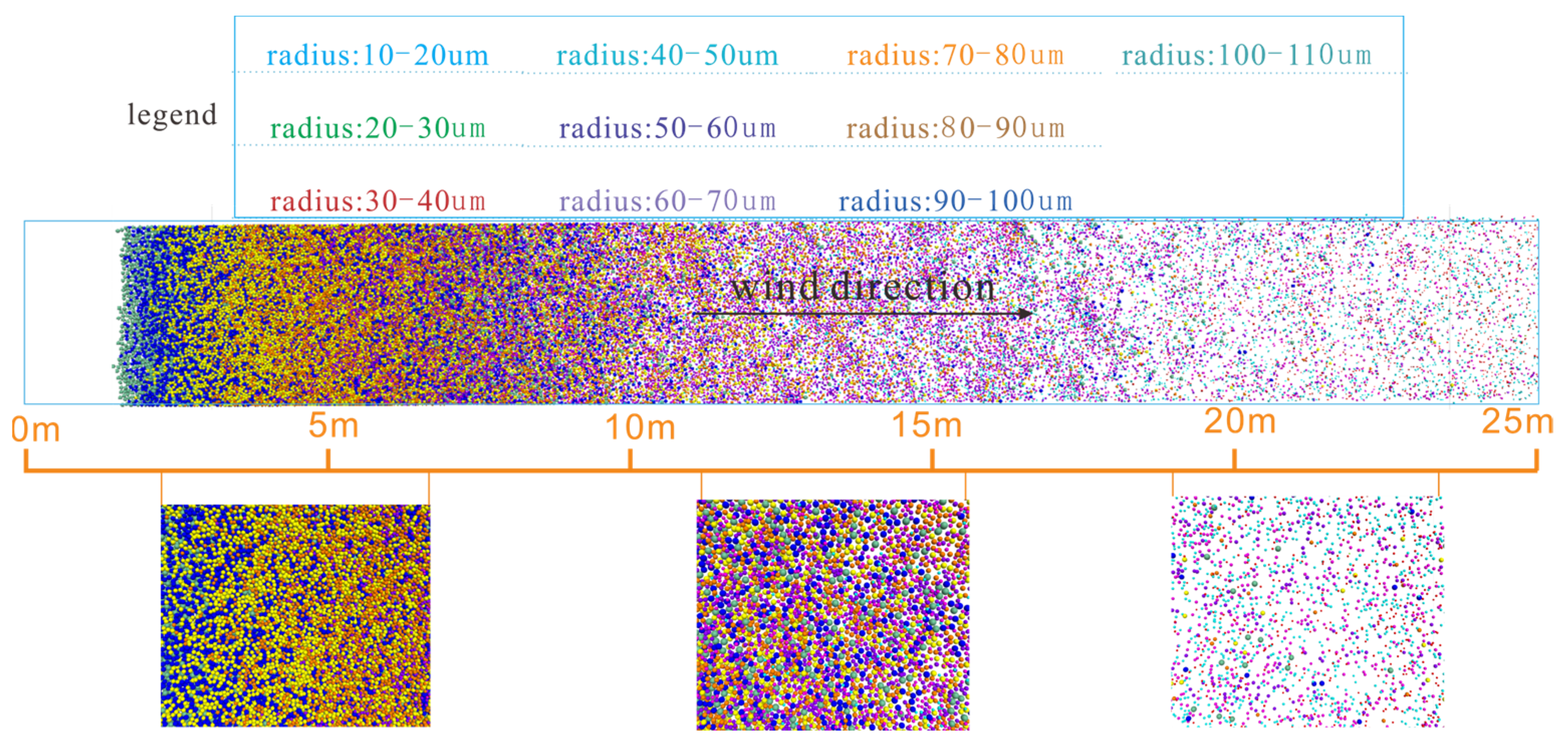

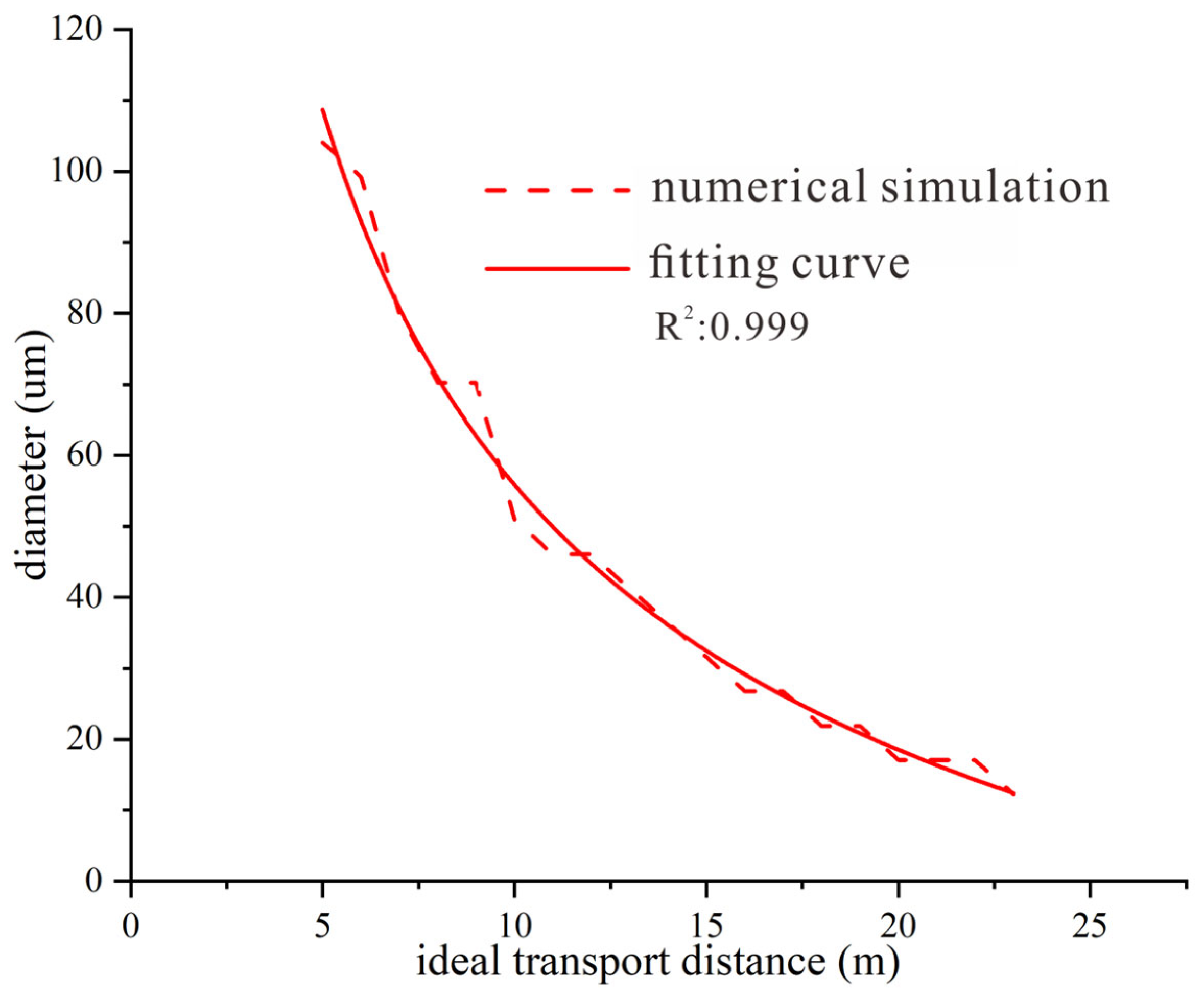

3.3. Numerical Simulation Results

3.3.1. Alignment of Numerical Simulation Results with Theoretical Formulas

3.3.2. Analysis of Other Conditions in Nature Based on Numerical Simulations

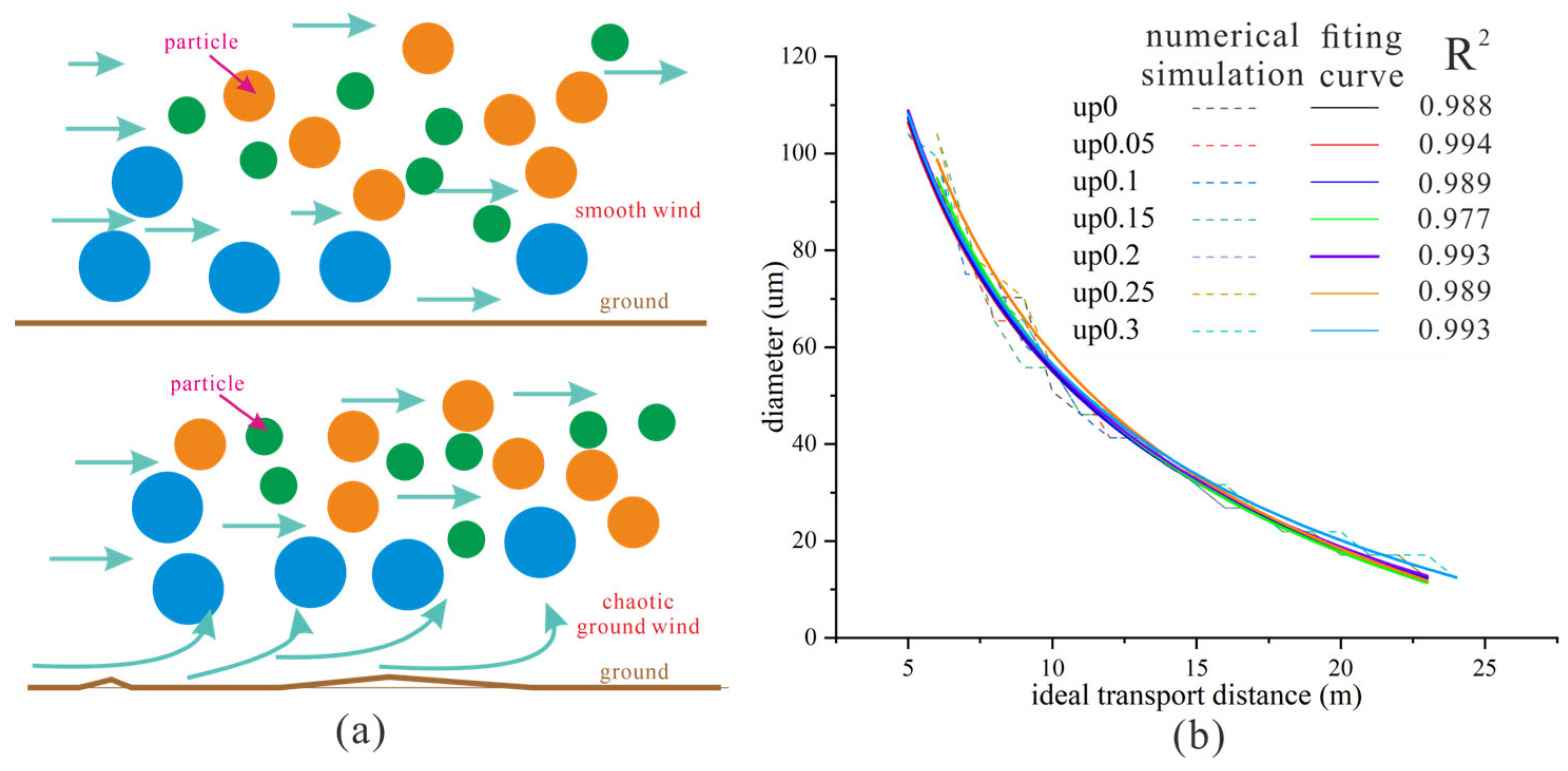

- (1)

- The impact of turbulent updrafts

- (2)

- The impact of turbulent surface winds

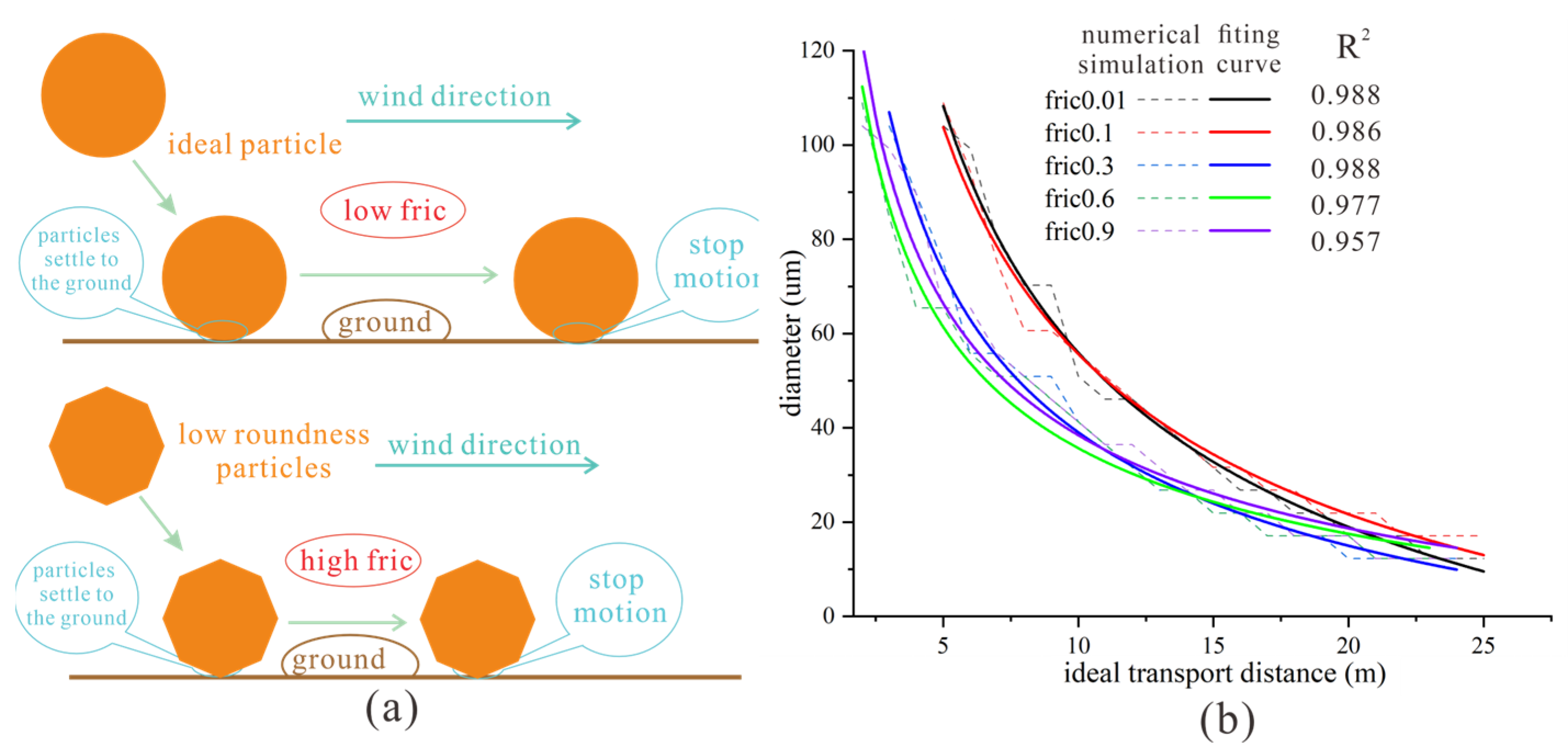

- (3)

- The impact of different friction coefficients

- (4)

- The impact of different damping coefficients

- (5)

- Comprehensive analysis of combined influences

4. Discussion

4.1. Comparison with Studies Conducted by Other Scholars

4.2. Reasons for Selecting the Sampling Location

4.3. Insufficient Research and Future Research Directions

5. Conclusions

- (1)

- In the wind tunnel experiment results, significant differences were observed in the mass distribution curves of particles at different transport distances, indicating effective particle sorting under wind forces for particles of different sizes.

- (2)

- For a specific particle size, the distance corresponding to the peak percentage content represents the ideal deposition distance for that particle size, with the ideal transport distance of particles being inversely proportional to the square of their size.

- (3)

- Turbulent wind fields have a minimal impact on dust transport, while particle roundness significantly influences the transport outcomes.

- (4)

- Both clay and silt particles in loess regions share the same sources and transport pathways, with clay particles depositing extensively in Chinese regions due to the shielding effect of silt particles, thereby affecting local engineering geological properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Muhs, D.R. 11.9 Loess and its Geomorphic, Stratigraphic, and Paleoclimatic Significance in the Quaternary. In Treatise on Geomorphology; Elsevier: Amsterdam, The Netherlands, 2013; pp. 149–183. [Google Scholar] [CrossRef]

- Sun, J. Provenance of loess material and formation of loess deposits on the Chinese Loess Plateau. Earth Planet. Sci. Lett. 2002, 203, 845–859. [Google Scholar] [CrossRef]

- Stevens, T.; Carter, A.; Watson, T.; Vermeesch, P.; Andò, S.; Bird, A.; Lu, H.; Garzanti, E.; Cottam, M.; Sevastjanova, I. Genetic linkage between the Yellow River, the Mu Us desert and the Chinese Loess Plateau. Quat. Sci. Rev. 2013, 78, 355–368. [Google Scholar] [CrossRef]

- Smalley, I.; O’Hara-Dhand, K.; Kwong, J. China: Materials for a loess landscape. Catena 2014, 117, 100–107. [Google Scholar] [CrossRef]

- Derbyshire, E. Geological hazards in loess terrain, with particular reference to the loess regions of China. Earth-Sci. Rev. 2001, 54, 231–260. [Google Scholar] [CrossRef]

- Zheng, Z.; Lei, J.; Li, S.; Wang, H.; Fan, J. Test and evaluation of aerodynamic characteristics of portable environmental wind tunnel. J. Desert Res. 2012, 32, 1551–1558. [Google Scholar]

- Goossens, D. Scale model simulations of the deposition of loess in Hilly Terrain. Earth Surf. Process Landf. 1988, 13, 533–544. [Google Scholar] [CrossRef]

- Cai, D.; Li, S.; Gao, X.; Lei, J. Wind tunnel simulation of the aeolian erosion on the leeward side of barchan dunes and its implications for the spatial distribution patterns of barchan dunes. Catena 2021, 207, 105583. [Google Scholar] [CrossRef]

- Liang, L.; Ma, S.; Zhang, W.; Tan, L.; Chen, S.; Tsunekawa, A. Investigating the impact factors of dust emission efficiency over gobi with portable wind tunnel field experiments. Earth Surf. Process Landf. 2024, 11, 5814. [Google Scholar] [CrossRef]

- Yassin, M.; Kato, S.; Ooka, R.; Takahashi, T.; Kouno, R. Field and wind-tunnel study of pollutant dispersion in a built-up area under various meteorological conditions. J. Wind. Eng. Ind. Aerodyn. 2005, 93, 361–382. [Google Scholar] [CrossRef]

- Merrison, J.P.; Bertelsen, P.; Frandsen, C.; Gunnlaugsson, P.; Knudsen, J.M.; Lunt, S.; Madsen, M.B.; Mossin, L.A.; Nielsen, J.; Nørnberg, P.; et al. Simulation of the Martian dust aerosol at low wind speeds. J. Geophys. Res. 2002, 107, 16-1–16-8. [Google Scholar] [CrossRef]

- Huang, H.-Y.; Capps, S.B.; Huang, S.-C.; Hall, A. Downscaling near-surface wind over complex terrain using a physically-based statistical modeling approach. Clim. Dyn. 2014, 44, 529–542. [Google Scholar] [CrossRef]

- Yarmohamadi, M.; Alesheikh, A.A.; Sharif, M.; Vahidi, H. Predicting Dust-Storm Transport Pathways Using a Convolutional Neural Network and Geographic Context for Impact Adaptation and Mitigation in Urban Areas. Remote Sens. 2023, 15, 2468. [Google Scholar] [CrossRef]

- Rodakoviski, R.; Kok, J.; Chamecki, M. Dust Settling from Turbulent Layers in the Free Troposphere: Implications for the Saharan Air Layer. J. Geophys. Res. Atmos. 2023, 128, e2022JD037724. [Google Scholar] [CrossRef]

- Jung, E.; Shao, Y.; Sakai, T. A study on the effects of convective transport on regional-scale Asian dust storms in 2002. J. Geophys. Res. 2005, 110, D20201. [Google Scholar] [CrossRef]

- Qin, X. A physcial model of loess dust transport process. Quat. Sci. 2009, 29, 1154–1161. [Google Scholar]

- Zhang, Y.; Gui, X.; Xu, Y. Study on the settling rule of dust in the dust removal pipe of screening workshop based on FLUENT software. Hydraul. Coalmining Pipeline Transp. 2010, 4, 11–15. [Google Scholar] [CrossRef]

- Chang, C.; Bo, J.; Qi, W.; Qiao, F.; Peng, D. Study on instability and damage of a loess slope under strong ground motion by numerical simulation. Soil Dyn. Earthq. Eng. 2021, 152, 107050. [Google Scholar] [CrossRef]

- Sun, D.; Lu, H. Grain-size and dust accumulation rate of late cenozoic aeolian deposits and the inferred atmospheric circulation evolutions. Quat. Sci. 1985, 2, 251–262. [Google Scholar]

- Liu, D. Loess and the Environment; China Ocean Press: Haidian, China, 1985. [Google Scholar]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Ministry of Water Resources of the People’s Republic of China. China Planning Press: Beijing, China, 2019.

- Hong, B. Microscopic anisotropy and genesis of Late Pleistocene loess particles in Yan’an. Geol. China 2021, 48, 900–910. [Google Scholar]

- Zhang, R.; Kravchinsky, V.A.; Zhu, R.; Yue, L. Paleomonsoon route reconstruction along a W–E transect in the Chinese Loess Plateau using the anisotropy of magnetic susceptibility: Summer monsoon model. Earth Planet. Sci. Lett. 2010, 299, 436–446. [Google Scholar] [CrossRef]

- Liu, D.; Li, W.; Peng, S.; Wang, L. Current Application of Grain Size Analysis in Chinese Loess Paleocl imatic Study. Period. Cean Univ. China 2010, 40, 79–84. [Google Scholar] [CrossRef]

- Wang, Z.; Su, H. Simple Derivation of Stokes Resistance Formula. J. Univ. Electron. Sci. Technol. China 1997, 26, 261–264. [Google Scholar]

- Timothy, S. Numerical Analysis; Pearson: London, UK, 2017. [Google Scholar]

- Wang, F. Computational Fluid Dynamics Analysis: Principles and Applications of CFD Software; Tsinghua University Press: Beijing, China, 2004. [Google Scholar]

- Tsoar, H.; Pye, K. Dust transport and the question of desert loess formation. Sedimentology 1987, 34, 139–153. [Google Scholar] [CrossRef]

- Vandenberghe, J. Grain size of fine-grained windblown sediment: A powerful proxy for process identification. Earth Sci. Rev. 2013, 121, 18–30. [Google Scholar] [CrossRef]

- Wen, Y.; Wu, Y.; Tan, L.; Li, D.; Fu, T. End-member modeling of the grain size record of loess in the Mu Us Desert and implications for dust sources. Quat. Int. 2019, 532, 87–97. [Google Scholar] [CrossRef]

- Li, X.-A.; Sun, J.; Ren, H.; Lu, T.; Ren, Y.; Pang, T. The effect of particle size distribution and shape on the microscopic behaviour of loess via the DEM. Environ. Earth Sci. 2022, 81, 290. [Google Scholar] [CrossRef]

- Huo, A.; Yang, L.; Peng, J.; Cheng, Y.; Jiang, C. Spatial characteristics of the rainfall induced landslides in the Chinese Loess Plateau. Hum. Ecol. Risk Assess. Int. J. 2020, 26, 2462–2477. [Google Scholar] [CrossRef]

- Ma, P.; Peng, J.; Wang, Q.; Zhuang, J.; Zhang, F. The mechanisms of a loess landslide triggered by diversion-based irrigation: A case study of the South Jingyang Platform, China. Bull. Eng. Geol. Environ. 2019, 78, 4945–4963. [Google Scholar] [CrossRef]

- Zheng, H.; Li, X.-A.; Deng, Y.-H.; Hao, Z.-T.; Wen, F. Study on the Influence of Initial State on Loess Erosion Characteristics and Microscopic Mechanism. Sustainability 2023, 15, 4676. [Google Scholar] [CrossRef]

- Yang, F.; He, Q.; Huang, J.; Mamtimin, A.; Yang, X.; Huo, W.; Zhou, C.; Liu, X.; Wei, W.; Cui, C.; et al. Desert Environment and Climate Observation Network over the Taklimakan Desert. Bull. Am. Meteorol. Soc. 2020, 102, E1172–E1191. [Google Scholar] [CrossRef]

- Ravi, S.; D’odorico, P.; Breshears, D.D.; Field, J.P.; Goudie, A.S.; Huxman, T.E.; Li, J.; Okin, G.S.; Swap, R.J.; Thomas, A.D.; et al. Aeolian processes and the biosphere. Rev. Geophys. 2011, 49, RG3001. [Google Scholar] [CrossRef]

- Di, L.; Gu, L. A brief talk on sandstorm disaster and its research progress in China. Resour. Conserv. Environ. Prot. 2013, 8, 94. [Google Scholar] [CrossRef]

| g (N/kg) | ρ1 (g/cm3) | ρ2 (kg/m3) | η (N × s/m2) | h0 (m) | vf (m/s) | |

|---|---|---|---|---|---|---|

| Value | 9.8 | 2.65 | 1.29 | 1.79 × 10−5 | 0.25 | 3.0 |

| Disturbed Upwind | Disturbed Surface Wind (0–0.3) | Fric (0.1–0.9) | Damp (0.1–0.9) | |

|---|---|---|---|---|

| influence | low | none | middle | high |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Li, X.; Wang, W.; Chai, H.; An, M.; Dai, Q. The Mechanism of Dust Transportation Based on Wind Tunnel Experiments and Numerical Simulations. Water 2024, 16, 1006. https://doi.org/10.3390/w16071006

Yang J, Li X, Wang W, Chai H, An M, Dai Q. The Mechanism of Dust Transportation Based on Wind Tunnel Experiments and Numerical Simulations. Water. 2024; 16(7):1006. https://doi.org/10.3390/w16071006

Chicago/Turabian StyleYang, Jinduo, Xi’an Li, Weiping Wang, Hao Chai, Mingxiao An, and Qianyi Dai. 2024. "The Mechanism of Dust Transportation Based on Wind Tunnel Experiments and Numerical Simulations" Water 16, no. 7: 1006. https://doi.org/10.3390/w16071006

APA StyleYang, J., Li, X., Wang, W., Chai, H., An, M., & Dai, Q. (2024). The Mechanism of Dust Transportation Based on Wind Tunnel Experiments and Numerical Simulations. Water, 16(7), 1006. https://doi.org/10.3390/w16071006