Circular Economy in Wastewater Treatment Plants—Potential Opportunities for Biogenic Elements Recovery

Abstract

:1. Introduction

2. Methods

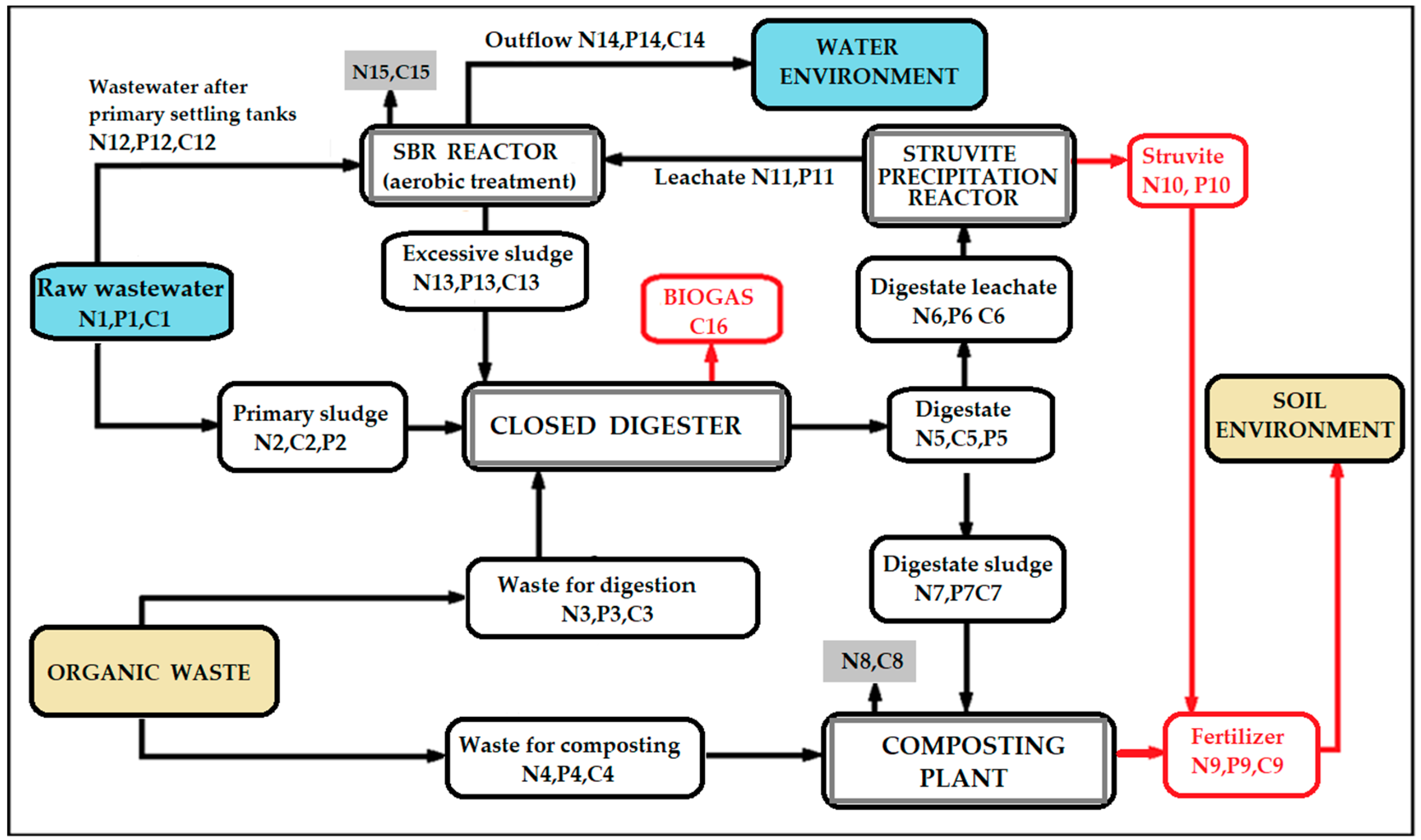

2.1. Model Wastewater Treatment Plant

2.2. Circulation of Biogenic Elements in the MWWTP

2.3. Analytical Methods and Measurement

- Phosphate concentrations were measured using commercial assays from Merck (Spectroquant® 114543). All colorimetric analyses were performed using a Spectroquant Vega 400 spectrophotometer (Merck, Darmstad, Germany).

- Nitrate and ammonium concentrations were measured using the AN-ISE sc Ammonium and Nitrate ion-selective probe (Hach Lange, Dusseldorf, Germany).

- The total dry matter (t.d.m.), volatile organic matter (v.m.), and dry mineral matter (d.m.) of samples were determined according to standard methods [56].

- Mass flows were measured using flow meters installed at WWTP ‘Swarzewo’: electromagnetic flow meters for sewage and thickened sludge (type DMA20 DMA20-AAABA1Z) and biogas flow meters with simultaneous determination of composition (type Proline Prosonic Flow B 200) (Endress &Houser, Frankfurt, Germany).

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Ctot | stream of total carbon |

| CE | circular economy |

| CH4 | methane |

| CO2 | carbon dioxide |

| COD | chemical oxygen demand |

| d.m. | mineral dry matter |

| DS | dissolved substances |

| MWWTP | model wastewater treatment plant |

| Ntot | stream of total nitrogen |

| OWO | organic carbon |

| Ptot | stream of total phosphorus |

| SBR | anaerobic/aerobic sequencing batch reactor |

| t.d.m. | total dry matter |

| v.m. | volatile organic matter |

| WWTP | wastewater treatment plant |

References

- EC (European Commission). Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions Towards a Circular Economy: A Zero Waste Programme for Europe. COM/2014/0398; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Smol, M.; Adam, C.; Preisner, M. Circular economy model framework in the European water and wastewater sector. J. Mater. Cycles Waste Manag. 2020, 22, 682–697. [Google Scholar] [CrossRef]

- Preisner, M.; Smol, M.; Horttanainen, M.; Deviatkin, I.; Havukainen, J.; Klavins, M.; Ozola-Davidane, R.; Kruopiene, J.; Szatkowska, B.; Appels, L.; et al. Indicators for resource recovery monitoring within the circular economy model implementation in the wastewater sector. J. Environ. Manag. 2022, 304, 114261. [Google Scholar] [CrossRef] [PubMed]

- Bhambhani, A.; Kapelan, Z.; van der Hoek, J.P. A new approach to circularity assessment for a sustainable water sector: Accounting for environmental functional flows and losses. Sci. Total Environ. 2023, 903, 166520. [Google Scholar] [CrossRef] [PubMed]

- Batstone, D.J.; Virdis, B. The role of anaerobic digestion in the emerging energy economy. Curr. Opin. Biotech. 2014, 27, 142–149. [Google Scholar] [CrossRef]

- Kataki, S.; West, H.; Clarke, M.; Baruah, D.C. Phosphorus recovery as struvite: Recent concerns for use of seed, alternative Mg source, nitrogen conservation and fertilizer potential. Resour. Conserv. Recycl. 2016, 107, 142–156. [Google Scholar] [CrossRef]

- Wainaina, S.; Awasth, M.K.; Sarsaiya, S.; Chen, H.; Singh, E.; Kumar, A.; Ravindran, B.; Awasthi, S.K.; Liu, T.; Duan, Y.; et al. Resource recovery and circular economy from organic solid waste using aerobic and anaerobic digestion technologies. Bioresour. Technol. 2020, 301, 122778. [Google Scholar] [CrossRef]

- Zubrowska-Sudol, M.; Bisak, A. Circular Economy Indicators and Measures in the Water and Wastewater Sector-Case Study. In Water in Circular Economy. Advances in Science, Technology and Innovation; Smol, M., Prasad, M.N.V., Stefanakis, A.I., Eds.; Springer: Cham, Switzerland, 2023; pp. 213–224. [Google Scholar]

- EC (European Commission). Review of the 2012 European Bioeconomy Strategy; European Commission: Brussels, Belgium, 2017. [Google Scholar] [CrossRef]

- Tsui, T.H.; Wong, J.W. A critical review: Emerging bioeconomy and waste-to energy technologies for sustainable municipal solid waste management. Waste Dispos. Sustain. Energy 2019, 1, 151–167. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; de Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Haupt, M.; Hellweg, S. Measuring the environmental sustainability of a circular economy. Environ. Sustain. Indic. 2019, 1–2, 100005. [Google Scholar] [CrossRef]

- Kacprzak, M.J.; Kupich, I. The specificities of the circular economy (CE) in the municipal wastewater and sewage sludge sector—Local circumstances in Poland. Clean Techn. Environ. Policy 2023, 25, 519–535. [Google Scholar] [CrossRef]

- Neczaj, E.; Grosser, A. Circular Economy in Wastewater Treatment Plant–Challenges and Barriers. Proceedings 2018, 2, 614. [Google Scholar] [CrossRef]

- Smol, M. Circular Economy in Wastewater Treatment Plant—Water, Energy and Raw Materials Recovery. Energies 2023, 16, 3911. [Google Scholar] [CrossRef]

- Raghuvanshi, S.; Bhakar, V.; Sowmya, C.; Sangwan, K.S. Waste Water Treatment Plant Life Cycle Assessment: Treatment Process to Reuse of Water. Procedia CIRP 2017, 61, 761–766. [Google Scholar] [CrossRef]

- Smol, M.; Marcinek, P.; Koda, E. Drivers and Barriers for a Circular Economy (CE) Implementation in Poland—A Case Study of Raw Materials Recovery Sector. Energies 2021, 14, 2219. [Google Scholar] [CrossRef]

- Molina-Moreno, V.; Leyva-Díaz, J.C.; Llorens-Montes, F.J.; Cortés-García, F.J. Design of Indicators of Circular Economy as Instruments for the Evaluation of Sustainability and Efficiency in Wastewater from Pig Farming Industry. Water 2017, 9, 653. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Growth Within: A Circular Economy Vision for a Competitive Europe. 2015. Available online: https://ellenmacarthurfoundation.org/growth-within-a-circular-economy-vision-for-a-competitive-europe (accessed on 10 September 2023).

- Schjoerring, J.K.; Cakmak, I.; White, P.J. Plant nutrition and soil fertility: Synergies for acquiring global green growth and sustainable development. Plant Soil 2019, 434, 1–6. [Google Scholar] [CrossRef]

- Dobrzycka-Krahel, A.; Bogalecka, M. The Baltic Sea under Anthropopressure—The Sea of Paradoxes. Water 2022, 14, 3772. [Google Scholar] [CrossRef]

- EC (European Commission). Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee of the Regions List of Critical Raw Materials for the EU. COM/2017/490; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Gruber, N.; Galloway, J. An Earth-system perspective of the global nitrogen cycle. Nature 2008, 451, 293–296. [Google Scholar] [CrossRef]

- Xiong, C.; Guo, Z.; Chen, S.S.; Gao, Q.; Kimirei, I.A.; Li, H.; Su, W. Sustainable nitrogen management strategies based on nitrogen flow in urban human system. Environ. Sci. Pollut. Res. 2023, 30, 52410–52420. [Google Scholar] [CrossRef]

- Britto, D.T.; Kronzucker, H.J. NH4+ toxicity in higher plants: A critical review. J. Plant Physiol. 2002, 159, 567–584. [Google Scholar] [CrossRef]

- Sutton, M.A.; Oenema, O.; Erisman, J.W.; Leip, A.; van Grinsven, H.; Winiwarter, W. Too much of a good thing. Nature 2011, 472, 159–161. [Google Scholar] [CrossRef] [PubMed]

- Arthurson, V. Closing the Global Energy and Nutrient Cycles through Application of Biogas Residue to Agricultural Land–Potential Benefits and Drawbacks. Energies 2009, 2, 226–242. [Google Scholar] [CrossRef]

- Maktabifard, M.; Awaitey, A.; Merta, E.; Haimi, H.; Zaborowska, E.; Mikola, A.; Mąkinia, J. Comprehensive evaluation of the carbon footprint components of wastewater treatment plants located in the Baltic Sea region. Sci. Total Environ. 2022, 806, 150436. [Google Scholar] [CrossRef] [PubMed]

- Atelge, M.R.; Krisa, D.; Kumar, G.; Eskicioglu, C.; Nguyen, D.D.; Chang, S.W.; Atabani, A.E.; Al-Muhtaseb, A.; Unalan, S. Biogas production from organic waste: Recent progress and perspectives. Waste Biomass Valorization 2020, 11, 1019–1040. [Google Scholar] [CrossRef]

- Khalid, A.; Arshad, M.; Anjum, M.; Mahmood, T.; Dawson, L. The anaerobic digestion of solid organic waste. Waste Manag. 2011, 31, 1737–1744. [Google Scholar] [CrossRef]

- Walczak, J.; Karolinczak, B.; Zubrowska-Sudol, M. Effect of co-digestion and hydrodynamic disintegration on the methane potential of sewage sludge and organic fraction of municipal solid waste with consideration of the carbon footprint. Energy 2023, 282, 128949. [Google Scholar] [CrossRef]

- Szymanska, M.; Szara, E.; Sosulski, T.; Wąs, A.; Gijs, W.P.; van Pruissen, G.W.; Cornelissen, R.L.; Borowik, M.; Konkol, M. A bio-refinery concept for N and P recovery—A chance for biogas plant development. Energies 2019, 12, 155. [Google Scholar] [CrossRef]

- den Boer, E.; Banaszkiewicz, K.; den Boer, J.; Pasiecznik, I. Energy recovery from waste–closing the municipal loop. Energies 2022, 15, 1246. [Google Scholar] [CrossRef]

- Statistics Poland. Warsaw (PL): Local Data Bank. 2021. Available online: https://bdl.stat.gov.pl/BDL/start (accessed on 10 September 2023).

- Esposito, G.; Frunzo, L.; Panico, A.; Pirozzi, F. Enhanced bio-methane production from co-digestion of different organic wastes. Environ. Technol. 2012, 33, 2733–2740. [Google Scholar] [CrossRef]

- Kaszycki, P.; Głodniok, M.; Petryszak, P. Towards a bio-based circular economy in organic waste management and wastewater treatment–The Polish perspective. New Biotechnol. 2021, 61, 80–89. [Google Scholar] [CrossRef]

- Jankowski, M.; Przewoźna, B.; Bednarek, R. Topographical inversion of sandy soils due to local conditions in Northern Poland. Geomorphology 2011, 135, 277–283. [Google Scholar] [CrossRef]

- Urra, J.; Alkorta, I.; Mijangos, I.; Epelde, L.; Garbisu, C. Application of sewage sludge to agricultural soil increases the abundance of antibiotic resistance genes without altering the composition of prokaryotic communities. Sci. Total. Environ. 2019, 10, 1410–1420. [Google Scholar] [CrossRef] [PubMed]

- Kowalik, R.; Latosinska, J.; Gawdzik, J. Risk Analysis of Heavy Metal Accumulation from Sewage Sludge of Selected Wastewater Treatment Plants in Poland. Water 2021, 13, 2070. [Google Scholar] [CrossRef]

- Cydzik-Kwiatkowska, A.; Milojevic, N.; Jachimowicz, P. The fate of microplastic in sludge management systems. Sci. Total Environ. 2022, 848, 157466. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.P.; Agrawal, M. Potential benefits and risks of land application of sewage sludge. Waste Manag. 2008, 28, 347–358. [Google Scholar] [CrossRef]

- Sharma, B.; Sarkar, A.; Singh, P.; Singh, R.P. Agricultural utilization of biosolids: A review on potential effects on soil and plant grown. Waste Manag. 2017, 64, 117–132. [Google Scholar] [CrossRef]

- Buta, M.; Hubeny, J.; Zielinski, W.; Harnisz, M.; Korzeniewska, E. Sewage Sludge in Agriculture—The Effects of Selected Chemical Pollutants and Emerging Genetic Resistance Determinants on the Quality of Soil and Crops—A Review. Ecotoxicol. Environ. Saf. 2021, 214, 112070. [Google Scholar] [CrossRef]

- Rastetter, N.; Gerhardt, A. Toxic Potential of Different Types of Sewage Sludge as Fertiliser in Agriculture: Ecotoxicological Effects on Aquatic, Sediment and Soil Indicator Species. J. Soils Sediments 2017, 17, 106–121. [Google Scholar] [CrossRef]

- Torri, S.I.; Corrêa, R.S.; Renella, G. Biosolid application to agricultural land—A contribution to global phosphorus recycle: A review. Pedosphere 2017, 27, 1–16. [Google Scholar] [CrossRef]

- Harish, V.; Aslam, S.; Chouhan, S.; Pratap, Y.; Lalotra, S. Iron toxicity in plants: A Review. Int. J. Environ. Clim. Chang. 2023, 13, 1894–1900. [Google Scholar] [CrossRef]

- Siciliano, A.; Limonti, C.; Curcio, G.M.; Molinari, R. Advances in Struvite Precipitation Technologies for Nutrients Removal and Recovery from Aqueous Waste and Wastewater. Sustainability 2020, 12, 7538. [Google Scholar] [CrossRef]

- Egle, L.; Rechberger, H.; Krampe, J.; Zessner, M. Phosphorus recovery from municipal wastewater: An integrated comparative technological, environmental and economic assessment of P recovery technologies. Sci. Total Environ. 2016, 571, 522–542. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.; Lobanov, S.; Lo, V.K. An overview of technologies to recover phosphorus as struvite from wastewater, Advantages and shortcomings. Environ. Sci. Pollut. 2019, 26, 19063–19077. [Google Scholar] [CrossRef] [PubMed]

- de-Bashan, L.E.; Bashan, Y. Recent advances in removing phosphorus from wastewater and its future use as fertilizer (1997–2003). Water Res. 2004, 38, 4222–4246. [Google Scholar] [CrossRef]

- Worwag, M.; Sobik-Szoltysek, J. The Influence of Soil Fertilization with Struvite on Water Efficiency–Lysymetric Columns. Annu. Set Environ. Prot. 2019, 21, 894–905. Available online: https://ros.edu.pl/images/roczniki/2019/055_ROS_V21_R2019.pdf (accessed on 10 September 2023).

- Battistoni, P.; Pavan, P.; Prisciandaro, M.; Cecchi, F. Struvite crystallization: A feasible and reliable way to fix phosphorus in anaerobic supernatants. Water Res. 2000, 34, 3033–3041. [Google Scholar] [CrossRef]

- Rahman, M.; Salleh, M.A.M.; Umer, R.; Ahsan, A.; Hossain, M.M.; Rae, C.S. Production of slow release crystal fertilizer from wastewaters through struvite crystallization—A review. Arab. J. Chem. 2014, 7, 139–155. [Google Scholar] [CrossRef]

- Pérez-Piqueres, A.; Ribó, M.; Rodríguez-Carretero, I.; Quiñones, A.; Canet, R. Struvite as a Sustainable Fertilizer in Mediterranean Soils. Agronomy 2023, 13, 1391. [Google Scholar] [CrossRef]

- Yan, B.; Hou, Y. Effect of Soil Magnesium on Plants: A Review. IOP Conf. Ser. Earth Environ. Sci. 2018, 170, 022168. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 20th ed.; Method 2540D; American Public Health Association: Washington, DC, USA, 1988. [Google Scholar]

- Terada, A. Lessons from a Simple Ecological Wastewater Treatment Technology for Scientific Research and Advanced Engineering. Clean Technol. Environ. Policy 2019, 21, 717–718. [Google Scholar] [CrossRef]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving energy neutrality in wastewater treatment plants through energy savings and enhancing renewable energy production. Rev. Environ. Sci. Biotechnol. 2018, 17, 655–689. [Google Scholar] [CrossRef]

- Đurđević, D.; Blecich, P.; Jurić, Ž. Energy Recovery from Sewage Sludge: The Case Case Study of Croatia. Energies 2019, 12, 1927. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Wang, Q.; Ren, X.; Zhao, J.; Huang, H.; Awasthi, S.K.; Lahori, A.H.; Li, R.; Zhou, L.; Zhang, Z. Role of biochar amendment in mitigation of nitrogen loss and greenhouse gas emission during sewage sludge composting. Bioresour. Technol. 2016, 219, 270–280. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, X.; Wei, Q.; Gou, J. Biochar enhances the retention capacity of nitrogen fertilizer and affects the diversity of nitrifying functional microbial communities in karst soil of southwest China. Ecotoxicol. Environ. Saf. 2021, 226, 112819. [Google Scholar] [CrossRef] [PubMed]

- Sohi, S.P.; Krull, E.; Lopez, C.E.; Bol, R. A review of biochar and its use and function in soil. Adv. Agron. 2010, 105, 47–82. [Google Scholar] [CrossRef]

- Czyzyk, F.; Rajmund, A. Nitrogen Loss During Composting Sewage Sludge in a Prism with Plant Remains. Woda Środowisko Obsz. Wiej. 2009, 9, 29–37. Available online: https://intapi.sciendo.com/pdf/10.2478/pjct-2014-0001 (accessed on 10 September 2023). (In Polish).

- McLaren, T.I.; Smernik, R.J.; McLaughlin, M.J.; Doolette, A.L.; Richardson, A.E.; Frossard, E. Chapter Two–The chemical nature of soil organic phosphorus: A critical review and global compilation of quantitative data. In Advances in Agronomy; Sparks, D.L., Ed.; Academic Press: Cambridge, MA, USA, 2020; Volume 160, pp. 51–124. [Google Scholar] [CrossRef]

- Wierzbowska, J.; Sienkiewicz, S.; Zalewska, M. Phosphorus fractions in soil fertilized with organic waste. Environ. Monit Assess. 2020, 192, 315. [Google Scholar] [CrossRef]

- Fink, J.R.; Inda, A.V.; Tiecher, T.; Barron, V. Iron oxides and organic matter on soil phosphorus availability. Ciência Agrotecnologia 2016, 40, 369–379. [Google Scholar] [CrossRef]

- Xu, H.; He, P.; Gu, W.; Wang, G.; Shao, L. Recovery of phosphorus as struvite from sewage sludge ash. J. Environ. Sci. 2012, 24, 1533–1538. [Google Scholar] [CrossRef]

- Doyle, J.D.; Parsons, S.A. Struvite formation, control and recovery. Water Res. 2002, 36, 3925–3940. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.; Liu, Z.; Peng, C.; Chai, L.Y.; Kuroda, K.; Okido, M.; Song, Y.X. New insights into the interaction between heavy metals and struvite: Struvite as platform for heterogeneous nucleation of heavy metal hydroxide. Chem. Eng. J. 2019, 365, 60–69. [Google Scholar] [CrossRef]

- Smith, S.R. A critical review of the bioavailability and impacts of heavy metals in municipal solid waste composts compared to sewage sludge. Environ. Int. 2009, 35, 142–156. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Luo, D.; Zhang, X.; Huang, R.; Cao, Y.; Liu, G.; Zhang, Y.; Wang, H. Biochar-based slow-release of fertilizers for sustainable agriculture: A mini review. Environ. Sci. Ecotechnol. 2022, 10, 100167. [Google Scholar] [CrossRef] [PubMed]

- Méndeza, A.; Terradillosb, M.; Gascó, G. Physicochemical and agronomic properties of biochar from sewage sludge pyrolysed at different temperatures. J. Anal. Appl. Pyrol. 2013, 102, 124–130. [Google Scholar] [CrossRef]

- Lu, T.; Yuan, H.; Wang, Y. Characteristic of heavy metals in biochar derived from sewage sludge. J. Mater. Cycles Waste Manag. 2016, 18, 725–733. [Google Scholar] [CrossRef]

- Wang, H.; Xiao, K.; Yang, J.; Yu, Z.; Yu, W.; Xu, Q.; Wu, Q.; Liang, S.; Hu, J.; Hou, H.; et al. Phosphorus Recovery from the Liquid Phase of Anaerobic Digestate Using Biochar Derived from Iron−rich Sludge: A Potential Phosphorus Fertilizer. Water Res. 2020, 174, 115629. [Google Scholar] [CrossRef]

- Dereszewska, A.; Cytawa, S. A proposal of low-cost technology for nutrient recovery from leachate of anaerobic digester at a biological wastewater treatment plant. IOP Conf. Ser. Earth Environ. Sci. 2021, 642, 012012. [Google Scholar] [CrossRef]

| Part A. Kitchen Waste Load 0 Mg | ||||||||||

| INPUT | OUTPUT | |||||||||

| Stream | 1 | 3 | 4 | ∑ | 8 | 9 | 14 | 15 | 16 | ∑ |

| N | 282.5 | 85 | 10.5 | 378 | 131.4 | 55.7 | 25 | 166 | 0 | 378 |

| P | 41.8 | 24.3 | 2.2 | 68.3 | 0 | 67 | 1.3 | 0 | 0 | 68.3 |

| C | 976.7 | 1166.2 | 440.6 | 2583.5 | 807 | 742 | 37.5 | 191.7 | 805.3 | 2583.5 |

| Recovery of agricultural fertilizer [Mg] | 5761 | Biogas recovery [m3] | 1,503,318 | |||||||

| Part B. Kitchen Waste Load 5000 Mg | ||||||||||

| INPUT | OUTPUT | |||||||||

| Stream | 1 | 3 | 4 | ∑ | 8 | 9 | 14 | 15 | 16 | ∑ |

| N | 282.5 | 107.5 | 13.9 | 403.9 | 139.3 | 73.8 | 25 | 165.8 | 0 | 403.9 |

| P | 41.8 | 39.3 | 2.8 | 83.9 | 0 | 82.6 | 1.3 | 0 | 0 | 83.9 |

| C | 976.7 | 1691.2 | 584.5 | 3252.4 | 886 | 984.2 | 37.5 | 217.8 | 1126.7 | 3252.4 |

| Recovery of agricultural fertilizer [Mg] | 7642 | Biogas recovery [m3] | 2,103,318 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dereszewska, A.; Cytawa, S. Circular Economy in Wastewater Treatment Plants—Potential Opportunities for Biogenic Elements Recovery. Water 2023, 15, 3857. https://doi.org/10.3390/w15213857

Dereszewska A, Cytawa S. Circular Economy in Wastewater Treatment Plants—Potential Opportunities for Biogenic Elements Recovery. Water. 2023; 15(21):3857. https://doi.org/10.3390/w15213857

Chicago/Turabian StyleDereszewska, Alina, and Stanislaw Cytawa. 2023. "Circular Economy in Wastewater Treatment Plants—Potential Opportunities for Biogenic Elements Recovery" Water 15, no. 21: 3857. https://doi.org/10.3390/w15213857

APA StyleDereszewska, A., & Cytawa, S. (2023). Circular Economy in Wastewater Treatment Plants—Potential Opportunities for Biogenic Elements Recovery. Water, 15(21), 3857. https://doi.org/10.3390/w15213857