Evaluation of Operational Safety Risk in Wastewater Treatment Plants Based on WSR and Matter–Element Extension Theory

Abstract

1. Introduction

2. Research Area and Data

2.1. Overview of the Study Area

2.2. Data Sources

3. Methods

3.1. WSR Theoretical Model

3.2. Indicator System

3.3. Analytic Hierarchy Process (AHP)

3.4. Entropy Weight Method

- Construction of an initial evaluation matrix: The original matrix is constructed with m objects and n indexes:

- With data normalization, there are differences in the characteristics of different indicators. To remove the influence of different dimensions, the index values are normalized in this study. For a positive index, the normalization formula is as follows:For negative indicators, the normalization formula is as follows:where is the original value of the jth indicator for the ith unit, and is the jth indicator for the ith unit after normalization.

- Calculation of the value of information entropy and information utility of the indicator:Formally, , is the information entropy value of the jth indicator; the smaller the entropy value e of an indicator, the larger its role in the integrated evaluation, and the smaller the entropy value, the smaller the weight. is the jth indicator in the ith year while accounting for the proportion of the indicator [1].

- Determination of evaluation indicator weights:Formally, 01.

3.5. Game Theory

3.6. Matter–Element Extension Theory Model

3.6.1. Determination of Elements to Be Evaluated

3.6.2. Determination Classical Domain

3.6.3. Determination Joint Domain

3.6.4. Determination of the Distance of the Evaluated Matter–Element

3.6.5. Determination of Risk Level

4. Results

4.1. Modeling Application

4.2. Risk Rating

4.3. The Weights of Operational Safety Risk Indexes for Sewage Treatment Plants

4.4. Construction of the Matter–Element Evaluation Model

- Establishment of a classical field: In the evaluation index system, the classical domain of quantitative indicators was set to 0–1 by the experts. The scope is assigned to four classical domains according to the risk level. The classical field with the first risk level was 1–0.75, the second risk level was 0.75–0.5, the third risk level was 0.5–0.25, and the fourth risk level was 0.25–0.

- Establishment of a controlled domain: The domain of each indicator was the total of all its classical domain values.

- Establishment of the matter–element evaluation: The detailed value of the object–element rating was obtained by statistically analyzing the results of the ratings of the experts and persons responsible for the Changchun City Development Zone North Wastewater Treatment Plant.

4.5. Correlation and Weight Coefficients

4.6. Comprehensive Correlation Calculation

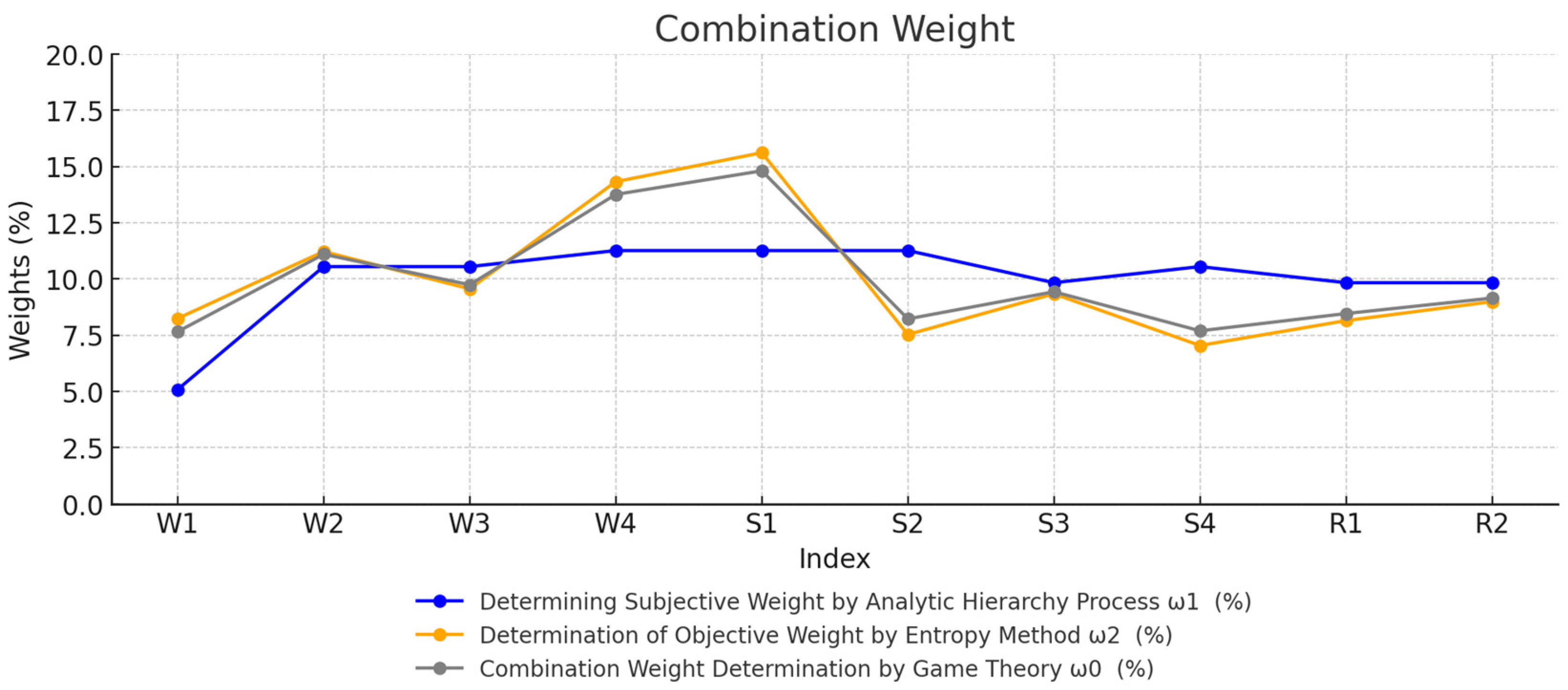

- According to the combined weights calculated using game theory, it was not difficult to see that different indicators had different impacts on the operational safety of sewage treatment plants, and in the weight calculation, the larger the weight value of the indicators, the greater the impact on operational safety. The weights of the 10 indicators in the whole evaluation index system can be seen in Table 3, in which safety inspection (S1) had the largest weight in safety risks in sewage treatment plants, and equipment integrity (W1) had the smallest weight. Safety inspection is a key factor in the operational safety of wastewater treatment plants. The weights of the indicators were different, and they were ranked as follows in descending order: S1 > W4 > W2 > W3 > S3 > R2 > R1 > S2 > S4 > W1. It was concluded that the weight ratio of safety inspection (S1) was the largest, which indicated that it could reflect the safety risk characteristics of the WWTP. In comparison with the other indicators, if a wastewater treatment plant can be improved in terms of safety inspection (S1), the operational safety of the whole plant can be significantly improved.

- According to the weight calculation in the previous section, the values of all evaluation indicators were ranked. The results showed that the operational safety correlations of the wastewater treatment plant were ranked in the following order: S2 > W1 > W2 > W4 > W3 > S1 > S4 > R1 > R2 > S3. All indicators were at the first level of safety, which indicated that the operation of the wastewater treatment plant was in a safe environment. The wastewater treatment plant did the best on the S2 indicator and received the highest rating. In terms of accident prevention (S3), the wastewater treatment plant needed further strengthening, in addition to accumulating experience in relevant aspects and making adjustments to accident prevention policies and measures, which would help improve its operational safety.

- According to the evaluation results, the operational safety risk of the WWTP was at a safe level (level 1). It was able to ensure the quality of effluent water while preventing casualties in the process of sewage treatment and preventing pollution of the surrounding environment. S1 and S3 were the most heavily weighted indicators and those that were rated the lowest; therefore, the wastewater treatment plant needs to be further developed and perfected so as to ensure that the discharge of effluent water can effectively reduce the environmental risk of water pollution and increase the degree of guaranteed safety of the aquatic environment.

4.7. Sensitivity Analysis

5. Conclusions

- For accident prevention (S3), it is recommended that a comprehensive risk assessment be carried out regularly to identify potential hazards and formulate appropriate preventive measures to effectively prevent accidents in wastewater treatment plants and safeguard the safety of personnel and facilities. For example, regular safety drills, especially simulation drills in the areas of equipment failure and accident prevention, can improve the speed and accuracy of employees’ response in the event of an accident. At the same time, it is recommended to introduce a real-time monitoring system for the continuous monitoring of the safety of critical equipment and processes to ensure that potential risks can be detected and prevented in time when they are elevated. These measures, combined with the strengthening of equipment maintenance, operational practices, and staff training, are expected to effectively reduce the risk of accidents in the operation of wastewater treatment plants and ensure the long-term stability and safety of the system.

- For safety inspection (S1), which has the largest weight value, it is recommended to strengthen the physical security measures in facilities, such as installing a sufficient number of monitoring cameras and setting up a high-standard lighting system. Biosecurity procedures should be reinforced, such as by frequently cleaning the working environment and installing high-efficiency air filtration systems in locations that are prone to creating dangerous biological aerosols. By taking these precautions, the risk of accidents can be reduced while also safeguarding the environment and personnel.

- It is recommended that a comprehensive safety management system be established with detailed safety management policies and procedures covering all operational aspects. A full-time safety management department should be established to oversee the day-to-day implementation of safety. The safety inspection system should be continuously updated and improved to adapt to the ever-changing work environment and technological advances.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiang, W.; Li, H.; Zheng, K.; Wang, Y.; Li, J. Operation Evaluation and Optimization of Wuxi Xibei Wastewater Treatment Plant. China Water Supply Drain. 2024, 40, 95–100. [Google Scholar] [CrossRef]

- Ning, L. Statistical analysis and countermeasure research on accidents in wastewater treatment plants in China. China Saf. Prod. Sci. Technol. 2012, 8, 125–128. [Google Scholar]

- Ono, Y.; Somiya, I.; Kawaguchi, T. Evaluation of toxic substances in effluents from a wastewater treatment plant. Desalination 1996, 106, 255–261. [Google Scholar] [CrossRef]

- Guo, Y.; Soup, B.; Sun, J.; Li, B.; Zhang, L.; Li, B.; Han, J.; Yu, L.; Wu, X.; Huang, Y. Construction and application of sponge city facilities construction effect monitoring system. China Water Supply Drain. 2023, 39, 8–15. [Google Scholar] [CrossRef]

- Li, F.; Yang, M.; Ma, S.; Li, J. Discussion on safe operation of urban wastewater treatment plants. China J. Saf. Sci. 2009, 6, 10–16. [Google Scholar]

- Hamed, M.M.; Khalafallah, M.G.; Hassanien, E.A. Prediction of wastewater treatment plant performance using artificial neural networks. Environ. Model. Softw. 2004, 19, 919–928. [Google Scholar] [CrossRef]

- Yuan, J.; Dan, G.; Li, Y. Engineering design of ultra-deep foundation pit buried reclaimed water plant in super-large complex. China Water Supply Drain. 2023, 39, 78–82. [Google Scholar] [CrossRef]

- Sun, P.; Shuai, R. Research on the risk assessment model of water influx in coastal gold mine based on improved material element topable method. Nonferrous Met. Eng. 2021, 11, 109–117. [Google Scholar]

- Zhu, Z. WSR 2.0 (2): Wuli-shili-renli notions. Syst. Res. Behav. Sci. 2022, 39, 1076–1098. [Google Scholar] [CrossRef]

- Yang, K.; Zhu, J.; Yang, L.; Lin, Y.; Huang, X.; Li, Y. Analysis of network public opinion on COVID-19 epidemic based on the WSR theory. Front. Public Health 2023, 10, 1104031. [Google Scholar] [CrossRef]

- Huang, S.; Ming, B.; Huang, Q.; Leng, G.; Hou, B. A case study on a combination NDVI forecasting model based on the entropy weight method. Water Resour. Manag. 2017, 31, 3667–3681. [Google Scholar] [CrossRef]

- Li, Z.; Luo, Z.; Wang, Y.; Fan, G.; Zhang, J. Suitability evaluation system for the shallow geothermal energy implementation in region by Entropy Weight Method and TOPSIS method. Renew. Energy 2022, 184, 564–576. [Google Scholar] [CrossRef]

- Zhou, Q.; Bao, Y.; Zhao, Y.; He, X.; Cui, C.; Liu, Y. Impacts of government credit on government performance of Public-Private partnership project in China: A WSR system theory perspective. Sustainability 2022, 14, 6886. [Google Scholar] [CrossRef]

- Abdelbasset, W.K.; Nambi, G.; El-Sakhawy, M.A.M.; Mahmoud, M.Z.; Alrawaili, B.S.; Elsayed, S.H. Study on WSR-based community healthy food distribution design method. Food Sci. Technol. 2021, 42, e70521. [Google Scholar] [CrossRef]

- Ying, Y. Research on Evaluation Method and Promotion Path of Port Intelligence. Master’s Thesis, Southeast University, Nanjing, China, 2021. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S. Shale gas industry sustainability assessment based on WSR methodology and fuzzy matter-element extension model: The case study of China. J. Clean. Prod. 2019, 226, 336–348. [Google Scholar] [CrossRef]

- Wang, J.; You, V.; Liu, F.; Yin, X. Fire safety evaluation of metro station based on WSR-D-S evidence theory. J. Saf. Environ. 2018, 18, 900–906. [Google Scholar] [CrossRef]

- Xin, J. Research on the performance evaluation index system of rural public sports service under the guidance of rural revitalization. S. Univ. 2023. [Google Scholar] [CrossRef]

- Yue, L. TK deep foundation pit project construction safety risk management research. Xi Univ. Archit. Technol. 2023. [Google Scholar] [CrossRef]

- Song, X.; Song, X.; Niu, F.; Ma, X. Application of improved fuzzy priority planning and vector pinch angle cosine in the operation and maintenance risk assessment of integrated pipeline corridors. J. Saf. Environ. 2023, 23, 4239–4246. [Google Scholar] [CrossRef]

- Liu, Y.; Eckert, C.M.; Earl, C. A review of fuzzy AHP methods for decision-making with subjective judgements. Expert Syst. Appl. 2020, 161, 113738. [Google Scholar] [CrossRef]

- Tsai, H.Y.; Huang, Y.L. An analytic hierarchy process-based risk assessment method for wireless networks. IEEE Trans. Reliab. 2011, 60, 801–816. [Google Scholar] [CrossRef]

- Xiao, Z.; Wang, Y. Notes on “Structural entropy weighting method for determining the weights of assessment indicators”. Oper. Res. Manag. 2020, 29, 145–149. [Google Scholar]

- Ju, W.; Wu, J.; Kang, Q.; Jiang, J.; Xing, Z. Fire risk assessment of subway stations based on combination weighting of game theory and topsis method. Sustainability 2022, 14, 7275. [Google Scholar] [CrossRef]

- Li, S.; Kuang, Z.; Xiao, Y.; Qiao, Z.; Yang, W. Rockburst tendency prediction based on an integrating method of combination weighting and matter-element extension theory: A case study in the Bayu Tunnel of the Sichuan-Tibet Railway. Eng. Geol. 2022, 308, 106796. [Google Scholar] [CrossRef]

- Meng, Y.; Jiang, X.; Zhang, Y.; Zhang, L.; Fan, C. Evaluation of groundwater quality based on improved material element topological model. J. Hebei Univ. Geol. 2021, 44, 90–98. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, Z.; Chen, Z.; Xie, H.; Peng, G.; Wang, G. Research on construction safety evaluation based on entropy weight-objective topable model. J. Eng. Manag. 2024, 38, 130–135. [Google Scholar] [CrossRef]

- Long, L. Research on benefit evaluation and strategy of green building energy saving and emission reduction based on entropy weight-matter element extension model. Qingdao Univ. Technol. 2023. [Google Scholar] [CrossRef]

- He, Y.X.; Dai, A.Y.; Zhu, J.; He, H.Y.; Li, F. Risk assessment of urban network planning in china based on the matter-element model and extension analysis. Int. J. Electr. Power Energy Syst. 2011, 33, 775–782. [Google Scholar] [CrossRef]

- Ma, L.; Chen, H.; Yan, H.; Li, W.; Zhang, J.; Zhang, W. Post evaluation of distributed energy generation combining the attribute hierarchical model and matter-element extension theory. J. Clean. Prod. 2018, 184, 503–510. [Google Scholar] [CrossRef]

- Ke, C. Research on multi-evaluation method of urban rail transit service quality. Chongqing Jiaotong Univ. 2023. [Google Scholar] [CrossRef]

- Shan, C.; Dong, Z.; Lu, D.; Xu, C.; Wang, H.; Ling, Z.; Liu, Q. Study on river health assessment based on a fuzzy matter-element extension model. Ecol. Indic. 2021, 127, 107742. [Google Scholar] [CrossRef]

- Wu, R.M.; Zhang, Z.; Yan, W.; Fan, J.; Gou, J.; Liu, B.; Wang, Y. A comparative analysis of the principal component analysis and entropy weight methods to establish the indexing measurement. PLoS ONE 2022, 17, e0262261. [Google Scholar] [CrossRef] [PubMed]

- He, F.; Cheng, X.; Li, M.; Jing, W.; Li, P.; Ma, S.; Wei, F. Based on color digitization combined with entropy weight method, the correlation between chromaticity value and internal components of Saposhnikovia divaricata was analyzed. Chin. Med. Mater. 2024, 03, 638–646. [Google Scholar] [CrossRef]

- Ji, G.; Zhang, Y.; Chen, J. A Delphi-improved fuzzy AHP method for risk evaluations of large complex bridges during construction. J. Bridge Eng. 2019, 24, 04019050. [Google Scholar]

- Qin, X.; Zha, X.; Wu, Z.; Zhang, L. Grey fuzzy comprehensive evaluation of bridge risk during periods of operation based on a combination weighting method. Appl. Sci. 2023, 13, 8964. [Google Scholar] [CrossRef]

| Importance Degree | Definition |

|---|---|

| 1 | Equal importance |

| 3 | Moderate importance of one over another |

| 5 | Strong importance of one over another |

| 7 | Very strong importance of one over another |

| 9 | Extreme importance of one over another |

| 2, 4, 6, and 8 | Intermediate values |

| Criterion | Index | Number of the Index | Correlation | Rating Value | ||||

|---|---|---|---|---|---|---|---|---|

| Level I | Level II | Level III | Level IV | Average | ||||

| W Wuli | Equipment integrity | W1 | 1.00 | 0.75 | 0.50 | 0.25 | 0.50 | 0.97 |

| Maintenance of equipment | W2 | 0.96 | ||||||

| Facility Layout | W3 | 0.95 | ||||||

| Surrounding environment | W4 | 0.96 | ||||||

| S Shili | Security checks | S1 | 0.95 | |||||

| Safety regime | S2 | 0.99 | ||||||

| Prevention of accidents | S3 | 0.86 | ||||||

| Technological improvements | S4 | 0.93 | ||||||

| R Renli | Cultural level | R1 | 0.92 | |||||

| Technical training | R2 | 0.89 | ||||||

| Index | Determination of Subjective Weights with the Analytic Hierarchy Process ω1 (%) | Determination of Objective Weights with the Entropy Weight Method ω2 (%) | Determination of Combined Weights with Game Theory ω0 (%) |

|---|---|---|---|

| W1 | 5.081 | 8.242 | 7.655 |

| W2 | 10.547 | 11.219 | 11.094 |

| W3 | 10.547 | 9.557 | 9.741 |

| W4 | 11.261 | 14.324 | 13.756 |

| S1 | 11.261 | 15.612 | 14.805 |

| S2 | 11.261 | 7.529 | 8.222 |

| S3 | 9.832 | 9.337 | 9.429 |

| S4 | 10.547 | 7.041 | 7.692 |

| R1 | 9.832 | 8.147 | 8.460 |

| R2 | 9.832 | 8.992 | 9.148 |

| Criterion | Index | Number of the Index | Correlation | Weights (%) | |||

|---|---|---|---|---|---|---|---|

| Level I | Level II | Level III | Level IV | ||||

| W Wuli | Equipment integrity | W1 | 0.134 | −0.866 | −0.933 | −0.955 | 7.655 |

| Maintenance of equipment | W2 | 0.162 | −0.838 | −0.919 | −0.946 | 11.094 | |

| Facility layout | W3 | 0.211 | −0.789 | −0.894 | −0.930 | 9.741 | |

| Surrounding environment | W4 | 0.163 | −0.837 | −0.918 | −0.946 | 13.756 | |

| S Shili | Security check | S1 | 0.193 | −0.807 | −0.903 | −0.936 | 14.805 |

| Safety regime | S2 | 4.000 | −0.960 | −0.980 | −0.987 | 8.222 | |

| Prevention of accidents | S3 | 0.429 | −0.429 | −0.714 | −0.810 | 9.429 | |

| Technological improvements | S4 | 0.286 | −0.714 | −0.857 | −0.905 | 7.692 | |

| R Renli | Cultural level | R1 | 0.311 | −0.689 | −0.844 | −0.896 | 8.460 |

| Technical training | R2 | 0.442 | −0.558 | −0.779 | −0.853 | 9.148 | |

| Object | Criterion | Correlation | Risk Rating | |||

|---|---|---|---|---|---|---|

| Level I | Level I | Level I | Level I | |||

| Changchun North District Wastewater Treatment Plant | W Wuli | 0.169 | −0.831 | −0.916 | −0.944 | Level I |

| S Shili | 0.268 | −0.732 | −0.866 | −0.911 | ||

| R Renli | 0.380 | −0.621 | −0.811 | −0.874 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Wang, Z.; Pan, D.; Zhang, Y.; Zhang, J.; Chen, Y. Evaluation of Operational Safety Risk in Wastewater Treatment Plants Based on WSR and Matter–Element Extension Theory. Water 2024, 16, 2925. https://doi.org/10.3390/w16202925

Liu X, Wang Z, Pan D, Zhang Y, Zhang J, Chen Y. Evaluation of Operational Safety Risk in Wastewater Treatment Plants Based on WSR and Matter–Element Extension Theory. Water. 2024; 16(20):2925. https://doi.org/10.3390/w16202925

Chicago/Turabian StyleLiu, Xin, Zicheng Wang, Dianqi Pan, Yichen Zhang, Jiquan Zhang, and Yanan Chen. 2024. "Evaluation of Operational Safety Risk in Wastewater Treatment Plants Based on WSR and Matter–Element Extension Theory" Water 16, no. 20: 2925. https://doi.org/10.3390/w16202925

APA StyleLiu, X., Wang, Z., Pan, D., Zhang, Y., Zhang, J., & Chen, Y. (2024). Evaluation of Operational Safety Risk in Wastewater Treatment Plants Based on WSR and Matter–Element Extension Theory. Water, 16(20), 2925. https://doi.org/10.3390/w16202925