Identifying Opportunities for Irrigation Systems to Meet the Specific Needs of Farmers in East Africa

Abstract

:1. Introduction

- What distinct market segments exist within the range of small-to-medium-scale EA farmers who participate in farmer-led irrigation? What are the user-driven needs of farmers in each of these segments?

- How do these unique needs translate into value propositions for irrigation systems that can articulate pathways to achieve the most desired irrigation benefits within the constraints of each segment?

- What technical requirements can be discerned from the user needs and value propositions of each market segment? How do those requirements compare to the current performance of feasible systems within each context?

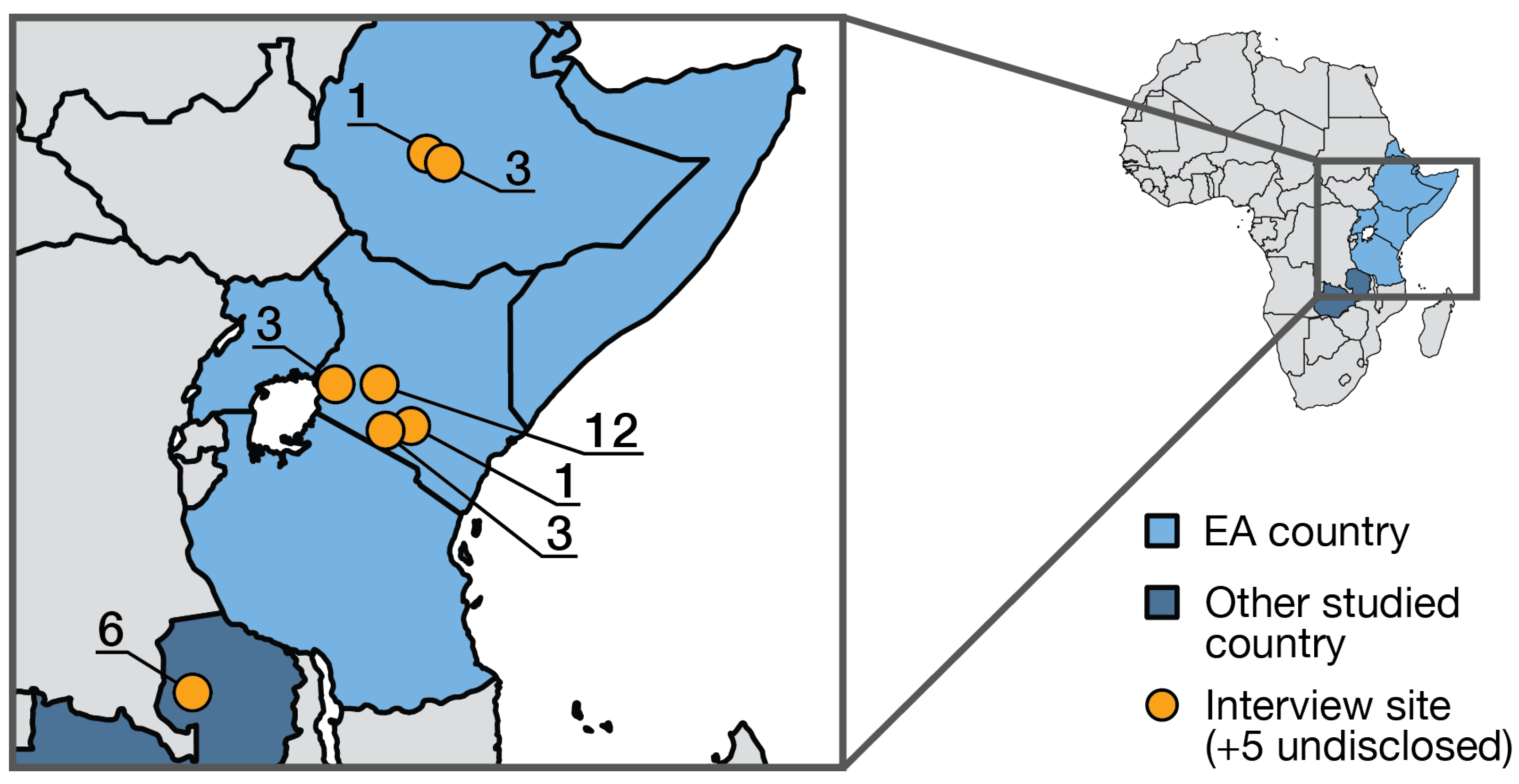

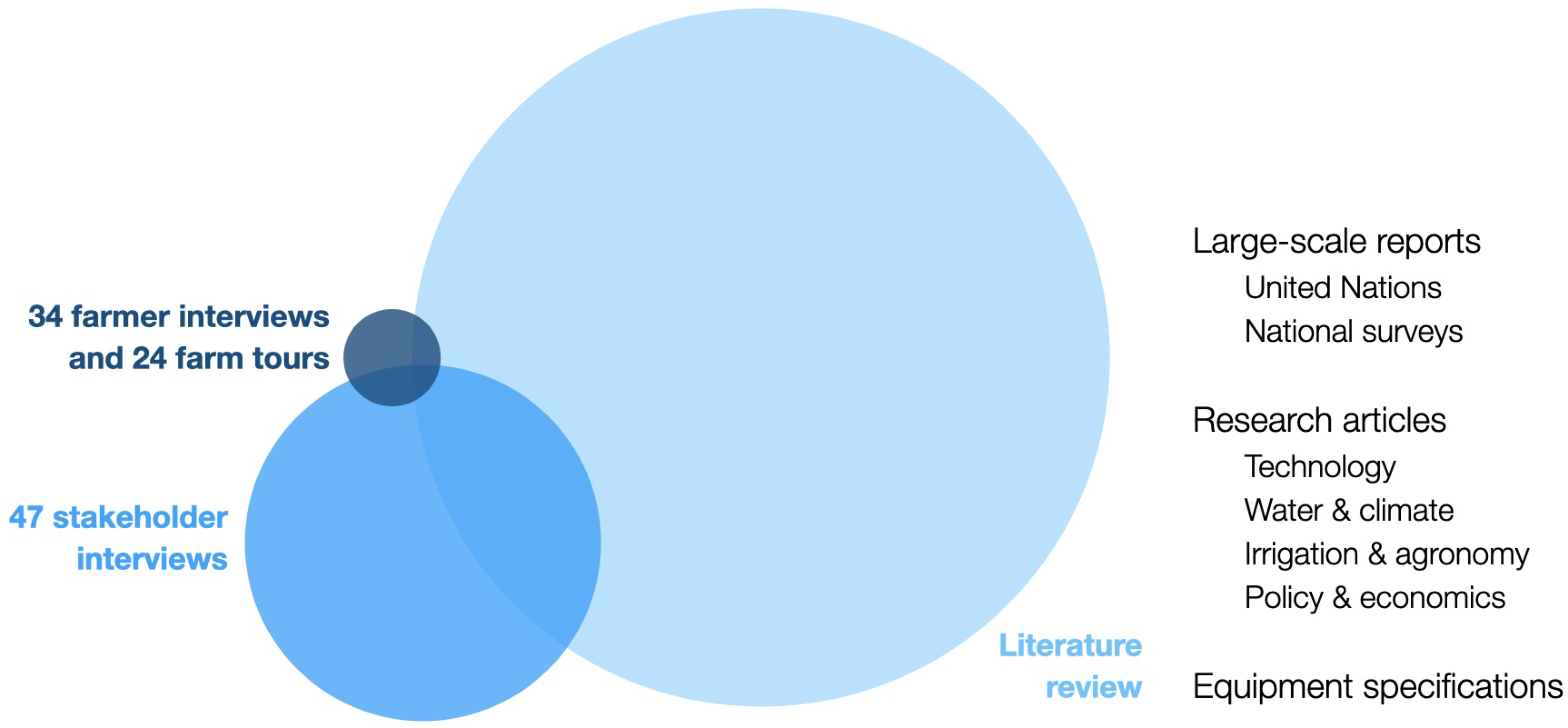

2. Interview-Based Market Assessment

2.1. Interviews with Farmers and Key Market Stakeholders

2.2. Market Segmentation Based on User-Driven Irrigation Needs

- Their farms were similarly sized and they were located in similar regions (e.g., rural or peri-urban);

- They cultivated the same types of crops (e.g., fruits, vegetables, or grains) and they used those crops for the same reasons (e.g., for in-home consumption or for market selling);

- They had similar economic profiles in terms of willingness and ability to invest in irrigation equipment;

- Their current irrigation practices were similar in terms of experience on similar equipment and similar irrigation knowledge or training, irrigation scheduling, and maintenance;

- Their desire for additional value add-ons that an irrigation system could offer were similar (e.g., cell phone charging or solutions for remote farm management).

- The traditional smallholder (10 farmers in this segment were interviewed);

- The semi-commercial smallholder (14 farmers were interviewed);

- The medium-scale contract farmer (7 farmers were interviewed);

- The remote farm owner (2 owners were interviewed).

2.2.1. Profile of the Traditional Smallholder

2.2.2. Profile of the Semi-Commercial Smallholder

2.2.3. Profile of the Medium-Scale Contract Farmer

2.2.4. Profile of the Remote Farm Owner

2.3. Value Propositions of Irrigation Systems for Each Market Segment

2.3.1. Traditional Smallholder

2.3.2. Semi-Commercial Smallholder

2.3.3. Medium-Scale Contract Farmer

2.3.4. Remote Farm Owner

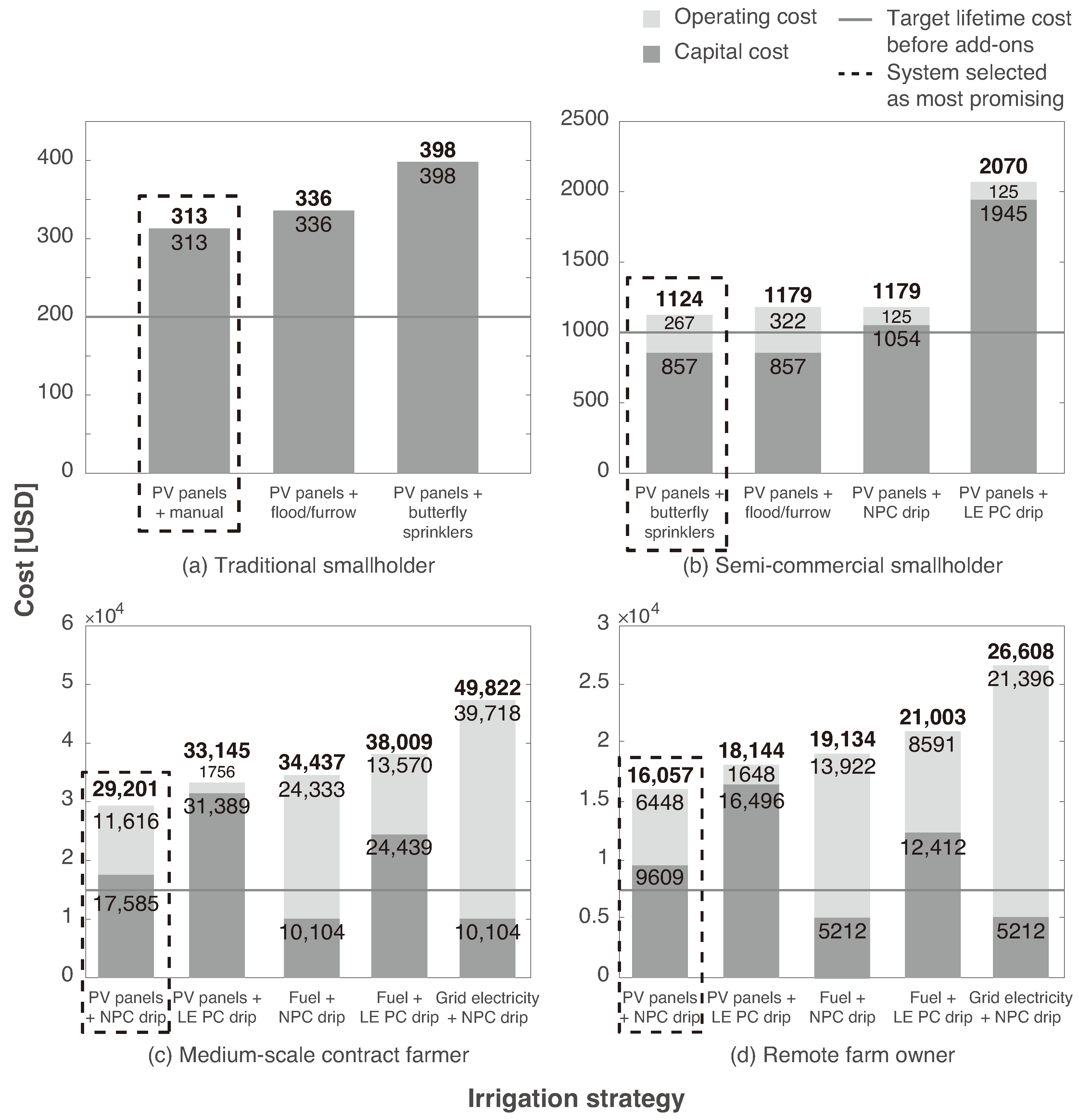

3. Techno-Economic Feasibility Analysis

3.1. Estimating the Cost of an Irrigation System

- Manual irrigation: Using buckets or handheld hoses to deliver water to the field;

- Flood or furrow irrigation: Covering the entire field with water or filling furrows between crop beds with water, respectively;

- Butterfly sprinklers: For this analysis, it is assumed that a farmer uses one set of five sprinklers that they move throughout their field every 30 to 60 min (based on interview data of common practices);

- Non-pressure-compensating (NPC) inline drip irrigation: Drip irrigation works by delivering water to rows of crops through a network of stationary main and submain pipes and lateral lines. The emitters within the lateral lines do not compensate for pressure changes expected in a pipe network, so the flow can be non-uniform;

- Low-energy pressure-compensating (LE PC) inline drip irrigation: PC drip emitters regulate their flow rates given the pressure changes expected in a pipe network, so flow is uniform throughout the field. LE PC drip is an emerging technology developed by the MIT Global Engineering and Research (GEAR) Lab [37]. LE PC emitters activate at lower pressures than conventional PC emitters, giving them the potential to save 42–54% in pumping power, which is an attribute that has shown promise in EA [38,39].

- Photovoltaic (PV) panels;

- Grid electricity;

- Fuel (e.g., diesel or petrol).

3.2. Candidate Irrigation Systems for Each Market Segment and Their Estimated Costs

3.3. Discussion of Opportunities to Deliver on Value Propositions and Irrigation Needs

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Details of Market Segment Profiles

Appendix A.1. Traditional Smallholder

Appendix A.2. Semi-Commercial Smallholder

Appendix A.3. Medium-Scale Contract Farmer

Appendix A.4. Remote Farm Owner

Appendix B. Elaboration on Irrigation Method and Energy Source Parameters in Table 3 and Table 4

Appendix B.1. Irrigation Methods

Appendix B.1.1. Manual Irrigation

Appendix B.1.2. Flood and Furrow Irrigation

Appendix B.1.3. Butterfly Sprinklers

Appendix B.1.4. NPC Inline Drip Irrigation

Appendix B.1.5. LE PC Inline Drip Irrigation

Appendix B.2. Energy Sources

Appendix B.2.1. PV Panels

Appendix B.2.2. Grid Electricity

Appendix B.2.3. Fuel

References

- Baquedano, F. International Food Security Assessment, 2020–2030; U.S. Department of Agriculture: Washington, DC, USA, 2020; p. 81. [Google Scholar]

- Amede, T. Technical and institutional attributes constraining the performance of small-scale irrigation in Ethiopia. Water Resour. Rural Dev. 2015, 6, 78–91. [Google Scholar] [CrossRef]

- Shah, T.; Verma, S.; Pavelic, P. Understanding smallholder irrigation in Sub-Saharan Africa: Results of a sample survey from nine countries. Water Int. 2013, 38, 809–826. [Google Scholar] [CrossRef]

- ICID Central Office. Agricultural Water Management for Sustainable Rural Development: Annual Report 2017–2018; Technical Report; ICID Central Office: New Delhi, India, 2018. [Google Scholar]

- FAO. The State of the World’s Land and Water Resources for Food and Agriculture (SOLAW)—Managing Systems at Risk; Food and Agriculture Organization of the United Nations: Rome, Italy; Earthscan: London, UK, 2011. [Google Scholar]

- Lefore, N.; Giordano, M.; Ringler, C.; Barron, J. Sustainable and Equitable Growth in Farmer-led Irrigation in Sub-Saharan Africa: What Will it Take? Water Altern. 2019, 12, 156–168. [Google Scholar]

- Nakawuka, P.; Langan, S.; Schmitter, P.; Barron, J. A review of trends, constraints and opportunities of smallholder irrigation in East Africa. Glob. Food Secur. 2018, 17, 196–212. [Google Scholar] [CrossRef]

- Lowder, S.K.; Skoet, J.; Raney, T. The Number, Size, and Distribution of Farms, Smallholder Farms, and Family Farms Worldwide. World Dev. 2016, 87, 16–29. [Google Scholar] [CrossRef]

- Tittonell, P.; Muriuki, A.; Shepherd, K.D.; Mugendi, D.; Kaizzi, K.C.; Okeyo, J.; Verchot, L.; Coe, R.; Vanlauwe, B. The diversity of rural livelihoods and their influence on soil fertility in agricultural systems of East Africa—A typology of smallholder farms. Agric. Syst. 2010, 103, 83–97. [Google Scholar] [CrossRef]

- Kansiime, M.K.; van Asten, P.; Sneyers, K. Farm diversity and resource use efficiency: Targeting agricultural policy interventions in East Africa farming systems. NJAS-Wagening. J. Life Sci. 2018, 85, 32–41. [Google Scholar] [CrossRef]

- Ulrich, K.T.; Eppinger, S.D.; Yang, M.C. Product Design and Development, 7th ed.; McGraw-Hill Education: New York, NY, USA, 2020. [Google Scholar]

- Schmitter, P.; Kibret, K.S.; Lefore, N.; Barron, J. Suitability mapping framework for solar photovoltaic pumps for smallholder farmers in sub-Saharan Africa. Appl. Geogr. 2018, 94, 41–57. [Google Scholar] [CrossRef]

- Salami, A.; Kamara, A.B.; Brixiova, Z. Smallholder Agriculture in East Africa: Trends, Constraints and Opportunities; African Development Bank: Tunis, Tunisia, 2010; p. 52. [Google Scholar]

- Abiyu, A.; Tebeje, M.; Mekonnen, E. Determinants of Small-Scale Irrigation Utilization by Smallholder Farmers’ in Rift Valley Basin, Wolaita Zone, Ethiopia. J. Nat. Sci. Res. 2015, 5, 6. [Google Scholar]

- Boithi, F.N.; Muchiri, E.; Birech, R.; Mulu-Mutuku, M. Factors Influencing Smallholder Farmers’ Adoption of Agricultural Water Technologies and Innovations in Lare and Elementaita Divisions of Nakuru County, Kenya. Int. J. Innov. Appl. Stud. 2014, 7, 1338–1343. [Google Scholar]

- Burney, J.A.; Naylor, R.L. Smallholder Irrigation as a Poverty Alleviation Tool in Sub-Saharan Africa. World Dev. 2012, 40, 110–123. [Google Scholar] [CrossRef]

- Kang’au, S.N.; Home, P.G.; Gathenya, J.M. Evaluation of the performance of smallholder pumped irrigation systems, in arid and semi-arid areas of Kenya. Agric. Eng. Int. CIGR J. 2011, 13, 14. [Google Scholar]

- Rapsomanikis, G. The Economic Lives of Smallholder Farmers; Technical Report; Food and Agriculture Organization of the United Nations: Rome, Italy, 2015. [Google Scholar]

- Wada, Y.; van Beek, L.P.H.; van Kempen, C.M.; Reckman, J.W.T.M.; Vasak, S.; Bierkens, M.F.P. Global depletion of groundwater resources: Global Groundwater Depletion. Geophys. Res. Lett. 2010, 37, L20402. [Google Scholar] [CrossRef]

- Jain, M.; Fishman, R.; Mondal, P.; Galford, G.L.; Bhattarai, N.; Naeem, S.; Lall, U.; Balwinder-Singh; DeFries, R.S. Groundwater depletion will reduce cropping intensity in India. Sci. Adv. 2021, 7, eabd2849. [Google Scholar] [CrossRef] [PubMed]

- Sachs, J.D. The African Green Revolution (Extended version). Scientific American, 1 May 2008. [Google Scholar]

- Blaustein, R.J. The Green Revolution Arrives in Africa. BioScience 2008, 58, 8–14. [Google Scholar] [CrossRef]

- Urban, G.L.; von Hippel, E. Lead User Analyses for the Development of New Industrial Products. Manag. Sci. 1988, 34, 569–582. [Google Scholar] [CrossRef]

- Miaskiewicz, T.; Kozar, K.A. Personas and user-centered design: How can personas benefit product design processes? Des. Stud. 2011, 32, 417–430. [Google Scholar] [CrossRef]

- KickStart International. By the Numbers. 2016. Available online: https://kickstart.org/impact/#by-the-numbers (accessed on 18 January 2020).

- Fisher, M. Scaling Solar Water Pumps in Asian and Africa. 2020. Available online: https://www.youtube.com/watch?v=vqSlFYzlm-I&feature=emb_logo&ab_channel=pManifoldBusinessSolutionsPvt.Ltd (accessed on 30 June 2020).

- Murphy, D.; Sharma, A. Scaling up Access to Electricity: The Case of Lighting Africa; Technical Report; World Bank Group: Washington, DC, USA, 2014. [Google Scholar]

- Deloitte. Sub-Saharan Africa Mobile Observatory; Technical Report; Deloitte: London, UK, 2012. [Google Scholar]

- Gowing, J.; Parkin, G.; Forsythe, N.; Walker, D.; Haile, A.T.; Alamirew, D. Shallow groundwater in sub-Saharan Africa: Neglected opportunity for sustainable intensification of small-scale agriculture? Hydrol. Earth Syst. Sci. Discuss. 2016, 1–33. [Google Scholar] [CrossRef]

- SunCulture. SunCulture Products. 2020. Available online: http://www.sunculture.com/index.php/products/ (accessed on 13 February 2020).

- Young, M. Mkulima Young Homepage. 2020. Available online: http://www.mkulimayoung.com/ (accessed on 18 January 2022).

- Farmingtech Solutions Limited. Committed, Empowered, Digitally Yours. 2019. Available online: https://digicow.co.ke/about-us/ (accessed on 18 January 2022).

- Tingey-Holyoak, J.; Pisaniello, J.; Buss, P.; Mayer, W. The importance of accounting-integrated information systems for realising productivity and sustainability in the agricultural sector. Int. J. Account. Inf. Syst. 2021, 41, 100512. [Google Scholar] [CrossRef]

- Hangzhou Qinjie Electromechanical Co., Ltd. Home Product Page. 2021. Available online: https://qjpump.en.alibaba.com/ (accessed on 18 January 2022).

- Taizhou Qingquan Pump Co., Ltd. Home Product Page. 2021. Available online: http://www.cn-qq.com/ (accessed on 18 January 2022).

- Kebede, H.; Birru, E. Guideline for Irrigation Agronomy; Ministry of Agriculture and Natural Resources Small-Scale Irrigation Development Directorate: Addis Ababa, Ethiopia, 2018. [Google Scholar]

- Ghodgaonkar, A.; Welsh, E.; Judge, B.; Bono, M.; Winter, A.G., V. An Empirical, Deterministic Design Theory for Compact Drip Emitter Labyrinths. In Volume 3B: 49th Design Automation Conference (DAC), Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 20–23 August 2023; ASME: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Sokol, J.A. Parametric Design and Performance Validation of Low-Cost, Low-Pressure Drip Emitters and Irrigation Systems. Ph.D. Thesis, MIT, Cambridge, MA, USA, 2020. [Google Scholar]

- Van de Zande, G.; Amrose, S.; Winter V, A.G. Evaluating the Potential for Low Energy Emitters to Facilitate Solar-Powered Drip Irrigation in Sub-Saharan Africa; Cambridge University Press: Cambridge, UK, 2020. [Google Scholar]

- Blimpo, M.P.; Cosgrove-Davies, M. Electricity Access in Sub-Saharan Africa; International Bank for Reconstruction and Development and The World Bank: Washington, DC, USA, 2019; p. 167. [Google Scholar]

- Grant, F.; Sheline, C.; Sokol, J.; Amrose, S.; Brownell, E.; Nangia, V.; Winter, A.G. Creating a Solar-Powered Drip Irrigation Optimal Performance model (SDrOP) to lower the cost of drip irrigation systems for smallholder farmers. Appl. Energy 2022, 323, 119563. [Google Scholar] [CrossRef]

- Grafton, R.Q.; Williams, J.; Molle, F.; Ringler, C.; Steduto, P.; Udall, B.; Wheeler, S.A.; Wang, Y.; Garrick, D.; Allen, R.G. The paradox of irrigation efficiency. Science 2018, 361, 748–750. [Google Scholar] [CrossRef] [PubMed]

- Jobbins, G.; Kalpakian, J.; Chriyaa, A.; Legrouri, A.; El Mzouri, E.H. To what end? Drip irrigation and the water-energy-food nexus in Morocco. Int. J. Water Resour. Dev. 2015, 31, 393–406. [Google Scholar] [CrossRef]

- IRENA. Solar PV in Africa: Costs and Markets; Technical Report; IRENA: Abu Dhabi, United Arab Emirates, 2016. [Google Scholar]

- FAO. Smallholders Dataportrait; FAO: Rome, Italy, 2020. [Google Scholar]

- Efficiency for Access Coalition and 60 Decibels. Uses and Impacts of Solar Water Pumps: Insights from Kenya, Rwanda, Senegal, Tanzania, Uganda, Zambia; Technical Report; Efficiency for Access: Nairobi, Kenya; 60 Decibels: New York, NY, USA, 2021. [Google Scholar]

- KickStart International. Our Tools to End Poverty. 2016. Available online: https://kickstart.org/how-we-work/ (accessed on 18 January 2022).

- Futurepump. Futurepump. 2020. Available online: https://futurepump.com/ (accessed on 13 February 2020).

- FAO. Prices: FAO Price Data and Analysis. 2022. Available online: https://www.fao.org/prices/en/ (accessed on 18 January 2022).

- Mediae Company. Welcome to Shamba Shape Up. 2021. Available online: https://shambashapeup.com/ (accessed on 2 June 2021).

- Jayne, T.; Chamberlin, J.; Traub, L.; Sitko, N.; Muyanga, M.; Yeboah, F.K.; Anseeuw, W.; Chapoto, A.; Wineman, A.; Nkonde, C.; et al. Africa’s changing farm size distribution patterns: The rise of medium-scale farms. Agric. Econ. 2016, 47, 197–214. [Google Scholar] [CrossRef]

- Neven, D.; Odera, M.M.; Reardon, T.; Wang, H. Kenyan Supermarkets, Emerging Middle-Class Horticultural Farmers, and Employment Impacts on the Rural Poor. World Dev. 2009, 37, 1802–1811. [Google Scholar] [CrossRef]

- Ochieng, D.O.; Veettil, P.C.; Qaim, M. Farmers’ preferences for supermarket contracts in Kenya. Food Policy 2017, 68, 100–111. [Google Scholar] [CrossRef]

- Alibaba.com. 150 ft Short Heavy Duty Lightweight Garden Hose. 2021. Available online: https://www.alibaba.com/product-detail/Garden-Hose-150-Ft-Short-Heavy_1600214226448.html?spm=a2700.galleryofferlist.normal_offer.d_image.7a197d181FMvfL&s=p (accessed on 28 May 2021).

- Postel, S.; Polak, P.; Gonzales, F.; Keller, J. Drip Irrigation for Small Farmers: A New Initiative to Alleviate Hunger and Poverty. Water Int. 2001, 26, 3–13. [Google Scholar] [CrossRef]

- Tagseth, M. Oral history and the development of indigenous irrigation. Methods and examples from Kilimanjaro, Tanzania. Nor. Geogr. Tidsskr.-Nor. J. Geogr. 2008, 62, 9–22. [Google Scholar] [CrossRef]

- Allen, R.; Pereira, L.S.; Raes, D.; Smith, M. FAO Irrigation and Drainage Paper No. 56; Technical Report; FAO: Rome, Italy, 1998. [Google Scholar]

- Ningbo Seninget Irrigation Co., Ltd. Product Catalog; Ningbo Seninget Irrigation Co.: Ningbo, China, 2020. [Google Scholar]

- Netafim. Streamline X Product Sheet. Available online: https://www.netafim.com/49296b/globalassets/products/drippers-and-dripperlines/streamline-x/new-product-sheets/streamline-x-product-sheet.pdf (accessed on 27 May 2021).

- Sheline, C. Lowering the Cost of Solar-Powered Drip Irrigation Systems for Smallholder Farmers through Systems-Level Modeling, Optimization, and Field Testing. Ph.D. Thesis, MIT, Cambridge, MA, USA, 2019. [Google Scholar]

- Grant, F.R. Development and Validation of a Systems-Level Cost Optimization Tool for Solar-Powered Drip Irrigation Systems for Smallholder Farms. Ph.D. Thesis, MIT, Cambridge, MA, USA, 2019. [Google Scholar]

- Sokol, J.; Narain, J.; Costello, J.; McLaurin, T.; Kumar, D.; Winter, A.G. Analytical model for predicting activation pressure and flow rate of pressure-compensating inline drip emitters and its use in low-pressure emitter design. Irrig. Sci. 2022, 40, 217–237. [Google Scholar] [CrossRef]

- Netafim. Uniram RC Product Sheet. Available online: https://www.netafim.com/49209a/globalassets/products/drippers-and-dripperlines/uniram/new-product-sheets/uniram-rc-product-sheet.pdf (accessed on 27 May 2021).

- Efficiency for Access Coalition. Global LEAP Awards: 2019 Buy’s Guide for Solar Water Pumps; Technical Report; Efficiency for Access Coalition: Nairobi, Kenya, 2019. [Google Scholar]

- Mohammed Wazed, S.; Hughes, B.R.; O’Connor, D.; Kaiser Calautit, J. A review of sustainable solar irrigation systems for Sub-Saharan Africa. Renew. Sustain. Energy Rev. 2018, 81, 1206–1225. [Google Scholar] [CrossRef]

- George, A.; Boxiong, S.; Arowo, M.; Ndolo, P.; Chepsaigutt-Chebet; Shimmon, J. Review of solar energy development in Kenya: Opportunities and challenges. Renew. Energy Focus 2019, 29, 123–140. [Google Scholar] [CrossRef]

- Kenya National Bureau of Statistics. 2015/16 Kenya Integrated Household Budget Survey: Basic Report; Kenya National Bureau of Statistics: Nairobi, Kenya, 2018. [Google Scholar]

- GlobalPetrolPrices.com. Kenya Electricity Prices. 2021. Available online: https://www.globalpetrolprices.com/Kenya/electricity_prices/ (accessed on 29 April 2021).

- de Fraiture, C.; Giordano, M. Small private irrigation: A thriving but overlooked sector. Agric. Water Manag. 2014, 131, 167–174. [Google Scholar] [CrossRef]

- GlobalPetrolPrices.com. Kenya Diesel Prices, 17-May-2021. 2021. Available online: https://www.globalpetrolprices.com/Kenya/diesel_prices/ (accessed on 24 May 2021).

| Traditional Smallholder | Semi-Commercial Smallholder | Medium-Scale Contract Farmer | Remote Farm Owner | |

|---|---|---|---|---|

| Water source(s) | Surface water or shallow wells up to 10 m deep | Surface or shallow wells/ boreholes up to 25 m deep | Boreholes up to 100 m deep | Boreholes up to 100 m deep |

| Farm area irrigated | 0.125 ha | 0.25 ha | 2–5 ha (this analysis uses 4 ha) | 1–4 ha (this analysis uses 2 ha) |

| Irrigation scheduling | Willing to irrigate 4 h/day | Willing to irrigate 6 h/day | Willing to irrigate 7 h/day | Willing to irrigate 7 h/day |

| practices | Can be flexible with crop subsections as needed | Can be flexible with crop subsections as needed | Crop subsections are ≥0.2 ha and take ≥0.5 h to irrigate | Crop subsections are ≥0.2 ha and take ≥0.5 h to irrigate |

| Crop types and intended use for crop | A mix of low-value crops (e.g., maize) and high-value vegetables (e.g., cabbage and tomato) | High-value vegetables (e.g., cabbage, tomato) and fruits | High-value crops (e.g., tomatoes, cabbage, herbs, fruits) | High-value crops (e.g., tomatoes, cabbage, herbs, fruits) |

| Intend to consume >90% of crop yield | Intend to consume >70% of crop yield and sell >30% | Intend to sell >95% of crop yield | Intend to sell >100% of crop yield | |

| Investment timescale | 2–3 seasons (this analysis uses 1 year) | 2–3 years (this analysis uses 3 years) | 5–10 years (this analysis uses 5 years) | 5–10 years (this analysis uses 5 years) |

| Lifetime cost over investment timescale | USD 300; USD 200 before value add-ons | USD 1300; USD 1000 before value add-ons | USD 18,000; USD 15,000 before value add-ons | USD 9000; USD 7500 before value add-ons |

| Non-irrigation value add-ons | Phone charging and home lighting; Under 50 kg for portability | Phone charging, home lighting, power for small home appliances (e.g., TV, fan, minifridge, and cooking appliances) | Increased data and prediction (irrigation, pests, disease, markets) Flexibility of system based on farm characteristics | Solutions for improved remote farm management Same value add-ons as medium-scale contract farmer |

| Core value proposition of an irrigation system | A low-cost, portable irrigation system that replaces human power and enables cell phone charging and home lighting | An irrigation system that helps farmers grow their businesses and lifestyles | An irrigation system that maximizes farmers’ profits | An irrigation system that farmers can monitor from the city and provides them with additional income |

| Irrigation Demand | Crop Water Requirement, |

|---|---|

| Medium (cabbage is representative) | 5 mm/day |

| High (tomato is representative) | 7 mm/day |

| Equipment Cost [USD/ha] , | Equipment Lifetime [years] | Operating Pressure [m] | Water Factor | |

|---|---|---|---|---|

| Manual irrigation | 50 | 2 | 1 | 0.5 |

| Flood or furrow irrigation | 25 | 2 | 1 | 1.0 |

| Butterfly sprinklers | 26.5 | 2 | 10 | 1.0 |

| NPC drip sections | 2400 | 3 | 14 | 0.5 |

| LE PC drip sections | 6000 | 10 | 5.9 | 0.5 |

| Cost, , | Equipment Lifetime [years], | |

|---|---|---|

| PV panels | 0.81 USD/W | 20 |

| Grid electricity | 0.06 USD/MJ | N/A |

| Fuel | 0.03 USD/MJ | N/A |

| Traditional Smallholder | Semi-Commercial Smallholder | Medium-Scale Contract Farmer | Remote Farm Owner | |

|---|---|---|---|---|

| Manual | Candidate | Non-candidate. The time needed | Non-candidate. The irrigated | Non-candidate. The |

| irrigation | to manually irrigate 0.25 ha | areas of 2–5 ha are too large | irrigated areas of | |

| for 6 h/day is too high for | for this irrigation method. | 1–4 ha are too | ||

| a farmer who is growing their | large for this method. | |||

| business. | ||||

| Flood or | Candidate | Candidate | Non-candidate. Crop uniformity | Non-candidate. Crop |

| furrow | is important for resale value in | uniformity is important | ||

| irrigation | this segment, and this method | for resale value; this | ||

| does not ensure uniformity. | method does not ensure | |||

| uniformity. | ||||

| Butterfly | Candidate | Candidate | Non-candidate. The irrigated | Non-candidate. The |

| sprinkler | areas of 2–5 ha are too large | irrigated areas of | ||

| irrigation | for this irrigation method. | 1–4 ha are too large | ||

| for this method. | ||||

| Drip | Non-candidate. Farmers lack | Candidate 2 | Candidate | Candidate |

| irrigation | the amount of training | |||

| (NPC or | needed to use drip | |||

| PC) | effectively. 1 | |||

| PV panels | Candidate | Candidate | Candidate | Candidate |

| Grid | Non-candidate. Farms are too | Non-candidate. Farms are too | Candidate | Candidate |

| electricity | rural to have reliable | rural to have reliable | ||

| connections. 3 | connections. 3 | |||

| Fuel | Non-candidate. The high and | Non-candidate. The high and | Candidate | Candidate |

| fluctuating cost of fuel | fluctuating cost of fuel | |||

| is a crutch in farmers’ | is a crutch in farmers’ | |||

| budgeting. Fuel can also | budgeting. Fuel can also | |||

| be difficult to source. 4 | be difficult to source. 4 |

| Traditional Smallholder | Semi-Commercial Smallholder | Medium-Scale Contract Farmer | Remote Farm Owner | |

|---|---|---|---|---|

| Irrigation | PV panels | PV panels | PV panels | PV panels |

| strategy | + manual | + butterfly | + NPC drip | + NPC drip |

| irrigation | sprinklers | irrigation | irrigation | |

| System | 0.8 | 2.9 | 20 | 10 |

| flow rate | ||||

| [m3/h] | ||||

| System | 11 | 35 | 114 | 114 |

| pressure | ||||

| head [m] | ||||

| Maximum | 15 cm | 10 cm | 10 cm | 10 cm |

| pump | ||||

| diameter | ||||

| [cm] | ||||

| Minimum | 1 | 3 | 5 | 5 |

| lifetime | ||||

| [years] | ||||

| Estimated | Capital: 313 | Capital: 857 | Capital: 17,585 | Capital: 9609 |

| system | Operating: 0 | Operating: 267 | Operating: 11,616 | Operating: 6448 |

| costs [USD] | Lifetime: 313 | Lifetime: 1124 | Lifetime: 29,201 | Lifetime: 16,057 |

| Target | 300 USD; | 1300 USD; | 18,000 USD; | 9000 USD; |

| system | 200 USD | 1000 USD | 15,000 USD | 7500 USD |

| lifetime | before value | before value | before value | before value |

| costs [USD] | add-ons | add-ons | add-ons | add-ons |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van de Zande, G.D.; Amrose, S.; Donlon, E.; Shamshery, P.; Winter V, A.G. Identifying Opportunities for Irrigation Systems to Meet the Specific Needs of Farmers in East Africa. Water 2024, 16, 75. https://doi.org/10.3390/w16010075

Van de Zande GD, Amrose S, Donlon E, Shamshery P, Winter V AG. Identifying Opportunities for Irrigation Systems to Meet the Specific Needs of Farmers in East Africa. Water. 2024; 16(1):75. https://doi.org/10.3390/w16010075

Chicago/Turabian StyleVan de Zande, Georgia D., Susan Amrose, Elliott Donlon, Pulkit Shamshery, and Amos G. Winter V. 2024. "Identifying Opportunities for Irrigation Systems to Meet the Specific Needs of Farmers in East Africa" Water 16, no. 1: 75. https://doi.org/10.3390/w16010075

APA StyleVan de Zande, G. D., Amrose, S., Donlon, E., Shamshery, P., & Winter V, A. G. (2024). Identifying Opportunities for Irrigation Systems to Meet the Specific Needs of Farmers in East Africa. Water, 16(1), 75. https://doi.org/10.3390/w16010075