Enhanced Simultaneous Nitrogen and Phosphorus Removal in a Continuous-Flow Granular Sludge System under Gradient-Controlled Hydraulic Loading

Abstract

1. Introduction

2. Materials and Methods

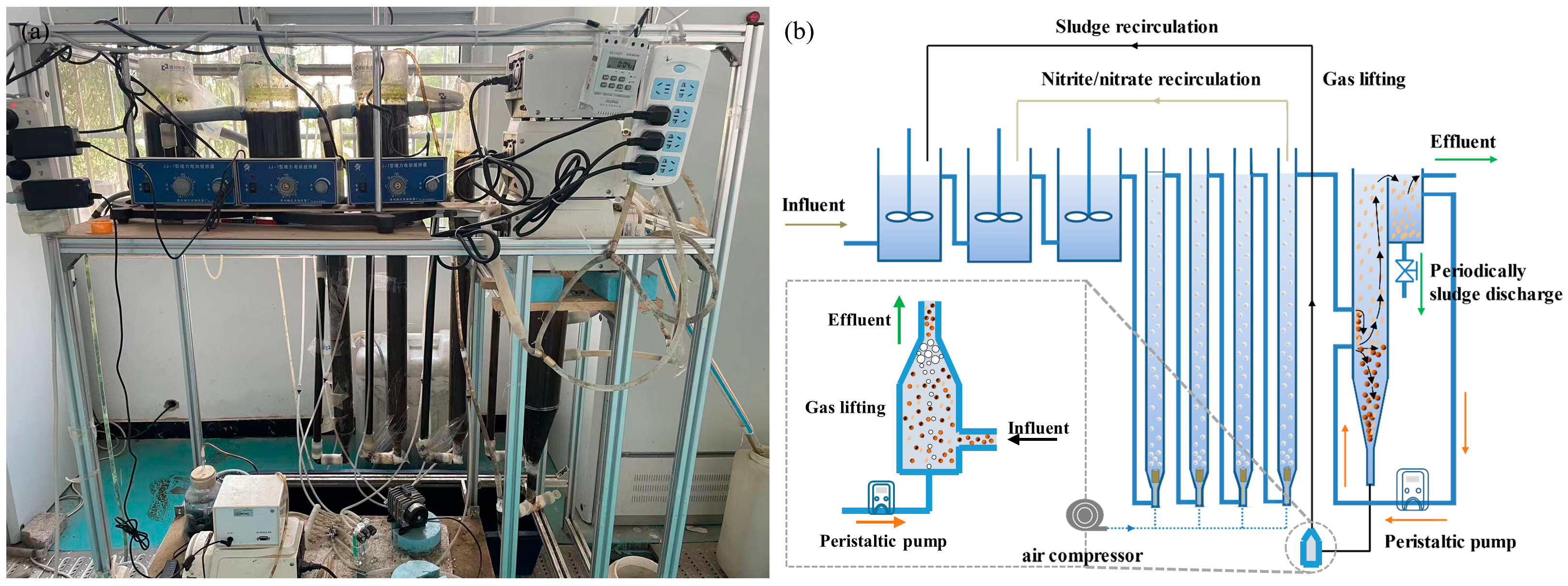

2.1. Experimental Setup

2.2. Substrate Composition and Seed Sludge

2.3. Analytical Methods

2.4. Microbial Community Analysis

2.5. Calculation of Pollutant Removal Efficiency

2.5.1. Continuous Operation

2.5.2. Batch Experiments

3. Results and Discussion

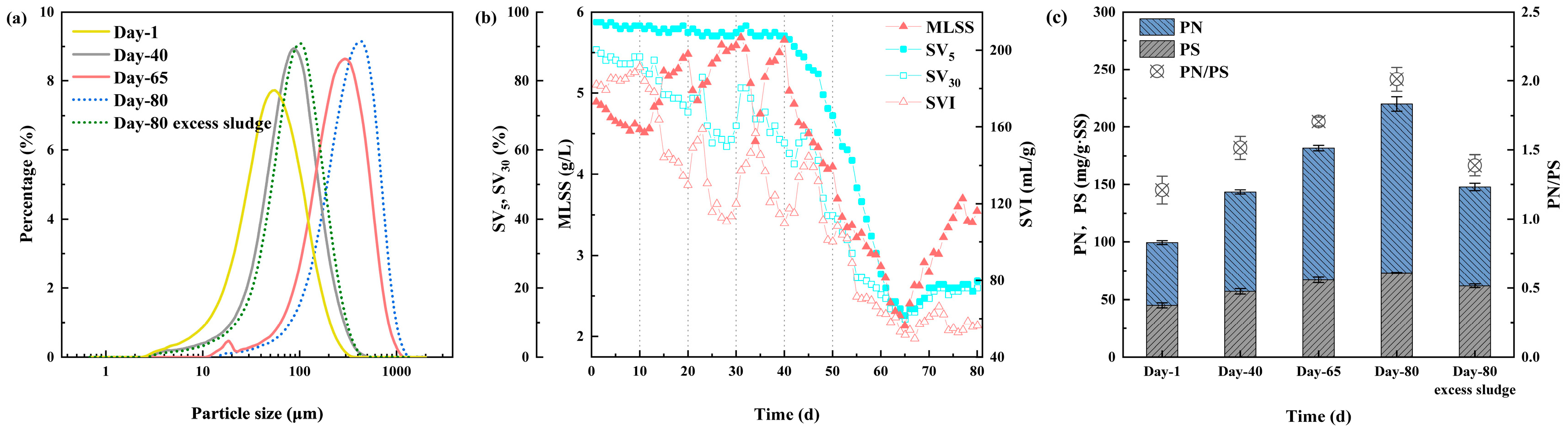

3.1. Effect of Hydraulic Load on Sludge Granulation

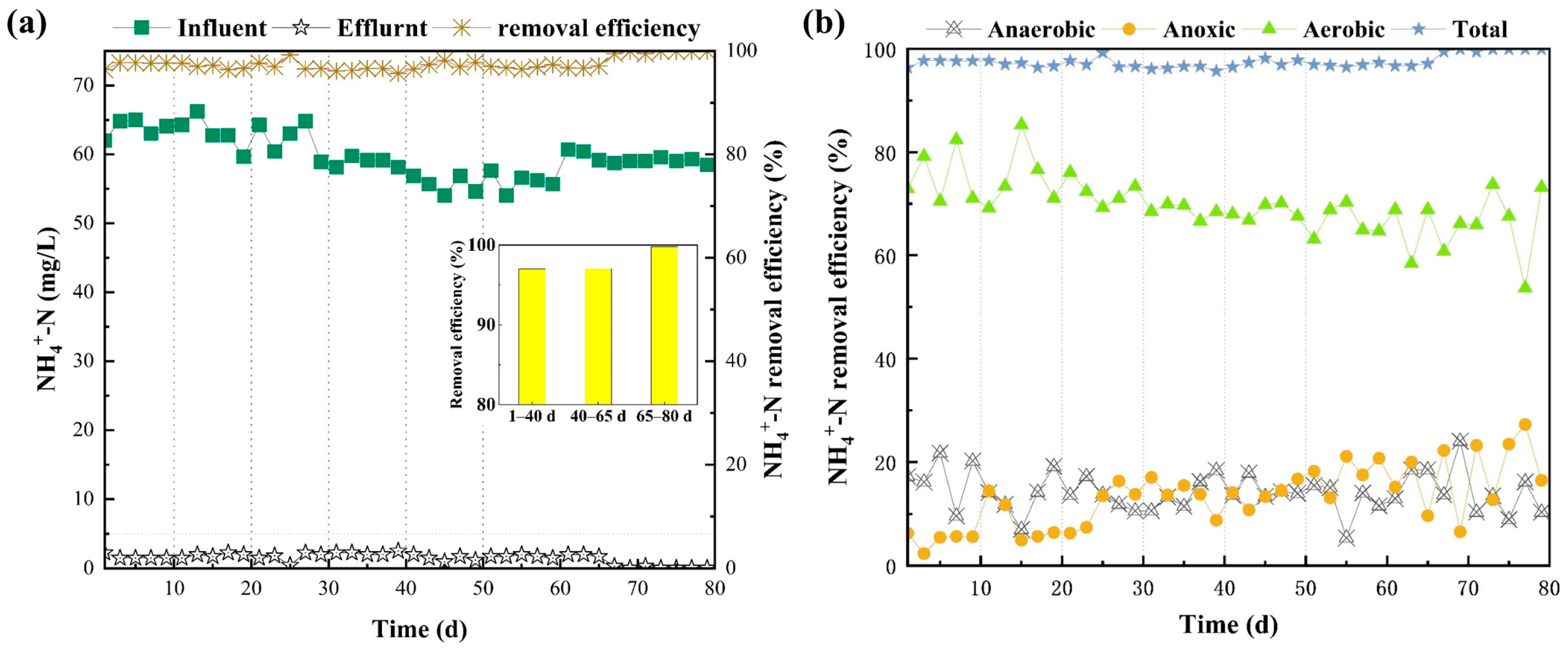

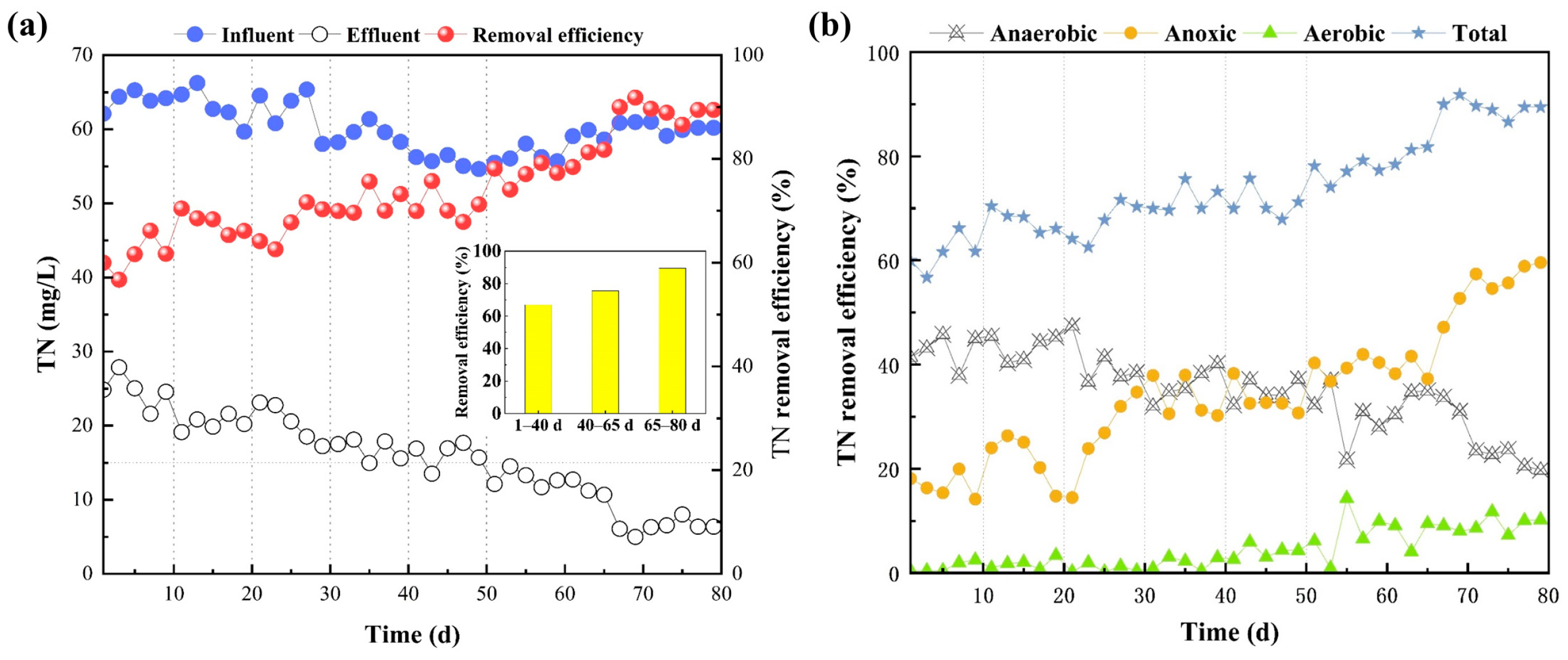

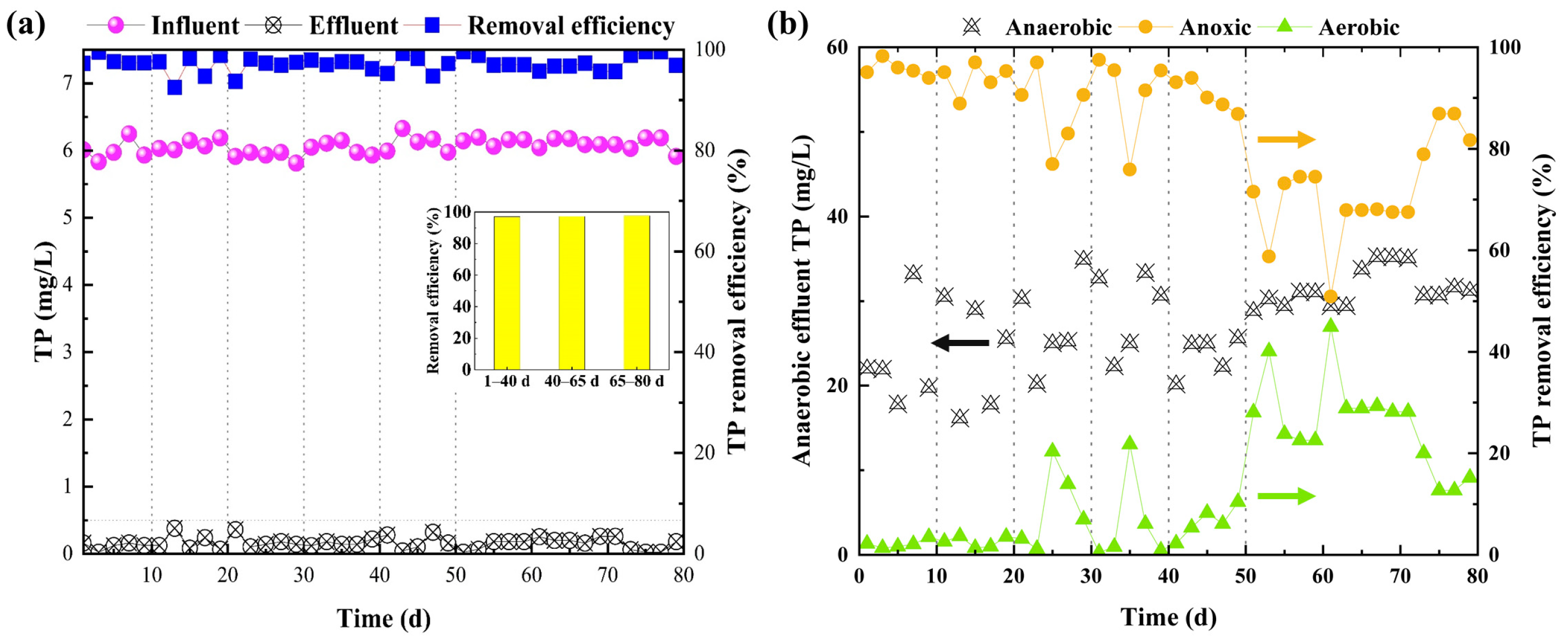

3.2. Removal Patterns of N and P in the Reaction System

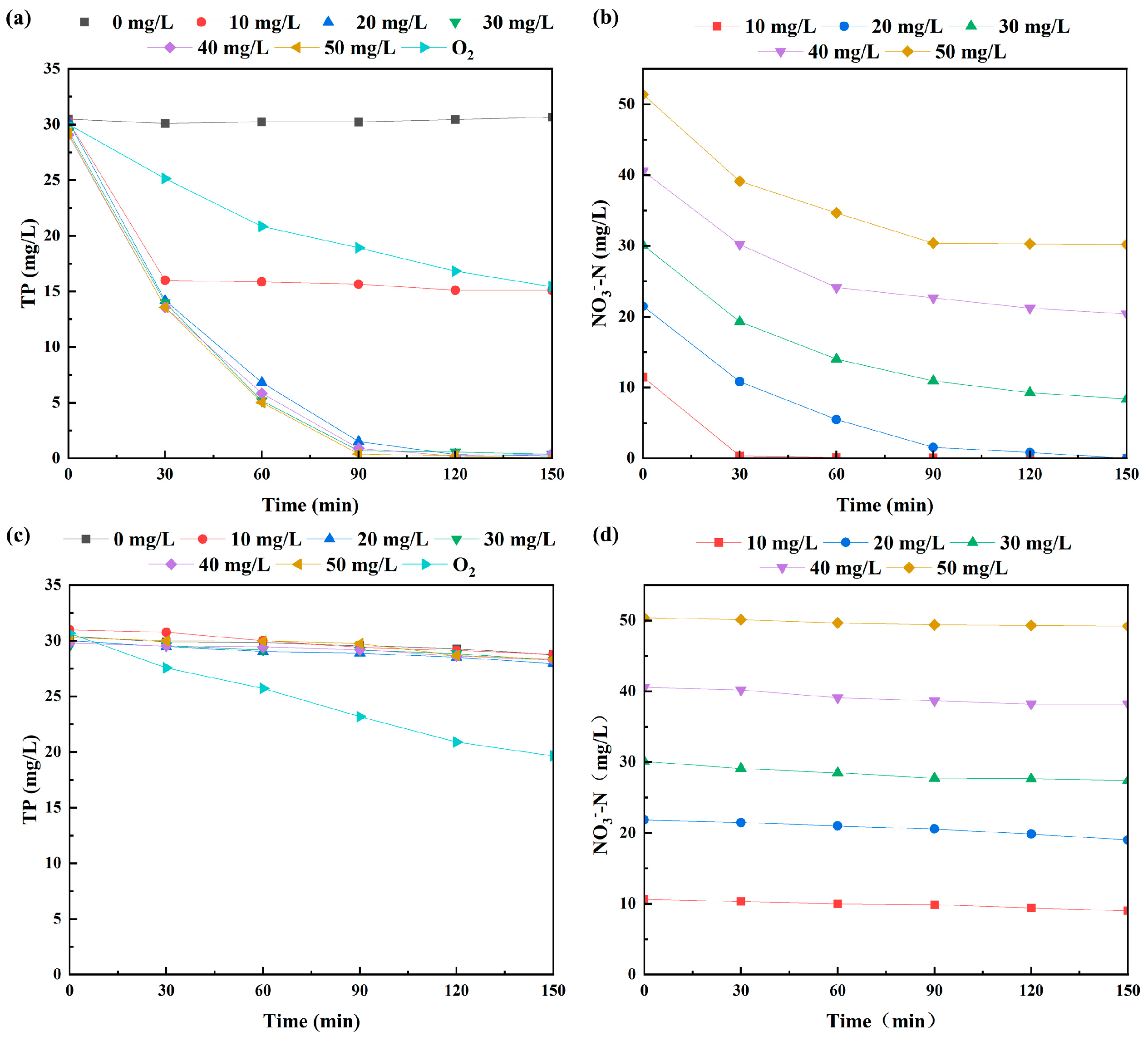

3.3. Mechanism of Nitrogen and Phosphorus Removal

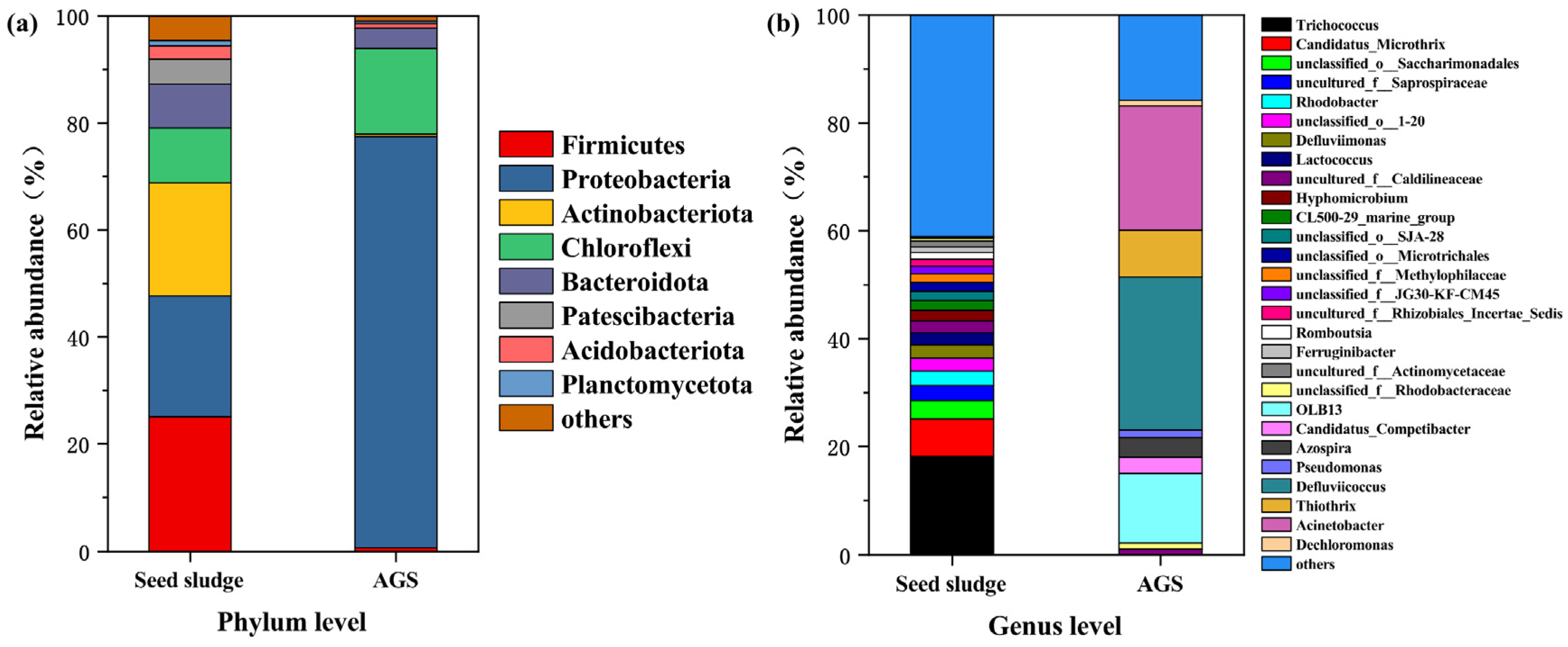

3.4. Microbial Structure Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pronk, M.; De Kreuk, M.K.; De Bruin, B.; Kamminga, P.; Kleerebezem, R.; Van Loosdrecht, M.C.M. Full Scale Performance of the Aerobic Granular Sludge Process for Sewage Treatment. Water Res. 2015, 84, 207–217. [Google Scholar] [CrossRef]

- Wilén, B.-M.; Liébana, R.; Persson, F.; Modin, O.; Hermansson, M. The Mechanisms of Granulation of Activated Sludge in Wastewater Treatment, Its Optimization, and Impact on Effluent Quality. Appl. Microbiol. Biotechnol. 2018, 102, 5005–5020. [Google Scholar] [CrossRef]

- Liu, W.; Song, J.; Wang, J.; Ji, X.; Shen, Y.; Yang, D. Achieving Robust Nitritation in a Modified Continuous-Flow Reactor: From Micro-Granule Cultivation to Nitrite-Oxidizing Bacteria Elimination. J. Environ. Sci. 2023, 124, 117–129. [Google Scholar] [CrossRef] [PubMed]

- Wan, C.; Lee, D.-J.; Yang, X.; Wang, Y.; Wang, X.; Liu, X. Calcium Precipitate Induced Aerobic Granulation. Bioresour. Technol. 2015, 176, 32–37. [Google Scholar] [CrossRef]

- Sharaf, A.; Guo, B.; Liu, Y. Impact of the Filamentous Fungi Overgrowth on the Aerobic Granular Sludge Process. Bioresour. Technol. Rep. 2019, 7, 100272. [Google Scholar] [CrossRef]

- Li, D.; Lv, Y.; Zeng, H.; Zhang, J. Enhanced Biological Phosphorus Removal Using Granules in Continuous-Flow Reactor. Chem. Eng. J. 2016, 298, 107–116. [Google Scholar] [CrossRef]

- Wang, B.; Yao, X.; Liu, X.; Zhou, A.; Qi, G.; Liu, Y. Research progress on influencing factors and application of continuous flow aerobic granular sludge. Ind. Water Treat. 2022, 42, 7–15. [Google Scholar] [CrossRef]

- Guo, D.; Jiang, X.; Guo, M.; Zeng, M.; Wu, N.; Hao, L.; Wang, C. Role of Hydrocyclone Separator on the Formation and Separation of Aerobic Granular Sludge: Evaluating Granulation Efficiency and Simulating Hydrodynamic Behavior. Sep. Purif. Technol. 2022, 283, 120231. [Google Scholar] [CrossRef]

- Liu, W.; Wu, Y.; Zhang, S.; Gao, Y.; Jiang, Y.; Horn, H.; Li, J. Successful Granulation and Microbial Differentiation of Activated Sludge in Anaerobic/Anoxic/Aerobic (A2O) Reactor with Two-Zone Sedimentation Tank Treating Municipal Sewage. Water Res. 2020, 178, 115825. [Google Scholar] [CrossRef]

- Sarma, S.J.; Tay, J.H.; Chu, A. Finding Knowledge Gaps in Aerobic Granulation Technology. Trends Biotechnol. 2017, 35, 66–78. [Google Scholar] [CrossRef]

- Ali, N.S.A.; Muda, K.; Mohd Amin, M.F.; Najib, M.Z.M.; Ezechi, E.H.; Darwish, M.S.J. Initialization, Enhancement and Mechanisms of Aerobic Granulation in Wastewater Treatment. Sep. Purif. Technol. 2021, 260, 118220. [Google Scholar] [CrossRef]

- Hamza, R.; Rabii, A.; Ezzahraoui, F.; Morgan, G.; Iorhemen, O.T. A Review of the State of Development of Aerobic Granular Sludge Technology over the Last 20 Years: Full-Scale Applications and Resource Recovery. Case Stud. Chem. Environ. Eng. 2022, 5, 100173. [Google Scholar] [CrossRef]

- He, Q.; Song, J.; Zhang, W.; Gao, S.; Wang, H.; Yu, J. Enhanced Simultaneous Nitrification, Denitrification and Phosphorus Removal through Mixed Carbon Source by Aerobic Granular Sludge. J. Hazard. Mater. 2020, 382, 121043. [Google Scholar] [CrossRef] [PubMed]

- Hu, B.; He, X.; Zhang, X.; Wu, Z.; Zhao, J. Survey of quantitative and qualitative characteristics for expressway service area wastewater. Water Purif. Technol. 2010, 29, 46–49. [Google Scholar] [CrossRef]

- Liang, H.; Liu, J.; Wei, Y.; Guo, X.; Shan, B. Investigation and analysis of rural wastewater discharge characteristics in three typical areas of China. Chin. J. Environ. 2011, 5, 2054–2059. [Google Scholar]

- Zhang, W.; Wang, Y.; Sun, Y.; Zheng, X.; Liu, J.; Zhu, L.; Gao, C.; Gu, M.; Tian, T. Measurement of domestic sewage pollutant production and its seasonal variation. China Water Wastewater 2022, 38, 69–73. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 1998. [Google Scholar]

- Zou, J.; Li, Y.; Zhang, L.; Wang, R.; Sun, J. Understanding the Impact of Influent Nitrogen Concentration on Granule Size and Microbial Community in a Granule-Based Enhanced Biological Phosphorus Removal System. Bioresour. Technol. 2015, 177, 209–216. [Google Scholar] [CrossRef] [PubMed]

- Frølund, B.; Griebe, T.; Nielsen, P.H. Enzymatic Activity in the Activated-Sludge Floc Matrix. Appl. Microbiol. Biotechnol. 1995, 43, 755–761. [Google Scholar] [CrossRef]

- DuBois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.A.; Smith, F. Colorimetric Method for Determination of Sugars and Related Substances. Anal. Chem. 1956, 28, 350–356. [Google Scholar] [CrossRef]

- Cheng, W.; Ma, C.; Bao, R.; Yang, X.; Zhou, X.; Liu, Y.; Liu, Q.; Ruan, A.; Li, X. Effect of Influent Ammonia Nitrogen Concentration on the Phosphorus Removal Process in the Aerobic Granular Sludge Reactor. J. Environ. Chem. Eng. 2023, 11, 110476. [Google Scholar] [CrossRef]

- De Kreuk, M.K.; Kishida, N.; Van Loosdrecht, M.C.M. Aerobic Granular Sludge—State of the Art. Water Sci. Technol. 2007, 55, 75–81. [Google Scholar] [CrossRef]

- Jahn, L.; Svardal, K.; Krampe, J. Accidently Aerobic Granules—Data Evaluation of a Full-Scale SBR Plant. Desalination Water Treat. 2019, 164, 11–17. [Google Scholar] [CrossRef]

- Wang, L.; Zhan, H.; Wang, Q.; Wu, G.; Cui, D. Enhanced Aerobic Granulation by Inoculating Dewatered Activated Sludge under Short Settling Time in a Sequencing Batch Reactor. Bioresour. Technol. 2019, 286, 121386. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Liu, F.; Wang, L.; Sun, J. Overcoming the Instability of Aerobic Granular Sludge under Nitrogen Deficiency through Shortening Settling Time. Bioresour. Technol. 2019, 289, 121620. [Google Scholar] [CrossRef] [PubMed]

- Samaei, S.H.-A.; Chen, J.; Xue, J. Current Progress of Continuous-Flow Aerobic Granular Sludge: A Critical Review. Sci. Total Environ. 2023, 875, 162633. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Liu, Z.; Huang, X.; Fang, F.; Guo, J.; Yan, P. Effect of EPS and Its Forms of Aerobic Granular Sludge on Sludge Aggregation Performance during Granulation Process Based on XDLVO Theory. Sci. Total Environ. 2021, 795, 148682. [Google Scholar] [CrossRef]

- Peng, T.; Wang, Y.; Wang, J.; Fang, F.; Yan, P.; Liu, Z. Effect of Different Forms and Components of EPS on Sludge Aggregation during Granulation Process of Aerobic Granular Sludge. Chemosphere 2022, 303, 135116. [Google Scholar] [CrossRef] [PubMed]

- Ma, B.; Wang, S.; Cao, S.; Miao, Y.; Jia, F.; Du, R.; Peng, Y. Biological Nitrogen Removal from Sewage via Anammox: Recent Advances. Bioresour. Technol. 2016, 200, 981–990. [Google Scholar] [CrossRef]

- Li, J.; Peng, Y.; Zhang, L.; Liu, J.; Wang, X.; Gao, R.; Pang, L.; Zhou, Y. Quantify the Contribution of Anammox for Enhanced Nitrogen Removal through Metagenomic Analysis and Mass Balance in an Anoxic Moving Bed Biofilm Reactor. Water Res. 2019, 160, 178–187. [Google Scholar] [CrossRef]

- Wan, C.; Fu, L.; Li, Z.; Liu, X.; Lin, L.; Wu, C. Formation, Application, and Storage-Reactivation of Aerobic Granular Sludge: A Review. J. Environ. Manag. 2022, 323, 116302. [Google Scholar] [CrossRef]

- Wang, Y.; Geng, J.; Ren, Z.; Guo, G.; Wang, C.; Wang, H. Effect of COD/N and COD/P Ratios on the PHA Transformation and Dynamics of Microbial Community Structure in a Denitrifying Phosphorus Removal Process. J. Chem. Technol. Biotechnol 2013, 88, 1228–1236. [Google Scholar] [CrossRef]

- Carvalho, G.; Lemos, P.C.; Oehmen, A.; Reis, M.A.M. Denitrifying Phosphorus Removal: Linking the Process Performance with the Microbial Community Structure. Water Res. 2007, 41, 4383–4396. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Peng, C.; Wang, J.; Ye, L.; Zhang, L.; Peng, Y. Effect of Nitrate Recycling Ratio on Simultaneous Biological Nutrient Removal in a Novel Anaerobic/Anoxic/Oxic (A2/O)-Biological Aerated Filter (BAF) System. Bioresour. Technol. 2011, 102, 5722–5727. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.M.; Lee, H.J.; Lee, D.S.; Jeon, C.O. Characterization of the Denitrification-Associated Phosphorus Uptake Properties of “Candidatus Accumulibacter Phosphatis” Clades in Sludge Subjected to Enhanced Biological Phosphorus Removal. Appl. Environ. Microbiol. 2013, 79, 1969–1979. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Song, T.; Zhu, C.; Fan, Y.; Soares, A.; Gu, X.; Wu, J. Roles of Nitrate Recycling Ratio in the A2/O—MBBR Denitrifying Phosphorus Removal System for High-Efficient Wastewater Treatment: Performance Comparison, Nutrient Mechanism and Potential Evaluation. J. Environ. Manag. 2020, 270, 110887. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y. Diffusion of Substrate and Oxygen in Aerobic Granule. Biochem. Eng. J. 2005, 27, 45–52. [Google Scholar] [CrossRef]

- Wang, P.; Yu, Z.; Qi, R.; Zhang, H. Detailed Comparison of Bacterial Communities during Seasonal Sludge Bulking in a Municipal Wastewater Treatment Plant. Water Res. 2016, 105, 157–166. [Google Scholar] [CrossRef] [PubMed]

- Huang, D. Study on the Performance and Membrane Fouling in Aerobic Granular Sludge Membrane Bioreactor: Effect of Superficial Air Velocity. Master’s Thesis, Chongqing Technology and Business University, Chongqing, China, 2021. [Google Scholar]

- Liang, Y.; Li, D.; Su, Q.; Zhang, J. Performances and Microbial Characteristics of Granular Sludge for Autotrophic Nitrogen Removal from Synthetic and Mainstream Domestic Sewage. Chem. Eng. J. 2018, 338, 564–571. [Google Scholar] [CrossRef]

- Shi, X.; Li, J.; Wang, X.; Zhang, X.; Tang, L. Effect of the Gradual Increase of Na2SO4 on Performance and Microbial Diversity of Aerobic Granular Sludge. J. Environ. Manag. 2021, 292, 112696. [Google Scholar] [CrossRef]

- Yu, H. Study on Culture and Stable Operation Characteristics of Aerobic Granular Sludge. Master’s Thesis, Beijing University of Chemical Technology, Beijing, China, 2019. [Google Scholar]

- Zhao, W.; Bi, X.; Peng, Y.; Bai, M. Research Advances of the Phosphorus-Accumulating Organisms of Candidatus Accumulibacter, Dechloromonas and Tetrasphaera: Metabolic Mechanisms, Applications and Influencing Factors. Chemosphere 2022, 307, 135675. [Google Scholar] [CrossRef]

- Li, S.; Guo, Y.; Zhang, X.; Feng, L.; Yong, X.; Xu, J.; Liu, Y.; Huang, X. Advanced Nitrogen and Phosphorus Removal by the Symbiosis of PAOs, DPAOs and DGAOs in a Pilot-Scale A2O/A+MBR Process with a Low C/N Ratio of Influent. Water Res. 2023, 229, 119459. [Google Scholar] [CrossRef] [PubMed]

- Maszenan, A.M.; Bessarab, I.; Williams, R.B.H.; Petrovski, S.; Seviour, R.J. The Phylogeny, Ecology and Ecophysiology of the Glycogen Accumulating Organism (GAO) Defluviicoccus in Wastewater Treatment Plants. Water Res. 2022, 221, 118729. [Google Scholar] [CrossRef] [PubMed]

- He, Q.; Chen, L.; Zhang, S.; Chen, R.; Wang, H. Hydrodynamic Shear Force Shaped the Microbial Community and Function in the Aerobic Granular Sequencing Batch Reactors for Low Carbon to Nitrogen (C/N) Municipal Wastewater Treatment. Bioresour. Technol. 2019, 271, 48–58. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Peng, Y.; Cheng, J.; Zhang, S.; Liu, C.; Zhang, L. A Novel Two-Stage Aerobic Granular Sludge System for Simultaneous Nutrient Removal from Municipal Wastewater with Low C/N Ratios. Chem. Eng. J. 2023, 462, 142318. [Google Scholar] [CrossRef]

- Du, R.; Cao, S.; Peng, Y.; Zhang, H.; Wang, S. Combined Partial Denitrification (PD)-Anammox: A Method for High Nitrate Wastewater Treatment. Environ. Int. 2019, 126, 707–716. [Google Scholar] [CrossRef]

| Components | Concentration (mg/L) | Trace Elements | Concentration (μg/L) |

|---|---|---|---|

| glucose | 280 | H3BO4 | 45 |

| sodium acetate | 385 | ZnSO4·7H2O | 36 |

| NH4Cl | 230 | FeCl3 | 45 |

| KH2PO4 | 26 | CuSO4·5H2O | 45 |

| CaCl2 | 5 | MnSO4 | 36 |

| MgSO4·7H2O | 55 | KI | 54 |

| KCl | 8 | EDTA | 300 |

| NaHCO3 | 250 |

| Phase | Time (day) | Hydraulic Loading (m3/(m2·h)) |

|---|---|---|

| Phase I | 1–10 | 2.04 |

| 11–20 | 2.69 | |

| 21–30 | 3.34 | |

| 31–40 | 3.99 | |

| Phase II | 41–51 | 4.50 |

| 51–65 | 5.00 | |

| Phase III | 65–80 | 5.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; An, P.; Wan, J.; Zhang, X. Enhanced Simultaneous Nitrogen and Phosphorus Removal in a Continuous-Flow Granular Sludge System under Gradient-Controlled Hydraulic Loading. Water 2024, 16, 1510. https://doi.org/10.3390/w16111510

Zhao Y, An P, Wan J, Zhang X. Enhanced Simultaneous Nitrogen and Phosphorus Removal in a Continuous-Flow Granular Sludge System under Gradient-Controlled Hydraulic Loading. Water. 2024; 16(11):1510. https://doi.org/10.3390/w16111510

Chicago/Turabian StyleZhao, Yaguang, Pengkun An, Junfeng Wan, and Xuehui Zhang. 2024. "Enhanced Simultaneous Nitrogen and Phosphorus Removal in a Continuous-Flow Granular Sludge System under Gradient-Controlled Hydraulic Loading" Water 16, no. 11: 1510. https://doi.org/10.3390/w16111510

APA StyleZhao, Y., An, P., Wan, J., & Zhang, X. (2024). Enhanced Simultaneous Nitrogen and Phosphorus Removal in a Continuous-Flow Granular Sludge System under Gradient-Controlled Hydraulic Loading. Water, 16(11), 1510. https://doi.org/10.3390/w16111510