Abstract

The sand media filter is a crucial component of micro-irrigation filtration systems. Investigating the effects of various factors on filtration performance and the migration patterns of sediment particles within the filter can enhance the healthy operation of sand media filters. This study, based on a sand media filter model, conducts indoor hydraulic experiments, selecting different experimental factors and observation indices for research under varying conditions. Results indicate that filter thickness and raw water concentration are positively correlated with the turbidity of filtered water samples, while changes in filtration rate have no obvious impact on turbidity. When filter thickness is large, particle content differs obviously from other filter thicknesses, and the effect of raw water concentration changes on particle content is similar to that of filter thickness changes. Sediment particle size distribution within the filter layer is primarily concentrated in the upper region. By focusing on the area situated 20 cm below the filter layer surface, the sediment retention rate reached 80% or higher at a depth of 20 cm below the filter layer surface. As the depth of the filter layer increases, the sediment retention characteristics show a decreasing trend for larger particle sizes and an increasing trend for smaller particle sizes. Head loss is positively correlated with filtration rate, raw water concentrations, and filter thickness changes. It is suggested that, when meeting micro-irrigation water quality requirements, the filter material particle size can be appropriately increased to improve filtration efficiency and reduce energy consumption. These research findings are highly significant for sand media filter material selection and working condition design.

1. Introduction

Micro-irrigation is widely used around the world on the basis of its high irrigation water utilization and low energy consumption, and it also improves crop quality and yields [1]. However, this economic and environmental potential can be put at risk by inadequate treatment of the water used. The flow channel of the emitter is very narrow, and it is easily blocked by impurities such as sediment particles and organic matter in the water, which affects the hydraulic performance of the system and the uniformity of irrigation [2,3,4,5]. Filtration is essential for the successful operation of micro-irrigation systems because it helps prevent emitter clogging caused by organic and inorganic particulate matter [6]. Sand media filters are widely used in different irrigation water treatment methods, based on their high efficiency in filtering organic matter and algae [7]. The main factors in micro-irrigation system clogging caused by suspended solid particles include sediment, clay, organic matter, and mineral particles; the sand media filter performs well in filtering suspended solid particles [8,9]. The three-dimensional pores formed by the sand media filter layer are conducive to the interception of impurities, and they have the advantages of a strong pollution absorption capacity and easy automatic backwash [10,11,12,13]. At the same time, the problem of large head loss with sand media filters has plagued producers and users [14]. The main factor affecting the filtration efficiency and head loss of sand media filters is the condition of the filter layer, filter cap, backwash valve, water distributor, and other components [15,16].

Large head loss has always been a disadvantage of gravel filter applications, and it is important to study how to reduce head loss during the operation of sand media filters for the popularization and application of micro-irrigation technology. Some scholars carry out physical modeling experimental research and believe that a pressure drop in sand media filters is mainly generated when water flows through the internal structure and filter layer [17]. There are obvious differences in the flow resistance characteristics and filter layer surface displacement under different water separators, and changing the water separator structure can produce vortices and tangential flow on the filter layer surface, which can improve the uniformity of water flow distribution on the filter layer surface. Based on the experimental results, combined with the CFD method to simulate the influence of a filter cap on the distribution of the surrounding flow field law to determine the optimization direction of the filter cap structure, a new type of filter cap has been designed to reduce the head loss [18,19]. Mesquita et al. analyzed the impact of different filter caps, water distributors, and filter layer configuration parameters on cleaning pressure drops in agricultural filters [20]. Pujol et al. analyzed the influence of the number and location of filter seams on the filtration performance of the filter cap, using an actual experimental model [21]. These predecessors have done a lot of research on the influence of the water separator, filter cap, and filter layer on the head loss of filters. There is limited research on the impact of sediment blockage within the filter layer on head loss, and this topic warrants further investigation. In the future, it is also of great significance to carry out a study of sediment blockage in the filter layer and head loss, which could provide a new research direction for the study of head loss.

Zhai Guoliang et al. used coal ash to prepare raw water and successively conducted model experiments on the effect of homogeneous filter media on the solid particle mass fraction and turbidity of coal ash water. The study found that the impurity removal ratio was negatively correlated with the filtration rate and positively correlated with the particle mass fraction of sand-containing water [22]. Analyzing the effect of sand media filters on filtering fly ash can provide a theoretical reference for sediment filtration research. Garcí a Nieto et al. conducted experiments on the changes in the turbidity, conductivity, dissolved oxygen, and other indicators of regenerated water after filtration using quartz sand media filter material. A prediction model of effluent quality was established using the Gaussian process regression method [23]. In order to study the filtration process of sand media filters, some scholars have combined porous media models with fractal theory models to construct the filtration performance function of quartz sand media filters and explored methods for the calculation of filtration rates and cleaning pressure drops [24]. Soyer et al. established the function of turbidity, particle interception, solid particle number, filtration efficiency index, and head loss over time, which has a better theoretical basis than other methods for evaluating the filtration effect [25]. Cui et al. analyzed the separation characteristics of particles deposited in porous media. The results show that adsorption and desorption phenomena existed simultaneously in the filter layer. Studying the desorption characteristics of particles is helpful in understanding the deep migration law of particles [26]. The aforementioned research has advanced the understanding of the hydraulic performance, filtration efficiency, and filtration mechanisms of sand medium filters. However, there is a scarcity of studies focusing on the transport and distribution characteristics of sediment in the filter layer. The development of a filtration performance model for sand medium filters under sediment conditions would further enrich the fundamental theoretical research in filtration.

Based on the above research results, the author believes that the sand media filter layer is a typical porous medium structure. The skeleton structure constructed by filter material particles is filled with tiny, interconnected pores of different shapes, forming a flow channel for gas, liquid, and impurity particles. In various fields, numerous investigations have been conducted to examine the transport and distribution of solid particles. However, the direct application of these research findings to the study of micro-irrigation sand media filters is challenging due to the substantial differences in raw water types, impurity particle size distributions, and porous media structural parameters across domains. Consequently, it has become increasingly crucial to conduct research focused on the transport of solid particles within sand media filters specifically under micro-irrigation conditions. This targeted approach will contribute to a better understanding of the underlying mechanisms and inform the development of effective strategies for optimizing filtration performance in micro-irrigation systems. This paper carries out experiments with the help of an indoor filter model, analyzes the impact of different experimental factors on the indicators of filtered water samples, and focuses on the study of sediment particles deposited inside the filter layer. At present, the sediment content and particle size distribution in the filter layer after filtration of the sand media filter are still unclear; by carrying out this experimental study, we can better grasp the sediment transport law and distribution characteristics in the filter layer, clarify the mechanism of the impact of different factors on the filtration performance, provide a reference for the mechanism study of the filtration process, and provide technical support for the operation of the sand media filter.

2. Materials and Methods

2.1. Equipment and Experimental Setup

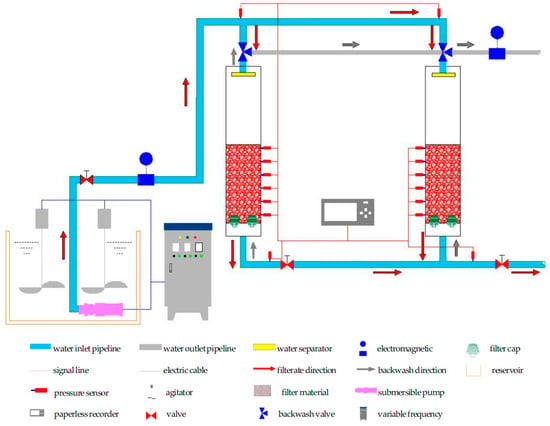

The model experiment was conducted at the Water Saving Equipment Research and Development Center, Institute of Agricultural Irrigation, Chinese Academy of Agricultural Sciences. The filtration system adopted a variable frequency and constant pressure water supply method, with valves (South Asia Plastics Industry Co., Ltd., Taiwan, China) and electromagnetic flow meters (Hangzhou Meikong Automation Technology Co., Ltd., Hangzhou, China) installed on the pipeline for flow rate regulation and monitoring. The filter column model was proportionally scaled based on the sand media filter product, using a transparent organic glass column with inner diameter of 220 mm and height of 1200 mm (Xiamen Sanli Plastic Pipeline Co., Ltd., Xiamen, China) for easy observation of internal water flow and blocking conditions. The interior of the filter column was filled with uniform quartz sand media, and filter caps were installed at the bottom. The pressure-measuring hole was set on the side of the organic glass column to observe the internal head loss of the filter. The water separation plate was installed at the top of the filter chamber to prevent water flow from scouring the filter layer. Under the action of the water separation plate, sand-containing water entered the model, and filtered water flowed out through the filter cap. The supporting facilities for the experiment included frequency conversion cabinets (Delixi Electric Appliance Co., Ltd., Shanghai, China), paperless recorders (Hangzhou Liance Automation Technology Co., Ltd., Hangzhou, China), pressure sensors (Hangzhou Liance Automation Technology Co., Ltd., Hangzhou, China), etc. The overall layout of the model experiment is shown in Figure 1.

Figure 1.

Experimental device schematic.

2.2. Experimental Design

Yellow River sediment was used to configure the raw water; sediment was taken from the New Magnetic Irrigation Canal section of the People’s Victory Canal in the Yellow River irrigation area Diversion Irrigation Area, and it was used after drying and screening. In practical applications, for water sources containing large-size sediment particles, centrifugal filters are usually selected for pretreatment, with sediment-containing water then entering a sand media filter for secondary filtration. Centrifugal filters are usually able to dispose of large particles above 150 μm, but large particles may still enter the sand media filter during the start and stop stages of the micro-irrigation system. Therefore, in this experiment, the selection of sediment was carried out by sampling multiple sections in the irrigation channel and mixing them. The range of sediment particle size was controlled below 350 μm; the particle size and volume percentage of the Yellow River sediment used are shown in Table 1. The main factors influencing filtration in the experiment included filter material particles, filter thickness, filtration rate, and raw water concentration. The level of the specific factors is shown in Table 2. We studied the variation pattern of effluent quality, controlled so that the particle size of filter material remained unchanged, and set different levels for other factors. Further, we studied the interception of sediment by the filter layer, controlled so that the filter thickness remained unchanged, and set different levels for other factors. Turbidity and particle content directly affect the clogging of emitters, and head loss directly determines the cost of filters. The turbidity and particle content of the filtered water samples, as well as model head loss, were measured.

Table 1.

Volume percentage of Yellow River sediment with different particle sizes.

Table 2.

Experimental treatment factor.

2.3. Experimental Procedure

According to the experimental treatment procedure, filter material was placed in the organic glass column, and different concentrations of sand-containing water were configured in the sand-containing water tank. Then, water and sand were fully mixed using a mixer. The sand-containing water was pressurized with a submersible pump and made to enter the model. The filter cycle was determined by the head loss at the inlet and outlet of the model, and we observed the pressure sensor readings during the filter cycle. The filtered water sample was extracted from the downstream outlet pipeline of the model device at a sampling frequency of 2 min. To ensure reliable results, each treatment group was replicated three times, and the average of the repeated measurements was calculated to represent the performance of each treatment group in the subsequent data analysis. In order to analyze the sediment deposition characteristics inside the filter layer, it was necessary to conduct a stratified sampling of the filter layer. In this experiment, the surface of the filter layer was defined as 0 mm, and the bottom plate for installing the filter cap was −600 mm. The filter layer was divided into 6 sections along the direction of the filtered water flow, namely, P1 (0–100 mm), P2 (−100–200 mm), P3 (−200–300 mm), P4 (−300–400 mm), P5 (−400–500 mm), and P6 (−500–600 mm). The filter material containing sediment particles was poured into a barrel for cleaning. During the flushing process, the filter material was intercepted with a sieve, and the sediment entered the barrel. After separation was completed, 2000 mL of uniform muddy water was dried to extract sediment particles. The remaining water in the muddy bucket was filtered with medium-speed filter paper (filter holes of 30–50 μm); filter paper and beaker were dried before use.

2.4. Experimental Indicators and Methods

We used a turbidity meter to measure the turbidity of the filtered water samples. Considering the deposition of sediment over time, the time from sampling to measurement was controlled within 30 min, and each water sample was measured twice. The particle content was measured with the drying method, and the sediment concentration per unit volume of the filtered water samples was obtained. Pressure sensors were arranged at the inlet and outlet of the model, and the pressure was observed using a paperless recorder to analyze the head loss of the model. After the end of the filtration cycle, different filter layer sections were sampled. The sediment in the filter layer was obtained with the test method of taking, separating, and drying, and the amount of material intercepted by each filter layer section was measured. The BT-9300 H laser particle size distribution instrument (Dandong Baxter Instrument Co., Ltd., Dandong, China) was used to analyze the sediment intercepted by the filter layer and determine its particle size distribution characteristics.

3. Results

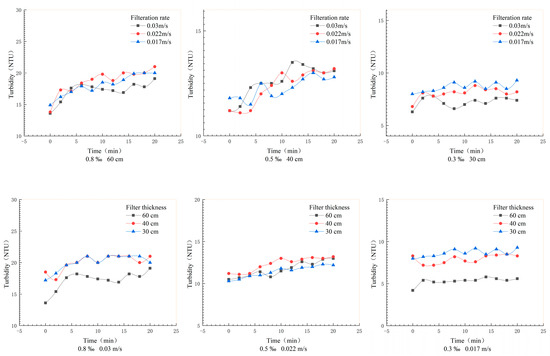

3.1. Influence of Different Factors on Turbidity

The variations in the turbidity of the filtered water samples over time under different filter thickness, raw water concentration, and filtration rate conditions are shown in Figure 2. From the figure, it can be seen that, when the raw water concentration and filter thickness were kept unchanged and the filtration rate was changed, the trends of the turbidity of the filtered water samples over time were similar, and the overall trend gradually increased. As the filtration rate increased, the difference in the turbidity changes of the water samples was not obvious. The change in filtration rate did not significantly affect the turbidity of the water samples filtered by the sand media filter, and it is believed that the influence of the filtration rate on turbidity is relatively weak. The turbidity of the filtered water samples showed a dynamic trend over time and fluctuated within a certain range. When the filtration rate and raw water concentration were fixed, the turbidity of the filtered water samples showed a decreasing trend as the filter thickness increased. The turbidity of the water samples with a filter thickness of 60 cm was significantly lower than that of the samples filtered using the other two filter layer thicknesses. When the filtration rate and filter thickness were kept unchanged, the turbidity of the filtered water samples fluctuated around a fixed value under different raw water concentration conditions, presenting a relatively stable state. The turbidity dispersion degree of each treatment was low, and the filtration process and effect of the sand media filter were relatively stable, as determined according to the turbidity index, which further verified the unique three-dimensional filtration process of the sand media filter. From the figure, it can be seen that, when the raw water concentration continued to increase, the turbidity of the filtered water samples showed an increasing trend; finally, it was found that the turbidity of the water samples was positively correlated with the raw water concentration.

Figure 2.

The turbidity of water samples varies with time under different filtration rate, filter thickness, and raw water concentration conditions.

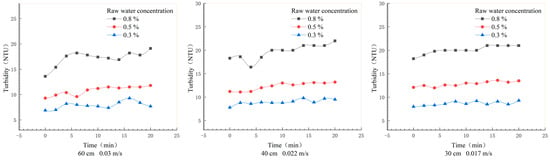

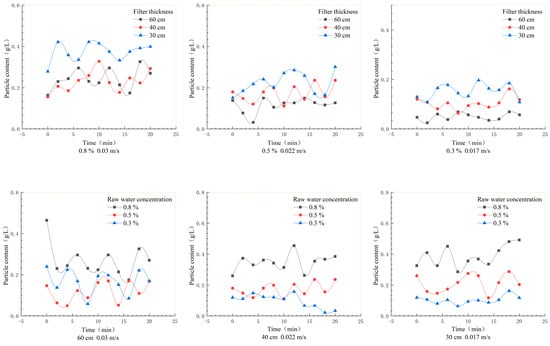

3.2. Influence of Different Factors on Particle Content

The variations in particle content in water samples over time under different filter thickness, filtration rate, and raw water concentration conditions are shown in Figure 3. As shown in the figure, with an increase in filtration rate, there were no significant differences in particle content in the filtered water samples under different treatment conditions. The particle content in water samples showed dynamic changes over time and fluctuated within a certain range. By assuming the particle content in the filtered water samples as an indicator to evaluate the filtration effect, different filtration rates did not significantly impact the filtration effect, and changes in filtration rate had a weaker impact on particle content in the filtered water samples. When the raw water concentration and filtration rate were the same, as the filter thickness increased, the particle content showed dynamic change over time. The particle content in the water samples with a filter thickness of 60 cm showed an obvious difference compared with the samples filtered using the other two filter layer thicknesses, while the difference in particle content between the latter water samples was not obvious. When the raw water had a particle concentration of 0.8‰, the particle content in the filtered water samples was obviously higher than that under the other two raw water particle concentration conditions. When comparing the dispersion degree of particle content values in water samples under different treatment conditions, it was found that there was a significant difference in the standard deviation of particle content values in the filtered water samples as the raw water concentration increased. It is assumed that the more stable the particle content index of a filtered water sample is, the better the filtration effect is. It was determined that the filtration effect was significantly different with an increase in raw water concentration.

Figure 3.

The content of water particle content with time under different filter thickness conditions, filtration rates, and filter thickness and raw water concentrations.

3.3. Analysis of Sediment Quantity Deposition in Filter Layer

The results of the interception of sediment by the filter layer under different conditions are shown in Table 3. From the table, it can be seen that the distribution trends of cumulative sediment interception are the same. Sediment was mainly distributed in the upper half of the filter layer, concentrated 20 cm below the surface of the filter layer, and the amount of sediment interception in the lower part of the filter layer was relatively small. It was found that the smaller the particle size of the filter material, the smaller the amount of sediment deposited in the filter layer; the interception of sediment mainly occurred in the surface filter material, which usually refers to 10 cm below the surface of the filter layer, indicating that this study is consistent with previous research on surface filtration [27]. As the particle size of the filter material increased, the mass distribution of sediment particles in the filter layer changed, and more sediment migrated along the filter layer towards the bottom layer. According to Table 3, under the same filtration rate conditions, as the particle size of the filter material continued to increase, the cumulative sediment retention showed a gradually decreasing trend, but the decrease was not obvious. The research found that the retention rate reached 80% or higher at a depth of 20 cm below the filter layer surface, and when the filter material particle was 1.0 mm, it was over 98%. As the filtration rate increased, 93% of the sediment was retained 10 cm below the surface of the filter layer. It is believed that the smaller the filter material particle is, the higher the filtration rate is, and the more likely it is that the surface filtration phenomenon occurs. The cumulative pollutant amount intercepted by the filter layer was above 340 g, and the difference was not obvious. It is believed that filter material particle size and filtration rate have little impact on the interception by the filter layer.

Table 3.

Sediment retention of filter layer.

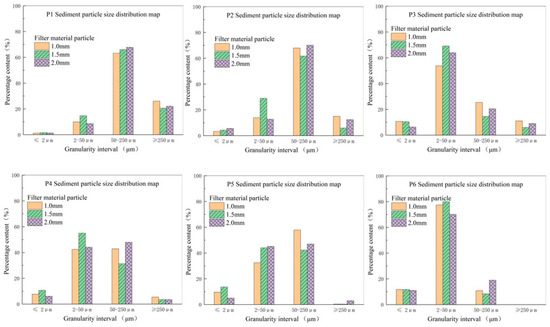

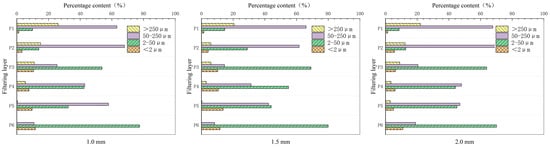

3.4. Analysis of Sediment Particle Size Distribution in Filter Layer

In order to analyze the distribution characteristics of intercepted particles in the filter layer, we referred to the sediment particle size classification standard formulated by the United States Department of Agriculture (USDA): clay particles (d ≤ 2 μm), powder particles (2 μm < d ≤ 50 μm), fine sand (50 μm < d ≤ 250 μm), medium sand (250 μm < d ≤ 500 μm), and coarse sand (500 μm < d ≤ 2000 μm) [28]. None of the sediment particles used in this test were coarse sand, so only the remaining four types of particles were analyzed. The distributions of sediment particle sizes in the filter layer under different filter particle size conditions are shown in Figure 4. From the figure, it can be seen that the particle size distribution trend of sediment in the upper half of the filter layer was the same as that of raw water, with the highest content of fine sand, medium content of medium sand and powder particles, and the lowest content of clay particles. As the depth of the filter layer increased, the distribution of sediment particle sizes changed: the content of fine sand gradually decreased, and the content of powder particles gradually increased, while the content of medium-sized sand did not change. As the depth of the filter layer increased, the characteristics of the intercepted sediment showed an increasing trend for large-sized sediment, a decreasing trend for small-sized sediment, and an increase in the content of powder particles and fine sand. The sediment distribution trends at the same depth under different filter particle size conditions were relatively similar to each other, but the sediment distributions were quite different at different depths of the filter layer. Under the condition of the same filter particle size, the distributions of sediment particle sizes in the filter layer are shown in Figure 5. From the figure, it can be seen that the particle size distributions of different filter layer sections with the same particle size are compared: the greater the depth of the filter layer section was, the lower the contents of fine sand and medium sand were, and the higher the content of powder particles was; the change in clay content was not obvious.

Figure 4.

Distribution of sediment particle size in the filter layer under different filter material particle conditions.

Figure 5.

Distribution of sediment particle size in the filter layer under the same filter material particle conditions.

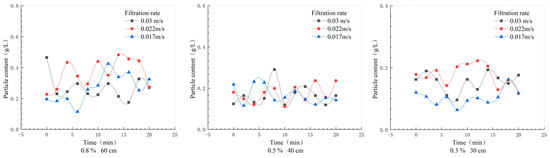

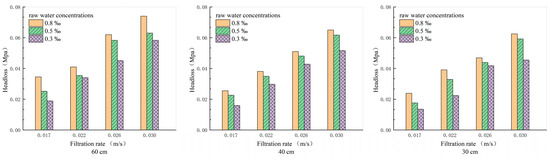

3.5. Influence of Different Factors on Head Loss

The variations in head loss with filtration rate under different raw water concentration conditions are shown in Figure 6. As shown in the figure, the trends of head loss changes under different filter thicknesses were similar. As the filtration rate increased, head loss showed an increasing trend, indicating that there was a positive correlation between filtration rate and head loss. Under the same filter thickness and filtration rate conditions, as the raw water concentration decreased, head loss also decreased. The raw water concentration was positively correlated with head loss, as head loss was obviously reduced when the raw water concentration was 0.3‰ compared with when it was 0.8‰. When raw water concentration and filtration rate were fixed, as the filter thickness gradually increased, head loss just showed a corresponding increasing trend. When the filter thickness and filtration rate were fixed, it was observed that, as the raw water concentration increased, head loss gradually increased.

Figure 6.

Effects of different filter thickness and raw water concentrations on head loss.

4. Discussion

1. As the thickness of the filter layer increases, the sand-containing water comes into contact with a larger amount of filter material throughout the filter layer, enhancing the interaction between the water and the filter material. The filter material effectively captures impurities through various filtration mechanisms, such as precipitation, pore interception, and adsorption on its surface. Consequently, the turbidity of the filtered water sample is considerably reduced compared to that of the raw water [29]. Here, the turbidity dispersion degree of each treatment was low, and the filtration process and effect of the sand media filter were relatively stable, as determined according to the turbidity index, which further verified the unique three-dimensional filtration characteristics of the sand media filter used. When raw water concentration and filter thickness were kept unchanged, with the change in filtration rate, the amount of sand-containing water entering the filter layer increased per unit time. However, the filtration ability of the filter layer itself has its limitations, as the pores can become clogged or saturated with captured particles over time, and the difference in turbidity changes of the filtered water samples was small. Particles in the effluent are generally evaluated through an analysis of turbidity. Turbidity is the most common parameter used for monitoring particles; however, it is insensitive to particles in the size of a few microns, and does not provide information on the size and concentration of the individual particles in the water [30].

2. Filter thickness obviously influences particle content. Analysis shows that, as the thickness of the filter layer increases, a structurally robust pore structure is formed inside the filter layer, which increases the interception rate of sediment particles and effectively intercepts more sediment particles [31]. As a result, the particle content in the filtered water samples remains stable. A small filter thickness makes it difficult for a stable pore structure to form, and sediment undergoes uncertainty during transportation, making it easier for sediment to pass through the filter layer and increasing the content of particles in the final filtered water sample, a conclusion that is consistent with previous research results on turbidity. Solid particle content is less affected by the filtration rate, as this analysis showed that increasing the filtration rate did not accelerate the sediment passing through the filter layer. An increase in filtration rate represents an increase in flow velocity per unit cross section; however, as there is not a simple linear correlation between the two, the process of sediment transport through pores is complex. In water samples, temporal trends of particle content and turbidity exhibit variations. The author posits that, during the analysis of particles in filtered water samples, turbidity should not serve as the sole evaluation criterion. Instead, a comprehensive assessment should incorporate both turbidity and particle content. This approach ensures a more accurate evaluation of filtered water sample quality.

3. Enlarging the particle size of the filter material is advantageous, as it mitigates the surface filtration phenomenon, reduces head loss within the filter layer, and enhances the filtration rate. However, with an increase in filter material particle size, the migrated sediment particles gradually increase, and the feasibility of sediment penetrating the filter layer increases. This analysis showed that the larger the filter material particle size was, the larger the pore diameter of the filter layer was. Under the action of high-speed water flow, the movement activity of sediment particles increases, and they are more likely to migrate. This analysis shows that, when the filtration rate was large, sediment was easily deposited on the surface of the filter material in a short time. As sediment accumulates, sediment migration is hindered, and the filter layer filtration function is not fully utilized.

4. This analysis demonstrates that, as the particle size of the filter material increases, both the average pore diameter and the maximum pore diameter formed within the filter layer also experience an increase. After sediment passes through the surface of the filter layer, large-particle sediment can move along the pores of the filter material. Under the impact of high-speed water flow, the movement activity of sediment particles increases, and sediment moves to the bottom of the filter layer more easily. In the initial stage of filtration, the degree of clogging is relatively light, and most large-grained sediment particles move to the bottom of the filter layer. The phenomenon of surface filtration leads to an increase in filter head loss, and the lower part of the filter material is subjected to increasing extrusion pressure, with the pore diameter decreasing accordingly [32]. An increase in filter material particle size can alleviate the occurrence of surface filtration, but with the increase in migrating sediment particles, some of them flow out with the water. Surface filter material is first exposed to the sediment in muddy water, and small pores are gradually blocked by sediment, while large pores gradually become small pores. As time goes by, it becomes more difficult for large particles of sediment to break through the pores of the surface filter material [33,34].

5. This analysis demonstrates that the filtration capacity of unit volume filter material in sand media filters is limited. As the filtration rate increases, the filter layer experiences greater resistance due to the accumulation of sediment and particles within the pores and on the surface of the filter material. This increased resistance results in a corresponding rise in head loss, as the water has to overcome the additional challenges posed by the filter layer. As the filter thickness increases, the sediment-laden water needs to overcome the larger pore resistance and surface tension of the filter material through the filter layer. This increased challenge contributes to greater head loss as the water passes through the filter layer. The analysis indicates that an increase in raw water concentration leads to a higher filtration load per unit volume of the filter layer during the initial stage of filtration. As the water’s sediment and particle concentration increases, the filter layer is required to intercept and adsorb a significant amount of contaminants through the filter media’s pores and surface within a limited time frame. This added strain on the filtration material contributes to a higher head loss, as the water must exert more effort to traverse the increasingly obstructed filter layer [35].

In this paper, by exploring the sediment mass distribution, particle size distribution, and head loss of the filter layer after filtration through filter media of different particle sizes, the deposition and migration rules of sediment in filter media were preliminarily analyzed, and some research conclusions were obtained. The findings of this research have significant implications for optimizing filtration systems and enhancing their accuracy and backwash efficiency. By identifying the factors that influence sediment deposition and migration, it becomes possible to develop strategies for mitigating these effects and maintaining optimal filter performance. This, in turn, can lead to more efficient water treatment processes and improved water quality. However, the study acknowledges a limitation in its scope, as it did not take into account the raw water configuration of sediment deposition in different irrigation channels. This is an important factor to consider, as the characteristics of raw water can significantly influence the filtration process and the distribution of sediment within the filter layer. In future research, it would be beneficial to incorporate this variable and explore its impact on sediment deposition and migration patterns.

5. Conclusions

1. The turbidity of the filtered water samples was negatively correlated with filter thickness and positively correlated with raw water concentration. The turbidity of the water samples showed a stable trend over time. As the filtration rate increased, the difference in the turbidity of the water samples over time was not obvious. Using turbidity as an indicator to evaluate filtration efficiency, we found that the filtration rate is not a key influencing factor.

2. A change in filtration rate had a weak influence on particle content in the water samples. By taking particle content as the evaluation index for the filtration effect, we found that the filtration rate is not the key influencing factor, which is consistent with conclusion 5.1. A change in filter layer thickness showed the same trend of influence on particle content in the water samples and showed that the particle content in the 30 cm filter layer was the largest. Under the condition of a raw water concentration of 0.8‰, the particle content in the water samples was obviously different from that obtained using other raw water concentrations.

3. The trends of the distribution of sediment intercepted by the filter layer under different filter particle size conditions were the same, with sediment being mainly distributed in the upper half of the filter layer. The smaller the particle size of the filter material was, the more easily the surface filtration phenomenon occurred. Filter material was more concentrated on the surface of the filter layer and failed to enter the interior of the filter layer. As the particle size of the filter material increased, the sediment that migrated to the bottom continuously increased. Filter material particle size and filtration rate had little effect on the interception of pollutants by the filter layer.

4. The distribution trend of retained sediment in the upper half of the filter layer was the same as that of the raw water particle size. With an increase in the depth of the filter layer, the content of fine sand and medium sand decreased, and the content of powder particles increased. The overall trend was that the content of large-particle-size sediment gradually increased, and the content of small-particle-size sediment gradually decreased. Head loss was positively correlated with filtration rate, raw water concentration, and filter thickness.

Author Contributions

Conceptualization, methodology, W.Z.; formal analysis, W.Z. and J.C.; investigation, W.Z., G.Z. and L.S.; writing—original draft preparation, W.Z.; writing—review and editing, W.Z. and M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Henan Provincial Key R&D and Promotion Special-Science and Technology Tackling Project (Project No. 232102321113).

Data Availability Statement

Anyone interested in experimental details or related publications by the group may contact the corresponding author directly lvmouchao@aliyun.com.

Acknowledgments

We would like to thank the anonymous reviewers and editors for their valuable comments and suggestions

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ramanjaneyulu, A.; Ramulu, V.; Ramana, M.; Mamatha, K. Crop performance, water use, economics and energy indices in rabi groundnut (Arachis hypogaea L.) under micro irrigation methods. J. Environ. Biol. 2022, 43, 326–337. [Google Scholar] [CrossRef]

- Al-Adamat, R.A.; Abu-Dieyeh, M.A. Emitter clogging in drip irrigation systems: Causes, consequences and remedies. J. Appl. Sci. Res. 2012, 8, 104–116. [Google Scholar]

- Duran-Ros, M.; Arbat, G.; Barragán, J.; de Cartagena, F.R.; Puig-Bargués, J. Assessment of head loss equations developed with dimensional analysis for micro irrigation filters using effluents. Biosyst. Eng. 2010, 106, 521–526. [Google Scholar] [CrossRef]

- Kandra, H.S.; Mccarthy, D.; Fletcher, T.D.; Deletic, A. Assessment of clogging phenomena in granular filter media used for stormwater treatment. J. Hydrol. 2014, 512, 518–527. [Google Scholar] [CrossRef]

- Borssoi, A.L.; Boas, M.A.V.; Reisdörfer, M.; Hernández, R.H.; Follador, F.A.C. Water application uniformity and fertigation in a dripping irrigation set. Eng. Agríc. 2012, 32, 718–726. [Google Scholar] [CrossRef]

- Lamm, F.R.; Ayars, J.E.; Nakayama, F.S. Microirrigation for Crop Production; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Testezlaf, R. Localized irrigation sand filters: Theory and practice. Eng. Agríc. 2008, 28, 604–613. [Google Scholar] [CrossRef]

- Bucks, D.A.; Nakayama, F.S.; Gilbert, R.G. Trickle irrigation water quality and preventive maintenance. Agric. Water Manag. 1979, 2, 149–162. [Google Scholar] [CrossRef]

- Capra, A.; Scicolone, B. Recycling of poor quality urban wastewater by drip irrigation systems. J. Clean. Prod. 2007, 15, 1529–1534. [Google Scholar] [CrossRef]

- De Deus, F.P.; Mesquita, M.; Ramirez, J.C.S.; Testezlaf, R.; de Almeida, R.C. Hydraulic characterisation of the backwash process in sand media filters used in micro irrigation. Biosyst. Eng. 2020, 192, 188–198. [Google Scholar] [CrossRef]

- Bové, J.; Pujol, J.; Arbat, G.; Duran-Ros, M.; de Cartagena, F.R.; Puig-Bargués, J. Environmental assessment of underdrain designs for a sand media filter. Biosyst. Eng. 2018, 167, 126–136. [Google Scholar] [CrossRef]

- Elbana, M.; de Cartagena, F.R.; Puig-Bargués, J. Effectiveness of sand media filters for removing turbidity and recovering dissolved oxygen from a reclaimed effluent used for micro-irrigation. Agric. Water Manag. 2012, 111, 27–33. [Google Scholar] [CrossRef]

- Capra, A.; Scicolone, B. Emitter and filter experimental for wastewater reuse by drip. Agric. Water Manag. 2004, 68, 135–149. [Google Scholar] [CrossRef]

- Tarjuelo, J.M.; Rodriguez-Diaz, J.A.; Abadía, R.; Camacho, E.; Rocamora, C.; Moreno, M.A. Efficient water and energy use in irrigation modernization: Lessons from Spanish case studies. Agric. Water Manag. 2015, 162, 67–77. [Google Scholar] [CrossRef]

- Burt, C.M. Hydraulics of Commercial Sand Media Filter Tanks Used for Agricultural Drip Irrigation; ITRC Report No. R10001; Irrigation Training and Research Center: San Luis Obispo, CA, USA, 2010. [Google Scholar]

- Mesquita, M.; de Deus, F.P.; Testezlaf, R.; da Rosa, L.M. Design and hydrodynamic performance experimentaling of a new pressure sand media filter diffuser plate using numerical simulation. Biosyst. Eng. 2019, 183, 58–69. [Google Scholar] [CrossRef]

- Arbat, G.; Pujol, T.; Puig-Bargués, J.; Duran-Ros, M.; Montoro, L.; Barragán, J.; de Cartagena, F.R. An experimental and analytical study to analyze hydraulic behavior of nozzle-type underdrains in porous media filters. Agric. Water Manag. 2013, 126, 64–74. [Google Scholar] [CrossRef]

- de Deus, F.P.; Testezlaf, R.; Mesquita, M. Efeito das dimensões da placa difusora no comportamento hidráulico de um modelo comercial de filtro de areia. Eng. Agríc. 2013, 33, 560–568. [Google Scholar] [CrossRef]

- Bové, J.; Arbat, G.; Pujol, T.; Duran-Ros, M.; de Cartagena, F.R.; Velayos, J.; Puig-Bargués, J. Reducing energy requirements for sand filtration in micro-irrigation: Improving the underdrain and packing. Biosyst. Eng. 2015, 140, 67–78. [Google Scholar] [CrossRef]

- Mesquita, M.; Experimentalezlaf, R.; Ramirez, J.C.S. The effect of media bed characteristics and internal auxiliary elements on sand media filter head loss. Agric. Water Manag. 2012, 115, 178–185. [Google Scholar] [CrossRef]

- Pujol, T.; Arbat, G.; Bove, J.; Puig-Bargues, J.; Duran-Ros, M.; Velayos, J.; de Cartagena, F.R. Effects of the underdrain design on the pressure drop in sand media filters. Biosyst. Eng. 2016, 150, 1–9. [Google Scholar] [CrossRef]

- Zhai, G.; Chen, G.; Zhao, H.; Deng, Z.; Feng, J.; Han, Q.; Liu, Y. Effects of filter with uniform sandy filtration medium used in micro-irrigation on mass fraction of particles and turbidity of water with fly ash. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2010, 26, 13–18. [Google Scholar]

- García-Nieto, P.J.; García–Gonzalo, E.; Puig–Bargués, J.; Duran-Ros, M.; de Cartagena, F.R.; Arbat, G. Prediction of outlet dissolved oxygen in micro-irrigation sand media filters using a Gaussian process regression. Biosyst. Eng. 2020, 195, 198–207. [Google Scholar] [CrossRef]

- Li, J.; Liu, Q.; Huang, X.; Zhai, G.; Han, Q. Flow state characteristics and fractal model parameters determination of quartz sand media filter layer used in micro-irrigation. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2015, 31, 113–119. [Google Scholar]

- Soyer, E. Performance comparison of granular media filter beds. Desalination Water Treat. 2016, 57, 24867–24881. [Google Scholar] [CrossRef]

- Cui, X.; Liu, Q.; Zhang, C. Detachment Characteristics of Deposited Particles in Porous Medium: Experimentation and Modeling. Transp. Porous Media 2017, 119, 633–647. [Google Scholar] [CrossRef]

- Zhang, W.; Zhai, G.; Deng, Z.; Liu, Y.; Chen, Z. Surface filtration and air-water backwash for sandy filter media in micro-irrigation. J. Irrig. Drain. 2023, 32, 86–90. [Google Scholar]

- Tao, H.; Shen, P.; Li, Q.; Jiang, Y.; Yang, W.; Wei, J. Research on head loss of pre-pump micro-pressure filter under clean water conditions. Water Supply 2022, 22, 3271–3282. [Google Scholar] [CrossRef]

- Selvadurai, A.P.S.; Gladwell, G.M.L. Elastic Analysis of Soil-Foundation Interaction; Elsevier: Amsterdam, The Netherlands, 1979; Volume 47. [Google Scholar]

- Mamane, H.; Kohn, C.; Adin, A. Characterizing Shape of Effluent Particles by Image Analysis. Sep. Sci. Technol. 2008, 43, 1737–1753. [Google Scholar] [CrossRef]

- Leverenz, H.L. Clogging in Intermittently Dosed Sand Media Filters Used for Wastewater Treatment. Ph.D. Thesis, University of California, Davis, CA, USA, 2008. [Google Scholar]

- Zhao, P.; Jin, A.; Xie, F.; Musa, R. Study on structural parameters optimization of a new inclined inserting and hole plate-type combined sand barrier. J. Mech. Eng. Sci. 2022, 236, 6593–6606. [Google Scholar] [CrossRef]

- Li, Q.; Song, P.; Zhou, B.; Xiao, Y.; Muhammad, T.; Liu, Z.; Zhou, H.; Li, Y. Mechanism of intermittent fluctuated water pressure on emitter clogging substances formation in drip irrigation system utilizing high sediment water. Agric. Water Manag. 2019, 215, 16–24. [Google Scholar] [CrossRef]

- Benamar, A.; Wang, H.; Ahfir, N.D.; Alem, A.; Masséi, N.; Dupont, J.P. Effets de la vitesse d’écoulement sur le transport et la cinétique de dépt de particules en suspension en milieu poreux sature. Comptes Rendus Geosci. 2005, 337, 497–504. [Google Scholar] [CrossRef]

- Deus, F.P.D.; Testezlaf, R.; Mesquita, M. Efficiency of pressurized sand filters in removing different particle sizes from irrigation water. Pesqui. Agropecu. Bras. 2015, 50, 939–948. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).