Wastewater and Grey Water Footprint Assessment of the Olive Oil Production Process in Northwest Argentina

Abstract

1. Introduction

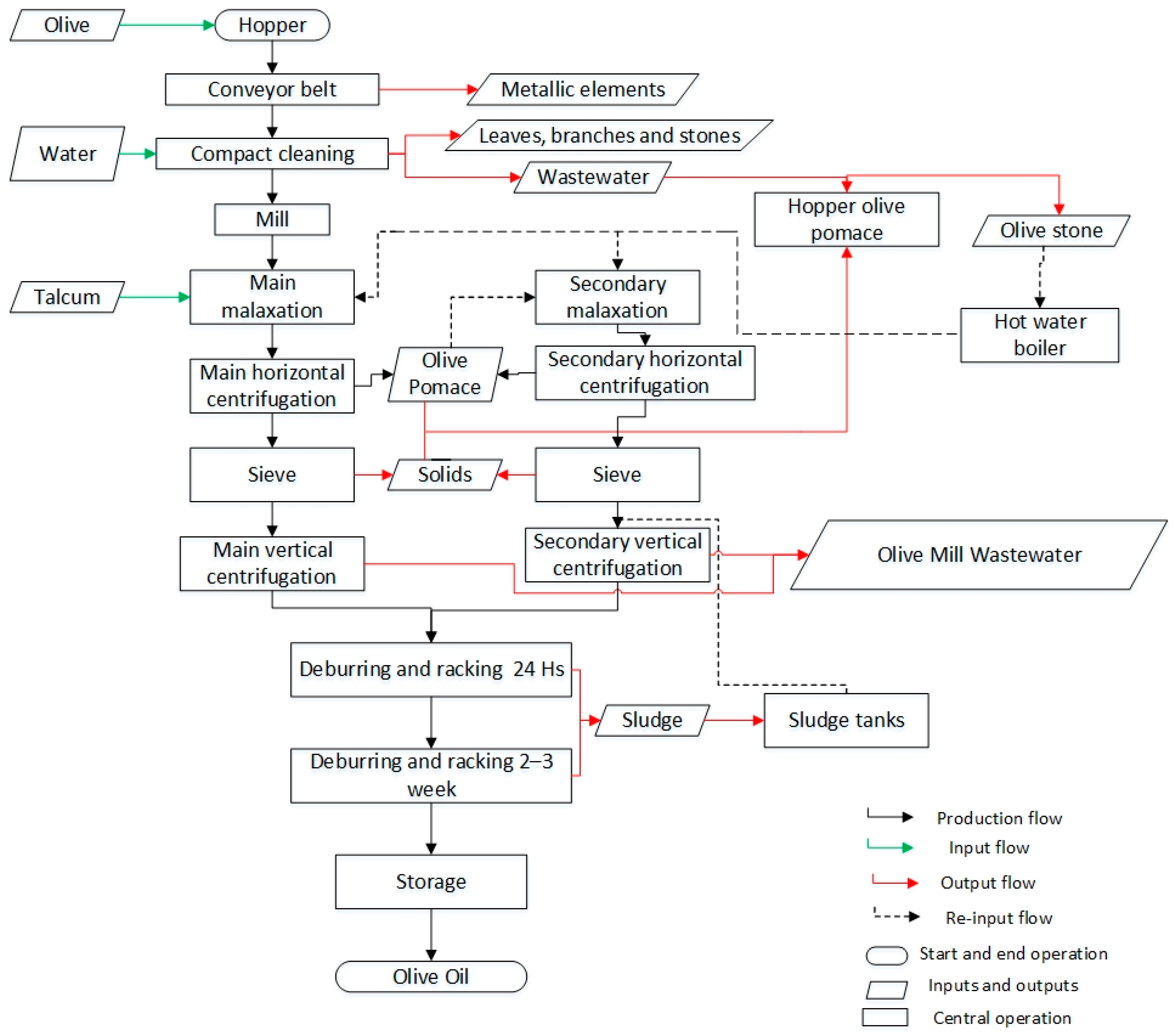

1.1. Production Process and Olive Mill Wastewater Generation

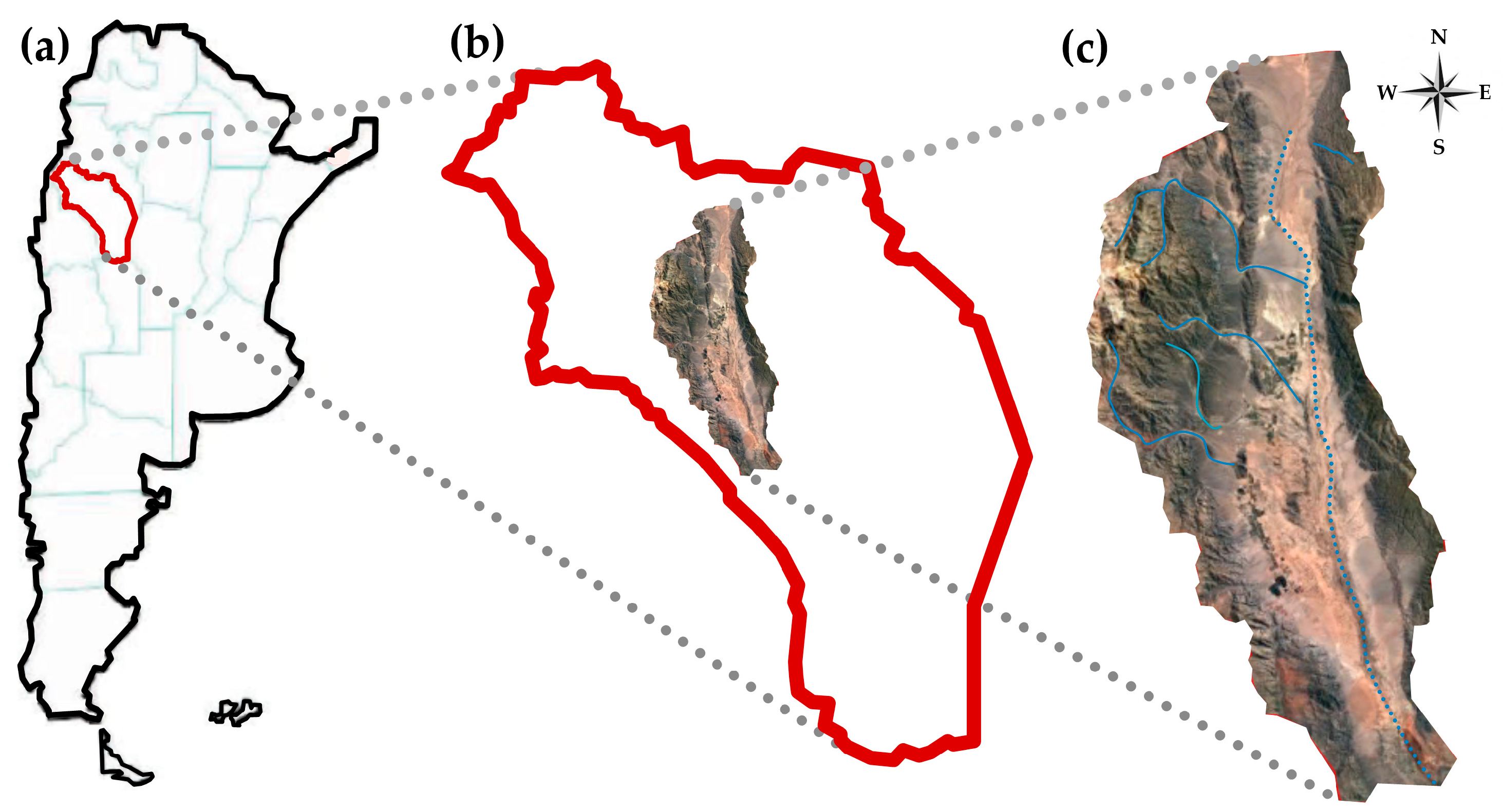

1.2. Study Area and Industrialization Process in the Region

1.3. Waste and Wastewater Treatment in the Olive Mill

2. Materials and Methods

2.1. Physico-Chemical Characterization and Gauging of Olive Mill Wastewater

2.2. Grey Water Footprint Estimation

- (a)

- The grey WF for nitrogen as nitrate (NO3−). In the nitrification processes, the generation of these oxidized forms of nitrogen is expected, which are mobilized by advective flow and percolate until they reach the groundwater resource [58]. The total value of nitrogen was taken as nitrate without considering transformation and retention values, and assuming that 100% of the nitrogen is transformed to nitrate.

- (b)

- The grey WF for chloride (Cl−) was calculated because of its importance as a conservative element [59].

2.2.1. Maximum Concentration Allowed

2.2.2. Natural Concentration

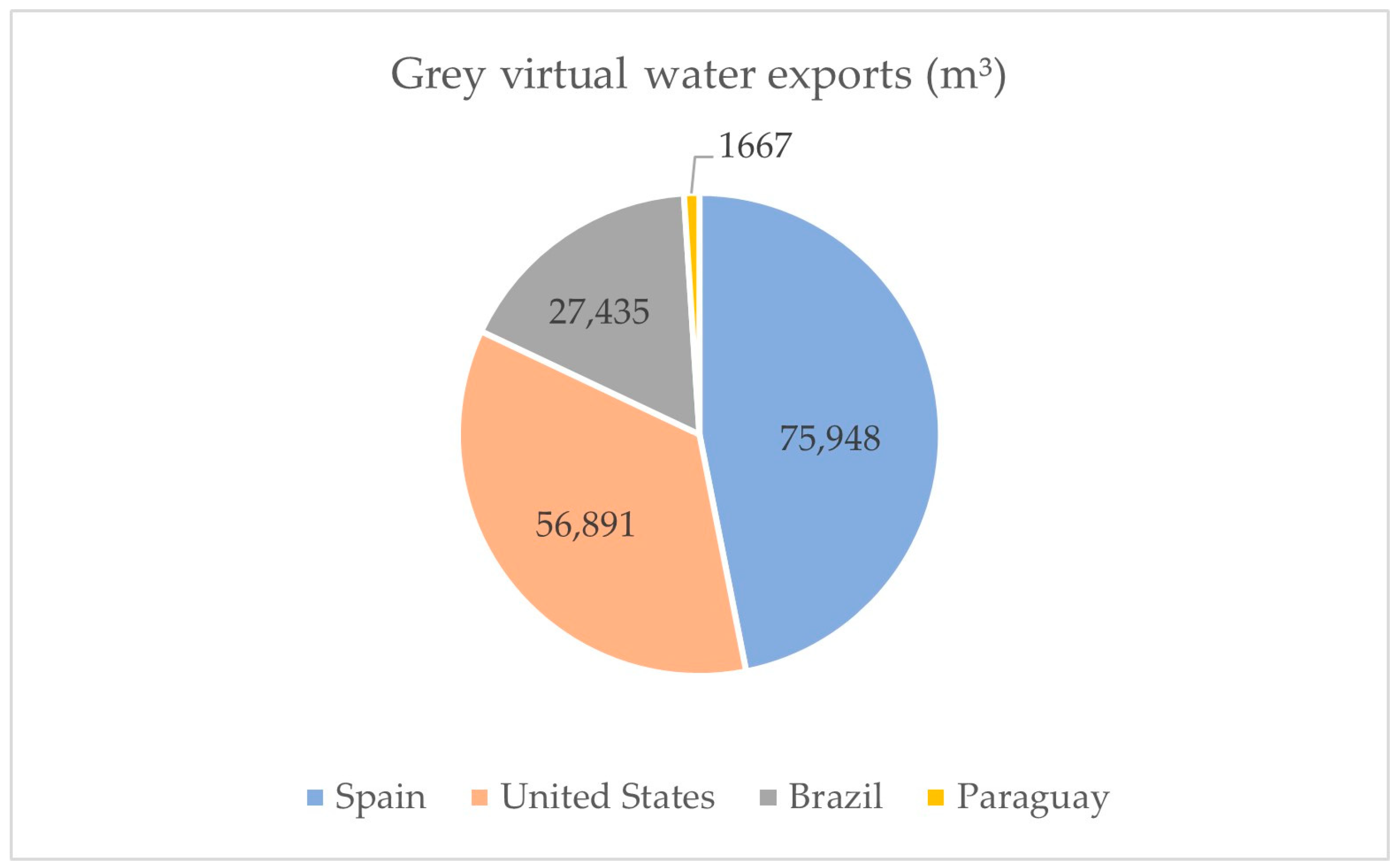

2.3. International Trade and Grey Virtual Water

3. Results

3.1. Physico-Chemical Characterization of the Olive Mill Wastewater

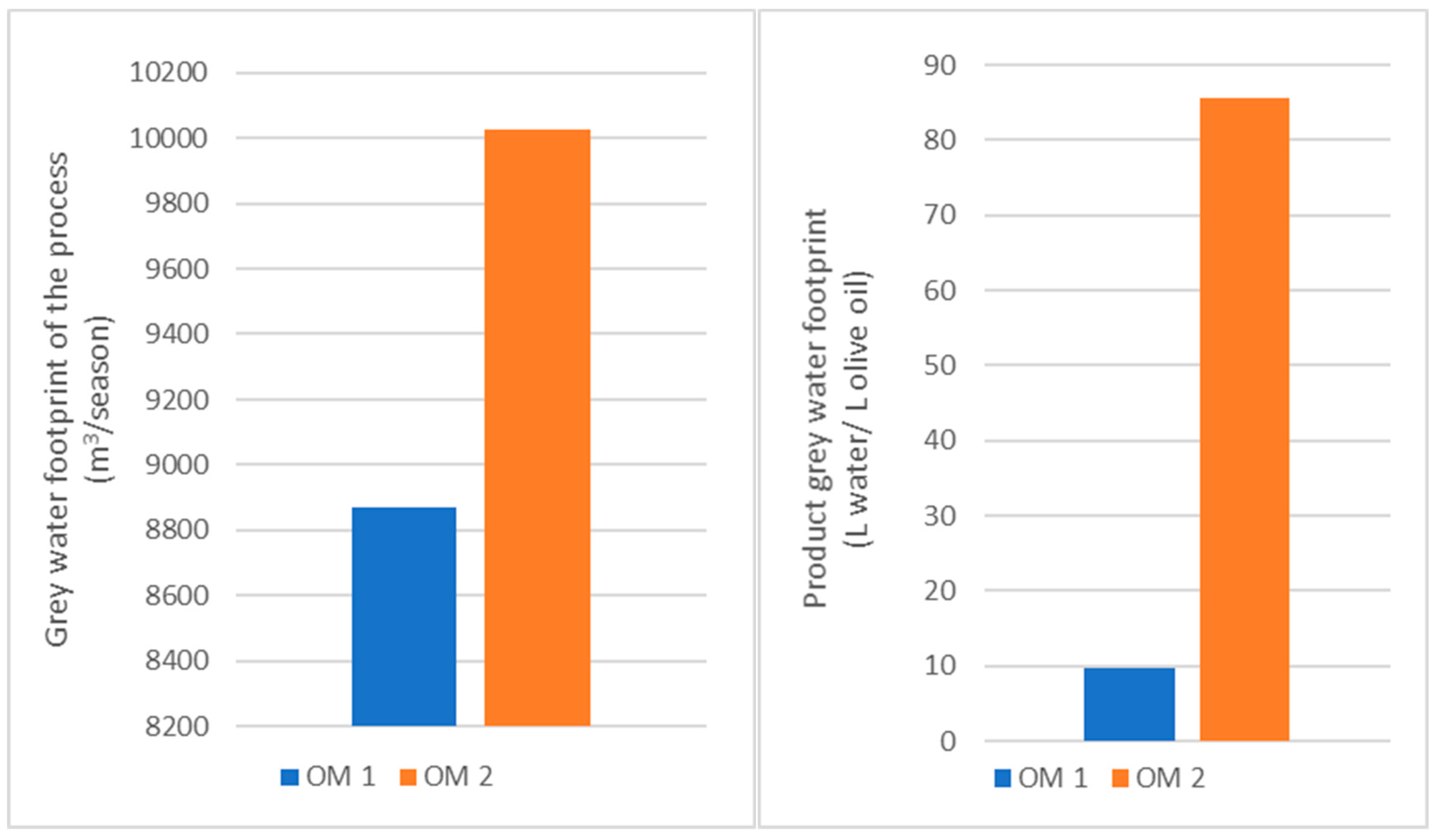

3.2. Grey Water Footprint of the Olive Oil Production Process

3.3. Grey Water Footprint and International Trade

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, W.; Kang, J.N.; Han, M.S. Global environmental inequality: Evidence from embodied land and virtual water trade. Sci. Total Environ. 2021, 783, 146992. [Google Scholar] [CrossRef]

- Wang, J.; Lin, J.; Feng, K.; Liu, P.; Du, M.; Ni, R.; Chen, L.; Kong, H.; Weng, H.; Liu, M.; et al. Environmental taxation and regional inequality in China. Sci. Bull. 2019, 64, 1691–1699. [Google Scholar] [CrossRef]

- Yu, Y.; Feng, K.; Hubacek, K. Tele-connecting local consumption to global land use. Glob. Environ. Chang. 2013, 23, 1178–1186. [Google Scholar] [CrossRef]

- Yu, Y.; Feng, K.; Hubacek, K. China’s unequal ecological exchange. Ecol. Indic. 2014, 47, 156–163. [Google Scholar] [CrossRef]

- Sarkodie, S.A.; Strezov, V. Effect of foreign direct investments, economic development and energy consumption on greenhouse gas emissions in developing countries. Sci. Total Environ. 2019, 646, 862–871. [Google Scholar] [CrossRef]

- Feng, H.; Yang, M.; Zeng, P.; Liu, Y.; Sun, F.; Wang, K.; Yang, K.; Che, Y. Transprovincial water quality impacts and the environmental inequity of grey water footprint transfer in China. Resour. Conserv. Recycl. 2022, 186, 106537. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. The Water Footprint Assessment Manual: Setting the Global Standard; Earthscan: London, UK, 2011. [Google Scholar] [CrossRef]

- Johnson, M.B.; Mehrvar, M. An assessment of the grey water footprint of winery wastewater in the Niagara Region of Ontario, Canada. J. Clean. Prod. 2019, 214, 623–632. [Google Scholar] [CrossRef]

- Ma, X.; Yang, D.; Shen, X.; Zhai, Y.; Zhang, R.; Hong, J. How much water is required for coal power generation: An analysis of gray and blue water footprints. Sci. Total Environ. 2018, 636, 547–557. [Google Scholar] [CrossRef]

- Martínez-Alcalá, I.; Pellicer-Martínez, F.; Fernández-López, C. Pharmaceutical grey water footprint: Accounting, influence of wastewater treatment plants and implications of the reuse. Water Res. 2018, 135, 278–287. [Google Scholar] [CrossRef]

- Allocca, V.; Marzano, E.; Tramontano, M.; Celico, F. Environmental impact of cattle grazing on a karst aquifer in the southern Apennines (Italy): Quantification through the grey water footprint. Ecol. Indic. 2018, 93, 830–837. [Google Scholar] [CrossRef]

- Joy, M.K.; Rankin, D.A.; Wöhler, L.; Boyce, P.; Canning, A.; Foote, K.J.; McNie, P.M. The grey water footprint of milk due to nitrate leaching from dairy farms in Canterbury, New Zealand. Australas. J. Environ. Manag. 2022, 29, 177–199. [Google Scholar] [CrossRef]

- Hu, Y.; Huang, Y.; Tang, J.; Gao, B.; Yang, M.; Meng, F.; Cui, S. Evaluating agricultural grey water footprint with modeled nitrogen emission data. Resour. Conserv. Recycl. 2018, 138, 64–73. [Google Scholar] [CrossRef]

- Lovarelli, D.; Ingrao, C.; Fiala, M.; Bacenetti, J. Beyond the Water Footprint: A new framework proposal to assess freshwater environmental impact and consumption. J. Clean. Prod. 2018, 172, 4189–4199. [Google Scholar] [CrossRef]

- Muratoglu, A. Grey water footprint of agricultural production: An assessment based on nitrogen surplus and high-resolution leaching runoff fractions in Turkey. Sci. Total Environ. 2020, 742, 140553. [Google Scholar] [CrossRef]

- Vergé, X.; VanderZaag, A.; Smith, W.; Grant, B.; Gordon, R. The consideration of time step in calculating grey water footprints of agricultural cropping systems. Ecol. Indic. 2017, 78, 31–36. [Google Scholar] [CrossRef]

- Corredor, J.A.G.; González, G.L.V.; Granados, M.V.; Gutiérrez, L.; Pérez, E.H. Use of the gray water footprint as an indicator of contamination caused by artisanal mining in Colombia. Resour. Policy 2021, 73, 102197. [Google Scholar] [CrossRef]

- Tamea, S.; Laio, F.; Ridolfi, L. Global effects of local food-production crises: A virtual water perspective. Sci. Rep. 2016, 6, 18803. [Google Scholar] [CrossRef]

- Arrien, M.M.; Aldaya, M.M.; Rodríguez, C.I. Water footprint and virtual water trade of maize in the province of Buenos Aires, Argentina. Water 2021, 13, 1769. [Google Scholar] [CrossRef]

- Allan, T. Water: Tackling the Threat to Our Planet’s Most Precious Resource; Tauris: London, UK, 2011. [Google Scholar]

- Hoekstra, A.Y.; Mekonnen, M.M. The water footprint of humanity. Proc. Natl. Acad. Sci. USA 2012, 109, 3232–3237. [Google Scholar] [CrossRef]

- Rossi, L.; Regni, L.; Rinaldi, S.; Sdringola, P.; Calisti, R.; Brunori, A.; Dini, F.; Proietti, P. Long-term water footprint assessment in a rainfed olive tree grove in the Umbria region, Italy. Agriculture 2019, 10, 8. [Google Scholar] [CrossRef]

- De Leo, F.; Miglietta, P.P. Water footprint and virtual water trade of olive oil. In Proceedings of the 18th IGWT Symposium of Technology and Innovation for a Sustainable Future: A Commodity Science Perspective, Roma, Italy, 24–28 September 2012; pp. 24–28. [Google Scholar] [CrossRef]

- Nogueira, A.M.; Paço, T.A.; Silvestre, J.C.; González, L.F.; Santos, F.L.; Pereira, L.S. Water Footprint of a Super-Intensive Olive Grove under Mediterranean Climate Using Ground-Based Evapotranspiration Measurements and Remote Sensing. EGU General Assembly. Vienna 2012. Available online: http://www.isa.utl.pt/files/pub/noticias/2012/nogueira_et_al_2012_poster_final_web.pdf (accessed on 25 August 2022).

- Dichio, B.; Palese, A.M.; Montanaro, G.; Xylogiannis, E.; Sofo, A. A preliminary assessment of Water Footprint components in a Mediterranean olive grove. Acta Hortic. 2014, 1038. [Google Scholar] [CrossRef]

- Pellegrini, G.; Ingrao, C.; Camposeo, S.; Tricase, C.; Conto, F.; Huisingh, D. Application of water footprint to olive growing systems in the Apulia region: A comparative assessment. J. Clean. Prod. 2016, 112, 2407–2418. [Google Scholar] [CrossRef]

- Salmoral, G.; Aldaya, M.M.; Chico, D.; Garrido, A.; Llamas, M.R. The water footprint of olive oil in Spain. In Papeles de agua virtual 2010, 7; Foundation Botin: Santander, Spain, 2010; Available online: https://ris.utwente.nl/ws/portalfiles/portal/13518159/Salmoral10water.pdf (accessed on 7 May 2024).

- Crovella, T.; Paiano, A.; Lagioia, G. A meso-level water use assessment in the Mediterranean agriculture. Multiple applications of water footprint for some traditional crops. J. Clean. Prod. 2022, 330, 129886. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. The green, blue and grey water footprint of crops and derived crop products. Hydrol. Earth Syst. Sci. 2011, 15, 1577–1600. [Google Scholar] [CrossRef]

- Chapagain, A.K.; Hoekstra, A.Y. Globalization of Water: Sharing the Planet’s Freshwater Resources; Blackwell Publishing: Oxford, UK, 2008. [Google Scholar] [CrossRef]

- Vuksinic, E. Caracterización Química y Ambiental de Efluentes Agroindustriales y Análisis de sus Implicancias Sobre el Agua Subterránea del Valle Central Antinaco-Los Colorados. Ph.D. Thesis, Universidad Nacional de Lujan, Luján, Argentina, 2022. Available online: https://repositoriosdigitales.mincyt.gob.ar/vufind/Record/INTADig_8ce46f8378ef58f3d593100c7f141960 (accessed on 25 August 2022).

- Roig, A.; Cayuela, M.L.; Sánchez-Monedero, M.A. An overview on olive mill wastes and their valorisation methods. Waste Manag. 2006, 26, 960–969. [Google Scholar] [CrossRef]

- Borja, R.; Raposo, F.; Rincón, B. Treatment technologies of liquid and solid wastes from two-phase olive oil mills. Grasas Y Aceites 2006, 57, 32–46. [Google Scholar] [CrossRef]

- Birame, B.; María, S.D.J.; Antonio, S.H.J.; Mercedes, P.C.M.; Amalia, V.C.; José, V.S.F.; Domingo, O.C. Planta Industrial de Tratamiento de las Aguas de Lavado Provenientes de Almazaras. 2007. Available online: http://infoil.gr/it/digital-library/doc_download/OMW_5.pdf_%3B%20modification-date%3D_Fri%2C%2012%20Nov%202010%2010_28_33%20%2B0200_%3B%20size%3D66369%3B (accessed on 12 December 2022).

- Saez, J.A.; Perez-Murcia, M.D.; Vico, A.; Martinez-Gallardo, M.R.; Andreu-Rodriguez, F.J.; Lopez, M.J.; Bustamante, M.A.; Sánchez-Hernández, J.C.; Moreno, J.; Moral, R. Olive mill wastewater-evaporation ponds long term stored: Integrated assessment of in situ bioremediation strategies based on composting and vermicomposting. J. Hazard. Mater. 2021, 402, 123481. [Google Scholar] [CrossRef]

- Cabezas, J.E. La Aceituna de Mesa: Nociones Sobre sus Características, Elaboración y Cualidades. Diputación de Sevilla. 2011, 16, 105–117. Available online: https://www.encurtidosmonica.es/medios/libroaceitunademesa.pdf (accessed on 23 December 2022).

- Barbera, A.C.; Maucieri, C.; Cavallaro, V.; Ioppolo, A.; Spagna, G. Effects of spreading olive mill wastewater on soil properties and crops, a review. Agric. Water Manag. 2013, 119, 43–53. [Google Scholar] [CrossRef]

- Caputo, M.C.; De Girolamo, A.M.; Volpe, A. Soil amendment with olive mills wasted. Impact to groundwater. J. Environ. Manag. 2013, 131, 216–221. [Google Scholar] [CrossRef]

- Elabdouni, A.; Haboubi, K.; Merimi, I.; El Youbi, M.S.M. Olive mill wastewater (OMWW) production in the province of Al-Hoceima (Morocco) and their physico-chemical characterization by mill types. Mater. Today: Proc. 2020, 27, 3145–3150. [Google Scholar] [CrossRef]

- Sierra, J.; Martí, E.; Garau, M.A.; Cruañas, R. Effects of the agronomic use of olive oil mill wastewater: Field experiment. Sci. Total Environ. 2007, 378, 90–94. [Google Scholar] [CrossRef]

- El Hassani, F.Z.; El Karkouri, A.; Errachidi, F.; Merzouki, M.; Benlemlih, M. The impact of Olive Mill Wastewater spreading on soil and plant in arid and semi-arid areas. Environ. Nanotechnol. Monit. Manag. 2023, 20, 100798. [Google Scholar] [CrossRef]

- Khalil, J.; Habib, H.; Bouguerra, S.; Nogueira, V.; Rodríguez-Seijo, A. The impact of olive mill wastewater on soil properties, nutrient and heavy metal availability–A study case from Syrian vertisols. J. Environ. Manag. 2024, 351, 119861. [Google Scholar] [CrossRef]

- Pritsa, T.S.; Voyiatzis, D.G. Correlation of ovary and leaf spermidine and spermine content with the alternate bearing habit of olive. J. Plant Physiol. 2005, 162, 1284–1291. [Google Scholar] [CrossRef]

- National Agricultural Census-CNA. Economy Ministry. National Institute of Statistics and Census 2018 (INDEC). Available online: https://www.indec.gob.ar/ftp/cuadros/economia/cna2018_resultados_definitivos.pdf (accessed on 12 December 2022).

- Ministry of Finance. Presidency of the Nation. Productive Report Provincial, La Rioja. 2018. Available online: https://www.argentina.gob.ar/sites/default/files/informe_productivo_la-rioja.pdf (accessed on 15 May 2023).

- National Institute of Statistics and Censuses. INDEC. Georeferenced Query System OPEX. 2023. Available online: https://www.indec.gob.ar/indec/web/Nivel4-Tema-3-2-79 (accessed on 9 August 2023).

- Miguel, R.E.; Gareis, M.C. El nexo agua, energía y alimentos en un valle árido bajo explotación intensiva. Estud. Sociales. Rev. Aliment. Contemp. Desarro. Reg. 2023, 33, 25. [Google Scholar] [CrossRef]

- Foti, P.; Romeo, F.V.; Russo, N.; Pino, A.; Vaccalluzzo, A.; Caggia, C.; Randazzo, C.L. Olive mill wastewater as renewable raw materials to generate high added-value ingredients for agro-food industries. Appl. Sci. 2021, 11, 7511. [Google Scholar] [CrossRef]

- Miguel, R.E.; Tálamo, E.; Cristos, D.; González Ribot, J.V.; Chayle, L. Análisis y evolución del proceso de salinización del acuífero Antinaco-Los Colorados en las colonias Vichigasta y Cantinzaco, La Rioja, Argentina. In Proceedings of the IX Congreso Argentino de Hidrogeología, San Fernando del Valle de Catamarca, Argentina, 21 September 2016; Available online: https://www.cohife.org/advf/LARIOJA/E13.pdf (accessed on 13 May 2024).

- Miguel, R.E.; Gonzalez Ribot, J.V.; Canelo, H.N. Evolución hidrogeológica del Valle Central Antinaco-Los Colorados. Parte 4: Vichigasta y Catinzaco. In Proceedings of the XI Congreso Argentino de Hidrogeología, Bahía Blanca, Argentina, 25 October 2022. [Google Scholar]

- El-Abbassi, A.; Kiai, H.; Raiti, J.; Hafidi, A. Application of ultrafiltration for olive processing wastewaters treatment. J. Clean. Prod. 2014, 65, 432–438. [Google Scholar] [CrossRef]

- Kavvadias, V.; Doula, M.; Theocharopoulos, S. Long-term effects on soil of the disposal of olive mill waste waters (OMW). Environ. Forensics 2014, 15, 37–51. [Google Scholar] [CrossRef]

- Kavvadias, V.; Elaiopoulos, K.; Theocharopoulos, S.; Soupios, P. Fate of potential contaminants due to disposal of olive mill wastewaters in unprotected evaporation ponds. Bull. Environ. Contam. Toxicol. 2017, 98, 323–330. [Google Scholar] [CrossRef]

- Komnitsas, K.; Modis, K.; Doula, M.; Kavvadias, V.; Sideri, D.; Zaharaki, D. Geostatistical estimation of risk for soil and water in the vicinity of olive mill wastewater disposal sites. Desalination Water Treat. 2016, 57, 2982–2995. [Google Scholar] [CrossRef]

- Paez, V.; Barrett, W.B.; Deng, X.; Diaz-Amigo, C.; Fiedler, K.; Fuerer, C.; Hostetler, G.L.; Johnson, P.; Joseph, G.; Konings, E.J.M.; et al. AOAC SMPR® 2016. 002. J. AOAC Int. 2016, 99, 1122–1124. [Google Scholar] [CrossRef]

- USEPA. Guidelines for Water Reuse; U.S. Environmental Protection Agency: Washington, DC, USA, 2012. Available online: https://www.epa.gov/regulatory-information-topic/regulatory-and-guidance-information-topic-water (accessed on 8 July 2020).

- American Public Health Association. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2012. [Google Scholar]

- Cisneros Basualdo, N.E.; Banda Noriega, R.B.; Migue, R.E.; Rodríguez, C.I.; Ruiz de Galarreta, A. Peligro de contaminación del agua subterránea por sistemas de lagunas para tratamiento de efluentes de tambos. Rev. De Geol. Apl. A La Ing. Y Al Ambiente 2023, 50. [Google Scholar] [CrossRef]

- Custodio, E.; Llamas, M.R. Hidrología Subterránea, 2nd ed.; Omega: Barcelona, Spain, 1983. [Google Scholar]

- Franke, N.A.; Boyacioglu, H.; Hoekstra, A.Y. Grey Water Footprint Accounting: Tier 1 Supporting Guidelines. In Value of Water Research Report Series Nº 65; UNESCO-IHE: Delft, The Netherlands, 2013; Available online: https://ris.utwente.nl/ws/portalfiles/portal/5141740/Report65-GreyWaterFootprint-Guidelines.pdf (accessed on 7 May 2024).

- Hallaq, A.H. The impact of soil texture on nitrates leaching into groundwater in the North Governorate, Gaza Strip. J. Soc. Sci. 2010, 38, 11. [Google Scholar]

- Argentine Food Code. Chapter XII: Water Drinks, Water and Aerated Water. Law 18.284, Argentina 2021. Available online: https://www.argentina.gob.ar/sites/default/files/capitulo_xii_aguas_actualiz_2024-04.pdf (accessed on 7 May 2024).

- Rocca, J.A.; Ortíz, A.; Zambrano, J.; Taballione, C.; Togores, E.; Robles, J.O.; Victora, J.A.; Pelegrino, J.; Salvioli, G.; Bosch, E.; et al. Investigación del Agua Subterránea en el Valle Antinaco-Los Colorados, Provincia de La Rioja; Publicación N° P-067. INA CRAS; Secretaría de Estado de Recursos Naturales y Ambiente Humano: La Rioja, Argentina, 1975; p. 350. [Google Scholar]

- Manzano, M.; Custodio, E.; Nieto, P. The natural background to the quality of groundwater: Implications for the implementation of the Framework Water Directive in Europe. Tecnol. Del Agua 2003, 241, 38–47. Available online: https://www.osti.gov/etdeweb/biblio/20412731 (accessed on 23 December 2022).

- Beily, M.E. Caracterización de Efluentes de Cerdos, con Énfasis en Biodegradabilidad Anaeróbica. Master’s Thesis, Buenos Aires Technological Institute, Buenos Aires, Argentina, 2015. Available online: https://repositorio.inta.gob.ar/handle/20.500.12123/2080 (accessed on 25 August 2021).

- Azzam, M.O.; Hazaimeh, S.A. Olive mill wastewater treatment and valorization by extraction/concentration of hydroxytyrosol and other natural phenols. Process Saf. Environ. Prot. 2021, 148, 495–523. [Google Scholar] [CrossRef]

- Dermeche, S.; Nadour, M.; Larroche, C.; Moulti-Mati, F.; Michaud, P. Olive mill wastes: Biochemical characterizations and valorization strategies. Process Biochem. 2013, 48, 1532–1552. [Google Scholar] [CrossRef]

- European Union. Olive Oil Wastewater Reuse for the Production and Commercialisation of Spirulina Alga. 2016. Available online: https://cordis.europa.eu/project/id/711725 (accessed on 22 May 2024).

- Khdair, A.; Abu-Rumman, G. Sustainable environmental management and valorization options for olive mill byproducts in the Middle East and North Africa (MENA) region. Processes 2020, 8, 671. [Google Scholar] [CrossRef]

- Sánchez-Sánchez, C.; González-González, A.; Cuadros-Salcedo, F.; Cuadros-Blázquez, F. Two-phase Olive mill waste: A circular economy solution to an imminent problem in Southern Europe. J. Clean. Prod. 2020, 274, 122789. [Google Scholar] [CrossRef]

- Hassen, W.; Hassen, B.; Werhani, R.; Hidri, Y.; Jedidi, N.; Hassen, A. Processes of Valorization and Management of Olive By-Products: The Pomace and Olive Mill Wastewater. In Wastewater from Olive Oil Production: Environmental Impacts, Treatment and Valorisation; Souabi, S., Anouzla, A., Eds.; Springer: Cham, Germany, 2023; pp. 1–25. [Google Scholar] [CrossRef]

- Agabo-García, C.; Repetto, G.; Albqmi, M.; Hodaifa, G. Evaluation of the olive mill wastewater treatment based on advanced oxidation processes (AOPs), flocculation, and filtration. J. Environ. Chem. Eng. 2023, 11, 109789. [Google Scholar] [CrossRef]

- Vlyssides, A.G.; Loizides, M.; Karlis, P.K. Integrated strategic approach for reusing olive oil extraction by-products. J. Clean. Prod. 2004, 12, 603–611. [Google Scholar] [CrossRef]

- OECD. Water Governance in Argentina, OECD Studies on Water; OECD Publishing: Paris, France, 2019. [Google Scholar] [CrossRef]

- Cao, Y.; She, Y.; Wang, Q.; Lin, J.; Chen, W.; Qu, S.; Liu, Z. Redefining virtual water allocation in China based on economic welfare gains from environmental externalities. J. Clean. Prod. 2024, 434, 140243. [Google Scholar] [CrossRef]

- Hoekstra, A.Y. The Relation between International Trade and Freshwater Scarcity; WTO Working Paper Series, No. 5. World Trade Organization: Geneva, Switzerland, 2010; Available online: https://ris.utwente.nl/ws/portalfiles/portal/5147042/Hoekstra10relation.pdf (accessed on 20 May 2024).

- Ospital, P.; Masson, D.; Beler, C.; Legardeur, J. Toward product transparency: Communicating traceability information to consumers. Int. J. Fash. Des. Technol. Educ. 2023, 16, 186–197. [Google Scholar] [CrossRef]

| Waste and Wastewater | Final Disposal | |

|---|---|---|

| Olive Mill 1 | Olive Mill 2 | |

| Leaves, branches, stones, mud | To the field | To the field |

| Washing water | Olive pomace hopper | To the field |

| Olive pomace | Olive pomace hopper | Olive pomace hopper and then storage pool |

| Residual olive pomace | To the field | To the field with wastewater |

| Olive mill wastewater | Primary treatment—evaporation ponds | Storage pool with olive pomace, then it is deposited to the field |

| Drainage and cleaning of storage tank | Primary treatment—evaporation ponds | Storage pool with olive pomace, then it is deposited to the field |

| Parameters (mg/L) | OM 1 | OM 2 | Regulatory Limits *1 | ||||

|---|---|---|---|---|---|---|---|

| Average | Min | Max | Average | Min | Max | Wastewater Regulations | |

| pH | 5.1 | 4.7 | 6.4 | 6.49 | 5.2 | 7.1 | 6.5–10 |

| EC (µS/cm) | 2168 | 1680 | 3240 | 1727 | 530 | 8500 | NR |

| BOD5 | 4434 | 1206 | 11,864 | 2920 | 1404 | 5166 | <200 |

| COD | 13,431 | 2880 | 33,900 | 6806 | 4290 | 13,800 | <500 |

| BOD5/COD | 0.33 | 0.14 | 0.67 | 0.43 | 0.32 | 0.53 | NR |

| Chloride | 410 | 255 | 477 | 218 | 96.5 | 921 | NR |

| Nitrogen | 706 | 141 | 1222 | 948 | 670 | 1718 | <105 |

| OM 1 | OM 2 | |

|---|---|---|

| Q (m3/season) | 1.120 | 943 |

| NO3− (mg/L) | 3.121 | 4.190 |

| Cl− (mg/L) | 410 | 218 |

| PL NO3− (kg/season) | 3.495 | 3.951 |

| PL Cl− (kg/season) | 459 | 205 |

| OM 1 | ||

| OM 2 |

| Industries | Production (L oil) | Q/p (L OMWW/ L oil) | Product Grey WF Related to Cl− (L water/L oil) | Product Grey WF Related to NO3− (L water/L oil) |

|---|---|---|---|---|

| OM 1 | 1,020,000 | 1.10 | 0.14 | 8.69 |

| OM 2 | 220,000 | 4.29 | 0.30 | 45.5 |

| Industries | Olive Oil Exports (tons) | Product Grey WF Related to NO3− (m3 water/t oil) | Grey Virtual Water Exports (m3) | ||

|---|---|---|---|---|---|

| 2019 | 2020 | Average 2019–2020 | |||

| OM 1 | 675 | 500 | 587.5 | 9.48 | 5569 |

| OM 2 | 877 | 252 | 564.5 | 49.6 | 28,000 |

| Total for La Rioja | 6639 | 4341 | 5490 | 29.5 | 161,955 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vuksinic, E.; Miguel, R.E.; Aldaya, M.M.; Rodriguez, C.I. Wastewater and Grey Water Footprint Assessment of the Olive Oil Production Process in Northwest Argentina. Water 2024, 16, 1612. https://doi.org/10.3390/w16111612

Vuksinic E, Miguel RE, Aldaya MM, Rodriguez CI. Wastewater and Grey Water Footprint Assessment of the Olive Oil Production Process in Northwest Argentina. Water. 2024; 16(11):1612. https://doi.org/10.3390/w16111612

Chicago/Turabian StyleVuksinic, Evelyn, Roberto Esteban Miguel, Maite M. Aldaya, and Corina Iris Rodriguez. 2024. "Wastewater and Grey Water Footprint Assessment of the Olive Oil Production Process in Northwest Argentina" Water 16, no. 11: 1612. https://doi.org/10.3390/w16111612

APA StyleVuksinic, E., Miguel, R. E., Aldaya, M. M., & Rodriguez, C. I. (2024). Wastewater and Grey Water Footprint Assessment of the Olive Oil Production Process in Northwest Argentina. Water, 16(11), 1612. https://doi.org/10.3390/w16111612