1. Introduction

It is increasingly common to build barriers around landfills to prevent soil and groundwater contamination [

1,

2,

3]. The application of attapulgite cut-off walls in landfills has attracted more and more attention because of its good adsorption capacity and insensitivity to chemical environments [

4,

5,

6,

7,

8,

9,

10,

11,

12,

13]. The final stress of the cut-off wall in the field is usually unknown. But this final stress is important because it not only affects the permeability of the wall, but higher in situ stress also increases the wall’s resistance to hydraulic fracturing and chemical erosion [

14]. In addition, the cut-off wall’s final stress state will affect the wall’s deformation and the surrounding soil and buildings. Therefore, it is necessary to further understand the stress state of sand–attapulgite cut-off walls in the field [

14,

15,

16].

The stress state of a cut-off wall in the field is much lower than the effective stress of the cut-off wall considering only the static load of the overlying soil [

17,

18,

19,

20,

21]. If the pressure under the static load of the overlying soil is used as the effective consolidation pressure or confining pressure to test the hydraulic conductivity of the cut-off wall, the obtained hydraulic conductivity will be much lower than that in the field, which will cause the overestimation of the anti-seepage performance of the cut-off wall.

At present, there are mainly two simplified theories used to calculate the stress distribution of clay-based cut-off walls in the field: the ‘arching theory’ and the ‘lateral squeezing theory’ [

17,

19]. Evans et al. [

17] applied the ‘arching theory’ to the stress calculation of a soil–bentonite cut-off wall. This theory assumes that the side wall of the trench is rigid and fixed and does not have lateral displacement. The soil–bentonite backfill filled into the trench is compressible, and the backfill will have vertical displacement in the process of gravity consolidation. In the process of displacement, the friction between the wall material and the side wall of the trench causes the vertical stress of the wall to be less than the gravity of the overlying soil. The assumption that the side wall of the trench is fixed and does not have lateral displacement will cause the theory to underestimate the influence of horizontal stress on the wall so that the stress of the wall calculated by the ‘arching theory’ is lower than the actual one.

Filz [

19] applied the ‘lateral squeezing theory’ to the stress calculation of soil–bentonite cut-off walls, which assumed that the friction between the wall and the sidewall of the trench was sufficient to offset the weight of the overlying soil on the wall, so that the wall does not bear the vertical stress but only bears the horizontal stress when the trench is displaced in the direction of the center line of the wall. Ruffing et al. [

21] then proposed a ‘modified lateral squeezing theory’ to calculate the in situ stress state of the cut-off wall by further considering the stress dependence of the compressibility of the wall. However, this theory has certain limitations because it assumes that the friction between the wall and the sidewall of the trench can offset the weight of the overlying soil on the wall, so it is not suitable for the analysis of wide and shallow walls [

22]. Li et al. [

22] combined the ‘arching theory’ and the ‘lateral squeezing theory’ and, based on Winkler’s idealization, simplified the foundation soil around the cut-off wall into independent elastic springs and proposed a new calculation model for the stress distribution of a clay-based cut-off wall.

Filz and Mitchell [

23] found that the stress of a cut-off wall is affected by the ‘lateral squeezing theory’ by analyzing the stress of a soil–bentonite cut-off wall at 23 m in the field, and only when the trench or wall width exceeds 3.3 m is the stress of the cut-off wall affected by the ‘arching theory’. However, in practical engineering, there will be almost no such wide trench and cut-off walls. Compared with the ‘arching theory’, the ‘lateral squeezing theory’ can more realistically reflect the stress state of a cut-off wall in the field [

19,

24].

Zhang et al. [

11] found that the effective consolidation pressure has an important influence on the hydraulic conductivity of sand–attapulgite cut-off walls. Therefore, the accurate calculation of the effective stress distribution of the sand–attapulgite cut-off wall in the field is very important for obtaining a more accurate hydraulic conductivity of the cut-off wall. However, most of the previous studies focus on the effective stress distribution of soil–bentonite cut-off walls in the field, and there are few studies on the effective stress distribution and hydraulic conductivity distribution of sand–attapulgite cut-off walls in the field.

In this paper, the ‘modified lateral squeezing model’ proposed by Ruffing et al. [

21] is used to calculate the stress distribution of the sand–attapulgite cut-off wall, and the relationship between the effective consolidation stress and the void ratio obtained by the previous research of the research group and the relationship between the void ratio and hydraulic conductivity are combined to calculate the hydraulic conductivity distribution of a sand–attapulgite cut-off wall in the field. In addition, the influence of different parameters on the stress distribution and hydraulic conductivity distribution of a sand–attapulgite cut-off wall was analyzed based on the ‘modified lateral squeezing model’. Our findings are expected to provide a valuable reference for the application of sand–attapulgite cut-off walls in landfills.

2. Model Description

Filz [

19] believes that the lateral displacement of the cut-off wall trench can be divided into three stages: (1) during trench excavation and mud filling, the trench sidewall will move inward; (2) the trench sidewall may rebound during the backfilling stage of the cut-off wall material; (3) the trench sidewall will move inward again during the consolidation stage of the cut-off wall material. Filz [

19] assumed that the friction between the cut-off wall and the sidewall of the trench is sufficient to offset the weight of the overlying soil on the wall material, and the wall only bears the horizontal stress when the trench is displaced toward the centerline of the wall. The stress of the wall is hypothesized to be lateral one-dimensional compression, and a ‘lateral squeezing model’ is proposed for calculating the stress distribution of the cut-off wall:

where

is the horizontal effective stress of the wall;

is the vertical effective stress of in situ foundation soil outside the trench;

is the buoyant unit weight of the wall material;

z is the depth of the cut-off wall;

is the unilateral deflection of the trench side wall;

is the mobilized active earth pressure coefficient of the in situ foundation soil, which is a function of

;

is the constrained modulus of the wall material; and

B is the width of the wall.

Db is not a constant; it varies with consolidation stress, or with the depth of the wall. This will make the calculation process of the ‘lateral squeezing model’ more complicated. To solve this problem, Ruffing et al. [

21] proposed a ‘modified lateral squeezing model’ for calculating the stress distribution of the cut-off wall:

where

C1 is the strain value under unit stress;

Ccε is the modified compression index; and

C1 and

Ccε are constants that can be obtained by a one-dimensional consolidation test in the laboratory.

3. Stress Distribution and Hydraulic Conductivity Distribution Calculation

3.1. Stress Distribution Calculation

Based on the previous work of our study, when the attapulgite content in the cut-off wall was ≥30%, the hydraulic conductivity of the sand–attapulgite cut-off wall was lower than 1.0 × 10

−9 m/s [

11]. The sand–attapulgite cut-off walls with 30% (A30S70), 40% (A40S60), and 60% (A60S40) attapulgite content presented in the work of Zhang et al. [

11] were selected for this study. The values of

,

C1, and

Ccε of the sand–attapulgite cut-off wall were calculated according to the research group’s preliminary test results [

11] and 1D consolidation tests [

25]. In addition, the geometric parameters of the cut-off wall and the related parameters of the in situ foundation soil were summarized from Ruffing et al. [

21] and Li et al. [

22]. The geometric and material parameters used to calculate the stress distribution of the cut-off wall are listed in

Table 1. The stress distribution of the cut-off walls is calculated by using Equation (3) when the wall width

B is 0.8 m and the in situ foundation soil is medium dense sand (the effective internal friction angle of the foundation soil is

= 35.0°;

= 25,200(Δ/

H)

2 − 127(Δ/

H) + 0.426,

H is the depth of the cut-off wall), considering the groundwater level at the surface of the wall.

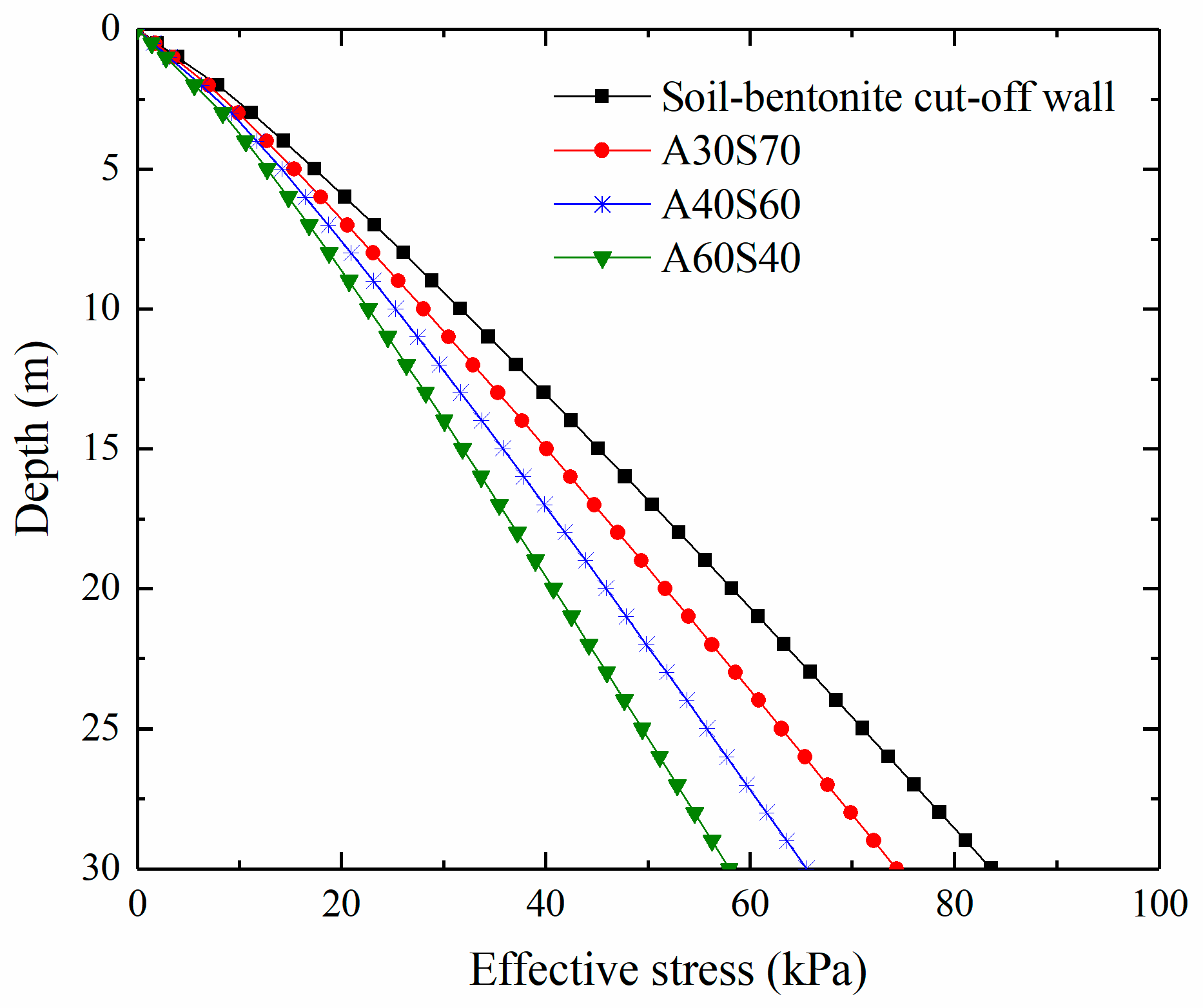

At the same time, the parameters presented in the work of Ruffing et al. [

21] were selected to calculate the stress distribution of the soil–bentonite cut-off wall, which was used to compare the stress distribution of the sand–attapulgite cut-off wall and the soil–bentonite cut-off wall. The calculation results are shown in

Figure 1.

According to

Figure 1, (1) the effective stress of the cut-off wall increases with the increase in depth; (2) the effective stress of the sand–attapulgite cut-off wall is less than 100 kPa; (3) at the same depth, the effective stress of the sand–attapulgite cut-off wall decreases with the increase in the content of attapulgite in the wall; (4) the effective stress of a sand–attapulgite cut-off wall is smaller than that of a soil–bentonite cut-off wall at the same depth, which is because the buoyant unit weight of the sand–attapulgite cut-off wall is smaller than that of the soil–bentonite cut-off wall.

3.2. Hydraulic Conductivity Distribution Calculation

The ‘modified lateral squeezing model’ assumes that the stress process of the wall is similar to the lateral one-dimensional compression of the wall. Therefore, the horizontal stress

calculated by the model can be equivalent to the effective consolidation pressure

σ′ of the one-dimensional consolidation test in the laboratory. When the stress distribution of the wall is known, the relation between the void ratio and consolidation pressure can be obtained by the consolidation test. The hydraulic conductivity of the wall can be calculated by the void ratio [

22].

According to the one-dimensional consolidation test, the relationship between the void ratio (e) and the effective consolidation pressure (σ′) and the relationship between the hydraulic conductivity (k) and the void ratio (e) of the sand–attapulgite cut-off wall can be obtained. For the sand–attapulgite cut-off wall A30S70, e = −0.1644log(σ′) + 0.9933 (R2 = 0.999), k = 1 × 10−10 × e2.4002e (R2 = 0.999); for A40S60, e = −0.2329log(σ′) + 1.2771 (R2 = 0.999), k = 2 × 10−10 × e1.229e (R2 = 0.996); for A60S40, e = −0.2964log(σ′) + 1.6133 (R2 = 0.998), k = 5 × 10−11 × e1.9014e (R2 = 0.949). Combining these equations, the relationship between the effective consolidation pressure (σ′) and the hydraulic conductivity (k) of the sand–attapulgite cut-off wall can be obtained. For the sand–attapulgite cut-off wall A30S70, k = 1 × 10−10 × e2.4002(−0.1644log(σ′) + 0.9933); for A40S60, k = 2 × 10−10 × e1.229(−0.2329log(σ′) + 1.2771); for A60S40, k = 5 × 10−11 × e1.9014(−0.2964log(σ′) + 1.6133).

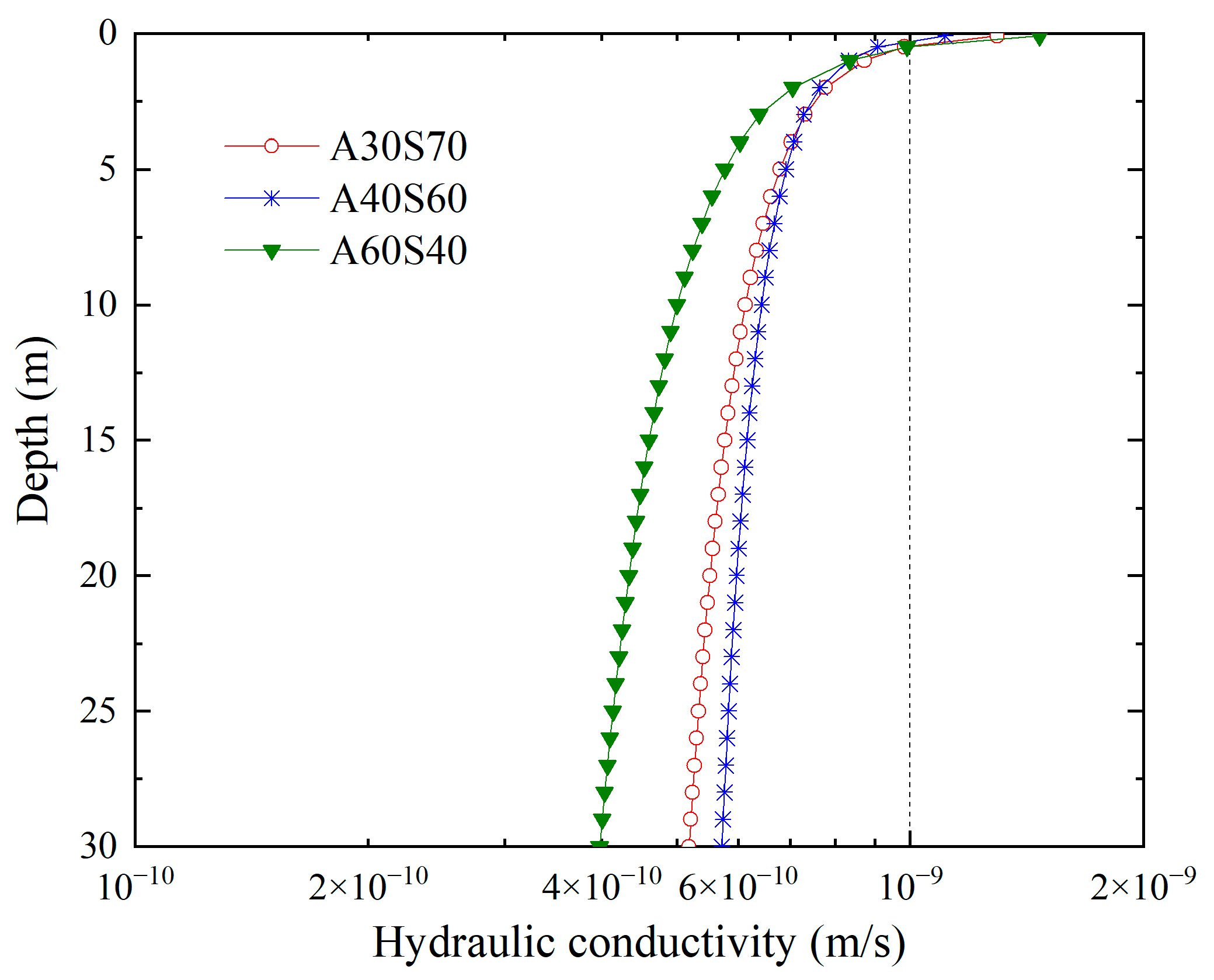

In this section, the expressions for the relationship between the effective consolidation pressure (

σ′) and the hydraulic conductivity (

k) of the sand–attapulgite cut-off wall are used to calculate the hydraulic conductivity distribution of the sand–attapulgite cut-off wall in the field, combined with the effective stress distribution of the sand–attapulgite cut-off wall with different attapulgite contents in

Section 3.1.

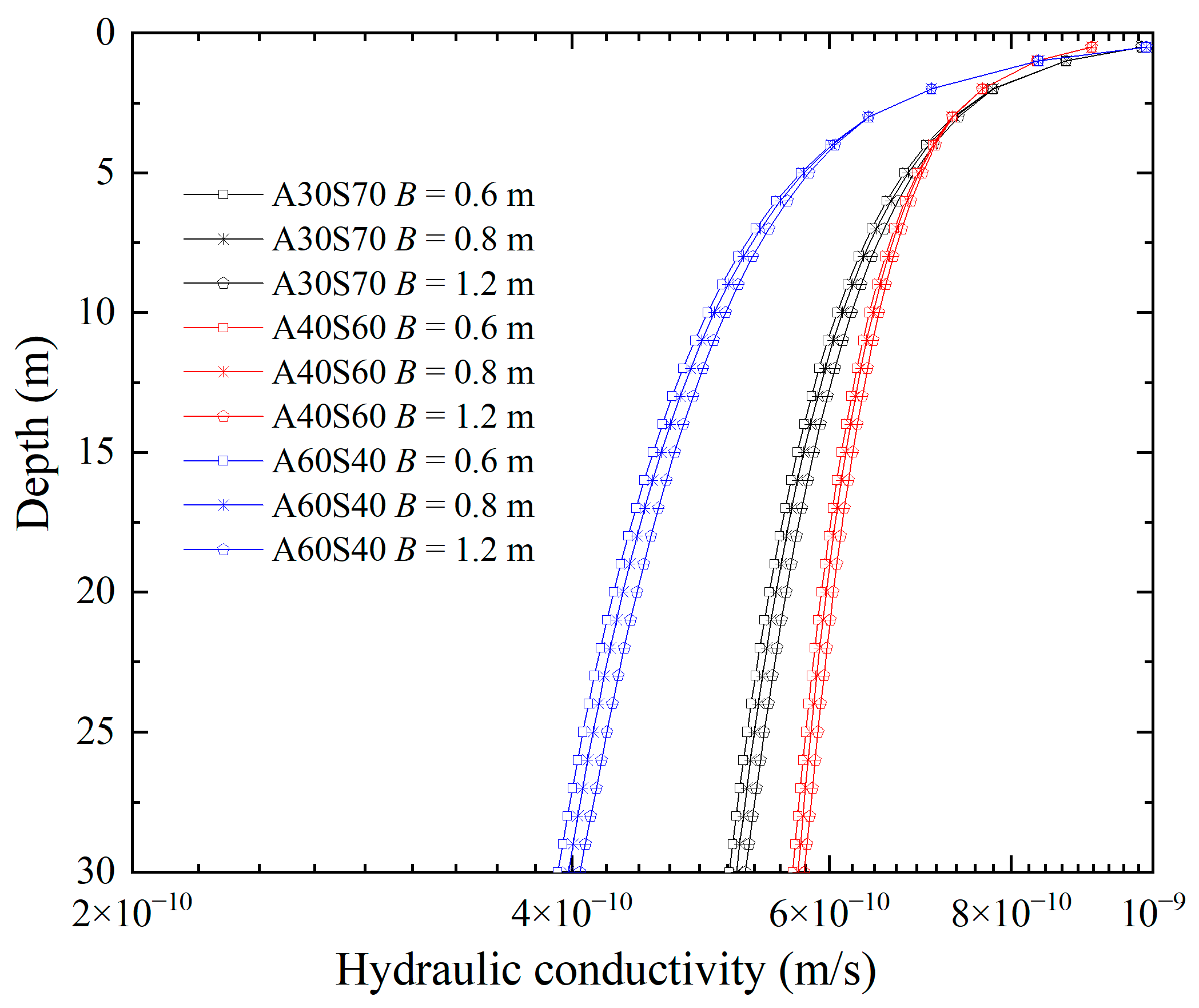

It can be seen from

Figure 2 that the hydraulic conductivity of the sand–attapulgite cut-off wall decreases with the increase in depth. This is caused by the fact that the effective stress of the wall increases with increasing depth (

Figure 1). However, when the depth of the wall exceeds 5 m, the decrease in the hydraulic conductivity becomes small (

Figure 2). Below 0.5 m, the hydraulic conductivity of the wall is less than 1.0 × 10

−9 m/s (

Figure 2). Pan [

28] calculated the hydraulic conductivity distribution of a soil–bentonite cut-off wall in the field and concluded that the hydraulic conductivity of the wall is relatively large in the shallow area less than 2.5 m. Therefore, during the actual construction, special attention should be paid to the anti-seepage measures at the shallow part of the cut-off wall.

4. Parametric Sensitivity Analysis

It can be seen from Equation (3) that the properties of in situ foundation soil near the cut-off wall and the geometric size of the wall will affect the stress distribution of the wall. The change in stress will lead to a change in hydraulic conductivity. In this section, the influence of these parameters on the stress distribution and hydraulic conductivity distribution of the wall will be discussed.

4.1. Influence of Foundation Soil Parameter

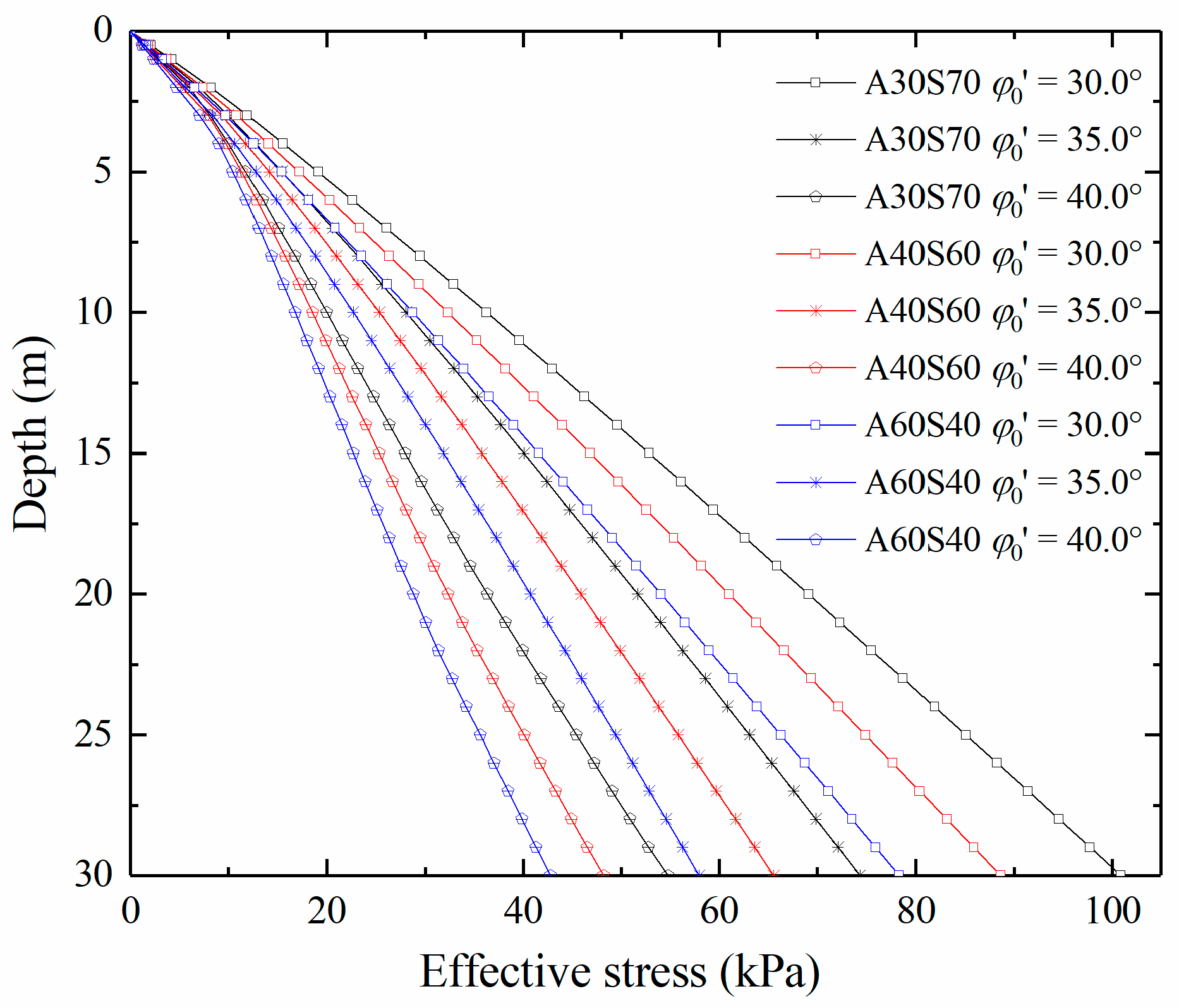

4.1.1. Influence of Foundation Soil Parameter on Stress Distribution

The relevant parameters used to study the influence of foundation soil on the stress distribution of a sand–attapulgite cut-off wall are listed in

Table 2. According to

Table 2 and Equation (3), the stress distribution of the wall is calculated. The values of effective internal friction angle

of foundation soil are 30.0°, 35.0°, and 40.0°, which represent the situations of the in situ foundation soil being saturated loose sand, medium dense sand, and dense sand, respectively [

21]. Accordingly, the relationship between

Kam and

is

Kam = 8260(Δ/

H)

2 − 74.5(Δ/

H) + 0.500,

Kam = 25,200(Δ/

H)

2 − 127(Δ/

H) + 0.426, and

Kam = 115,000(Δ/

H)

2 − 255(Δ/

H) + 0.357 [

21].

It can be seen from

Figure 3 that the effective internal friction angle

of foundation soil has a significant influence on the stress distribution of the sand–attapulgite cut-off wall. At the same depth, with the increase in

, the effective stress of the wall decreases (

Figure 3). As the foundation soil changes from saturated loose sand to dense sand, the lateral displacement of the foundation soil decreases, and the lateral extrusion effect of the trench side wall on the cut-off wall decreases, so the effective stress of the cut-off wall decreases. For example, at the depth of 20 m, when the in situ foundation soil changes from loose sand to dense sand, the effective stresses of sand–attapulgite cut-off walls A30S70, A40S60, and A60S40 decrease from 69 kPa, 61 kPa, and 54 kPa to 36 kPa, 32 kPa, and 29 kPa, respectively.

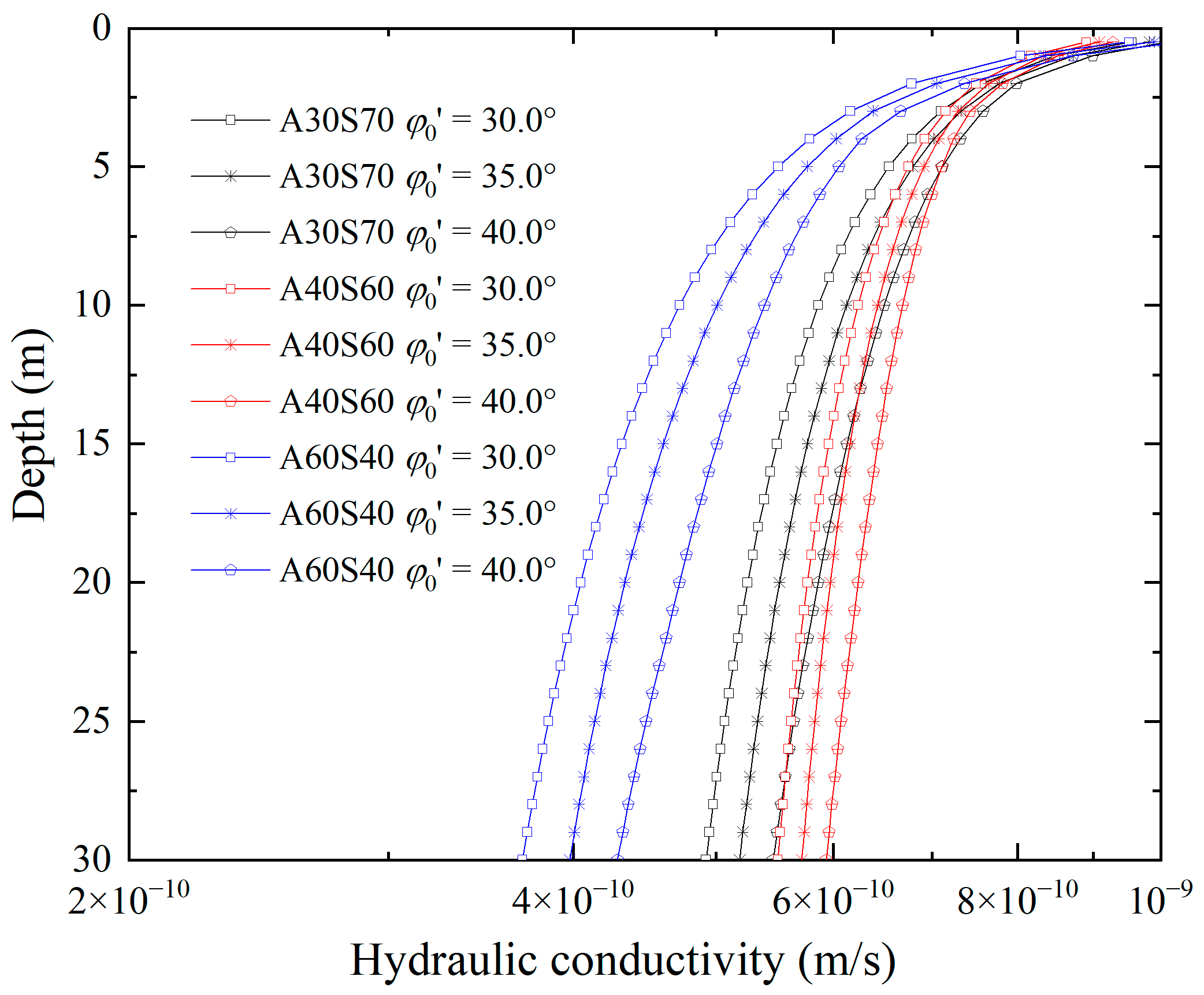

4.1.2. Influence of Foundation Soil Parameter on Hydraulic Conductivity Distribution

At the same depth, the hydraulic conductivity of the sand–attapulgite cut-off wall increases with the increase in the effective internal friction angle

of the foundation soil (

Figure 4). This is caused by the fact that the effective stress of the sand–attapulgite cut-off wall decreases with the increase in

. In addition, with the increase in depth, the hydraulic conductivity of the wall increases more and more with the increase in

, and the increase remains unchanged when the wall depth exceeds 10 m. As shown in

Figure 4, at the deepest 30 m, when

increases from 30° to 35° and 40°, the hydraulic conductivity of the sand–attapulgite cut-off wall A30S40 increases from 4.9 × 10

−10 m/s to 5.2 × 10

−10 m/s and 5.5 × 10

−10 m/s, increasing by 6.1% and 12.2%, respectively. For A40S60, the hydraulic conductivity of the wall increases from 5.5 × 10

−10 m/s to 5.7 × 10

−10 m/s and 5.9 × 10

−10 m/s, increasing by 3.6% and 7.3%, respectively. For A60S40, the hydraulic conductivity of the wall increases from 3.7 × 10

−10 m/s to 4.0 × 10

−10 m/s and 4.3 × 10

−10 m/s, increasing by 8.1% and 16.2%, respectively.

It can be concluded that the hydraulic conductivity of the sand–attapulgite cut-off wall increases with the increase in the effective internal friction angle of the foundation soil, and the increase is limited, no more than one time, and the content of attapulgite in the cut-off wall does not affect this increasing trend.

4.2. Influence of the Geometric Size of the Wall

4.2.1. Influence of Geometric Size on Stress Distribution

The relevant parameters used to study the influence of wall geometry size on the stress distribution of sand–attapulgite cut-off walls are listed in

Table 3. According to

Table 3 and Equation (3), the stress distribution of the sand–attapulgite barrier wall is calculated.

According to

Figure 5, at the same depth, the effective stress of the sand–attapulgite cut-off wall decreases with the increase in wall width

B. For example, at 20 m depth, when the wall width

B increases from 0.6 m to 1.2 m, the effective stress of sand–attapulgite cut-off walls A30S70, A40S60, and A60S40 decreases from 55 kPa, 49 kPa, and 43 kPa to 47 kPa, 42 kPa, and 37 kPa, respectively. The main reason is that with the increase in wall width, the lateral extrusion effect of the trench side wall on the cut-off wall is weakened, so the effective stress of the cut-off wall is reduced.

It can be seen from

Figure 3 and

Figure 5 that, compared with the wall width, the properties of the in situ foundation soil have a greater impact on the effective stress of the sand–attapulgite cut-off wall.

4.2.2. Influence of Geometric Size on Hydraulic Conductivity Distribution

At the same depth, the hydraulic conductivity of the sand–attapulgite cut-off wall increases with the increase in the wall width

B (

Figure 6). This is caused by the fact that the effective stress of the sand–attapulgite cut-off wall decreases with the increase in wall width

B. However, the hydraulic conductivity of the wall increased only slightly with the increase in the wall width

B. At the deepest 30 m, when the wall width

B increases from 0.6 m to 0.8 m and 1.2 m, the hydraulic conductivity of A30S40 increases from 5.1 × 10

−10 m/s to 5.2 × 10

−10 m/s and 5.3 × 10

−10 m/s, increasing by 2.0% and 3.9%, respectively. For A40S60, the hydraulic conductivity increases from 5.6 × 10

−10 m/s to 5.7 × 10

−10 m/s and 5.8 × 10

−10 m/s, with an increase of 1.8% and 3.6%, respectively. For A60S40, the hydraulic conductivity increases from 3.9 × 10

−10 m/s to 4.0 × 10

−10 m/s and 4.1 × 10

−10 m/s, increasing by 2.6% and 5.1%, respectively. Therefore, the hydraulic conductivity of the sand–attapulgite cut-off wall increases by a very limited number with the increase in wall width

B, which is no more than 0.2 times, and the content of attapulgite in the wall does not affect this increasing trend.

5. Conclusions

In this paper, the stress distribution of a sand–attapulgite cut-off wall in the field is calculated by the ‘modified lateral squeezing model’. At the same time, the hydraulic conductivity of the sand–attapulgite cut-off wall in the field is calculated by combining the relationship between the effective consolidation pressure and the void ratio and the relationship between the void ratio and the hydraulic conductivity obtained from a one-dimensional consolidation test. Finally, the influence of different parameters on the stress and hydraulic conductivity distribution of a sand–attapulgite cut-off wall is analyzed. The main conclusions are as follows:

(1) The effective stress of a sand–attapulgite cut-off wall increases with the increase in wall depth, and the effective stress is less than 100 kPa. At the same depth, the effective stress decreases with the increase in the content of attapulgite in the wall. The hydraulic conductivity of the sand–attapulgite cut-off wall decreases with the increase in wall depth. When the depth is less than 0.5 m, the hydraulic conductivity is less than 1.0 × 10−9 m/s. Therefore, during the actual construction, special attention should be paid to the seepage prevention measures for the shallow part of the cut-off wall.

(2) The properties of the in situ foundation soil (the effective internal friction angle ) have a significant influence on the stress distribution of the sand–attapulgite cut-off wall. The effective stress decreases with the increase in the effective internal friction angle . The hydraulic conductivity distribution of the sand–attapulgite cut-off wall is also affected by the effective internal friction angle ; it increases with the increase in , but the increase is very limited, no more than one time.

(3) The wall width B also affects the stress distribution of the sand–attapulgite cut-off wall, and the effective stress decreases with the increase in wall width B. The hydraulic conductivity of the sand–attapulgite cut-off wall is also affected by wall width B, which increases with the increase in wall width B, but the increase is not more than 0.2 times.

Author Contributions

Conceptualization, W.Z., W.R. and Y.S.; methodology, W.Z., L.Z. and Y.S.; software, W.Z.; validation, Y.L., L.Z. and X.X.; writing—original draft preparation, W.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Project of Zhejiang Huadong Geotechnical Investigation and Design Institute Corporation Limited (No. ZKY2023-HDJS-02-06).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Author Wenbing Zhang was employed by the company PowerChina Huadong Engineering Corporation Limited and Zhejiang Huadong Geotechnical Investigation and Design Institute Corporation Limited. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential con-flict of interest.

References

- Lee, T.; Benson, C.H. Flow past bench-scale vertical ground-water cutoff walls. J. Geotech. Geoenviron. 2000, 126, 511–520. [Google Scholar] [CrossRef]

- Xu, H.Q.; Zhu, W.; Qian, X.D.; Wang, S.W.; Fan, X.H. Studies on hydraulic conductivity and compressibility of backfills for soil-bentonite cutoff walls. Appl. Clay Sci. 2016, 132–133, 326–335. [Google Scholar] [CrossRef]

- Xu, H.Q.; Shu, S.; Wang, S.W.; Zhou, A.Z.; Jiang, P.M.; Zhu, W.; Fan, X.H.; Chen, L. Studies on the chemical compatibility of soil-bentonite cut-off walls for landfills. J. Environ. Manag. 2019, 237, 155–162. [Google Scholar] [CrossRef] [PubMed]

- Tobin, W.R.; Wild, P.R. Attapulgite: A clay liner solution? Civ. Eng. ASCE 1986, 56, 56–58. [Google Scholar]

- Ryan, C.R. Soil-bentonite cutoff walls. In Geotechnical Practice for Waste Disposal’87; Woods, R.D., Ed.; American Society of Civil Engineers: New York, NY, USA, 1987; pp. 182–204. [Google Scholar]

- Broderick, G.P.; Daniel, D.E. Stabilizing compacted clay against chemical attack. J. Geotech. Eng. ASCE 1990, 116, 1549–1567. [Google Scholar] [CrossRef]

- Day, S.R. The compatibility of slurry cutoff wall materials with contaminated groundwater. In Hydraulic Conductivity and Waste Contaminant Transport in Soils; Daniel, D.E., Trautwein, S.J., Eds.; ASTM STP 1142; American Society for Testing and Materials: West Conshohocken, PA, USA, 1994. [Google Scholar]

- Stern, R.T.; Shackelford, C.D. Permeation of sand-processed clay mixtures with calcium chloride solutions. J. Geotech. Geoenviron. Eng. 1998, 124, 231–241. [Google Scholar] [CrossRef]

- Zhu, W.; Xu, H.Q.; Wang, S.W.; Fan, X.H. Hydraulic conductivity of model clay-based cut-off wall backfills. In Proceedings of the 7th International Congress on Environmental Geotechnics, Melbourne, Australia, 10–14 November 2014; pp. 1516–1523. [Google Scholar]

- Zhu, W.; Xu, H.Q.; Wang, S.W.; Fan, X.H. Influence of CaCl2 solution on the permeability of different clay-based cutoff walls. Rock Soil Mech. 2016, 37, 1224–1230. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, W.B.; Rao, W.B.; Li, L.; Liu, Y.; Wang, S.; Jin, K.; Zheng, F.W. Compressibility and hydraulic conductivity of sand-attapulgite cut-off wall backfills. J. Zhejiang Univ.-Sci. A 2019, 20, 218–228. [Google Scholar] [CrossRef]

- Zhang, W.B.; Rao, W.B.; Li, L.; Brusseau, M.L.; Liu, Y. Adsorption of cadmium onto sand-attapulgite cutoff wall backfill media. Water Air Soil Pollut. 2021, 232, 47. [Google Scholar] [CrossRef]

- Zhang, W.B.; Rao, W.B.; Ye, H.; Lv, Y.Y.; Zhou, L.P.; Xiong, X. The chemical compatibility of sand-attapulgite cut-off walls for landfills. Water 2023, 15, 2940. [Google Scholar] [CrossRef]

- Filz, G.M. Mechanical properties of soil-bentonite materials. In Proceedings of the International Containment Technology Workshop, Baltimore, MA, USA, 29–31 August 1995. [Google Scholar]

- Khoury, M.A.; Fayad, P.H.; Ladd, R.S. Design, construction and performance of a soil-bentonite cutoff wall constructed in two stages. Slurry Wall Des. Constr. Qual. Control 1992, 1129, 289–308. [Google Scholar]

- Evans, J.C. Hydraulic conductivity of vertical cutoff walls. In Hydraulic Conductivity and Waste Contaminant Transport in Soil; ASTM Special Technical Publication: Philadelphia, PA, USA, 1994; pp. 79–94. [Google Scholar]

- Evans, J.C.; Costa, M.J.; Cooley, B. The State-of-Stress in Soil-Bentonite Slurry Trench Cutoff Walls; ASCE Geotechnical Specialty Publication: Reston, VA, USA, 1995; pp. 1173–1191. [Google Scholar]

- McCandless, R.; Bodocsi, A. Investigation of Slurry Cutoff Wall Design and Construction Methods for Containing Hazardous Wastes; U.S. Environmental Protection Agency: Washington, DC, USA, 1987; pp. 1–205.

- Filz, G.M. Consolidation stresses in soil-bentonite backfilled trenches. In Proceedings of the Second International Conference on Environmental Geotechnics, Osaka, Japan, 5–8 November 1996; pp. 497–502. [Google Scholar]

- Bennert, T.A.; Maher, A.; Jafari, F. Piezocone evaluation of a shallow soil-bentonite slurry wall. In Proceedings of the Geo-Frontiers Congress, Austin, TX, USA, 24–26 January 2005; pp. 1–14. [Google Scholar]

- Ruffing, D.G.; Evans, J.C.; Malusis, M.A. Prediction of earth pressures in soil-bentonite cutoff walls. In GeoFlorida 2010: Advances in Analysis, Modeling and Design; Geotechnical Special Publication No. 199; ASCE: Reston, VA, USA, 2010; pp. 2416–2425. [Google Scholar]

- Li, Y.C.; Cleall, P.J.; Wen, Y.D.; Chen, Y.M.; Pan, Q. Stresses in soil-bentonite slurry trench cutoff walls. Géotechnique 2015, 65, 843–850. [Google Scholar] [CrossRef]

- Filz, G.M.; Mitchell, J.K. Design, construction, and performance of soil-and cement-based vertical barriers. In Assessment of Barrier Containment Technologies, A Comprehensive Treatment for Environmental Remediation Applications; Rumer, R.R., Mitchell, J.K., Eds.; International Containment Technology Workshop: Baltimore, MD, USA, 1995. [Google Scholar]

- Filz, G.M.; Baxter, D.Y.; Bentler, D.J.; Davidson, R.R. Ground deformations adjacent to a soil-bentonite cutoff wall. In Proceedings, Geo-Engineering for Underground Facilities; ASCE Geotechnical Special Publication: Reston, VA, USA, 1999; pp. 121–139. [Google Scholar]

- ASTM D2435M-11; ASTM (American Society for Testing and Materials) Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading. ASTM International: Philadelphia, PA, USA, 2011.

- Ryan, C.R.; Spaulding, C.A. Strength and permeability of a deep soil bentonite slurry wall. In Proceedings of the GeoCongress 2008: Geotechnics of Waste Management and Remediation, New Orleans, LA, USA, 9–12 March 2008; ASCE: Reston, VA, USA, 2008; pp. 644–651. [Google Scholar]

- Jones, S.; Spaulding, C.; Smyth, P. Design and construction of a deep soil-bentonite groundwater barrier wall at Newcastle, Australia. In Proceedings of the 10th Australian New Zealand Conference on Geomechanics Common Ground, Brisbane, QLD, Australia, 21–24 October 2007; Volume 1, pp. 362–367. [Google Scholar]

- Pan, Q. Mechanical Behavior of Soil-Bentonite Cutoff Walls and Its Impact on Contaminant Control. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2016; 180p. (In Chinese). [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).