Use of Zero-Valent Iron Nanoparticles (nZVIs) from Environmentally Friendly Synthesis for the Removal of Dyes from Water—A Review

Abstract

1. Introduction

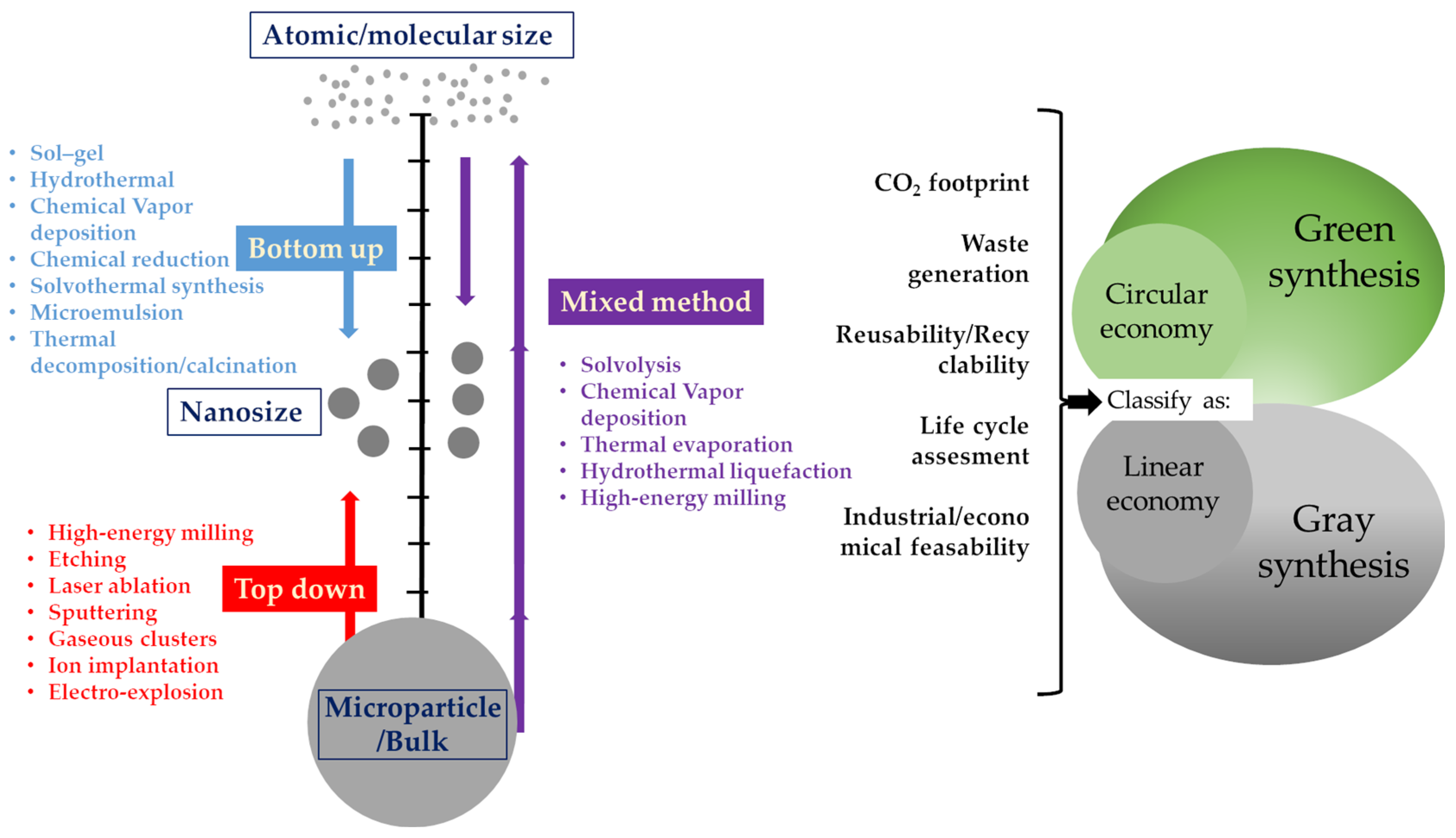

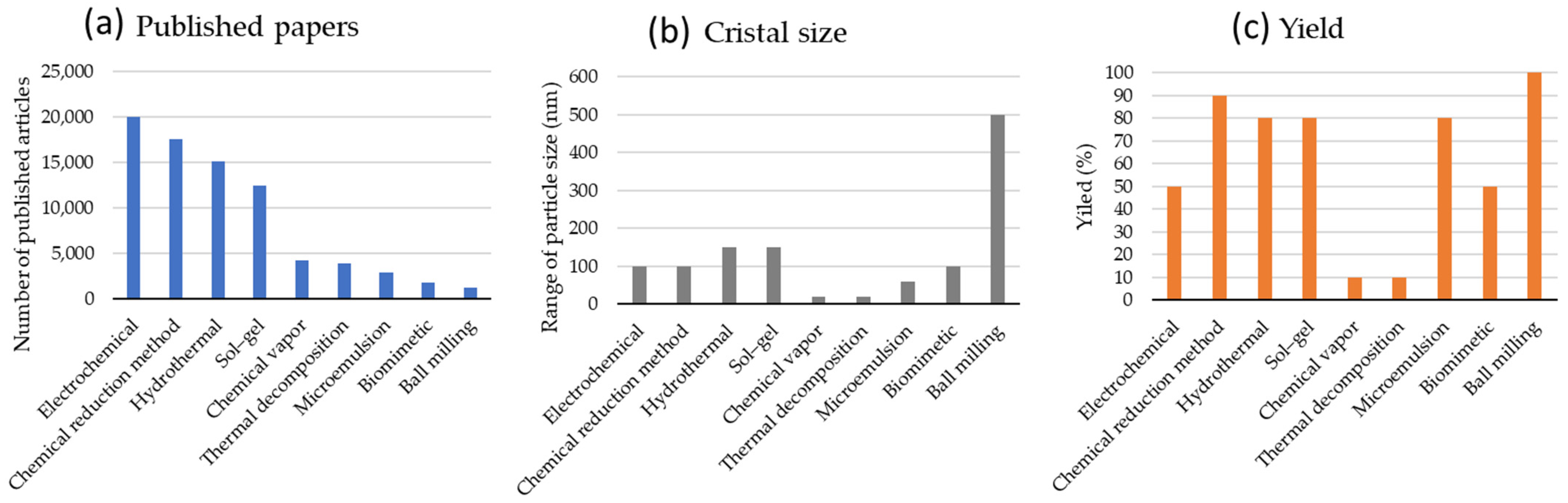

2. Nanoparticles in Environmental Applications

3. Nanoparticle Synthesis Strategies

3.1. Sol–Gel

3.2. Hydrothemal

3.3. Chemical Vapor Condensation of a Metal

3.4. Chemical Reduction Methods

3.5. Co-Precipitation

3.6. Electrochemical Methods

3.7. Precision Milling

| Nanoparticles | Support | Synthesis Techniques | Environmental Applications | Reference |

|---|---|---|---|---|

| Removal of Dyes | ||||

| ZnO | - | Sol–gel co-precipitation in KOH | Methylene blue | [55] |

| Zr-doped Fe2O3 | CoOx | Hydrothermal | Orange II | [59] |

| Ca peroxide | Starch | Precipitation | Methylene blue | [63] |

| TiO2 | g-C3N4(g-CN) nanolayers | Co-precipitation; thermal polymerization | Methylene blue | [64] |

| Au | Au/VO2/CeO2 | Photodeposition | Methylene blue | [69] |

| Magnetite (MN) | Fe3O4@C | Microwave-induced | Methylene blue | [70] |

| Ag | Na0.5Bi0.5TiO3 nanospheres | Chemical solution, hydrothermal | Rhodamine B | [71] |

| HRC-Ag/Agar | Agarose hydrogel | Reduction with KBH4 | Methylene blue, rhodamine B | [72] |

| Cationic polyethyleneimine (PBVPR218) | - | - | Dyes | [73] |

| EC-Ag | Elettaria cardamomum | Reduction with NaBH4 | Methylene blue, rhodamine B | [74] |

| nZVI | Janus particles | Reduction with NaBH4 | Methyl orange | [75] |

| CdAl2O4 | Fe | Co-precipitation | Brilliant blue, brilliant green | [76] |

| CuNiFe2O4 | g-C3N4 | Gel auto combustion | Methylene blue | [77] |

| Black phosphorus (BPQDs)-IO TiO2 | - | Sonication assisted; liquid exfoliation | Rhodamine B, methylene orange | [78] |

| g-C3N4-Fe3O4@KF | Kapok fiber | One step | Rhodamine B | [79] |

| CeO2 | - | Co-precipitation, calcination | Methylene blue | [80] |

| PLA/CMC/GO _f-COOH@Ag | Polymeric matrix | Reduction with ascorbic acid | Methylene blue | [81] |

| (B-GNP) | Graphene | Polyvinyl alcohol film | Atrazine | [82] |

| Magnetite nanoparticles (MNs) | β-cyclodextrin (β-CD) and quaternary ammonium salts | Co-precipitation | Methylene blue, Orange G | [83] |

| C3N5-LDH-Ag | C3N5-LDH | Precipitation in NaOH | Tartrazine | [84] |

| Removal of Organic Compounds | ||||

| Ferrihydrite (Fh) | Non-ionic surfactant Brij L4 | Co-precipitation | Cooking oils | [44] |

| TiO2 | - | Sol–gel | Phenol | [56] |

| Zr-doped Fe2O3 | CoOx | Hydrothermal | Bisphenol A | [59] |

| AuNPs | Au/VO2/CeO2 | Photodeposition | Aromatic alcohols, p-nitrophenol | [69] |

| nZVI | Janus particles | Reduction with NaBH4 | Trichloroethylene | [75] |

| Fe3O4/FeS | Biochar | Pollen pyrolysis | phenol | [85] |

| AA@Fe° | Amino acids | Reduction with KBH4 | Tributyl phosphate, n-dodecane | [86] |

| Biochar | - | Pyrolysis | Bisphenol A | [87] |

| Fe3O4 | rGO | Co-precipitation | 4-Aminophenol | [88] |

| Aptamer-MrGO@Au and ssDNA-AuNP@MBs | BPA aptamer | Reduction with trisodium citrate | Bisphenol A | [89] |

| ZnO@SCF SppCobalt Ferrite | Spinel cobalt ferrite | Precipitation | Phenantrene | [90] |

| Fe⁰@C/surfactant | Carbon | Hydrothermal; carbothermic; reduction with NaBH4 | Nitrobenzene | [91] |

| Zn/FeO | Surfactant foams | Reduction with NaBH4 | Diesel | [92] |

| Removal of Pharmaceutical Compounds | ||||

| CuO and nZVI | - | Sol–gel; precipitation in NaOH; reduction with NaBH4 | Levofloxacin | [57] |

| CuO | - | Co-precipitation; calcination | Metronidazol | [93] |

| Ag-Cu-Li | Multimetal nanorods | Precipitation in NaOH | Antibacterial activity | [94] |

| WS2 | - | Hydrothermal thiourea | Tetracycline | [95] |

| ZnO | Alginate nanofibers | Hydrothermal | Tetracycline | [96] |

| BiFeO3 | - | Combustion | Ofloxacin | [97] |

| TGC/NiCr2O4 | Tubular g-C3N4 (TGC) | Calcination | Tetracycline | [98] |

| ZnO | Carbon cloth (CC) | Hydrothermal | Hydroxychloroquine | [99] |

| Ag/Ag3PO4-VAg | Ag nanocluster with vacancies of Ag (Ag/Ag3PO4-Vag) | Reduction with NaBH4 | Sulfamethoxazole | [100] |

| Au | - | Reduction with NaBH4/320 °C | Penicillin G, sulfamethazine, tetracycline, enrofloxacin, skewered fish | [101] |

| Bi-Ag nanoalloys | - | Solvothermal | Bacterial infections | [102] |

| TiO2NW-CuO- cellulose | Cellulose | Solvothermal | Escherichia coli | [103] |

| Removal of Pesticides | ||||

| Ag (SNP) | - | Reduction with NaBH4 | Miticidal activity | [104] |

| Au | Ovalbumin | Reduction with trisodium citrate | Carbaryl | [105] |

| Au@ZIF-67 | ZIF-67 | Hydrothermal | Thiram, Carbendazim | [106] |

| Chitosan (CS) | - | Ionic gelation | Plant diseases | [107] |

| Cu (ChNC@Cu) | Chitin nanocrystals (ChNC) | TEMPO oxidation | Pesticides | [108] |

| SiO2 | Biopolymers | Sol–gel | Plastic films | [109] |

| ZnO and TiO2 | - | One-pot | Polycyclic aromatic hydrocarbons | [110] |

| Pd-nZVI and S-nZVI | - | Reduction with NaBH4 | Trichloroethylene | [111] |

| Toxicity abatement | ||||

| PbO2 | Humic acid | Chlorination | Toxicity in medaka fish | [112] |

| Metal, metal oxide, carbon, plastic | - | Phytotoxicity | [113] | |

| nFe@Fe3O4, nFe3O4 nFe2O3 | - | Toxic effects on zebra fish | [114] | |

| ZnO and Ag | - | Sol–gel+ reduction with NaBH4 | Acute toxicity in zebra fish | [115] |

| Chemical processes | ||||

| Pt@S-1 | β zeolite | - | Synthesis of naphtha | [116] |

| ZnO | Molasses and urea | Precipitation | Synthesis of fertilizer | [117] |

| OMGR Oximagnesite/green rust | - | Hydrothermal | Phosphate recovery | [118] |

| CrMnFeCoNi-HEO; MgCoNiCuZn-HEO | Spinel-structure sHEO | Sol–gel | Desalination techniques of seawater | [119] |

| RuNi-rGO@ MNCs | N-doped C nanosheets | Reduction with H2 | Hydrogen evolution reaction (HER) | [120] |

| Others | ||||

| TiO2 | Recycled rubber tiles | Sol–gel | Airborne pollution | [121] |

3.8. Commercial Nanoparticles

| Nanoparticles | Support | Environmental Applications | Reference |

|---|---|---|---|

| SiO2@CA MSs | Microspheres | Removal of dyes | [122] |

| UHMWPE/TiO2 | Polyethylene | Removal of methyl orange, methylene blue, Congo red, and tetracycline | [123] |

| nZVI, Fe2O3, Fe3O4 | - | Florfenicol containing cow manure | [124] |

| ZnO | - | Escherichia coli | [125] |

| nZVI | - | Tetracyclines | [126] |

| ZnO and TiO2 | - | Tetranychus urticae and Neoseiulus californicus | [127] |

| NiO | - | Neurotoxicity in zebra fish | [128] |

| ZnO | Film of chitosan | Loaf bread shelf life | [129] |

| nZVI | - | Polycyclic aromatic hydrocarbons | [130] |

| ZnO | - | Gut microbiome alterations in rats | [131] |

| Ag | - | Improved quality of Capsicum annum crops | [132] |

| SiO2, Al2O3, and O-CNT | - | Clofibric acid, acetaminophen, sulfamerazine | [133] |

| nZVI | - | Hydrophobic organic compounds, sediments | [134] |

| ZnO | - | Biofortification of Dracocephalum moldavica | [135] |

| ZnO | Pannonibacter- phragmitetus | Inhibition of microbial Cr(VI) reduction | [136] |

| Se | - | As (III), soybean roots | [137] |

3.9. Emerging Green Alternatives

| Nanoparticles | Support | Reactive Agent | Environmental Applications | Reference |

|---|---|---|---|---|

| Removal of Dyes | ||||

| Ag/Ti | - | Aloe vera L.e. | Rhodamine B | [46] |

| MoO3 and WO3 nanorods | - | Leidenfrost (H2O) with NaOH | Methylene blue | [138] |

| Ag | - | Antidesma acidum L.e. | Congo red, methylene blue | [139] |

| B-doped g-C3N4/TiO2 | g-C3N4 | Spinacia oleracea | Methylene blue | [140] |

| Au | - | Wedelia urticifolia | Rhodamine B | [141] |

| ZnS/Fe3O4 | Carboxymethyl cellulose | Co-precipitation of Fe(II) and Fe(III) | Methylene blue, methyl orange Congo red, and rhodamine B | [142] |

| ZnO | - | Citrus x lemon | Reactive green 19 | [143] |

| IRCFA-PDA@Ag | Iron-rich coal fly ash (IRFA)-Polydopamine (PDA) | Floral | Methylene blue | [144] |

| ZnO, CuO, MnO2 and MgO | - | Leucaena leucocephala | Golden yellow-145, Direct red-31 | [145] |

| nZVI | - | Cow and goat milk | Methyl orange | [146] |

| Au | - | Cell-free filtrate of Penicillium rubens | Methylene blue, phenol red, bromothymol blue, methyl orange | [147] |

| ZnO | Mesoporous carbon | Firecracker waste | Methyl orange | [148] |

| ZnO | - | Aloe vera | Malachite green, Basic violet 3 | [149] |

| ZnO and SiO2 | - | Cyperus alternifolius | Methylene blue | [150] |

| Organic Compounds | ||||

| Pt-SnO2 | rGO-CH | Amaranthus spinosus | Methanol | [151] |

| nZVI | - | Tung, aspen, and holly L.e. | Tetrabromobisphenol A | [152] |

| CeO2 | - | Dillenia indica | 2,2-difphenyl-1- -picrylhydrazyl | [153] |

| GM-Ag | - | Gnetum montanum | 3-nitrophenols and 4-nitrophenols | [154] |

| MgO | - | Jatropha oil | Compounds in air, HC, CO, CO2 | [155] |

| Fe-C, Co-C, and Ni-C | - | Tea residue | Cystine | [156] |

| Removal of Microorganisms | ||||

| ZnO | Brassica oleracea | Gram-negative Bc Escherichia coli | [157] | |

| Ag | Pseudomonas canadensis bacterial isolate | Pseudomonas tolaasii Pt18 | [158] | |

| CuO | Alpinia officinarum | Colletotrichum gloeosporioides | [159] | |

| nZVI | Common mantle | Pathogenic fungi, wheat plants | [160] | |

| Removal of Pharmaceutical Compounds | ||||

| ZnO | - | Aloe vera | Amoxicillin | [149] |

| Ag | - | Passiflora foetida | Antibacterial | [161] |

| Ag | - | Calotropis procera | Fungal and bacterial pathogens | [162] |

| Ag, Cu, and Fe | Catharanthus roseus L.e. | Several anti-inflammatory drugs | [163] | |

| Lignin | Nanocellulose cryogels | Kraft lignin | Diclofenac, metropolol, tramadol, carbamazepine | [164] |

| Removal of Inorganic Compounds | ||||

| MgO | - | Jatropha oil | CO, CO2 in air | [155] |

| Fe-C, Co-C, and Ni-C | - | Tea residue | CrO42¯ | [156] |

| Chitosan | - | Salix subserrata bark extract | As in rats | [165] |

| Magnetite | - | Amla (tree bark) | U(VI) | [166] |

| ZnO | - | Acacia catechu L.e. | As | [167] |

4. Zero-Valent Iron Nanoparticles: Conventional and Eco-Friendly Synthesis

4.1. Zero-Valent Iron Nanoparticles

4.2. Influence of Synthetic Methods for the Preparation of nZVIs

4.3. Stabilization of nZVIs

- Incorporating a second metal into nZVIs.

- Coating the surface of nZVIs with organic substances.

- Synthesizing emulsified nZVIs.

- Fixed support.

- Encapsulation.

- Electrostatic stabilization.

- Steric stabilization.

4.3.1. Incorporating a Second Metal into nZVIs

4.3.2. Coating of nZVI Surfaces

4.3.3. Emulsified nZVIs

4.3.4. Fixed Support

4.3.5. Encapsulation of nZVIs

4.3.6. Electrostatic Stabilization

4.3.7. Steric Stabilization

| FeNPs | Precursor | Support | Size/nm | Morphology | Characterization | Reference |

|---|---|---|---|---|---|---|

| MCMZVI | FeCl3·6H2O+ glucose+CO(NH2)2 | Mesoporous carbon | 20–100 | Uneven size | XRD, SEM, XPS, FTIR, BET | [194] |

| CS-nZVI (core–shell) | FeCl3·6H2O+NaBH4 | - | 15.42–97.57 | Spherical | UV–vis, FTIR, TEM, SEM EDX, XRF | [198] |

| nZVI | FeCl3·6H2O+NaBH4 | - | 34–110 | Spherical | UV, XRD, SEM, EDX, TEM, DSL | [208] |

| nZVI@FSG | FeSO4·7H2O+NaBH4 | Flaxseed gum | 73–87 | Spherical | DLS, FESEM, EDX, FTIR, DR5000 | [216] |

| CMC-S-nZVI | FeSO4·7H2O+NaBH4 | Carboxymethyl cellulose (CMC) | 90 | Spherical | TEM-EDS, UV–vis, PSD, ζ-potential | [218] |

| nZVI/SS/BC | FeSO4·7H2O+NaBH4 | Biochar with stable starch | 45.7–37 | - | SEM, EDS, BET, FTIR, XRD | [220] |

| nZVI | FeSO4·7H2O+KBH4 | Guar gum | 87.4 | Cubic | TEM, XRD, SEM, XPS | [221] |

| nZVI | FeSO4·7H2O+KBH4 | Attapulgite | - | - | FTIR, SEM-EDS, XPS | [225] |

| Fe@SiO2 | FeSO4·7H2O+KBH4 | Silica | 40–50 | Nanospheres | XRS, FTIR, TEM, EDS | [227] |

| nZVI/AC | FeSO4·7H2O+NaBH4 | Activated carbon | 40–100 | Rough | SEM, XRD, BET XPS | [228] |

| CS@nZVI | FeSO4·7H2O+NaBH4 | Chitosan | 13.12 | - | XRD, FESEM, EDS, FTIR | [232] |

| CaCO3-nZVI | FeSO4·7H2O+NaBH4 | CaCO3 | 75–89 | Spherical | SEM-EDX, XRD, TEM, FTIR, XPS, BET | [233] |

| nZVI-A and nZVI-S | FeCl3·6H2O+NaBH4 | Rhamnolipids | 60 and 42 | - | SEM, XRD, FTIR, TG, DLS, ζ-potential | [236] |

| FG-nZVI | FeSO4·7H2O+NaBH4 | Flaxseed gum extract | <100 | Spherical | DLS, FESEM, RDX, FTIR | [237] |

| nZVI | FeCl3·6H2O+NaBH4 | - | 20–60 | Uniform morphology | XRD, SEM, TEM | [238] |

| nZVI | FeSO4·7H2O+NaBH4 | - | 14.3 | - | XRD, SEM, TEM, FTIR | [239] |

| nZVI/GO | Fe (NO3)3·9H2O+NaBH4 | Graphene oxide | 10–20 | Dispersed | SEM, TEM-EDS, FTIR | [240] |

| nZVI-kaol/PES | FeCl3·6H2O+NaBH4 | Kaolin and poly-ethersulfone (PES) | 42 | Ridge and valley | XRD, FESEM, FTIR | [241] |

| NC-nZVI | FeCl3·6H2O+NaBH4 | Nanocelluloses (NC) | 116–200 | Spherical | SEM, TEM-EDX, FTIR, XRD, XPS | [242] |

| Fe@BC | Black liquor lignin and Fenton sludge in one step | Biochar | 20–50 | Notable aggregation | XRD, FTIR, BET, BJH, FESEM, TEM | [243] |

| MFO@nZVI | FeCl3·6H2O+NaBH4 | MnFe2O4 (MFO) hydrogel | - | Mass of spheroidal particles | XRD, SEM, FTIR, UV–vis DRS | [244] |

| CDLA@nZVI and CDCA@nZVI | FeCl3·6H2O+NaBH4 | β-cyclodextrin (CD): CDLA and CDCA | 25 and 30 | Amorphous | NMR, FTIR, HRTEM, DLS, ζ-potential, FESEM, EDAX, VSM, XRD, XPS, TGA | [245] |

| Fe3O4@nZVI-PEI | Fe3O4+FeSO4·7H2O+NaBH4 | Poly ethylenimine | - | - | SEM, TEM, FTIR, XRD, XPS | [246] |

| S-nZVI | FeSO4·7H2O+KBH4 | - | [247] | |||

| nZVI-LBC | FeCl3·6H2O+NaBH4 | Biochar | - | - | FTIR, XRD, TEM, XPS, VSM, BET, ζ-potential | [248] |

| nZVI/GAC | FeSO4·7H2O+NaBH4 | Granular activated carbon (GAC) | 40 | Spherical | SEM, BET, XRD | [249] |

| nZVI/GO | FeCl3·6H2O+NaBH4 | Graphene oxide (GO) | 4.97 | - | SEM-EDS, XRD, FTIR | [250] |

| nZVI/Sch-AP and nZVI/ Sch-CO | FeSO4·7H2O+NaBH4 | Schwermannite (Sch) | 50 | Spherical | SEM, XRD, BET, XPS | [251] |

| A400-nZVI | FeSO4·7H2O+NaBH4 | Polystyrenic gel (Purolite A400) | 75–150 | - | FTIR, SEM, EDAX, XRD, TGA | [252] |

| nZVI@ Zr(OH)4 | FeCl3·6H2O+NaBH4 | Zirconium hydroxide | - | - | TEM-EDS, XRD, BET, FTIR, XPS | [253] |

| pyGA-nZVI | FeCl3·6H2O+NaBH4 | Pyrogallic acid (pyGA) | 40–90 | Spherical | SEM, TEM-EDS, BET, ζ-potential, XRD, FTIR, XPS | [254] |

| Ox-nZVI | FeCl3·6H2O+NaBH4 | Oxalate | 30–40 | Spherical | BET, SEM-EDS, FTIR, XRD, XPS | [255] |

| nZVI 1 and nZVI 2 | FeSO4·7H2O+NaBH4 FeCl3·6H2O+NaBH4 | - | 72 and 38 | Spherical | SEM, TEM-EDS, XRD, BET, XPS, Raman spectroscopy | [256] |

| nZVI/ copper slag | FeCl3·6H2O+NaBH4 | Copper slag | 30 | - | FE-SEM, EDX, XRD, FTIR, BET, VSM, ζ-potential | [257] |

| WPANF/ nZVI | FeCl3·6H2O+NaBH4 | Polyacrylonitrile fiber (WPANF) | 15–50 | - | XRD, FTIR, BET, XPS, SEM-EDS, TEM | [258] |

| nZVI, ds-coated nZVI, and ds-FeS | FeSO4·7H2O+NaBH4 | - | 60.12 and 110 | Spherical | SEM, XRD, FTIR, ζ-potential, DLS | [259] |

| nZVI | Self-combustion of Fe2O3 and NaBH4 | - | 2–8 | Amorphous | XRD, HRTEM, EDS | [260] |

| nZVI | Laser fragmentation in liquids (LFL) ethylene glycol and polyethylene glycol 400 | - | 10.5 and below 3 | - | DLS, LDE, TEM, XPS | [261] |

| CS@BC/ S-nZVI | FeSO4·7H2O+NaBH4 | Chitosan and Biochar | - | - | SEM, BET, FTIR, XRD, XPS | [262] |

| 3D-RGO@nZVI/ Al2O3 | FeSO4·7H2O+NaBH4 | Reduced graphene oxide | <100 | Spherical | SEM, BET, Raman spectroscopy, XRD, XPS | [263] |

| nZVI/n-lignin | FeCl3·6H2O+NaBH4 | Lignin | - | - | TEM, XPS, XRD | [264] |

| BP-S-nZVI | FeCl3+NaBH4+sulfate- reducing bacteria (SRB) | - | - | - | FESEM, TEM, XRD, BET | [265] |

| nZVI-DE | FeCl2·4H2O+NaBH4 | Diatomaceous earth (DE) | 20–40 | Spherical | XRD, SEM, EDX, TEM, BET | [266] |

| CnZVI | FeSO4·7H2O+NaBH4 | - | 80–99 | Spherical | UV, FTIR, XRD, TEM | [267] |

| G-nZVI-BC and C-nZVI-BC | FeSO4·7H2O+NaBH4 | Biochar | - | - | SEM, XRD, FTIR, XRF | [268] |

| Iron oxide | FeCl3·6H2O+FeCl2·4H2O+ NaOH | - | 10 ± 4 | Regular crystalline | TEM | [269] |

| CS/nZVI | FeCl3+NaBH4 | Chitosan | 25 | Spherical | SEM, FTIR, XRD, EDX, VSM, BET, TGA, DSC | [270] |

| BC@nFe-CA | FeSO4·7H2O+NaBH4 | Biochar | - | - | SEM, EDS, FTIR, Raman spectroscopy, XRD, XPS | [271] |

| PDA@Fe/rGO | FeSO4·7H2O+NaBH4 | Reduced graphene oxide (rGO) and polydopamine (PDA) | 51 | - | TEM, XRD, FTIR, XPS, VSM | [272] |

| PDCA@nZVI | FeCl3+NaBH4 | 2,6-pyridinedicarboxylic acid, (PDCA) | 115 | Nanospheres | SEM, EDS, EDX, XRD, FTIR | [273] |

| nZVI | FeSO4·7H2O+NaBH4 | - | - | Spherical | SEM, TEM, BET | [274] |

| nZVI/BC | Pyrolysis (Fe2O3+biochar) | - | 200 | - | XRD, SEM | [275] |

| CMC-nZVI, bare-nZVI, PAA-nZVI, PSM-nZVI, PVP-nZVI | FeCl3+NaBH4 | CMC, PAA, PSM, PVP | 9.53, 65.4, 106.4, 106.6, and 109 | Spherical | SEM-EDX, XRD, FTIR, TEM | [276] |

| nZVI-HPB | FeCl3·6H2O+NaBH4 | Hydrophilic biochar | 52–243 | - | SEM, TEM, XRD, FTIR, XPS | [277] |

| nZVI | FeSO4·7H2O+NaBH4 | - | 20–60 | Spherical | BET, SEM EDX, BET, XRPD, XPS | [278] |

| nZVI/SBA-15 | FeCl3·6H2O+NaBH4 | Mesoporous silica (Santa Bárbara-15) | 50–80 | Spherical | SEM EDS, TEM, BET | [279] |

| nZVI | FeCl3·6H2O+NaBH4 | - | 36 | Regular and irregular | XRD, SEM, EDX, UV–vis | [280] |

| nZVI-chitosan | FeCl3·6H2O+NaBH4 | Chitosan | 15–20 | - | SEM, XRD, TEM, FTIR | [281] |

| nZVI | Bulk iron disks+ solvents+ laser | - | 9.4 and 3.5 | Spherical | TEM EDS, XPS | [282] |

| nZVI/RS | FeSO4·7H2O+NaBH4 | Biochar | - | - | FTIR, XRD, Raman spectra, BET | [283] |

| AHG@nZVI | FeSO4·7H2O+KBH4 | Aluminum hydroxide gel | - | Irregular and rough | SEM, FTIR, XPS, XRD | [284] |

| S-nZVI/GA | FeSO4·7H2O+NaBH4 | Graphene aerogel (GA) | - | Flake-like shell | TEM, SEM, BET, XRD, XPS, FTIR, Raman spectrum | [285] |

| nZVI and SnZVI | FeCl2·4H2O+ FeSO4·7H2O+NaBH4 | - | - | Cross-linked spherical | TEM EDX, XPS, XRD, XAS | [286] |

| Fe0@p-SiO2 | FeCl3·6H2O+KBH4 | SiO2 | 30–40 | - | TEM, XRD, XPS, ζ-potential | [287] |

| Fe/TRGO | Carbothermal GO+ Fe(NO3)3·9H2O | Graphene oxide | - | - | HRTEM, XRD, XPS, Fe Mössbauer spectroscopy | [288] |

| nZVI | FeCl2·4H2O+NaBH4 | - | - | Chain-like | FTIR, SEM, TEM, XRD, XPS | [289] |

| Fe@CQDs MNCs | FeCl3+NaBH4 | - | - | Smooth | FTIR, XRD, SEM, TEM | [290] |

| nZVI | FeCl3·6H2O+NaBH4 | - | - | Irregular and noncircular | XRD, TEM EDS, FESEM | [291] |

| Nanostructured nZVI | FeSO4·7H2O+NaBH4 | - | - | Rough | XRD, SEM, TEM, DLS | [292] |

5. Environmentally Friendly Methods for the Synthesis of nZVI

- Enhanced removal capacity and longevity: The presence of polyphenols in these extracts enhances their removal capabilities because bioactive compounds such as polyphenols have several benzene groups substituted by hydroxyl functional groups in their structure, so they can reduce metal ions to their elemental state, obtaining nanoparticles. They are also low cost or economically viable, reducing the consumption of organic compounds and the generation of toxic products.

- Environmentally friendly: This method is hailed as a potential environmentally friendly process, characterized by lower toxicity levels, the absence of aggressive reagents, and the generation of non-harmful by-products.

- Cost-effective: Many authors claim it might provide a low-cost alternative for nanoparticle synthesis.

- Inherent stabilization: The extract matrix often acts as a stabilizer, reducing nanoparticle agglomeration without requiring the addition of dispersants.

- Biomass valorization: The method offers potential for biomass valorization, further contributing to its sustainability.

| FeNPs | Precursor | Support | Size/nm | Morphology | Characterization | Reference |

|---|---|---|---|---|---|---|

| BC-nZVI-BC | Oak+FeCl3 | Biochar | 68–521 | Twister and serpentine | SEM, EDS, XRD, DLS | [230] |

| nZVI, ds-coated-nZVI+ds-FeS | Phoenix dactylifera +FeSO4·7H2O | - | Spherical | SEM, XRD, FTIR, ζ-potential, DLS | [259] | |

| GnZVI | Amaranthus dubius leaf extract+ FeSO4·7H2O | - | 1–3 | Spherical | UV, FTIR, XRD, TEM | [267] |

| G-nZVI-BC and C-nZVI-BC | Green tea residues+FeSO4·7H2O | - | - | - | SEM, XRD, FTIR, XRF | [268] |

| Iron oxide | Cymbopogon citratus extract+ FeCl3·6H2O+Na2CO3 | - | 9 ± 4 | Regular crystalline | TEM | [269] |

| nZVI | Azadirachta indica (neem) Mentha longifolia (mint) L.e.+FeCl3·6H2O | - | Spherical | SEM, TEM, BET | [274] | |

| GT-nZVI | Black tea+FeCl3·6H2O | - | 80 | Regular and irregular | XRD, SEM, EDX, UV–vis | [280] |

| Fe-NP-GV | Mansoa alliacea +FeSO4·7H2O | - | 18.22 | Spherical | XRD, UV–vis, AAS FTIR, TGA | [295] |

| nZVI | Shirazi thyme L.e.+FeSO4·7H2O/ Pistachio green hulls pomegranate/banana/ mango+FeCl3 black tea+ FeCl3·6H2O | - | 40–70 114, 76, 95 | - | - | [298] |

| nZVI | Green tea+ Fe (NO3)3·9H2O | - | 5–45 | Amorphous spherical | TEM, SEM/EDS, XRD, BET | [299] |

| AC/nZVI | Pomegranate peel extract+FeCl2 | Activated carbon | Crystalline | FTIR, XRD, BET, FESEM | [300] | |

| nZVI | Cleistocalyx operculatus L.s+FeCl3 | - | 100 | Spherical | SEM, XRD, FTIR | [301] |

| nZVI @gBC | Carbothermal (sawdust+FeCl3·6H2O) | Graphene | - | - | - | [302] |

| nZVI | Cleistocalyx operculatus L.s+FeCl3 | - | 100 | Spherical | SEM, XRD, FTIR | [303] |

| TP-nZVI/PE | Tea polyphenols | Polyethylene | - | Rough | SEM, TEM, ζ-potential, XRD, FTIR, XPS | [304] |

| Fe@C | Rice powder+ Fe (NO3)3·9H2O | Biomass- derived carbon | 30–150 | Irregular | XRD, FTIR, SEM, TEM, EDS | [305] |

| nZVI@GNPs | Cleistocalyx operculatus Leaf extract+ graphene NPs | Graphene nanoplatelets (GNPs) | 30–100 | Spherical | SEM, XRD, EDS, FTIR | [306] |

| G-nZVI | Ripe mango peels+FeCl3·6H2O | - | - | - | XRD, FTIR, TEM, BET, SEM-EDX | [307] |

| EGnZVI | Eucalyptus grandis+FeSO4·7H2O | - | 50–500 | Spherical | XRD, FTIR, Raman, SEM, TEM/EDS | [308] |

| G-nZVI/B | Green tea+ FeSO4·7H2O | Calcined bentonite | 8 30 | Irregular | BET, SEM, TEM, FTIR, XRD, XPS | [309] |

| nZVI | Corn+ FeCl3·6H2O | - | 150–300 | Spherical | SEM, TEM-EDS, XRD, XPS | [310] |

| EL-nZVI | Eucalyptus L.e.+FeSO4·7H2O | - | 87 | Spherical | SEM, FTIR | [311] |

| SnZVI@HPAC | Green tea+FeSO4·7H2O | - | - | - | SEM-EDS, TGA, FTIR, XRD | [312] |

| SC-nZVI | Green tea waste +FeCl3·6H2O | Silty clay | - | - | FTIR, SEM, XRD, BET, ζ-potential | [313] |

| nZVI/CF | Carbothermal (cotton fiber +Fe (NO3)3·9H2O) | Cotton carbon fiber | - | - | XRD, SEM, BET | [314] |

| nZVI @TP-Mont | Green tea+FeSO4·7H2O | Montmorillonite | 15–30 | Spherical | TEM, XRD, FTIR, SBET, XPS, ζ-potential | [315] |

| RCL-nZVI | Ricinus communis L.e.+FeCl3·6H2O | - | 4.84 25.6 | Irregular | SEM, TEM, FTIR, EDS, XRD, XPS, ζ-potential | [316] |

| B-BT-nZVI | Black tea+ FeCl3 | Bentonite | <50 | - | AFM, SEM, ζ-potential, BET | [317] |

| GT-nZVI@VC | Green tea+ Vit C+ FeSO4·7H2O | - | 100 | - | XRD, TEM, SEM, FTIR | [318] |

| nZVI | Pomegranate peel extract+ FeCl3·6H2O | - | 40–60 | Spherical | UV–visible, FTIR, SEM | [319] |

| k-nZVI | Ruellia tuberosa+FeCl3·6H2O | Kaolin | 20–40 | Spherical | XRD, SEM, TEM, EDS | [320] |

| R-FeNPs | Green tea+FeCl3·6H2O | Resin | 20–40 | Spherical | SEM, TEM, EDS | [321] |

| nZVI @Fe3O4 @HMIMPF6 | Camellia sinensis+ FeCl3·6H2O+ FeCl2·4H2O | Magnetite+ 1-hexyl-3-methylimidazolium hexafluorophosphate | 30 | Spherical | FTIR, XRD, VSM, BET, SEM, TEM | [322] |

| FeNPsJF | Jackfruit peel (JFP) extract+FeCl2 | - | 33 | Irregular spherical | FTIR, TEM, XRD, SEM, EDX | [323] |

| G-nZVI | Pomegranate fruit peel+FeCl3·6H2O | - | 60–75 | Spherical to cubical | UV–vis, XRD, TEM, SEM, DLS, ζ-potential | [324] |

| nZVI coupling with MR-1 | Green tea+ FeSO4·7H2O | Shewanella oneidensis MR-1 | - | - | SEM-EDS, XPS, FTIR, Raman, EEM | [325] |

| RC-nZVI | Ricinus communis seed extract+Fe3+ | - | 20 | Spherical | SEM, TEM, FTIR, XRS, EDS, XRD, XPS, ζ-potential | [326] |

| FeNPs | Denitrifying bacteria+ +FeCl3 | - | - | - | UV–vis, XPS, FTIR, TEM | [327] |

| AC/nZVI | Pomegranate peel extract+FeSO4·7H2O | Activated carbon | - | - | XRD, FTIR, FESEM | [328] |

| Zeolite/ nZVI | Pomegranate peel extract+FeCl2·4H2O | Zeolite | 30 | - | FTIR, FESEM, BET, XRF | [329] |

| BGT-nZVI | Green tea+FeCl3·6H2O | Bentonite | - | - | [330] | |

| PPAC-nZVI | Pomegranate peel extracts+FeCl2·4H2O | Activated carbon | 19–24 | - | FESEM, BET, FTIR | [331] |

| nZVI-RBC | Rice husk+FeSO4·7H2O Rice husk-derived biochar (RBC) | Rice husk-derived biochar (RBC) | 100 | - | SEM EDS, XRD, FTIR, BET, XPS | [332] |

| S-nZVI/AC | Ulva. prolifera+ FeCl2·4H2O | Algal carbon | - | Flower-like | SEM EDS, TEM, XRD, BET, XPS | [333] |

| Fe/N-OB | Carbothermal (hematite oak wood biochar) | - | - | XRD, XPS, SEM EDS, FTIR, BET | [334] | |

| GT-nZVI | Black tea+FeCl3·6H2O | - | 83 | Irregular | XRD, SEM, EDAX | [335] |

| n-ZVI-NPs | Mentha piperita+FeCl3 | - | 5–10 | Spherical | UV–vis, SEM-EDX, DLS | [336] |

| Fe0+ Fe1.91C0.09+ Fe3O4 | Neurospora crassa +urea+FeSO4 | - | 50 | - | SEM EDX, XRD, XPS, BET | [337] |

| TP-ZVI-OB | Green tea+FeCl3·6H2O | Oak wood biochar | - | - | BET, FTIR, SEM, EDS, XPS, XRD | [338] |

| F–Fe0 ads | Ficus sycomorus dry L.e.+FeCl3·6H2O | Wheat bran (B), rice bran (RB), activated charcoal (Ach), and bentonite (Bent) | 2.46–11.49 | Circular | UV–vis, HRTEM | [339] |

| NA-FeNPs | Nephrolepis auriculata+ FeCl3 | - | 40–70 | Spheroidal | TEM, XRD, EDS, XPS, FTIR | [340] |

| GMP-nZVI | Mango peel extract+FeCl3·6H2O | - | 1–10 | - | UV–vis, EDX, XRD, XPS, FTIR | [341] |

| DOX@GTCs-FeNPs | Green tea catechin powder+FeCl3·6H2O | 159 | TEM, UV–vis, AAS, | [342] | ||

| Micro/FeNPs | Mango, rose, Neem L.e. carom seeds, and clove buds+FeCl2·4H2O | Polyvinyl alcohol (PVP) | 75–6500 | Spherical or irregular | SEM, XRD, EDX, FTIR, UV–vis | [343] |

| Iron oxide | Eucalyptus L.e. +FeCl3·6H2O | Cetyltrimethylammonium bromide (CTA) | 80–90 | Spherical | XRD, EDS, FTIR, TGA | [344] |

| FeNPs | Eichhornia crassipes L.s +FeSO4·7H2O | - | - | Rod | UV–vis, SEM, TEMXRD, FTIR | [345] |

| Iron oxide | Cocos nucifera+FeCl3 | - | 10–100 | Clustered | UV–vis, TEM, XRD, XPS | [346] |

| FeNPs | Eucalyptus globulus, Mangifera indica, Syzygium cumini, Psidium guajava+FeCl3·6H2O | - | 38–47 | Irregular | UV–vis, FTIR, FESEM EDS, XRD | [347] |

| VI | Oak L.e.+FeCl3·6H2O | - | 20–100 | Irregular | TEM, EDS, XRD | [348] |

| Fe3O4NPs | Coriandrum sativum L.e. +FeCl3 | - | 20–90 | Spherical | UV–vis, FTIR, XRD SEM EDX | [349] |

| Iron oxide | Lantana camara fruit+FeSO4·7H2O+ FeCl3·6H2O | - | 28 | Spherical | FTIR, TGA, PSA, SEM EDAX, ζ-potential | [350] |

| Iron oxide | Lantana camara L.e.+FeSO4·7H2O | - | 10–20 | Nanorods | XRD, FTIR, SEMEDX, UV–vis | [351] |

| LGFeNPs | Eucalyptus L.e.+ laterite | - | 20–70 | Spherical | FESEM EDX, XRD, FTIR, BET | [352] |

| FeNPs | Eucalyptus L.e.+FeSO4·7H2O | - | 70 ± 20 | Spherical | SEM EDS, FTIRE, XRD, TEM, XPS, XRD, BET | [353] |

| Fe2O3@SiO2 | Zanthoxylum rhetsa +FeCl3·6H2O | SiO2 | 12.2 ± 0.8 | Cluster-like | FTIR, XRD, SEM EDX, HRTEM | [354] |

| SJA-FeNPs | Syzgium jambos +FeCl3 | - | 13.7 ± 5 | Spherical | UV–vis, TEM, XRD, XPS | [355] |

| nZVI | Vaccinium corymbosum +FeCl3·6H2O | - | 52.4 | Irregular | TEM, SEM, BET, XRD | [356] |

| Fe3O4@ZnO | Azadirachta indica(neem)+ FeSO4·7H2O+ Fe (NO3)3·9H2O | ZnO | 38 | Brick-like | XRD, FTIR, SEM EDX, TEM, TGA | [357] |

| Ec-Fe-NPs | Eichhornia crassipes+FeCl3 | - | 20–80 | Amorphous | SEM, EDS, TEM, XPS, FTIR, DLS, ζ-potential | [358] |

| FeNPS | Moringa oleifera+FeCl3 | - | 2.6–6.2 and 3.4–7.4 | Spherical | UV–vis, XRD, FTIR, TEM | [359] |

| Iron oxide | Black tea+FeSO4·7H2O | - | 5–50 | Amorphous | XRD, FTIR, SEM, TEM, EDS | [360] |

| nZVI | Green tea L.e.+FeCl3 | - | 116 | - | FTIR, SEM | [361] |

| FeNPs | Rosa damascene (RD), Thymus vulgaris (TV), and Urtica dioica (UD) +FeCl3·4H2O | - | 100 | Nonuniform | FTIR, SEM, TEM, XRD | [362] |

| FeNPs | Euphorbia cochinchensis +FeCl3 | - | 100 | Spherical | GMS, TEM, XPS, XRD, BET | [363] |

| FeNPs | Eucalyptus L.e. +FeSO4·7H2O | - | 20–80 | Polydisperse | SEM, XRD, XPS, FTIR | [364] |

| Iron oxide | Sapindus mukorossi +Fe(NO3)3·9H2O)+FeCl3 | - | <50 | Nanorods | XRD, FESEM, TEM | [365] |

| Iron oxide nanorods (IONRs) | Mangifera indica L.e. +FeSO4·7H2O | 3.0 ± 0.2 | Nanorods | FESEM, EDX, XRD, TEM | [366] | |

| FeNPS | Mangifera indica, Murraya koenigii, Azadiracta indica, Magnolia champaca +FeSO4·7H2O | AI (96–110), MC (99–129), MIAND MK (100–150) | Spherical | UV–vis, SEM-EDS-FTIR | [367] | |

| GT-Fe NPs and EL-Fe NPs | Eucalyptus L.e.+green tea L.e.+FeSO4·7H2O | 20–80 | Quasi-spherical | SEM, XRD, FTIR | [368] | |

| nZVIs | Waste from citrus juice (orange, lime, lemon and mandarin) +FeSO4·7H2O | 3–300 | Spherical, cylindrical, irregular | TEM, XRD, Mössbauer spectroscopy | [369] | |

| nZVI | Black tea, grape mark vine L.e. +FeCl3·6H2O | 15–45 | - | TEM | [370] | |

| (ZVI) NPs | Terminalia chebula+FeSO4·7H2O | <80 | Amorphous | TEM, XRD, UV–vis, FTIR | [371] | |

| nZVI | 26 tree leaf extracts+FeCl3 | 10–20 | Spherical | TEM | [372] |

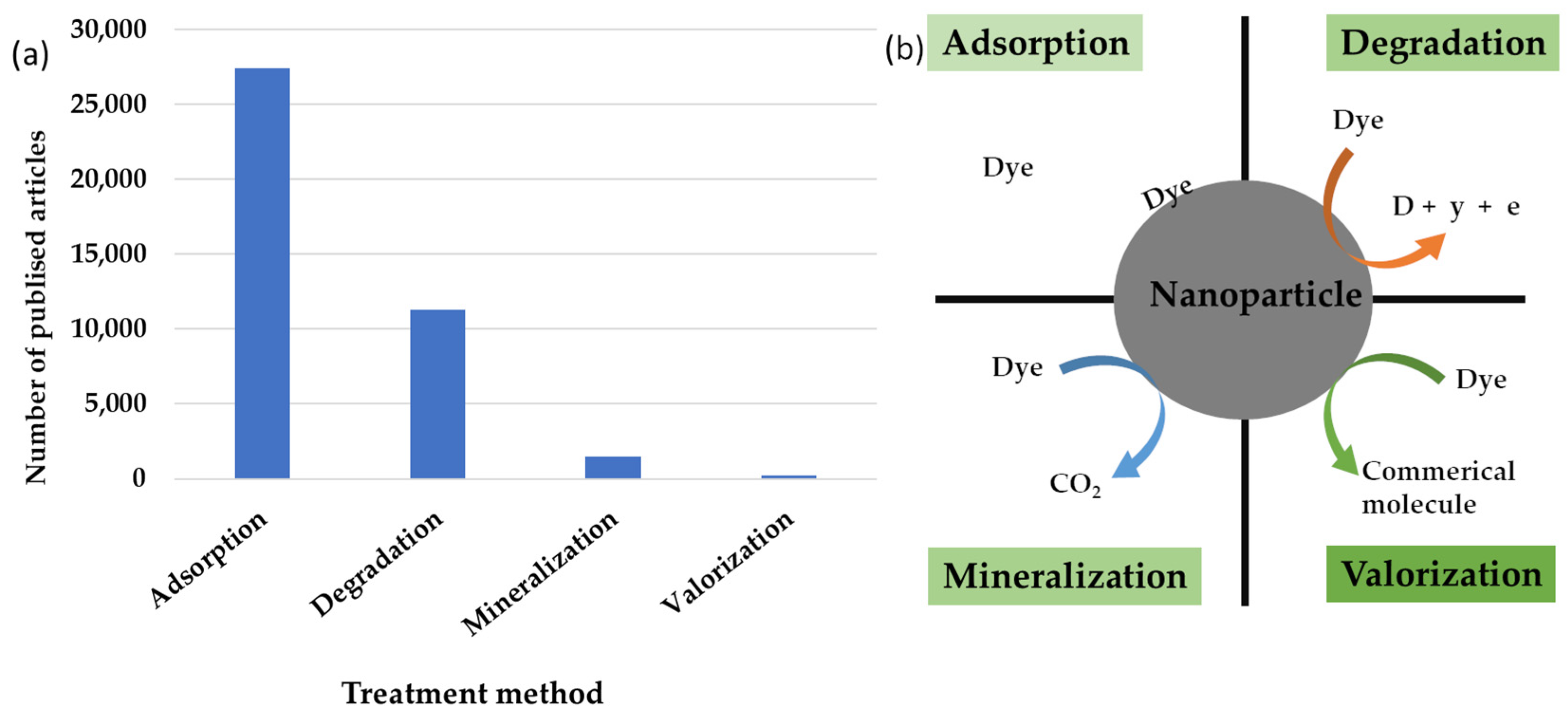

6. Dye Pollution in Wastewater and Current Removal Strategies

| NPs | Leaf Extract of Plant | Fe Source | Dye | Concentration (mgL−1) | Removal (%) | React. Time (min) | Reference |

|---|---|---|---|---|---|---|---|

| nZVI | Green tea | Fe (NO3)3∙9H2O | Malachite green | 50 | 93 | 60 | [294] |

| nZVI | Eucalyptus | FeCl3·6H2O | Acid black 194 | 100 | 80.5 | 200 | [296] |

| nZVI | Eucalyptus L.e. | FeSO4·7H2O | Crystal violet | 30 | 97.6 | 1800 | [311] |

| nZVI | Black tea | FeCl3·6H2O | Reactive blue 238 | 49.6 | 90.5 | 60 | [317] |

| nZVI | Ruellia tuberosa | FeCl3·6H2O | Reactive black 5 | 25–400 | 95.3–99.8 | 30 | [320] |

| nZVI | Artocarpus heterophyllus | FeCl3·6H2O | Fuchsin basic | 4 | 87.5 | 20 | [323] |

| nZVI | Ricinus communis | FeCl3·6H2O | Methylene blue | 25–200 | 96.8 | 160 | [326] |

| nZVI | Green tea | FeCl3·6H2O | Reactive blue 238 | 49.5 | 96.2 | 40 | [330] |

| nZVI | Mango peel | FeCl3·6H2O | Methyl orange | 100 | 94.23 | 60 | [341] |

| nZVI | Pomegranate L.e. | FeCl3·6H2O | Malachite green | 156 | 95 | 36 | [396] |

| nZVI | Vine L.e. | FeCl2·4H2O | Orange II | 100 | 80 | 120 | [398] |

| nZVI | Vine L.e. | FeCl2·4H2O | Orange II | 100 | 92 | 200 | [401] |

| nZVI | Tea | FeSO4·7H2O | Malachite green, methylene blue | 200 | 90.7, 90.75 | 30 | [402] |

| nZVI | Camellia sinensis tea | FeCl3·6H2O | Bromothymol blue | 500 | - | 60 | [403] |

| nZVI | Green tea | FeCl2·4H2O | Methylene blue, methyl orange | 50 | 360 | 80 | [404] |

| nZVI | Oolong tea | FeSO4·7H2O | Malachite green | 50 | 75.5 | - | [405] |

| nZVI | Ferula persica | FeSO4·7H2O | Crystal violet | 200 | 99.8 | 210 | [406] |

| nZVI | Catharanthus roseus | FeSO4·7H2O | Methyl orange | 50 | 50 | 360 | [407] |

| α-Fe2O3 | Phyllanthus niruri, Moringa stenopetala | FeCl3·6H2O | Methylene blue | 156 | 92–96 | 36 | [408] |

| nZVI | Chlorophytum comosum | FeCl3·6H2O | Methyl orange | 4 | 77 | 25 | [409] |

| nZVI | Parthenium | FeSO4·7H2O | Crystal violet | 120 | 95 | 30 | [410] |

| Fe3O4 | Thunbergia grandiflora | FeSO4·7H2O | Acid blue 113 | 25 | 94.38 | 210 | [411] |

| Fe2O3 | Raphanus sativus L.e. | FeCl3·6H2O | Methylene blue, methyl red | 100 | 100 | 60 | [412] |

| Fe2O3 | Fan palm, Dombeya wallichii, Pyrus communis | FeSO4·7H2O | Reactive blue | 200 | 94, 81, 88 | 210 | [413] |

| Fe3O4 | Jatropha curcas, Cinnamomum tamala | FeCl2·H2O+ FeCl3 | Methylene blue | 200 | 46.66 | 120 | [414] |

| Iron oxide | Artemisia vulgaris L.e. | FeCl3·6H2O | Methyl orange | 25 | 98.6 | 360 | [415] |

| Iron oxide | Daphne mezereum | FeCl3·6H2O | Methyl orange | 25 | 81 | 360 | [416] |

| Fe3O4 | Fraxinus sinensis Roxb | FeCl3·6H2O+ FeSO4·7H2O | Crystal violet | 4 | 98.57 | 25 | [417] |

| nCluster | Cupressus sempervirens | FeCl3·6H2O | Methyl orange | 25 | 95.8 | 360 | [418] |

| nZVI | Psidium guajava L.e. | FeCl3·6H2O | Methylene blue | 50 | 94 | 5 | [419] |

| nZVI | Hibiscus sabdariffa, roselle flower | FeCl3·6H2O | Rhodamine B | 17 | 100 | 5 | [420] |

| nZVI | Trigonella foenum-graecum | FeCl3·6H2O | Methyl orange | 25 | 95 | 90 | [421] |

| ZVI | Camellia sinensis and pomegranate L.e. | FeSO4·7H2O | Textile wastewater | 2.330 - | >95 pH 8.5 (Pt-Co) | 120 | [422] |

| Fe3O4 | Azolla filiculoides and fig. L.e. | FeCl3·6H2O+ FeSO4·4H2O | Crystal violet Methylene blue | 500 | 100 | 210 | [423] |

| Fe3O4 | Pissum sativum peel | FeCl3·6H2O | Methyl orange | 100 | 96.2 | 360 | [424] |

| nZVI | Eucalyptus | FeSO4·7H2O | Methyl orange | 10 | 99.6 | 180 | [425] |

| Iron oxide | Pomegranate L.e. | FeCl3·6H2O | Congo red | 100 | 93 | 60 | [426] |

| Ni-iron oxide | Moringa oleifera | FeCl3·6H2O + NiCl2·6H2O | Malachite green | 20 | ~91.6 | 25 | [427] |

| Fe3O4 | Green tea L.e. | FeCl3·6H2O+ FeSO4∙ 4H2O | Methylene blue | 3.5 | 95 | 16 | [428] |

| Pd-iron oxide | Pepper | Fe (NO3)3∙9H2O+ FeCl2·4H2O | Acid black, acid brown | 20.2 | 97.85 | 120 | [429] |

| Iron oxide | Cynometra ramiflora fruit | FeCl2·H2O+FeCl3 | Methylene blue | 20 | 100 | 110 | [430] |

| Iron oxide | Cynometra ramiflora | FeSO4·7H2O | Rhodamine B | 134 | 100 | 15 | [431] |

| Iron oxide | S. cumini | Ferrous oxalate | Reactive blue 235 | 10 | 98.75 | 240 | [432] |

| nZVI | Tea | FeSO4·7H2O | Methylene blue | 50 | 85.7, 34.4 | 5 | [433] |

| Fe3O4 | Ridge gourd peels | FeCl3·6H2O | Methylene blue | 120 | 96 | 30 | [434] |

| nZVI | Tieguanyin tea | FeCl3·6H2O | Bromothymol blue | 100 | >90 | 30 | [435] |

| nZVI | Green tea | FeCl3·6H2O | RBB-R, DR80 mixture | 250 | 90 | 20 | [436] |

| Fe3O4 | Maize cob | FeCl2·4H2O+ 2FeCl3·6H2O | Methylene blue | 156 | 99.63 | 36 | [437] |

| nZVI | Eucalyptus tereticornis, Melaleuca nesophila, Rosemarinus officinalis | FeSO4·7H2O | Acid black 194 | 100 | 100 | 200 | [438] |

| nZVI | Green tea, oolong tea, black tea | FeSO4·7H2O | Malachite green, methylene blue | 50 | 81.2, 75.6, 67.1 | 60 | [439] |

| nZVI | Aspalathus linearis | Acid mine drainage | Orange II | 50 | 94 | 30 | [440] |

| nZVI | Calotropis gigantea | Fe (NO3)3·9H2O | Methylene blue | 50–400 | 83.9 | 30 | [441] |

nZVI | Amaranthus dubius L.e. | FeCl3·6H2O | Methyl orange | 20 | 81 | 360 | [442] |

7. Future Perspectives and Challenges

- ▪

- Critical to note is the considerable variability in extracted biomolecules from plant extracts, constituting an unpredictable factor in green chemistry nanoparticle synthesis. The diverse nature of plants, encompassing distinct plant parts and geographical locales, complicates the prognostication of extracted biomolecules and their quantities. Moreover, not all biomolecules involved in nanoparticle synthesis are comprehensively understood. Controllable factors such as solvent, temperature, pH, precursor iron salts, and solution agitation profoundly influence nanoparticle growth, morphology, size, aggregation, coating, and stability within green chemistry procedures.

- ▪

- Furthermore, it is imperative to recognize the industrial implications of nanoparticle synthesis, necessitating large-scale production. Consequently, material supply assumes critical importance, with the agrifood industry wielding significant influence due to the pronounced variability influenced by geographical location and climate.

- ▪

- A standardized protocol is imperative for achieving greater reproducibility in nanoparticle synthesis concerning size and shape, thereby optimizing dye decontamination processes in the environment. Furthermore, the development of methodologies aimed at minimizing waste generation or enabling waste reuse is critical for fostering more sustainable processes. The extraction processes from agrifood industries entail significant solvent consumption, resulting in solid residues, necessitating a reduction in energy consumption. Analogous to numerous other fields, the reutilization and recycling of these by-product streams are pivotal for practical industrial implementation.

- ▪

- Regarding applications, substantial challenges persist. Ongoing efforts are directed towards exploring novel applications in diverse sectors such as food, textiles, healthcare, and construction, extending beyond environmental objectives.

- ▪

- In the realm of water purification, wastewater treatment plants are transitioning towards pollutant mineralization and biorefinery models, aiming to derive commercially viable products. Accordingly, pollutant removal processes must align with this philosophy and be seamlessly integrated into wastewater treatment plants. This mandates that new nanoparticles, acting as catalysts, should adsorb and convert pollutants into products that can be easily desorbed at low energy costs.

- ▪

- The authors underscore the potential for the wastewater industry to operate as a biorefinery, extracting commercial products from wastewater. However, these treatment methodologies are still nascent, as depicted in Figure 6.

- ▪

- It is noteworthy that a mere 242 articles, less than 0.001%, focus on dye recovery, with the majority concentrating on repurposing waste for dye treatment using alternative methods. Only a fraction of these articles address the recovery of solid waste from the textile industry [443,444]. Marazzi et al. [445] propose the use of algae for the treatment of dyes and their subsequent transformation into energy in biogas plants through anaerobic digestion.

- ▪

- Since clean, high-quality water is a valuable and essential commodity, and given that one of the main and most obvious parameters indicating water quality is its color, the application of iron nanoparticles as an available technology for dye removal is easy to use, cost-effective, and very efficient. The two main removal processes are adsorption and decolorization. This implies that studies should be directed to investigate the optimal conditions of these processes, such as the influence of the effects of initial dye concentration, pH, temperature, as well as nanoparticle size, morphology, and dosage, and to generate new general trends based on these studies.

- ▪

- A plethora of literature exists on environmentally friendly methods, often associated with biomass or bio-resources as feedstock sources. While these methodologies hold significant promise, presuming their environmental friendliness without thorough environmental impact assessments would be erroneous [446]. Thus, it is imperative to evaluate the environmental footprint of the chosen method to ensure its sustainability and assess its economic viability for industrialization. Furthermore, methods employing industrial chemical reagents can be rendered environmentally friendly provided energy consumption is minimized, and by-products or residues are recycled or integrated into a circular economy framework.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zaki, M.S.; Abou Zaid, A.A.; Abdelzaher, M.F.; Shalaby, S.I. Clinicopathological Changes in Fish Exposed to Pollutants. Life Sci. J. 2014, 11, 271–278. [Google Scholar]

- Dwivedi, S.; Shikha, D. Water Pollution: Causes, Effects and Control. Biochem. Cell Arch. 2016, 16, 96–102. [Google Scholar]

- Agoha, E.E.C. Crude Oil in Drinking Water: Chitosan Intervention. IFMBE Proc. 2019, 68, 741–743. [Google Scholar] [CrossRef]

- Larios-Meoño, J.F.; Morales, Y.; Gonzalez-Taranco, C.; Mougenot, B. Impact of Water Quality on the Economy and Health of Latin America: The Case of Peru and Colombia. In Proceedings of the 33rd International Business Information Management Association Conference, IBIMA 2019: Education Excellence and Innovation Management through Vision 2020, Granada, Spain, 10–11 April 2019; pp. 8960–8969. [Google Scholar]

- Gupta, J.K.; Shah, K.; Mishra, P. Inadmissible Planktons in Potable Water: A Potential Risk for Human Health. Curr. Sci. 2020, 119, 1627–1632. [Google Scholar] [CrossRef]

- Russ, J.; Zaveri, E.; Desbureaux, S.; Damania, R.; Rodella, A.-S. The Impact of Water Quality of GDP Growth: Evidence from around the World. Water Secur. 2022, 17, 100130. [Google Scholar] [CrossRef]

- du Plessis, A. Global Water Quality Challenges; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Das, J.; Sarkar, S.; Saha, K.; Roy, S.; Nag, S. Emerging Environmental Contaminants: Sources, Consequences, and Future Challenges. In Bioremediation Technologies: For Wastewater and Sustainable Circular Bioeconomy; Walter de Gruyter: Berlin, Germany, 2023; ISBN 978-3-11101-682-5. [Google Scholar] [CrossRef]

- Snyder, S.A.; Anumol, T. Emerging Chemical Contaminants: How Chemical Development Outpaces Impact Assessment. In Still Only One Earth: Progress in the 40 Years Since the First UN Conference on the Environment; Royal Society of Chemistry: London, UK, 2015; Volume 2015, ISBN 978-1-78262-076-1. [Google Scholar] [CrossRef]

- Stefanakis, A.I.; Becker, J.A. A Review of Emerging Contaminants in Water: Classification, Sources, and Potential Risks. In Impact of Water Pollution on Human Health and Environmental Sustainability; IGI Global: Pennsylvania, PA, USA, 2019; ISBN 978-1-79981-211-1. [Google Scholar] [CrossRef]

- Sivasubramaniyan, S.G.; Kandasamy, S.; Manickam, N.K. Biotechnological Approaches for Removal of Emerging Contaminants. In Biotechnology for Zero Waste: Emerging Waste Management Techniques; Wiley: Hoboken, NJ, USA, 2021; ISBN 978-3-52783-206-4. [Google Scholar] [CrossRef]

- Khan, S.; Naushad, M.; Govarthanan, M.; Iqbal, J.; Alfadul, S.M. Emerging Contaminants of High Concern for the Environment: Current Trends and Future Research. Environ. Res. 2022, 207, 112609. [Google Scholar] [CrossRef]

- Ngeno, E.; Shikuku, V.O. Emerging Contaminants: Pollution Control and Abatement. In Research Anthology on Emerging Techniques in Environmental Remediation; IGI Global: Pennsylvania, PA, USA, 2022; Volume 2, ISBN 978-1-66843-886-2. [Google Scholar] [CrossRef]

- Lofrano, G.; Sacco, O.; Venditto, V.; Carotenuto, M.; Libralato, G.; Guida, M.; Meric, S.; Vaiano, V. Occurrence and Potential Risks of Emerging Contaminants in Water. In Visible Light Active Structured Photocatalysts for the Removal of Emerging Contaminants; Elsevier: Amsterdam, The Netherlands, 2020; ISBN 978-0-12818-334-2. [Google Scholar] [CrossRef]

- Morin-Crini, N.; Lichtfouse, E.; Liu, G.; Balaram, V.; Ribeiro, A.R.L.; Lu, Z.; Stock, F.; Carmona, E.; Teixeira, M.R.; Picos-Corrales, L.A.; et al. Worldwide Cases of Water Pollution by Emerging Contaminants: A Review. Environ. Chem. Lett. 2022, 20, 2311–2338. [Google Scholar] [CrossRef]

- Sauvé, S.; Desrosiers, M. A Review of What Is an Emerging Contaminant. Chem. Cent. J. 2014, 8, 15. [Google Scholar] [CrossRef]

- Noguera-Oviedo, K.; Aga, D.S. Lessons Learned from More than Two Decades of Research on Emerging Contaminants in the Environment. J. Hazard. Mater. 2016, 316, 242–251. [Google Scholar] [CrossRef] [PubMed]

- Lellis, B.; Fávaro-Polonio, C.Z.; Pamphile, J.A.; Polonio, J.C. Effects of Textile Dyes on Health and the Environment and Bioremediation Potential of Living Organisms. Biotechnol. Res. Innov. 2019, 3, 275–290. [Google Scholar] [CrossRef]

- Tkaczyk, A.; Mitrowska, K.; Posyniak, A. Synthetic Organic Dyes as Contaminants of the Aquatic Environment and Their Implications for Ecosystems: A Review. Sci. Total Environ. 2020, 717, 137222. [Google Scholar] [CrossRef]

- Jankowska, A.; Ejsmont, A.; Galarda, A.; Goscianska, J. The Outcome of Human Exposure to Environmental Contaminants. Importance of Water and Air Purification Processes. In Sustainable Materials for Sensing and Remediation of Noxious Pollutants; Elsevier: Amsterdam, The Netherlands, 2022; ISBN 978-0-32399-425-5. [Google Scholar] [CrossRef]

- Rahman, M.; Tabassum, Z. Biotechnological Approach to Treat Textile Dyeing Effluents: A Critical Review Analysing the Practical Applications. Text. Leather Rev. 2024, 7, 124–152. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Q.; Zhang, T.; Liu, S.; Ho, S.S.H.; Tian, J.; Su, H.; Zhang, Y.; Wang, L.; Wu, T.; et al. Elaborations of the Influencing Factors on the Formation of Secondary Inorganic Aerosols in a Heavily Polluted Urban Area of China. J. Environ. Sci. 2024, 138, 406–417. [Google Scholar] [CrossRef]

- Bai, Y.; Lin, H.; Wang, C.; Wang, Q.; Qu, J. Digitalizing River Aquatic Ecosystems. J. Environ. Sci. 2024, 137, 677–680. [Google Scholar] [CrossRef]

- Brown, A.M.; Bass, A.M.; Skiba, U.; MacDonald, J.M.; Pickard, A.E. Urban Landscapes and Legacy Industry Provide Hotspots for Riverine Greenhouse Gases: A Source-to-Sea Study of the River Clyde. Water Res. 2023, 236, 119969. [Google Scholar] [CrossRef]

- Wei, Z.; Wei, Y.; Liu, Y.; Niu, S.; Xu, Y.; Park, J.-H.; Wang, J.J. Biochar-Based Materials as Remediation Strategy in Petroleum Hydrocarbon-Contaminated Soil and Water: Performances, Mechanisms, and Environmental Impact. J. Environ. Sci. 2024, 138, 350–372. [Google Scholar] [CrossRef]

- Shi, C.; Liu, Z.; Yu, B.; Zhang, Y.; Yang, H.; Han, Y.; Wang, B.; Liu, Z.; Zhang, H. Emergence of Nanoplastics in the Aquatic Environment and Possible Impacts on Aquatic Organisms. Sci. Total Environ. 2024, 906, 167404. [Google Scholar] [CrossRef]

- Castaño-Ortiz, J.; Gil-Solsona, R.; Ospina-Álvarez, N.; Alcaraz-Hernández, J.; Farré, M.; León, V.; Barceló, D.; Santos, L.; Rodríguez-Mozaz, S. Fate of Pharmaceuticals in the Ebro River Delta Region: The Combined Evaluation of Water, Sediment, Plastic Litter, and Biomonitoring. Sci. Total Environ. 2024, 906, 167467. [Google Scholar] [CrossRef]

- Khezami, F.; Gómez-Navarro, O.; Barbieri, M.V.; Khiari, N.; Chkirbene, A.; Chiron, S.; Khadhar, S.; Pérez, S. Occurrence of Contaminants of Emerging Concern and Pesticides and Relative Risk Assessment in Tunisian Groundwater. Sci. Total Environ. 2024, 906, 167319. [Google Scholar] [CrossRef]

- Hung, V.Q.; Egodawatta, P.; Gallage, C.; Dawes, L.; Nguyen-Xuan, T.; Nguyen-Viet, T.; Bui-Tien, T.; Nguyen-Quang, T.; De Roeck, G. Leaching Mechanism of Metals from Recycled Concrete Aggregates (RCA) and Potentially Environmental Issues. In Proceedings of the 4th International Conference on Sustainability in Civil Engineering, Hanoi, Vietnam, 25–27 November 2024; Volume 344, ISBN 978-981-99-2344-1. [Google Scholar] [CrossRef]

- Tudor, V.C.; Stoicea, P.; Chiurciu, I.-A.; Soare, E.; Iorga, A.M.; Dinu, T.A.; David, L.; Micu, M.M.; Smedescu, D.I.; Dumitru, E.A. The Use of Fertilizers and Pesticides in Wheat Production in the Main European Countries. Sustainability 2023, 15, 3038. [Google Scholar] [CrossRef]

- Bukomeko, H.; Taulya, G.; Schut, A.G.T.; van de Ven, G.W.J.; Kubiriba, J.; Giller, K. Evaluating Combined Effects of Pesticide and Crop Nutrition (with N, P, K and Si) on Weevil Damage in East African Highland Bananas. PLoS ONE 2023, 18, e0282493. [Google Scholar] [CrossRef] [PubMed]

- Mir, A.A.; Ahad, U.; Inayatullah, M.; Ali, U.; Ahmed, P. Evaluation of Water Quality Status of Pohru Watershed, Kashmir Valley, Jammu and Kashmir, India. Water Air Soil Pollut. 2023, 234, 154. [Google Scholar] [CrossRef]

- Holkar, C.R.; Jadhav, A.J.; Pinjari, D.V.; Mahamuni, N.M.; Pandit, A.B. A Critical Review on Textile Wastewater Treatments: Possible Approaches. J. Environ. Manage. 2016, 182, 351–366. [Google Scholar] [CrossRef] [PubMed]

- Anandita; Raees, K.; Shahadat, M.; Ali, S.W. Mechanistic Interaction of Microbe in Dye Degradation and the Role of Inherently Modified Organisms: A Review. Water Conserv. Sci. Eng. 2023, 8, 43. [Google Scholar] [CrossRef]

- Boretti, A.; Rosa, L. Reassessing the Projections of the World Water Development Report. NPJ Clean Water 2019, 2, 15. [Google Scholar] [CrossRef]

- Pokrajac, L.; Abbas, A.; Chrzanowski, W.; Dias, G.M.; Eggleton, B.J.; Maguire, S.; Maine, E.; Malloy, T.; Nathwani, J.; Nazar, L.; et al. Nanotechnology for a Sustainable Future: Addressing Global Challenges with the International Network4Sustainable Nanotechnology. ACS Nano 2021, 15, 18608–18623. [Google Scholar] [CrossRef] [PubMed]

- Saleh, H.M.; Hassan, A.I. Synthesis and Characterization of Nanomaterials for Application in Cost-Effective Electrochemical Devices. Sustainability 2023, 15, 10891. [Google Scholar] [CrossRef]

- Li, L.; Hu, J.; Shi, X.; Fan, M.; Luo, J.; Wei, X. Nanoscale Zero-Valent Metals: A Review of Synthesis, Characterization, and Applications to Environmental Remediation. Environ. Sci. Pollut. Res. 2016, 23, 17880–17900. [Google Scholar] [CrossRef] [PubMed]

- Crane, R.A.; Scott, T.B. Nanoscale Zero-Valent Iron: Future Prospects for an Emerging Water Treatment Technology. J. Hazard. Mater. 2012, 211–212, 112–125. [Google Scholar] [CrossRef]

- Malik, S.; Muhammad, K.; Waheed, Y. Nanotechnology: A Revolution in Modern Industry. Molecules 2023, 28, 661. [Google Scholar] [CrossRef]

- Hasirci, V.; Vrana, E.; Zorlutuna, P.; Ndreu, A.; Yilgor, P.; Basmanav, F.B.; Aydin, E. Nanobiomaterials: A Review of the Existing Science and Technology, and New Approaches. J. Biomater. Sci. 2006, 17, 1241–1268. [Google Scholar] [CrossRef]

- Khin, M.M.; Nair, A.S.; Babu, V.J.; Murugan, R.; Ramakrishna, S. A Review on Nanomaterials for Environmental Remediation. Energy Environ. Sci. 2012, 5, 8075–8109. [Google Scholar] [CrossRef]

- Mi, J.L.; Nørby, P.; Bremholm, M.; Becker, J.; Iversen, B.B. The Formation Mechanism of Bimetallic PtRu Alloy Nanoparticles in Solvothermal Synthesis. Nanoscale 2015, 7, 16170–16174. [Google Scholar] [CrossRef] [PubMed]

- Veronico, L.; Gentile, L. Removal of Pollutants by Ferrihydrite Nanoparticles Combined with Brij L4 Self-Assembled Nanostructures. ACS Appl. Nano Mater. 2023, 6, 720–728. [Google Scholar] [CrossRef]

- Ganesan, S.; Lakshmisankar, S.; Deepak, S.; Selvakumar, M.; Venkatesan, S.P.; Hemanandh, J. Environmental Impact of One-Step Hydrothermal Green Synthesized ZnO Nanoparticles in DI Diesel Engine Performance Analysis Using Duel Fuel. Nanotechnol. Environ. Eng. 2023, 8, 361–375. [Google Scholar] [CrossRef]

- Muraro, P.C.L.; Wouters, R.D.; Pavoski, G.; Espinosa, D.C.R.; Ruiz, Y.P.M.; Galembeck, A.; Rech, V.C.; da Silva, W.L. Ag/TiNPS Nanocatalyst: Biosynthesis, Characterization and Photocatalytic Activity. J. Photochem. Photobiol. A Chem. 2023, 439, 114598. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, Applications and Toxicities. Arab. J. Chem. 2019, 12, 908–931. [Google Scholar] [CrossRef]

- Guerra, F.D.; Attia, M.F.; Whitehead, D.C.; Alexis, F. Nanotechnology for Environmental Remediation: Materials and Applications. Molecules 2018, 23, 1760. [Google Scholar] [CrossRef] [PubMed]

- Westerhoff, P.; Song, G.; Hristovski, K.; Kiser, M.A. Occurrence and Removal of Titanium at Full Scale Wastewater Treatment Plants: Implications for TiO2 Nanomaterials. J. Environ. Monit. 2011, 13, 1195–1203. [Google Scholar] [CrossRef] [PubMed]

- Batley, G.E.; Kirby, J.K.; McLaughlin, M.J. Fate and Risks of Nanomaterials in Aquatic and Terrestrial Environments. Acc. Chem. Res. 2013, 46, 854–862. [Google Scholar] [CrossRef]

- Gallocchio, F.; Biancotto, G.; Moressa, A.; Pascoli, F.; Pretto, T.; Toffan, A.; Arcangeli, G.; Montesi, F.; Peters, R.; Ricci, A. Bioaccumulation and in Vivo Formation of Titanium Dioxide Nanoparticles in Edible Mussels. Food Chem. 2020, 323, 126841. [Google Scholar] [CrossRef] [PubMed]

- Baig, N.; Kammakakam, I.; Falath, W. Nanomaterials: A Review of Synthesis Methods, Properties, Recent Progress, and Challenges. Mater. Adv. 2021, 2, 1821–1871. [Google Scholar] [CrossRef]

- Khanna, P.; Kaur, A.; Goyal, D. Algae-Based Metallic Nanoparticles: Synthesis, Characterization and Applications. J. Microbiol. Methods 2019, 163, 105656. [Google Scholar] [CrossRef] [PubMed]

- Kumar, J.A.; Krithiga, T.; Manigandan, S.; Sathish, S.; Renita, A.A.; Prakash, P.; Prasad, B.S.N.; Kumar, T.R.P.; Rajasimman, M.; Hosseini-Bandegharaei, A.; et al. A Focus to Green Synthesis of Metal/Metal Based Oxide Nanoparticles: Various Mechanisms and Applications towards Ecological Approach. J. Clean. Prod. 2021, 324, 129198. [Google Scholar] [CrossRef]

- Alzahrani, H.A.H.; Almulaiky, Y.Q.; Alsaiari, A.O. The Photocatalytic Dye Degradation of Methylene Blue (MB) by Nanostructured ZnO under UV Irradiation. Phys. Scr. 2023, 98, 045703. [Google Scholar] [CrossRef]

- Soleimani-Gorgani, A.; Al-Sabahi, J.; Nejad, S.A.T.; Heydari, M.; Al-Abri, M.; Namaeighasemi, A. Visible-Light-Driven Super-Active Sn and GO Single- and Sn/Cu Co-Doped Nanophotocatalysts for Phenol Degradation: Thin-Film Printability, Thermal Stability, and Cytotoxicity Assay. J. Ind. Eng. Chem. 2023, 120, 514–528. [Google Scholar] [CrossRef]

- Hamad, M.T.M.H.; El-Sesy, M.E. Adsorptive Removal of Levofloxacin and Antibiotic Resistance Genes from Hospital Wastewater by Nano-Zero-Valent Iron and Nano-Copper Using Kinetic Studies and Response Surface Methodology. Bioresour. Bioprocess. 2023, 10, 1. [Google Scholar] [CrossRef] [PubMed]

- Ranjith, R.; Vignesh, S.; Balachandar, R.; Suganthi, S.; Raj, V.; Ramasundaram, S.; Kalyana Sundar, J.; Shkir, M.; Oh, T.H. Construction of Novel G-C3N4 Coupled Efficient Bi2O3 Nanoparticles for Improved Z-Scheme Photocatalytic Removal of Environmental Wastewater Contaminant: Insight Mechanism. J. Environ. Manag. 2023, 330, 117134. [Google Scholar] [CrossRef] [PubMed]

- Manikandan, V.; Anushkkaran, P.; Hwang, I.S.; Chae, W.S.; Lee, H.H.; Choi, S.H.; Mahadik, M.A.; Jang, J.S. Synergistic Role of In-Situ Zr-Doping and Cobalt Oxide Cocatalysts on Photocatalytic Bacterial Inactivation and Organic Pollutants Removal over Template-Free Fe2O3 Nanorods. Chemosphere 2023, 310, 136825. [Google Scholar] [CrossRef]

- Choi, C.J.; Dong, X.L.; Kim, B.K. Characterization of Fe and Co Nanoparticles Synthesized by Chemical Vapor Condensation. Scr. Mater. 2001, 44, 2225–2229. [Google Scholar] [CrossRef]

- Sun, H.; Zhou, G.; Liu, S.; Ang, H.M.; Tadé, M.O.; Wang, S. Nano-Fe0 Encapsulated in Microcarbon Spheres: Synthesis, Characterization, and Environmental Applications. ACS Appl. Mater. Interfaces 2012, 4, 6235–6241. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Chen, C.; Zhu, K.; Wang, X. Nanoscale Zero-Valent Iron Particles Modified on Reduced Graphene Oxides Using a Plasma Technique for Cd(II) Removal. J. Taiwan. Inst. Chem. Eng. 2016, 59, 389–394. [Google Scholar] [CrossRef]

- Amerhaider Nuar, N.N.; Siti Nurul, S.N.A.; Choong, T.S.Y.; Mat Azmi, I.D.; Abdul Romli, N.A.; Abdullah, L.C.; Chiang, P.C.; Li, F. Synthesis of Calcium Peroxide Nanoparticles with Starch as a Stabilizer for the Degradation of Organic Dye in an Aqueous Solution. Polymers 2023, 15, 1327. [Google Scholar] [CrossRef] [PubMed]

- Vijayan, M.; Manikandan, V.; Rajkumar, C.; Hatamleh, A.A.; Alnafisi, B.K.; Easwaran, G.; Liu, X.; Sivakumar, K.; Kim, H. Constructing Z-Scheme g-C3N4/TiO2 Heterostructure for Promoting Degradation of the Hazardous Dye Pollutants. Chemosphere 2023, 311, 136928. [Google Scholar] [CrossRef] [PubMed]

- Xia, Q.; Jiang, Z.; Wang, J.; Yao, Z. A Facile Preparation of Hierarchical Dendritic Zero-Valent Iron for Fenton-like Degradation of Phenol. Catal. Commun. 2017, 100, 57–61. [Google Scholar] [CrossRef]

- El-Sheekh, M.; Elshobary, M.; Abdullah, E.; Abdel-Basset, R.; Metwally, M. Application of a Novel Biological-Nanoparticle Pretreatment to Oscillatoria Acuminata Biomass and Coculture Dark Fermentation for Improving Hydrogen Production. Microb. Cell Fact. 2023, 22, 34. [Google Scholar] [CrossRef] [PubMed]

- Ribas, D.; Pešková, K.; Jubany, I.; Parma, P.; Černik, M.; Benito, J.A.; Martí, V. High Reactive Nano Zero-Valent Iron Produced via Wet Milling through Abrasion by Alumina. Chem. Eng. J. 2019, 366, 235–245. [Google Scholar] [CrossRef]

- Stefaniuk, M.; Oleszczuk, P.; Ok, Y.S. Review on Nano Zerovalent Iron (NZVI): From Synthesis to Environmental Applications. Chem. Eng. J. 2016, 287, 618–632. [Google Scholar] [CrossRef]

- Li, J.; Zhang, S.; Gui, S.; Chen, G.; Wang, Y.; Wang, Z.; Zheng, X.; Meng, S.; Ruan, C.; Chen, S. Photothermal Synergistic Engineering of CeO2 and Au Co-Modified VO2 for Efficient and Selective Oxidation of Aromatic Alcohols. Appl. Surf. Sci. 2023, 611, 155616. [Google Scholar] [CrossRef]

- Li, W.W.; Cheng, L.; Liu, J.; Yang, S.Y.; Zan, S.T.; Zhao, G.C. Recyclable Magnetic Fe3O4@C for Methylene Blue Removal under Microwave-Induced Reaction System. Chemosphere 2023, 310, 136821. [Google Scholar] [CrossRef]

- Shi, X.; Li, L.; Cao, W.; Xuan, X.; Zheng, J.; Wang, C. Piezoelectric Assisted Photocatalytic Degradation of Dyes by Plasmon Ag Nanoparticles Modified Na0.5Bi0.5TiO3 Nanospheres. Mater. Lett. 2023, 335, 133827. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Song, Y.; Xu, X.; Cai, M.; Li, P.; Yuan, W.; Xiahou, Y. Functionalized Agarose Hydrogel with in Situ Ag Nanoparticles as Highly Recyclable Heterogeneous Catalyst for Aromatic Organic Pollutants. Environ. Sci. Pollut. Res. 2023, 30, 43950–43961. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Fang, K.; Liu, X.; Qiao, X.; Wang, J. Simplified and Efficient Inkjet Printing of Cotton Fabrics Using Cationic Colored Nanoparticles. Ind. Crops Prod. 2023, 193, 116217. [Google Scholar] [CrossRef]

- Zahid, M.; Segar, A.S.M.; Al-Majmaie, S.; Shather, A.H.; Khan, M.F.; Alguno, A.C.; Capangpangan, R.Y.; Ismail, A. Elettaria Cardamomum Seed Extract Synthesized Silver Nanoparticles for Efficient Catalytic Reduction of Toxic Dyes. Environ. Nanotechnol. Monit. Manag. 2023, 20, 100809. [Google Scholar] [CrossRef]

- Pandey, K.; Saha, S. Encapsulation of Zero Valent Iron Nanoparticles in Biodegradable Amphiphilic Janus Particles for Groundwater Remediation. J. Hazard. Mater. 2023, 445, 130501. [Google Scholar] [CrossRef] [PubMed]

- Rajesh, G.; Kumar, P.S.; Akilandeswari, S.; Rangasamy, G.; Mandal, A.; Shankar, V.U.; Ramya, M.; Nirmala, K.; Thirumalai, K. A Synergistic Consequence of Catalyst Dosage, PH Solution and Reactive Species of Fe-Doped CdAl2O4 Nanoparticles on the Degradation of Toxic Environmental Pollutants. Chemosphere 2023, 318, 137919. [Google Scholar] [CrossRef] [PubMed]

- Waheed, I.F.; Hamad, M.A.; Jasim, K.A.; Gesquiere, A.J. Degradation of Methylene Blue Using a Novel Magnetic CuNiFe2O4/g-C3N4 Nanocomposite as Heterojunction Photocatalyst. Diam. Relat. Mater. 2023, 133, 109716. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, B.; He, Y.; Sun, L.; Hou, P.; Gan, Z.; Yu, L.; Dong, L. Design and Synthesis of Black Phosphorus Quantum Dot Sensitized Inverse Opal TiO2 Photonic Crystal with Outstanding Photocatalytic Activities. Appl. Surf. Sci. 2023, 609, 155442. [Google Scholar] [CrossRef]

- Zheng, C.; Song, X.; Gan, Q.; Lin, J. High-Efficiency Removal of Organic Pollutants by Visible-Light-Driven Tubular Heterogeneous Micromotors through a Photocatalytic Fenton Process. J. Colloid. Interface Sci. 2023, 630, 121–133. [Google Scholar] [CrossRef]

- Gadge, S.; Tamboli, A.; Shinde, M.; Fouad, H.; Terashima, C.; Chauhan, R.; Gosavi, S. Sonocatalytic Degradation of Methylene Blue Using Spindle Shaped Cerium Oxide Nanoparticles. J. Solid. State Electrochem. 2023, 27, 2005–2015. [Google Scholar] [CrossRef]

- Al-Arjan, W.S. Self-Assembled Nanofibrous Membranes by Electrospinning as Efficient Dye Photocatalysts for Wastewater Treatment. Polymers 2023, 15, 340. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Dong, S.; Hu, H.; He, Z.; Dong, F.; Tang, J.; Lu, X.; Wang, L.; Song, S.; Ma, J. Catalytic Ozonation of Atrazine with Stable Boron-Doped Graphene Nanoparticles Derived from Waste Polyvinyl Alcohol Film: Performance and Mechanism. Chem. Eng. J. 2023, 455, 140316. [Google Scholar] [CrossRef]

- Liu, B.; Wang, S.; Wang, H.; Wang, Y.; Xiao, Y.; Cheng, Y. Quaternary Ammonium Groups Modified Magnetic Cyclodextrin Polymers for Highly Efficient Dye Removal and Sterilization in Water Purification. Molecules 2023, 28, 167. [Google Scholar] [CrossRef] [PubMed]

- Akbarzadeh, A.; Khazani, Y.; Khaloo, S.S.; Ghalkhani, M. Highly Effectual Photocatalytic Degradation of Tartrazine by Using Ag Nanoparticles Decorated on Zn-Cu-Cr Layered Double Hydroxide@ 2D Graphitic Carbon Nitride (C3N5). Environ. Sci. Pollut. Res. 2023, 30, 12903–12915. [Google Scholar] [CrossRef] [PubMed]

- Cheng, A.; He, Y.; Liu, X.; He, C. Honeycomb-like Biochar Framework Coupled with Fe3O4/FeS Nanoparticles as Efficient Heterogeneous Fenton Catalyst for Phenol Degradation. J. Environ. Sci. 2024, 136, 390–399. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Ming, F.; Wang, J.; Xu, L. Amino Acids Modified Nanoscale Zero-Valent Iron: Density Functional Theory Calculations, Experimental Synthesis and Application in the Fenton-like Degradation of Organic Solvents. J. Environ. Sci. 2024, 135, 296–309. [Google Scholar] [CrossRef] [PubMed]

- Xing, J.; Qi, Z.; Dong, W.; Chen, Q.; Wu, M.; Yi, P.; Pan, B.; Xing, B. Aggregation of Biochar Nanoparticles and the Impact on Bisphenol A Sorption: Experiments and Molecular Dynamics Simulations. Sci. Total Environ. 2023, 875, 162724. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Feng, L. A Carbon Based-Screen-Printed Electrode Amplified with Two-Dimensional Reduced Graphene/Fe3O4 Nanocomposite as Electroanalytical Sensor for Monitoring 4-Aminophenol in Environmental Fluids. Chemosphere 2023, 323, 138238. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Cui, J.; Wang, Y.; Jia, J. An Ultrasensitive Electrochemical Biosensor for Bisphenol A Based on Aptamer-Modified MrGO@AuNPs and SsDNA-Functionalized AuNP@MBs Synergistic Amplification. Chemosphere 2023, 311, 137154. [Google Scholar] [CrossRef]

- Naderi, A.; Hasham Firooz, M.; Gharibzadeh, F.; Giannakis, S.; Ahmadi, M.; Rezaei Kalantary, R.; Kakavandi, B. Anchoring ZnO on Spinel Cobalt Ferrite for Highly Synergic Sono-Photo-Catalytic, Surfactant-Assisted PAH Degradation from Soil Washing Solutions. J. Environ. Manag. 2023, 326, 116584. [Google Scholar] [CrossRef]

- Li, S.; Feng, D.; Liu, J.; Liu, Q.; Tang, J. Surfactant-Enhanced Reduction of Soil-Adsorbed Nitrobenzene by Carbon-Coated NZVI: Enhanced Desorption and Mechanism. Sci. Total Environ. 2023, 856, 159186. [Google Scholar] [CrossRef] [PubMed]

- Priyadarshini, I.; Chowdhury, A.; Rao, A.; Roy, B.; Chattopadhyay, P. Assessment of Bimetallic Zn/Fe0 Nanoparticles Stabilized Tween-80 and Rhamnolipid Foams for the Remediation of Diesel Contaminated Clay Soil. J. Environ. Manag. 2023, 325, 116596. [Google Scholar] [CrossRef] [PubMed]

- Banu, T.; Rashid, M.H.; Tofail, S.A.M.; Haq, E.U.; Gulshan, F. Photocatalytic Degradation of Metronidazole (MNZ) Antibiotic by CuO Nanoparticles for Environmental Protection from Pharmaceutical Pollution. Surf. Interface Anal. 2023, 55, 430–436. [Google Scholar] [CrossRef]

- Rawashdeh, R.Y.; Qabaja, G.; Albiss, B.A. Antibacterial Activity of Multi-Metallic (Ag–Cu–Li) Nanorods with Different Metallic Combination Ratios against Staphylococcus Aureus. BMC Res. Notes 2023, 16, 23. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Arshad, M.; Chuang, Y.; Hong, Y.L.; Nguyen, T.B.; Wu, C.H.; Chen, C.W.; Dong, C. Di Facile Fabrication of Efficient Tungsten Disulfide Nanoparticles for Enhanced Photocatalytic Removal of Tetracycline (TC) and Pb (II) Photoreduction. Colloids Surf. A Physicochem. Eng. Asp. 2023, 662, 131004. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, Y.; Li, L.; Jia, L. Fabrication of Alginate-Based Nanofibers Loaded with ZnO Nanoparticles for Adsorption of Tetracyclines from Environmental Waters. Mater. Today Commun. 2023, 34, 105214. [Google Scholar] [CrossRef]

- Gupta, G.; Kansal, S.K.; Umar, A.; Akbar, S. Visible-Light Driven Excellent Photocatalytic Degradation of Ofloxacin Antibiotic Using BiFeO3 Nanoparticles. Chemosphere 2023, 314, 137611. [Google Scholar] [CrossRef] [PubMed]

- Hemmati-Eslamlu, P.; Habibi-Yangjeh, A.; Khataee, A. Anchoring Spinel NiCr2O4 Nanoparticles on Tubular G-C3N4: Efficacious p-n Heterojunction Photocatalysts for Removal of Tetracycline Hydrochloride under Visible Light. J. Alloys Compd. 2023, 932, 167571. [Google Scholar] [CrossRef]

- Kokulnathan, T.; Wang, T.J.; Murugesan, T.; Anthuvan, A.J.; Kumar, R.R.; Ahmed, F.; Arshi, N. Structural Growth of Zinc Oxide Nanograins on Carbon Cloth as Flexible Electrochemical Platform for Hydroxychloroquine Detection. Chemosphere 2023, 312, 137186. [Google Scholar] [CrossRef]

- Liu, X.; Xu, J.; Zhang, T.; Zhang, J.; Xia, D.; Du, Y.; Jiang, Y.; Lin, K. Construction of Ag Nanocluster-Modified Ag3PO4 Containing Silver Vacancies via in-Situ Reduction: With Enhancing the Photocatalytic Degradation Activity of Sulfamethoxazole. J. Colloid. Interface Sci. 2023, 629, 989–1002. [Google Scholar] [CrossRef]

- Lei, X.; Xu, X.; Liu, L.; Xu, L.; Wang, L.; Kuang, H.; Xu, C. Gold-Nanoparticle-Based Multiplex Immuno-Strip Biosensor for Simultaneous Determination of 83 Antibiotics. Nano Res. 2023, 16, 1259–1268. [Google Scholar] [CrossRef]

- Ma, S.; Luo, X.; Kong, J.; Li, X.; Cao, Z.; Wang, X.; Cai, W.; Wang, L.; Ran, G. Plasmonic Silver Loaded Hybrid Bi-Ag Nanoalloys for Highly Efficient Disinfection by Enhancing Photothermal Performance and Interface Capability. Chem. Eng. J. 2022, 450, 138016. [Google Scholar] [CrossRef]

- Ahmed Shehab, M.; Szőri-Dorogházi, E.; Szabó, S.; Valsesia, A.; Chauhan, T.; Koós, T.; Muránszky, G.; Szabó, T.; Hernadi, K.; Németh, Z. Virus and Bacterial Removal Ability of TiO2 Nanowire-Based Self-Supported Hybrid Membranes. Arab. J. Chem. 2023, 16, 104388. [Google Scholar] [CrossRef]

- Ghani, S.B.A.; Al-Azzazy, M.M.; Alhewairini, S.S.; Al-Deghairi, M.A. The Miticidal Activity of Silver Nanoparticles towards Date Palm Mite (Oligonychus Afrasiaticus (McGregor)): Efficacy, Selectivity, and Risk Assessment. Braz. J. Biol. 2022, 84, e261262. [Google Scholar] [CrossRef] [PubMed]

- Hao, H.; Zhu, J.; Yang, B.; Peng, L.; Lou, S. Ovalbumin-Coated Gold Nanoparticles with Interesting Colloidal Stability for Colorimetric Detection of Carbaryl in Complex Media. Food Chem. 2023, 403, 134485. [Google Scholar] [CrossRef] [PubMed]

- Tran, H.N.; Nguyen, N.B.; Ly, N.H.; Joo, S.W.; Vasseghian, Y. Core-Shell Au@ZIF-67-Based Pollutant Monitoring of Thiram and Carbendazim Pesticides. Environ. Pollut. 2023, 317, 120775. [Google Scholar] [CrossRef] [PubMed]

- Hoang, N.H.; Le Thanh, T.; Sangpueak, R.; Thepbandit, W.; Saengchan, C.; Papathoti, N.K.; Treekoon, J.; Kamkaew, A.; Phansak, P.; Buensanteai, K. The Effect of Chitosan Nanoparticle Formulations for Control of Leaf Spot Disease on Cassava. Phytoparasitica 2023, 51, 621–636. [Google Scholar] [CrossRef]

- Cao, Z.; Ma, X.; Zou, A.; Shi, Z.; Xiang, S.; Xu, J.; Cai, L.; Huang, J.; Sun, X. Chitin Nanocrystals Supported Copper: A New Nanomaterial with High Activity with P. Syringae Pv. Tabaci. Pest. Manag. Sci. 2023, 79, 2017–2028. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Ahari, H.; Zhang, Z.; Jafari, S.M. Role of Silica (SiO2) Nano/Micro-Particles in the Functionality of Degradable Packaging Films/Coatings and Their Application in Food Preservation. Trends Food Sci. Technol. 2023, 133, 75–86. [Google Scholar] [CrossRef]

- Bouzidi, I.; Sellami, B.; Boulanger, A.; Joyeux, C.; Harrath, A.H.; Albeshr, M.F.; Pacioglu, O.; Boufahja, F.; Beyrem, H.; Mougin, K. Metallic Nanoparticles Affect Uptake of Polycyclic Aromatic Hydrocarbons and Impacts in the Mediterranean Mussels Mytilus Galloprovincialis. Mar. Pollut. Bull. 2023, 188, 114641. [Google Scholar] [CrossRef]

- Gong, L.; Zhang, Z.; Xia, C.; Zheng, J.; Gu, Y.; He, F. A Quantitative Study of the Effects of Particle’ Properties and Environmental Conditions on the Electron Efficiency of Pd and Sulfidated Nanoscale Zero-Valent Irons. Sci. Total Environ. 2022, 853, 158469. [Google Scholar] [CrossRef] [PubMed]

- Kung, T.A.; Chen, P.J. Exploring Specific Biomarkers Regarding Neurobehavioral Toxicity of Lead Dioxide Nanoparticles in Medaka Fish in Different Water Matrices. Sci. Total Environ. 2023, 856, 159268. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Chang, J.; Wang, Z.; Zhang, H.; Wang, T. Advances in Transport and Toxicity of Nanoparticles in Plants. J. Nanobiotechnol. 2023, 21, 75. [Google Scholar] [CrossRef] [PubMed]

- Zheng, N.; Sun, X.; Shi, Y.; Chen, L.; Wang, L.; Cai, H.; Han, C.; Liao, T.; Yang, C.; Zuo, Z.; et al. The Valence State of Iron-Based Nanomaterials Determines the Ferroptosis Potential in a Zebrafish Model. Sci. Total Environ. 2023, 855, 158715. [Google Scholar] [CrossRef] [PubMed]

- Mahjoubian, M.; Naeemi, A.S.; Moradi-Shoeili, Z.; Tyler, C.R.; Mansouri, B. Toxicity of Silver Nanoparticles in the Presence of Zinc Oxide Nanoparticles Differs for Acute and Chronic Exposures in Zebrafish. Arch. Environ. Contam. Toxicol. 2023, 84, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Luo, H.; Shao, Z.; Zhou, H.; Lu, J.; Chen, J.; Huang, C.; Zhang, S.; Liu, X.; Xia, L.; et al. Converting Plastic Wastes to Naphtha for Closing the Plastic Loop. J. Am. Chem. Soc. 2023, 145, 1847–1854. [Google Scholar] [CrossRef] [PubMed]

- Beig, B.; Niazi, M.B.K.; Jahan, Z.; Haider, G.; Zia, M.; Shah, G.A.; Iqbal, Z.; Hayat, A. Development and Testing of Zinc Sulfate and Zinc Oxide Nanoparticle-Coated Urea Fertilizer to Improve N and Zn Use Efficiency. Front. Plant Sci. 2023, 13, 1058219. [Google Scholar] [CrossRef] [PubMed]

- Tao, X.; Xu, J.; Yang, K.; Lin, D. Novel Oxymagnesite/Green Rust Nanohybrids for Selective Removal and Slow Release of Phosphate in Water. Sci. Total Environ. 2023, 856, 159207. [Google Scholar] [CrossRef] [PubMed]

- Triolo, C.; Santangelo, S.; Petrovičovà, B.; Musolino, M.G.; Rincón, I.; Atxirika, A.; Gil, S.; Belaustegui, Y. Evaluation of the Specific Capacitance of High-Entropy Oxide-Based Electrode Materials in View of Their Use for Water Desalination via Capacitive Method. Appl. Sci. 2023, 13, 721. [Google Scholar] [CrossRef]

- Zhang, C.; Sun, L.; Ouyang, Y.; Xu, F.; Zou, Y.; Chu, H.; Zhang, K.; Li, B.; Pan, H. Improved Electrochemical Water Splitting by RuNi Nanoparticles Supported on RGO@mesoporous N-Doped Carbon Nanosheets. J. Alloys Compd. 2023, 937, 168334. [Google Scholar] [CrossRef]

- Benjak, P.; Radetić, L.; Tomaš, M.; Brnardić, I.; Radetić, B.; Špada, V.; Grčić, I. Rubber Tiles Made from Secondary Raw Materials with Immobilized Titanium Dioxide as Passive Air Protection. Processes 2023, 11, 125. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Y.; Shi, W.D.; Yan, W.C. Electric Field Assisted Assembly of Nanoparticle Loaded Microspheres toward Industrial Applications for Organic Dye Removal. Sep. Purif. Technol. 2023, 306, 122565. [Google Scholar] [CrossRef]

- Zhang, G.; Yu, Y.; Tu, Y.; Liu, Y.; Huang, J.; Yin, X.; Feng, Y. Preparation of Reusable UHMWPE/TiO2 Photocatalytic Microporous Membrane Reactors for Efficient Degradation of Organic Pollutants in Water. Sep. Purif. Technol. 2023, 305, 122515. [Google Scholar] [CrossRef]

- Ma, J.; Yu, Z.; Shu, L.; Ke, S.; He, Q.; Zhao, Q.; Ke, Q. The Disinhibition Effect of Iron-Based Particles on Anaerobic Digestion of Florfenicol-Containing Cow Manure: Performance and Mechanism. Environ. Res. 2023, 223, 115471. [Google Scholar] [CrossRef] [PubMed]

- Markowicz, A.; Borymski, S.; Adamek, A.; Sułowicz, S. The Influence of ZnO Nanoparticles on Horizontal Transfer of Resistance Genes in Lab and Soil Conditions. Environ. Res. 2023, 223, 115420. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Lu, H.; Yang, K.; Zhu, L. Attenuation of Tetracyclines and Related Resistance Genes in Soil When Exposed to Nanoscale Zero-Valent Iron. J. Hazard. Mater. 2023, 448, 130867. [Google Scholar] [CrossRef] [PubMed]

- Senbill, H.; Hassan, S.M.; Eldesouky, S.E. Acaricidal and Biological Activities of Titanium Dioxide and Zinc Oxide Nanoparticles on the Two-Spotted Spider Mite, Tetranychus Urticae Koch (Acari: Tetranychidae) and Their Side Effects on the Predatory Mite, Neoseiulus Californicus (Acari: Phytoseiidae). J. Asia Pac. Entomol. 2023, 26, 102027. [Google Scholar] [CrossRef]

- Wang, Z.; Bi, Y.; Li, K.; Song, Z.; Pan, C.; Zhang, S.; Lan, X.; Foulkes, N.S.; Zhao, H. Nickel Oxide Nanoparticles Induce Developmental Neurotoxicity in Zebrafish by Triggering Both Apoptosis and Ferroptosis. Environ. Sci. Nano 2023, 10, 640–655. [Google Scholar] [CrossRef]

- Bakouei, M.; Sadeghizadeh Yazdi, J.; Ehrampoush, M.H.; Salari, M.; Madadizadeh, F. The Effect of Active Chitosan Films Containing Bacterial Cellulose Nanofiber and ZnO Nanoparticles on the Shelf Life of Loaf Bread. J. Food Qual. 2023, 2023, 1–12. [Google Scholar] [CrossRef]

- Alvan, Z.B.A.; Asgari, H.M.; Amanipoor, H.; Buazar, F.; Motaghed, S. Evaluation of the Effects of Zero-Valent Iron Nanoparticles in the Treatment of Soils Polluted with Refinery Effluent Hydrocarbons. Water Air Soil. Pollut. 2023, 234, 40. [Google Scholar] [CrossRef]

- Zhu, X.; Li, H.; Zhou, L.; Jiang, H.; Ji, M.; Chen, J. Evaluation of the Gut Microbiome Alterations in Healthy Rats after Dietary Exposure to Different Synthetic ZnO Nanoparticles. Life Sci. 2023, 312, 121250. [Google Scholar] [CrossRef] [PubMed]

- Aqeel, M.; Khalid, N.; Nazir, A.; Irshad, M.K.; Hakami, O.; Basahi, M.A.; Alamri, S.; Hashem, M.; Noman, A. Foliar Application of Silver Nanoparticles Mitigated Nutritional and Biochemical Perturbations in Chilli Pepper Fertigated with Domestic Wastewater. Plant Physiol. Biochem. 2023, 194, 470–479. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, N.; Du, C.; Wang, Y.; He, K.; Zheng, H.; Xue, Z.; Chen, Q.; Li, X. Various Hydrogen Bonds Make Different Fates of Pharmaceutical Contaminants on Oxygen-Rich Nanomaterials. Environ. Pollut. 2023, 316, 120572. [Google Scholar] [CrossRef] [PubMed]

- Albarano, L.; Toscanesi, M.; Trifuoggi, M.; Guida, M.; Lofrano, G.; Libralato, G. In Situ Microcosm Remediation of Polyaromatic Hydrocarbons: Influence and Effectiveness of Nano-Zero Valent Iron and Activated Carbon. Environ. Sci. Pollut. Res. 2023, 30, 3235–3251. [Google Scholar] [CrossRef] [PubMed]

- Nekoukhou, M.; Fallah, S.; Abbasi-Surki, A.; Pokhrel, L.R.; Rostamnejadi, A. Improved Efficacy of Foliar Application of Zinc Oxide Nanoparticles on Zinc Biofortification, Primary Productivity and Secondary Metabolite Production in Dragonhead. J. Clean. Prod. 2022, 379, 134803. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, C.; Liu, Y.; Tan, X.; Li, X.; Shi, Y.; Ding, C. The Interaction of ZnO Nanoparticles, Cr(VI), and Microorganisms Triggers a Novel ROS Scavenging Strategy to Inhibit Microbial Cr(VI) Reduction. J. Hazard. Mater. 2023, 443, 130375. [Google Scholar] [CrossRef] [PubMed]

- Zeeshan, M.; Hu, Y.X.; Guo, X.H.; Sun, C.Y.; Salam, A.; Ahmad, S.; Muhammad, I.; Nasar, J.; Jahan, M.S.; Fahad, S.; et al. Physiological and Transcriptomic Study Reveal SeNPs-Mediated AsIII Stress Detoxification Mechanisms Involved Modulation of Antioxidants, Metal Transporters, and Transcription Factors in Glycine Max L. (Merr.) Roots. Environ. Pollut. 2023, 317, 120637. [Google Scholar] [CrossRef] [PubMed]

- Moghazy, M.A. Leidenfrost Green Synthesis Method for MoO3 and WO3 Nanorods Preparation: Characterization and Methylene Blue Adsorption Ability. BMC Chem. 2023, 17, 5. [Google Scholar] [CrossRef] [PubMed]

- Basumatary, S.; Kumar, K.J.; Daimari, J.; Mondal, A.; Kalita, S.; Dey, K.S.; Deka, A.K. Biosynthesis of Silver Nanoparticles Using Antidesma Acidum Leaf Extract: Its Application in Textile Organic Dye Degradation. Environ. Nanotechnol. Monit. Manag. 2023, 19, 100769. [Google Scholar] [CrossRef]

- Faryad, S.; Azhar, U.; Tahir, M.B.; Ali, W.; Arif, M.; Sagir, M. Spinach-Derived Boron-Doped g-C3N4/TiO2 Composites for Efficient Photo-Degradation of Methylene Blue Dye. Chemosphere 2023, 320, 138002. [Google Scholar] [CrossRef]

- Rather, M.Y.; Shincy, M.; Sundarapandian, S. Photocatalytic Degradation of Rhodamine-B by Phytosynthesized Gold Nanoparticles. Int. J. Environ. Sci. Technol. 2023, 20, 4073–4084. [Google Scholar] [CrossRef]

- Mansur, A.A.P.; Custódio, D.A.C.; Dorneles, E.M.S.; Coura, F.M.; Carvalho, I.C.; Lage, A.P.; Mansur, H.S. Nanoplexes of ZnS Quantum Dot-Poly-L-Lysine/Iron Oxide Nanoparticle-Carboxymethylcellulose for Photocatalytic Degradation of Dyes and Antibacterial Activity in Wastewater Treatment. Int. J. Biol. Macromol. 2023, 231, 123363. [Google Scholar] [CrossRef] [PubMed]

- Singh, K.; Nancy; Singh, G.; Singh, J. Sustainable Synthesis of Biogenic ZnO NPs for Mitigation of Emerging Pollutants and Pathogens. Environ. Res. 2023, 219, 114952. [Google Scholar] [CrossRef] [PubMed]

- Ashraf, I.; Singh, N.B.; Agarwal, A. Iron-Rich Coal Fly Ash-Polydopamine-Silver Nanocomposite (IRCFA-PDA-Ag NPs): Tailored Material for Remediation of Methylene Blue Dye from Aqueous Solution. Environ. Monit. Assess. 2023, 195, 322. [Google Scholar] [CrossRef] [PubMed]

- Munir, R.; Ali, K.; Naqvi, S.A.Z.; Maqsood, M.A.; Bashir, M.Z.; Noreen, S. Biosynthesis of Leucaena Leucocephala Leaf Mediated ZnO, CuO, MnO2, and MgO Based Nano-Adsorbents for Reactive Golden Yellow-145 (RY-145) and Direct Red-31 (DR-31) Dye Removal from Textile Wastewater to Reuse in Agricultural Purpose. Sep. Purif. Technol. 2023, 306, 122527. [Google Scholar] [CrossRef]

- Gautam, I.; Grady, T.; Fernando, H. Degradation of the Dye Methyl Orange Using Cow and Goat Milk Iron Nanoparticles. Green Chem. Lett. Rev. 2023, 16, 2174818. [Google Scholar] [CrossRef]

- Bhandari, Y.; Varma, S.; Sawant, A.; Beemagani, S.; Jaiswal, N.; Chaudhari, B.P.; Vamkudoth, K.R. Biosynthesis of Gold Nanoparticles by Penicillium Rubens and Catalytic Detoxification of Ochratoxin A and Organic Dye Pollutants. Int. Microbiol. 2023, 26, 765–780. [Google Scholar] [CrossRef] [PubMed]