Advances in Drinking Water Treatment through Piloting with UF Membranes

Abstract

:1. Introduction

- To determine the effectiveness of the ultrafiltration system to treat raw feed water at the drinking water treatment plant.

- To demonstrate that the ultrafiltration system produces a high-quality filtrate, which has a turbidity <0.1 NTU.

- To define operational flux and in situ cleaning protocols.

- To define operating parameters for a full-scale ultrafiltration system, including chemical dosing, membrane flux, and recovery.

2. Materials and Methods

- Type: HFU2020-AN (cross-flow filtration).

- Membrane Material: PVDF (polyvinylidene fluoride)

- Nominal Pore Size: μm 0.01

- Outer Membrane Surface Area: m² (ft²) 72 (775)

- Operating Temperature Range: °C (°F) 0–40 (32–104)

- pH Range During Filtration: 1–10

- pH Range During Cleaning: 0–12

- Maximum Feed Water/Filtrate Flow: m³/h (gpm) 12 (53)

- Maximum Backwash Flow: m³/h (gpm) 13.5 (59)

- Maximum Air Flow: Nm³/h (scfm) 9.0 (5.3)

- Maximum Inlet Pressure: bar 3

- Maximum Backwash Pressure: bar 3

- Normal Operating Transmembrane Pressure: bar 0–2

- Diameter: mm (in) 216 (8.5)

- Length: mm (ft) 2160 (7.087)

- Weight:

- Full of Water: kg (lbs) 92 (203)

- After Draining: kg (lbs) 49 (108)

- Casing: uPVC

- Cap: uPVC

- Potting: epoxy resin

- O-ring: EPDM

3. Results

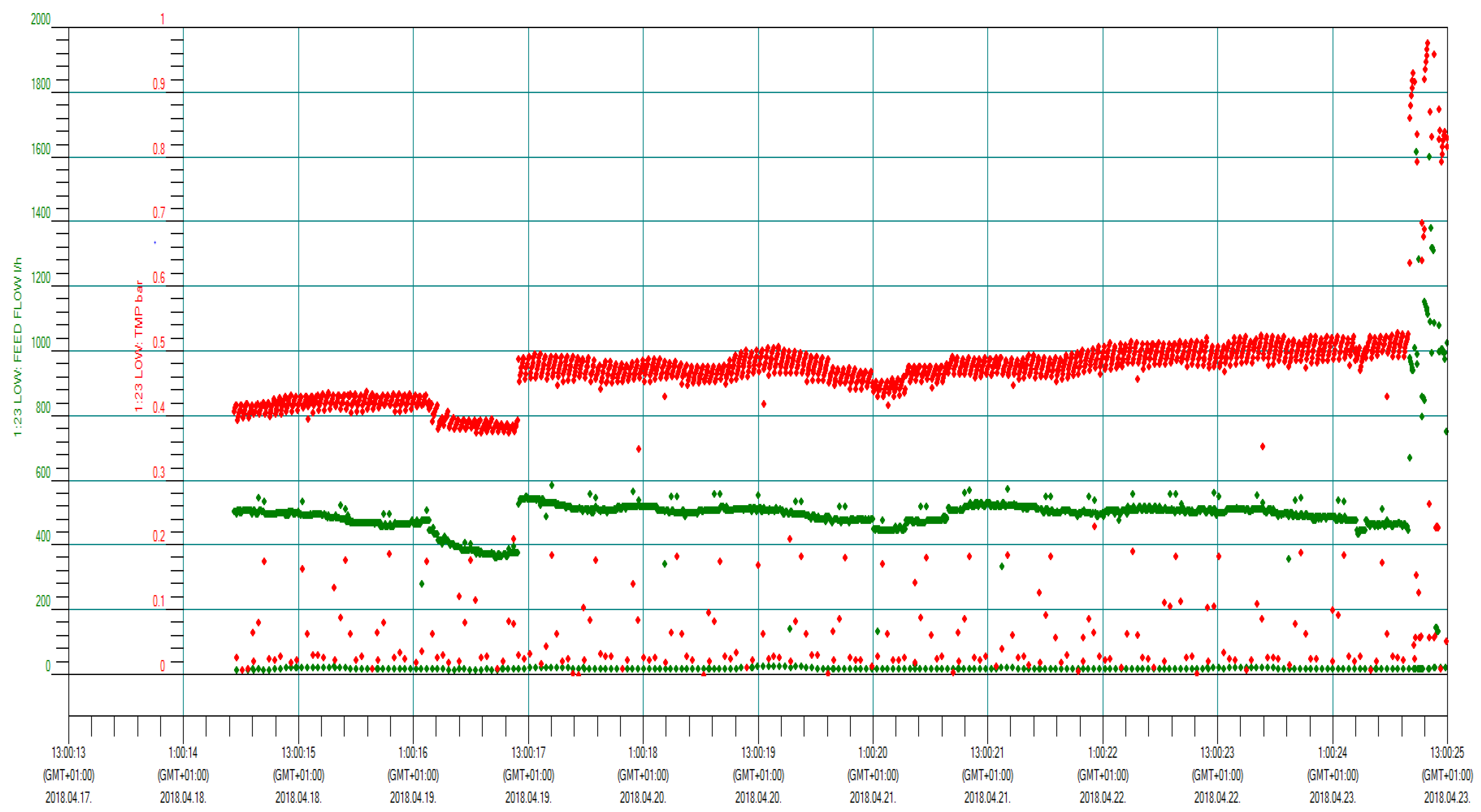

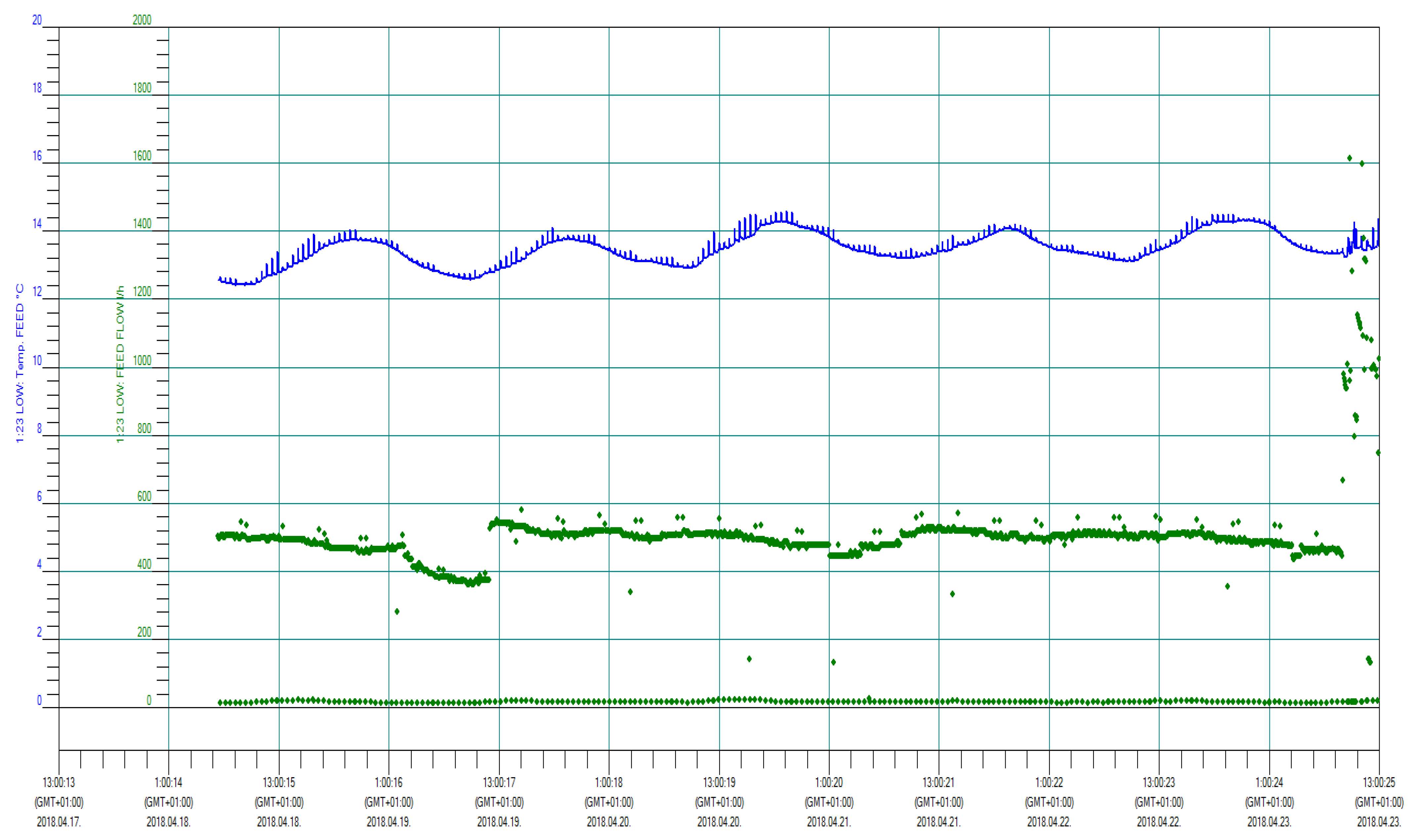

3.1. Phase 1 (Demonstration Phase)

- ○

- Instantaneous flux rate of 45–50 L/m2h.

- ○

- Average feed temperature of 13 °C.

- ○

- Operating trans-membrane pressure (TMP) of 0.42 to 0.5 bar.

- ○

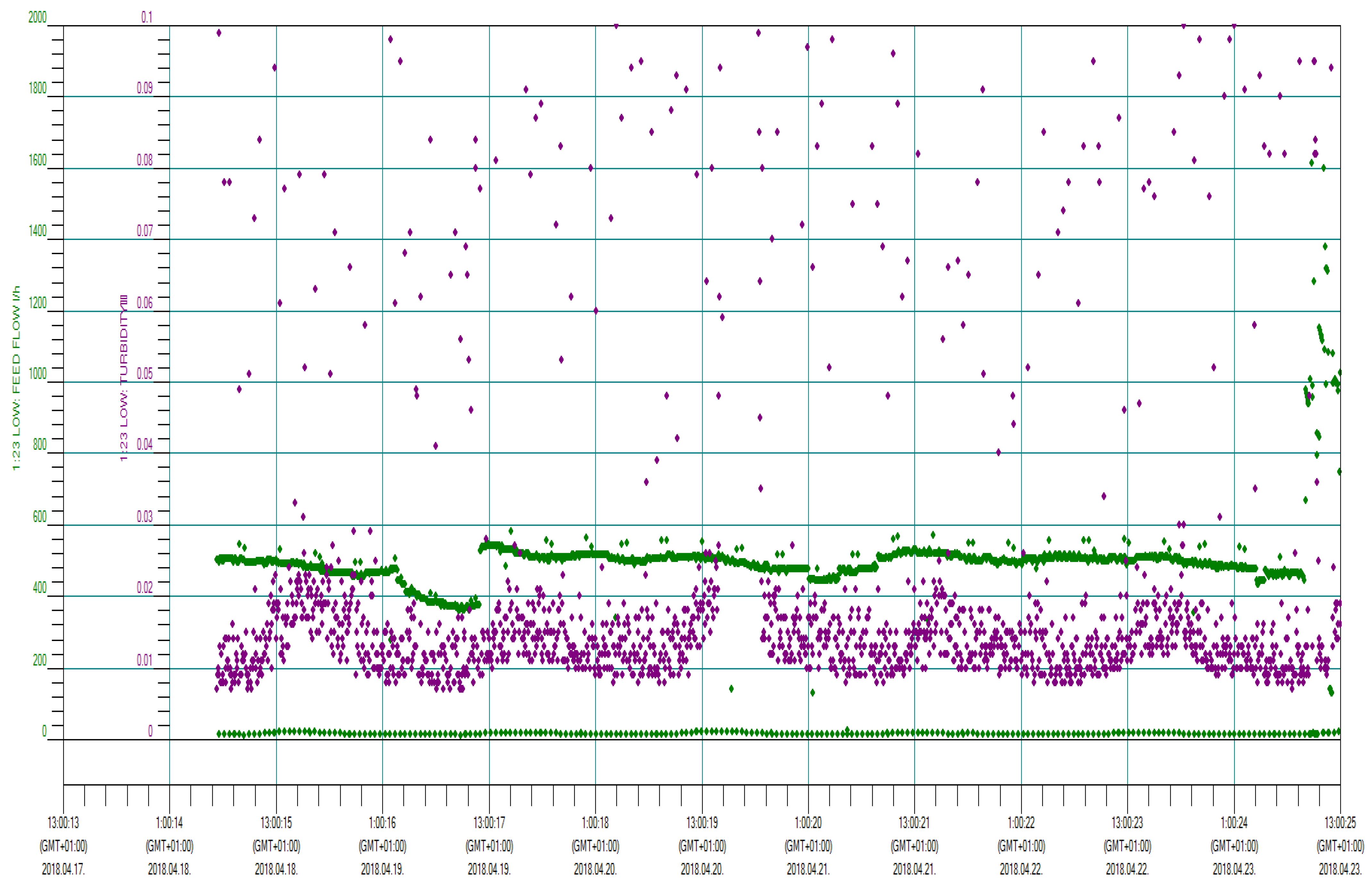

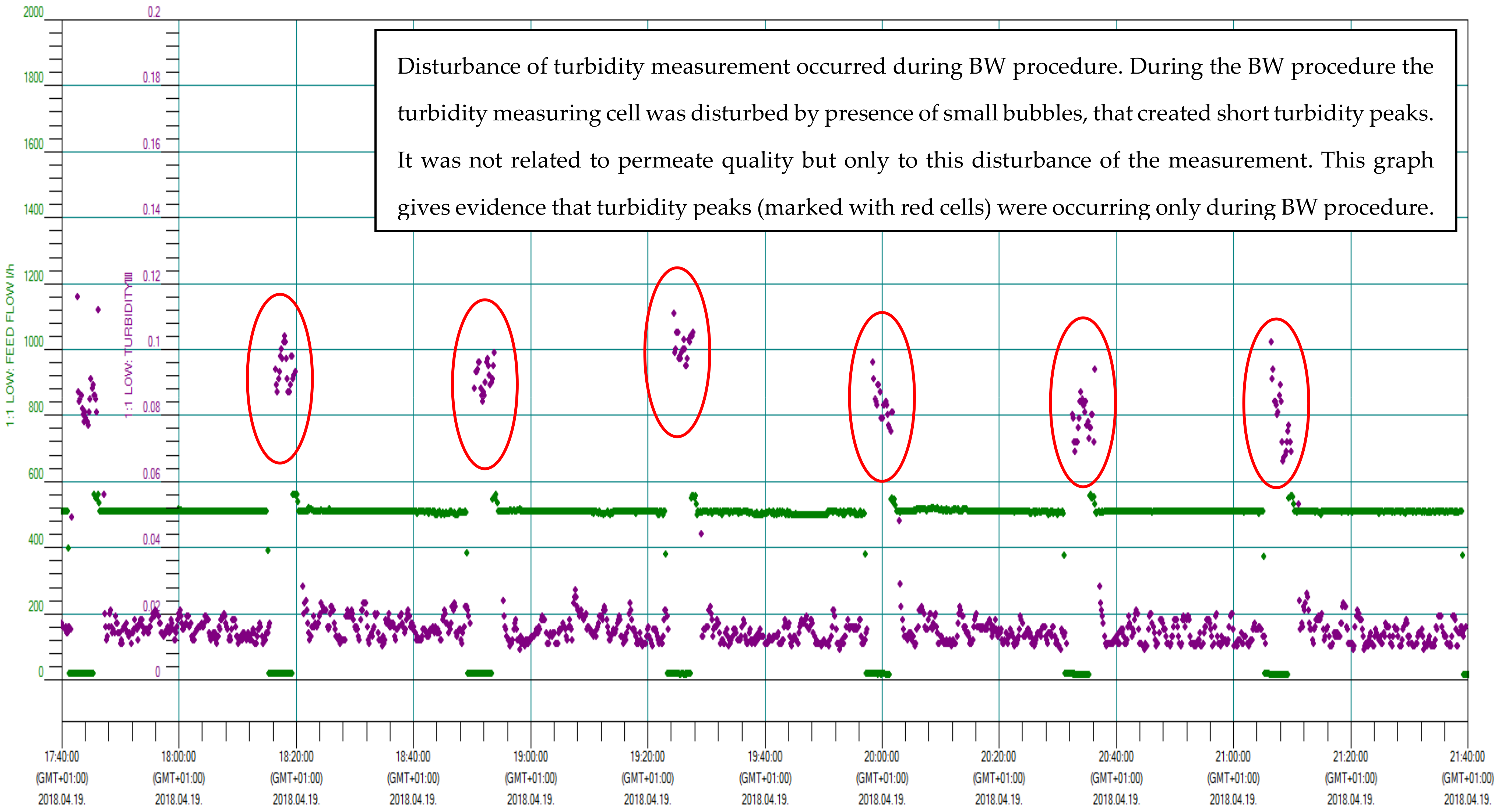

- Average permeate turbidity of <0.03 NTU (peaks during the BW procedure due to the presence of bubbles in the measuring cells).

- ○

- Temperature-corrected permeability (20 °C) ranging from 90 to 95 L/(hm2bar) (in the 45–50 L/m2h range).

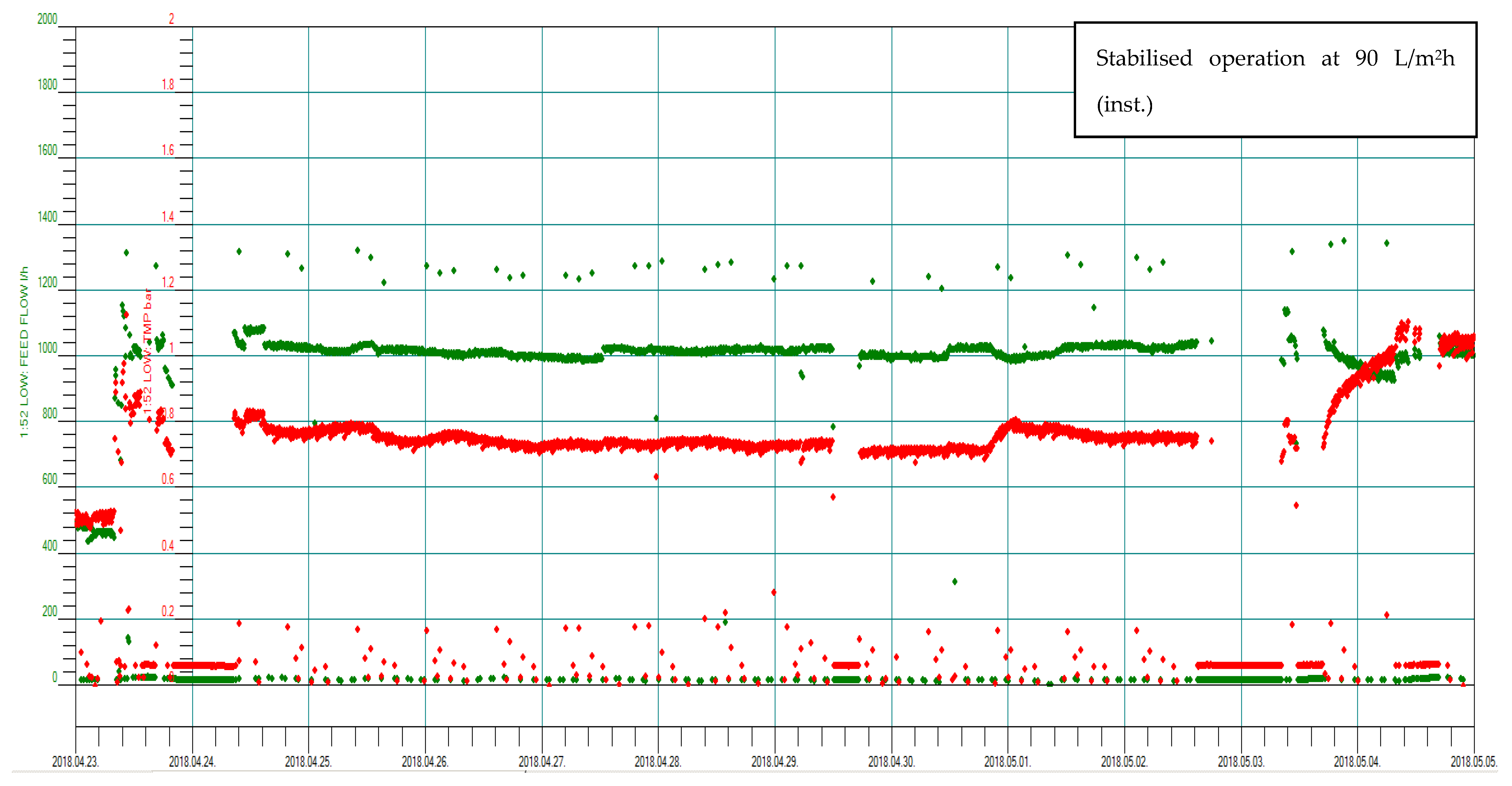

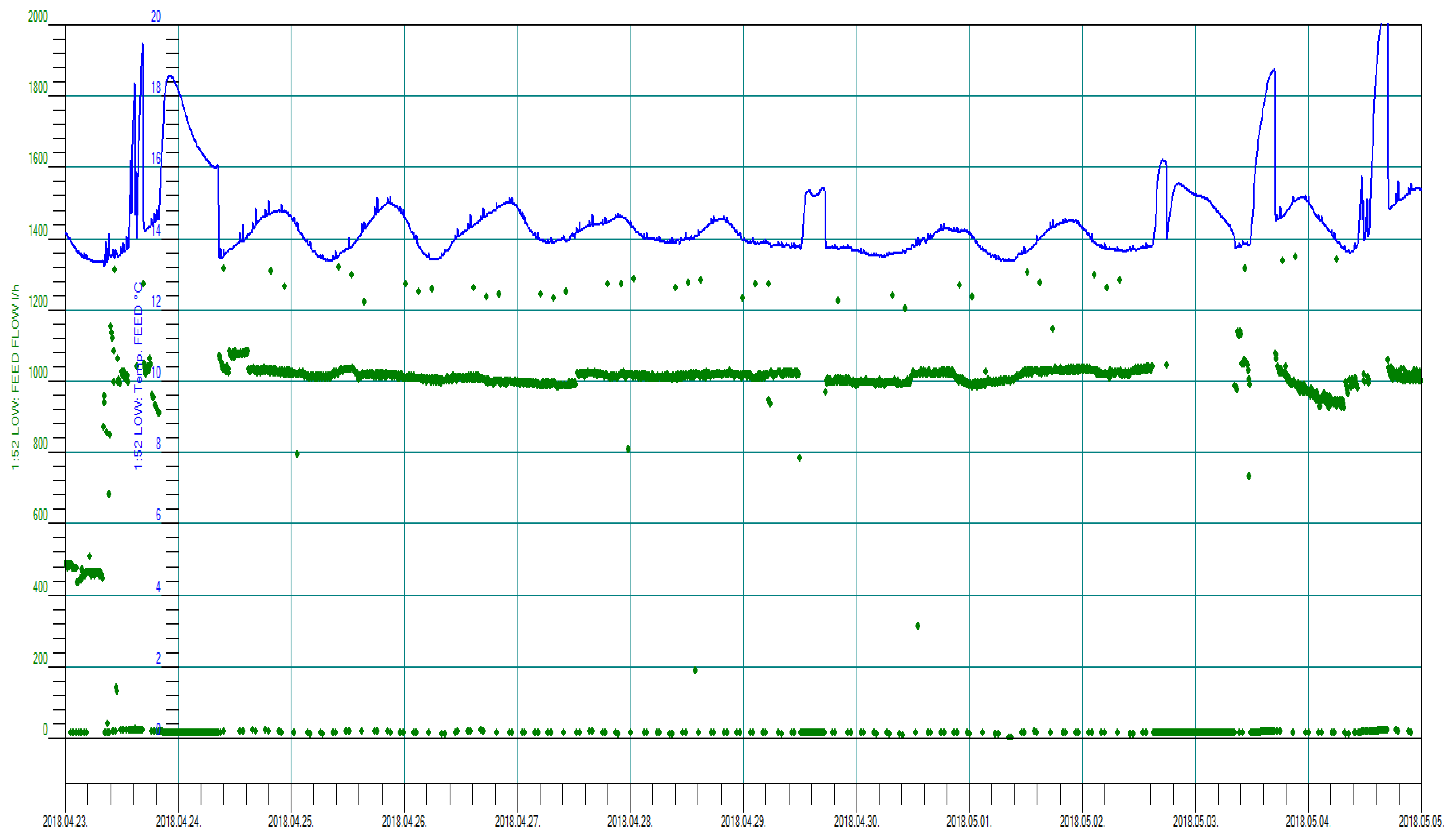

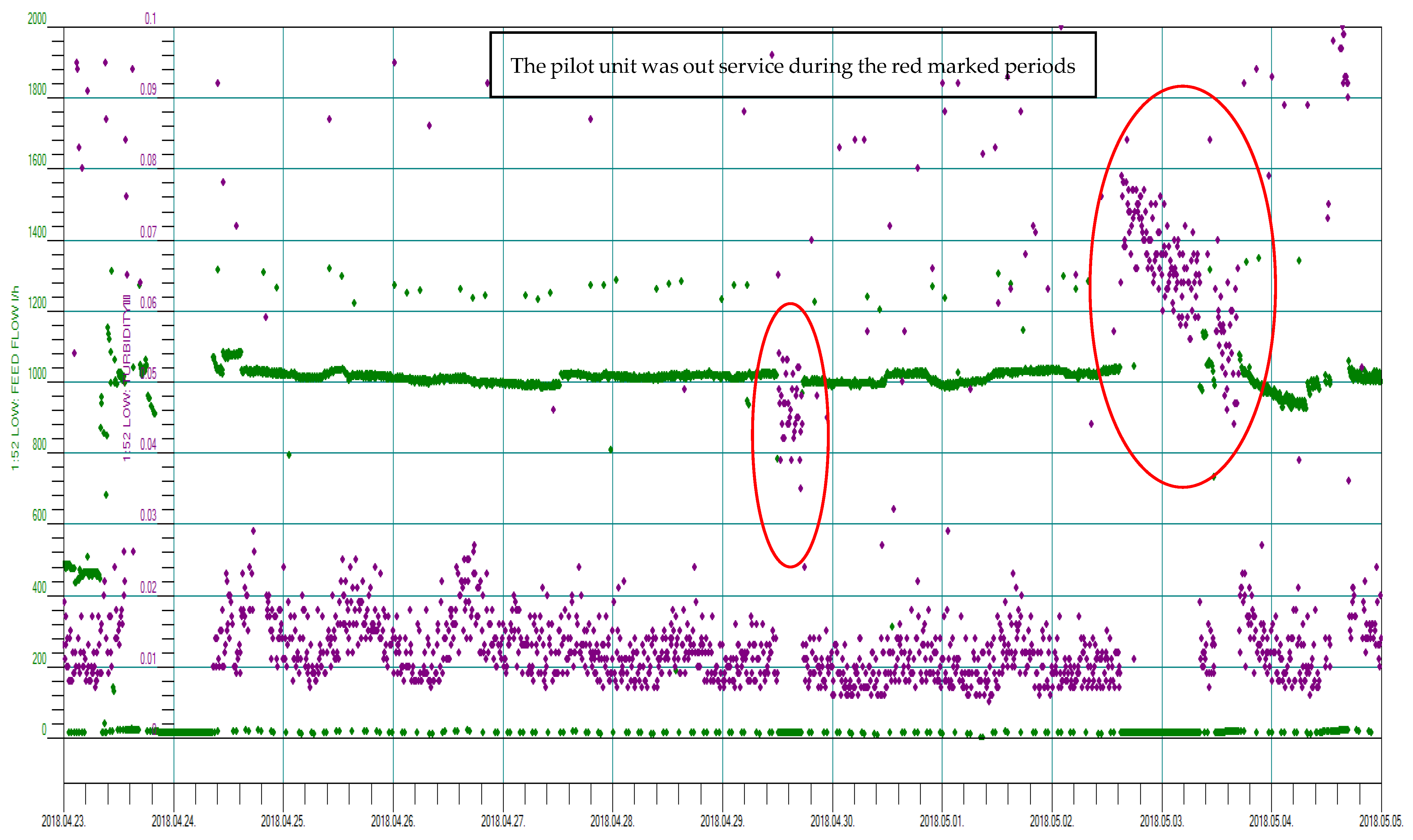

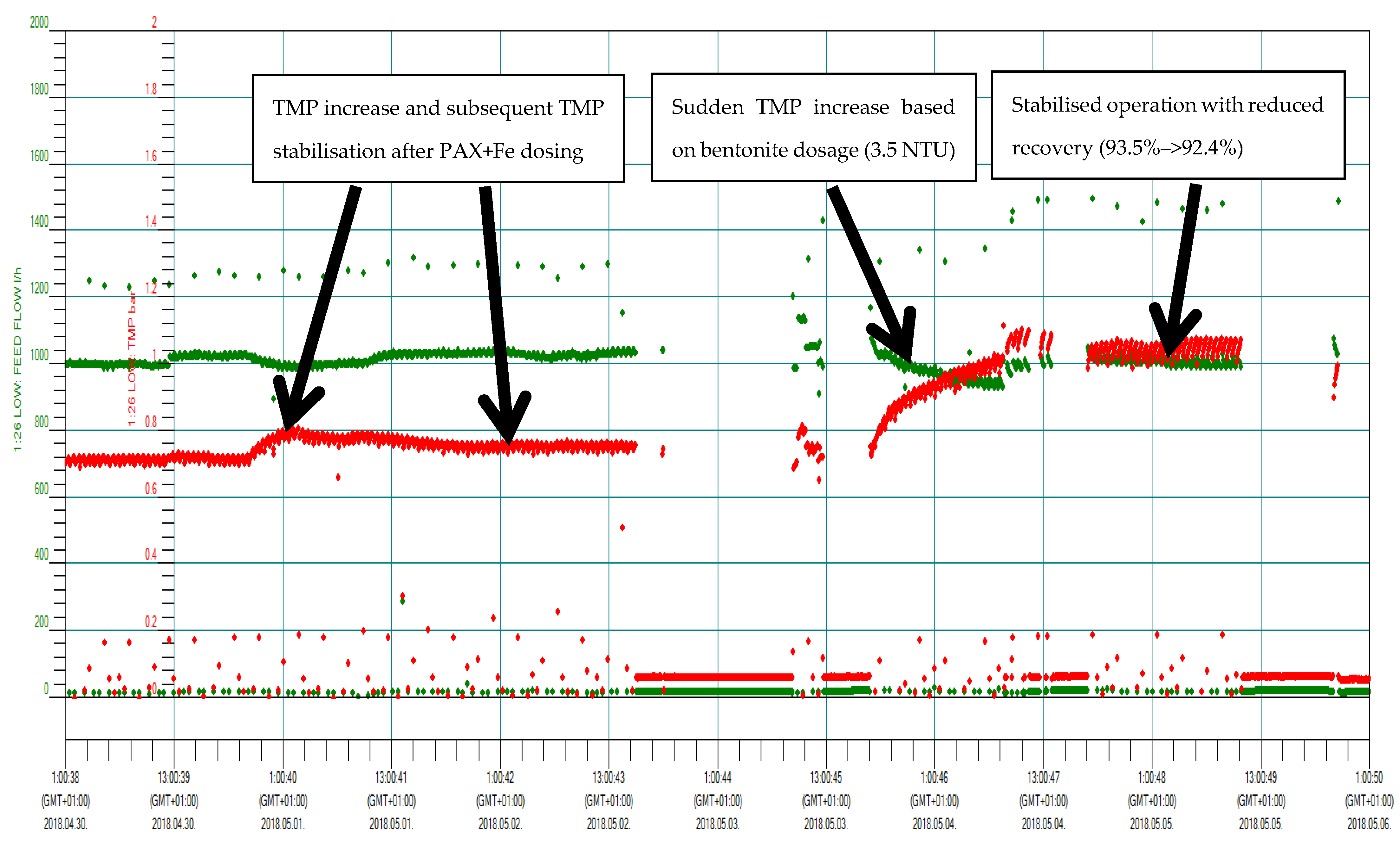

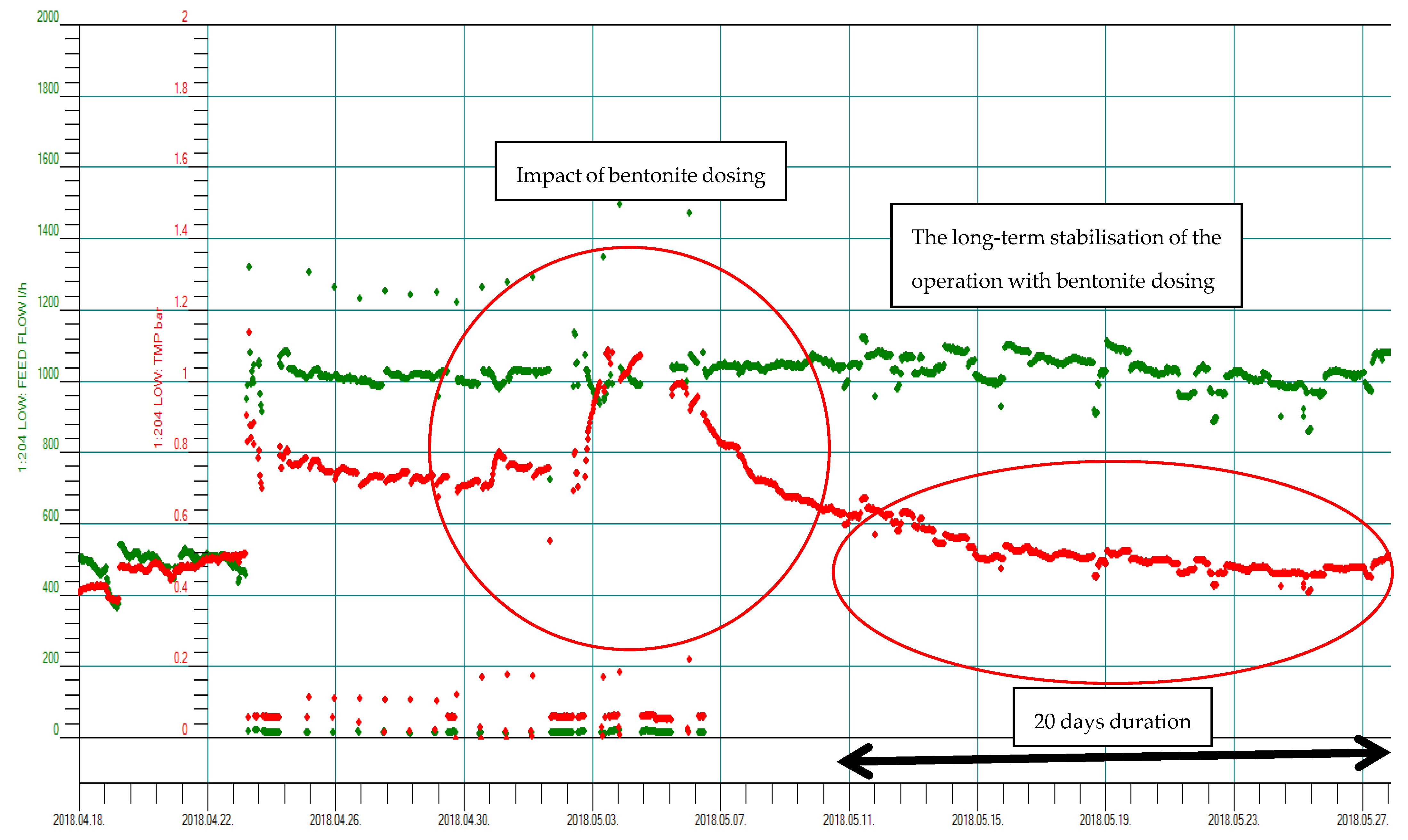

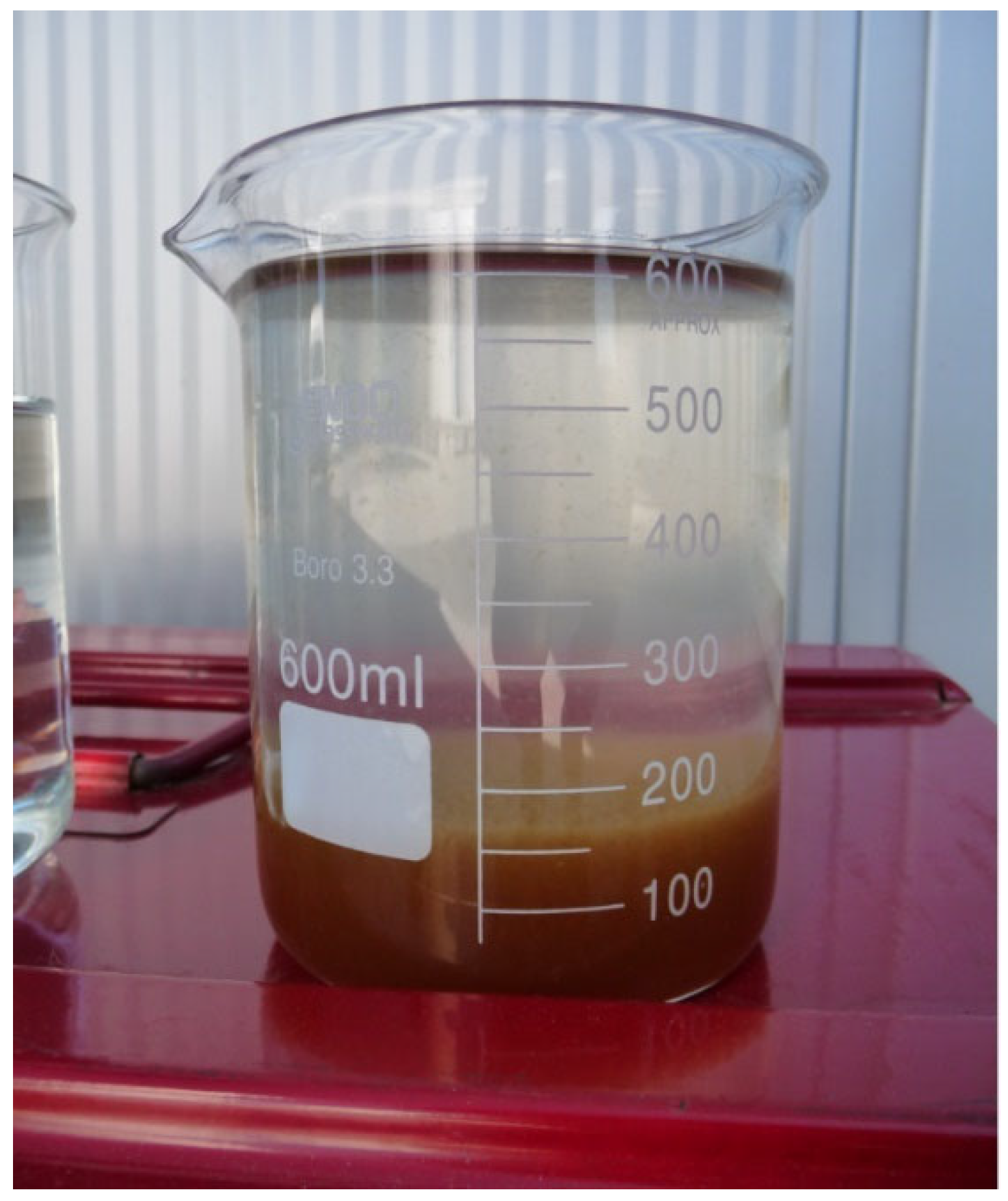

3.2. Phase 2—Operation at 90 L/m2h + Simulating Turbidity Peaks by Bentonite Dosing

- ○

- Instantaneous flux rate of 90 L/m2h.

- ○

- Average feed temperature of 14 °C.

- ○

- Operating trans-membrane pressure (TMP) of 0.7 to 0.8 bar.

- ○

- Average permeate turbidity of <0.03 NTU (peaks during the BW procedure due to the presence of bubbles in the measuring cells).

- ○

- Temperature-corrected permeability (20 °C) ranging from 131 to 150 L/m2hbar at 90 L/m2h.

- ○

- Instantaneous flux rate of 90–95 L/m2h (because of some technical issues, the feed flow control was not fully stable).

- ○

- Average feed temperature of 14 °C.

- ○

- Operating trans-membrane pressure (TMP) of 1 to 0.5 bar.

- ○

- Average permeate turbidity of <0.03 NTU (peaks during the BW procedure due to the presence of bubbles in the measuring cells).

- ○

- Temperature-corrected permeability (20 °C) ranging from 105 to 220 L/m2hbar at 90 L/m2h.

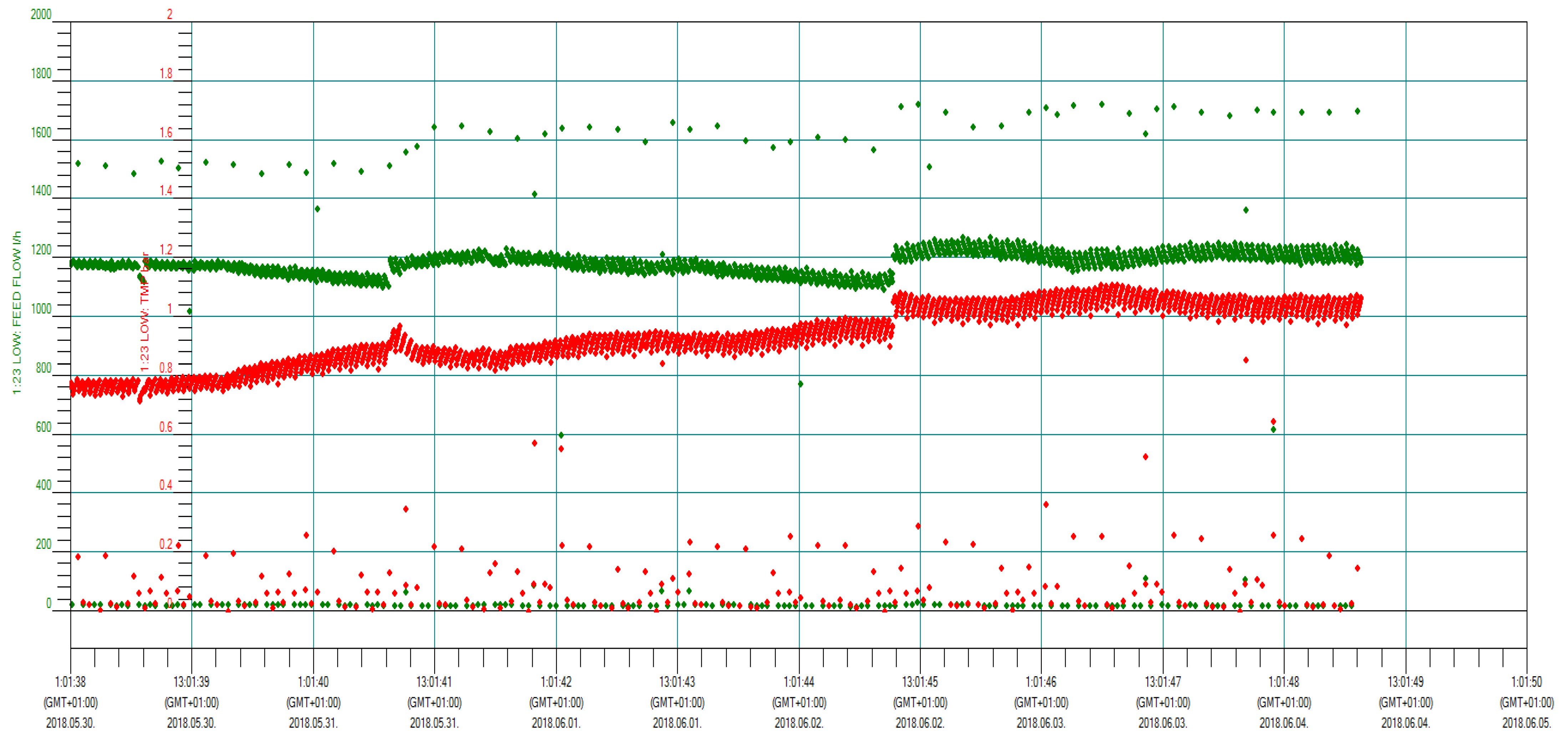

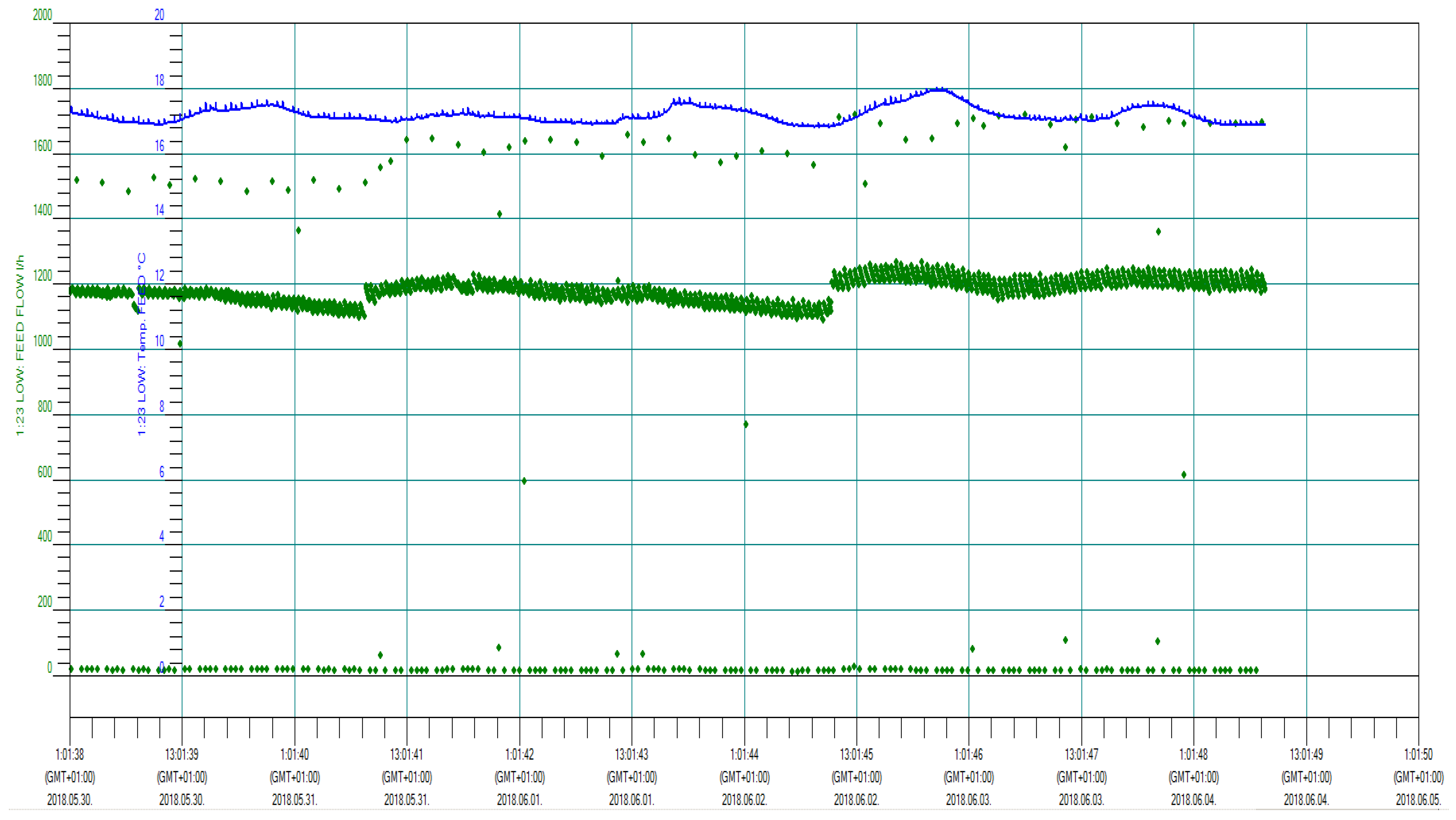

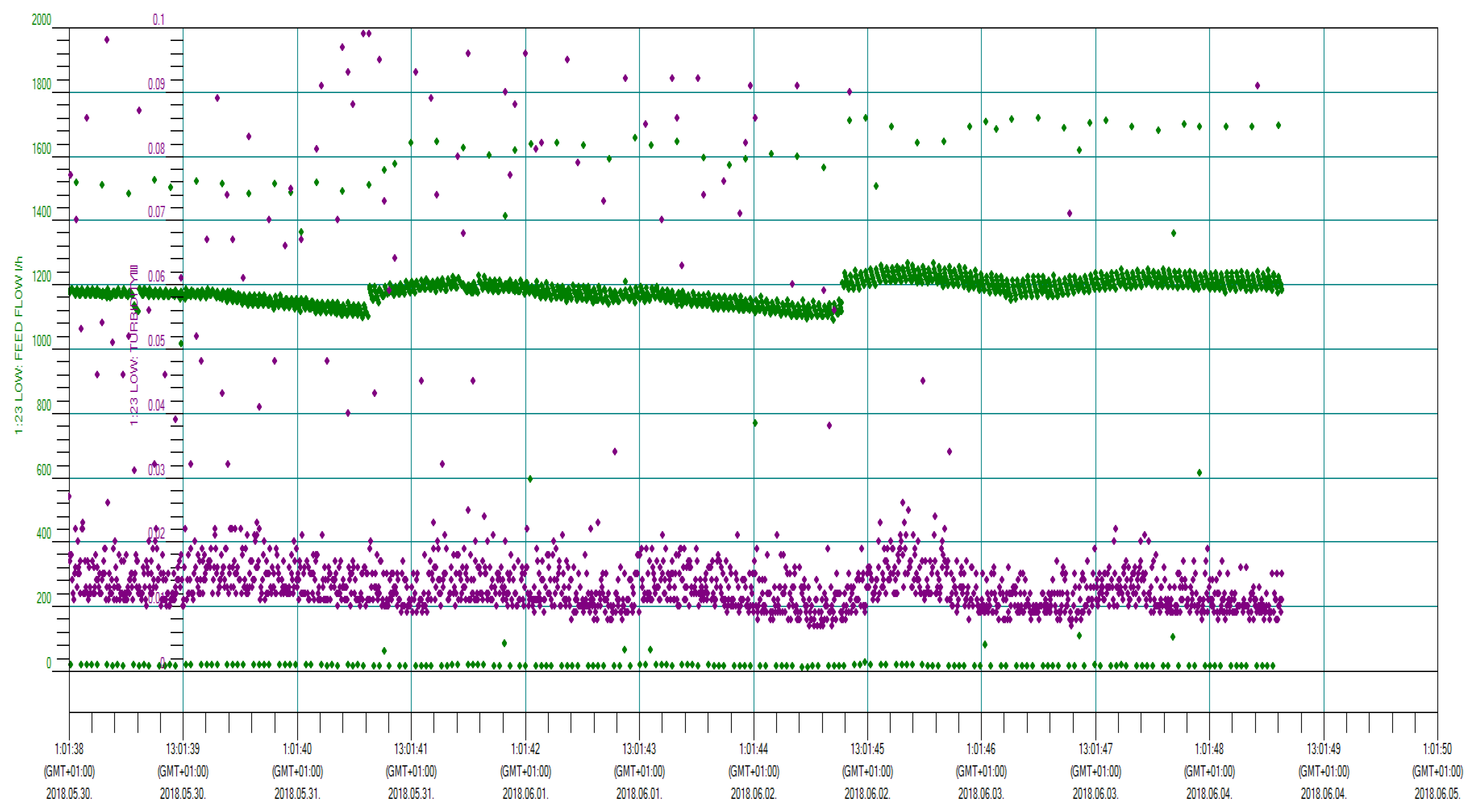

3.3. Phase 3—Operation at 105 L/m2h

- ○

- Instantaneous flux rate of 105 L/m2h.

- ○

- Average feed temperature increased to 17 °C.

- ○

- Operating trans-membrane pressure (TMP) of 1 to 0.5 bar.

- ○

- Average permeate turbidity of <0.03 NTU (peaks during the BW procedure due to the presence of bubbles in the measuring cells).

- ○

- Temperature-corrected permeability (20 °C) ranging from 103 to 153 L/m2hbar at 105 L/m2h.

3.4. Cleaning Results

4. Conclusions and Future Lines

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

Appendix C

References

- Rajewska, P.; Janiszewska, J.; Rajewska, J. Integration of Ultra- and Nanofiltration for Potato Processing Water (PPW) Treatment in a Circular Water Recovery System. Membranes 2023, 13, 59. [Google Scholar] [CrossRef] [PubMed]

- Tshindane, P.; Mamba, B.B.; Motsa, M.M.; Nkambule, T.T.I. Delayed Solvent–Nonsolvent Demixing Preparation and Performance of a Highly Permeable Polyethersulfone Ultrafiltration Membrane. Membranes 2023, 13, 39. [Google Scholar] [CrossRef]

- Cano, G.; Moulin, P. Treatment of Boiler Condensate by Ultrafiltration for Reuse. Membranes 2022, 12, 1285. [Google Scholar] [CrossRef] [PubMed]

- Kurihara, M. Seawater Reverse Osmosis Desalination. Membranes 2021, 11, 243. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-García, A.; Melián-Martel, N.; Nuez, I. Short Review on Predicting Fouling in RO Desalination. Membranes 2017, 7, 62. [Google Scholar] [CrossRef]

- Silva, J.; Torres, P.; Madera, C. Reúso de aguas residuales domésticas en agricultura. Una revisión. Rev. Agron. Colomb. 2008, 26, 347–359. [Google Scholar]

- World Health Organization—WHO. Wasstewater Use in Agricultura. In WHO Guidelines for the Safe Use of Wastewater, Excreta and Greywater; WHO: Paris, France, 2006; Volume II, p. 222. [Google Scholar]

- WHO. World Health Organization—Water, Fact Sheet 391. Available online: http://www.who.int/mediacentre/factsheets/fs391/en/2014 (accessed on 5 August 2014).

- Quist-Jensen, C.A.; Macedonio, F.; Drioli, E. Membrane technology for water production in agricultura: Desalination and wastewater reuse. Desalination 2015, 364, 17–32. [Google Scholar] [CrossRef]

- Latorre, F.J.G.; Báez, S.O.P.; Gotor, A.G. Energy performance of a reverse osmosis desalination plant operating with variable pressure and flow. Desalination 2015, 366, 146–153. [Google Scholar] [CrossRef]

- Kheriji, J.; Mnif, A.; Bejaoui, I.; Hamrouni, B. Study of the influence of operating parameters on boron removal by a reverse osmosis membrane. Desalination Water Treat. 2015, 56, 2653–2662. [Google Scholar] [CrossRef]

- Schallenberg-Rodríguez, J.; Veza, J.M.; Blanco-Marigorta, A. Energy efficiency and desalination in Cape Verde. Renew. Sustain. Energy Rev. 2014, 40, 741–748. [Google Scholar] [CrossRef]

- Zerpa, F.L.; Martín, A.R.; Pino, C.A.M. Prueba piloto de membranas de alta eficiencia para la optimización de sistemas de membranas en la planta de desalinización de Carboneras. DYNA 2021, 96, 260–263. [Google Scholar] [CrossRef]

- Bosque Maurel, J.; Valenti, J.V. Geografía De España; Ariel: Barcelona, Spain, 2022; p. 10. [Google Scholar]

- De España, G. Available online: https://administracion.gob.es/pag_Home/espanaAdmon/comoSeOrganizaEstado/ComunidadesAutonomas.html (accessed on 31 May 2021).

- Morales Matos, G. Las Islas Canarias ¿Una Región Aislada? Boletín de la A.G.E. N. 2001, 32, 155. [Google Scholar]

- Parlamento Europeo. Tratado De Funcionamiento De La Unión Europea (TFUE)—Artículos 349 Y 355—Las Regiones Ultraperiféricas (Rup). In Fichas Técnicas Sobre La Unión Europea; Parlamento Europeo: Strasbourg, France, 2016. [Google Scholar]

- León-Zerpa, F.; Peñate-Suárez, B.; Roo-Filgueira, J.; Vaswani, J. Reutilización de elementos de ósmosis inversa de los procesos de desalación. DYNA 2021, 96, 429–434. [Google Scholar] [CrossRef]

- Instituto Nacional de Estadística (INE), Gobierno de España. Revisión Del Padrón Municipal a 1 de Enero de 2020. Available online: https://www.ine.es (accessed on 28 May 2021).

- Gamero, B.D.R. Mitigación del Cambio Climático en el Ciclo Integral del Agua: Aplicación al Proceso de Tratamiento de Aguas Residuales. Ph.D. Thesis, Universidad de Las palmas de Gran Canaria, Las Palmas, Spain, 2022. [Google Scholar]

- Veza, J.M.; Rodriguez-GonzalezJuan, J. Second use for old reverse osmosis membranes: Wastewater treatment. Desalination 2003, 157, 65–72. [Google Scholar] [CrossRef]

- Basterrechea, J.M.E. Planificación y gestión del agua. DYNA 2000, 75, 61–63. [Google Scholar]

- León Zerpa, F.; Ramos Martín, A. Sistema de medición en continuo de bajo coste para determinar la relación entre la conductividad eléctrica “EC” y la temperatura “T” en aguas salobres. DYNA 2021, 96, 364–367. [Google Scholar]

- Dow, N.; Gray, S.; Zhang, J.; Ostarcevic, E.; Liubinas, A.; Atherton, P.; Roeszler, G.; Gibbs, A.; Duke, M. Pilot trial of membrane distillation driven by low grade waste heat: Membrane fouling and energy assessment. Desalination 2016, 391, 30–42. [Google Scholar] [CrossRef]

- Mazlan, N.M.; Peshev, D.; Livingston, A.G. Livingston. Energy consumption for desalination—A comparison of forward osmosis with reverse osmosis, and the potential for perfect membranes. Desalination 2016, 377, 138–151. [Google Scholar] [CrossRef]

- Lawler, W.; Bradford-Hartke, Z.; Cran, M.J.; Duke, M.; Leslie, G.; Ladewig, B.P.; Le-Clech, P. Towards new opportunities for reuse, recycling and disposal of used reverse osmosis membranes. Desalination 2012, 299, 103–112. [Google Scholar] [CrossRef]

- Rodriguez, J.J.; Jimenez, V.; Trujillo, O.; Veza, J.M. Reuse of reverse osmosis membranes as a filtration stage in advanced wastewater treatment. Desalination 2002, 150, 219–226. [Google Scholar] [CrossRef]

- Espíndola, J.C.; Caianelo, M.; Scaccia, N.; Rodrigues-Silva, C.; Guimarães, J.R.; Vilar, V.J. Trace organic contaminants removal from municipal wastewater using the FluHelik reactor: From laboratory-scale to pre-pilot scale. J. Environ. Chem. Eng. 2021, 9, 105060. [Google Scholar] [CrossRef]

- Maniakova, G.; Polo-López, M.I.; Oller, I.; Abeledo-Lameiro, M.J.; Malato, S.; Rizzo, L. Simultaneous disinfection and microcontaminants elimination of urban wastewater secondary effluent by solar advanced oxidation sequential treatment at pilot scale. J. Hazard. Mater. 2022, 436, 129134. [Google Scholar] [CrossRef] [PubMed]

- Govardhan, B.; Fatima, S.; Madhumala, M.; Sridhar, S. Modification of used commercial reverse osmosis membranes to nanofiltration modules for the production of mineral-rich packaged drinking water. Appl. Water Sci. 2020, 10, 230. [Google Scholar] [CrossRef]

- Zhou, J.; Chang, V.W.C.; Fane, A.G. Environmental life cycle assessment of brackish water reverse osmosis desalination for different electricity production models. Energy Environ. Sci. 2011, 4, 2267–2268. [Google Scholar] [CrossRef]

- Garcia, R. Nanofiltration and ultrafiltration membranes from end-of-life reverse osmosis membranes. A study of recycling. Ph.D. Thesis, Universidad de Alcalá de Henares, Madrid, Spain, 2017. [Google Scholar]

- Melian Martel, N. Universidad de las Palmas de Gran Canaria, tesis doctoral “Caracterización y evaluación del ensuciamiento en membranas de ósmosis inversa con combinación de agentes ensuaciantes”, June 2021. Available online: https://accedacris.ulpgc.es/bitstream/10553/17090/4/0722378_00000_0000.pdf (accessed on 1 June 2021).

- IAGUA.ES. Available online: https://www.iagua.es/noticias/inge-gmbh-basfs-ultrafiltration-membrane-business/ultrafiltration-uf-india (accessed on 1 June 2021).

- Dupont Water Solutions “Data Sheet IntegraFlux SFP-2880XP Ultrafiltration Membrane”. Available online: https://www.dupont.com/products/integrafluxsfp2880xp.html (accessed on 1 December 2020).

- De Beer, D.; Stoodley, P. Microbial Biofilms. The Prokaryotes: Applied Bacteriology and Biotechnology; Springer: Berlin/Heidelberg, Germany, 2014; pp. 343–372. [Google Scholar] [CrossRef]

- Flemming, H.C.; Wingender, J. The Biofilm Matrix. Nat. Rev. Microbiol. 2010, 8, 623–633. [Google Scholar] [CrossRef]

- Dimitriou, E.; Mohamed, E.S.; Karavas, C.; Papadakis, G. Experimental comparison of the performance of two reverse osmosis desalination units equipped with different energy recovery devices. Desalination Water Treat. 2015, 55, 3019–3026. [Google Scholar] [CrossRef]

- Dimitriou, E.; Mohamed, E.S.; Kyriakarakos, G.; Papadakis, G. Experimental investigation of the performance of a reverse osmosis desalination unit under full-and part-load operation. Desalination Water Treat. 2015, 53, 3170–3178. [Google Scholar] [CrossRef]

- Walton, N.R.G. Electrical Conductivity and Tottal Dissolved Solids—What is Their Precise Relationship? Desalination 1989, 72, 275–292. [Google Scholar] [CrossRef]

- Boerlage, S.; Nada, N. Algal toxin removal in seawater desalination processes. Desalination Water Treat. 2015, 55, 2575–2593. [Google Scholar] [CrossRef]

- Pichardo-Romero, D.; Garcia-Arce, Z.P.; Zavala-Ramírez, A.; Castro-Muñoz, R. Current Advances in Biofouling Mitigation in Membranes for Water Treatment: An Overview. Processes 2020, 8, 182. [Google Scholar] [CrossRef]

- Castro-Muñoz, R. Pressure-driven membrane processes involved in waste management in agro-food industries: A viewpoint. AIMS Energy 2018, 6, 1025–1031. [Google Scholar] [CrossRef]

- Galanakis, C.M.; Cvejic, J.; Verardo, V.; Segura-Carretero, A. Food Use for Social Innovation by Optimizing Food Waste Recovery Strategies. In Innovation Strategies in the Food Industry: Tools for Implementation; Academic Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Liu, B.; Wang, D.; Yu, G.; Meng, X.; David Giraldo, J.; Thakur, V.K.; Gutiérrez, E. The History and State of Art in Membrane Technologies Tarragona, Erasmus 2005. J. Membr. Sci. 2013, 16, 1–28. [Google Scholar]

- Kabsch-Korbutowicz, M.; Kutylowska, M. The Possibilities of Modelling the Membrane Separation Processes. Environ. Prot. Eng. 2008, 34, 15. [Google Scholar]

- Kayvani Fard, A.; McKay, G.; Buekenhoudt, A.; Al Sulaiti, H.; Motmans, F.; Khraisheh, M.; Atieh, M. Inorganic membranes: Preparation and application for water treatment and desalination. Materials 2018, 11, 74. [Google Scholar] [CrossRef]

- Castro-Muñoz, R. The Role of New Inorganic Materials in Composite Membranes for Water Disinfection. Membranes 2020, 10, 101. [Google Scholar] [CrossRef]

| Scenario | Date |

|---|---|

| untreated raw water | From 6 March 2018 |

| re-mineralized water with chlorine and adding 0.5 mg/L of Fe | From 20 March 2018 |

| re-mineralized water with chlorine and adding 1 mg/L of Fe | From 26 March 2018 |

| re-mineralized water pre-chlorination and 10 mg/L PAX | From 3 April 2018 |

| re-mineralized water pre-chlorination and PAX 30 mg/L | From 9 April 2018 |

| re-mineralized water pre-chlorination and PAX 50 mg/L | From 17 April 2018 |

| re-mineralized water pre-chlorination and PAX 10 mg/L and 0.5 mg/L of iron | From 27 April 2018 |

| re-mineralized water pre-chlorination and adding bentonite until 3.5 NTU | From 3 May 2018 |

| re-mineralized water pre-chlorination and adding bentonite until 7 NTU | From 8 May 2018 |

| re-mineralized water pre-chlorination and adding bentonite until 10 NTU | From 10 May 2018 |

| re-mineralized water pre-chlorination and adding bentonite 10 NTU + 10 mg/L de PAX + 0.5 mg/L Fe | 14 May 2018 to 21 May 2018 |

| normal operational regime with re-mineralized raw water | After 1 May 2018 |

| Parameter | Unit | Data | ||

|---|---|---|---|---|

| Min. | Avg. | Max. | ||

| Total suspended solids (TSS) | mg/L | n/a | 2 | 5 |

| Turbidity | NTU | 4 | 10 | |

| pH | - | 5.8 | n/a | 7.3 |

| Temperature | °C | 8 | 14 | 25 |

| Parameter | Unit | Data | ||

|---|---|---|---|---|

| Min. | Avg. | Max. | ||

| Colour | degree | 0 | 11.3 | 38 |

| Free chlorine | mg/L | 0 | 0.7 | 1.5 |

| Turbidity | NTU | 0.2 | 5.1 | 50.1 |

| Total iron (Fe) | mg/L | 0 | 0.47 | 3 |

| Aluminium (Al) | mg/L | 0.016 | 0.52 | 1.9 |

| Alkalinity (as CaCO3) | mEq/L | 0.3 | 1.8 | 3.0 |

| Conductivity | μS/cm | 21.6 | 57.9 | 78.6 |

| Oxidability | Mg O2/L | 0.5 | 1.2 | 2.4 |

| Total manganese (Mn) | mg/L | 0.0007 | 0.023 | 0.181 |

| Hardness (as CaCO3) | mEq/L | 0.2 | 2.0 | 6.2 |

| pH | - | 5.4 | 7 | 7.7 |

| Coliforms | CFU/mL | 0 | 0.1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leon-Zerpa, F.A.; Vaswani-Reboso, J.; Tavares, T.; Ramos-Martín, A.; Mendieta-Pino, C.A. Advances in Drinking Water Treatment through Piloting with UF Membranes. Water 2023, 15, 1031. https://doi.org/10.3390/w15061031

Leon-Zerpa FA, Vaswani-Reboso J, Tavares T, Ramos-Martín A, Mendieta-Pino CA. Advances in Drinking Water Treatment through Piloting with UF Membranes. Water. 2023; 15(6):1031. https://doi.org/10.3390/w15061031

Chicago/Turabian StyleLeon-Zerpa, Federico A., Jenifer Vaswani-Reboso, Tomas Tavares, Alejandro Ramos-Martín, and Carlos A. Mendieta-Pino. 2023. "Advances in Drinking Water Treatment through Piloting with UF Membranes" Water 15, no. 6: 1031. https://doi.org/10.3390/w15061031

APA StyleLeon-Zerpa, F. A., Vaswani-Reboso, J., Tavares, T., Ramos-Martín, A., & Mendieta-Pino, C. A. (2023). Advances in Drinking Water Treatment through Piloting with UF Membranes. Water, 15(6), 1031. https://doi.org/10.3390/w15061031