Abstract

Sturgeon farming poses an interesting decision: give priority to highly prized caviar or meat. Indeed, sturgeons are mainly reared in aquaculture to produce caviar. However, the economic profitability of a sturgeon farm also depends on the existence of a meat market. Meat is still an important product for sturgeon farmers once the stock of caviar-producing females has been established. This paper takes a case study approach and analyses how an Italian producer addresses the trade-off, adopting a methodology that measures the value of the economic productivity of production inputs, e.g., the measure of the profitability of the inputs, and compares them with the costs of the inputs and the prices of the outputs. This analysis is the first attempt, to our knowledge, to adopt an economic analysis to address this choice problem, based on a very representative case study. This helps monitor whether the farm’s production choices are economically efficient and effective and whether and how those can be improved. The results show that the farm maximizes profit but does not reach its optimal production level. This implies that both (1) producing more output and (2) a further switch to caviar production for less meat are economically efficient production strategies.

1. Introduction

Sturgeon aquaculture has developed to cope with the increasing demand for caviar and to diminish the pressure on the overexploited wild resource. Since 1997, all sturgeon species have been added to the appendices of the CITES (Convention on the International Trade in Endangered Species) to protect the population from extinction [1]. This determined a definitive shift from wild to farmed sturgeon to produce both eggs, i.e., caviar, and meat in many countries. Global caviar production, which totals approximately 600 tons annually, is led by China, accounting for at least one-third of the volume, followed by Russia. Italy ranks third worldwide and first within the EU, contributing approximately 10% of the global supply, with 62 tons in 2022 (Aquaculture Data Collection, Reg. (EC) 762/2008, Italian Ministry of Agriculture) [2].

Sturgeon aquaculture has emerged as a source of caviar that is less impactful than fishing but requires significant initial investment and time, since most of the sturgeon species are large, slow-growing fish with late sexual onset, and its production is, consequently, an extremely long process. This limits the amount of farmed caviar that can meet demand, keeping prices high, and short-term profitability. Nonetheless, techniques for sex determination and growth acceleration are being explored to improve efficiency and profitability [3]. Sustainable caviar production, moreover, requires responsible aquaculture practices, such as the use of optimal feed formulations, water quality monitoring, and broodstock management. Sturgeon aquaculture is water-intensive and implies careful management of the farming processes to minimize environmental impacts, including water quality control and waste management, activities that can add operational costs. Sturgeon aquaculture also faces additional challenges: start-up costs are high, as building and operating sturgeon farms require significant investments in infrastructure and specialized expertise. Caviar quality, in turn, is influenced by multiple factors, such as the sturgeon species (e.g., the Beluga, Huso huso, representing the most expensive; Siberian sturgeon, Acipenser baerii; white sturgeon, A. transmontanus, and Russian sturgeon, A. gueldenstaedtii), the formulated diets, the farming conditions, the egg processing methods, and the size and color of the eggs [4]. Superior quality translates to a premium price. From this perspective, the limited and controlled supply of caviar combined with high production costs translate into high caviar prices for consumers, even if different caviar grades and types exist, satisfying a wide range of price points and consumer preferences [5].

The scientific literature on the economics of aquaculture topic is scarce and fragmented and, for the most part, not published in economic journals but developed in broader studies on aquaculture. Several studies focus on issues of farm profitability management and examine factors that influence the sturgeon’s economic viability. This includes issues such as consumer preferences, production cost structure and efficiency (particularly feed and labor), caviar yield and price, and local and global market dynamics [3,6,7,8,9].

Some studies present economic models to help producers make informed decisions. These models consider factors such as harvest times for meat and caviar production to maximize farm profits [10,11]. Sturgeon farming presents the farmer with an interesting and challenging business dilemma: how to prioritize the production of highly prized caviar while not debasing the production of the less valuable sturgeon meat, for which a market exists. To our knowledge, there is a gap in the economic literature except for a European Market Observatory for Fisheries and Aquaculture Products (EUMOFA) report, according to which, for each ton of caviar, on average, approximately 20 tons of sturgeon meat and other by-products and waste, such as tails, heads, and entrails, are produced [2]. Depending on the species, female sturgeons take 3 to 10 years to reach sexual maturity. During this phase, the meat of male sturgeons represents the main product produced by farmers. Therefore, fish fillets are still an important yield for sturgeon farms once the stock of caviar-producing females has been established.

This paper takes a representative case study approach and analyzes how the trade-off is addressed by one of the most important sturgeon farming companies in Italy. This study measures the value of the economic productivity of production inputs, i.e., the measure of the input profitability, and compares it with input costs and output prices. This allows for us to monitor whether the farm’s production choices are economically efficient and effective and whether and how these can be improved. This analysis is the first attempt, to our knowledge, to adopt an economic perspective to address this choice problem.

2. Materials and Methods

2.1. Sturgeon Aquaculture Context

Most wild sturgeon populations are fragile and need conservation measures. This is the consequence of multiple biological, ecological, and economic factors that made these species highly susceptible to overfishing and poaching. Aquaculture has emerged as a lifeline for the sturgeon caviar industry, offering a more sustainable alternative to the exploitation of wild populations. Moreover, several conservation and restoration aquaculture programs have been implemented to fight declines of or maintain current wild population levels for several sturgeon species [12].

The most prized product derived from sturgeons has historically been caviar, yielding a significant commercial venue and symbolizing luxury. The supply chain of farmed caviar is intricate and influenced by several economic factors. Unlike poultry or other farmed fish, sturgeon requires years to mature and produce caviar. This limits the ability to quickly ramp up production in response to market fluctuations. Setting up a sturgeon farm requires significant capital investment in facilities, broodstock, and specialized staff training. This creates a barrier to entry, influencing the number of producers. Research on sex determination, growth acceleration, and disease control can significantly impact production efficiency and potentially increase caviar output in terms of quantity and quality. Fluctuations in consumer demand for caviar can affect production decisions. Farmers need to forecast future demand while managing the long production cycle.

Sturgeon caviar production is a complex business with high potential profits and significant economic challenges and opportunities. The most effective way to summarize it is through SWOT analysis, where strengths and weaknesses are categorized as internal factors, which refer to the characteristics and resources within your organization that directly influence its operations and performance. These factors are completely within your organization’s control, so they can be modified, improved, or capitalized upon. Opportunities and threats are categorized as external factors, i.e., elements outside the organization’s control that have an impact on its operations, market position, and success. These factors arise from the industry climate and the broader business environment. You typically have no control over external factors, but you can respond to them. The SWOT analysis carried out for the sturgeon caviar aquaculture sector is presented in Table 1.

Table 1.

SWOT analysis for the aquaculture sturgeon caviar sector.

Focusing on the scope of this paper, it is highlighted that farming sturgeon poses an interesting decision: giving priority to the highly prized caviar or the meat. The decision to harvest sturgeon for meat or caviar depends on several factors. Some sturgeon species are valued more for their caviar, while others are better for their meat. For instance, the highly valued Beluga sturgeon is known for its large and expensive eggs. However, caviar production usually requires the sacrifice of mature females, which can take many years to reach maturity. Some farms use a two-pronged approach: they initially focus on meat production as their female stock matures; once the females are ready, they can harvest the caviar alongside the ongoing meat production. Ultimately, the choice depends on the farmers’ specific goals and the reference market, according to the country and its traditions. Table 2 summarizes the main costs and benefits.

Table 2.

Qualitative costs and benefits of the choice between meat and caviar.

2.2. Italian and Case Study Context

Caviar production from aquaculture sturgeon in Italy is relatively recent, with the first sturgeon farm established in the early 1990s. Since then, the sector has grown considerably, reaching a production of 62 tons of caviar and 950 tons of meat in 2022 [2]. Aquaculture sturgeon caviar is produced in Italy by 16 companies, mainly located in Lombardy, Piedmont, and Veneto, all characterized by very homogeneous farming practices. The main export markets for Italian caviar are Europe, Japan, and the United States. Most of the caviar produced in Italy is from Siberian sturgeon, which is a robust and adaptable species that is well suited to aquaculture. Other sturgeon species farmed include the Russian sturgeon and the Beluga. The price of sturgeon caviar produced in Italy varies depending on the quality, the species, and the production method. Caviar from aquaculture is generally cheaper than wild caviar, with a retail price between 1.000 and 5.000 euros per kilo [8]. The Italian market for aquaculture caviar is served by several distributors, including importers, wholesalers, and retailers. Caviar is sold in a variety of formats, including tins, jars, and gift boxes. It is also available in some restaurants and specialty food stores.

Even though the sector is not mature and still growing, it is possible to highlight weaknesses/threats versus strengths/opportunities. Table 3 presents the results of the SWOT analysis to highlight the potentiality of the Italian sector.

Table 3.

SWOT analysis for the Italian aquaculture sturgeon caviar sector.

In the study at issue, the present analysis applies to a specific Italian sturgeon farm located in Northern Italy, one of the most representative for caviar production. The company, consisting of several on-growing sites and a processing plant, is dedicated to the production of both caviar and meat fillets. The rearing facilities consist of flow-through systems (raceways and ponds), characteristic for sturgeon farming. The production of caviar is from four species: Siberian sturgeon, Russian sturgeon, white sturgeon, and Beluga. The fattening phase, which represents the longest breeding phase, is carried out in flow-through raceways on a total area of 20 hectares. The company follows all the growth stages of the animals, including reproduction, through the hatching and nursery phase in a closed recirculating system, and the maturation of the females and the subsequent extraction of the ovarian sacs in the transformation plant. Once the eggs have reached the stage of maturation suitable for collection, the mature specimens are transported from the breeding sites to the processing plant from which the two main products, caviar and filleted meat, are obtained and subsequently marketed in different formats.

The multi-product farm uses the same production input for different outputs. Table 4 and Table 5 synthesize the main economic performance indicators.

Table 4.

Economic performance (June 2022/June 2023). Total values for caviar and meat are reported in grey shaded rows.

Table 5.

Stock of resource (June 2022/June 2023).

It is worth highlighting that, in the case study, the rate of substitution meat–caviar is 5.9:1. This differs from the values reported by EUMOFA, according to which caviar accounted for 10–30% of the female sturgeon total body weight, including by-products, resulting in a rate of substitution of 20:1, on average [2]. This apparent difference relies on the fact that our ratio considers marketable meat of both males and females, net of waste (tails, heads, entrails).

2.3. Economic Valuation Method

The methodology used is based on the analysis of the economic and technical relationships between production factors (inputs) and the produced quantity of output. Such a relationship is often described by a mathematical function called the production function (FDP). The production function highlights that the quantity produced (in a given sector or market) depends on the quantity of production factors used and how these factors are used (technology). The study of the production function helps to better understand the production processes and related production efficiencies and inefficiencies. When the data are not sufficient to estimate the production function, as in the case in question, a methodology based on the calculation of the marginal factor productivity and the value of the marginal factor productivity is chosen [13,14].

The selected methodology aims at computing the marginal factor productivity (MFP) of each selected production input (or factor). This is an indicator that measures the marginal impact on the final production output (output of farmed aquatic products in this case) following an additional increase (marginal variation) of a production input (land, labor, capital, machinery, natural capital such as water and other resources, including biodiversity), as described in the Formula (1):

In Formula (1), the marginal factor productivity (MFP—see Supplementary Materials for details) is a measure of the impact variation that an incremental, marginal variation in the nth input (that is used to produce) has on the final output. This is a measure of factor productivity, that is, the factor’s capability to produce output. The main question addressed by the indicator is the following: If an additional quantity of labor, water, or any other production input is used, how much more output will be produced, and given the production technology constraint in the present case, if another sturgeon female is selected or another worker is hired, how much additional caviar is produced? The marginal productivity of production factors is an important economic indicator of the value of a productive resource in terms of technological efficiency but does not contain indications of value expressed in monetary terms. It indicates the ways in which scarce resources are used.

This monetary information is provided by a second indicator: the economic value of the marginal factor productivity (VPFM—see Supplementary Materials for details). This economic indicator, calculated as indicated in the Formula (2), is equal to the marginal productivity of the factors multiplied by the market price of the final product:

The indicator is an economic indicator (expressed in monetary terms) of the value of the production input in terms of the value of the finished product traded on the markets. It differs from the marginal value of the production factor, which is nothing other than the marginal cost resulting from an incremental use of the production factor [15]. The indicator addresses the following question: If an additional input is used, how much money is earned if the additional output is sold? In alternative terms, if an additional input is used, what is the additional marginal revenue?

Such indicators are easy to compute and are fundamental to comparing the costs and benefits of the company’s production choices and obtaining information on their efficiency and sustainability.

In economic neoclassical theory, the firm produces according to the marginal condition (in the short run) and the average condition (in the long run). The long run, in economic theory, implies the possibility for the firm to change all production inputs and the combination and use of the same. Solving a profit maximization problem, constrained by technology, the firm produces as much output as described by the profit-maximizing condition, as synthesized in Equation (3):

Marginal (average) Revenue (MR) = Marginal (average) Cost (MC)

A profit-maximizing level of output can be described as where the revenue from selling one more unit of output (P or MR) is exactly equal to the cost of producing that last unit of output (MC). If, at a given level of production, P (MR) > MC, then the addition to revenue exceeds the addition to cost by producing and selling one more unit of output, and the firm will be able to increase profits by selling that additional unit. If the opposite is true, P (MR) < MC, then additions to costs exceed the additions to revenue (via the production and sale of one more unit of output), and the firm will be able to increase profits by reducing output by one unit.

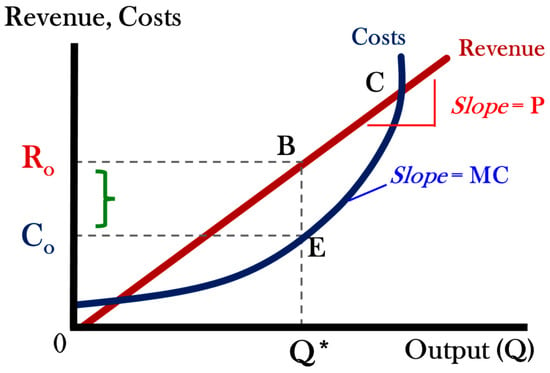

Figure 1 shows that the profits are maximum when the difference between revenues and costs is positive, and production Q occurs at the point where the revenue and costs curves have the same slope (e.g., derivatives). This is why the optimal production condition implies that MR = MC.

Figure 1.

Profits maximization equation (modified from “Profit Maximizing Behavior” Douglas A. Ruby. 1990–2020. (http://www.digitaleconomist.org/microeconomics/profit_maximization.html, accessed on 1 July 2024).

Figure 1 represents the costs function curve and the revenue function. The costs function describes how total costs vary when produced quantity Q (of an output) varies. Likewise, the revenue function represents how total revenue varies when additional quantities of output Q are produced and sold. In the figure, the costs and revenue functions are described by the selected slope and line for example purposes, but they can take whatever form. In the case at issue, the revenue changes proportionally to the quantity variations, while the costs increase more than proportionally with respect to the quantity increase. The computation of the derivatives on each point of the curve allows for an understanding of the measure of the variations (slope MC for the costs). In the case at issue, it is constant for the revenues (slope P). Let us also recall that the profits are the difference between revenue and costs. They vary at each level of produced quantity. Figure 1 shows the optimal quantity for profit maximization, given the costs and revenue functions. Profits are surely NOT maximized in point C, where the functions cross. At that level, the produced output Q is very large and so are the costs and revenue. However, the difference between costs and revenue is zero. Profits are zero.

At the opposite case, the segment BE represents the maximum distance between the revenue and costs functions. That segment corresponds to Q*, the optimal quantity to produce to maximize profits. In both cases, where the firm decided to produce more or less, profits would not be at their maximum value, and all possible infinite segments representing the difference between revenue and costs would be shorter than BE. At the level of Q*, the two functions have the same slope inclination, and the marginal costs equal the marginal revenue. Profits are maximized (with revenue R0 and costs C0). The choice of producing an amount of output equal to Q* is a profit-maximizing equilibrium. If the firm decides to produce more quantity, for instance, the slope of the costs function becomes “steeper”. The slope of the revenue function does not change. Therefore, for more output, marginal costs would be larger than marginal revenue, and this would generate a situation that is worse off than the Q* equilibrium. The trade-off between costs and benefits is solved with the Q* profit-maximizing equilibrium.

The methodology, therefore, computes the economic value of the marginal condition (that are also interpreted as marginal revenues) with the MC of production to assess if the firm is maximizing profits in economically efficient terms. The percentage markup of price above marginal cost, (P-MC)/P, has been measured with the Lerner index, a measure of a firm’s market power, i.e., the capability to set a price above marginal cost.

3. Results and Discussion

Table 6 and Table 7 present the computed marginal productivities and value of the marginal productivities per selected input and output, respectively. The values are computed as explained in Section 2.3.

Table 6.

Marginal productivity (in kg of produced sturgeons) for every selected factor of production. Caviar and meat products are reported in white and grey shaded rows, respectively.

Table 7.

Value (in euro) of marginal productivity for every selected factor of production. Caviar and meat products are reported in white and grey shaded rows, respectively.

Table 6 provides the measure of the economic value that the farm makes by using each additional unit of the selected input to produce the selected output. For instance, focusing on labor, we can assess that the use of additional workers has different productivities for different outputs. For instance, the indicator shows that, if the farm decided to hire an additional worker, he/she contributes to producing 85 kg per year of Beluga caviar and 1150 kg per year of White sturgeon, given the current technology. The different productivities generated by the same amount of additional input or factor (an additional worker) have a different value, as shown in Table 6, column “Labor”.

Economic information is crucial for the efficient use of resources and production. The input of production (additional/marginal) is more efficient when used in the most productive and valuable setting. The reasoning that underlies the example can be applied to all selected inputs for all outputs.

The marginal benefits (the value of the marginal productivity that we recall is the marginal revenue generated) using different inputs must be compared with the related marginal costs of the very same input to assess whether the resource use is economically efficient (see Supplementary Materials for details about the different values used for each typology). This is presented in Table 8.

Table 8.

Value of the marginal productivity compared with input cost. Caviar and meat products are reported in white and grey shaded rows, respectively.

When MR > MC, the farm will maximize profits by using more input that will produce more output. This will imply supporting additional costs. The farm will produce the amount of output to the point where MC = MR. When MR < MC, the farm will maximize profits by using less input that will produce less output. For instance, the marginal revenues are lower than the marginal costs in the case of the input feed. This might imply that the input is used inefficiently because the farm is producing too many meat sturgeons for the quantity that would maximize profits, ceteris paribus (see Figure 1). On the other hand, labor is a very productive and profitable input, and the farm should increase output using labor.

Overall, the results show the reality of a production unit using inputs efficiently, with some exceptions (i.e., the use of feed, energy for second-grade caviar, and so on), for the good of profit maximization. Profit maximization, however, is not at its optimal point. As shown in Figure 1, the farm is choosing in a space between 0 and Q*. To deepen the issue, we have performed a simple check, computing the average condition. Recalling the theory presented in Section 2, the firm maximizes profits (i.e., the distance between the revenue and costs curves is the largest) when the marginal revenue equals the marginal costs in the short run, and the average revenue (AR) equals the average costs (AC) in the long run. In Box 1, the results, computed with the use of economic data provided by the firm, are presented.

Box 1. Profit maximization conditions.

| Caviar |

| AR = AP > AC ⇨ 327, 8 ≠ 420 > 33 |

| Lerner Index = 0.92 |

| Meat |

| AR = AP > AC ⇨ 8.02 ≈ 8.9 > 5.6 |

| Lerner Index = 0.37 |

For caviar production, the average revenue (AR, computed as the value of the additional productivity of the selected input) largely offsets the average production costs (AC, costs of the selected inputs) but is lower than the average price of the product (AP). This implies that the firm is profit maximizing but not at the optimal level. The production of caviar (and prices) can be increased. The large value of the Lerner Index (0.92), in addition, shows the high monopolistic power enjoyed by the firm. This strengthens the overall emerging evidence according to which caviar production by the firm efficiently uses input, is profit maximizing, and needs to be pushed further with extra output.

For meat production, the average revenue (AR, computed as the value of the additional productivity of the selected input) is larger than the average production costs (AC, costs of the selected inputs) but is slightly lower than the average price of the product (AP). This implies, again, that the firm is profit maximizing but not at the optimal level. The proximity of AR and AP implies that the firm competes in the meat sturgeon market with much less market power. In this perspective, the value of the Lerner Index is 0.37, signaling a market structure with characteristics closer to a market in perfect competition, where firms are price takers and not price makers. This might signal the requirement to use the existing stock of sturgeon for producing more caviar and less meat by using the input (labor, energy, and feed) for the most profitable products.

The current market structure (with 2020 and 2021 data) is not clearly defined, most probably because of the settling of the market dynamics and the relatively recent establishment of the sector. About the meat market, the farm under scrutiny held 3.4% of the market share in 2021 and 9.7% in 2022. It is worth highlighting that, in 2020, three farms (over 13) produced approximately 65% of the total output, and in 2021, four farms produced 70% of the total output. This would suggest a homogenous Cournot structure (farms compete on quantity but cannot differentiate prices that are very close to marginal costs). This might drive to several equilibria, spanning from a Cournot oligopolistic structure, where only a few players remain and compete on quantities (increasing prices) or a situation where a small group of firms behave as monopolists/leaders (setting the first-choice, skimming price, above MC) and an increasing number of farms and new entrants behave as the competitive fringe (pricing at MC). In synthesis, the economic analysis perspective, although limited by the scarcity of data, helps shed light on a reality that is profit maximizing, even if not at the optimal point. Input and production factors and resources, despite being costly, are used efficiently in the production process (with some exceptions, such as feed, as shown in Table 8). This is what matters from an economic perspective. Profits are maximized, even in the face of high production costs (vis-à-vis to other realities, but this will need to be verified with further analysis). This could be stimulated by large, highly segmented, and probably inelastic, domestic, and international demand. The Lerner Index, from this perspective, confirms a leading price-making strategy. However, an important point must be highlighted. If demand is the driver of profit maximization (because the farm can set high prices without the risk of losing customers, even with the high prices of the inputs used), then a crucial point refers to environmental sustainability and animal welfare. Environmental concerns enter modern production from an integrated and sustainable perspective.

4. Conclusions

This study investigated, for the first time, the production choices and trade-offs (meat vs. caviar) faced by a typical Italian sturgeon producer. The case study allowed for us to throw light on a concrete reality and to better understand production choices, disentangling from more general approaches. The research adopted a methodology that evaluates the economic productivity of the production inputs, e.g., the measure of the input profitability, and compares it with the input costs and output prices. This allows for us to monitor whether the farm’s production choices are economically efficient and effective and whether and how these can be improved. The results show that the farm is profit maximizing but not at the optimal output level. This implies that both (1) producing more output and (2) a further shift to producing caviar (for less meat) are economically efficient production strategies. For example, the potential application at a commercial level of recent genetic research [16] that developed an early sex-determination technique for sturgeons might allow for farmers to slaughter males at a younger age than is currently possible. In the near future, the application of this research finding may help to optimize production strategies by cutting down inputs (in particular, feed and labor) and, at the same time, maximizing profits with a further shift to producing caviar for less meat.

While the use of methodologies developed under data scarcity have provided interesting and useful insights, further research should focus on studying the entire sector based on thorough data collection and econometric estimation of the production function. This would allow for an integrated approach that looks at the sustainability of the sector. In fact, the study of production efficiency through the analysis of the relationships between input and production output is the economic counterpart of the environmental life cycle analysis (LCA). The evaluation of the economic efficiency of the use of the input should be accompanied by the analysis of whether this use, while being profitable, is also sustainable from an environmental point of view. Additionally, an in-depth analysis of industry demand (actual and latent) and the structure of the domestic and international market is required to better design industrial and political strategies for the promotion of Italian excellence.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/w16182618/s1, Document: Supplementary Materials.docx.

Author Contributions

Conceptualization, F.C. and L.O.; methodology, L.O.; validation, F.C. and D.P.; formal analysis, L.O.; investigation, A.M. and R.N.; data curation, M.M. and D.P.; writing—original draft preparation, F.C., L.O. and D.P.; writing—review and editing, F.C., D.P., A.M., M.M., R.N. and N.T.; visualization, M.M. and N.T.; supervision, F.C.; project administration, F.C.; funding acquisition, F.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Italian Ministry of Agriculture, Food Sovereignty and Forests within the Research Project INNOFISHFARM (grant n. J89J21004200001).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

Author Laura Onofri was employed by the company Metroeconomica Consulting. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The authors declare that this study received funding from MASAF. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication.

References

- Boscari, E.; Vitulo, N.; Ludwig, A.; Caruso, C.; Mugue, N.S.; Suciu, R.; Onara, D.F.; Papetti, C.; Marino, I.A.M.; Zane, L.; et al. Fast genetic identification of the Beluga sturgeon and its sought-after caviar to stem illegal trade. Food Control 2017, 75, 145–152. [Google Scholar] [CrossRef]

- EUMOFA. Sturgeon Meat and Other By-Products of Caviar. Production, Trade and Consumption in and Outside the EU; European Commission: Brussels, Belgium, 2023. [Google Scholar]

- Yom Din, G.; Degani, G. Economic Evaluation of Early Sex Determination for Farmed Russian Sturgeon: The Case of Northern Israel. Mod. Econ. 2020, 11, 1977–1983. [Google Scholar] [CrossRef]

- Lopez, A.; Vasconi, M.; Bellagamba, F.; Mentasti, T.; Moretti, V.M. Sturgeon Meat and Caviar Quality from Different Cultured Species. Fishes 2020, 5, 9. [Google Scholar] [CrossRef]

- Tavakoli, S.; Luo, Y.; Regenstein, J.M.; Daneshvar, E.; Bhatnagar, A.; Tan, Y.; Hong, H. Sturgeon, Caviar, and Caviar Substitutes: From Production, Gastronomy, Nutrition, and Quality Change to Trade and Commercial Mimicry. Rev. Fish. Sci. Aquac. 2021, 29, 753–768. [Google Scholar] [CrossRef]

- Bronzi, P.; Rosenthal, H.; Gessner, J. Global sturgeon aquaculture production: An overview. J. Appl. Ichthyol. 2011, 27, 169–175. [Google Scholar] [CrossRef]

- Tretiak, O.; Pashko, S. Economic efficiency of caviar production from brood Siberian sturgeon (Acipenser baerii Brandt, 1869) grown in industrial conditions. Ribogospodarsʹka Nauk. Ukraïni. 2022, 3, 105–120. [Google Scholar] [CrossRef]

- Sicuro, B. The future of caviar production on the light of social changes: A new dawn for caviar? Rev. Aquac. 2019, 11, 204–219. [Google Scholar] [CrossRef]

- Degani, G.; Yom Din, G. A Business Analysis of Innovations in Aquaculture: Evidence from Israeli Sturgeon Caviar Farm. Businesses 2022, 2, 290–299. [Google Scholar] [CrossRef]

- Sanders, B.; Fadel, J.; Wade, E. Economic optimization modeling of white sturgeon (Acipenser transmontanus) caviar and meat production under different management conditions. Aquaculture 2003, 217, 409–430. [Google Scholar] [CrossRef]

- Piotrowska, I.; Kozłowski, M. Preliminary rearing outcomes of Siberian sturgeon, Acipenser baerii Brandt, juveniles in autonomous hatching and rearing modules. Fish. Aquat. Life 2024, 32, 26–33. [Google Scholar] [CrossRef]

- Anderson, W.G.; Schreier, A.; Crossman, J.A. Conservation aquaculture—A sturgeon story. In Fish Physiology; Academic Press: Cambridge, MA, USA, 2022; pp. 39–109. [Google Scholar]

- Onofri, L.; Lange, G.M.; Portela, R.; Nunes, P.A.L.D. Valuing ecosystem services for improved national accounting: A pilot study from Madagascar. Ecosyst. Serv. 2017, 23, 116–126. [Google Scholar] [CrossRef]

- Onofri, L.; Volpe, M. Pricing agricultural inputs from biodiversity-rich ecosystems and habitats without input markets. Afr. J. Econ. Manag. Stud. 2020, 11, 122–133. [Google Scholar] [CrossRef]

- Varian, H.R. Intermediate Microeconomics: A Modern Approach; WW Norton & Co.: New York, NY, USA, 2006. [Google Scholar]

- Kuhl, H.; Guiguen, Y.; Höhne, C.; Kreuz, E.; Du, K.; Klopp, C.; Lopez-Roques, C.; Yebra-Pimentel, E.S.; Ciorpac, M.; Gessner, J.; et al. A 180 Myr-old female-specific genome region in sturgeon reveals the oldest known vertebrate sex determining system with undifferentiated sex chromosomes. Philos. Trans. R. Soc. B Biol. Sci. 2021, 376, 20200089. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).