Study and Neural Network Analysis on Durability of Basalt Fibre Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Test Mixes

2.3. Durability Test Methods

2.3.1. Mechanical Properties Test Procedure

2.3.2. Durability Test Procedure

- (1)

- The 100 mm × 100 mm × 100 mm cube specimen was taken out after 26d of standard maintenance, wiped off the surface moisture and placed in a ventilated environment for 48 h to dry out the moisture.

- (2)

- The dried specimens were placed in a well-configured mixed solution tank; the solution should be 20 mm above the highest layer of concrete specimens and the spacing between specimens should not be less than 20 mm. The immersion time was calculated when the solution is ready, and the solution needs to be prepared for less than 30 min and replaced every 30d. The solution should be temperature controlled to avoid errors caused by temperature, which should be controlled at 20 °C ± 2 °C.

- (3)

- When the concrete specimens are removed after erosion to the specified age for the compressive test, they should be wrapped in wet towels and transported to the laboratory for the compressive test; to carry out the mass loss test, a balance must first be prepared with an accuracy of 0.01 g, then the surface of the specimen should be dried, removed from the erosion tank and immediately weigh the saturated mass of concrete; to carry out the porosity test, the weighed saturated concrete specimens were wrapped in towels, transported to the laboratory, dried in an oven at a controlled temperature of 105 °C ± 5 °C, dried at high temperature for 48 h, then weighed again for mass and finally the corresponding chloride ion measurements.

2.4. Artificial Neural Networks

2.5. Decision Trees

2.6. Grey Clustering Analysis

3. Results and Discussion

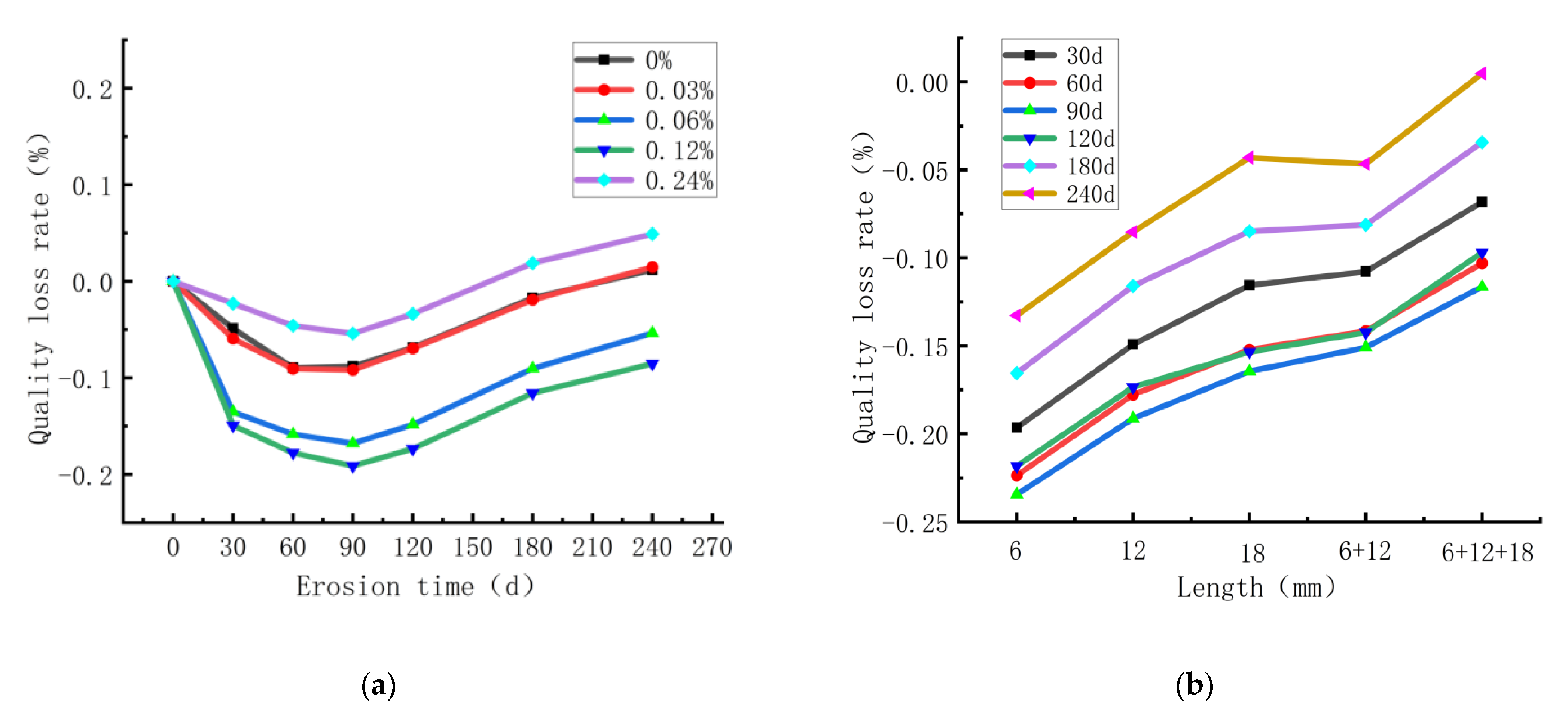

3.1. Effects of Length on Quality Loss Rate

3.2. Effects of Length on Effective Porosity

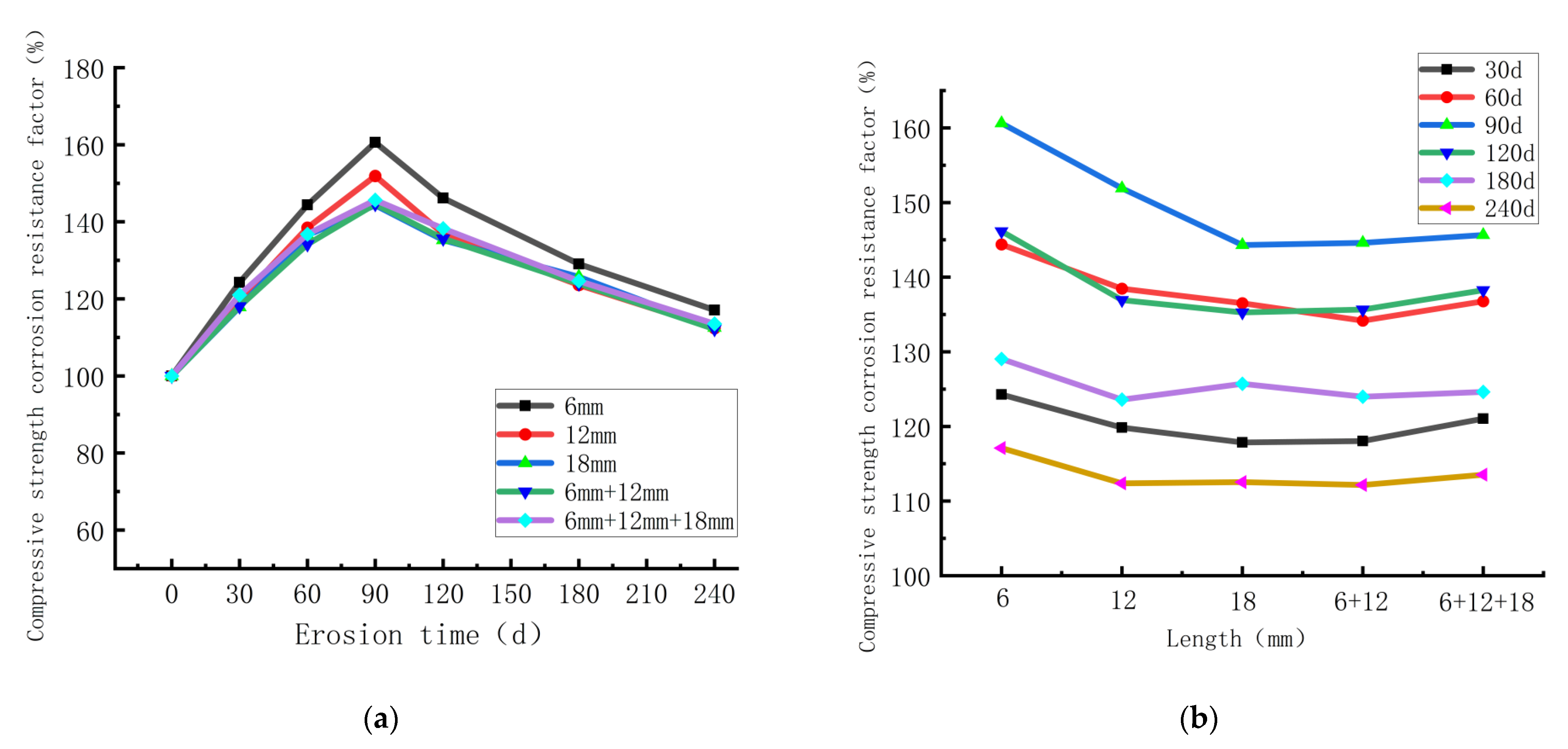

3.3. Effects of Length on the Corrosion Resistance Factor of Compressive Strength

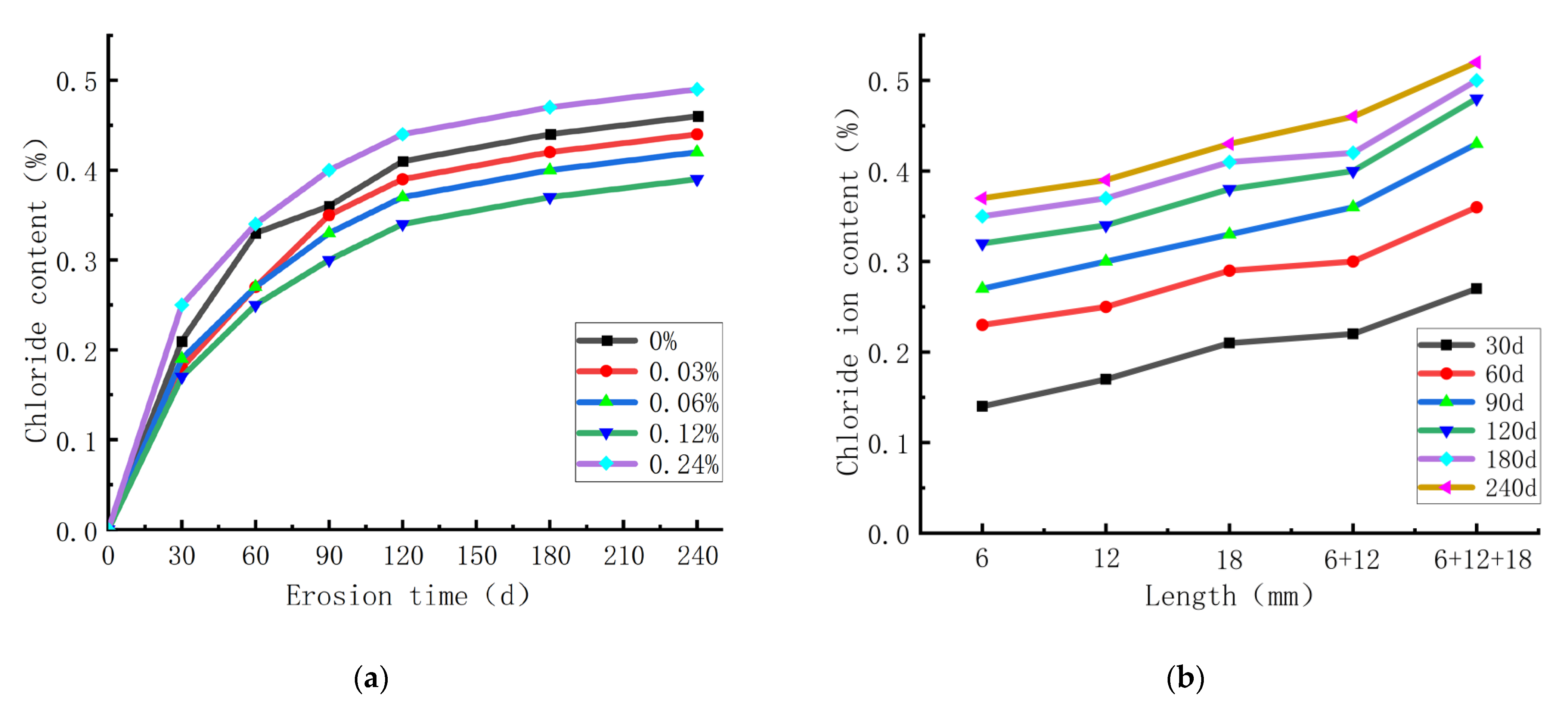

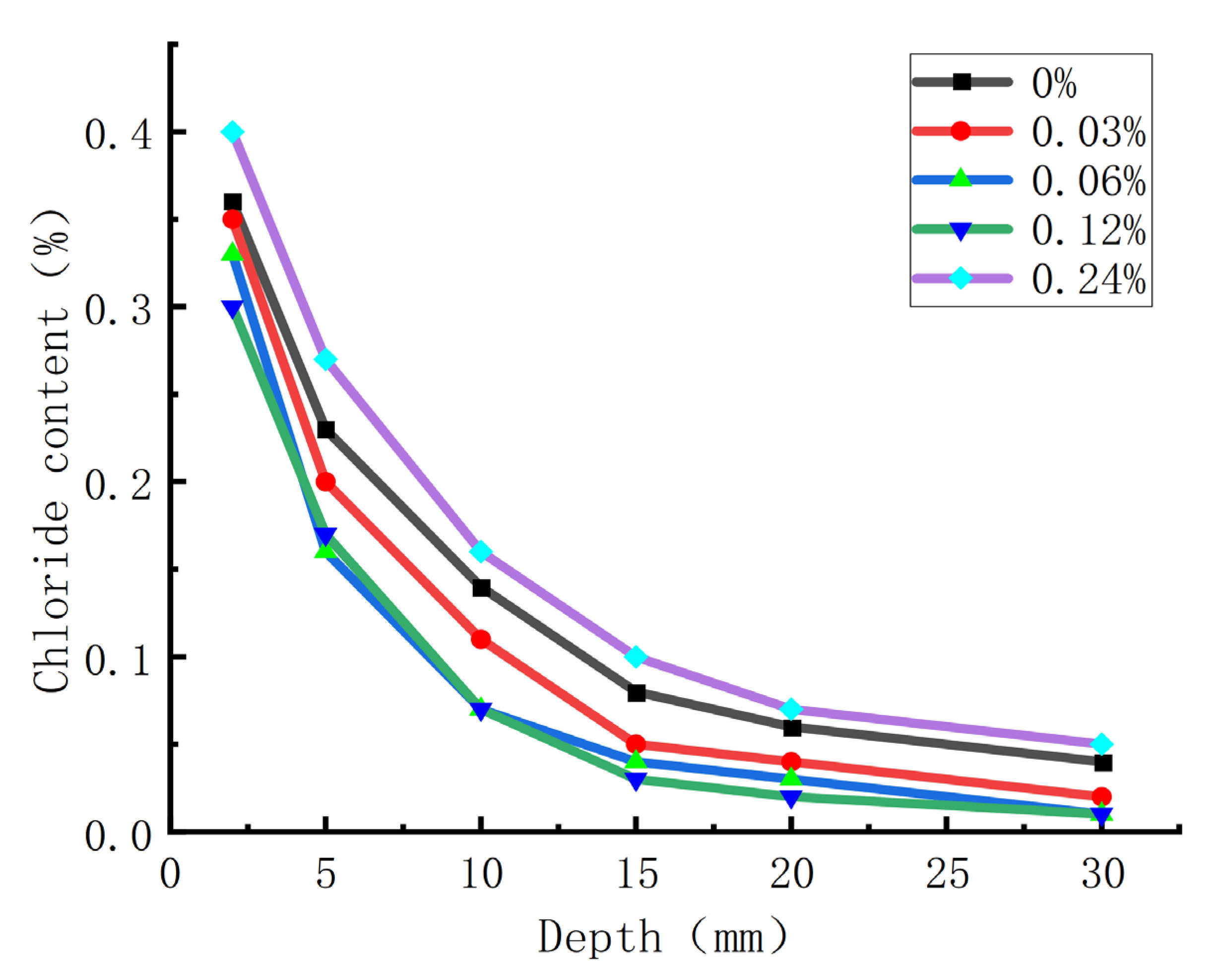

3.4. Effects of Length on Chloride Content

3.5. Effects of Curing Age on the Resistance of Concrete to Multi-Salt Attack at Different Fibre Lengths

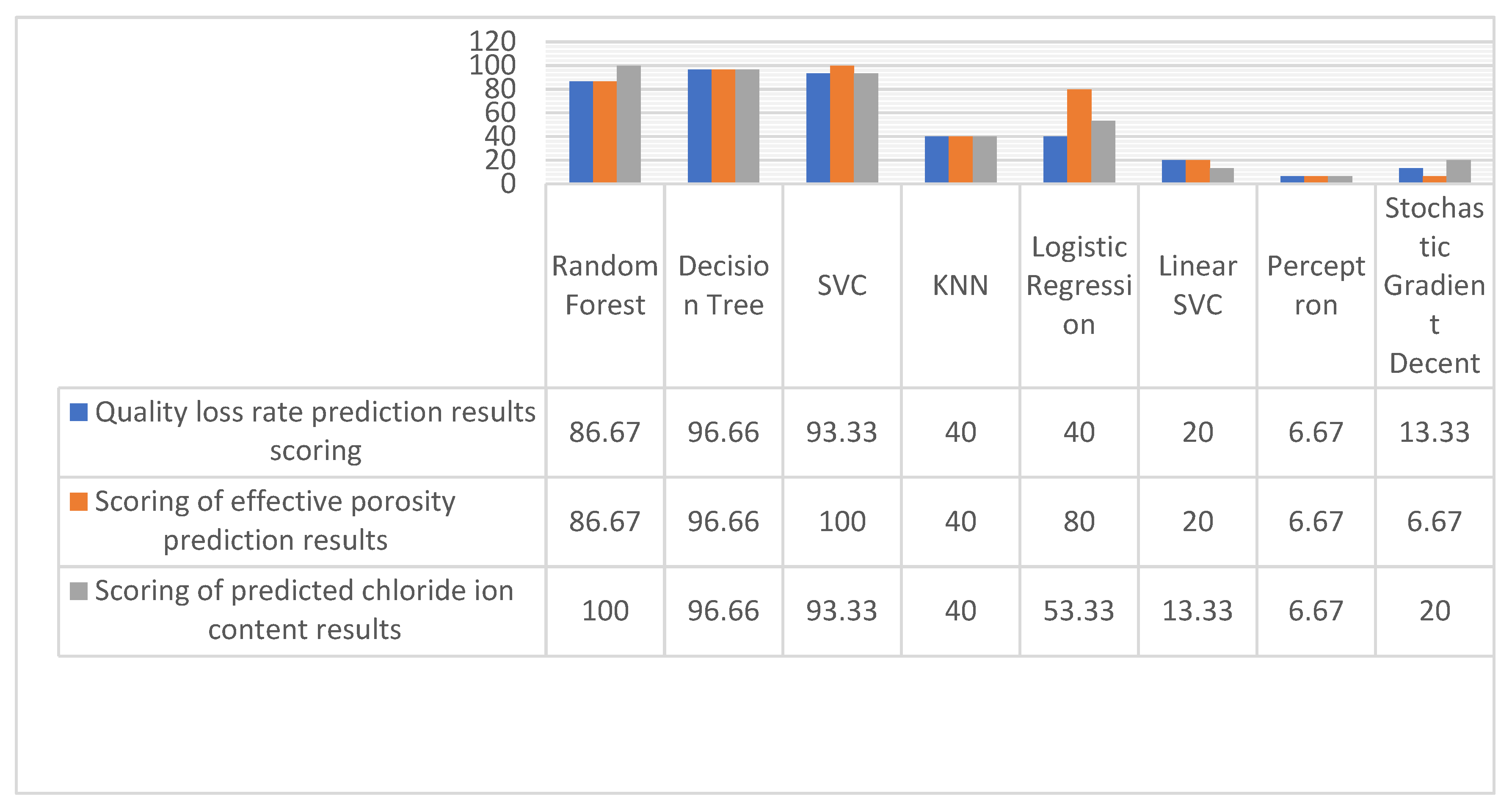

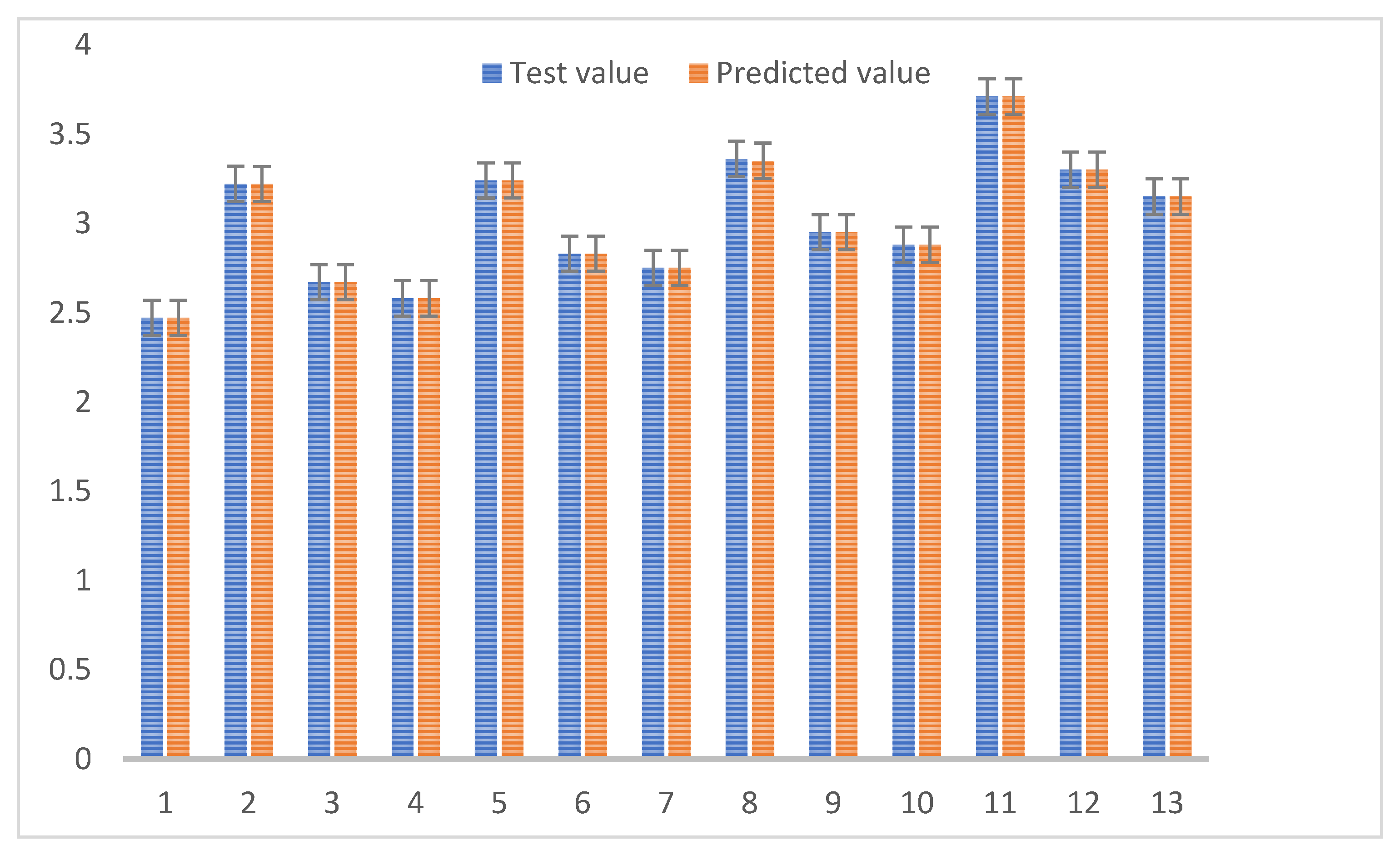

3.6. Artificial Neural Network Prediction Analysis

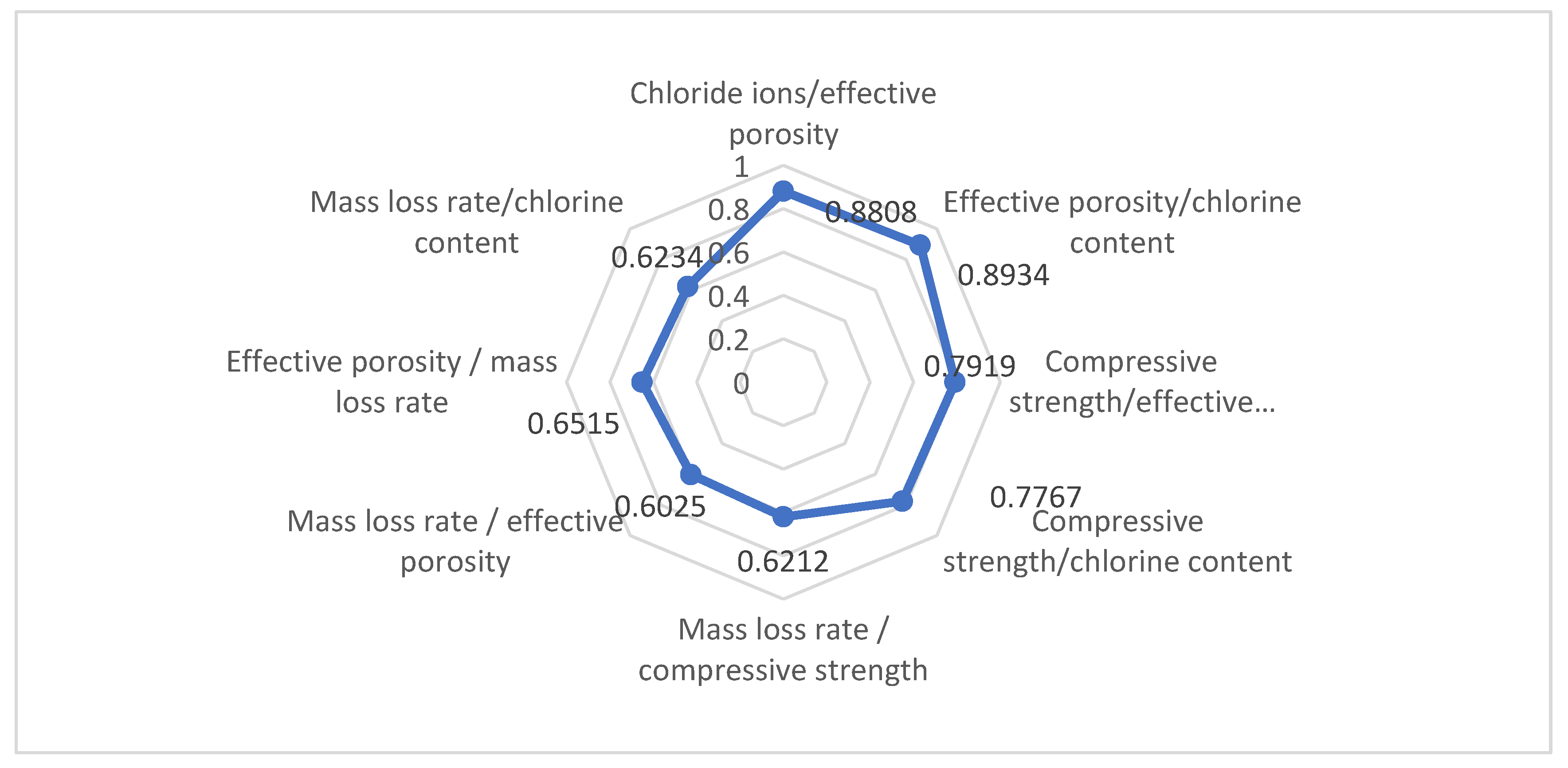

3.7. Grey Clustering Analysis

4. Conclusions and Discussion

4.1. Conclusions

- (1)

- Increasing the length of basalt fibres can enhance the mechanical properties of concrete but weaken its durability. This is exacerbated by the mixing of fibres, but none of the increases are significant. The ranking of basalt fibre lengths for concrete resistance to mass loss and chloride erosion is as follows: 6 mm > 12 mm > 18 mm > 6 mm + 12 mm > 6 mm + 12 mm + 18 mm; the ranking of basalt fibre length for effective porosity is 6 mm + 12 mm + 18 mm > 6 mm + 12 mm > 18 mm > 12 mm > 6 mm.

- (2)

- With large quantities of mineral admixtures and basalt fibres, the concrete can be eroded by the mixed salt solution for a relatively longer period of time. The 120d erosion time is the turning point in the mechanical and durability performance of basalt fibre fly-ash concrete, compared to the usual 60d for conventional concrete.

- (3)

- The extension of the age of maintenance improves the performance of the concrete in terms of mechanical properties and durability, but to a lesser extent.

- (4)

- The artificial neural network model was used to make predictions, and the results were accurate and reliable; the artificial neural network prediction model with decision trees had the highest accuracy with a score of 99.6. The decision tree was able to effectively model the durability-related indicators (effective porosity, mass loss rate, chloride ion content) of basalt fibre fly-ash concrete, providing a reference for subsequent studies such as simplified indoor tests.

- (5)

- The grey clustering model analysis resulted in the compressive strength, effective porosity and chloride content being grouped into one cluster for uniform analysis, while the mass loss rate needed to be grouped separately. Analysis of the results reduces the collection of unnecessary variables (factors) and saves on the cost of the experiment.

4.2. Discussion

- (1)

- Basalt fibre, fly ash and mineral powder are all green and pollution-free environmental protection materials, and their comprehensive application research in concrete is small, and it remains to be studied to develop different mixing ratios for different environments such as impact load, freeze–thaw environment and dry and wet cycle environment, for the selection of the best mix ratio.

- (2)

- In this paper, basalt fibre fly-ash concrete is analyzed at the macroscopic level; the microscopic performance mechanism of basalt fibre dispersion and mineral admixture products, during the erosion period, on the mechanical properties and durability of concrete needs to be studied.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tu, Q.; Wang, S.; Pan, D.; Huang, J. Detection and evaluation of offshore concrete structure based on durability life prediction. Water Transp. Eng. 2008, 12, 64–69. [Google Scholar] [CrossRef]

- Gao, X.; Jia, J.; Wang, W.; Zhang, L. Research on seismic performance of combined rubber concrete and conventional concrete piles. J. Northeast. Univ. (Nat. Sci. Ed.) 2021, 42, 886–892. [Google Scholar]

- Zhang, C.; Liu, Q. Advances in the study of coupled chloride and sulphate erosion in reinforced concrete. Mater. Guide 2022, 36, 69–77. [Google Scholar]

- Zhang, Y.; Zhou, J.; Zou, Y.; Yang, J.; Ji, X. The effect of sulphate attack on the shear resistance of concrete. J. Civ. Eng. 2020, 53, 64–72. [Google Scholar]

- Bao, J.; Wei, J.; Zhang, P.; Li, S.; Zhao, T. Progress in the study of the similarity of concrete resistance to chloride ion attack in the marine environment. J. Silic. 2020, 48, 689–704. [Google Scholar]

- Matteo, L.; Zvonek, M.; Cech, V.; Scheffler, C.; Tirillò, J.; Sarasini, F. Low temperature plasma polymerization: An effective process to enhance the basalt fibre/matrix interfacial adhesion. Compos. Commun. 2021, 27, 100769. [Google Scholar] [CrossRef]

- Raman, S.V.; Murugan, S.B.; Rahim, S.J.A.; Prakash, S.J.; Kumar, S.D. Experimental Study on PCC Beams Strengthened With External Wrapping of Basalt Fibre Reinforced Polymer (BFRP). IOP Conf. Ser. Mater. Sci. Eng. 2021, 1145, 012085. [Google Scholar] [CrossRef]

- Meyyappan, P.L.; Jemimah Carmichael, M. Studies on strength properties of basalt fibre reinforced concrete. Mater. Today Proc. 2021, 43, 2105–2108. [Google Scholar] [CrossRef]

- Pirmohammad, S.; Amani, B.; Shokorlou, Y.M. The effect of basalt fibres on fracture toughness of asphalt mixture. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1446–1460. [Google Scholar] [CrossRef]

- Loh, Z.P.; Tan, C.G.; Yeo, S.H. Mechanical characteristics and flexural behaviour of fibre-reinforced cementitious composite containing PVA and basalt fibres. Sādhanā 2019, 44, 98. [Google Scholar] [CrossRef] [Green Version]

- Shafiq, N.; Fadhilnuruddinb, M.; Elshekhc, A.E.A.; Fathid, A. Correlation between compressive strength and ultrasonic pulse velocity of high strength concrete incorporating chopped basalt fibre. AIP Conf. Proc. 2015, 1669, 020010. [Google Scholar] [CrossRef]

- Fenu, L.; Forni, D.; Cadoni, E. Dynamic behaviour of cement mortars reinforced with glass and basalt fibres. Compos. Part B 2016, 92, 142–150. [Google Scholar] [CrossRef]

- El-Gelani, A.M.; High, C.M.; Rizkalla, S.H.; Abdalla, E.A. Effects of Basalt Fibres on Mechanical Properties of Concrete. MATEC Web Conf. 2018, 149, 01028. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Moura, D.; Ding, Y.; Jalali, S. Composition, strength and workability of alkali-activated metakaolin based mortars. Constr. Build. Mater. 2011, 25, 3732–3745. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Zhang, J.; Yu, Y.; Zhang, G. The strength and microstructure of two geopolymers derived from metakaolin and red mud-fly ash admixture: A comparative study. Constr. Build. Mater. 2012, 30, 80–91. [Google Scholar] [CrossRef]

- Poulesquen, A.; Frizon, F.; Lambertin, D. Rheological behavior of alkali-activated metakaolin during geopolymerization. J. Non-Cryst. Solids 2011, 357, 3565–3571. [Google Scholar] [CrossRef]

- Gulbandilar, E.; Kocak, Y. Application of expert systems in prediction of flexural strength of cement mortars. Comput. Concr. 2016, 18, 1–16. [Google Scholar] [CrossRef]

- Muhammad, K.; Mohammad, N.; Rehman, F. Modeling shotcrete mix design using artificial neural network. Comput. Concr. 2015, 15, 167–181. [Google Scholar] [CrossRef]

- Mohammed, S.I.; Najim, K.B. Mechanical strength, flexural behavior and fracture energy of Recycled Concrete Aggregate self-compacting concrete. Structures 2020, 23, 34–43. [Google Scholar] [CrossRef]

- Garg, A.; Aggarwal, P.; Aggarwal, Y.; Belarbi, M.; Chalak, H.; Tounsi, A.; Guli, R. Machine learning models for predicting the compressive strength of concrete containing nano silica. Comput. Concr. 2022, 30, 33–42. [Google Scholar]

- Amirreza, K.; Farid, S.; Mahdi, K. Predicting Compressive Strength of Concrete Containing Recycled Aggregate Using Modified ANN with Different Optimization Algorithms. Appl. Sci. 2021, 11, 485. [Google Scholar] [CrossRef]

- Ayaz, A.; Chaiyasarn, K.; Farooq, F.; Ahmad, W.; Suparp, S.; Aslam, F. Compressive Strength Prediction via Gene Expression Programming (GEP) and Artificial Neural Network (ANN) for Concrete Containing RCA. Buildings 2021, 11, 324. [Google Scholar] [CrossRef]

- Dantas, A.T.A.; Leite, M.B.; de Jesus Nagahama, K. Prediction of compressive strength of concrete containing construction and demolition waste using artificial neural networks. Constr. Build. Mater. 2013, 38, 717–722. [Google Scholar] [CrossRef]

- Naderpour, H.; Mirrashid, M. Estimating the compressive strength of eco-friendly concrete incorporating recycled coarse aggregate using neuro-fuzzy approach. J. Clean. Prod. 2020, 265, 121886. [Google Scholar] [CrossRef]

- Zewdu, T.W.; Leonardo, E.-L. A machine learning method for predicting the chloride migration coefficient of concrete. Constr. Build. Mater. 2022, 348, 128566. [Google Scholar] [CrossRef]

- Sun, G.W.; Sun, W.; Zhang, Y.S.; Liu, Z.Y. Prediction of the Effective Diffusion Coefficient of Chloride Ions in Cement-Based Composite Materials. J. Mater. Civ. Eng. 2012, 24, 1245–1253. [Google Scholar] [CrossRef]

- Pan, S.; Zheng, Z.; Guo, Z.; Luo, H. An optimized XGBoost method for predicting reservoir porosity using petrophysical logs. J. Pet. Sci. Eng. 2022, 208, 109520. [Google Scholar] [CrossRef]

- Taffese, W.; Sistonen, E.; Puttonen, J. Prediction of concrete carbonation depth using decision trees. In Proceedings of the 23rd European Symposium on Artificial Neural Networks, Computer Intelligence Machine Learning, Bruges, Belgium, 22–23 April 2015. [Google Scholar]

- Dong, W.; Huang, Y.; Lehane, B.; Ma, G. XGBoost algorithm-based prediction of concrete electrical resistivity for structural health monitoring. Autom. Constr. 2020, 114, 103115. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Sistonenm, E.; Puttonen, J. CaPrM: Carbonation prediction model for reinforced concrete using machine learning methods. Constr. Build. Mater. 2015, 100, 70–82. [Google Scholar] [CrossRef]

- Lavercombe, A.; Huang, X.; Kaewunruen, S. Machine Learning Application to Eco-Friendly Concrete Design for Decarbonisation. Sustainability 2021, 13, 13663. [Google Scholar] [CrossRef]

- Liu Kaihua, M.; Alam, S.; Zhu, J.; Zheng, J.; Chi, L. Prediction of carbonation depth for recycled aggregate concrete using ANN hybridized with swarm intelligence algorithms. Constr. Build. Mater. 2021, 301, 124382. [Google Scholar] [CrossRef]

- Duan, Z.H.; Kou, S.; Poon, C.S. Using artificial neural networks for predicting the elastic modulus of recycled aggregate concrete. Constr. Build. Mater. 2013, 44, 524–532. [Google Scholar] [CrossRef]

- Oliveira, V.; Sousa, V.; Dias-Ferreira, C. Artificial neural network modelling of the amount of separately-collected household packaging waste. J. Clean. Prod. 2019, 210, 401–409. [Google Scholar] [CrossRef]

- Chen, L.; Shi, L. Effect of mixed fiber on early cracking performance of concrete. Shanxi Archit. 2008, 33, 7–8. [Google Scholar]

| Compressive Strength/MPa | Flexural Strength/MPa | Condensation Time/min | |||

|---|---|---|---|---|---|

| 3d | 28d | 3d | 28d | Initial coagulation | Final coagulation |

| 21.4 | 46.8 | 6.2 | 8.6 | 155 | 230 |

| Length (mm) | Diameter (μm) | Density (g/cm3) | Elastic Modulus (GPa) | Tensile Strength (MPa) |

|---|---|---|---|---|

| 6/12/18 | 15 | 2.65 | 91 | 3900 |

| Chemical Composition | SO3 | CaO | SiO2 | Al2O3 | Fe2O3 | MgO |

|---|---|---|---|---|---|---|

| Content | 0.36 | 2.83 | 50.26 | 31.14 | 4.16 | 0.78 |

| Apparent Density (g/cm3) | Moisture Content (%) | Strength Activity Index (%) | Loss on Ignition (%) | Fineness (%) | Water Demand Ratio (%) |

|---|---|---|---|---|---|

| 2.25 | 0.52 | 86 | 2.34 | 20 | 98 |

| Number | Cement | Fly Ash | Mineral Powder | Fine Aggregates | Coarse Aggregates | Water | Water Reducing Agents | Short-Cut Basalt Fibres (%) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (kg/m3) | (%) | 6 mm | 12 mm | 18 mm | ||||||

| C0.12L6 | 237 | 118.5 | 39.5 | 735 | 1089 | 142 | 0.13 | 0.12 | — | — |

| C0.12L12 | 237 | 118.5 | 39.5 | 735 | 1089 | 142 | 0.27 | — | 0.12 | — |

| C0.12L18 | 237 | 118.5 | 39.5 | 735 | 1089 | 142 | 0.30 | — | — | 0.12 |

| C0.12L6–12 | 237 | 118.5 | 39.5 | 735 | 1089 | 142 | 0.29 | 0.06 | 0.06 | — |

| C0.12L6–12–18 | 237 | 118.5 | 39.5 | 735 | 1089 | 142 | 0.29 | 0.04 | 0.04 | 0.04 |

| Content of the Test | Specific Test Indicators |

|---|---|

| Conservation age | 28d, 56d, 84d |

| Erosion solutions | Sodium sulphate at 10%, sodium chloride at 7% |

| Erosion patterns | Soaking erosion |

| Fibre length | 6 mm, 12 mm, 18 mm, 6 mm + 12 mm, 6 mm + 12 mm + 18 mm |

| Fibre bulk rate | 0.12% |

| Erosion time | 0d, 30d, 60d, 90d, 120d, 180d, 240d |

| Test content | Compressive strength corrosion resistance factor, mass loss rate, effective porosity, chloride ion content |

| Length (mm) | 6 | 12 | 18 | 6 + 12 | 6 + 12 + 18 | |

|---|---|---|---|---|---|---|

| Compressive strength (MPa) | 28d | 72.6 | 74.7 | 73.3 | 72.9 | 75.5 |

| 56d | 74.1 | 76.6 | 74.7 | 75.1 | 76.9 | |

| 84d | 74.6 | 76.9 | 75.4 | 75.8 | 77.4 | |

| Quality loss rate (%) | 28d | −0.2345 | −0.1913 | −0.1645 | −0.1509 | −0.1165 |

| 56d | −0.2662 | −0.2271 | −0.2035 | −0.1859 | −0.1541 | |

| 84d | −0.2737 | −0.2353 | −0.2147 | −0.1982 | −0.1697 | |

| Effective porosity (%) | 28d | 2.91 | 3.22 | 3.24 | 3.36 | 3.71 |

| 56d | 2.53 | 2.67 | 2.83 | 2.95 | 3.30 | |

| 84d | 2.47 | 2.58 | 2.75 | 2.88 | 3.15 | |

| Chloride ion content (%) | 28d | 0.27 | 0.30 | 0.33 | 0.36 | 0.43 |

| 56d | 0.27 | 0.28 | 0.31 | 0.33 | 0.39 | |

| 84d | 0.26 | 0.27 | 0.30 | 0.31 | 0.37 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, S.; Wang, R.; Gong, A.; Li, R.; Xu, J.; Wang, F.; Liu, F. Study and Neural Network Analysis on Durability of Basalt Fibre Concrete. Water 2023, 15, 1016. https://doi.org/10.3390/w15061016

Shao S, Wang R, Gong A, Li R, Xu J, Wang F, Liu F. Study and Neural Network Analysis on Durability of Basalt Fibre Concrete. Water. 2023; 15(6):1016. https://doi.org/10.3390/w15061016

Chicago/Turabian StyleShao, Shanqing, Ran Wang, Aimin Gong, Ruijun Li, Jing Xu, Fulai Wang, and Feipeng Liu. 2023. "Study and Neural Network Analysis on Durability of Basalt Fibre Concrete" Water 15, no. 6: 1016. https://doi.org/10.3390/w15061016

APA StyleShao, S., Wang, R., Gong, A., Li, R., Xu, J., Wang, F., & Liu, F. (2023). Study and Neural Network Analysis on Durability of Basalt Fibre Concrete. Water, 15(6), 1016. https://doi.org/10.3390/w15061016